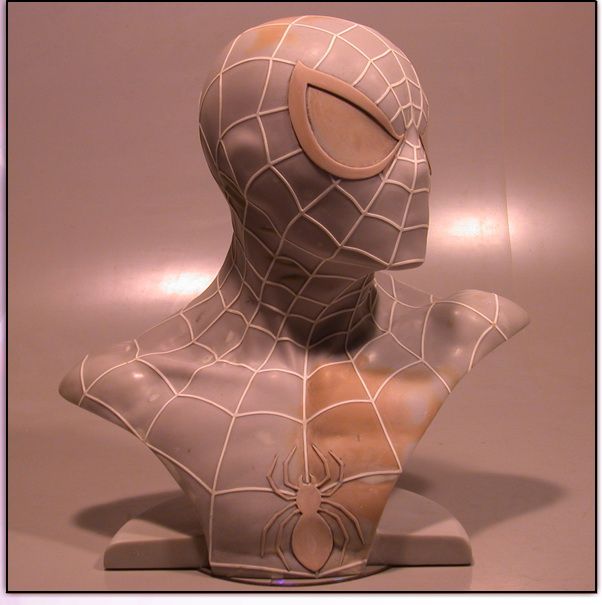

Spider man bust 3d print

Spider Man Bust 3D Printing Airbrush Painting

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Click to zoom

21 sales |

4.€300.00

Loading

Only 1 available

Local taxes included (where applicable)

Rare find — this item is hard to come by.

Arrives by Dec 1-5 if you order today.

Dec 1-5

The delivery date is provided by the seller, and can be based on your purchase date, the recipient's location, the seller's processing time and location, and the shipping carrier.

Learn more

Listed on Oct 24, 2022

4 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies. Tell us more about how this item violates our policies.

Tell us more about how this item violates our policies.

▷ spiderman bust 3d models 【 STLFinder 】

spiderman bust

cults3d

spiderman bust marvel

Spiderman Bust

pinshape

Spiderman Bust, its a must have ! This Version works pretty good and was printed by us, we fixxed all known errors. It needs no supports and is ready to print. ... Recommended settings for 3D printers: ...

SPIDERMAN Bust

myminifactory

Time-lapse print video : https://youtu. be/Ljx36CBOkzY Remix to support free bust and printed. Multicolour remix please go to https://www.myminifactory.com/object/3d-print-157537

Subscribe to find out more support free 4K Time-lapse video:

...

be/Ljx36CBOkzY Remix to support free bust and printed. Multicolour remix please go to https://www.myminifactory.com/object/3d-print-157537

Subscribe to find out more support free 4K Time-lapse video:

...

Spiderman Bust

thingiverse

Another mesh from 3dregenerator (I think) that I sculptured for printing. The webs and spider insignia will need to be added freehand after printing. ...Have Fun!

Spiderman Bust - STL

cults3d

Modification of a bust of Spiderman Original: https://www.thingiverse.com/thing:2079001

black suit Spiderman bust

cults3d

the black suit spiderman, my favorite suit design hope you guys like it!

