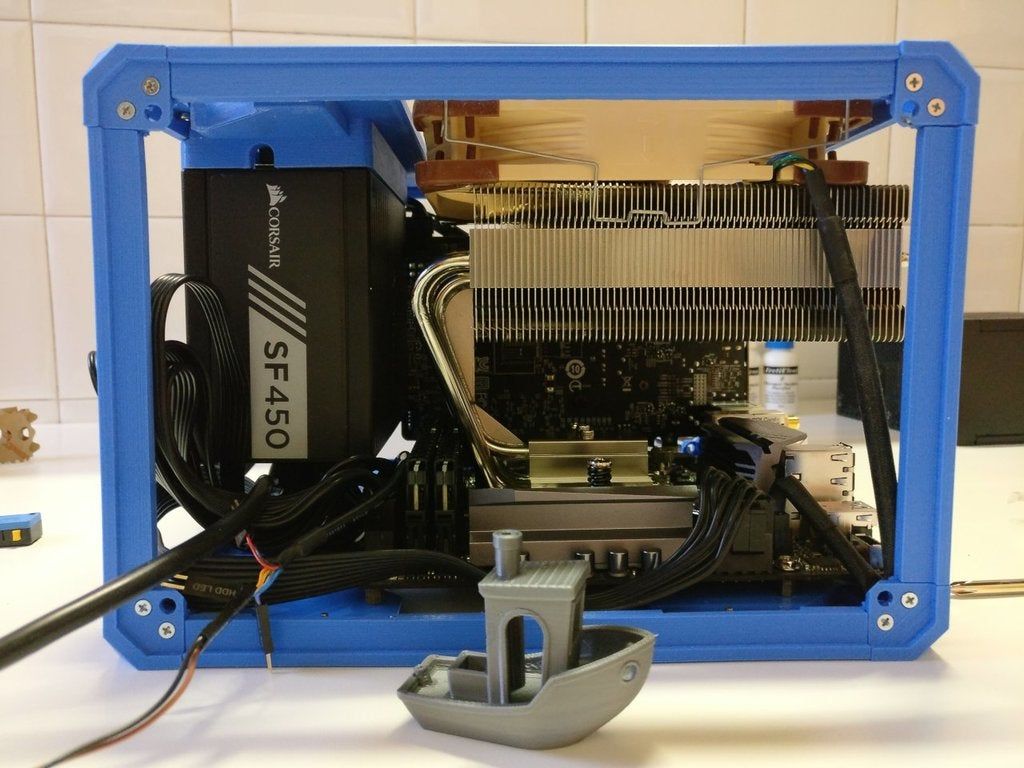

Winter soldier arm 3d print

▷ winter soldier arm 3d models 【 STLFinder 】

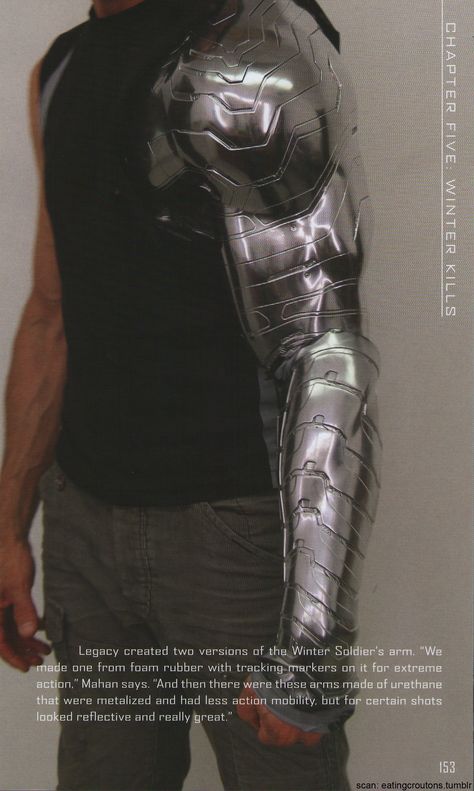

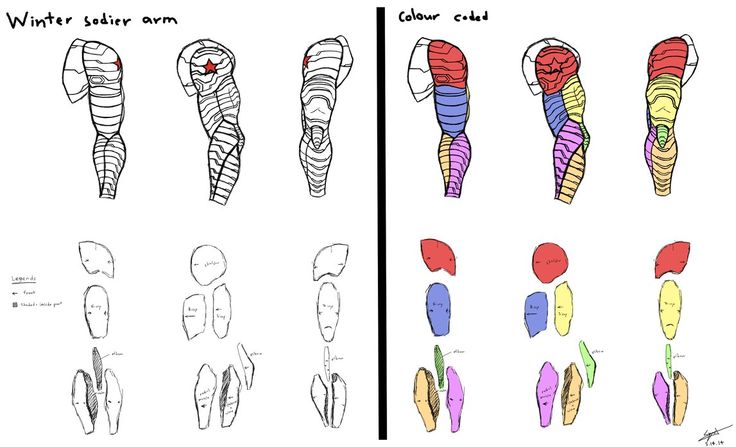

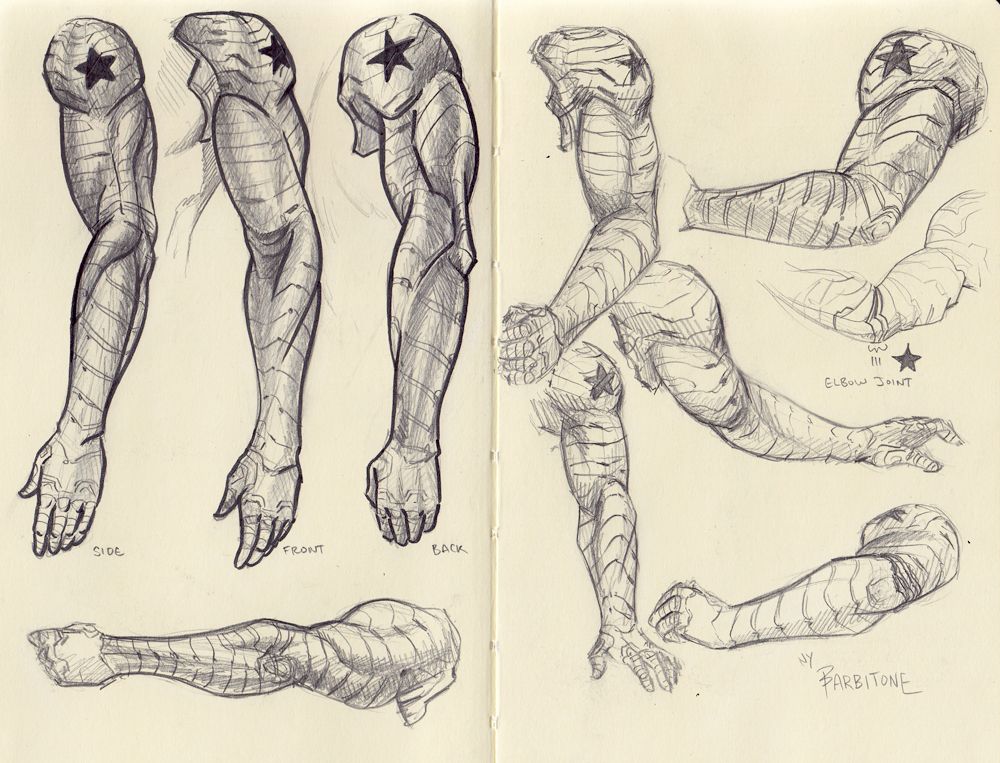

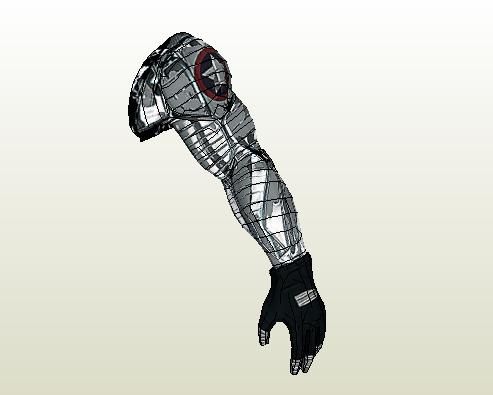

Marvel Winter Soldier Arm

cults3d

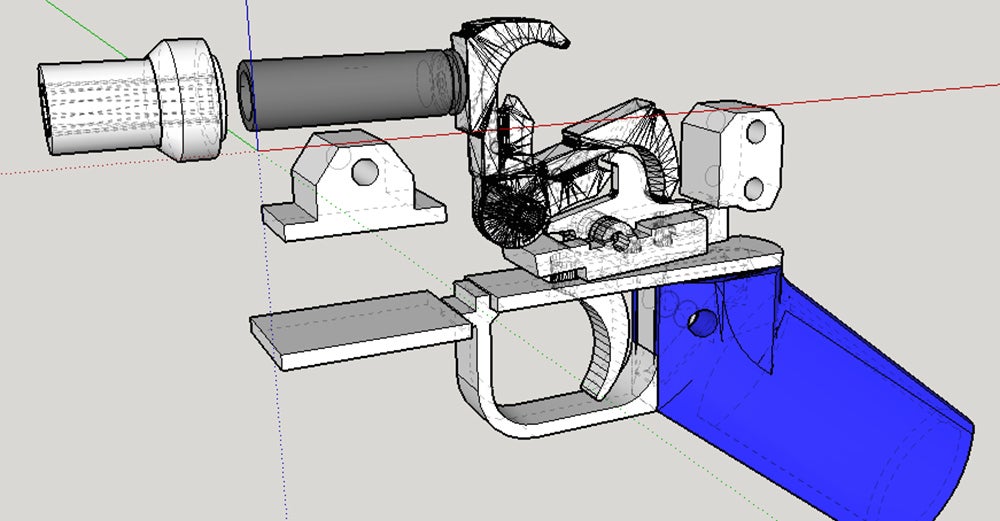

A basic printable model of the arm of the winter soldier from the MCU

Winter Soldier Arm (Captain Amercia)

thingiverse

I've had a couple of request for this model and I couldnt really decide which best suits the Winter Soldier character. So I've posted 3 different versions for you the people to choose. ...Give me some feed back onwhich one you like and I'll slice it up...

