3D printing with liquid resin

Resin vs. Filament 3D Printer: Which is Best for You?

Research Hub > Resin vs. Filament 3D Printer

June 27, 2022

Article

4 min

Resin and filament are the two most common materials used in 3D printing. But which is better for your project, and what equipment do you need?

What's Inside

- What is Stereolithography (SLA) 3D Printing?

- What is Digital Light Processing (DLP) 3D Printing?

- What is Fused Deposition Modeling (FDM) 3D Printing?

-

Filament vs.

Resin Printers

- Which 3D Printer Should You Buy?

SLA and DLP are two different types of resin 3D printers, while FDM are filament 3D printers. Read our breakdown below to compare.

What is Stereolithography (SLA) 3D Printing?

Stereolithography (SLA) is the oldest form of 3D printing. It works by exposing a layer of photosensitive liquid resin to a UV-laser beam; the resin then hardens in the desired pattern, and the object is built layer by layer until it is complete. This allows you to print a model with extremely fine detail.

Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. SLA resin printers tend to have smaller build plates, so you can't make larger pieces on them. Printing via SLA involves a longer process as printed objects need to be rinsed using a solvent and then put into an ultraviolet oven to complete processing.

SLA resin printers tend to have smaller build plates, so you can't make larger pieces on them. Printing via SLA involves a longer process as printed objects need to be rinsed using a solvent and then put into an ultraviolet oven to complete processing.

What is Digital Light Processing (DLP) 3D Printing?

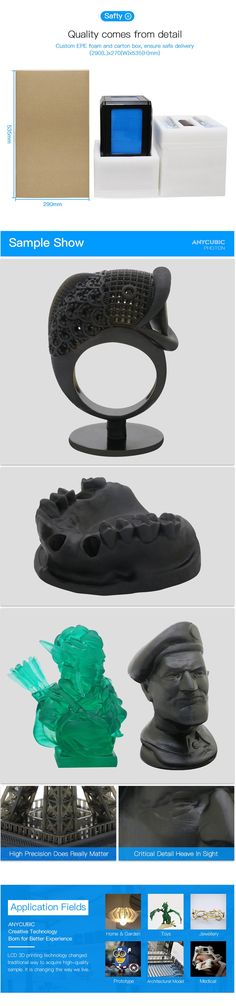

Digital Light Processing (DLP) is the fastest of all 3D printing methods. A layer of hardened material can be printed in a few seconds and quickly transferred to allow for printing of the next layer. Like SLA, DLP 3D printers use liquid plastic resin, but instead of a UV-laser beam, the resin is melted with arc lamps. This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. DLP is a robust technology that produces high-resolution models every time, even allowing you to use cheaper materials for complex and detailed objects.

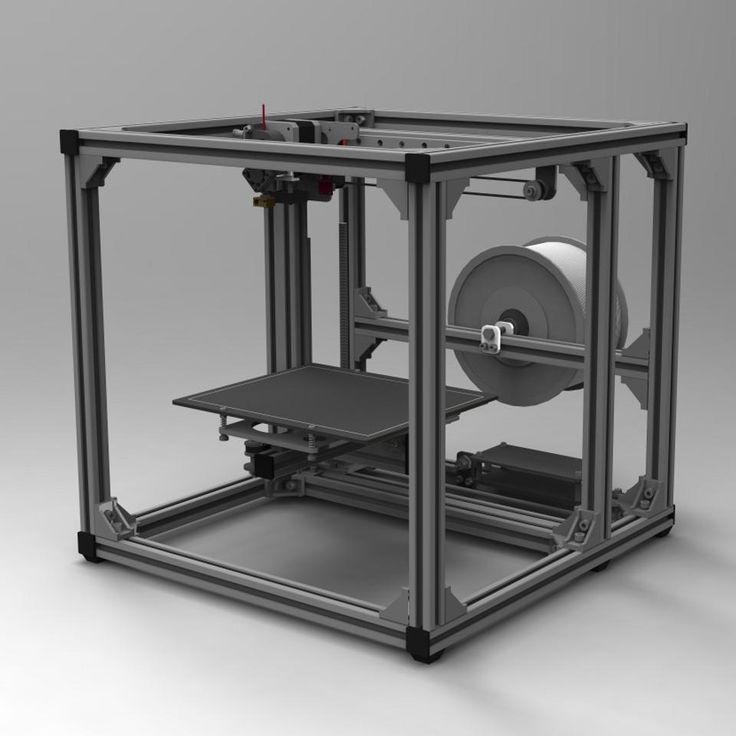

What is Fused Deposition Modeling (FDM) 3D Printing?

