3D printing jewelry

Guide to Jewelry 3D Printing

Two techniques have historically defined jewelry making: handcrafting and lost-wax casting. Both techniques require significant technical expertise, are highly time-intensive, and mistakes in the process can prove expensive.

But today, digital design and 3D printing are primed to disrupt these age-old practices in a major way. Supplementing traditional processes with digital techniques such as jewelry 3D printing brings new possibilities in design and production to jewelers, as well as exciting new customization options for customers.

White Paper

In this white paper, learn how to cast fine jewelry pieces from 3D printed patterns and how direct investment casting, or lost wax casting, works as a moldmaking technique.

Download the White Paper

3D printed jewelry production augments the principles of investment casting, or lost wax casting with the advantages of a digital design and manufacturing process.

With traditional lost-wax casting, jewelry designers hand-carve the original pattern in wax, place the wax pattern in a mold to be burned out, and then pour precious metals like gold or silver into the mold cavity to create the cast piece. To achieve its final appearance, designers polish and finish the cast piece to shine.

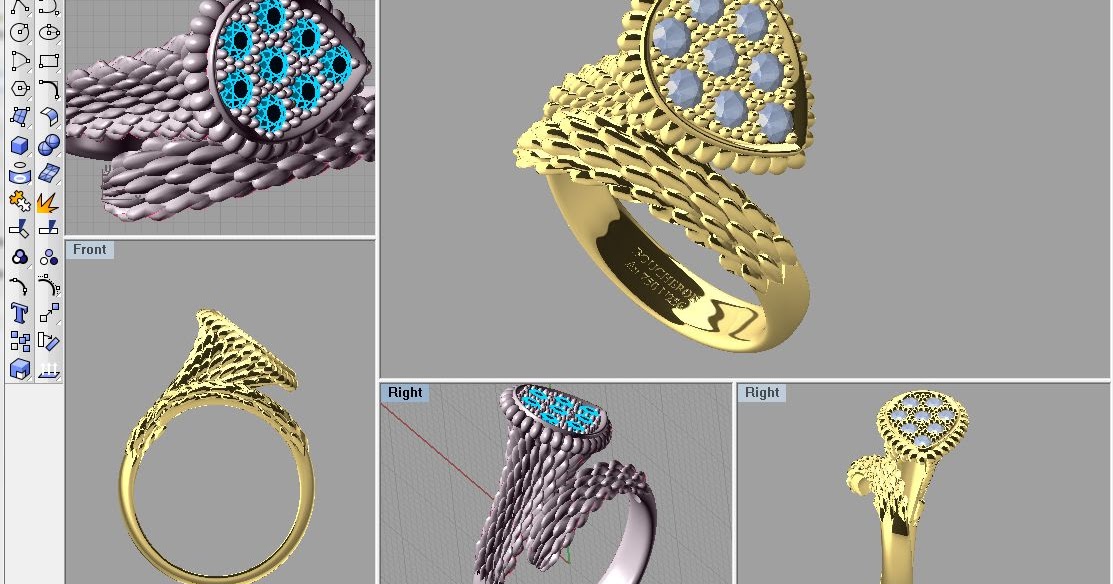

With the digital workflow, jewelers use CAD software tools for jewelry design to create the models digitally and a high-resolution 3D printer to produce the 3D printed jewelry patterns that can then be cast in a mold. After burnout of the positive pattern, the process follows the same path as traditional investment casting. Thanks to the digital techniques, the need for time-intensive manual labor is reduced and the design itself is easy to preserve, modify, and recreate when needed.

Sample part

Curious to see our materials firsthand? Click here and we'll ship you a free jewelry sample part printed on our 3D printer.

Request a Free Sample Part

Until now, the complexity of the design and production process made customized jewelry an expensive privilege. With digital tools, however, jewelers have already started offering personalized creations as part of their basic service or as a value add. If you go to a jeweler today and ask for an engagement ring, often you'll have the option to customize a unique design.

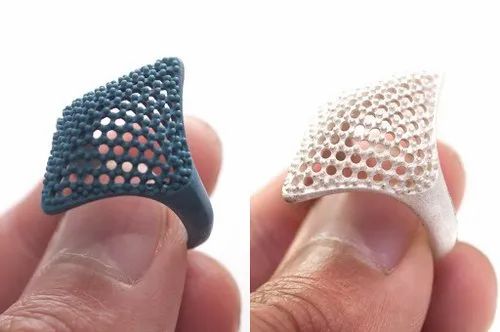

3D printed jewelry try-on pieces drastically shorten the feedback loop between designer and customer.

Jeweller and customer can discuss the design together, and an hour later, the customer can hold and try on a real, physical model of the ring. In jewelry retail, on-site digital design combined with the speed of 3D printing has drastically shortened the feedback loop between designer and customer.

Moving from design to production is easier and faster, as hand carving a precious one-off is no longer a requirement. The try-on pieces can be tailored based on the customer’s requests, 3D printed again, and then manufactured with lost-wax casting, which translates to a considerable reduction in the cost of making customized 3D printed jewelry.

