House 3d printer price

The cost of 3D printed houses in 2021

3D printed houses bring the benefits of additive manufacturing to the construction space. The material costs incurred by construction 3D printing are usually an order of a magnitude less when compared to conventional methods. This is while we take into account the fact that 3D printing concrete tends to be more expensive than normal construction concrete.

As for labor costs, they drop down basically to the daily wages of at most two or three operators. And that too is for a much shorter length of time as the 3D printed house would be ready for finishing and furnishing in days instead of months.

The cost to build an average sized 3-bedroom house with conventional building methods is from $250,000 to $320,000. Building the same home with 3D printing technology would cost from 20 percent to 40 percent less to build. So that same 3-bedroom house would presumably cost between $140,000 to $240,000 to build with 3D printing technology.

It should be noted at this point, that most construction 3D printers will not build, or 3D print the foundations, nor would the construction 3D printer be of any cost-saving benefit when it comes to roofing the house.

All those things: the roof, the windows, the doors, electrical wiring, paint and finishing – all of these costs remain the same as with a conventional house, as all this fall outside the scope of what a construction 3D printer is capable of.

University of Nantes researchers designed and constructed a full-size single-family house via construction 3D printer in France at a cost of $232,000 in 2018. Which was twenty percent less than what a similar sized building would have cost to construct via conventional means.

Haus.me – the business that sells the PassivDom highly insulated prefabricated houses, charges $210,000 for a ready to move in luxury 3D printed smart house that is entirely self-sufficient and filled to the brim with smart features.

The Dubai Future Foundation office that was 3D printed off-site by Winsun cost $140,000 at the time for the entire structure. With the fit and finish of this luxury office, a hundred and forty thousand dollars is quite a bargain seeing as how by using construction 3D printing technology, the government estimates that it saved almost 50% on the total (assembly, electrical, and technical) labor costs.

All three of the above are examples of luxury or large-sized 3D printed houses that cost a sizably less amount than what an equivalent construction done via conventional methods would cost.

On the other end of the scale are the small size houses that have been making headlines and have successfully been 3D printed at a fraction of conventional costs.

COBOD’s construction 3D printing services provide an online project cost calculator based on various factors such as the square meter area of all the walls, labor cost and number of operators, and the cost per unit of 3D printing concrete.

The cost of construction comes out to be around $15,000 for a small sized house (single bedroom). $20,000-25,000 for a medium sized house (two bedroom). And around $50,000 for a large sized 4 bedrooms house.

Compare this with the fact that building one’s own house can cost anywhere between $95 to $150 per square foot and it quickly becomes clear that even construction 3D printing services have a lot to offer in terms of cost savings.

On the extreme end of affordable housing of course, stand ICON and WASP’s efforts.

ICON and New Story’s 500 sq. Foot houses 3D printed on-site in El Salvador cost around $4,000-5,000 per house.

And WASP’s earthen house village made with their construction 3D printer. The average raw material cost per house came out to only 48 euros per house.

While costs are often the most quoted benefits of shifting to construction 3D printers. The time scale benefits are one of the most staggering numbers.

The time scale benefits are one of the most staggering numbers.

As a matter of fact, most 3D construction projects never need more than a month to 3D print even the most complex designs.

The Future Foundation Office of Dubai took a total of 3 months to go from idea to operational office.

Europe’s first 3D printed office, The BOD, only took 22 days on their first attempt, and this was reduced to just 3 days when COBOD reperformed the construction 3D printing of the building as a test 2 years later.

Front entrance of Icon Labs’s 3D printed house located in Austin Texas.And of course, ICON’s 500 sq. foot houses take only a day each to go from nothing to a completely finished and ready-to-move-in house.

The mere thought of constructing an entire house in a single day is nothing short of amazing.

Compare this with conventional construction, and it is normal to expect ANY house to take at least several months to be ready to move in.

