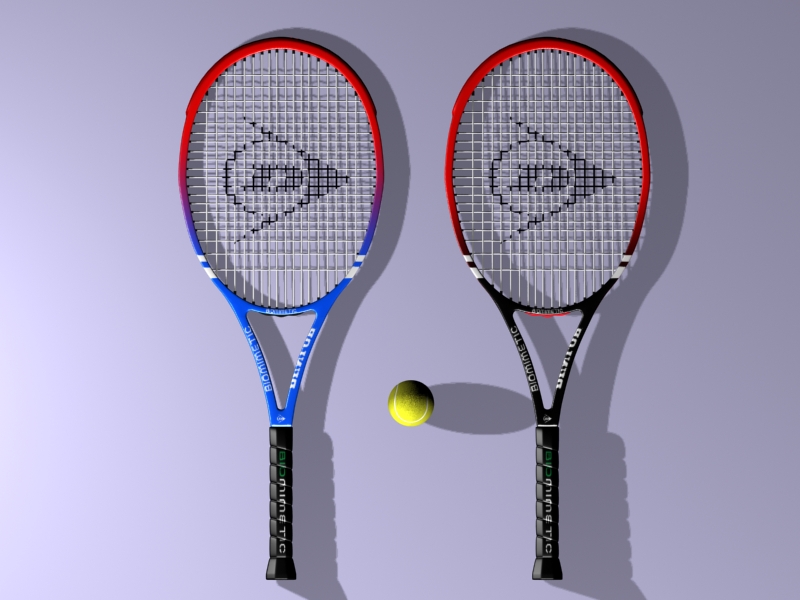

3D printed tennis racket

3D Printing is Changing the Look and Aerodynamics of The Typical Tennis Racket - 3DPrint.com

If any of you have ever played tennis, then you know that besides the skill of your opponent and yourself, the racket is the single most influential part of the game. Play with a cheap $15 racket that you bought on Amazon.com (like I did last time I played) and your game will likely suffer, but play with a quality racket and you may just surprise yourself and your opponent.

Ever since Howard Head and the Prince brand introduced the very first over-sized racket head in 1976, this integral part of the game has remained relatively unchanged. CRP Technology, and two very promising design students from the Rimini Academy of Fine Arts, named Mario Coppola and Salvatore Gallo, have teamed up to create what may become the next generation of tennis rackets.

The team first broke a typical racket down into three separate units, the handle, the neck, and the head. Their goal was to create an aerodynamic product which would hopefully improve a player’s game, while also featuring quite the intriguing aesthetics. The focus was primarily on the handle, which as you can see from the images, is quite unique. Once they figured out the perfect design for each of the three parts of the racket by fabricating structural variants for each, it was now time to put it all together. The team worked to figure out how to produce a frame which would allow for uniformity within the racket, leading to smooth, balanced play.

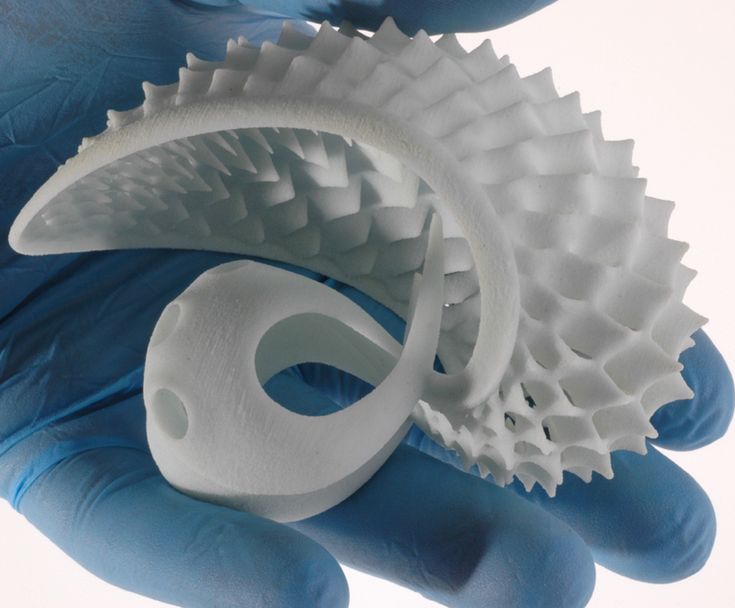

To create the prototype, they used CRP Technology’s Windform XT 2.0 material. This material, which is made for use in a laser sintering 3D printer, combines carbon fiber with a polymer base to produce parts which can stand up to extreme stress, while being relatively resistant to damage, and very light in weight; everything you’d want in an actual tennis racket. In fact, Windform material is used heavily within the space and motorsport industries for final production runs as well as prototyping because of its unique physical properties.

