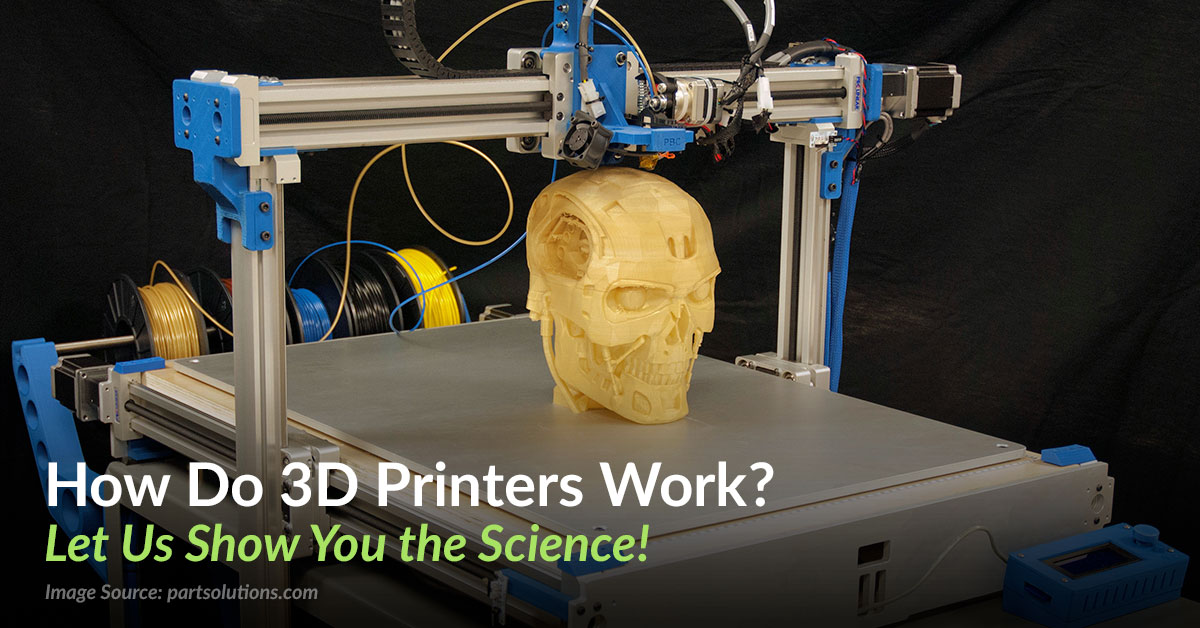

How accurate is 3d printing

Guide to 3D Printing Tolerances, Accuracy, and Precision

Just because a 3D printer has "high resolution” in the printer specifications doesn’t mean your 3D printed parts will be accurate or precise.

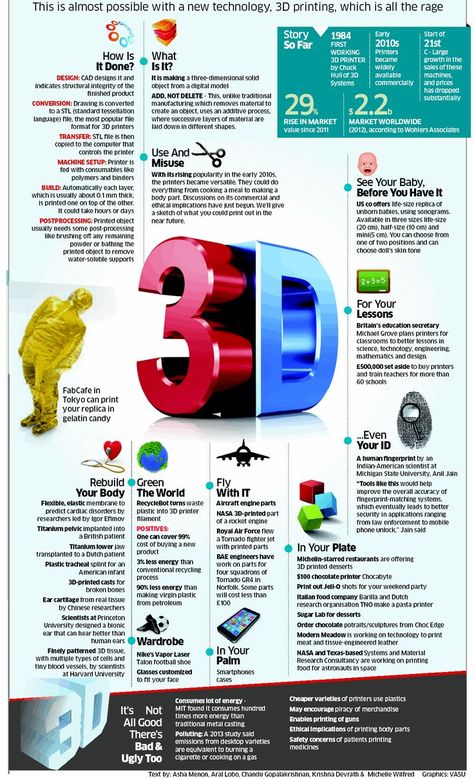

Understanding the meaning of accuracy, precision, and tolerance is imperative for achieving meaningful 3D print performance for any application. In this post, we’ll parse through what these terms mean and how to think about them in the context of 3D printing. Then, we'll compare the tolerance ranges you can expect from different 3D printing processes and provide a detailed overview for tolerancing 3D printed assemblies.

Download our free white paper for a breakdown of how to measure and apply tolerances for each type of fit, with specific recommendations for Formlabs Engineering Resins.

Whitepaper

Tolerance and fit are essential concepts that engineers use to optimize the functionality of mechanical assemblies and the cost of production. Use this white paper as a resource when designing functional 3D printed assemblies, or as a starting point when designing the fit between parts printed.

Download the White Paper

Let’s start with definitions: What’s the difference between accuracy, precision, and tolerance? For each term, we’ll use a target—a common example for unpacking these concepts—to help visualize meaning.

Accuracy is how close a measurement is to true value. In the case of a target, true value is the bullseye. The closer you are to hitting the bullseye, the more accurate your shot. In the world of 3D printing, true value equals the dimensions you design in CAD. How closely does the 3D print line up to the digital design?

Precision measures the repeatability of a measurement—how consistent are your shots at the target? Precision measures this consistency only; your shots could be hitting near the same spot every time, but that spot doesn’t have to be the bullseye. In 3D printing, this ultimately translates to reliability; can you rely on your machine to produce your expected results for every print?

In 3D printing, this ultimately translates to reliability; can you rely on your machine to produce your expected results for every print?

Exactly how precise do you need to be? That’s defined by tolerance, and tolerance is defined by you. How much wiggle room do you have in your application? What’s an acceptable variance in the closeness to the measurement that precision is hitting? That will depend on your project, for example, a component with a dynamic mechanical assembly will require tighter tolerances than something like a simple plastic enclosure.

If you’re defining a tolerance, you’ll likely want accuracy too, so let’s assume we’re measuring precision of shooting at the bullseye. Earlier, we defined the shots on the target pictured on the right as not precise.

However, if your tolerance range is fairly wide, it may be okay. The shots aren’t as close to each other as in the target on the left, but if the acceptable range of precision is the distance of ±2. 5 rings, then you’re within spec.

5 rings, then you’re within spec.

Generally, achieving and holding tighter tolerances means higher manufacturing costs and quality assurance.

Webinar

Watch our webinar for a walk through the SLA 3D printing workflow, material options, and expert tips to optimize the part-to-print workflow to get the most value out of 3D printing.