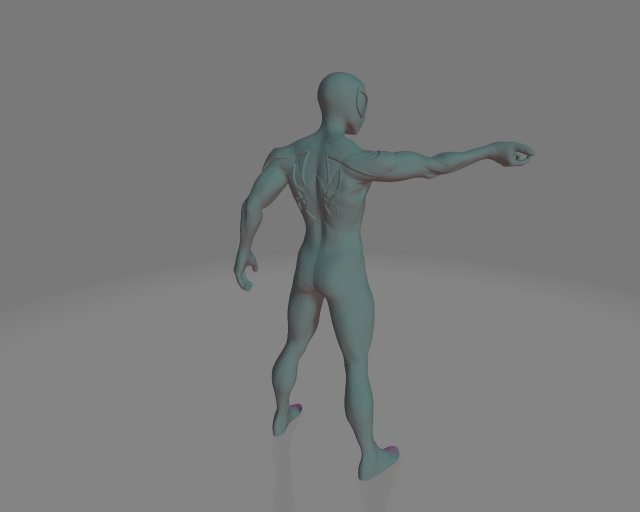

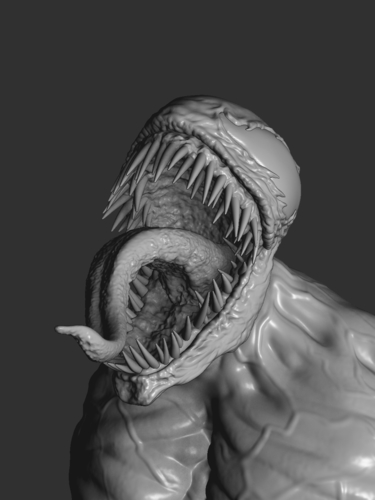

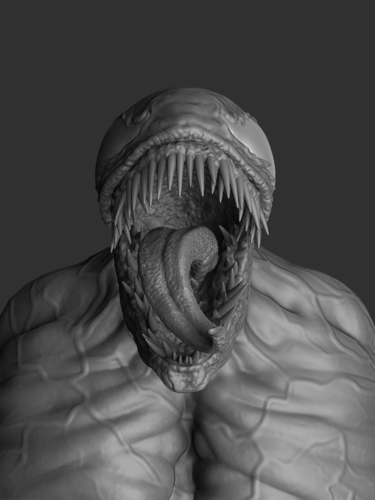

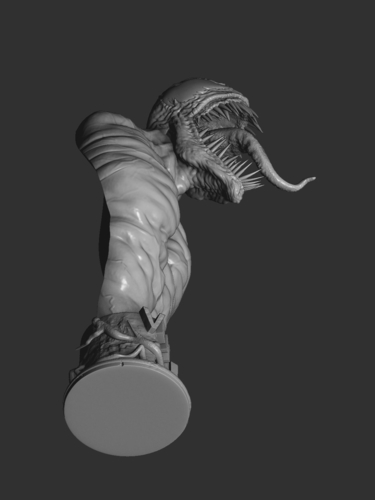

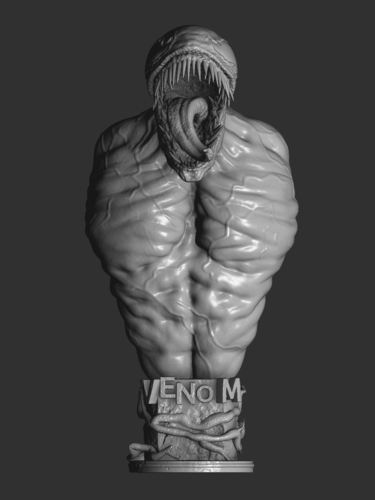

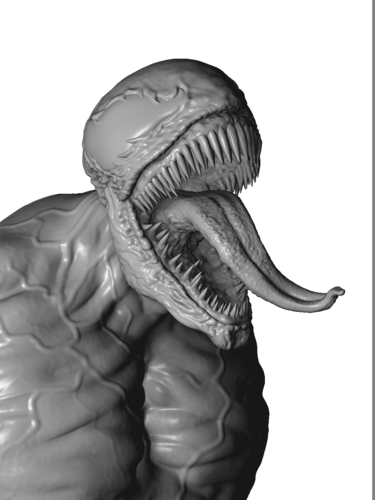

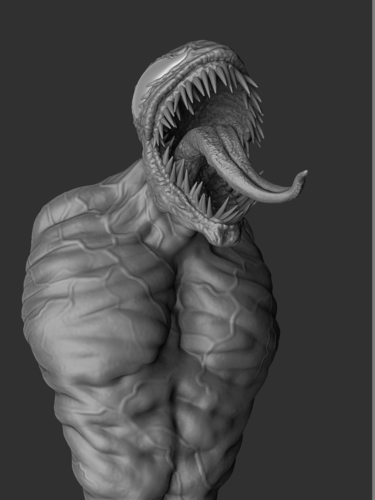

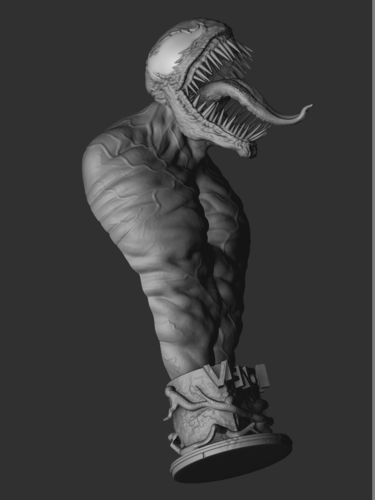

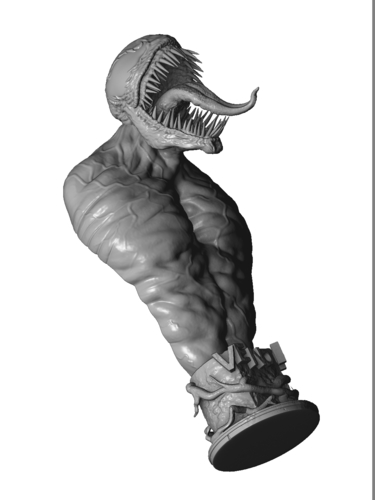

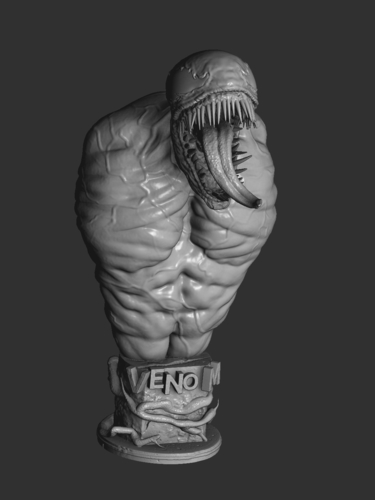

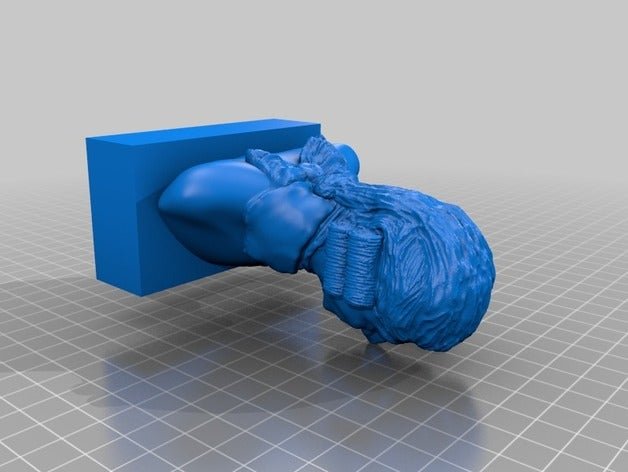

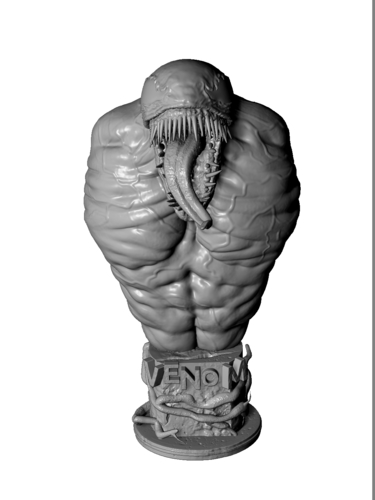

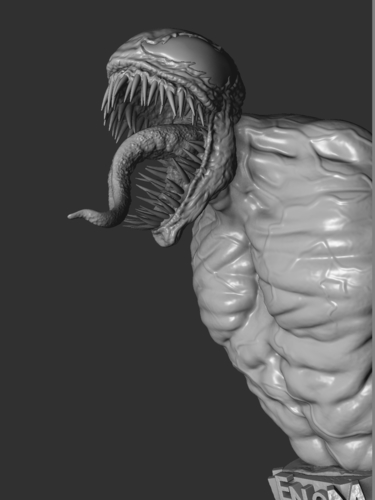

Marvel Venom Spiderman Bust

thingiverse

I just used his model removed the tongue and placed spiderman. ... venom model by: https://www.thingiverse.com/burulanikita

https://www.thingiverse.com/thing:2133381

... venom model by: https://www.thingiverse.com/burulanikita

https://www.thingiverse.com/thing:2133381

Spiderman Bust Bank

thingiverse

Edit it online https://www.tinkercad.com/things/2BfLeGVHwzZ This project uses Original model Scan Spiderman by ThinknDoFr Feb 2, 2017. Show love by liking the original design. Thank you ThinknDoFr. This was a wonderful model for a bank. I enlarged...

Spiderman Bust Edit

thingiverse

In my quest to find a spidey bust I wanted, the original here was the best I could find in the style I preferred. The only trouble is I did not want to paint the bust but print it out in @prox3dregina 's Bronze PLA. So after many hours of playing...

So after many hours of playing...

Spiderman Bust/Head 1.04

thingiverse

This is our Spider-Man Bust with Base. For the Base we used the T800 Base and modified it to fit our needs. This Version works pretty good and was printed by us, we fixxed all known errors. It needs no supports and is ready to print. DONATION: If you...

SPIDERMAN PS4 BUST

thingiverse

SPIDERMAN PS4 BUST FOR NEWS FOLLOW: https://www.instagram.com/masterclip3d/ HIGH RES MODELS AT: https://www.cgtrader.com/Masterclip

SPIDERMAN PS4 BUST

cults3d

SPIDERMAN PS4 BUST FOR NEWS FOLLOW:https://www. instagram.com/masterclip3d/ HIGH RES MODELS AT: https://www.cgtrader.com/Masterclip

instagram.com/masterclip3d/ HIGH RES MODELS AT: https://www.cgtrader.com/Masterclip

TOBEY MAGUIRE SPIDERMAN BUST

cults3d

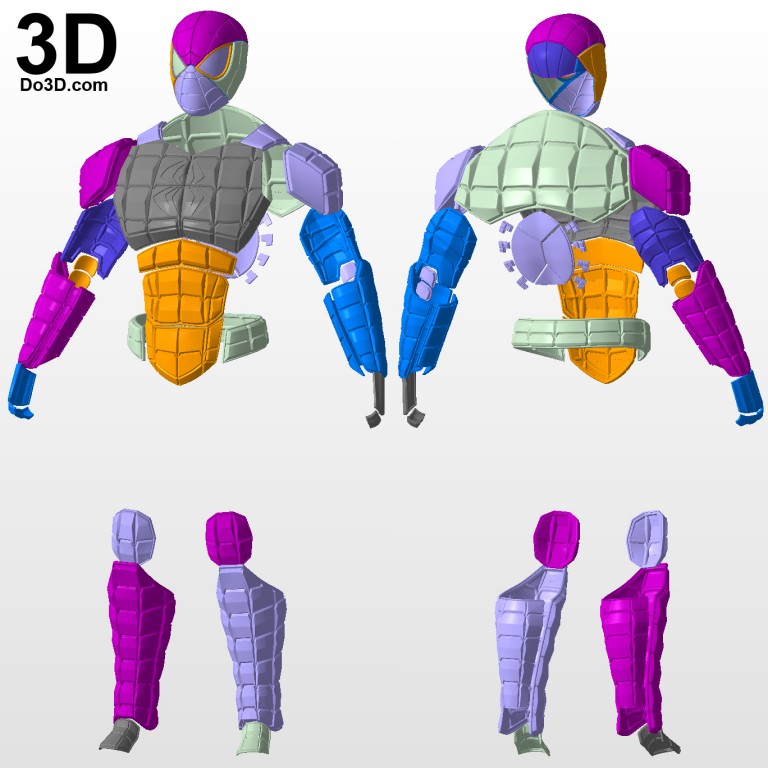

UPGRADE TO A FULLY POSEABLE ACTION FIGURE NOW!!! ...Download the parts here: https://3dzipguy.gumroad.com/l/wrglk Use 3mm x 100mm zipties for 1/12 scale Use 5mm x 20mm (or bigger) zipties for 1/6 scale Theoretically can be scaled up to 1:1, but make...