Will this new racket be the future of tennis? Maybe not. However, it’s certainly a step in the right direction, a direction in which complexity of design does not equate to complexity within the manufacturing process. Through the use of exciting new additive manufacturing materials and machines, the future of all sports may soon look a lot different than the cookie cutter designs we are all used to seeing.

However, it’s certainly a step in the right direction, a direction in which complexity of design does not equate to complexity within the manufacturing process. Through the use of exciting new additive manufacturing materials and machines, the future of all sports may soon look a lot different than the cookie cutter designs we are all used to seeing.

Let us know you thoughts on this uniquely designed tennis racket and what it could mean for the future of the sport. Discuss in the Windform Tennis Racket forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d print sports • 3d printed tennis racket • crp technologies • windform • Windform XT 2.0

Please enable JavaScript to view the comments powered by Disqus.

3D Printed Pallets System — Unstrung Customs

UNSTRUNG PRINTED PALLET SYSTEM

Introducing our ground breaking new 3D Printed Pallet system!!

Here's a short video on how our custom designed 3D Printed Pallets are made.

The Unstrung Printed Pallet System allows you to apply any grip shape & size pallet on to any racket. For example, you can have a Babolat grip size 3 that will fit a Wilson racket. Or a Wilson L2 pallet that will fit a Head racket. The options and combinations are endless.

At the moment the only other way to do this would be through grip moulding. However we believe grip moulding is an outdated and time consuming process. The rackets need to be sent away for roughly a week to be moulded. Furthermore there can be many issues with moulding, for example; weight variations, density and also setting the racket perfectly centred in the mould as any slight deviation would result in a bad mould.

Therefore we came up with the idea for our;Unstrung Printed Pallet System.

Our pallets are printed with 0.1mm of accuracy, meaning each and every pallet will come out exactly the same. The density and feeling in the hand will be identical every single time. There will be no issues with with centring the rackets as the pallets are 2 simple halves that lock into one another.

The locking mechanism also means there are no ‘gaps’ in the sides of the pallets like you would often find with other brands traditional pallets.

Another big advantage with the UPPS is that the clients rackets will not need to be sent off anywhere. Any competent stringer/customiser will be able to change a pallet in 10/15 minute.

This means shops and stringers can have a stock of our pallets and offer grip shape and size changing on the spot to their customers.

Furthermore, for pro players and anyone who wants a personal grip made we can offer this service at a fraction of the price to tradition moulding (usually £2,000). This means that a player will have the same printed pallet time and time again.

We have teamed up with one of the UK’s leading 3D printing specialists that design and print parts for aircrafts, racing cars and many more. Each pallet printed goes through their quality control tests resulting in high quality pallets every time.

Combinations and Possibilities

The options for the pallets are virtually endless, if it can be designed it can be printed. So we can offer any cross brand designs.

So we can offer any cross brand designs.

Custom grip designs like the replication of a favourite grip shape and size. Often players have their racket grips sanded and the shape altered, we can replicate this in the design and then it be reproduced in the printing perfectly every time.

We can print pallets that extend the rackets to + lengths.

Even hybrid grip shapes, like a L3 on the top half and an L2 on the bottom half for example.

We’re also able to print flares and ‘leather grip’ textured pallets. Some pros prefer this option where you would only apply an over grip to the pallet.

We have attached our current index sheet that gives you all the current options that we have. We’re always expanding our design inventory so some special shafts or shapes can be requested.

A 3D-printed settlement will be built in the USA

Technology

close

100%

In California, the world's first neighborhood will be built, consisting of houses that were created using a 3D printer. Experts believe that this technology has a lot of advantages and prospects, but there are also significant disadvantages regarding, in particular, communications. How the settlement, which was literally "printed out", will look like - in the material of Gazeta.Ru.

Experts believe that this technology has a lot of advantages and prospects, but there are also significant disadvantages regarding, in particular, communications. How the settlement, which was literally "printed out", will look like - in the material of Gazeta.Ru.

Construction company Mighty Buildings plans to solve housing crisis with robots and 3D printing technology, Business Insider reports . In the California city of Rancho Mirage, a settlement will be built entirely consisting of custom houses created on a 3D printer.

Mighty Buildings is far from the first company to take notice of this promising technology, but the area that will appear in Rancho Mirage is positioned by the developer as "the world's first residential complex of" printed "houses." The project will include 15 houses on an area of 20 thousand square meters. m. Its cost will be $15 million.

close

100%

“This will be the first realization of our vision for a future of residential construction that can be rolled out very quickly,” said Alexey Dubov, co-founder and COO of Mighty Buildings.

According to him, such houses will be more affordable than ordinary residential buildings.