Watch the Webinar Now

There are a variety of factors to consider when thinking about accuracy and precision in 3D printing. Knowing that the printer will consistently work as promised and produce the quality expected from it, within the tolerances the user is used to, could be crucial to a successful experience.

Here are four big factors at play in determining the accuracy and precision of 3D printing:

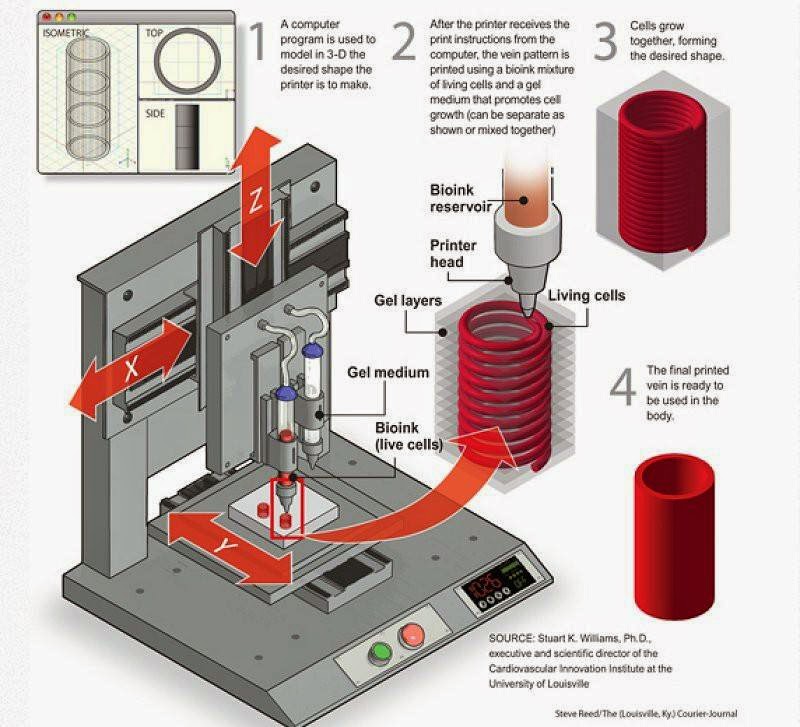

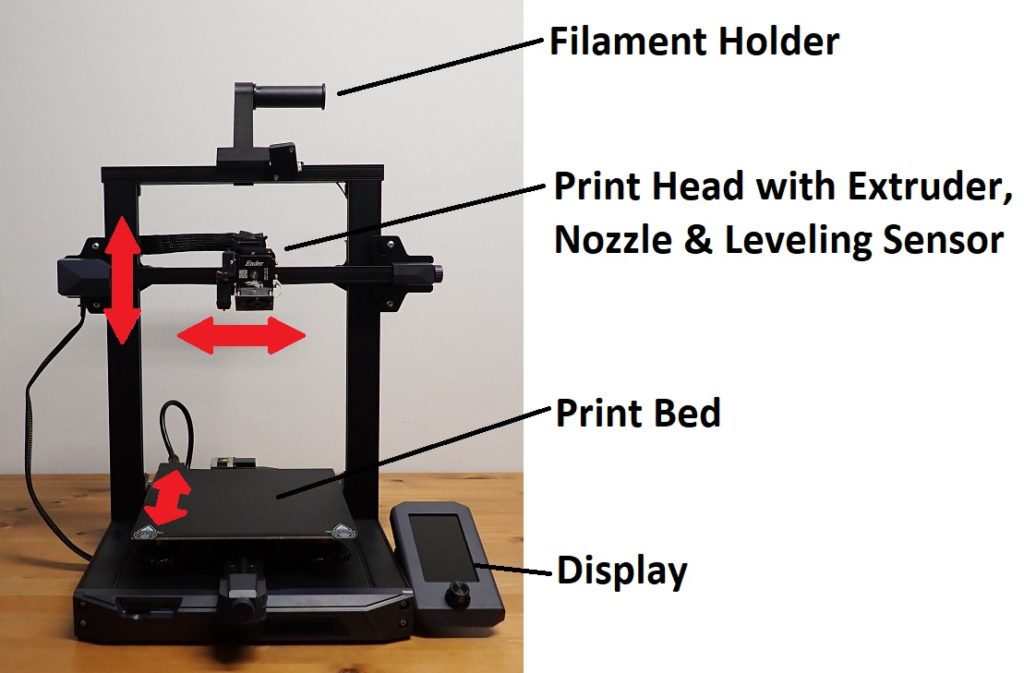

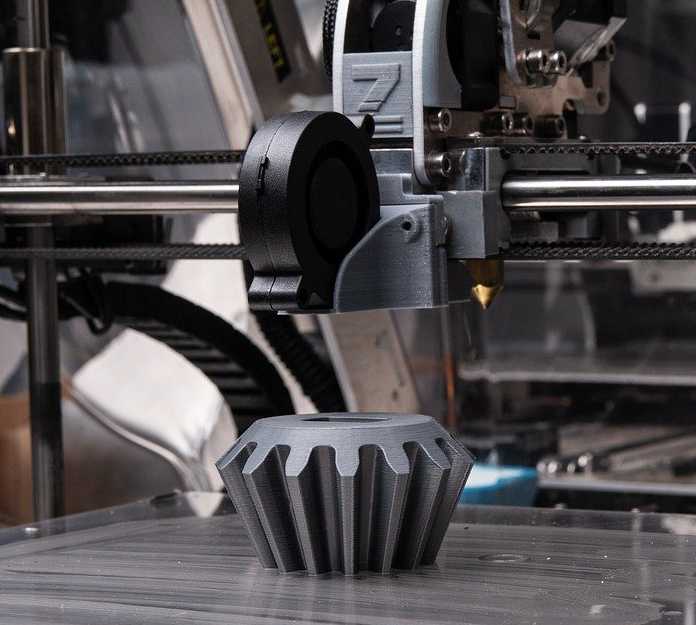

3D printing is an additive process, so parts are built layer by layer. Each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, or repeatability, of the accuracy of each layer. Let's look at the typical 3D printer tolerances for the most common plastic 3D printing processes:

Let's look at the typical 3D printer tolerances for the most common plastic 3D printing processes:

- Stereolithography (SLA) and digital light processing (DLP): ± 0.2% (lower limit: ± 0.1 mm)

In resin 3D printing, liquid resin material is selectively exposed to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. Thanks to the highly-precise light sources, these processes can achieve fine details and can consistently produce high quality results. Depending on the model geometry, resin 3D printed parts require support structures, which can be essential to achieve dimensional accuracy, especially with complex geometries or large and thin walls. - Selective laser sintering (SLS) and multi jet fusion (MJF): ± 0.3% (lower limit: ± 0.3 mm)

Powder bed fusion 3D printers also rely on the precision of a light source—SLS a laser, MJF a fusing lamp—to fuse powder materials into solid parts. As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features.