Winter Soldier Arm (Captain Amercia)

prusaprinters

I've had a couple of request for this model and I couldnt really decide which best suits the Winter Soldier character. So I've posted 3 different versions for you the people to choose. ...Give me some feed back onwhich one you like and I'll slice it up...

Winter Soldier Inspired Arm

thingiverse

Winter Soldier Inspired Arm Glove NOT included Enjoy (Edit) I noticed the thumb wasn't finished. I fixed and uploaded a fixed one. Very sorry about any confusion You can use Meshmixer or your choice of modeling software to separate the fingers...

Winter Soldier Inspired Arm

prusaprinters

Winter Soldier Inspired Arm Glove NOT included Enjoy (Edit) I noticed the thumb wasn't finished. ...I fixed and uploaded a fixed one.</p> <p>Very sorry about any confusion</p> <p>You can use Meshmixer or your choice of modeling software to separate the...

...I fixed and uploaded a fixed one.</p> <p>Very sorry about any confusion</p> <p>You can use Meshmixer or your choice of modeling software to separate the...

Winter Soldier Arm Mk II

thingiverse

I removed the star to make it match Infinity War and ran it through MeshMixer's Make Solid tool, then sliced it up to print on my Anet A8. ... ** Edit - The STL files have been fixed with the Make Printable app.