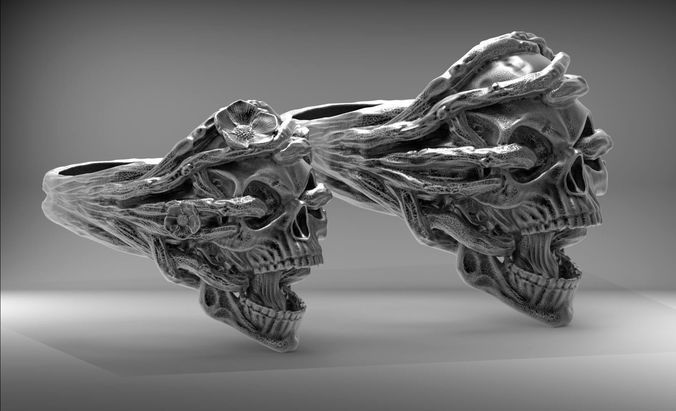

With 3D printing, jewelry designers are able to produce designs that would be incredibly difficult to hand carve in the traditional manner. Breakthroughs in castable resins are setting new standards for the quality available through an affordable desktop 3D printer.

3D printing jewelry patterns in Formlabs’ Castable Wax 40 Resin combines the smooth surface finish characteristic of stereolithography (SLA) 3D printing technology with precise print settings. Thanks to a precisely controlled laser, extraordinary design details—delicate filigrees, raised text, and detailed pavé stone settings—can be captured with amazing sharpness.

Stereolithography 3D printing can reproduce complex features that’d be difficult to hand carve.

With these long-established design restrictions now removed, we're seeing entirely new genres of design emerging from jewelers who digital capabilities in the US as well as in South Asia and Asia Pacific, and the Middle East.

Webinar

In this webinar, Patrick Diggins, our Jewelry Vertical Manager, will teach you how Castable Wax 40 can help you push the boundaries of design and production efficiency.

Watch the Webinar

Digital tools are not only making jewelry easier to customize, but also simpler to mass-produce designs.

Vulcanized rubber molds are used to produce wax patterns in quantity for lost-wax casting, but the “master” pattern is traditionally made from an investment cast, hand-carved wax pattern.

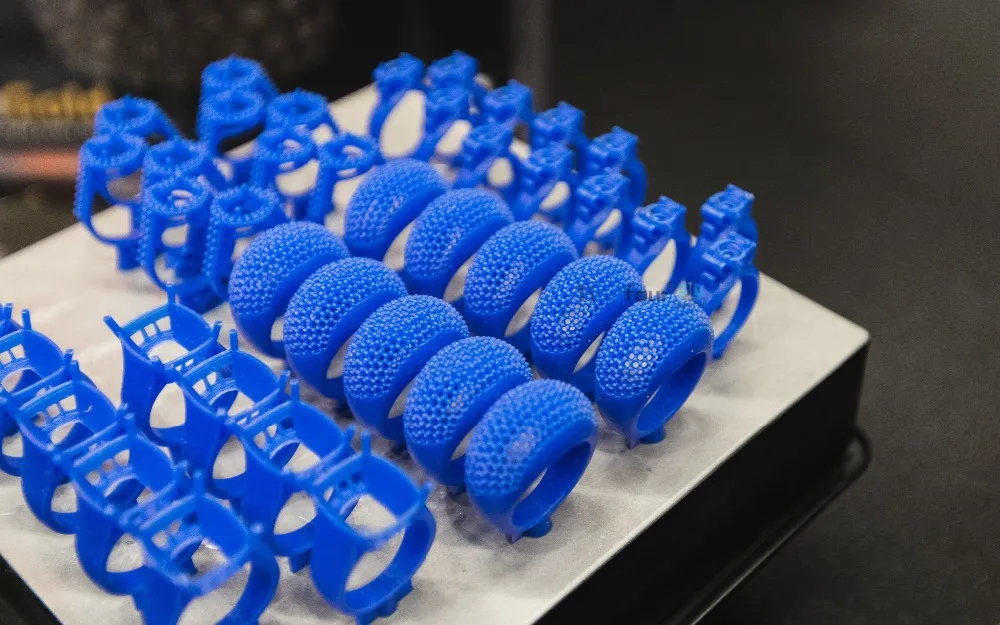

3D printers can produce master models that are used to form room temperature vulcanization (RTV) molds and even durable high temperature vulcanized rubber molds.

Directly 3D printed jewelry patterns can be used for room temperature vulcanization (RTV) and vulcanization of high temp natural rubber.

“With the quality that you can get with SLA 3D printing for printing these jewelry pieces, you can jump straight from the 3D printed part to a master mold,” said Formlabs' Jewelry Vertical Product Manager Amos Dudley. “The surface finish is already so smooth that it doesn't require very much finishing. You can use that as the rubber mold for creating the final wax parts that go into production. ”

”

White Paper

3D printing with high-performance materials allows designers and casters to leverage digital technology in their production processes. Read now to learn how 3D printing can be used in the production of small metal parts.

Download the White Paper

When new technology is finally made available to the public, it usually comes with a high price tag and a complicated interface, restricting it to users with deep pockets and technical savvy. Previous generations of jewelry 3D printers required both significant maintenance and a skilled operator in addition to thousands of dollars of investment that limited them to the largest jewelry manufacturers and casting houses. Nevertheless, Dudley notes, “3D printing has become much more affordable, offering unique opportunities to independent jewelry makers.”