Fused Deposition Modeling (FDM) is filament 3D printing, the most popular and readily available form of 3D printing available on the market. Developed and originally implemented in the 1980s, FDM allows you to print operational prototypes as well as ready-to-use products as such LEGO, plastic gears and much more

All components printed with FDM can go in high performance and engineering-grade thermoplastic, which makes this technology useful for mechanical engineers and manufacturers. Printed pieces have excellent mechanical strength and heat resistance. FDM printers construct 3D objects layer by layer, starting at the bottom and moving upwards by heating and extruding thermoplastic filament. This form of 3D printing is useful in all fields, from new product development to prototyping to end-product manufacturing.

Filament vs. Resin Printers

There are several key factors to consider when deciding whether an FDM or SLA/DLP printer is the right choice for you.

- Cost - When purchasing a 3D printer, it is not only the printer cost that you must take into account; it is the filament or resin cost, as well as other accessory and time demands. On printer cost, FDM printers easily win over SLA/DLP printers at every level. Especially for novices, budgetand entry-level SLA/DLP printers are few and far between.

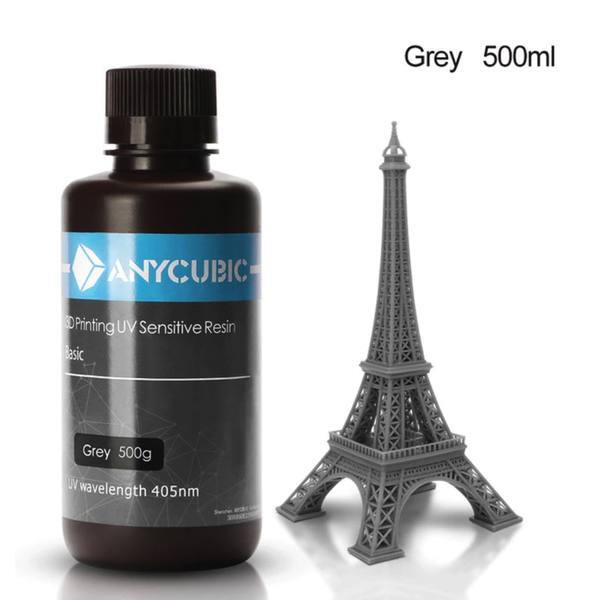

In addition, you must consider the upkeep of the printer. A spool of filament will cost you $25 or less, with infrequent nozzle replacement given regular cleaning and maintenance. With resin printers, you will need to replace both resin and resin tanks frequently. A tank costs $40 or so, and a liter of resin is around $80.

When comparing costs, an FDM printer is far more affordable.

When comparing costs, an FDM printer is far more affordable.

- Quality - A major consideration in 3D printing is the quality of objects that you will be printing. FDM printers rely on several factors, such as extruder precision, nozzle size and adhesion between layers. Warping, shrinkage and shifting are not uncommon as the layers are slowly squeezed together. However, these issues can be cleaned up in post-processing.

On the other side, SLA/DLP printers provide superb quality because the laser determines fine details, leading to extremely precise, high-quality print jobs. When comparing finished products, resin 3D printing yields better final results.

- Ease of Use - There is a definite learning curve no matter if you choose a filament or resin 3D printer. For filament printers, you will need to remove the final print from the print bed using a palette knife and then perform some post-processing snipping off of excess plastic, as well as a bit of sanding.

For resin printers, removing the final print is a bit more cumbersome as there is a lot of excess resin leftover. In addition, objects will need to be wiped with isopropyl alcohol and sometimes put into an ultraviolet oven for final processing. Both printer types require postprocessing, though filament printers might be a little easier to use.

- Durability - Both types of printers have been shown to form pieces offering high durability. Alternatively, materials such as PETG and ABS can be exposed to heat and UV rays, adding more durability to filament printing. This means that anything from a children’s toy to an outdoor coaster can be printed and they will stay intact if left outside for an extended period.

- Build Volume - Resin printers can vary from smaller build volume to much bigger based on the printer. Many of the entry level printers are standardized at 130 x 80 x 160 mm, printing anything an individual or business could need. 192 x 120 x 150 mm is a smaller size in which more advanced resin printers can produce products at, much smaller than that of your everyday resin printer.

