For over twenty five years we have revolutionized product development through the application of SLA® (Stereolithography), SLS® Systems (Selective Laser Sintering) and DMS; (Direct Metal Sintering) Production 3D Printers to generate concept models, precision and functional prototypes, master patterns and molds for tooling, and real end-use parts. Our customers have helped us push the boundaries of what’s possible with production 3D printing and the results are well worth the effort.

Stereolithography SLA

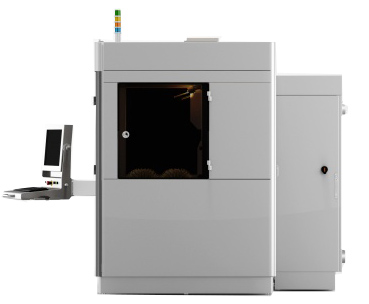

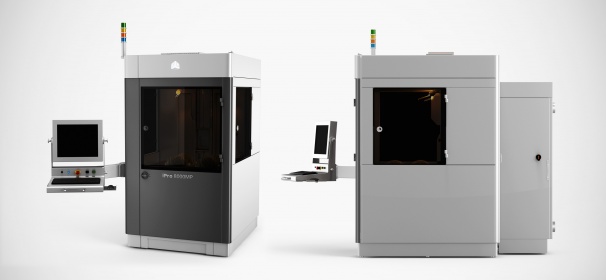

iPro™ 8000

High-productivity, mid-range SLA® 3D printing system that builds robust parts with outstanding surface smoothness, feature resolution, edge definition and tolerances.

SLA technology is extremely versatile and it can be used in any number of areas that require precision above all else. It is all about precision and accuracy, so it is often used where form, fit and assembly are critical.

The tolerances on an SLA part are typically less than .05mm, and it offers the smoothest surface finish of any additive manufacturing process. Considering the level of quality SLA can achieve, it’s particularly useful for creating highly precise casting patterns (e.g., for injection molding, casting and vacuum casting) as well as functional prototypes, presentation models, and for performing form and fit testing.

iPro™ 8000 MP

High-productivity, mid-range Stereolithography 3D printing system that builds robust medical parts with outstanding surface smoothness, feature resolution, edge definition and tolerances and is equipped with automated, push-button data processing to build hundreds of parts at a time.

The system’s mid-range build envelope and high-throughput capabilities make it ideal for the rapid mass customization of medical parts, including orthodontics, implant drill guides, dental restorations and hearing aid shells, among others.

SLA technology is extremely versatile and it can be used in any number of areas that require precision above all else. It is all about precision and accuracy, so it is often used where form, fit and assembly are critical.

ProX™ 950

The largest-format, highest-speed, greatest accuracy and greenest 3D printer available today, offering revolutionary new ways to quickly manufacture precise plastic parts and forgo the design limitations of CNC or injection molding.

Equipped with the newest PolyRay™ print head technology that can manufacture real parts at up to 10 times the speed of other 3D printers, drawing on the widest choice of proven high-performance engineered materials that are qualified for the most demanding aerospace, medical device and industrial use-cases. It can produce precision parts with accuracy that rivals CNC machining, ranging in sizes smaller than the eye of a needle all the way to parts larger than a life-size tiger without compromising feature details or true-to-CAD accuracy.

Laser Sintering SLS

ProX™ 500

Designed for the manufacturing floor, produces ready-to-use functional parts and complete assemblies for a variety of aerospace, automotive, patient specific medical devices, fashion accessories, and mobile device use cases. With over 80% material reusability, the integration of both new printer and material yields the most economical material utilization available.

Direct Metal Sintering (DMS)

All 3D Systems’ DMS printers create chemically pure, fully dense metal and ceramic parts, and they deliver accuracy compatible with EN ISO 2768 (fine) machining tolerances and a repeatability of about 20 microns in all three axes. Materials include stainless steel, tool steel, super alloys, non-ferrous alloys, precious metals and alumina. The outstanding output quality, with high accuracy, finish, reliability and repeatability, and a choice of more than 15 materials, makes these industry-leading machines highly attractive to manufacturers.

The ProX line of DMS 3D printers are providing seamless and intuitive metal 3D printing in a variety of industries: custom dental prostheses, orthopedic implants, tire molds, watch manufacturing, aerospace parts and more. In addition, these systems are wisely used for direct creation of conformal tooling, tooling insert and blow mold production.