Winter Soldier Face Mask

thingiverse

Hi Simon, I look forward to seeing this completed along with your Cosplay Winter Soldier Arm project. ...; ) Cheers Jace As always check the sizing suits your needs : )

Winter Soldier Keychain

thingiverse

This is a key chain of the Winter Soldier's arm

Winter Soldier Face Mask

prusaprinters

Hi Simon, I look forward to seeing this completed along with your Cosplay Winter Soldier Arm project. ...; ) Cheers Jace<br/> As always check the sizing suits your needs : )</p>

...; ) Cheers Jace<br/> As always check the sizing suits your needs : )</p>

WINTER SOLDIER PROP BOMB

cults3d

Winter soldier prop bomb

The winter soldier

cults3d

The winter soldier full

Winter Soldier stencil

thingiverse

Winter Soldier stencil

Winter Soldier Inspired Mask

thingiverse

Winter Soldier inspired mask and goggles Enjoy

Winter Soldier Ear Saver

thingiverse

Winter Soldier COVID Surgical Mask Strap Ear Saver

Winter Soldier M406 replica

thingiverse

Replica M406 40mm grenade round for Winter Soldier cosplay. Try print at 40mm unless you have a more accurate sizing. ...Designed in Blender, noob designer.

Try print at 40mm unless you have a more accurate sizing. ...Designed in Blender, noob designer.

Winter Soldier for Tabletop

thingiverse

Winter Soldier (Bucky Barnes) miniature for tabletop gaming. Created from an XPS from the Future Fight Game. ... Posed, cleaned, repaired and added the gun and knife.

SHIELD logo - Winter Soldier

thingiverse

The S.H.I.E.L.D. ...logo monument seen in Captain America: Winter Soldier in S.H.I.E.L.D. headquarters. ... I used edu.sketchup.com to make this, the files are STLs

Winter Soldier Combat Mask

thingiverse

This Thing is a break apart of the Winter Soldier mask by Jace1969 to fit on my print bed. ...I broke each part (mask and goggles) into half and then half again.

...I broke each part (mask and goggles) into half and then half again.

Winter Soldier - Marvel

thingiverse

The Winter Soldier aka Bucky Barnes created in my mini style. If you want more models released weekly and access to exclusives join my Patreon! ... patreon.com/ziemba3D Enjoy!

Winter Soldier strap sliders

thingiverse

Strap sliders for Winter Soldier cosplay. Print one "triangle slider" for front of chest harness (try 62mm long to fit 2" strap). I believe you need 4 "sliders" at 43mm for 1.5" straps and two at 55mm for 2" straps. ...Designed in Blender, noob. ..

..

Winter Soldier Popsocket Cover

prusaprinters

A winter soldier design for popsockets. Designed to replace the cover of a normal popsocket. Remixed from JustinSpaniers blank popsocket cover.</p> <p>Fixed a problem with the scale of the model being off. ...The correct dimensions should be about 39 mm...

Winter Soldier Knife

thingiverse

This is a prop knife that the winter soldier uses. It is made in 3 parts. Print the half blade twice and glue them together. I scaled up the blade about 3% so it would be a snug fit into the handle. ...Printed with Wanhao i3 v2.

Winter Soldier, double blade

thingiverse

Started a project; Winter Soldier cosplay costume. First model for me to design and to print for this project, was the Gerber Yari Mk2. This was used by Bucky Barnes in "Captain America: the Winter Soldier". He carried two of these sheathed blades...

First model for me to design and to print for this project, was the Gerber Yari Mk2. This was used by Bucky Barnes in "Captain America: the Winter Soldier". He carried two of these sheathed blades...

Winter Soldier Face Mask

cults3d

Easy to print Winter Soldier Face Mask. Not for cosplays Designed flat in bed. You need to heat the print then fold it. (Hot water or heatgun) Three layers so that you may swap your filaments, you don't need to paint it. Notes: Holes in the...

Winter Soldier Face Mask

thingiverse

Easy to print Winter Soldier Face Mask.

Not for cosplays

Designed flat in bed. You need to heat the print then fold it. (Hot water or heatgun)

Three layers so that you may swap your filaments, you don't need to paint it.

Notes:

Holes in...

You need to heat the print then fold it. (Hot water or heatgun)

Three layers so that you may swap your filaments, you don't need to paint it.

Notes:

Holes in...