- Print Speed - For most resin printers, a print speed of around 100mm/hour is a good speed if an individual or business has the time on their hands and does not worry too much about efficiency. DLP and SLA printers can achieve a top speed of 720 mm/hour if the details do not matter as much. Those printers tend to be the most effective amongst the rest, so normally the job will be done at a high rate of print speed and look great.

Conclusion: Which 3D Printer Should You Buy?

Choosing the 3D printer that is right for you depends on your needs and the objects that you are creating. Filament and an FDM printer is the right choice for hobbyists and makers, those building low-cost materials, when strength and durability are important or when precision and surface finish aren’t crucial. Resin and an SLA/DLP printer is the right choice when high precision and smooth finish is of utmost importance and cost isn't a factor.

Looking for a 3D printer? Find what you need on CDW.com.

What is 3D Printer Resin? – HATCHBOX 3D

WHAT IS 3D PRINTER RESIN?

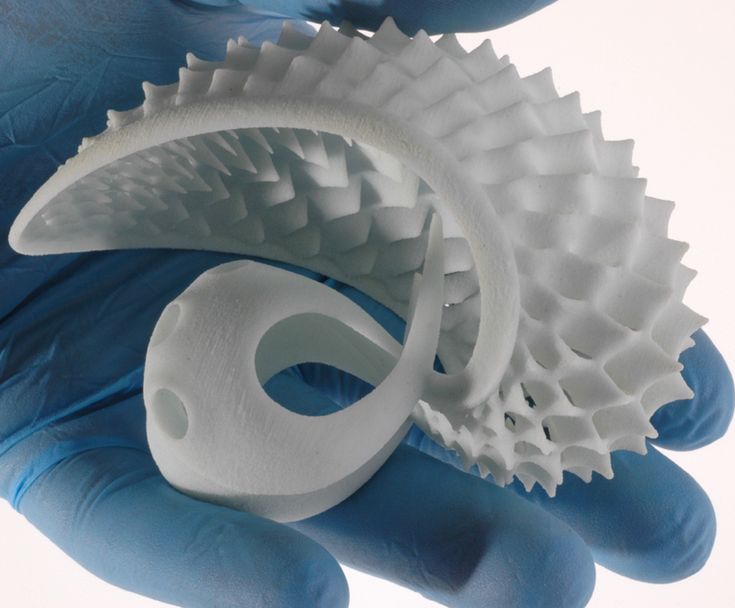

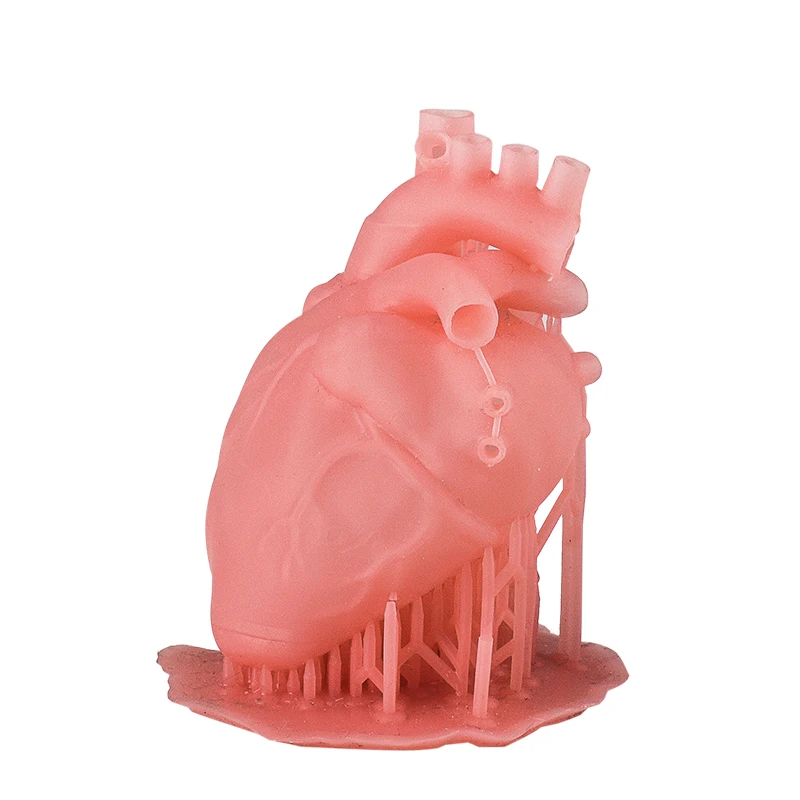

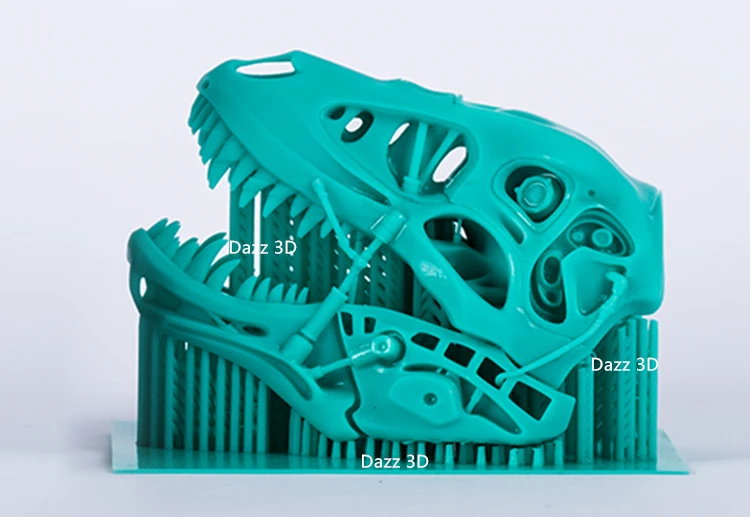

Resin printing lets engineers, designers, artists and hobbyists 3D print high-quality objects that they cannot get from filament-based fused deposition modeling (FDM) printers. The process beams ultraviolet (UV) light into a tank of liquid, resin, triggering a reaction that solidifies the resin into a hard plastic. This photo-polymerization happens in a small volume thanks to the narrow ultraviolet beams. As a result, the final object can have much finer details and smoother surfaces than those produced by FDM printers.

Recent innovations have made the decades-old technology of resin 3D printing more accessible than ever. Here’s everything you need to know to get started.

HOW DOES A RESIN 3D PRINTER WORK?

All resin 3D printers use the same basic physics to turn liquid resin into solid objects. Each slice from the print file is turned into a pattern of ultraviolet (UV) light that shines into a tank of liquid resin. The photopolymer cures into a solid layer and then the bed repositions for the next layer.