Mighty Buildings houses will be created using the patented material Light Stone, which changes shape under the influence of ultraviolet radiation. In this way, prefabricated panels will be created that can be assembled on the spot - like a constructor. This construction method is fast, but not at the expense of the strength of the building being erected. 3D printing helps Mighty Buildings cut construction costs by 40% while reducing waste by 9%, according to Sam Reuben, chief sustainability officer at the company.9%.

close

100%

3D-printed houses are indistinguishable from conventional houses made of concrete or brick and are not inferior to them in quality, the developer assures. The area of the building will be about 134 square meters. m., and each individual plot - 929 sq. m. Each house contains three bedrooms and two bathrooms. There will be a private swimming pool in the backyard. Also, all premises will receive a smart air and water quality control system.

Also, all premises will receive a smart air and water quality control system.

These houses will be powered by solar panels installed on the roof, which can be supplemented with Tesla Powerwall batteries.

“Our project aims to minimize environmental impact and create smart and healthy homes for environmentally conscious buyers,” Mighty Buildings said in a press release.

close

100%

Construction of houses using 3D printers is already our reality, says Artem Deev, head of the analytical department at AMarkets. Such projects are being actively implemented not only in the USA, but also in China, India, European countries, and also in Russia.

“Technology has a lot of advantages - low cost of construction, reduction in the number of personnel to install such a house, speed of construction of objects, cleanliness at the construction site (houses are assembled on site), simplicity (it's like a designer) and savings.

There are also disadvantages - significant initial costs for special equipment, since the printer can cost about $ 2-3 million. In addition, communications are carried out using old technologies.

In addition, communications are carried out using old technologies.

But this construction of houses and entire settlements is the best way out when you need to build a large amount of housing in a short time (for example, after natural disasters). Therefore, in the future, the technology will be actively developed, and the volume of such housing construction will grow, ”the expert believes.

Subscribe to Gazeta.Ru in News, Zen and Telegram.

To report a bug, select the text and press Ctrl+Enter

News

Zen

Telegram

Picture of the day

Russian military operation in Ukraine. Day 271st

Live broadcast of the Russian military special operation in Ukraine — Day 271

Kyiv demands that Moscow pay more for pumping oil to Europe via Druzhba

Transneft received a notification from Ukrnafta about an increase in the cost of oil transit in 2023

Security line: construction of defensive structures began in the Belgorod Region

Governor of the Belgorod Region Gladkov announced the creation of a defense line in the region

IAEA: two reactors of Zaporozhye NPP remain in hot shutdown mode

CPC: Zelensky violated EU requirement by abolishing lifelong financial monitoring of politicians

The Ministry of Digital Development is preparing an additional list for deferment from conscription for the Ministry of Defense

A fire broke out on the 36th floor of a residential building in Moscow City

News and materials

Blogger Ilya Maddison stated that he was forced to leave Serbia

In Finland, the technology forum Slush canceled the victory of a startup due to ties with Russia

Dailyfaceoff called Malkin the most underrated superstar in hockey history0005

Source: Chelsea are going to sign Zakharyan in the winter transfer window

Fashion designer Raf Simons announced the closure of his own brand

Zakharova urged the IAEA to clearly point out those who are shelling the Zaporozhye nuclear power plant

TAC: NATO fell into a trap because of Zelensky's statements about

missiles that fell in PolandPentagon: US and UAE confirm military partnership

Xiaomi five years ago updated to Android 13

RT announced the cooperation of the APU brigade that shot the prisoners with NATO

Netherlands national team player Bergwijn: Promes would help us at the World Cup, he is the king of Russia

TSMC Founder Confirms Company Plans to Make Advanced Chips in Arizona

A memorial to Soviet soldiers was desecrated in Latvia

Rudkovskaya reported that the mobilized husband of Lipnitskaya refused the proposed delay

The IAEA did not find a threat to nuclear safety at ZNPP

The teacher told how to help the child overcome the fear of mathematics

The IAEA declared a non-radioactive leak at the ZNPP due to shelling

A priest of the 76th Airborne Assault Division of the Airborne Forces, wounded in the NVO zone, died Tsyganov

All news

Interview with the Mirage group about new songs, the trial with Sukhankina and concerts in Europe in 2022

Mirage group members stated that they did not encounter Russophobia at concerts in Europe

“Today no one even remembers their names”

How Iran provoked an uprising in Bahrain, and the Saudis and the United States suppressed it

“Peaceful solution is determined on the battlefield”: NATO urged to supply more weapons to Ukraine

NATO Secretary General called for increased military assistance to Ukraine for a peaceful settlement

Benefits will be combined, central banks will be abolished: what new laws Putin signed