Winter Soldier - Marvel Coasters

thingiverse

Winter Soldier Coaster = Part of my Marvel's Avengers Coaster collection. Other Coasters in the collection include: • [Ant-Man](https://www.thingiverse.com/thing:4752862 "Ant-Man") • [Black Panther](https://www.thingiverse.com/thing:4726053...

falcon and the winter soldier

thingiverse

falcon and the winter soldier keychain

Falcon and Winter Soldier Stencils

thingiverse

Stencils from the Falcon and Winter Soldier

Captain America Winter Soldier Buckle

thingiverse

Captain America Winter Soldier Buckle for Suit Belt

Falcon and Winter soldier Redwing

thingiverse

New Redwing design from Falcon and Winter soldier D+

STL file Marvel Winter Soldier Arm・3D printable model to download・Cults

Metal Gear Rising Jetstream Sam Muramasa Sword And Sheath Assembly

€8

Final Fantasy VII Sephiroth Masamune Sword Printable Assembly

€8

League Of Legends KDA Evelynn Claws

€4

Sword Art Online Sinon Hecate II Rifle Basic Model

€8. 50

50

Hololive Mori Calliope Scythe Assembly

€7

Valorant Jett Knife

€6

Demon Slayer Shinobu Katana And Scabbard Printable Assembly

€7

Gate Rory Mercury Axe Printable Assembly

€7

Best 3D printer files of the Art category

Plague Doctor bust

Free

Raava and Vaatu articulated, print-in-place

€3.51

Cat returns Diorama

€4.89

Given X

€1

Batman bust

€1.40

Pass Q

€0.60

Pinocchio by Guillermo del Toro

€7. 50

50

Transforming Robot cube

Free

Best sellers of the category Art

Baby Crystalwing Dragon, Cinderwing3D, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€3.74

Cute Flexi Print-in-Place Turtle

€1.82

Bearded Dragon Articulated Toy, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3.26

Tiny Wyvern Dragon Baby, Cute Articulating Easy Print-in-Place

€3.27

Cute Flexi Print-in-Place Kitten

€2.76

Flexi Print-in-Place Skeleton Hand

€1.86

FLEXI PRINT-IN-PLACE STANDING YETI

€2.76

Adorable Articulated Axolotl, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3. 26

26

ZOU GHOST - GHOST WITH LEGS

€2.77

Cute Flexi Print-in-Place Sloth

€2.76

Flexi Print-in-Place kangaroo and Joey

€2.76

POKEMON - VALENTINE EEVEE (EASY PRINT NO SUPPORT)

€1.56

Blue Dragon / Glaucus Atlanticus ("The real life pokemon")

€1.40

Cute Flexi Print-in-Place T-Rex Dinosaur

€2.76

Flexi PRINT-IN-PLACE Hand

€1.82

MR. NICE GUY WITH SURPRISE - MULTIPARTS

€2.80 -25% €2.10

💖 Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your banner blocker (AdBlock, …) and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via Ko-Fi 💜.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Homo printablecus. Is it possible to create a person using a bioprinter? | Science | Society

Dmitry Pisarenko

Estimated reading time: 5 minutes

2639

Israeli scientists have 3D printed a heart for the first time in the world. / AMIR COHEN / Reuters

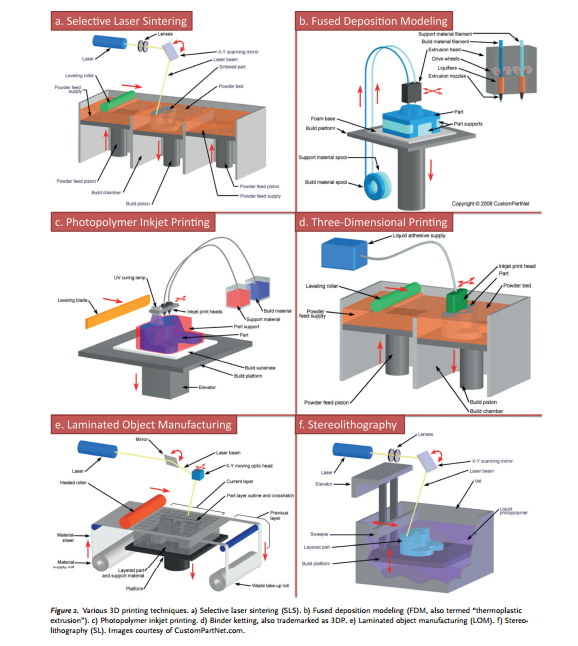

Biotechnology is developing rapidly. 3D printing of organs and tissues is the very direction that you can observe with your mouth open. It is possible that even during our lifetime, printers, as if off the assembly line, will begin to issue new organs to everyone who wants them. For example, kidneys.