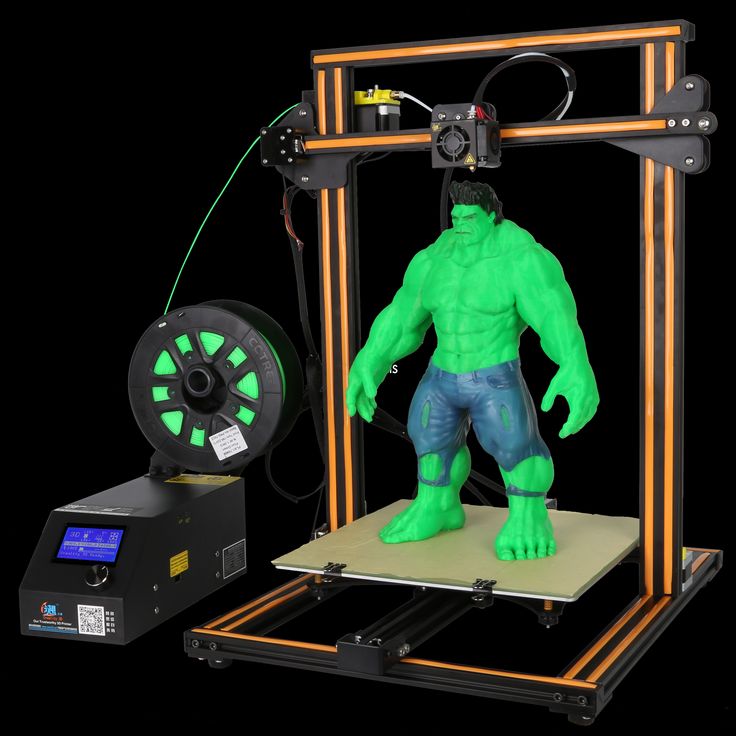

As the unfused powder supports the part during printing, there’s no need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. - Fused deposition modeling (FDM): ± 0.5% (lower limit: ± 0.5 mm)

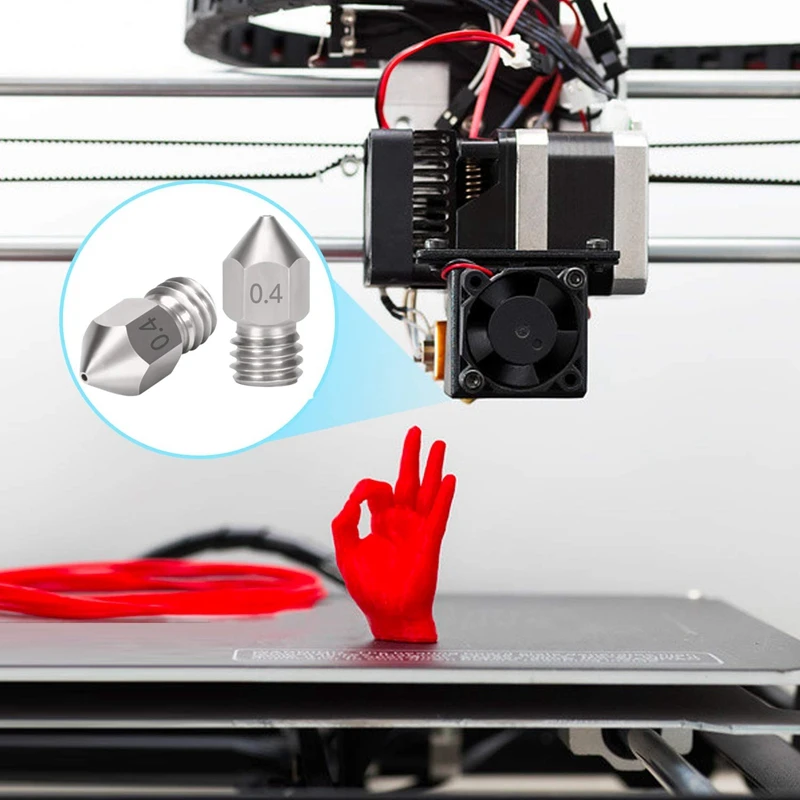

- In FDM 3D printing, layers of thermoplastic filaments are extruded by a nozzle, which lacks the control and ability to achieve intricate details that other 3D printing processes can offer. FDM parts are also prone to warping or shrinkage, as the printed part cools at different rates and the internal stress cause the print to deform. Higher-end professional systems mitigate these issues, but they also come at a higher cost.

Because layers are extruded, FDM parts might show inaccuracies around complex features. (FDM part on the left, SLA part on the right).

3D printer specs alone do not represent final dimensional accuracy. One common misrepresentation of accuracy for various 3D printing technologies is the descriptions of XY resolution or Z resolution (layer thickness) as dimensional accuracy.

However, this data has no implications for how accurate a printed part will be. There are many sources of error that still have an impact on accuracy, which we'll cover next.

Ultimately, the best way to evaluate a 3D printer is to inspect real parts.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

White Paper

Download this report for an internal test that Formlabs created to determine the dimensional accuracy of the Form 3 and Form 3B.

Download the White Paper

Accuracy may also vary depending on which materials you use to print, and the mechanical properties of those materials, which can also affect how likely a print is to warp.

Formlabs Rigid 10K Resin for SLA 3D printing has high green modulus, or stiffness, which enables successful printing of thin, intricate features.

Due to the lack of support structures and great mechnical properties, Nylon Powders used in SLS 3D printing are also ideal for printing complex parts with demanding tolerance requirements.

With resin 3D printers, when a material has a high green modulus (modulus before post-curing), that means it’s possible to print very thin parts with precision and a lower chance of failure.

For FDM 3D printers, materials extruded at higher tempetatures are generally more prone to warping than others. For example, ABS is known to be more susceptible to warping than PLA as the printed parts shrink more during cooldown.