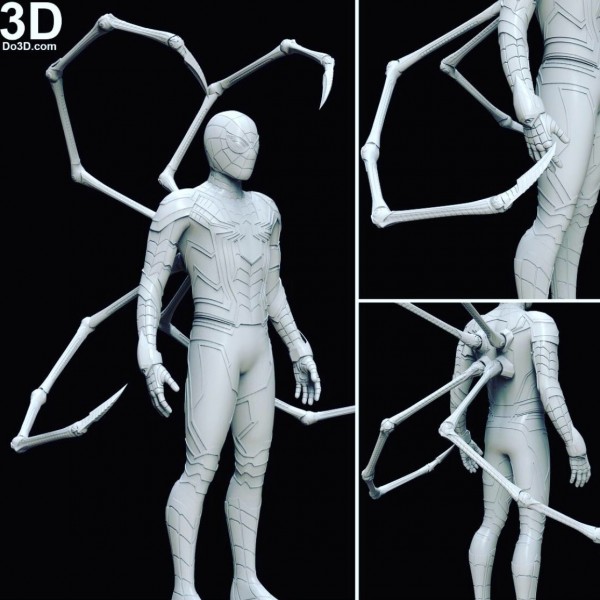

Infinity War Iron-Spider Spiderman Bust 3D print model

cgtrader

Infinity War Iron-Spider Spiderman Bust 3D printable model You will need to glue in the arms to the back and print with supports most likely. I made this model mainly because I haven't seen another Iron Spiderman Bust from Infinity War. Enjoy! If you...

I made this model mainly because I haven't seen another Iron Spiderman Bust from Infinity War. Enjoy! If you...

Spiderman bust 3d print model Free

cults3d

Sculpture and painting bust of spiderman from Marvel's Spider-Man game. The file is splited and keyed, and ready for print in FDM or resin printer. If you like of this, follow me on my you tube channel, and soon i'll share more contents with you.

Spiderman Bust - Easy print, no supports.

cults3d

This bust was designed to print completely support free and also is able to be rescaled to any scale your printer can handle and will retain the detail, even up to 1:1 scale. ... Infill is really optional, I have printed this with 0% infill and 3...

... Infill is really optional, I have printed this with 0% infill and 3...

spiderman bust 3D print model

cgtrader

ÑÑилÑнÑй бÑÑÑ Ñеловека паÑка, Ð¼Ð¾Ð´ÐµÐ»Ñ Ð¿ÑовеÑена и подгоÑовлена к пеÑаÑи, вÑÑÑавленнÑй ÑÐ°Ð·Ð¼ÐµÑ 80мм

3D Print Spiderman Bust - No supports 3D print model

cgtrader

This bust was designed to print completely support free and also is able to be rescaled to any scale your printer can handle and will retain the detail. Sample print in Blue was printed on an uncalibrated ender 3 at 0. 2mm layer height, an SLA...

2mm layer height, an SLA...

Spiderman Venomized Bust

thingiverse

My Patreon : https://www.patreon.com/BODY3D https://www.gambody.com/3d-models/tapion-dragonball?refId=BODY3DESIGN My Youtube Channel : https://www.youtube.com/c/BODY3D My Facebook : https://www.facebook.com/Body.3D.Youtube TEAM BODY3D :...

Spiderman 2099 Bust

myminifactory

like what you see ? ...consider visiting my store for more cool stuff, https://payhip.com/3dp

Spiderman statue bust 3D print model

cgtrader

Here is fan man Spiderman Figurine that i sculpted in zbrush for the purpose of 3d printing. I had alot of fun builing this model. I based spidermans suit on the ps4 spiderman game. This is anstl files that can be used for any 3d printer. enjoy. ...:)...

I had alot of fun builing this model. I based spidermans suit on the ps4 spiderman game. This is anstl files that can be used for any 3d printer. enjoy. ...:)...

SAM RAIMI SPIDERMAN ARTICULATED BUST

myminifactory

UPGRADE TO A FULLY POSEABLE ACTION FIGURE NOW!!! Download the parts here: https://3dzipguy.gumroad.com/l/wrglk Use 3mm x 100mm zipties for 1/12 scale Use 5mm x 20mm (or bigger) zipties for 1/6 scale Theoretically can be scaled up to 1:1, but...

BUST Spiderman Miles Morales - Fanart

cults3d

This download includes a solid spiderman bust figure and its base. Files include stl and .3mf (watermarked) extensions that can be used in any 3d printer. ... The model is 12 cm (4.7 inches) tall For the full body version you can go here:...

Files include stl and .3mf (watermarked) extensions that can be used in any 3d printer. ... The model is 12 cm (4.7 inches) tall For the full body version you can go here:...

Spiderman Noir / Night Monkey (support free bust)

myminifactory

Get all main villains from the Spiderman Comics on my website: https://www.printingbros3d.com/3d-printing-spiderman/ If you like my work you can always support me on my Patreon: https://www.patreon.com/3DprintingwithRoberRollin/

Spiderman 2099 + free extras

pinshape

buy here: https://payhip.com/b/3LFe everything is in parts for easy fdm printing, free chibi spiderman + bust

Spiderman Bank

thingiverse

This is a kid's 'piggy bank' except that it's in the shape of a bank with spiderman's bust on the top. ...The cover slides and there is a slot to put money in (Spiderman watches!)

...The cover slides and there is a slot to put money in (Spiderman watches!)

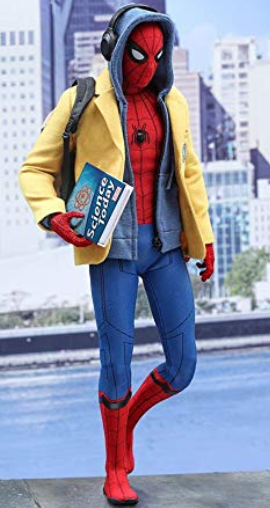

Hoodey Spiderman Scuplture

myminifactory

use a spiderman free download file to us as my base reference for my own verison of spiderman bust. can be print with minimal supports and with no support. ... printer use: G3D DLP 3D Printer resin: Red Matte and Tough Gray

Spiderman

sketchfab

spiderman

Spiderman

cults3d

Spiderman

spiderman

grabcad

spiderman

Types of resins for photopolymer 3D printer, characteristics, application

In recent years, the introduction of photopolymer printers in various areas of production is gaining more and more popularity. In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

In order for the printer to reach its full potential, it is necessary to choose the right material - photopolymer resin.

Now there is a wide variety of resins designed to solve a wide range of problems. Sometimes it can be difficult not to get confused in such a variety of materials. It is conditionally possible to divide photopolymer resins into several types - standard, engineering, dental, jewelry (burned).

Standard resins

Standard resins are well suited for making decorative models. They are strong and hard enough for making miniatures, master models, paintable figures or mock-ups, but their strength is usually not strong enough for functional products.

But standard resins are different from each other. Some of them can be washed not with alcohol, but with plain water, there are transparent types of resins or, for example, with a wide color palette.

Standard

Compared to other types of photopolymers, standard resins have a richer color palette. The main advantages are an inexpensive price, good detail and fast curing time.

The main advantages are an inexpensive price, good detail and fast curing time.

ESUN Standard

A good resin for professionals and beginners who are just getting acquainted with photopolymer printing. The advantages of ESUN Standard are a large palette of colors, no smell and fast printing speed.

ESUN Standard is suitable for printing decorative models or any other product that will not be subjected to heavy physical exertion.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm (transparent 395-410nm)

Shore hardness: 80-82 D

Impact strength according to Izod: 18 - 40 J/m

Bending strength: 46-72 Mpa

Modulus of elasticity: 1000 - 1400 MPa

Elongation at break: 28-35%

Exposure time per layer (recommended): 5-10 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 0. 5 kg, 1 liter.