3D printing of organs and tissues is the very direction that you can observe with your mouth open. It is possible that even during our lifetime, printers, as if off the assembly line, will begin to issue new organs to everyone who wants them. For example, kidneys.

A transplant-ready heart will appear in 10 years

“The heart we received is completely biocompatible and suitable for the patient. This is a full-fledged working body, ”says the lead author of the study conducted in Israel, Professor Tal Dvir .

So far, scientists have only been able to print an artificial heart out of silicone. Only parts of it, fragments, were obtained from human tissues. In addition, the artificial heart in previous experiments withstood very few contractions.

This time, the researchers grew heart muscle cells from stem cells, which, in turn, were "reprogrammed" from fat cells. The process took three hours. The heart turned out to be the size of a finger knuckle, like a rabbit's. Most likely, in the near future, scientists will try to transplant such an organ into an animal in order to check how easily it takes root. The authors of the experiment hope that in 10 years, with the help of bioprinting, it will be possible to create a heart that is completely ready for human transplantation. It will not irritate the immune system and will successfully replace a real organ.

The process took three hours. The heart turned out to be the size of a finger knuckle, like a rabbit's. Most likely, in the near future, scientists will try to transplant such an organ into an animal in order to check how easily it takes root. The authors of the experiment hope that in 10 years, with the help of bioprinting, it will be possible to create a heart that is completely ready for human transplantation. It will not irritate the immune system and will successfully replace a real organ.

3D printing in medicine is already widely used. First of all, in dentistry and surgery: a variety of prostheses, implants, fragments of internal organs and bones are printed on devices. Moreover, such bones have a number of advantages. First, they can be made quickly enough. Secondly, they are lightweight. Thirdly, their porous structure allows the prosthesis to grow faster with living tissues.

Doctors use 3D printing to eliminate problems associated with intervertebral discs - such implants also take root very quickly. Dentists, thanks to this technology, create high-quality and durable models of inlays, crowns and bridges.

Dentists, thanks to this technology, create high-quality and durable models of inlays, crowns and bridges.

True, in these cases we are talking about "dead" materials, and not at all about living cells.

3D factory in orbit

Wake Forest University (USA) has long been trying to design a 3D bioprinter to print new tissues from cells of specific patients. Five years ago, engineers unveiled a prototype device that can create large sheets of human skin that can be cut to the right size and transplanted into people who have been burned, for example.

More recently, researchers at the same university demonstrated a new device. It prints two layers of the patient's own skin directly onto the wound. The portable printer can be moved within the hospital. To avoid rejection, the patient's own cells are taken as the material for bioprinting. Namely, fibroblasts (connective tissue cells) and keratinocytes (the main cells of the outer layer of the skin). From them, a 3D printer builds a structure for wound healing. In the future, it is planned to be used to treat burns, diabetic ulcers and other skin lesions that do not heal on their own.

In the future, it is planned to be used to treat burns, diabetic ulcers and other skin lesions that do not heal on their own.

As you know, some scientific ideas are first tested in space. The European Space Agency is developing a bioprinter that can print skin, bones and even body parts for astronauts on future interplanetary missions. After all, anything can happen on a long flight. The project is still at an early stage. But Russian scientists are already ready to boast of concrete achievements on the International Space Station.

Last December, a 3D bioprinter installed in the Russian Segment of the ISS was able to print six human cartilage and six mouse thyroid glands. These biological samples will soon be delivered to Earth and their histological studies will be carried out. Scientists want to test the hypothesis that living tissues and organs are best printed in the absence of gravity. Their maturation under weightless conditions should occur much faster and more efficiently than on Earth.