In most resin printers, the bed starts one layer height above the source beneath the tank. The bed peels the newly-solidified layer from the bottom of the tank as it rises another layer height to bring in more resin for the next layer.

HOW MUCH IS A RESIN 3D PRINTER?

Resin 3D printer pricing spans a vast range. Industrial printers from companies like 3D Systems run well into the six-figures. At the other extreme, LCD printers aimed at hobbyists can cost less than two hundred dollars. Resins themselves can vary in price from $20 per liter for basic prototyping to hundreds of dollars per liter for specialty resins.

Resins themselves can vary in price from $20 per liter for basic prototyping to hundreds of dollars per liter for specialty resins.

3D PRINTER RESIN

VS. FILAMENT

The difference between resin-based 3D printing and filament-based 3D printing is visible when you pull the object from the bed. Objects produced through resin printing can be more detailed and consistent with fewer printing artifacts. Objects produced with filament printing, however, have better engineering properties and a wider range of materials and styles. Safety can be an issue with both materials. Like some filaments, resins are irritants and poison hazards. Wearing gloves and having adequate ventilation is a must. Users must be trained in proper safety procedures when handling and disposing of resins.

RESIN PRINTS

The ultraviolet light beams in DLP and LCD printers are larger than in SLA printers but still produce finer details than FDM printers. And with finer increments in bed positioning, the thinner layers can produce final objects with no visible layer marks.

And with finer increments in bed positioning, the thinner layers can produce final objects with no visible layer marks.

Unlike FDM printing, print orientation does not change the strength of resin-printed parts. The curing process is not instantaneous so the solidifying resin chemically bonds with its surroundings. Each new layer bonds with the layer above to create a solid piece without the gaps filament printers leave behind or varying strength depending on orientation.