Most 3D printed parts require some form of post-processing after printing:

- SLA and DLP: Washing, post-curing (optional), removal of support structures (if needed), sanding (optional)

- SLS and MJF: Removal of excess powder, media blasting or media tumbling

- FDM: Removal of support structures (if needed), sanding (optional)

Some of these post-processing steps have an influence on the dimensions and the surface of the parts, which in turn influence accuracy and tolerances. Some of these are easy to account for during design and print preparation, but others can vary print to print.

Some of these are easy to account for during design and print preparation, but others can vary print to print.

For example, in resin 3D printing, parts often need to be post-cured after 3D printing, and post-curing causes shrinkage. This is normal for any parts produced with resin-based SLA or DLP 3D printing processes, and may need to be considered in designs depending on the printer. PreForm, Formlabs’ free print file preparation software, automatically compensates for this shrinkage to ensure post-cured prints are dimensionally accurate to the original CAD designs.

On the other hand, FDM printed parts often require sanding to improve the surface quality by removing support marks and layer lines, but this process changes the dimensions of the parts slightly, increasing the variation between the original design and the finished part.

Producing accurate and precise 3D prints requires attention to more than the printer itself, and consideration for the entire process.

The print preparation software, printing technology, quality and calibration of the printer and its components, quality of 3D printing materials, and post-processing tools and methods can all contribute to final results.

Overall, integrated systems that are designed to work together generally produce more reliable results. For example, each new SLA and SLS 3D printing material from Formlabs goes through a series of validation tests on each compatible printer model before release to ensure reliability, consistency, and accuracy. That's not to say that generic printers and off the shelf materials can't produce good results—they might just have a steeper learning curve and require more experimentation and calibration from the users.

An air-powered, functional scale model of a flat two-cylinder internal combustion engine printed in Tough and Durable Resins and lubricated with mineral oil.

In traditional machining, tighter tolerances are exponentially related to increased cost. Tighter tolerances require additional and slower machining steps than wider tolerances, so machined parts are designed with the widest tolerances allowable for a given application.

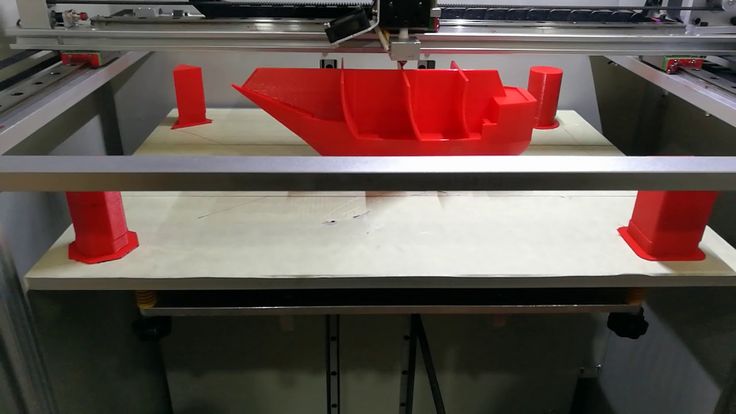

Unlike machining, 3D printing has a single automated production step. Tighter 3D printing tolerances may require more effort in the design stage, but can yield significant savings in time and costs in prototyping and production.

Tighter 3D printing tolerances may require more effort in the design stage, but can yield significant savings in time and costs in prototyping and production.

Also, while complex surfacing adds costs to a process like CNC milling, complexity in 3D printing is essentially free, though the tolerances of a 3D printed part can't be automatically refined beyond what the printer can produce without resorting to subtractive methods. 3D printing is great option if you have gross complexity like undercuts and complex surfaces, and don't necessarily need higher surface precision than ±0.005 in (standard machining). Tolerances beyond standard machining have to be reached subtractively, either through hand finishing or machining, in both 3D printed parts and CNC parts.

Overall, resin 3D printing (SLA and DLP) and powder bed fusion 3D printing (SLS and MJF) have the highest tolerance of commercially available plastic 3D printing technologies. Compared to machined accuracy, resin and powder 3D printing tolerance is somewhere between standard machining and fine machining.

Tolerance is the predicted range of possible dimensions for parts at the time of manufacture.

Tolerance and fit are essential concepts for any engineer designing mechanical assemblies. Accounting for tolerances ultimately optimizes both the prototyping and production processes, reducing the material cost of iteration, lowering post-processing time, and mitigating the risk of accidentally broken parts. The static cost-per-part for 3D printing makes it a cost-effective method for prototyping and low volume manufacturing, especially for custom parts that would otherwise require significant investment in molds.

Generally, more compliant 3D printing materials will have a wider tolerance zone than more rigid materials. When printing parts for assemblies specifically, designing for proper tolerance and fit lowers post-processing time and ease of assembly, and reduces the material cost of iteration.

Post-processing steps for 3D printed parts assemblies commonly include cleaning, sanding supports, and lubrication. Sanding an active surface is a reasonable method for achieving the correct fit if the part is a one-off, because less tolerancing work is required in the design phase. With larger assemblies, or when producing multiples of something, proper dimensional tolerancing quickly becomes worthwhile.

Sanding an active surface is a reasonable method for achieving the correct fit if the part is a one-off, because less tolerancing work is required in the design phase. With larger assemblies, or when producing multiples of something, proper dimensional tolerancing quickly becomes worthwhile.

In this section we’ll walk through the different engineering fits to describe the basics of clearance, transition, and interference fits and when it makes sense to choose each for an assembly design.

In order to understand and design the optimal 3D printing tolerances, it’s important to determine which type of fit works best for your assembly.

The functional needs of your assembly define how parts should fit together.

Engineering fit can be divided into three types: clearance, transition, and interference. Each of the these types of fit can then be broken down into two major subcategories.

There will always be some variation in tolerances for different manufacturing methods and depending on the 3D printing process, which means that fit is a continuum rather than completely separate stages. For example, larger clearance fits trade precision for freedom of movement. Tighter transition fits are stronger, but cause more wear on the connection. An interference fit that requires more force to join will be more challenging to disassemble.

For example, larger clearance fits trade precision for freedom of movement. Tighter transition fits are stronger, but cause more wear on the connection. An interference fit that requires more force to join will be more challenging to disassemble.

Free movement of a component requires clearance, or space between the active surfaces. Achieve clearance by ensuring that the tolerance zones of the active surfaces do not overlap.

An active surface is a model region where two surfaces touch and either move against each other or have a static fit.

Subcategories:

- A sliding fit has some lateral play, while a running fit has almost no play.

- A running fit has slightly more friction, but more accurate motion.

Play is the amount of space for movement in an unintended direction within a mechanism.