5 kg, 1 liter.

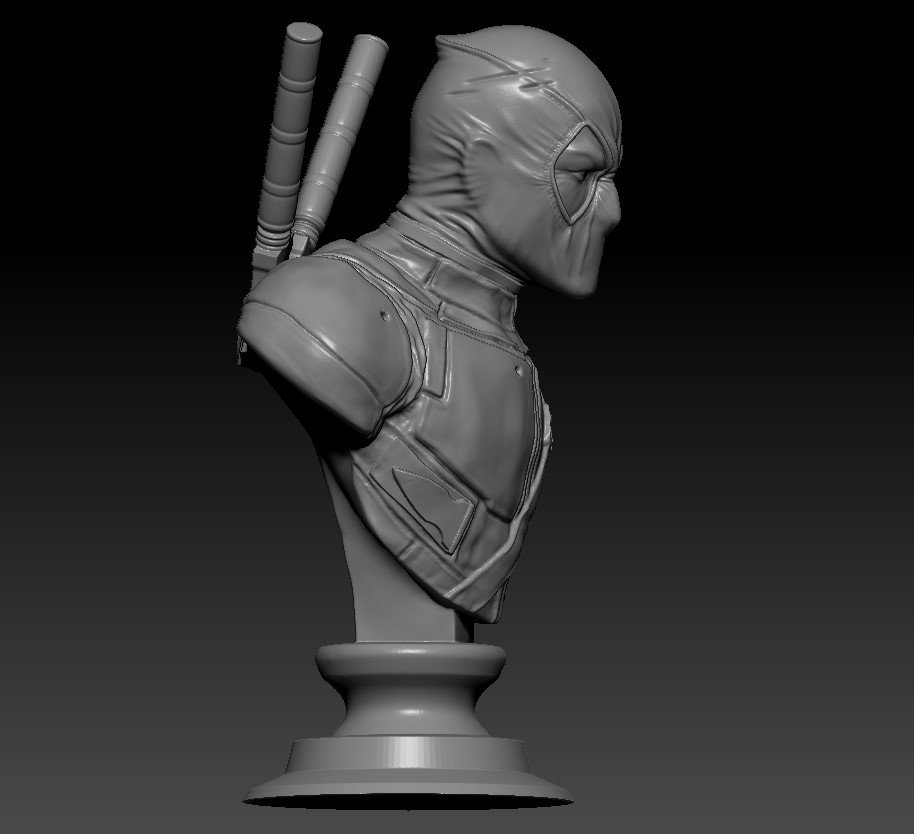

Deadpool figurine

Bust of a military man

Moving castle, miniature

Users note good detailing, a good balance of strength and light elasticity, and excellent adhesion to the platform. The print time of the layer corresponds to the one declared by the manufacturer (5-10s) even on 3D printers with a weak UV source.

Of the minuses - sometimes the resin can be difficult to stir and a fine suspension comes across. This does not reduce print quality, but it does make me nervous. The gray color is slightly transparent, many users would like the color to be more “dense”.

ESUN eResin-PLA

eResin-PLA is based on PLA monomer, familiar to many from FDM printing. This makes the resin environmentally friendly and the finished product very tough and scratch resistant.

Resin is well suited for decorative items, master models or functional models without load.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 75-80 D

Elongation at break: 20-50%

Modulus of elasticity: 600 - 800 MPa

Impact strength according to Izod: 15 - 32 J/m

Tensile strength: 35-50 Mpa

Exposure time per layer (recommended): 15-20 sec.

Color palette: white, black, gray, red, blue, yellow, green, light green, flesh, orange, transparent.

Volume: 1 liter

Shoe model

Figurine of a cartoon girl

Play miniature

Non-standard focusing rings for lens

Phrozen Aqua 4K

The Phrozen Aqua 4K is specifically designed to unlock the full potential of 4k resolution photopolymer printers. A pleasant bonus is the almost complete absence of shrinkage.

Resin is well suited for precision printing of decorative patterns. The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K.

The manufacturer specifies that all properties of the resin are revealed when using printers with high resolution, such as Sonic Mini 4K / Sonic Mighty 4K.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 77 D

Color palette: gray, ivory.

Volume: 1 kg

Armor printed in gray resin Phrozen Aqua 4K

Bust Predator

Figurine war with a bear, to demonstrate the capabilities of Phrozen Aqua 4K

Phrozen Beige Low Irritation

This resin is hypoallergenic. Phrozen Beige Low-Irritation has passed the ISO-10993 10 test, which means that the resin does not contain heavy metals and the finished models can directly contact the human body.

The resin can be used in dentistry or for products that will come into contact with the skin.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Color palette: beige

Volume: 0. 5 kg

5 kg

Decorative figurine

Jaw

ESUN Precession Model

Resin is designed for fast printing of high-precision models. In addition, finished products are tough and can withstand heat up to 80 degrees.

ESUN Precession Model is a good choice for models that need high detail.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85 D

Elongation at break: 12.1%

Bending strength: 77 Mpa

Tensile strength: 335-410 Mpa

Color palette: red.

Volume: 1 liter

DC Universe Riddler's Head

Miniature model of ICE

Clear resins

Clear resins are present in other photopolymer ranges, but may become yellow or cloudy over time. If optical transparency without yellowness is important in the finished model, then you should pay attention to special polymers.

Phrozen SC-801 Clear

The main advantage of Phrozen SC-801 Clear is its optical transparency. Models made from Phrozen SC-801 Clear will not become hazy or yellow during post-curing or use.

This photopolymer is suitable for the manufacture of durable and accurate models for which optical transparency is important.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 70 D

Color palette: transparent

Volume: 1 liter

Material transparency model

Left product made of Phrozen SC-801 Clear, right RESINMAGIC3D High-Grade Clear

Figure printed with Phrozen SC-801 Clear

Miniature bottles printed for a articulated doll. Left made from Phrozen SC-801 Clear, right made from another polymer.

Washable

Finished models made on a photopolymer printer are recommended to be washed from photopolymer residues with alcohol. There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water.

There are situations where this is not acceptable, such as when the printer is being used in schools. For such cases, manufacturers have created the Washable line. Washable are resins that can be washed with plain water.

ESUN Water Washable

ESUN Water Washable is as strong and precise as ESUN Standard resins. The only difference is that the finished product can be washed not with alcohol, but with plain water.

ESUN Water Washable is well suited for printing at home or in educational institutions due to its low toxicity and odorlessness.

Print Technology: DLP/LCD/LED

UV wavelength: 395-410 nm

Shore hardness: 76 D

Tensile strength: 68 MPa

Elongation at break: 5-10%

Bending strength: 45-70 MPa

Modulus of elasticity in bending: 900-1400 MPa

Izod impact strength: 18-39 J/m

Color palette: white, transparent, flesh, gray, black.

Volume: 0. 5 kg

5 kg

Rings and pendant printed in clear ESUN Water Washable

Fox figurine

Phrozen Water Washable

Phrozen Water Washable compares favorably with other water-washable resins in terms of strength, durability, and short flash-over time.

The resin is suitable for making prototypes and other models at home and in educational institutions where it is undesirable to use strong-smelling alcohols for washing.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80 D

Color palette: gray, black.