What about the brain?

Every day, Dmitry Fadin's mailbox receives letters with the same question: "Can you print a human thyroid gland?" Dmitry Fadin is the Development Director of 3D Bioprinting Solutions, one of the most prominent companies in this field of research.

“So far we are only talking about scientific experiments. We can’t say for sure what opportunities these technologies will open for us,” he admits. — The final goal of our company is to print a workable human kidney. But the task is difficult: the structure of this organ is specific. Initially, we planned to solve it in 30 years. I think by the mid-2030s the first printed human kidney will be on the market.”

According to Dmitry Fadin, bioprinting is currently developing in several directions. For example, it makes it possible to test drugs for their toxicity. You can’t conduct such tests on humans, but you can print tissues on a 3D printer and test a new medicine on them.

Another trend is artificial food. They have already learned how to grow meat in laboratory test tubes, and a well-known chain of eateries released such a burger in early April. But if you master the printing of steaks on 3D printers, then the process will go faster.

Unfortunately, bioprinting is not yet widely used in transplantation, although it is there that the need for it is greatest. But technologies are moving in this direction and sooner or later the result will be. When organs begin to print based on the patient's own cells, this will fundamentally change the industry. There will be no need for donors. The problem of survival of organs will be solved. The same artificial kidney, printed on a bioprinter, will save the lives of thousands of people. Now patients suffering from renal insufficiency are forced to resort to hemodialysis (extrarenal blood purification). In addition to the fact that it is inconvenient for the person himself (several times a week you need to come to the hospital), it also costs the state dearly. Obviously, a kidney seal would be a great solution to the problem.

Obviously, a kidney seal would be a great solution to the problem.

What about the prospects of printing all the human organs and then, if possible, putting them together? The very formulation of this question makes scientists smile. Even if it is possible to make artificial kidneys, a heart, a liver and lungs, then what about the brain? Only Mother Nature can create it. Therefore, "homo pechatkus", if he is destined to leave the laboratories of the future, will remain brainless.

3D printerartificial organsbiotechnology

Next article

The most interesting in social networks

Media news2

Will we live in 3D printer houses? Now, with the help of technology, they will try to create housing - a start-up Mighty Buildings for the production of houses on a 3D printer was launched by technology entrepreneurs from Russia (CEO and co-founder of the project Vyacheslav Solonitsyn, founder of the Ruvento Ventures venture fund).

Two residential modules of the company have already appeared in California. The price varies between $100,000-250,000, and this is almost half the price of traditional analogues. The construction of such houses is going twice as fast, and they save on labor and up to 95%, say the startup. Investors believe in the project: in 2018, the startup passed the Y Combinator winter batch and raised $30 million from venture funds. As, by the way, in other players - in August, the ICON startup from the USA, which prints at home, received $ 35 million, the construction printer was made by the Russian company Apis Cor, in 2019 the PIK group bought equipment from it. But what risks can stand in the way of 3D printing in mass construction and are there any solutions waiting for the domestic market?

Two residential modules of the company have already appeared in California. The price varies between $100,000-250,000, and this is almost half the price of traditional analogues. The construction of such houses is going twice as fast, and they save on labor and up to 95%, say the startup. Investors believe in the project: in 2018, the startup passed the Y Combinator winter batch and raised $30 million from venture funds. As, by the way, in other players - in August, the ICON startup from the USA, which prints at home, received $ 35 million, the construction printer was made by the Russian company Apis Cor, in 2019 the PIK group bought equipment from it. But what risks can stand in the way of 3D printing in mass construction and are there any solutions waiting for the domestic market?

Migrants slow down the 3D printer

Almost the main barrier to technology remains the cost of labor. In the West, where the price tag for it is very high, the reduction in wage costs will become a driver for the introduction of 3D printing in construction, says Vladislav Levushkin . The 3D printer works 24 hours a day and allows you to minimize the number of maintenance personnel, he notes. In addition, labor productivity is almost not growing in the industry, and the situation really requires the replacement of manual labor. However, not in the case of Russia, as well as with other emerging markets.