FILAMENT PRINTS

Although Fused Deposition Modeling (FDM) printers cannot achieve the same level of detail as a resin 3D printer, these printers allow more creative control. FDM printers can be reconfigured — by swapping out nozzles, for example — to better balance quality versus speed for a specific job.

Many different filament materials, such as PLA, nylon or TPU, let you get the right properties for your part. And each filament type can have a range of colors and other additives to deliver a specific look. FDM printing is the best choice for long-lasting objects or anything that needs to be kids-safe.

FDM printing is the best choice for long-lasting objects or anything that needs to be kids-safe.

ADVANTAGES AND

DISADVANTAGES OF RESIN

IS PHOTOPOLYMER RESIN

3D PRINTING RIGHT FOR ME?

What kind of objects are you printing? Resin works best when producing limited quantities of small, finely-detailed parts that do not need the strength and material options of filament printing.

Are you prepared to operate and maintain the printer? You will be committing to the inconveniences of handling resin safely as well as cleaning and curing parts.

Can you afford the total cost of ownership? More capable printers are not cheap. And resin printing has long-term costs for consumables and replacement parts.

Frequently Asked Questions

Yes, the first step after every print is to rinse away the uncured — including any resin inside the part — before letting the part dry. This is also the point where you remove all traces of the supports. You may need to cure the object further in an enclosure with UV lighting.

This is also the point where you remove all traces of the supports. You may need to cure the object further in an enclosure with UV lighting.

Your part may need more typical post-processing beyond this point to achieve the final surface finish.

Many of the skills needed for FDM printing —3D design skills, engineering or aesthetic experience, etc. — apply to SLA printing. But these are different processes using different materials. Consistent success with SLA printing only comes with study and experience. Fortunately, there are plenty of resources out there to help you get started.

Auto manufacturers use SLA printers to prototype dashboards more than a meter across. In that scenario, spending millions on acquisition, operation and maintenance makes sense. At the other extreme, artists and hobbyists who need low-cost options will use FDM printers for their large print jobs.

No. Most photopolymer resins are poison hazards and skin irritants. You should seek medical attention after inhaling, touching or ingesting resin. Finished prints may retain some resin after curing and the solid photopolymer could leach material. As a result, even “biocompatible” resins for medical applications should not be used with food.

You should seek medical attention after inhaling, touching or ingesting resin. Finished prints may retain some resin after curing and the solid photopolymer could leach material. As a result, even “biocompatible” resins for medical applications should not be used with food.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

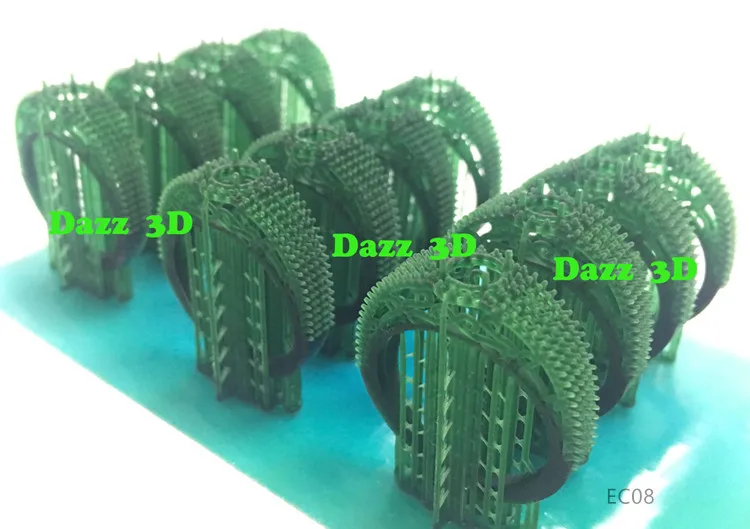

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

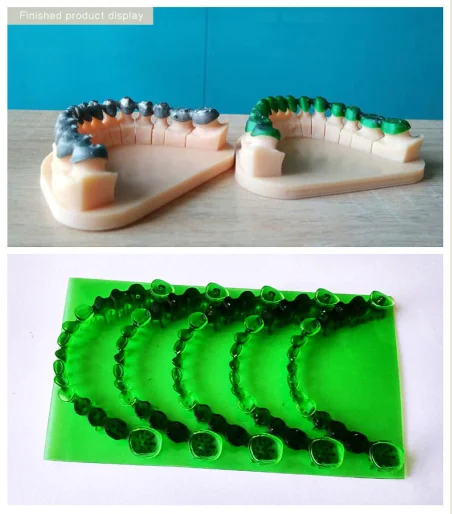

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you!