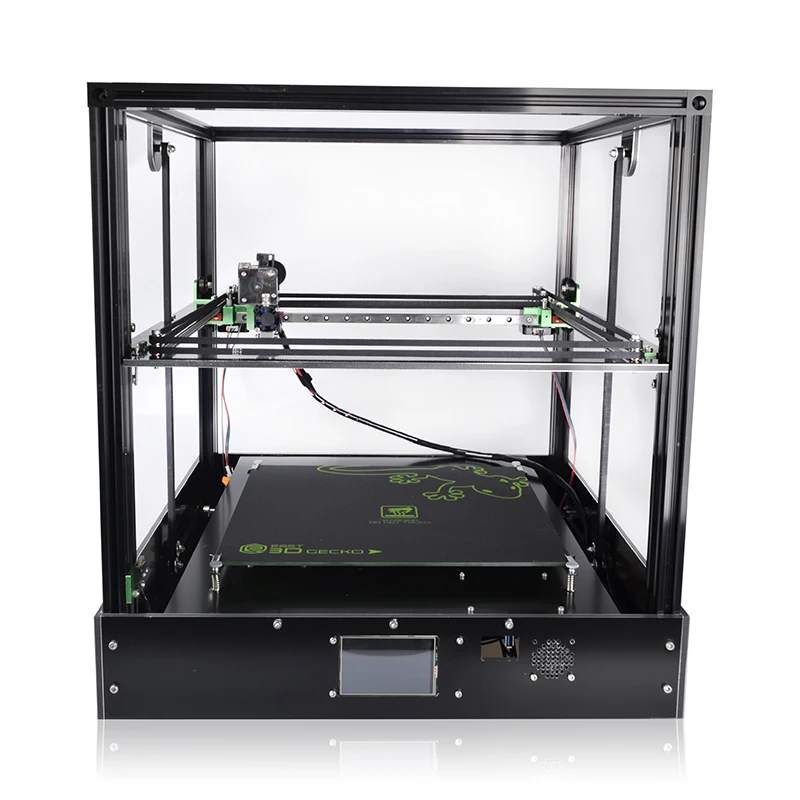

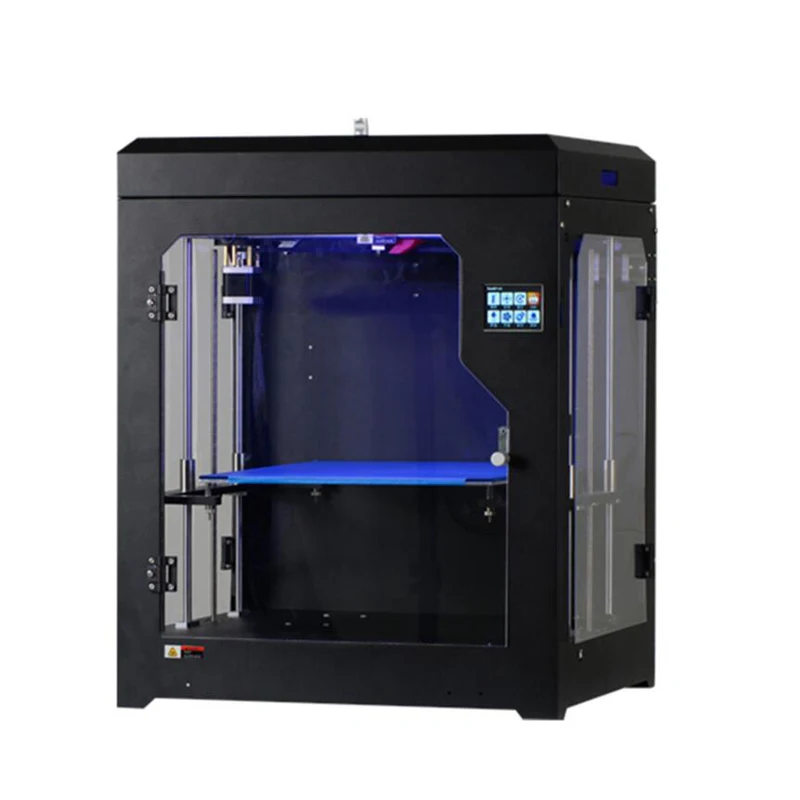

As it stands, consumers in most cases would be unable to commission a 3D printed house construction directly. The printers themselves are expensive investments for any local construction company. 3D construction printer generally starts at $39,000 for the small basic models, to the upwards of $100,000 for the larger models.

Apart of from the cost of equipment and materials, there’s another major hurdle in purchasing a 3D printed house depending on where you are located. Only a handful of construction permit have been handed out for 3D printed houses, in special experimental cases, in select areas.

The mass of 3D printed houses is currently being developed in more technologically primitive areas. However, for anyone interested, a good place to start would be to contact the large-size local construction companies first. And then, as option B, contact the construction 3D printer makers themselves.

One exception of course, is Haus.me. The luxury prefabricated home maker readily sells its houses conveniently online via both monthly installments plans as well as outright cash purchases.

Others such as COBOD (www.cobod.com) provide construction 3D printing services, albeit in limited areas of Europe.

Another potential website to check out is www.weprinthouses.com. However, they are currently only taking requests and not orders. Additionally, at a cost of $100 per square foot for the construction alone, there is not much of a cost saving benefit transferred to the customers.

The company based out of Austin Texas has been awarded the first commercial permit to build a 3D printed house that can appraised and sold in the U.S. The construction project has been given the code name the Genesis. Construction begins February of 2020.

See our post, when will 3D printed houses finally become available where we look at the viability of 3D printed houses, plus when and where 3D printed houses will be commercially available to begin with.

Tags: 3D printing3D printing housesHouse

Ultimate guide to construction 3D printers in 2022 (concrete 3D printing)

What are the best house 3D printers?