If no motion between parts is needed, a transition fit allows for easy assembly and disassembly. A transition fit has partially overlapping tolerance zones.

Subcategories:

- With a keying fit, a component accurately inserts into or around another part, with only a light force needed to install and remove it.

- A push fit requires more force to join and remove the parts, but they can be connected by hand.

An interference fit provides a rigid, strong connection, but requires much more force applied in assembly. Tolerance zones fully intersect in interference fits.

Subcategories:

- A force fit requires substantial force to install, likely with additional hand tools like a hammer, and is intended to be permanently joined.

- A press fit needs much more force to install, applied by an arbor press or similar tool.

Fit ranges for common geometries can be broadly applied to many designs. Once you know the best fit, you'll need to select materials and design tolerances for your application. Our white paper, “Engineering Fit: Optimizing Design for Functional 3D Printed Assemblies,” was written to help guide these decisions.

Download the white paper for a breakdown of how to measure and apply tolerances for each type of fit, with specific recommendations for Formlabs Tough Resin and Durable Resin. The resource also includes links to downloadable test models and suggestions for lubricants, bonded components, and machining.

Download the White Paper

There are tons of other attributes to consider when evaluating 3D printers–do your parts need to be isotropic? What mechanical properties do your parts (and therefore, materials) require? One of the best ways to get started is to see real printed parts. Choose a free sample from Formlabs in a variety of materials to see SLA quality for yourself.

Request a Free Sample 3D Print

A quick guide to dimensional accuracy for 3D printing » 3D Printing Media Network

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Dimensional accuracy refers to how well a printed object matches the size and specifications of the original file. For accurate parts, choose the printing process and materials that are most appropriate for the design.

For accurate parts, choose the printing process and materials that are most appropriate for the design.

What impacts dimensional accuracy?

3D printing is an imperfect process. Decisions that impact the final dimensional accuracy can be made while designing the object, choosing a printing method and selecting the materials that the object will be made from. Once the design is finalized, the 3D printing service can take steps to make sure that the final product is as accurate as possible.

Machine accuracy

- Machine accuracy: Some 3D printers are simply more accurate than others. Many manufacturers provide standard dimensional accuracies for well-designed parts made on a well-maintained machine.

Materials

- Materials: Choosing the correct material for your object will greatly increase the accuracy to which it can be printed. Standard SLA resin has a high dimensional accuracy compared to flexible SLA resin.

Object size

- Object size: In general, small objects can be printed with higher accuracy than large ones.

Bigger objects have more room for manufacturing errors.

Bigger objects have more room for manufacturing errors.

Warping and shrinkage

- Warping and shrinkage: The processes involved in 3D printing have a chance to warp and shrink the materials. Large expanses of material, flat surfaces, and unsupported structures can all warp and should be avoided in your final design.

Support structures

- Support structures: The presence of support structures may be necessary to achieve a high level of accuracy. However, the removal of these support structures will affect the surface finish of the product.

Post processing

- Post processing: Decisions made during the final stages of production can impact or preserve the final accuracy. Proper cooling procedures are necessary to keep objects in the desired shape.

Dimensional accuracies of common printing processes

Most 3D printing processes are chosen to fulfill a specific purpose. Prototypes are made with FDM printing and complex objects are made with selective laser sintering. Dimensional accuracy should be taken into consideration when selecting a process. Even if the printing method has already been chosen, an understanding of the standard accuracy and the common reasons for failure will help with the design process.

Dimensional accuracy should be taken into consideration when selecting a process. Even if the printing method has already been chosen, an understanding of the standard accuracy and the common reasons for failure will help with the design process.

FDM

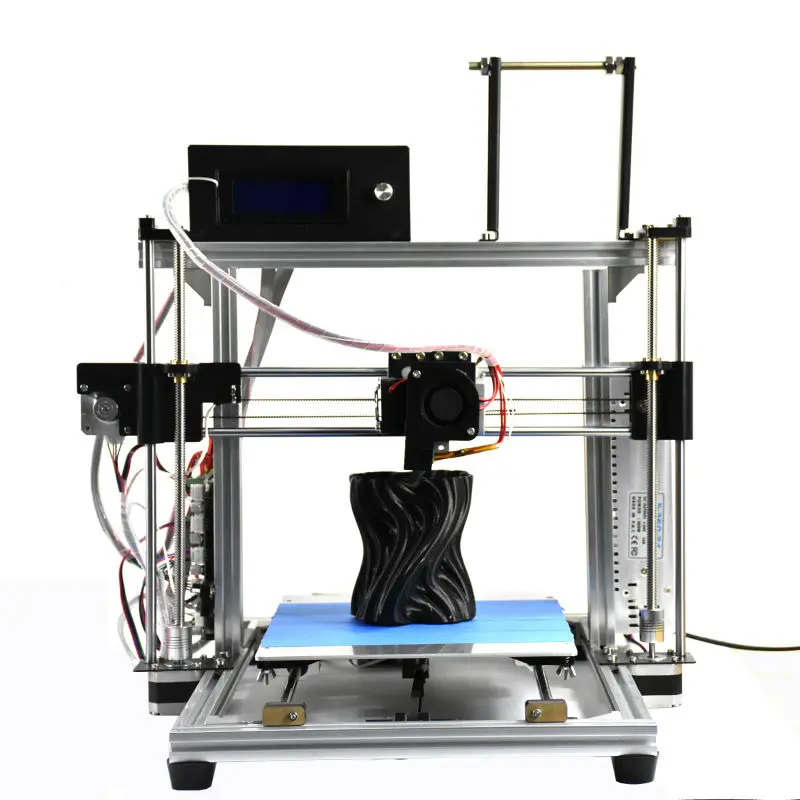

Fused deposition modeling (FDM) is one of the most common 3D printing processes and is often used to produce quick prototypes or functional parts. Industrial FDM printing has a dimensional tolerance of ± 0.15% and a lower limit of ± 0.2 mm.

FDM 3D printing creates objects by extruding thermoplastics through a heated nozzle. Objects are printed one layer at a time, and these layers cool at different speeds depending on their size and structure. This can cause warping and slight variations in the accuracy of the final object. Materials that need higher print temperatures, like ABS, have a greater risk of warping.

FDM ABS materials:Commodity plastic, improved mechanical and thermal properties compared to PLA

SLA

Stereolithography (SLA) printing produces smooth, visually accurate parts made from cured resin. Industrial SLA printing has a dimensional tolerance of ± 0.15% and a lower limit of ± 0.01 mm.