Volume: 1 kg

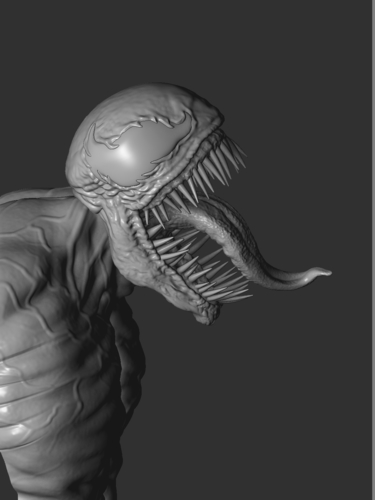

Bust made from Phrozen Water Washable

Alien printed from Phrozen Water Washable

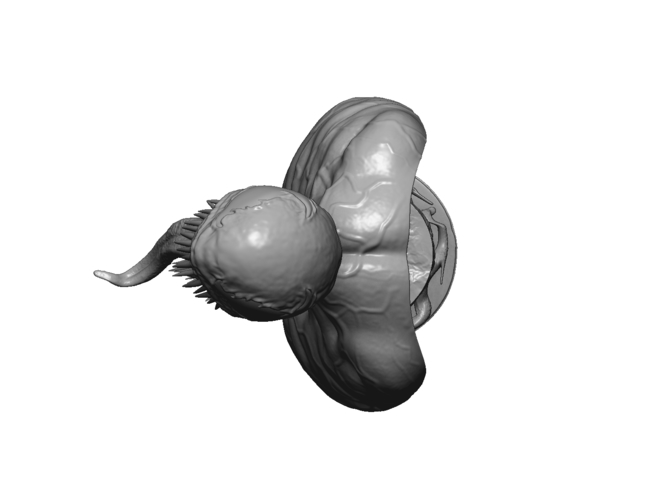

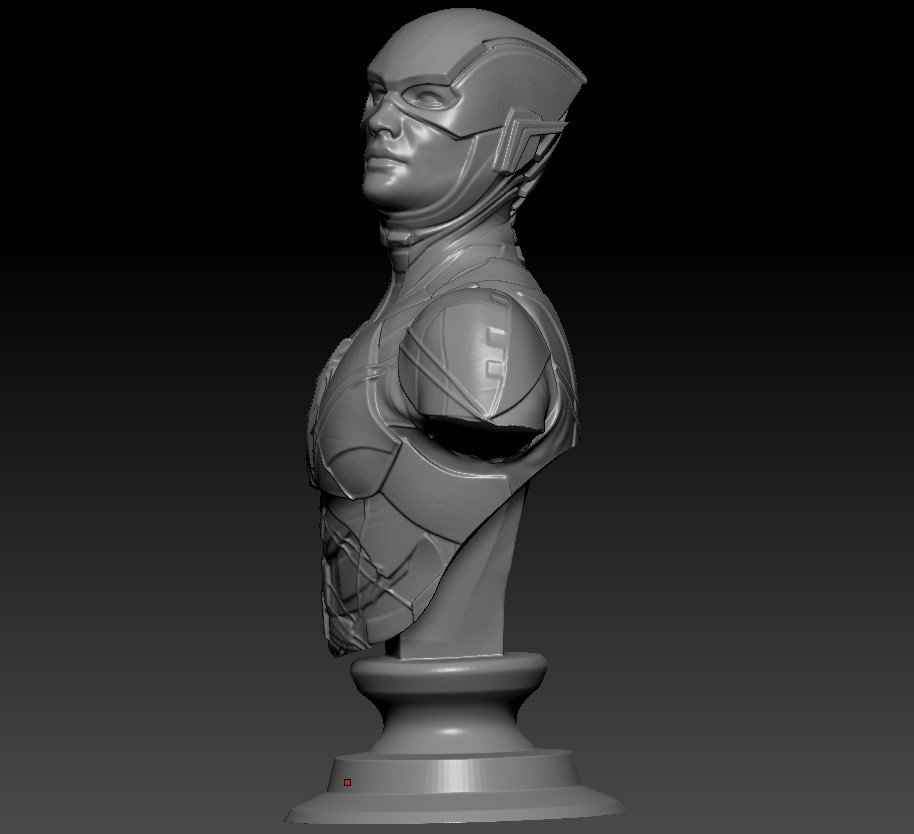

Bust of Spiderman

Wanhao Water washable

It is a resin with high resolution and good hardness. Wanhao Water washable has very little shrinkage and a wide range of colors.

Wanhao Water washable has very little shrinkage and a wide range of colors.

Resin is well suited for printing master models and decorative models when it is not possible to use alcohol to wash the final product.

Print Technology: DLP/LCD/LED

UV wavelength: 395~420nm

Shore hardness: 75D

Color palette: white, transparent, black, gray

Volume: 0.5 kg, 1 kg

Han Solo in transparent Wanhao Water washable

Test model of transparent Wanhao Water washable

Test patterns in different colors Wanhao Water washable

Engineering

Previously, photopolymer printers were mainly used for making master models and products with high accuracy. Now they face a wider range of tasks. It is much more convenient to make a ready-made, functional model right away. For this, engineering photopolymer resins with improved characteristics have been developed. Depending on the application required, they can be harder, heat resistant and durable than standard resins.

Depending on the application required, they can be harder, heat resistant and durable than standard resins.

Reinforced

These are polymers with improved characteristics - for example, high heat resistance or impact strength. They can be used to produce functional prototypes, engineering models, etc.

Phrozen TR250-LV

The Phrozen TR250-LV has been specifically designed to meet engineering challenges. In addition to high strength and hardness, the resin has increased heat resistance and can withstand heating up to 150 degrees.

The Phrozen TR250-LV is suitable for the production of models for subsequent thermoforming or products that require increased heat resistance.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Tensile strength 25 MPa

Izod impact strength: 6.31 kJ/m2

Color palette: gray

Volume: 1 kg

Jaw Layout

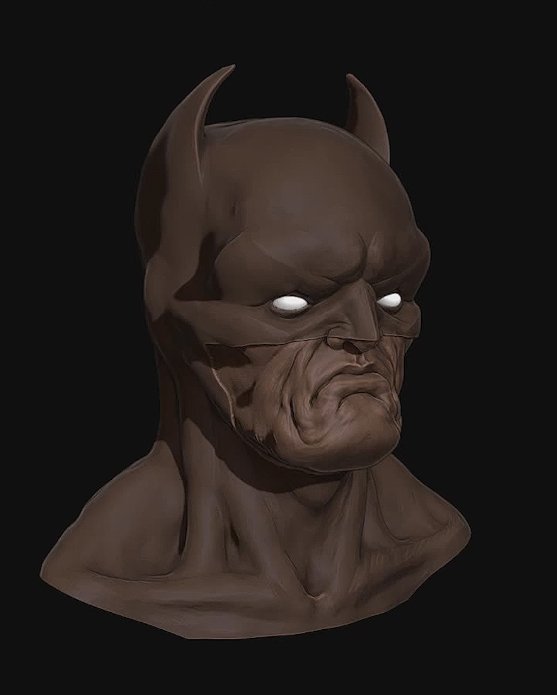

Orc Bust

Phrozen ABS-like

This resin is similar in characteristics to ABS plastic, familiar to many from FDM printing. There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

There is a white color in the palette, this allows, if necessary, to easily paint the finished product.

Phrozen ABS-like is suitable for printing functional models and prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 79D

Izod Impact Strength: 2.32 kJ/m2

Color palette: gray, white

Volume: 1 kg

Skull Model

Weapons for miniature figures

1/4 mask

Phrozen Rock-Black Stiff

When creating Rock-Black Stiff, emphasis was placed on strength, wear resistance and heat resistance (up to 97 degrees). Models are strong and slightly flexible to withstand shock loads.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 81D

Elongation at break: 4%

Izod impact strength: 2. 68 kJ/m2

68 kJ/m2

Color palette: black

Volume: 1 kg

Elf bust

Bust printed in Phrozen Rock-Black Stiff

Phrozen Nylon Green Tough

Photopolymer is an analogue of nylon. Nylon is a very strong and wear-resistant material, familiar to many from FDM printing. Products are very durable and resistant to stress. Finished models printed in Nylon Green Tough can be folded.