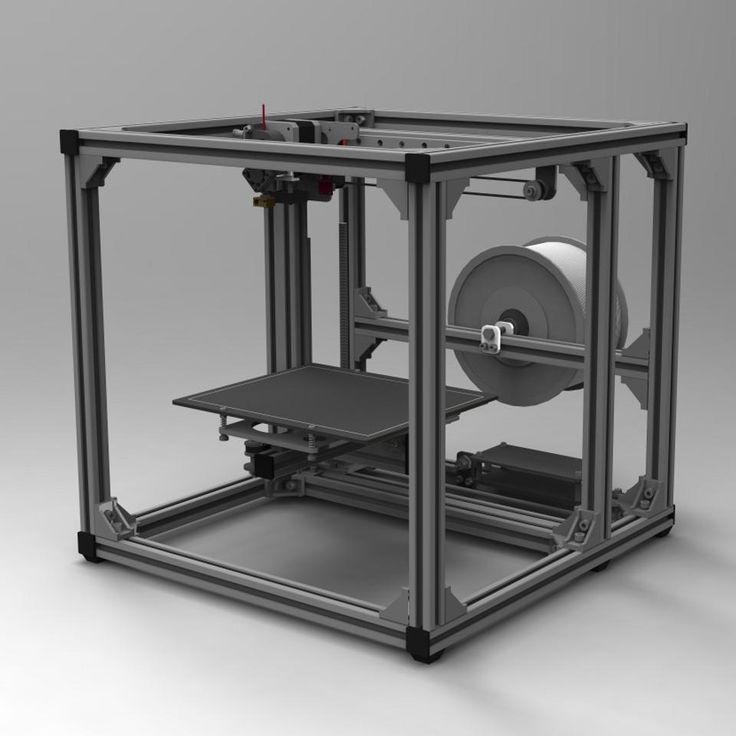

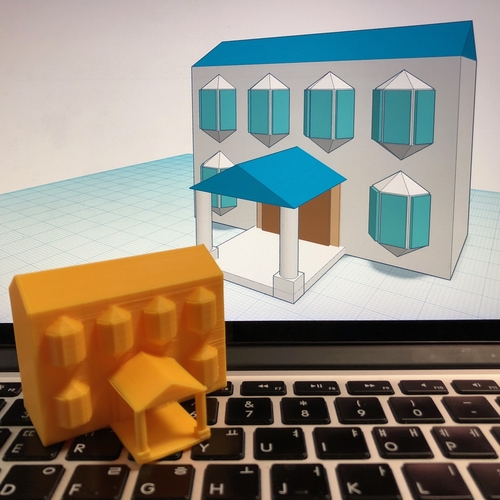

A construction 3D printer is a machine that can build houses by depositing a material (concrete for example) layer by layer. Concrete 3D printing – a.k.a. “Construction 4.0” – is a similar 3D printing technology to the one that FFF 3D printers use. Paste-type material, in this case, concrete or earth materials, is pushed through a nozzle in layers to print buildings in 3D.

Concrete 3D printing – a.k.a. “Construction 4.0” – is a similar 3D printing technology to the one that FFF 3D printers use. Paste-type material, in this case, concrete or earth materials, is pushed through a nozzle in layers to print buildings in 3D.

Concrete 3D printing in the construction industry helps save time, effort, and material compared to traditional construction methods. It’s important to note, though, that 3D printers are not yet capable of creating a fully functional house.

Only the frame and walls of the house are built; other elements, such as windows, electricity, or plumbing, need to be installed separately. But concrete 3D printers can also be used to print bridges, benches, or simply outdoor decorations.

To provide a complete overview of the construction 3D printer market, we have listed 12 house 3D printing solutions. Some of them are 3D printers available for sale, while some are still at the start-up prototype stage or are external construction 3D printing services.

13 house construction 3D printers

| House 3D printer | Category* | Type** | Build size (m) | Country |

|---|---|---|---|---|

| BetAbram P1 | Available | Gantry system | 16 x 8.2 x 2.5 | Slovenia |

| COBOD BOD2 | Available | Gantry system | 14.62 x 50.52 x 8.14 | Denmark |

| MAXI PRINTER | Available | Robotic arm | 12.25 x 12.25 x 7 | France |

| CyBe Construction CyBe RC 3Dp | Available | Robotic arm | 2.75 x 2.75 x 2.75 | Netherlands |

| ICON Vulcan II | Available | Gantry system | 2.6 x 8.5 x ∞ | United States |

| MudBots 3D Concrete Printer | Available | Gantry system | 1.83 x 1.83 x 1.22 | United States |

| Total Kustom StroyBot 6.2 | Available | Gantry system | 10 x 15 x 6 | United States |

| WASP Crane WASP | Available | Delta system | Ø 6. 3 x 3 3 x 3 | Italy |

| Apis Cor | Project | Robotic arm | 8.5 x 1.6 x 1.5 | Russia |

| Batiprint3D 3D printer | Project | Robotic arm | Up to 7m high | France |

| SQ4D – ARCS | Service | Gantry system | 9.1 x 4.4 x ∞ | United States |

| Contour Crafting | Service | Gantry system | – | United States |

| XtreeE | Service | Robotic arm | – | France |

Build volumes are indicative and may vary based on the specific configuration of the machine.

*Category: some 3D printers are available for sale, others are working projects, and some are only available via a rental service.

**Type: construction 3D printers either use a gantry system (like oversized desktop 3D printers with X, Y, and Z axes) or a mechanical, robotic arm.

How to build 3D printed houses?

Here we explain how 3D printers are able to print houses with paste extrusion.

House 3D printing technology

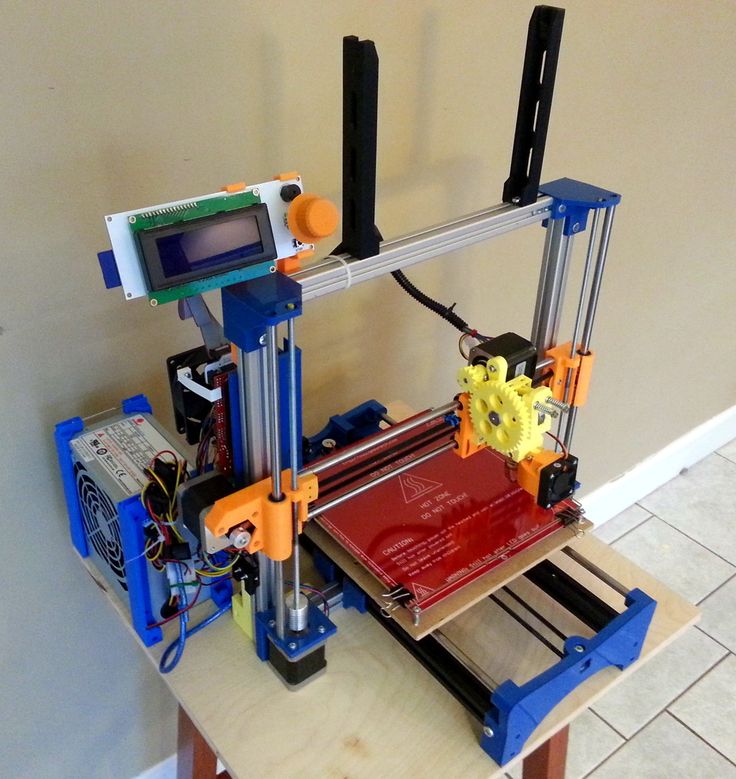

House 3D printers use extrusion technology. Some construction 3D printers look like super-sized desktop FFF/FDM 3D printers (gantry style), whereas others consist of a rotating mechanical arm.