Industrial SLA printing has a dimensional tolerance of ± 0.15% and a lower limit of ± 0.01 mm.

The resin used for SLA printing takes time to harden completely. When large, unsupported spans of material are printed, they are likely to warp underneath their own weight or the weight of the surrounding layers. The material might also warp when the object is peeled away from the printing bed during the final stage of the printing process.

SLA Resin materials:High detail and smooth surface, injection mold-like prototyping

SLS

Selective laser sintering (SLS) is a particularly accurate process that is often used to produce complex geometries. SLS printing has a dimensional tolerance of ± 0.3% and a lower limit of ± 0.3 mm.

SLS printing uses lasers to sinter layers of powder together. Although this process is more accurate than FDM, there is still a chance that the layers will not cool at the same rates. This can result in warping, especially in larger SLS parts. The solution is often to leave the object in the powder bed until it is fully cooled.

The solution is often to leave the object in the powder bed until it is fully cooled.

SLS is ideal for fabricating functional prototypes from durable, chemically resistant engineering thermoplastics

Material jetting

Material jetting is the most accurate 3D printing process. Material jetting has a dimensional tolerance of ± 0.1% and a lower limit of ± 0.05 mm.

Heat is not used in the material jetting process, so warping and shrinking problems are unlikely to occur. However, thin walls and extremely detailed features might not be printed correctly. Objects made from material jetting are also not as durable as those made with FDM; they might warp when exposed to environmental conditions like heat or humidity.

Metal 3D printing

Metal 3D printing works very similarly to other 3D printing processes. Metal printing has a dimensional tolerance of ± 0.1 mm.

Although there are several different metal 3D printing services, the most common ones use technologies similar to selective laser sintering. Metal powders are heated and fused together into layers; because these layers might cool at different temperatures, warping is a consistent issue. Metal printing requires support structures, and a heat-based stress relief treatment is often used to prevent warping after production is complete.

Metal powders are heated and fused together into layers; because these layers might cool at different temperatures, warping is a consistent issue. Metal printing requires support structures, and a heat-based stress relief treatment is often used to prevent warping after production is complete.

In general, material jetting has the highest dimensional accuracy. SLA has high accuracy for parts smaller than 1000 cubic centimeters, and SLS has high accuracy for parts greater than 1000 cubic centimeters. FDM is a relatively accurate and cost-effective solution for most parts, especially when the lower limits are respected.

Once the correct process has been chosen, try these tips to increase the accuracy of the final product:

Avoid large, flat surfaces support structures

- When creating designs, always avoid large, flat surfaces. Use support structures to hold up areas that might be susceptible to sagging.

Multiple small parts

- When large objects are needed, consider printing multiple small parts that can be connected later on.

Standard materials

- Unless a specific feature is required, choose standard materials that are less susceptible to warping.

Lower limits

- Pay attention to the lower limits of the chosen process. The digital design should not have any features or details smaller than these limits.

Calibrated and working heated printing beds

- If operating a printer directly, make sure that the device is calibrated and in working order before production starts. Consider using heated printing beds to keep objects at a uniform temperature until printing is complete.

Check the 3D Hubs Knowledge Base for information about specific printing processes and design considerations to improve the accuracy of printed objects. Concerns about a specific design can often be brought up with the 3D printing services before production begins.

3D Hubs Design for Manufacturing analysis will automatically check any design for viability with a chosen printing process. Upload a file to see if it meets the requirements for size, details and wall thickness. If no flags are listed, the object can be created with the dimensional accuracy normal for that printing process.

This article was published in collaboration with 3D Hubs.

Related Articles

Back to top button

Clarity, Accuracy & Tolerances in 3D Printing

Just because your 3D printer says it has "high resolution" does not mean it will produce accurate or sharp prints.

Understanding the meaning of the terms precision, clarity, and tolerance is a prerequisite for achieving quality 3D printing results, regardless of industry. In this article, we will analyze what these terms mean in the context of 3D printing.

Webinar

Want to learn how to use 3D printing for design? Watch our webinar and learn about the stereolithography (SLA) 3D printing process, different types of materials, and tips from experts on how to optimize your printing process to make it as efficient as possible.

Watch the webinar now

Let's start with some definitions: what is the difference between precision, clarity and tolerance? For each term, we will use a target - a common example for understanding these concepts, helping to visualize them.

Precision determines how close the measured value is to the true value. In the target example, the true value is the bullseye. The closer you are to the bullseye, the more accurate your throw. In the world of 3D printing, the true value is the dimensions of your CAD model. To what extent does a product made on a 3D printer correspond to a digital model?

Clarity corresponds to measurement reproducibility - how consistent are your hits on the target? Clarity only measures this reproducibility. You can always hit the same spot, but it doesn't have to be the bullseye. In 3D printing, this ultimately leads to reliability. Are you sure that you will get the expected results for each model produced by your printer?

You can always hit the same spot, but it doesn't have to be the bullseye. In 3D printing, this ultimately leads to reliability. Are you sure that you will get the expected results for each model produced by your printer?

In engineering terms, "clarity" is used to measure the reproducibility of results. Applied to materials for 3D printing, “clear” can mean the ability to manufacture complex geometries. For example, Formlabs Gray Pro Resin and Rigid Resin resins have a high "green modulus", or modulus of elasticity, that can successfully print thin and intricate details.

What accuracy is required in this case? This is determined by tolerances , which you define. How much wiggle room do you have based on the purpose of the model? What is the allowable variability in the closeness of the measurements to the exact ones? It depends on the specifics of your project. For example, a component with a dynamic mechanical assembly needs tighter tolerances than a conventional plastic housing.

If you're specifying tolerance, you'll probably need precision as well, so let's assume we're measuring bullseye accuracy. Earlier we called the shots in the picture with the target on the right fuzzy.

But if you have wide tolerances, this may not be a problem. The shots are not as close to each other as they are on the target on the left, but if the acceptable range of sharpness is ±2.5 hoops, then you are not out of range.

As a rule, achieving and maintaining tighter tolerances entails higher production and quality control costs.

White Paper

Tolerance and fit are important concepts that engineers use to optimize mechanical functionality and manufacturing cost. Use this white paper when designing 3D printed workpieces or as a starting point when designing a fit between parts printed with Formlabs Tough Resin or Durable Resin.

Download white paper

There are many factors to consider when thinking about precision and clarity in 3D printing, but it's also important to get your needs right.