Suitable for the manufacture of finished products or functional prototypes.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 68D

Elongation at break: 130%

Tensile strength: 19 MPa

Izod impact strength: 23.79 kJ/m2

Color palette: green

Volume: 1 kg

Phrozen Nylon Green Tough Vase

Test model

Spectacle frame

Phrozen TR300 Ultra-High Temp

TR300 Ultra-High Temp allows you to quickly produce durable, shock and heat resistant products (up to 160 degrees). The photopolymer compares favorably with its competitors by its short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer).

The photopolymer compares favorably with its competitors by its short exposure time (on 3D printers of the Phrozen Sonic series, 1.3 seconds per layer).

Phrozen TR300 is suitable for the manufacture of heat-resistant and durable products. For example, it can be a model for subsequent thermoforming or manufacturing an industrial layout.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Tensile strength: 32MPa

Izod impact strength: 8 kJ/m2

Elongation at break: 2%

Color palette: gray

Volume: 1 kg

Phrozen Onyx Rigid Pro410

The main properties of models made from Onyx Rigid Pro410 are amazing detailing and durability. The resin was developed in partnership with Henkel and is intended primarily for home workshops.

Photopolymer is perfect for models with an abundance of small details that need high detail. Or for engineering/functional models where high accuracy and strength are important.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color Palette: Black

Volume: 1 kg

Tablet stand

Fruit bowl

Wall mounted spice holder

Wall hanger

Flexible

Products made from such resins will look like silicone or rubber. Such photopolymers make it possible to obtain flexible and durable functional products resistant to tearing.

Phrozen Biege Flex

This is a resin designed for products that need to be strong and slightly flexible. Phrozen Biege Flex is suitable for functional models that need some flexibility.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 65D

Tensile strength: 40 MPa

Modulus of elasticity: 192 MPa

Color palette: beige

Volume: 0. 5 kg

5 kg

Bust of Harley Quinn

Miniature from Phrozen Biege Flex

Functional carabiner

HARZ Labs Industrial Flex

By its properties, finished products from HARZ Labs Industrial Flex resemble polyurethane. Products from it are elastic and very durable.

HARZ Labs Industrial Flex is suitable for the manufacture of gaskets or any other model where softness and tensile strength are important.

Industrial Flex can be used as an additive for other HARZ Labs resins. This allows you to increase the flexibility and strength of the finished model. Depending on the resin ratio, different degrees of flexibility can be achieved in the finished product.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 63D

Shrinkage: 0.5%

Elongation at break: 103%

Tensile strength: 13 N/mm2

Color palette: transparent

Volume: 0. 5kg 1kg

5kg 1kg

Various gaskets printed from HARZ Labs Industrial Flex

ESUN Flex

Flexible and durable material with good wear resistance. Good tear resistance and accuracy make ESUN Flex suitable for engineering models.

For example, products that must be strong and flexible at the same time. These can be engineering prototypes or functional models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 85-90 A

Shrinkage: 6.9%

Elongation at break: 100-150%

Bending strength: 77 Mpa

Tensile strength: 390-320 kN-m

Color palette: transparent yellow

Volume: 0.5 kg

Test model from ESUN Flex

Dental resins

From the very beginning of its existence, photopolymer printers have taken the place of indispensable assistants in the dental industry, therefore, in the assortment of many companies that manufacture photopolymer resins, there are materials intended for use by dentists.

Special photopolymers

These are special polymers that are focused on solving specific problems. No one forbids using them for other than their intended purpose, but they fully reveal their potential precisely in the task for which they were created.

Harz Labs Dental Soft

Dental Soft was created as a material to simulate gums in demonstration models. The finished print is pink in color and has high strength and chemical resistance. Despite its flexibility, the finished model will be resistant to deformation. Harz Labs Dental Soft is certified for medical use.

The material is suitable for gum printing or other medical applications.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 87-90D

Shrinkage: <0.5%

Elongation at break: 68%

Tensile strength: 1.2 N/mm2

Color palette: pink

Volume: 0.5 kg, 1 kg

Gums from Harz Labs Dental Soft

Gums from Harz Labs Dental Soft

NextDent Gingiva Mask

Another gum simulation resin from NextDent. Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

Gingiva Mask is a flexible and durable resin that blends beautifully with model material.

The resin is suitable for various models in the dental industry.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 60 - 75 A

Elongation at break: 40 - 60%

Color palette: pink

Volume: 1 kg

Gingiva made from NextDent Gingiva Mask

Part of the gum made from NextDent Gingiva Mask

Jaw Demo with NextDent Gingiva Mask Inserts

Harz Labs Dental Clear

Products from this resin are durable and hard. The main feature is the resin is transparent, without turbidity and yellowness. Harz Labs Dental Clear is certified for medical use.

This photopolymer is suitable for the manufacture of surgical templates, demonstration models and even aligners.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent

Volume: 0.5 kg, 1 kg

Jaw Demo Model

Piece of jaw printed from Harz Labs Dental Clear

Dental Yellow Clear

Very similar in its properties to Harz Labs Dental Clear - just as strong and hard. The only difference is that the color of the resin is not crystal clear, but yellow. The resin is certified for use in medicine.

Dental Yellow Clear is suitable for making aligners or demonstration models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 90-92D

Elongation at break: 4-6%

Shrinkage: less than 0.5%

Color palette: transparent yellow

Volume: 0. 5 kg, 1 kg

5 kg, 1 kg

Gingiva pad made of Dental Yellow Clear

Jaw models

Dental Yellow Clear Demonstration Product

Burnout

In addition to specialized resins in dentistry, low-ash burnable or smelted materials are needed for direct casting.

Before casting, be sure to read the instructions from the manufacturer. Each resin has its own burnout cycle in order to obtain a good casting quality.

ESUN Castable Dental

ESUN Castable is designed for direct casting in dentistry. Finished products are smooth and hard. When burning, the ash content is practically absent.

High precision allows ESUN Castable to be used for crowns, bridges and other castings.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80D

Elongation at break: 11-20%

Bending strength: 49-58 Mpa

Impact strength according to Izod: 44 - 49 J/m

Color palette: green

Volume: 1 kg

Crowns printed from ES

ESUN Castable jaw

Example of printed and molded model

Phrozen Wax-like Dental Green

Wax-like Dental Green is a waxy resin with low shrinkage and zero ash content. Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Due to the low shrinkage, the finished products are very accurate, and the matte surface will help to see even small imperfections.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: green

Volume: 0.5 kg

Ring made from Phrozen Wax-like Dental Green

HARZ Labs Dental Cast Cherry

HARZ Labs Dental Cast Cherry was developed for direct casting of dental products. With the correct burnout cycle, it is possible to achieve almost zero ash content. The photopolymer is certified for medical use.

Dental Cast Cherry is suitable for casting metal or ceramic crowns and bridges.

The manufacturer recommends the use of phosphate-based phytomass, because they can be used at high temperatures, which are required for high-quality burning of the model.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 40-50D

Shrinkage: less than 1%

Color palette: red

Volume: 1 kg

Crown models printed with Dental Cast Cherry

Cast crowns

NextDent Cast

It is an easy-to-burn-out resin with zero ash content. Designed for the manufacture of burn-out dental models.

Designed for the manufacture of burn-out dental models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Shore hardness: 80-90D:

Color palette: red

Volume: 1 kg

Crowns made from NextDent Cast

Demo Model

DETAX Freeprint cast UV

High precision resin designed for fast manufacturing of dental products. Finished products can be used for direct casting. DETAX Freeprint cast UV burns out ashless even with large casting volumes. For molding, it is recommended to use phosphate-based masses.

Print Technology: DLP/LCD/LED

UV wavelength: 378-388 nm

Color palette: red

Volume: 1 kg

Overlay made of DETAX Freeprint cast UV

Crowns made from DETAX Freeprint cast UV

Burnout resins

In addition to dentistry, 3D printers have firmly established themselves in the jewelry industry. 3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers.

3D printing allows you to create complex products much faster than classical methods (manual wax cutting, CNC machine). Burnt-out resins were created especially for jewelers.

ESUN Castable for jewelers

Photopolymer specially designed for printing and casting small models with high detail. Products from ESUN Castable are smooth, and almost zero ash content makes it easy to get the desired product in the metal.