In both cases, paste-type components such as concrete are used as filament. The material is pushed out of a special nozzle to form layers. To put it (very) simply, paste extrusion is similar to using a piping bag to spread frosting on a cake.

The printer creates the foundations and walls of the house or building, layer by layer. The ground is literally the printer’s build plate. Some concrete 3D printers, however, are used to 3D print brick molds. When molded, the bricks are then piled atop each other manually (or with a robotic arm).

When molded, the bricks are then piled atop each other manually (or with a robotic arm).

Benefits of house 3D printing

Eco-friendly

3D printed houses can be built with organic, eco-friendly materials. Moreover, some house 3D printers use solar energy and generate low CO2 emissions.

Affordable

House 3D printers can build affordable housing, being of great aid for people in poverty-stricken regions or after natural disasters.

Scalable

Construction 3D printing reduces certain building costs. For example, the cost for 1 square meter of a wall using traditional construction methods is approximately $75, whereas with the Apis Cor house 3D printer it is only $27.

Efficient

Since the materials are 3D printed on-demand, the machines produce less waste. Also, construction 3D printers can finish a home’s foundations in less than a few days, while traditional construction methods take several weeks or even months.

Also, construction 3D printers can finish a home’s foundations in less than a few days, while traditional construction methods take several weeks or even months.

Design flexibility

With a 3D construction printer, it’s possible to easily create curved walls and unique facades. (Good thing it’s possible to 3D print furniture to match the curves!)

Limits of 3D printing houses

Expensive initial investment

House 3D printers can sometimes cost up to one million dollars.

Partially-built houses

House 3D printers only build house frames. The 3D printing process is usually paused to manually settle plumbing, wiring, and rebars.

Rough exterior

Most 3D printed homes’ exteriors are not as smooth as traditionally-built houses.

Lack of certification

Construction sites are regulated by laws and there are important safety standards that need to be met, which can be challenging with 3D printing techniques (varying repeatability, dimensional stability, etc. ).

).

Another downside that has been noted over the years is that house 3D printing can potentially harm local economies, especially in poverty-stricken regions or cities with high unemployment rates. Indeed, since construction 3D printers reduce the need for manual labor, they create much less employment for local workers.

Differences between 3D printed houses and traditional houses

Concrete 3D printing saves time, uses less material, and requires less manual labor. Even 3D printed houses have a rougher exterior, post-processing is an option just as it is for regular 3D printed objects. 3D printed houses tend to be smaller due to 3D printer build volume limits, but this is not always the case.

Construction 3D printers: overview

We break down construction 3D printers into three categories: house 3D printers that are available for sale, concrete printer prototypes, and 3D concrete printing services.

House 3D printers available for sale

BetAbram is a small Slovenian team that has been working on construction 3D printing hardware since 2012. Their flagship home 3D printer, the BetAbram P1, is currently in its second version and is available with optional print heads: basic, “Orto” for smoother layers, and rotating for more design possibilities.

Contact manufacturer Get a quote Add to comparison

This construction 3D printer is fast, reaching announced speeds of up to 60 meters per minute. The BOD2 is modular and can be adapted is many different sizes. COBOD is a 3D Printhuset company.

Contact manufacturer Get a quote Add to comparison

Constructions-3D is a subsidiary of French 3D printer retailer Machines-3D.

Their MAXI PRINTER machine is mobile thanks to its caterpillar-style rubber tracks and fits into a 20-foot shipping container for easy transport from one construction site to another.

Contact manufacturer Get a quote Add to comparison

The CyBe RC 3Dp consists of a single robotic arm with a nozzle at its end.

This easy-to-move house 3D printer is capable of reaching up to 2.75 meters high and requires only two people to operate it.

Contact manufacturer Get a quote Add to comparison

ICON wishes to revolutionize the construction field with their Vulcan II printer. The whole process is designed to be user-friendly with a tablet-based interface, and ICON’s Lavacrete concrete mix is optimized to be easier to print.

Contact manufacturer Get a quote Add to comparison

MudBots is a concrete 3D printer manufacturer based in the United States. Their smallest model (1830 x 1830 x 1220 mm approx.) is available at the price of $35,000. Larger build sizes are available as well, reaching up to 30 meters long.

According to MudBots, their 3D printers can 3D print a small house in only 12 hours and can drive costs down 70% compared to traditional construction methods.

Contact manufacturer Get a quote Add to comparison

The StroyBot, also known as the Rudenko 3D construction printer (made by Andrey Rudenko), is an all-in-one mobile construction printing system delivered as a kit to be assembled by the user. On average, it is able to print a 100-square-meter house in 48 hours (walls only).

On average, it is able to print a 100-square-meter house in 48 hours (walls only).