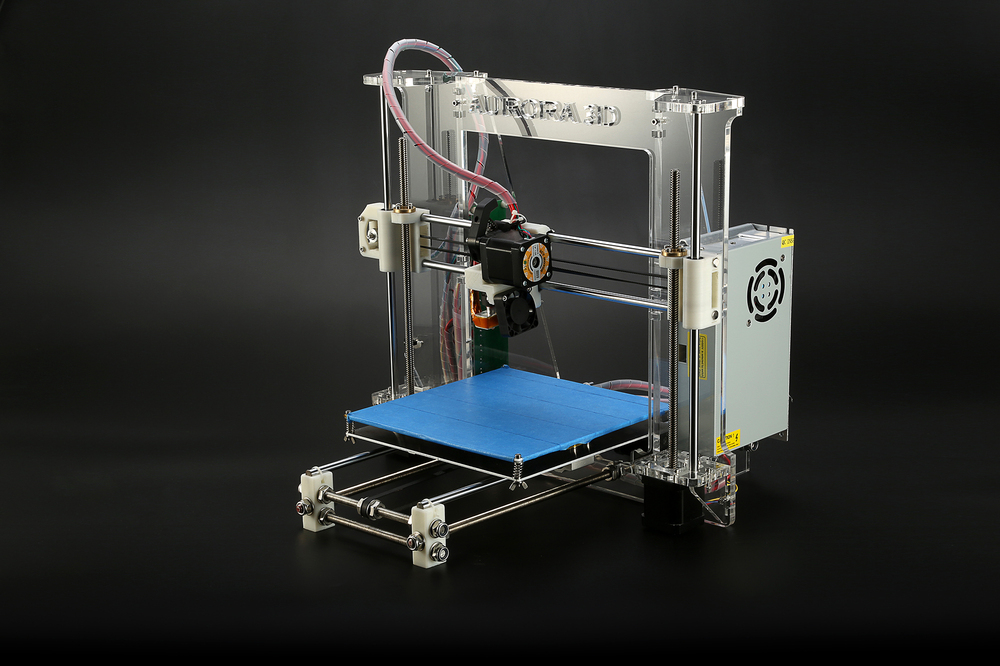

For example, a sharp but inaccurate 3D printer may be optimal for some applications. An inexpensive Fused Deposition Modeling (FDM) machine will produce less accurate parts, but for a teacher teaching students 3D printing for the first time, the exact fit of the student's CAD model doesn't matter as much.

But if the printer performs to specifications and delivers the quality expected of it within the tolerances the user is accustomed to, this may be sufficient for successful operation.

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

There are four main factors that affect the accuracy and clarity of a 3D printer:

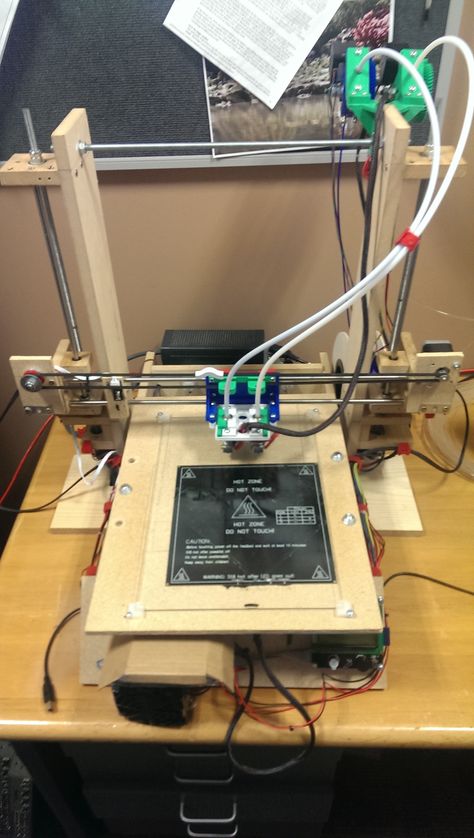

3D printing is a type of additive manufacturing where models are made layer by layer. Violations can potentially occur in every layer. The layering process affects the level of clarity (or reproducibility) of each layer's accuracy. For example, when printing on an FDM printer, layers are formed using a nozzle, which cannot provide the same accuracy for obtaining complex parts as other 3D printing technologies.

For example, when printing on an FDM printer, layers are formed using a nozzle, which cannot provide the same accuracy for obtaining complex parts as other 3D printing technologies.

Because layers are extruded, FDM models often show layer lines and inaccuracies around complex features. (Left is an FDM printed part, right is a SLA printed part.)

In stereolithography (SLA) 3D printing, each layer is formed by curing a liquid polymer with a high-precision laser, resulting in more detailed models and achieve high quality on a consistent basis.

Selective Laser Sintering (SLS) also uses a laser to accurately convert nylon powder into lightweight, durable parts.

The specifications of a 3D printer alone do not give an idea of the accuracy of the models produced. One of the common misconceptions about the accuracy of various 3D printing technologies is describing XY resolution as dimensional accuracy.

For digital light processing (DLP) printers, the XY resolution corresponds to the projected pixel size. Many 3D printer systems use this projected pixel size, or XY resolution, as a general measure of accuracy, such as stating that with a projected pixel size of 75 µm, the accuracy of the device is ±75 µm.

Many 3D printer systems use this projected pixel size, or XY resolution, as a general measure of accuracy, such as stating that with a projected pixel size of 75 µm, the accuracy of the device is ±75 µm.

Check out our guide to SLA and DLP 3D printing, where we talk about the features of the two processes and how they differ.

But this data does not affect the accuracy of the printed model. There are many other sources of error that affect accuracy, from components and calibration to materials and post-processing. We will consider the last two factors in more detail.

The best way to evaluate a 3D printer is to study the models printed on it.

Accuracy may also vary depending on the media you are printing on and the mechanical properties of those media, which can also affect the likelihood of model warping.

Formlabs Rigid Resin has a high "green modulus", or modulus of elasticity before final polymerization, which allows you to print very thin models with high definition and reliability.

But, again, it all depends on your goals. For example, in dentistry, the accuracy of 3D printed models is critical. But if you're printing a concept model, chances are you just want to get a general idea of the physical product, and accuracy won't be that important.

Margins, mold surfaces, and contact surfaces printed with Formlabs Model Resin are accurate to within ±35 µm of the digital model at over 80% of surface points when printed at 25 µm settings. The overall accuracy across the entire arc is within ±100 µm on 80% of surfaces when printed with settings of 25 or 50 µm.