The resin is suitable for printing jewelry - rings, pendants, earrings and for other burn-out models, in which accuracy and perfect surface quality are important.

Print Technology: DLP/LCD/LED

UV wavelength: 395-405nm

Shore hardness: 60 D

Color palette: yellow, green

Volume: 1 kg

Ring printed from ESUN Castable

Ring from ESUN Castable

Phrozen Wax-like Castable Violet

Waxy polymer with low shrinkage and zero ash content. Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Products made of Phrozen Wax-like Castable Violet have a nice matte surface, which will show the slightest imperfections.

Wax-like Castable is suitable for making any castable models.

Print Technology: DLP/LCD/LED

UV wavelength: 405 nm

Color palette: purple

Volume: 0.5 kg

Ring printed in Wax-like Castable and finished casting

Wax-like Castable Openwork Rings and Precast Castings

Wax-like Castable pendant and finished product

HARZ Labs Jewelry J-Cast

This is a photopolymer designed for the manufacture of burn-out models for subsequent casting in metal. High precision, low shrinkage (less than 1%) and low ash content (less than 0.1%) make it possible to print even very small products without distortion.

HARZ Labs Jewelry J-Cast is suitable for printing jewelry. Due to its high thermoplasticity, the photopolymer can be burned out over a wide temperature range. The result is a product with a smooth surface.

The result is a product with a smooth surface.

Print technology: DLP/LCD/LED

UV wavelength: 405 nm

Shrinkage: less than 1%

Color palette: blue

Volume: 1 kg

Ring molded with a model made from HARZ Labs Jewelry J-Cast

Totals

A wide variety of photopolymer materials make it possible to make a 3D printer an almost universal tool for the production of products of various directions. 3D printing not only helps to shorten the production chain in large enterprises, but also becomes an indispensable tool for small home workshops.

When working with photopolymer resins, do not forget about safety precautions.

-

Try to print in a well-ventilated area.

-

Read the information about the resin on the manufacturer's website, important nuances may be indicated there. For example, some resins cannot be immersed in isopropyl alcohol for a long time.

"3D printing has changed the way we think"

Dreamers are those who hover in the world of ideas, but do not particularly strive to bring them to life. But people who are constantly working on their own idea, coming up with new business strategies, but still dreaming of the victory of progress, are already entrepreneurs. In just one year, Andrey Isupov , CEO of PICASO 3D, turned his student hobby into a successful high-tech business.

The history of PICASO 3D, the first Russian manufacturer of three-dimensional printers, began like this: Andrey Isupov and Maxim Anisimov graduated from the fourth year of the Moscow Institute of Electronic Technology. The guys were looking for a material from which to make a body for a six-fingered spider robot. The robot was designed to work in extreme conditions - for example, on Mars. And then one day, students accidentally stumbled on the Internet for information about 3D printers. We ordered a kit for assembling a RepRap printer from Canada, tested it and immediately began to generate ideas on how to improve this machine.

The first printer model Gen-X was assembled by hand, right in the apartment.

The PICASO 3D Builder was the first mass-produced device that allowed the established PICASO 3D company to become self-sustaining. Soon, the new PICASO 3D Designer machine, the flagship product of the startup, was launched.

It took Isupov only a year to go from student to co-owner of a promising technology company.

Routine and creativity

In 2011, when Andrei and Maxim started their business, only a few people in Russia knew about 3D printing. Here it was important to see what others do not see, to catch the trend before anyone else and take a risk.

Now the office of PICASO 3D is located in Zelenograd in the building of the former research institute directly opposite MIET .

On the tables and shelves are models of buildings, a robot arm, a quadcopter body, a bust of Dmitry Medvedev and Jimi Hendrix - all this is printed on a 3D printer. On Andrey's desktop there is an aquarium with a tarantula - not a plastic one, but a real one.

On Andrey's desktop there is an aquarium with a tarantula - not a plastic one, but a real one.

The PICASO 3D team has a little over twenty people, most of whom are MIET graduates.

Andrey is probably the youngest among the developers. He's wearing jeans, a plaid shirt—the CEO doesn't wear a business suit like most young businessmen who want to look solid and independent. Rather, he will easily merge with the crowd of students.

— When we made the first 3D printer and realized what it could do, it revolutionized our thinking, — Andrey says enthusiastically. - Our consciousness has literally expanded! You are trying to create something, you are designing, you have one view of things. You think in patterns. Let's say the body of the robot. When we thought about what to assemble it from, there was only one thing in our head - laser cutting. But now the approach is completely different. We began to think on a larger scale, stopped bothering about how it could be done, and began to proceed from considerations of functionality and design. You can come up with absolutely any shape and print anything!

You can come up with absolutely any shape and print anything!

- Your 3D printers appear in universities, schools. For young people, your development can serve as an incentive to invent.

- Naturally, - Andrey nods. — Three-dimensional printing develops spatial thinking. This is an opportunity to look at things from an unexpected angle. Learning 3D printing is simply fascinating! It's no secret that learning can be difficult and not always interesting. And when something is of interest, a person is drawn in and starts digging himself. I know for myself. At the institute, to be honest, I didn’t really like to study. But when we launched this project, I just fired up. Rummaged through the literature, studied, spent a lot of time on it.

— You studied at MIET. What did they give you that really came in handy?

- Naturally, this is the technical base, the basis from which I started. And, probably, the most important thing that gives higher education is the ability to independently acquire knowledge. The business part was learned, roughly speaking, on the go.

And, probably, the most important thing that gives higher education is the ability to independently acquire knowledge. The business part was learned, roughly speaking, on the go.

- That is, you also had to master entrepreneurship from scratch. What influenced you the most, what helped you the most?

- Probably, like any young entrepreneur, I read Robert Kiyosaki's "Rich Dad Poor Dad", "The Richest Man in Babylon" by George Clason, - lists Andrew. — At first it was an interest, so to speak, business philosophy. Then, when I already understood what I was missing, I studied the production system. The Japanese philosophy and practice of kaizen, the principles of the Tao of Toyota are a very interesting thing! Life Story of Konosuke Matsushita (founder of the Japanese company Matsushita Electric, known for its brands Panasonic, National and Technics, he is considered one of the most striking examples of an innovator - approx. "PP").

"PP").

- Having successfully offered your development to the market, you have actually become a businessman. As a student, you could be messing around with pieces of iron, and now you need to think about how to sell your product. Has your work turned into a routine, has your creativity disappeared?

- It's still very interesting. When the company is small, the manager is also involved in operations. Naturally, everything is tied to employees, without whom no enterprise can function. These people are not just hired workers, they are a team of specialists who create something new every day. I study the market and understand what the client needs, but the product itself is formed in the minds of all members of our team. My task is to tie all the strings together.

Revolutionary technology

When you sell apples, you are selling a clear product to an existing customer. But to offer consumers 3D printers, especially in the early years of their appearance, is a very difficult job.

PICASO 3D is a real successful start-up, by all the rules, which managed to shoot. Its founders had to bring to the market not just a new product, but a completely incomprehensible product for Russia. It used to be the same with computers. When the first computers appeared, no one could have imagined that everyone would have them, - Andrei argues.

- Now the main application of 3D printing is still construction, education, architecture, design and medicine. We are working to ensure that our development comes to every home. To do this, it is necessary to ensure not only the ease of use of a 3D printer and affordable software, but also to answer the question: “Why do you need a 3D printer at home?” DIY enthusiasts, creative people will definitely have a personal 3D printer. People who do not have such a need will go somewhere and order everything they need to print. After all, until now, not every house has a regular printer.

— So far, 3D printing seems to me such an inconspicuous technology, but which has every chance to change our world. Do you believe that something is drastically changing?

Do you believe that something is drastically changing?

- Definitely, yes. It used to be a novelty for people. We said: "3D printer". They: "Does he print those plastic cards that change the image?", - Andrey laughs. — Now even children know what 3D printing is, understand how it works. And most importantly, we have changed the way our customers think about design.