The Crane WASP is the evolution of WASP’s previous construction printer, the BigDeltaWASP 12MT. This open source construction printer is modular and multiple Crane printers can work together on one project, for theoretically infinite 3D printing possibilities.

Concrete printer working projects

Apis Cor, a 3D construction company, is based in San Francisco and claims to be able to 3D print a house in under 24 hours. Their Apis Cor printer is similar to a robotic arm and has won first place in NASA’s Phase 3 3D-Printed Habitat Competition.

Contact manufacturer Get a quote Add to comparison

Batiprint 3D made international headlines when completing their Yhnova 3D printed house in Nantes, France. Their 3D printer not only prints cement but also insulation foam, which makes it one of the most complete 3D construction solutions.

Construction printing services

This automated construction system is able to 3D print large buildings and tall infrastructures. Contour Crafting (a.k.a. CC Corp) aims to make disaster relief more efficient with their concrete additive manufacturing technology.

Contour Crafting (a.k.a. CC Corp) aims to make disaster relief more efficient with their concrete additive manufacturing technology.

SQ4D – ARCS aims to provide quick, robust, eco-friendly, and affordable housing solutions for impoverished areas.

XtreeE develops specific 3D printing solutions for construction, engineering, and architectural design. This startup is based in France and has already completed a number of 3D construction projects.

Special mentions: interesting 3D construction projects

DFAB HOUSE

This unique building was completed by a consortium of companies in early 2019 and is based in Switzerland. The 3-story DFAB building offers 200 square meters of space.

Branch Technology C-FAB and WATG’s Curve Appeal design

The WATG architectural design firm won the Branch Technology Freeform Home Design Challenge in 2016. In 2019, their project is set to be printed in Tennessee by Branch Technology’s C-FAB freeform construction 3D printing method.

DUS Architects XL 3D printer (KamerMaker)

The XL 3D printer was created by DUS Architects to build a prototype canal-house (simply dubbed “3D Print Canal House”) in Amsterdam using recycled materials.

Haus.me

This US-based company, previously known as PassivDom (dom.ai), 3D prints walls, floors, and roofs for their fully autonomous prefab houses.

Autodesk metal construction printer

Autodesk may or may not be working on a construction 3D printer that uses metal material. This 3D printer, which is more a pair of robotic arms than a printer, is able to make metal components for construction sites. We can’t wait to hear more about this!

CONCR3DE Armadillo stone 3D printer

CONCR3DE is a Dutch company that manufactures stone 3D printers. They are able to 3D print stone thanks to a special binder jetting process. Their two 3D printers, Armadillo Black and Armadillo White, aren’t able to print a house but can 3D print stone decorations or molds.

Discontinued projects and printers

Many startups have come and gone in the construction 3D printing industry.

D-Shape construction 3D printer

The D-Shape 3D printer is a multifunctional construction 3D printer that can 3D print very large objects, including houses and prototypes. D-Shape seems to be inactive since 2015.

Winsun house 3D printer

The Winsun 3D printer is a house 3D printer that was in the spotlight a few years ago. In 2015, however, Contour Crafting’s CEO accused Winsun of stealing their patented technology. Winsun’s website has since been taken down.

Cazza X1 3D printer

Cazza was founded in 2016 with its X1 construction 3D printer. However, it seems that one of the co-founders stole the company’s funding in 2018, and Cazza is now on standby.

HuaShang Tengda

HuaShang Tengda 3D printed a house capable of withstanding a base 8 earthquake on the Richter magnitude scale. Today, the company seems to be off the radar.

Today, the company seems to be off the radar.

3D printed house time and cost

Construction 3D printing is faster and more affordable than traditional construction methods.

However, since construction 3D printing is still in its early years, it is difficult to provide definitive statements about how long it takes to 3D print a house and how much it costs to 3D print a house.

How long does it take to 3D print a house?

Various construction 3D printer manufacturers such as Apis Cor or ICON boast that they are able to 3D print a small house in 24 hours. As mentioned before though, print jobs generally only include laying down the house’s foundations and walls.

This does save whatever amount of time it usually takes for a standard team to build walls for a certain project. The rest of the timeframe for building a house remains equal.

3D printed house price

In general, it is estimated that a 3D printed house costs 30% to 55% less than a traditionally-built house.

For reference, Apis Cor’s small house cost less than $10,000 to produce, and ICON’s compact 3D printed home even cost less than $4,000.

Construction 3D printer price

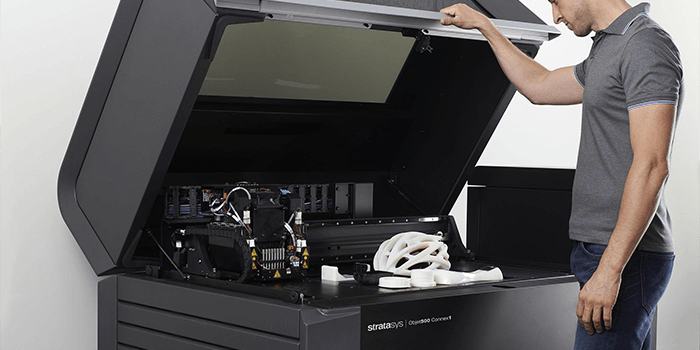

A construction 3D printer can cost anywhere between around $180K to over $1M. Robotic arm systems tend to have higher price tags than gantry-type systems.

Other 3D printed infrastructures

Aside from housing or buildings, construction 3D printers are able to 3D print bridges and space-station infrastructures.