The lower cost and higher-quality jewelry 3D printing technology have made the digital workflow a viable method of manufacturing. “In the coming years, we're going to see a growing trend in that segment, with smaller jewelers adopting these technologies and becoming less centralized,” Dudley said.

“In the coming years, we're going to see a growing trend in that segment, with smaller jewelers adopting these technologies and becoming less centralized,” Dudley said.

This shift to increasingly competitive independent jewelers will continue as the industry becomes more familiar with castable resin 3D printing. Historically jewelry 3D printing has been dominated by complex and expensive wax 3D printers. With affordable desktop jewelry 3D printers like the Form 3+, the technology is becoming available to more jewelers, especially smaller independent ones.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Owing to the formerly high cost of large-scale jewelry 3D printers and the perceived barrier-to-entry of digital jewelry design, 3D printed jewelry, despite its potential, currently represents a relatively small fraction of the market.

Nevertheless, with increasingly easy to use and accessible jewelry 3D printers, the digital workflows in the jewelry market are poised for growth. Desktop stereolithography 3D printers are an important component in this expansion.

High-resolution desktop 3D printers, like the Formlabs Form 3+, have made jewelry 3D printing accessible for independent designers as well as large casting houses.

“SLA resins have a reputation for being cheaper, but also less functional than wax. At Formlabs, we're looking to break that impression with products that are more foolproof and eliminate some of the extra work that’s still present in the jeweler's workflow,” Dudley said.

New, easy-to-use materials like Castable Wax 40 Resin are easing the learning curve, leading to greater adoption of the workflow and the subsequent expansion of the market.

3D printed jewelry is not just a matter of technology. The newer cohorts of jewelry designers entering the industry have started education with digital methods, including training on 3D printers, as opposed to the traditional ones.

“They're going to be looking for the printer that really meets their needs,” Dudley said. “I think then we'll start to see more adoption as they take over from the currently embedded user base.”

3D printing in jewelry has a bright horizon. With the wider industry adoption of workflow techniques, the arrival of new generations of designers skilled in them, and the creation of new, more foolproof materials and hardware, we're seeing the stage set for a major positive disruption.

Request a Jewelry Sample Part

Why you should start thinking about it?

3D Learning Hub

See all categories

Contents:

- Introduction

- Top 5 advantages of 3D printing your jewelry

- How to start producing 3D printed jewelry?

- Get fully on board with 3D printing

Introduction

Top 5 advantages of 3D printing your jewelry

There are many reasons to start producing 3D printed jewelry. What benefits can Additive Manufacturing bring to your business? What can this technology do that others can’t? Let’s find out!

What benefits can Additive Manufacturing bring to your business? What can this technology do that others can’t? Let’s find out!

#1 Unimagined freedom of design

We need to start with the fact that 3D printing works only thanks to 3D modeling. Without a 3D model, you can’t produce anything. And here comes the new design freedom you can reach thanks to 3D modeling. Basically, anything you can imagine can be designed on a computer and then brought to life, layer by layer.

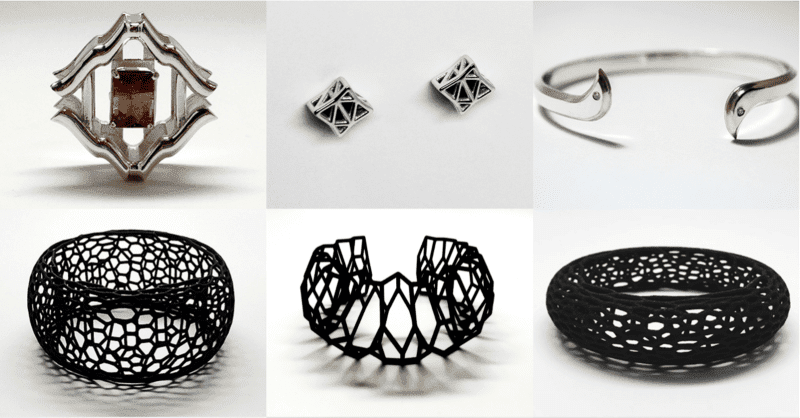

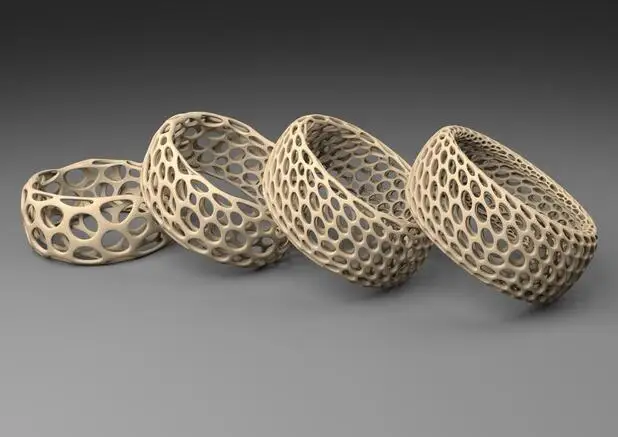

Traditional technologies would struggle or even fail to produce complex geometries and great details on such a small scale, such as earrings. 3D printing gives you the freedom to design abstract shapes or interlocking structures. It can even give you the option to close one object inside another and produce them in parallel.