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

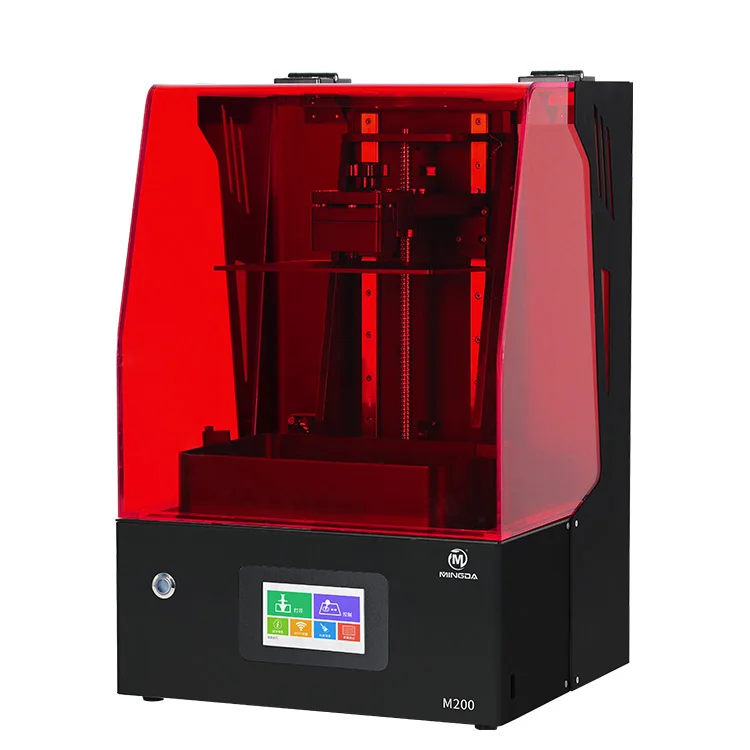

Photopolymer 3D printer

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

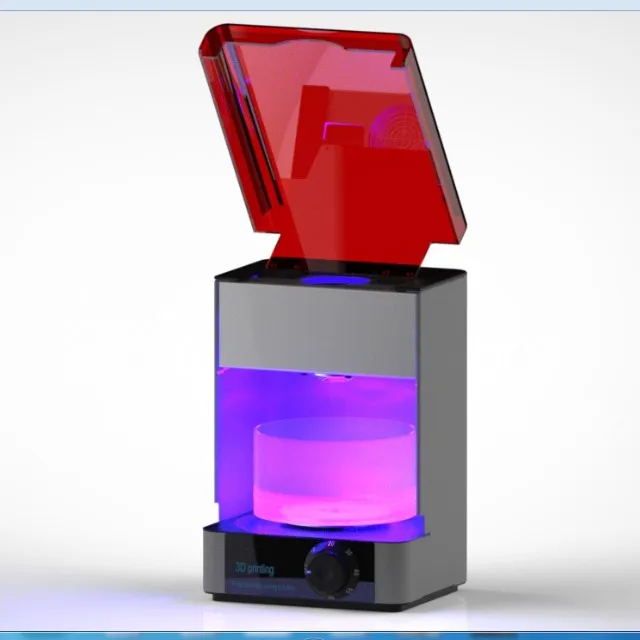

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting.

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones.

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

SLA Model

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam.

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation diagram

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Animation of the build process

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the installation dimensions and raise the price to an unacceptable level for most users.

Despite the success of this technology, projected stereolithography is considered to be a more promising, albeit very similar, method.

Projector Stereolithography (DLP)

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

Layers are illuminated using a digital projector that highlights the patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type units, but this technology used physical photomasks, making the process costly, time consuming, slow and noisy.

FTI continues to exist, a development of SGC that is virtually indistinguishable from DLP printing, as it also uses digital LED projectors.

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems.

Projection size can be quite significant, reaching the average of popular FDM printers.

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer.

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

MJM printer 3D Systems ProJet 3500HDMax

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows for very high printing speeds, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use.

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

3D Pens

CreoPop 3D Resin 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld photopolymer printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters.

The pen only extrudes resin through the tip surrounded by LED emitters.

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature - there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy.

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin for domestic use.

Additional Lighting

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part.