3D printed bridges

Construction 3D printers can also 3D print bridges. In 2015, the world’s first 3D printed steel bridge was 3D printed for testing in Amsterdam by MX3D. MX3D printed the final version of their stainless steel bridge in 2018 and installed it in Summer 2021.

In 2017, a 12-meter-long pedestrian bridge was 3D printed in Madrid, Spain. In the same year, the first 3D printed concrete bridge was built in the village of Gemert in the Netherlands.

In the same year, the first 3D printed concrete bridge was built in the village of Gemert in the Netherlands.

More recently, in 2019, Shanghai became home to the world’s longest concrete 3D printed bridge. It is 26.3-meters long and 2.6-meters wide, and was 3D printed in only 18 days.

3D printed infrastructures in space

NASA’s 3D-Printed Habitat Challenge has given life to a number of teams dedicated to bringing 3D printing to space. Apis Cor, namely, won the top prize for one of this project’s phases. The goal is to create sustainable and efficient 3D printed housing for deep space exploration.

Many other companies have been involved in space-building projects, including the European Space Agency and Elon Musk’s SpaceX. It is possible that we will see the first space house 3D printers in space sometime in the next couple of decades (!).

Apis Cor and SEArch+ team’s 3D printed space infrastructure (render) for the NASA 3D-Printed Habitat Challenge. Source: Apis Cor and SEArch+

Source: Apis Cor and SEArch+FAQ: construction 3D printing

What is a 3D-printed house?

A 3D printed house is a house composed of 3D printed elements, such as 3D printed walls, floors, or roofs. It is also possible to use the term “3D-printed home”.

How much does it cost to 3D print a home?

It can cost as low as $4,000 to 3D print a home. Prices vary greatly according to the material being used and the size of the home to be 3D printed.

What are the best 3D printed house companies?

See our selection of the best 3D printed house companies here.

Where are there 3D-printed houses for sale?

There are 3D printed houses for sale in the US (Los Angeles, San Francisco), China, France, Russia, UAE, and many other countries.

Is concrete 3D printing just for houses?

No, concrete 3D printing is also for infrastructures such as bridges.

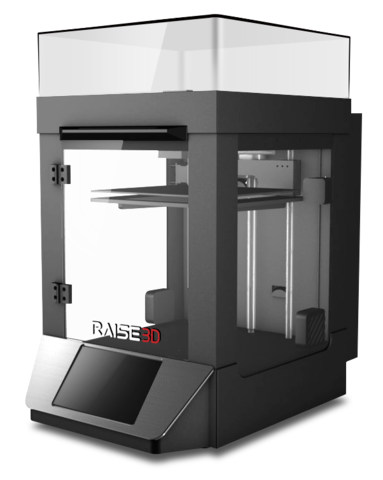

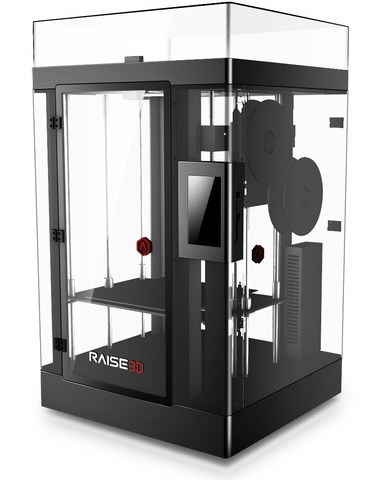

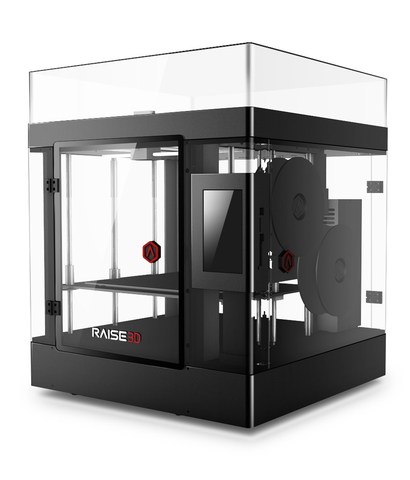

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao Flash Forge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Voxelab |

| Construction area size | 200*200*200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (5. 9 l) 9 l) |

| Chamber volume | 5.9 l |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 198 × 123 × 210 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Flash Forge |

| On order/Transit | Goods in transit |

| Construction area size | 200*200*250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (print volume 5. 9 l) 9 l) |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | QIDI |

| On order/Transit | Goods in transit |

| Construction area size | 270 x 200 x 200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 200x125x220 mm |

| Country of origin | Taiwan |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 325*325*350 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Wanhao|

| Construction area size | 500x500x500 mm |

| Number of extruders (print heads) | 2 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 192 x 120 x 200 mm |