#2 Don’t worry about the weight

Some jewelry is problematic, as it is heavy, which makes it uncomfortable to wear and not practical. You can forget about that issue if you decide to use Additive Manufacturing technologies. There are many ways to reduce the weight of your 3D printed jewelry.

You can forget about that issue if you decide to use Additive Manufacturing technologies. There are many ways to reduce the weight of your 3D printed jewelry.

First of all, some materials are pretty lightweight as it is. Technologies such as SLS or Jet Fusion works with plastic powder, which already makes them much lighter than if you were using traditional manufacturing technologies.

Your 3D printed jewelry can also be filled with lattices. Bigger designs such as decorative ornaments, brooches, or necklaces don’t have to be solid inside. An interesting solution to lightweight 3D printed jewelry is lattice structures.

Last but not least, your parts can be hollowed. There are some 3D printing materials that may not allow it, but they’re also plenty of options to choose from where hollowing is allowed and even advised. Learn everything about hollowing with our guide.

#3 Reach a new level of quality

You might be one of those people who see 3D printing as a low-quality FDM 3D printer, where the layers are very visible. That’s old news. Professional 3D printing brings to the stage HD quality for your 3D printed jewelry.

That’s old news. Professional 3D printing brings to the stage HD quality for your 3D printed jewelry.

Depending on the technology, Additive Manufacturing is capable of reaching layer thickness as little as 25 µm, which is 0.025 mm. For comparison, average hair thickness is 100 µm. New production techniques allow you to reach the ultimate quality, also at a low cost.

#4 Innovative 3D materials

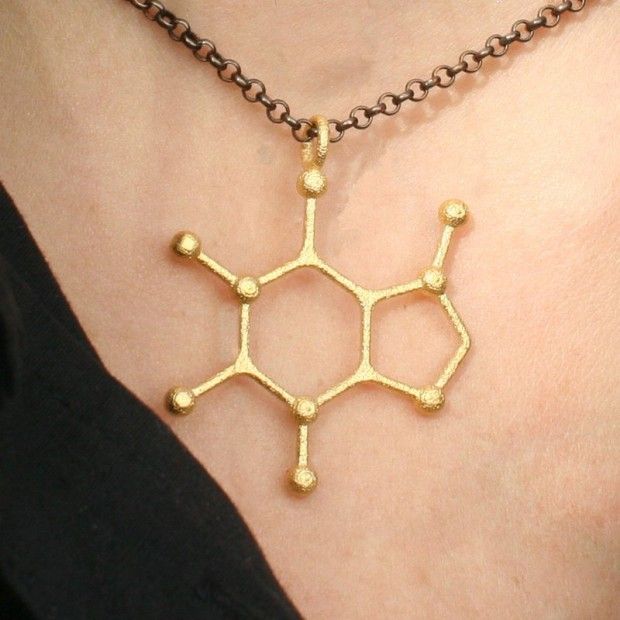

Metal 3D printing can also be beneficial for you, you can produce your designs in precious metals such as Brass, Bronze, or Silver with different plating options. You can learn more about Metal 3D printing and Wax Casting with our free ultimate guide.

However, as we mentioned above, you can use even plastic for your 3D printed jewelry. Don’t limit yourself only to metals, there can be also other, innovative materials. One of our clients 3D printed bag ornaments for her collection with plastic technology SLS 3D printing, which then were finished in different colors.

Also worth mentioning are resins. Both plastic and resin for 3D printing are strong materials, robust and resistant to scratching. For instance, VeroWhite resin can give you 3D printed jewelry with a very smooth surface thanks to UV curing and is available in 12 colors. Other resins, such as EPU, are flexible and can be recommended for bracelets or watch straps.

#5 Manufacture 3D printed jewelry molds

If you decide Additive Manufacturing is not the right technology to produce your jewelry, it can still be a great asset to your design process. An interesting application of 3D printing is molds. Your production process can be improved thanks to 3D printing as it can provide you with a perfect master model to later be used for mold making.

Creating molds with the help of 3D printing is quite popular, read more about the advantages coming from 3D printed molds.

How to start producing 3D printed jewelry?

The first step is 3D modeling. It can be easier than you think as there are special software dedicated just for jewelry design. Choose the best one for your project with our top 11 of the best jewelry design software. However, if you would like to start by taking baby steps in the virtual world, check out the easiest 3D modeling software of 2019.

It can be easier than you think as there are special software dedicated just for jewelry design. Choose the best one for your project with our top 11 of the best jewelry design software. However, if you would like to start by taking baby steps in the virtual world, check out the easiest 3D modeling software of 2019.

It might so happen that you’re very serious about starting your own jewelry business. There are numerous benefits of that and to make it easier for you, we prepared 5 easy steps to start a jewelry business.

Get inspired with 3D printed jewelry projects

You can already find pretty impressive 3D printed jewelry projects, such as Nylon 3D printed bracelets, luxury rings, or award-winning flexible clutch with our blog post. But we keep an eye on the latest projects, as there are new ones popping up all the time, and they are truly inspiring.