— 3D printing is linked to the third industrial revolution. Probably, thanks to her, there will be a cultural upheaval, I reflect. - Stamping, copying, loss of uniqueness. Aren't you afraid that the technologies that you create can somehow bring harm?

- Harm? - Andrey is surprised. - No. Well, maybe at first. Then people will adjust. If a person created a 3D model and gave access to it, then he himself allowed this object to be copied. He can put a license on it. But will these rights be respected? Europe is following this quite well, I think we will come to this in Russia as well.

— Nevertheless, we must admit that we are only at the very beginning. 3D printing is a hot trend. I recently heard the news - they printed a car. Cool, but in addition to the printer, eight other machines were involved, and it took 16 months. What do you as a professional think when you hear about such sensations?

- I understand that this is pure marketing, - Andrey explains. - I am well aware of the possibilities of 3D printing, I know that they are really enormous. It was 3D printing that made it possible to create at a low price those products that used to cost space money. Small-scale production is just a godsend. And the "inner" world of 3D printers is no less interesting, - Andrey adds.

— Let's go to the factory! There, a large 3D printer prints small ones.

Printing house

We are entering the territory of the research and production association "Kvant" is, one might say, a Mecca for Russian electronics manufacturers. In the workshops of the company "ALT Master" , a contract electronics assembler, the main production of PICASO 3D printers is located - the creation of electronic filling, assembly and testing.

In the workshops of the company "ALT Master" , a contract electronics assembler, the main production of PICASO 3D printers is located - the creation of electronic filling, assembly and testing.

We go to the office of Ravil Dianov , General Director of ALT Master:

— We have been working since 1987, when perestroika began, — he starts right away and on business. — Almost everyone here has a Ph.D.: out of hopelessness, I had to go to production — I need to eat for something. Today we are one of the largest printed circuit board manufacturers in the country. Despite such a pretentious tone, we, of course, understand that big things in Russia are like pilot production in Shenzhen. - What the guys started doing in Russia is right, - Dianov notes. - There are eight thousand PCB factories in China that work almost on their knees. People who order something from them regularly appear here, and we are forced to treat any disgrace.

— Well done Chinese! Clever, cunning, tough, commercial, - Dianov minted in a patter. - If you are friends with them, then everything will be more or less decent. If you are just a customer from the street, you will get 20-30 percent of the marriage. That is, they do not care how to work. And you don't control them. And here cooperation with customers is our bread, and we try to earn it as honestly, efficiently and promptly as possible.

- This is very important , - Andrey adds. - Because the printer is completely dependent on electronics, and if there are any problems with it, then the whole device will act up.

— Let's go and feel the atmosphere of production. Simple, proletarian, - Ravil Dianov gets up from the table, and we go to the workshop.

Huge space with high ceilings. Machines and devices are state-of-the-art. Workers in blue coats leaned over the tables. On the walls are flow charts and instructions.

On the walls are flow charts and instructions.

All components produced according to PICASO 3D drawings in other factories flow here. 70 percent of the parts are Russian.

- So, I'll leave you on this, - Ravil Dianov says goodbye to us and throws a comic parting word to the workers: - Wrinkle your forehead when you are photographed!

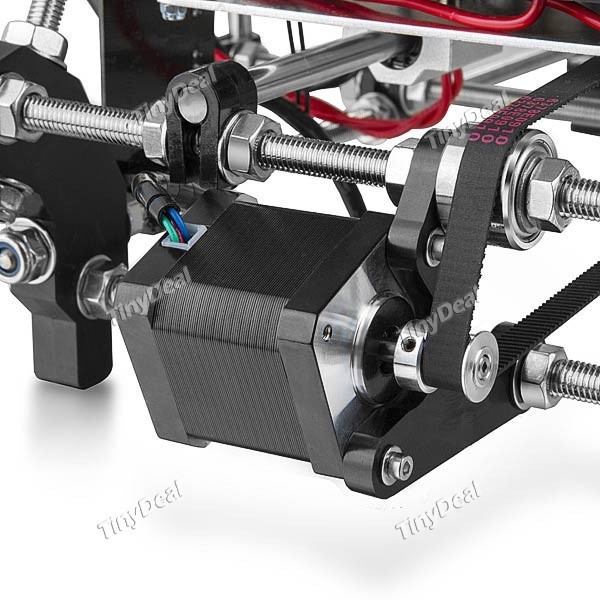

- This is our pride, we call it the letter "P" , - Andrey takes a metal frame from the table. - This is a design for moving the print head of the printer along the X and Y axes. Its feature is that the motors are completely fixed. For all competitors, one of the motors must be on the carriage and move along with the axis. The print head itself is extremely lightweight. This ensures minimal inertia during movement and contributes to high-quality printing at high speeds. We have filed a patent for this system. And now we are working on a 3D printer that will print several materials at once. This will be a breakthrough for us and for the entire 3D printing market, - Andrey says with rapture.

This will be a breakthrough for us and for the entire 3D printing market, - Andrey says with rapture.

After all parts are assembled, each printer is sent for testing.

24 hours the machine performs the operations necessary for a complete check. This is important to achieve high quality products so that the customer does not have any problems after purchasing the device.

— Did you have any clients who wanted to buy a printer to create something very unusual?

- Somehow they wrote to us from the team "Formula Student" MSTU. N.E. Bauman , - recalls Tatyana Shagova, a colleague of Andrei Isupov, who joined us. — We consulted and gave them a 3D printer. They printed wing ribs and brackets, a steering wheel for their racing car. This made it possible to reduce the weight of the car and significantly gain speed - the guys realized their dream.

- Personally, I was surprised when I found out that toothbrushes print on our printer, - Andrey added.

PICASO 3D principle

We return to the office, the working day is coming to an end, but it seems that employees are in no hurry to go home.

- You have a great atmosphere. Feel the spirit of the team, family. How did you get along?

- Our distinguishing feature is that everyone's eyes are burning, - Tatyana answers. — You feel like you are doing something different from everything else.

— Successful companies always have their own ideology and values. How are you with this?

— The most important thing for us is to create a product that we want to use ourselves. So that a 3D printer does not just stand on the table, but brings benefits, helps to develop, save and earn, - Andrey argues.

— What are your personal goals? After all, what you are doing is only a means to ...

- It seems to me that the basis of happiness is self-realization, - Andrey is ahead of me. — I have always wanted to start a company. By doing business, I satisfy my need to do something of my own, worthwhile.

— I have always wanted to start a company. By doing business, I satisfy my need to do something of my own, worthwhile.

- And you have already achieved this goal, but what's next?

— An entrepreneur is a person who develops all his life. Achieve goals and set new ones. It's an endless process.

— How much has your life changed since you became an entrepreneur?

- Everything has changed. For me, this is a different life. I was a technical student, and in three years I understood how to do business, how to develop production, create a product and promote it on the market. Imagine, we were guys who had not yet graduated from the institute, insecure in ourselves, did not understand a lot, but plowed a lot. And when they received negative reviews on the Internet or attempts to accuse us of simply sawing the money we received, they got really angry. Then we realized that there is a time for everything.

Now I am sure that business is the only right way for me.

It seems that Andrei Isupov, a techie by education, an entrepreneur by vocation, is just getting used to his new life. He freely interweaves the words “plow”, “drive”, “cool” into a conversation about business, but already naturally pronounces the business concepts of “customers”, “competitors”, “sales”.

— Do you ever feel guilty about not getting enough done in a day?

- Yes. Not every day, of course. When something is not in time, you go to bed with this feeling. And this terrible feeling, - Andrey says with an emphasis on the last phrase.

— Business for me is a drive. I enjoy doing this. Without it, I simply cannot imagine my life. She would be boring. Sometimes on weekends, when I have free time, I understand that I am uncomfortable that I am not at work. At such moments, I call Maxim and plan the next steps to develop our project.

Learn more