| Country of origin | China |

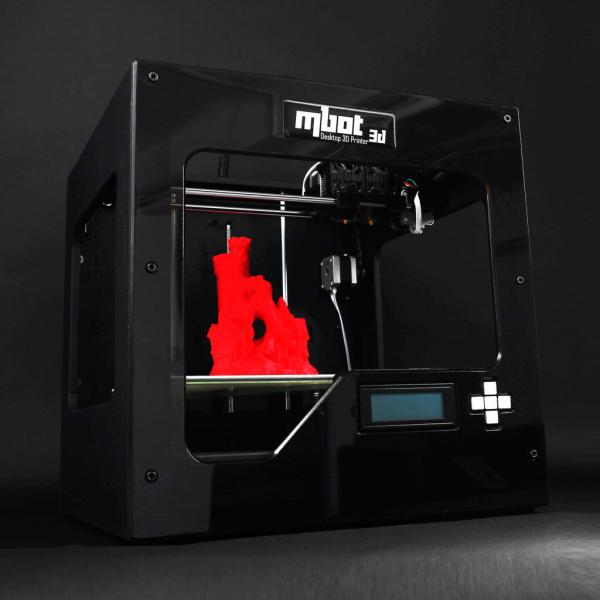

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

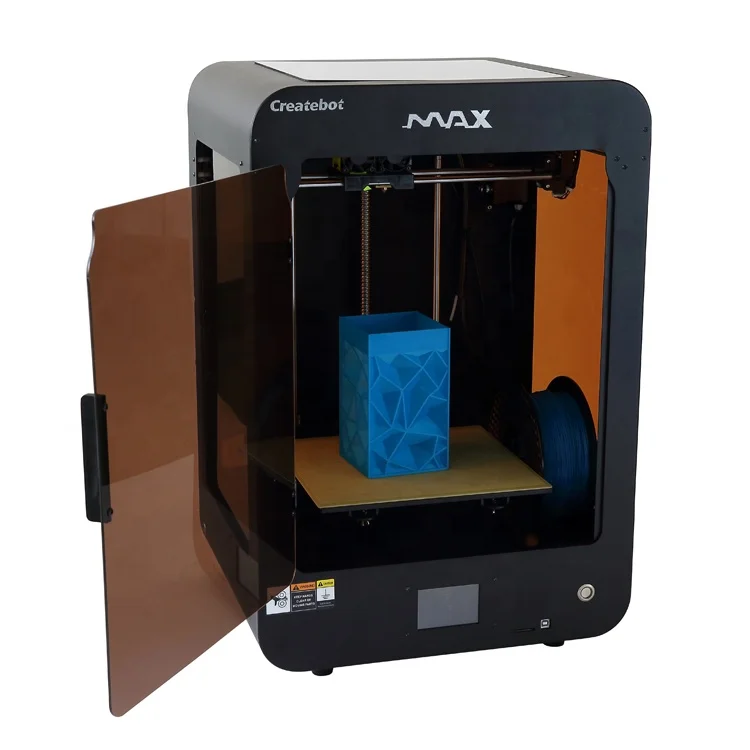

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

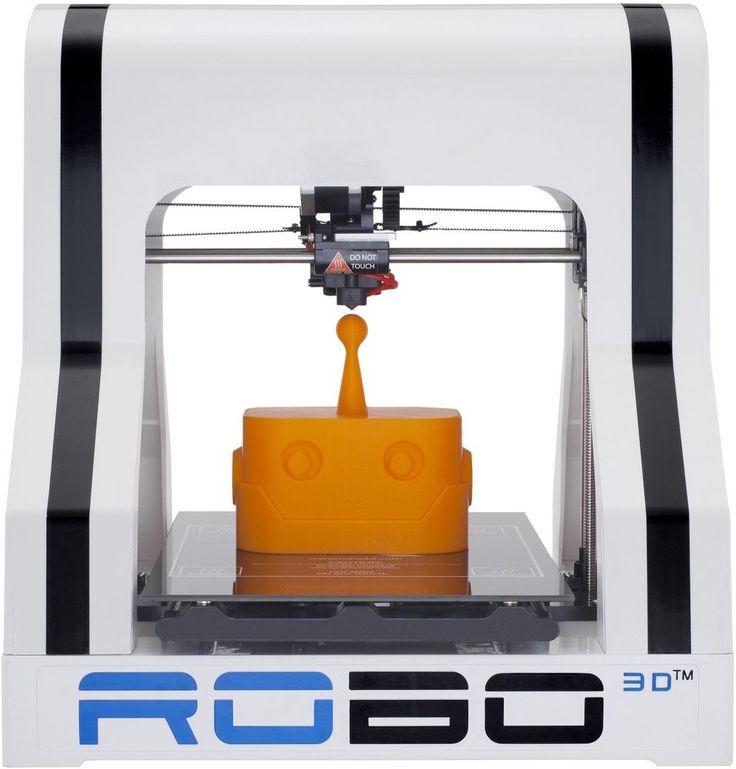

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

I wonder how much a 3D printer costs? Find out the answer!

The real cost of a 3D printer

Now that you know about all the intricacies of 3D printing techniques, types of technologies and devices, it's time to answer the question "How much does a 3D printer cost?". In this section, we will give you the answer and explain what the price of a 3D printer depends on.