Nervous System

https://n-e-r-v-o-u-s.com/shop/product.php?code=213

Collections of rings, bracelets and matching necklaces, Nervous System designs beautiful, nature-inspired structures, which would be impossible to achieve without 3D technologies. They use computer simulations of plants, such as leaf venation, to create those breathtaking designs. Maybe your inspiration for 3D printed jewelry is right next to you? Take a curious look!

They use computer simulations of plants, such as leaf venation, to create those breathtaking designs. Maybe your inspiration for 3D printed jewelry is right next to you? Take a curious look!

RADIAN

Nefertiti Ring | Brass | Gold

On the other hand, those creators mastered the precision of geometry. RADIAN says that ‘’working with 3D printing as production method opens up a new world of shapes and aesthetics. It allows RADIAN to use innovative materials and create unique and artistic statement pieces’’. Their 3D printed jewelry is minimalistic and one could say simple, but how magnetizing is this simplicity of straight lines. Inspired by graphics and architecture, RADIAN sends a clear message about their mission.

HI Jewellery

https://www.hijewellery.nz/

HI Jewellery is short for Human Interface Jewelry. Ameria Diggle is the founder of the company, and, as you can guess, User Interface designer. She developed her collection of 3D printed jewelry because as she says ‘’Jewelry is something quite personal. It can reflect your style and personality, or it can be sentimental and hold a lot of meaning. People always have stories about the things they wear”. And therefore, she wanted to celebrate women working in the tech industry, to give them something special and personalized. She commented on her development that ‘It’s about giving women a symbol, like a badge of honor that says they belong in the tech industry, and there’s something made for them because they work in tech”.

She developed her collection of 3D printed jewelry because as she says ‘’Jewelry is something quite personal. It can reflect your style and personality, or it can be sentimental and hold a lot of meaning. People always have stories about the things they wear”. And therefore, she wanted to celebrate women working in the tech industry, to give them something special and personalized. She commented on her development that ‘It’s about giving women a symbol, like a badge of honor that says they belong in the tech industry, and there’s something made for them because they work in tech”.

Get fully on board with 3D printing

As you can see, 3D printed jewelry is happening now and there is nothing to stop you from making the most of 3D technologies. Get inspired by 3D printed bracelets and other decorative elements to get the idea of what you can achieve with Additive Manufacturing. Start 3D modeling jewelry with one of the dedicated software and discover absolutely new design freedom and level of details impossible to produce with traditional manufacturing methods.

Once you have your models, don’t worry about investing in expensive 3D printers. You can use an online 3D printing service for production. It is as easy as uploading your file to our website and you will get an instant quote! We can also provide you with any design advice you might need, just contact us.

Stay updated with the latest 3D printing news! Subscribe to our newsletter and follow us on Facebook!

Can you 3D print jewelry?

What is 3D printed jewelry made of?

Can you 3D print gold jewelry?

Can you wear 3D printed jewelry?

Can I make metal jewelry with a 3D printer?

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Choice of technology and 3D printer for jewelry making, pros and cons

Currently, there are many new technologies that are designed to simplify production in various industries. Progress does not stand still and, despite some opponents, 3D printing has its own niche in the production of jewelry.

3D printing can speed up and reduce the cost of jewelry production due to the low cost of consumables. With 3D printers, jewelers have the ability to quickly change the design of a product and make prototypes at least several times a day. For many jewelry industries, 3D printing is becoming a good alternative or addition to milling machines and other equipment.

Until now, some believe that handmade is a sign of craftsmanship, especially when it comes to creative work, and models made using 3D modeling and printing are amateurish. But many people forget that behind the computer is the same person who not only mechanically presses the buttons, but also puts his soul into his creation.

Benefits of 3D printing

In order to understand how justified the use of a 3D printer is, you need to know how jewelry is made. This is very painstaking work. No wonder the expression "jewelry work" appeared, denoting a very delicate and complex work.

Any decoration begins with a sketch. Usually several sketches are made in order to accurately determine the design and location of the inserts. Not only stones are used as decor, it can be elements made of wood, bone, precious metals, it all depends on the designer's imagination.

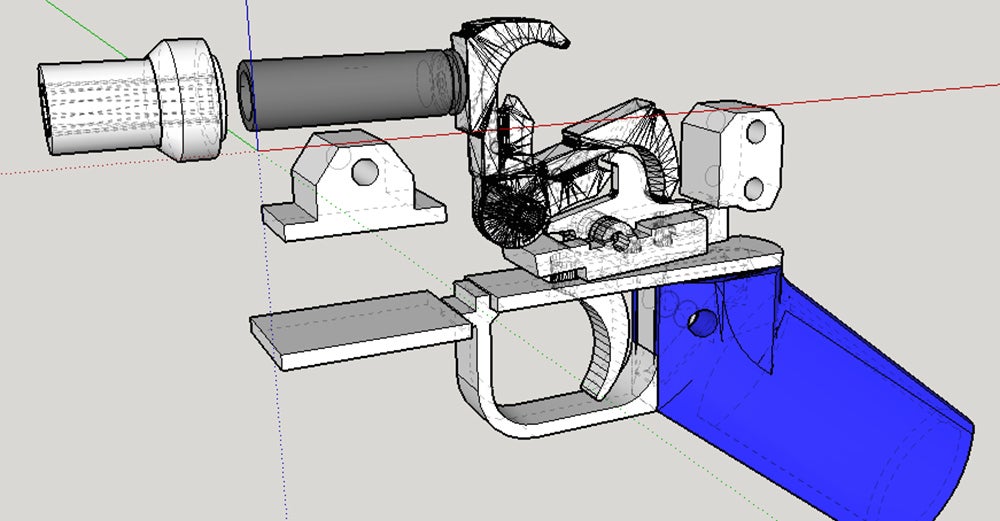

At the next stage, the product is drawn in a 3D editor. This allows not only to visualize the future product, but also to correct some errors and inaccuracies made at the design stage.