The 3D printer works 24 hours a day and allows you to minimize the number of maintenance personnel, he notes. In addition, labor productivity is almost not growing in the industry, and the situation really requires the replacement of manual labor. However, not in the case of Russia, as well as with other emerging markets.

“ Whoever we talked to, we always heard in response that as long as there are cheap labor, mechanisms are not needed,” he says.

Even taking into account the high staff turnover and construction delays due to the poor quality of work, builders are not ready to give up migrant labor.

"In countries where labor costs less than $5 a day, it is not economically feasible to build using 3D printers" - agree Diana Stepanova G. V. Plekhanov.

Against - habit and fear

The extreme conservatism of the construction industry players also remains a barrier.

“When you propose new technologies, the question “why” always arises, and the builders are right in many ways. Houses have to stand for many decades, and it’s not easy to understand how justified innovations are,” says Levushkin, co-founder of Vertical Printing Technologies.

Reluctant to test innovations and customers.

“Buying a house for people is the biggest expense in life, they are afraid to experiment in such an important deal,” says investment director of Fort Ross Ventures Egor Abramov .

And in order to encourage a person to experiment, you need to offer a stunning advantage, so serious that he turns a blind eye to the risks, he elaborates.

“The industry is conservative for a reason, many tried to “storm” it, few succeeded,” explains Egor Abramov .

Technology for low-rise buildings

3D printing of houses is mainly used in low-rise housing construction, but in Russia the majority of the population lives in high-rise buildings, recalls Yegor Abramov. He clarifies that the country is characterized by strong temperature and humidity fluctuations in summer and winter, which requires more capital construction.

He clarifies that the country is characterized by strong temperature and humidity fluctuations in summer and winter, which requires more capital construction.

Such solutions may be suitable for low-rise and individual construction, Diana Stepanova agrees. There will also be demand for the construction of budget or even temporary housing, for example, in the event of disasters or hostilities, she believes.

In the meantime, this is a bespoke solution for discerning customers, so the family can design their own house using 3D printing for ease and simplicity of construction. And in the future, in the USA, China, and Europe, it will be possible to lease 3D printing equipment and build a house according to the instructions, suggests Stepanova.

Material

Residential printing materials have long been a challenge in terms of durability and cost. In recent years, the barrier has been overcome; many companies print houses or parts of them, says Evgeny Matveev , CEO of F2 innovations (resident of Skolkovo). For work, either concrete or polymer composites are used.

For work, either concrete or polymer composites are used.

"I admit that modern composite materials make it possible to create durable and flexible materials for buildings" - speaks Maksim Semyonov , Head of the Product Management Department of the Grundfos Industrial and Household Equipment Department.

However, there are questions about the maintainability of houses from a 3D printer.

“If I want to change the socket, can this panel be chiselled? How to transfer communications? What will be the soundproofing? This is very important,” Maxim Semenov reflects on .

By the way, 3D printing does not solve the issue of finishing and fine repairs.

From nursery to kindergarten

Regulatory is considered to be one of the barriers to 3D printers, but difficulties are unlikely to arise if the technologies prove to be really effective. As long as there are chances. Where solutions used to be treated like toys, now tens of millions of dollars are being invested in projects. A selection period has begun in the industry, different technologies will be tested for some time, and the one that will prove to be the most cost-effective will survive.

As long as there are chances. Where solutions used to be treated like toys, now tens of millions of dollars are being invested in projects. A selection period has begun in the industry, different technologies will be tested for some time, and the one that will prove to be the most cost-effective will survive.

“This is already perceived as a business; houses will be built, this is already serious, we have moved from a nursery to a kindergarten, ”says Vladislav Levushkin on .

“The homebuilding industry is interesting in terms of innovation, because it is very conservative and one of the few that has remained unchanged for the last hundred years. Houses are built of concrete, brick or wood, mostly by hand and primitive machinery. An industry-changing technology could be a trillion-dollar valuation for a company.” — believes Egor Abramov.

In Russia, the technology of 3D printing of houses, if it comes, then with a delay, after Europe and the USA.