Types of 3D printers

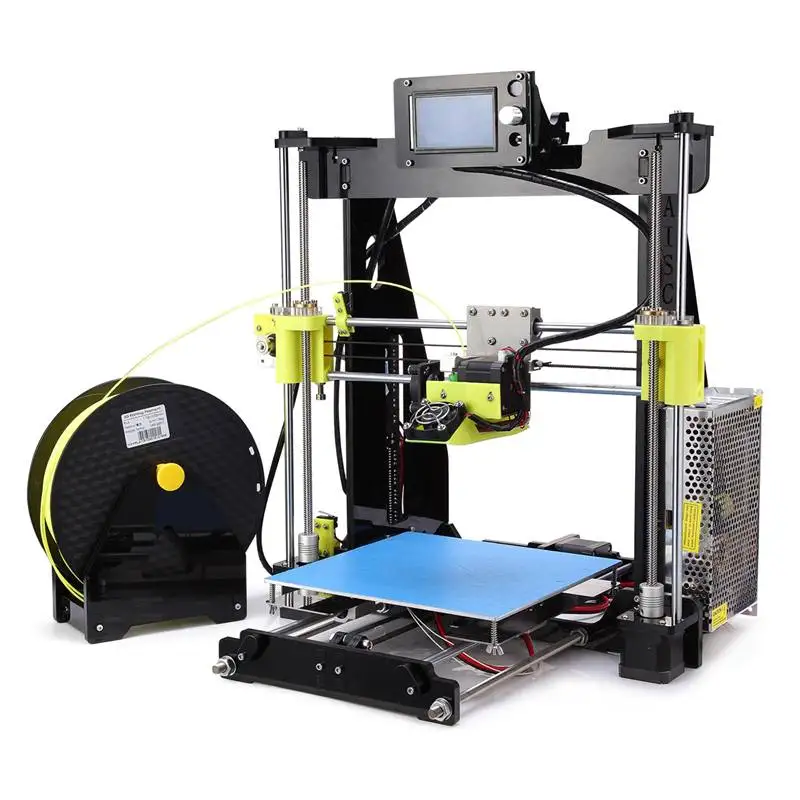

As you already know from our previous articles, additive manufacturing techniques are very different from each other. Not only the reproduction process itself differs, but also, accordingly, the working materials. Of the most common technologies worth noting:

- FDM printers that print with filaments of various polymeric materials;

- SLA 3D printers, where a special liquid photopolymer resin acts as a consumable;

- SLS 3D printers that use metal, plaster or plastic powder.

Of course, such a huge difference in the methods of production of models cannot but be reflected in the cost of devices for 3D printing. In each of the presented categories there is a division into budget and professional devices, however, all SLS 3D printers are one step higher than devices of other classes. There are a number of reasons for this, which our article on 3D printing technologies will help you figure out. After all, in order to determine how much a 3D printer costs, you need to understand the specifics of the techniques. Conventionally, the cost of printers can be placed in the same order in which they are presented above. Let's explain why.

In each of the presented categories there is a division into budget and professional devices, however, all SLS 3D printers are one step higher than devices of other classes. There are a number of reasons for this, which our article on 3D printing technologies will help you figure out. After all, in order to determine how much a 3D printer costs, you need to understand the specifics of the techniques. Conventionally, the cost of printers can be placed in the same order in which they are presented above. Let's explain why.

Application of 3D printers

Finding out how much a 3D printer costs, first of all, you should pay attention to its type and intended application. Depending on the 3D printing technology, the device can be "sharpened" for specific tasks. For example:

- SLA 3D printers are optimal for jewelry and dental applications, as well as for creating miniature detailed products. Although more serious, professional models of such printers are used for the production of larger objects.

The price corresponds to the quality, but remains quite high due to the peculiarities of the methodology;

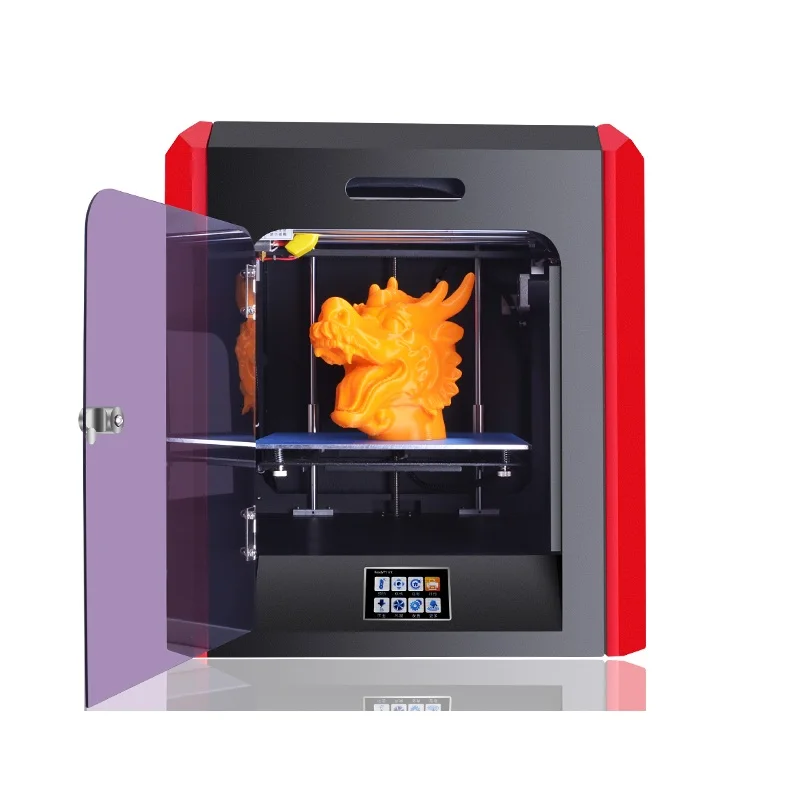

The price corresponds to the quality, but remains quite high due to the peculiarities of the methodology; - FDM 3D printers are the least expensive and have a huge variety of models. The most affordable option for home use, and more professional models are suitable for meeting the needs of a small business; The

- SLS printers are the most professional option for a variety of industrial applications. Due to the ability to print with metal, they are used in the aerospace, automotive, medical industries, etc. For the most part, these are large installations weighing several tons, not for home use. The most expensive 3D printers on the market.

How much does a 3D printer cost? Yes, the manufacturer is just as important in 3D printing as it is in everything else. And often the user has to overpay a lot of money for the brand. On the other hand, at the same time, he pays for the quality of the product, which he does not want to risk at all.

So, we have reviewed the main types of devices for 3D printing and identified the factors on which their price depends.