Ring model

Some craftsmen still carve "stencils" by hand. Such work requires certain skills and perseverance. Usually this is how products are made that will be cast in a single copy.

A finished 3D model can have several ways to be implemented in a physical version - this is milling or 3D printing.

Stencil milling

Currently, 3D printing is not much inferior in accuracy to a milling machine and often has a significant advantage in speed, despite the fact that after printing it is still necessary to separate the supports and clean up the points of contact with the model. Once a physical model has been obtained, it can be cast immediately if the material used is wax or a burnable polymer.

If it is necessary to cast a large batch of products, then a mold is made from the master model made with the help of special rubber for subsequent wax casting. There are many types of rubber that vary in hardness and curing temperature. Rubber is selected depending on the material from which the master model is made.

For pouring molds, a special machine is usually used - an injector. In some models, you can not only heat the wax, but also vacuum it or leave it under pressure. This helps to reduce the number and size of air bubbles for better pouring of the rubber mold.

This helps to reduce the number and size of air bubbles for better pouring of the rubber mold.

In home workshops, silicone is used instead of special rubber. After all, a special machine is needed to vulcanize rubber. But rubber molds are too soft and short-lived for making a large batch of stencils.

After making the required number of stencils, they are collected in "Christmas trees". "Elks" are waxes soldered to a wax rod. To save space, the distance between them is very small and they resemble fluffy Christmas trees, hence the name. The finished Christmas tree is weighed to calculate the required amount of metal. In some places, stones are immediately inserted into the stencils, unless another mounting option is provided.

Stencil Christmas trees

Ready "Christmas trees" are placed in a special cylindrical "cassette" without a bottom, which is called a flask, and filled with a gypsum-based molding mass. The flask with uncured gypsum must be evacuated to get rid of unnecessary air bubbles that can lead to defects on the surface of the finished casting.

The flask with uncured gypsum must be evacuated to get rid of unnecessary air bubbles that can lead to defects on the surface of the finished casting.

After hardening, the gypsum flask is sent to a muffle furnace to melt the wax.

The calcination mode is selected depending on the material of the wax. For wax or burnout polymer, different modes are needed in order for the material to be completely removed from the gypsum!!!!!!

When all the wax is melted, cavities are formed inside the gypsum, repeating the contours of the wax. Metal is poured into these voids. After casting, the flask is cooled and the gypsum mold mass is washed out under the pressure of water. The result is a metal Christmas tree.

Herringbone after casting

Finished castings are cut from the Christmas tree and washed, polished, if necessary, blackened by the master until the desired appearance is achieved.

3D printers for jewelers

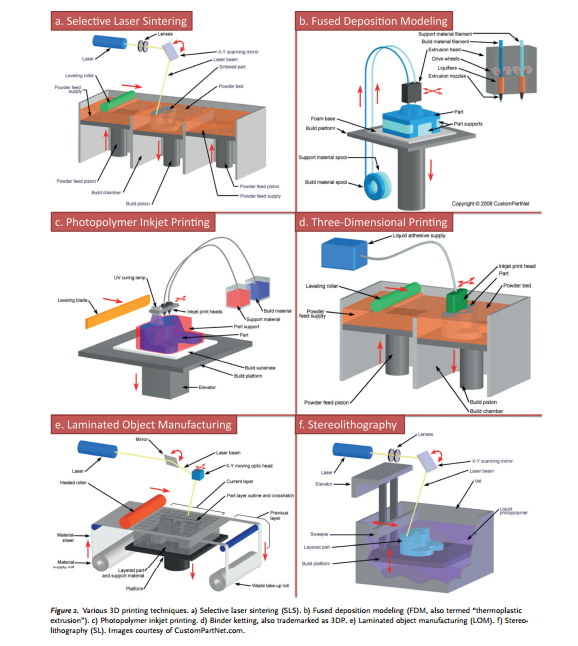

There are several 3D printing technologies that may be suitable for the needs of jewelers. Each has its pros and cons. Some 3D printers are ideal for a large workshop, and some are ideal for a small workshop.