ProX™ 100

The ProX™ range of Direct Metal Sintering (DMS) 3D printers builds on 3D Systems’ stellar laser sintering capabilities by incorporating 10 years of research and development in metal 3D printing.The smallest of the ProX DMS line, the ProX 100 is designed as the starting point for people wishing to manufacture small, complex metal parts at high quality and speed using DMS.

The ProX 100 features a build volume of 100mm x 100mm x 80mm along with manual material loading and an optional external recycling station. The system supports materials including Maraging 1.2709, Stainless 17-4PH, Ti6Al4V, AlSi12. The ProX 100 also includes 3D Systems’ software tools, which are specifically designed to ensure successful direct metal or ceramic manufacturing processes.

ProX™ 100 Dental

Enables you to use Direct Metal Sintering (DMS) to produce high-quality, metal dental prostheses, which can be directly used by dental laboratories. Supporting certified Ni-free CoCr materials for dental use, its a perfect starting point for clients wishing to quickly manufacture small, complex dental prostheses. To streamline your workflow includes a high-performance software solution for managing the manufacure of fixed and removable dental prostheses.

This seamless, intuitive interface quickly guides you from dental file import to the creation of manufacturing files.The ProX 100 Dental system is the smallest of the metal 3D printing systems, with a build volume of 100mm x 100mm x 80mm. It has manual loading of materials and an optional external recycling station, with materials that can be manipulated safely.

ProX™ 200

The latest addition to the ProX™ range, the ProX 200 integrates a powerful laser adapted to an intermediary production volume for the streamlined manufacturing of precise, medium-sized metal parts. The ProX 200 is a high-performance, high-quality alternative to traditional manufacturing processes, offering reduced waste, greater speeds for production, short set up times, very dense metal parts, and the ability to produce very complex assemblies as a single part.

In addition, the ProX 200 gets you to your part faster with seamless, intuitive 3D printing software.The ProX 200 system offers a build volume of 140mm x 140mm x 100mm height. It features semi-automated material loading and an optional external recycling system, and supports materials, including Maraging 1.2709, Stainless 17-4PH, Ti6Al4V, AlSi12 as well as ceramics.

ProX™ 200 Dental

The ProX™ 200 Dental brings the power of laser sintering to the production of metal dental parts using Cobalt Chromium. This high-performance, high-quality alternative to traditional manufacturing processes offers reduced waste, greater speeds for production, short set-up times, very dense parts, and the ability to produce complex assemblies as a single parts.

The ProX 200 Dental system is a large dental printer, offering a build volume of 140mm x 140mm x 100mm height. It features a semi-automated material loading and optional external recycling system, and supports certified Ni-free CoCr material for dental printing.The ProX 200 series offer laboratories the most suitable system for larger volume print runs with the ease of intuitive 3D printing software.

ProX™ 300

3D Systems brings its legendary reliability and repeatability to production-level Direct Metal Sintering (DMS) with the ProX™ 300 3D printer.The ProX 300 3D printer makes additive manufacturing an industrial option for the production of metal parts. The ProX 300 is the largest in our DMS range, offering a build volume of 9.8 x 9.8 x 11.8 in (250 x 250 x 300 mm). It features an automated material loading and recycling system, and supports materials including Maraging 1.2709, Stainless 17-4PH, Ti6Al4V, AlSi12.

The ProX 300 is a high-performance, high-quality alternative to traditional manufacturing processes, offering reduced waste, greater speeds for production, short set up times, very dense parts, and the ability to produce very complex assemblies as a single parts.

ProX™ DMP 320

High precision, high throughput.

The ProX DMP 320, developed from the outcome of nearly half-a-million prints, offers fast build turnaround times in demanding 24/7 production environments.

PRODUCTION READY

Designed for productivity with quick-swap build modules and fast powder recycling.

STRONGER MECHANICAL PROPERTIES

The lowest O2 during builds (25 ppm) for exceptionally strong parts of high chemical purity.

LOW OPERATING COSTS

Efficient consumables management and shared ancillary equipment lower the total cost of ownership.

EXTENSIVELY TESTED MATERIALS

Thousands of hours of parameter optimization ensure predictable and repeatable print quality.

APPLICATIONS VERSATILITY

The ProX DMP 320’s robust, streamlined print process means you can print virtually any geometry and avoid trial-and-error steps.

Contact us