President Putin signed the law on a single benefit for pregnant women and families with children

"Paratrooper with combat experience". Mayor of Chita resigned to go to Ukraine0005

Mayor of Chita resigned to go to Ukraine0005

Wagner versus Mozart: which PMCs are involved in the fighting in Ukraine

The LPR reported about a dozen private military companies fighting on the side of Kyiv

"The Walking Dead": actors of the series in life and in movies

"Moscow has not fulfilled its duty." Erdogan explained the start of the operation in Syria by the refusal of the Russian Federation from the agreements

Erdogan accused Russia of refusing to clean up terrorists in northern Iraq and Syria

"Can't speak for the Ministry of Defense." Peskov - about the second wave of mobilization and the change of power in Kyiv

Peskov said that the Kremlin is not discussing the second wave of mobilization

"Kyiv definitely needs to be returned. " Rogozin urged to bring the SVO to a victorious end

" Rogozin urged to bring the SVO to a victorious end

The former head of Roscosmos Rogozin announced the need to "return" Kyiv to Russia

Why Pavel Astakhov's son received a term in colony

Pavel Astakhov's son was sentenced to 3.5 years in prison for fraud

1899 TV series - a new dark mystery from the authors of the cult "Darkness"

Review of the Netflix series "1899" from the creators of "Darkness"

"I have to dig through the supplies." The West reported difficulties with the supply of weapons to Ukraine

WP: The West faced a shortage of weapons due to the supply of the Ukrainian army

First 3D printed modular turntable built, DIY kit planned for mass production

The Dutch manufacturer of 3D printers RepRapUniverse and the Swiss company Lenco, which creates turntables, decided to please fans of the archaic with another electrophone. Unlike other companies that duplicate devices from the good old 70s and 80s, the tandem of manufacturers intends to launch a DIY kit into a series. It will allow everyone to assemble the Lenco-MD turntable with their own hands, having previously printed most of the parts on a 3D printer.

Unlike other companies that duplicate devices from the good old 70s and 80s, the tandem of manufacturers intends to launch a DIY kit into a series. It will allow everyone to assemble the Lenco-MD turntable with their own hands, having previously printed most of the parts on a 3D printer.

A working prototype of the turntable was presented at the IFA 2018 Consumer Electronics Faire in Berlin. A kickstarter campaign was launched to support the project, and likely to explore global demand. Under the cut, a few words about what the electrophone promises to be for self-printing and assembly, and what has already been implemented in the prototype.

What was shown in Berlin?

The Lenco-MD prototype shown at IFA 2018 is a turntable assembled from a set of components and 3D printed parts and equipped with a tone arm. Due to the fact that the modules for the electrophone are still being developed, it was shown in a standard wired version.

The turntable is equipped with a belt drive, which the manufacturers claim provides smooth movement, an original design tonearm with an AT3600 cartridge from Audio-Technica.

The table is mounted on special damping feet.

In the basic configuration of the prototype there is also a built-in preamplifier (phono stage) with headphone output and RCA.

At the demonstration of the project in Berlin, representatives of the manufacturers noted that it was a “green” project. The main parts of the player's construction are made of PLA, a biodegradable thermoplastic that does not harm the environment. It is planned to use renewable energy sources for food.

The latter is popular as a reliable and stable device. All components used in the Lenco-MD have already been tested with the serial Lenco L-85 turntable.

The 3D printer used to print the prototype and the player that formed the basis of the development

The assembly of Lenco-MD deserves special mention, which, according to the assurances of the developers, takes only a few minutes.

quick assembly process

The

Lenco-MD Solar Powered Wireless Turntable promises to be the world's first turntable that can literally be printed at home and assembled with a few extra parts that come with the kit (motor, belt, cartridge, etc. ). The device assumes a quick replacement of modules and the possibility of individualizing the design.

). The device assumes a quick replacement of modules and the possibility of individualizing the design.

Now it is planned to implement a module with a small amplifier and speakers, a Bluetooth module, a module with a solar battery. Each of them will be sold separately.

It will be possible to change almost everything in the player (tonram, cartridge, phono stage, etc.)

There is a way out of this situation - buy a partially or completely printed set of parts. Manufacturers rightly reasoned that not everyone has 3D printers or the size of a home 3D printer does not match the size of the parts. There are several options for basic kits, for those who have a small 3D printer - partial and for those who do not have one at all - full.

Moreover, those wishing to assemble Lenco-MD are offered to buy ready-made spare parts for small-scale screwdriver assembly. With a strong desire and sufficient demand, you can turn a hobby into a business. Lenco's flexible policy encourages electronics manufacturers to create modules for the turntable, effectively opening up opportunities for expanding functionality.