SLA

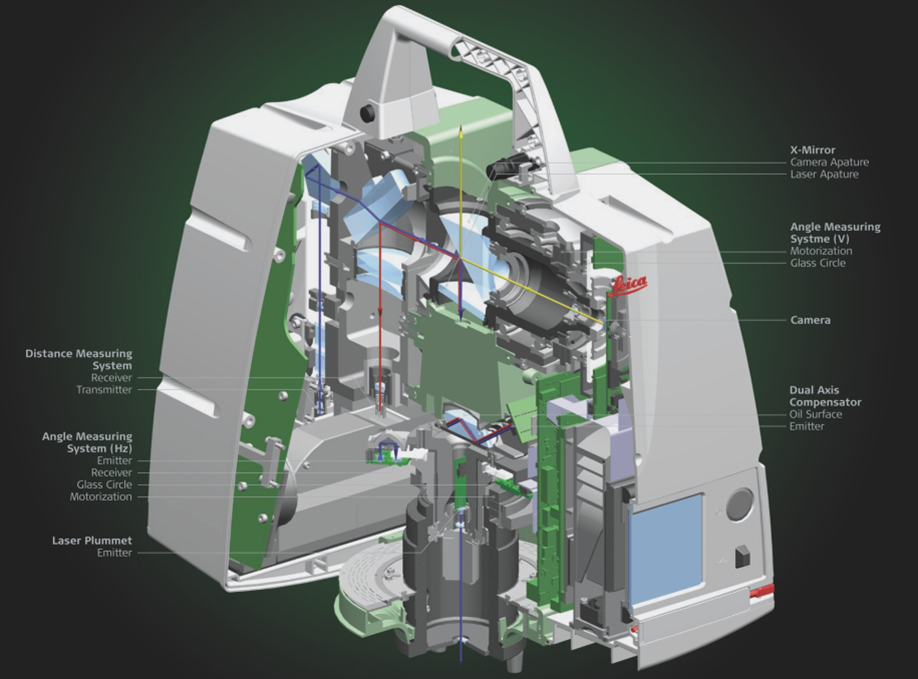

SLA or stereolithography is based on the principle of layer-by-layer solidification of a photopolymer resin under the action of a UV beam. The UV beam is focused by means of mirrors on the surface of the resin and illuminates the model in layers.

How the SLA Printer Works

SLA 3D printers were the first to be noticed by jewelers. SLA devices are compact, while they have high printing accuracy.

Pros and cons

pros

Minuses

Print examples

From prototype to finished product

Cast and printed ring

Rating of printers.

Leadership among the production of SLA 3D printers is held by Formlabs.

Formlabs Form 3

Formlabs Form 3

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 14.5×14.5×18.5cm

Layer thickness: 25 – 300 µm

A professional 3D printer that is popular with professional jewelers and dentists.

Formlabs Form 3L

Formlabs Form 3L

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 33.5×20×30cm

Layer thickness: 25 – 300 µm

Form 3L differs from younger models in its large print area, which allows you to produce truly large products without losing quality and accuracy.

DLP/LCD

DLP is very similar to SLA, only as a source of UV radiation, to illuminate the photopolymer resin, not a directed beam of light is used, but a DLP projector. DLP printers illuminate the entire work area at once, so they greatly outperform SLA in print speed.

DLP printers illuminate the entire work area at once, so they greatly outperform SLA in print speed.

How a DLP Printer Works

Today it is one of the most affordable photopolymer 3D printing technologies. In terms of cost, LCD printers have caught up with the price level of amateur FDM. DLP printers are much more expensive due to the use of an expensive projector as a UV source.

The projector is of course more expensive, but more durable, on the other hand, the LCD display is not so expensive and can be easily seen, unlike the projector. What to choose each user decides for himself.

Pros and cons.

pros

Minuses

Print examples

Comparison between 3D printed master model and molded part

Burnout resin model and finished product

Demonstration of products cast with burnout resin

Rating of printers.

The print accuracy of LCD printers depends on the pixel size, so you should pay attention to this parameter when choosing a printer.

Anycubic Photon Mono

Anycubic Photon Mono

Specifications:

LCD display resolution: 2560x1620 (2K)

XY Positioning Accuracy: 0.051mm

UV wavelength: 405 nm

Working area size: 130x80x165 mm

Layer thickness: 0.01-0.15mm

The Anycubic Photon Mono is an inexpensive LCD machine ideal for hobby printing. The monochrome display allows you to reduce the exposure time and speed up printing.

Phrozen Sonic 4K

Phrozen Sonic 4K

Specifications:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x200 mm

Layer thickness: 0.01-0.30mm

Phrozen Sonic 4K is specifically designed for use in the dental and jewelry industry. Despite its compact size, the printer is not inferior to professional machines in accuracy, and the exposure time of one layer is only a few seconds.

Despite its compact size, the printer is not inferior to professional machines in accuracy, and the exposure time of one layer is only a few seconds.

Phrozen Sonic Mighty 4K

Phrozen Sonic Mighty 4K

Specifications:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mighty 4K is a professional device with a large print area. This allows you to quickly produce small batches of models.

Phrozen Sonic XL 4K

Phrozen Sonic XL 4K

Specifications:

LCD resolution: 8.9" 4K Mono-LCD

XY positioning accuracy: 50 microns

UV wavelength: 405 nm

Working area size: 190x120x200 mm

Layer thickness: 0.01-0.3mm

The Phrozen Sonic XL 4K is a professional machine with a large print area and a high resolution monochrome LCD display. This allows you to quickly produce batches of products with high accuracy.

This allows you to quickly produce batches of products with high accuracy.

Peopoly Phenom XXL

Peopoly Phenom XXL

Specifications:

LCD display resolution: 3840x2160 (23.8", 16:9, UHD 4K)

XY positioning accuracy: 137 µm

UV wavelength: 405 nm

Working area size: 527x296x550 mm

Layer thickness: 0.01-0.3mm

The Peopoly Phenom XXL is a device with a huge build area, which is ideal for serial production of not only jewelry.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Specifications:

LCD resolution: 15" 8K Mono LCD

XY Positioning Accuracy: 43 µm

UV wavelength: 405 nm

Working area size: 330 x 185 x 400 mm

Layer thickness: 0.01-0.3mm

This is the first LCD printer with 8k monochrome matrix resolution, and a huge working area allows you to produce large batches of products in one print.

MJM/MJP

MJM (or similar PolyJet technology) is a technology for layering photopolymer or wax through many fine nozzles. Typically, the print head is located from 96 to 448, depending on the printer model.

If a photopolymer is used as a material, it is immediately cured by a UV lamp, which is located on the printer's head.

How the MJM printer works

In addition to photopolymer, MJM 3D printers can use wax as a material for printing.

MJM printers can print multiple materials at the same time. This allows you to print complex models with soluble or investment supports. This makes it possible to produce complex models with a smooth surface quickly and easily.

Pros and cons

pros

-

Ability to print multiple materials at the same time. This means that another, soluble material can be used as a support. This allows you to save a lot of time on removing the support from the finished model and cleaning up the places where the supports come into contact with the print.

Minuses

-

To install the printer, most likely, you will need a separate room. 3D printers based on MJM technology are quite bulky in their dimensions, this is not a device that can simply be placed on a desktop or nightstand.

Print examples

Seal of a lot of stencils

Ring printed with wax

Master models made on MJM printer

Lot of jewelry stencils for further casting

Printer rating

FlashForge WaxJet 410

FlashForge WaxJet 410

Specifications:

Materials: Wax, support material.

Resolution: 1200*1200*1600

Building area size: 289*218*150mm

Layer thickness: 16 microns

Accuracy: ±0. 04mm / 20mm

04mm / 20mm

The FlashForge WaxJet 410 is an industrial machine designed for serial printing of wax models, which will then be cast from metal. Machines of this class can be useful not only in jewelry production, but also in the dental industry, aerospace, mechanical engineering, prototyping, etc.

Totals

Photopolymer 3D printers are no longer inferior in detail to professional milling machines. The main advantage of a 3D printer is the ability to produce models of complex geometry with many internal cavities that are physically impossible to produce on a router.

Large firms will appreciate the flexibility that allows them to quickly adapt to customer requirements, as well as quickly produce large and small batches of products due to the shortening of the production chain.

And for a small workshop, a small photopolymer printer with a can of burn-out resin can be a good help, eliminating the need to purchase some expensive machines.

Jewelery - printing master models for direct casting

3D modeling and printing technologies have revolutionized the jewelry industry. The fact is that in this area a lot depends not only on talent, but also on the precise work of the hands. And this work is truly "jewelry". It requires a lot of attention, concentration and time, it is also difficult to eliminate human errors (jewelry).

3D printing has improved the process of making jewelry and souvenirs. Products are fully modeled on a computer, and then sent to print in a 3D printer. And neither hand can compare with this tandem in terms of accuracy and perfection. It is possible to create even the most complex products in terms of geometry and execution, including completely miniature ones. With the use of printing, the manufacture of jewelry can be carried out by two methods. The choice depends on which batch of products you need. Various approaches are used to reduce the cost of one product.

Our company is professional in 3D printing. We provide 3D printing services in the jewelry field due to the availability of specialized high-quality equipment, which is characterized by the highest accuracy. This allows us to quickly carry out 3D printing at affordable prices.

We provide 3D printing services in the jewelry field due to the availability of specialized high-quality equipment, which is characterized by the highest accuracy. This allows us to quickly carry out 3D printing at affordable prices.

If the product will be a piece, then you can use individual models, burned out during direct casting. At the same time, based on the STL file, which contains information about the modeled product, 3D printing is carried out. A special wax or photopolymer can be used. Products do not require additional processing, as they are distinguished by high precision and an ideal surface. In the future, each individual product is fixed on the leg and a so-called "tree" is created. This tree is placed in a capsule filled with a special material. The capsule is placed in an oven where the material is cured and the models are fired without ash. Then molten gold, silver or other metal is poured into the resulting mold. After cooling, finished jewelry is obtained. This approach is optimal when creating piece jewelry or a small batch.

This approach is optimal when creating piece jewelry or a small batch.

In our company you can order high-quality 3D printing of individual models of jewelry for direct casting.

Printing master models for rubber vulcanization

If a decent series of products is required, then it is more expedient to print master models used for rubber vulcanization. In this case, with the help of a rubber mold, the required number of products will also be created from the burnt-out ashless plastic. This approach allows you to reduce the cost of one product.

The essence of the method is to print a master model, which is placed in a rubber blank. This blank goes through the vulcanization process and a reusable mold is obtained for casting plastic blanks for future jewelry. And the further process is similar to the previous one - a “tree” is built, placed in a special cylinder, the products are burned out without ash in a furnace, and molten metal is poured into the resulting form.