3D printed models often need to be cured, which in turn often leads to shrinkage. This is normal for any part made using SLA or DLP 3D printing. Depending on the printer, this phenomenon may need to be considered in the design. PreForm, Formlabs' free file preparation software, automatically compensates for this shrinkage, ensuring that the final cured models are the same dimensions as the original CAD model.

How does the final polymerization work? Learn more about the theory behind the process and see efficient ways to successfully finish curing models made with stereolithographic 3D printers.

Producing quality models on a 3D printer requires attention not only to the printer itself, but to the entire production process.

The final result may be affected by the print preparation software, post-processing materials and tools used. In general, integrated systems designed to work together produce more reliable results.

Unlike machining, where parts are progressively improved to tighter tolerances, 3D printing has only one automated manufacturing step. While complex coating adds cost to processes such as CNC milling, creating complex features with 3D printing is essentially free, although the tolerances of a 3D printed model cannot be automatically improved beyond the capabilities of the printer. without resorting to subtractive methods.

3D printing is a great option if you have rough, complex features such as undercuts and complex surfaces, and don't necessarily need surface accuracy better than ±0.125mm (standard machining). Tolerances beyond standard machining must be achieved using subtractive methods, either through manual or machine processing, for both 3D printed and CNC models.

SLA has the highest tolerance compared to other commercial 3D printing technologies. The tolerances for stereolithographic 3D printing are somewhere between standard and precision machining.

In general, more malleable stereolithography materials will have a wider tolerance zone than more rigid materials. Designing subassembly parts for tolerance and fit reduces post-processing time and simplifies assembly, as well as reduces material costs per iteration.

There are many other factors to consider when evaluating 3D printers. Should your models be isotropic? What mechanical properties should your models (and, accordingly, the materials from which they are made) have? The best place to start is to get familiar with the physical models printed on a 3D printer. Order a free material sample from Formlabs of your choice and see for yourself the quality of your stereolithography print.

Order a free material sample from Formlabs of your choice and see for yourself the quality of your stereolithography print.

Request a sample 3D model

3D printer accuracy or which printer is better in terms of print quality?

Article applies to printers:

Anycubic Photon ZOBU 3.0 3D ARTEL Wanhao Duplicator 7 PLUSWe are often asked the following questions: 'How accurate is this 3D printer?' or 'I'm a jeweler and I need 10 micron accuracy, what printer would you recommend?', or perhaps my favorite question is 'Which printer is better for print quality?'

To answer these questions, we must first understand what is the 'print quality' of a printer? What is 'positioning accuracy'? What is 'repeatability'? And also have a general idea of what 'stray light' and 'polymer accuracy' are.

So, let's understand the terms:

Positioning resolution is a value that shows how accurately you can set the movement in the 3D printer's coordinate system. It depends on the pitch angle of the motor with discrete angular movements of the rotor, the driver and its pitch division mode, as well as on the propeller and its pitch per revolution. But we need to remember another parameter - positioning repeatability . If we send the table along the axis to the same point from different positions, then each time we will get a slightly different result due to mechanical errors - the table will stop at some distance from the required point. The repeatability indicates how large the spread of this distance is, or more precisely, the repeatability is directly proportional to the standard deviation of the positioning error. In a word, repeatability characterizes the magnitude of the 'scatter' of the positioning error relative to the mean value. The repeatability depends mainly on the transmission backlash and the resulting elastic deformations, it only tells whether the positioning error is stable or not, but does not say anything about its magnitude, and thus it is possible to build a completely inaccurate printer with excellent Z-axis repeatability.

It depends on the pitch angle of the motor with discrete angular movements of the rotor, the driver and its pitch division mode, as well as on the propeller and its pitch per revolution. But we need to remember another parameter - positioning repeatability . If we send the table along the axis to the same point from different positions, then each time we will get a slightly different result due to mechanical errors - the table will stop at some distance from the required point. The repeatability indicates how large the spread of this distance is, or more precisely, the repeatability is directly proportional to the standard deviation of the positioning error. In a word, repeatability characterizes the magnitude of the 'scatter' of the positioning error relative to the mean value. The repeatability depends mainly on the transmission backlash and the resulting elastic deformations, it only tells whether the positioning error is stable or not, but does not say anything about its magnitude, and thus it is possible to build a completely inaccurate printer with excellent Z-axis repeatability. Information about the positioning resolution and positioning repeatability are usually not specified by LCD printer manufacturers, but what then is called 'printer accuracy'?

Information about the positioning resolution and positioning repeatability are usually not specified by LCD printer manufacturers, but what then is called 'printer accuracy'?

Axis Positioning Accuracy is a generalized value showing how far the real axis coordinate can be after positioning is completed. This accuracy depends on the repeatability, but includes not only the magnitude of the 'scatter' of the position error, but also its average value, i.e. is a more general characteristic. When marketers of LCD 3D printer manufacturers talk about 'printer accuracy', they usually mean Z-axis positioning accuracy. Thus, if a manufacturer specifies 10 micron positioning accuracy, this is an indication of how large the Z-axis positioning error can be, but this does not mean that all layers can be printed with a thickness of 0.01 mm (10 micrometers).

Let's see what happens in the other two planes - XY. A 3D printer with a 2K LCD screen at a resolution of 2560x1440 along the XY axes has a screen pixel size of 47 microns and, even if theoretically the software allows you to cut a layer close to 0. 01 mm, the high intensity of stray illumination of adjacent pixels will do its job and this whole idea with printing in layers 10 microns, loses all practical meaning (stray light of LCD printers, although lower than that of 3D printers with a DLP projector, is higher than that of SLA printers). True, at least two photopolymer 3D printers have already appeared (3D Artel ZOBU 3.0 and Anycubic Photon S), which have an improved UV matrix module, in which each UV diode has a focusing lens. This allows you to get higher accuracy and reduces the likelihood of stray light, but the declared 10 microns they still refer to the accuracy of positioning along the Z axis. the probability of getting 10 microns along the XY axes remains purely theoretical.

01 mm, the high intensity of stray illumination of adjacent pixels will do its job and this whole idea with printing in layers 10 microns, loses all practical meaning (stray light of LCD printers, although lower than that of 3D printers with a DLP projector, is higher than that of SLA printers). True, at least two photopolymer 3D printers have already appeared (3D Artel ZOBU 3.0 and Anycubic Photon S), which have an improved UV matrix module, in which each UV diode has a focusing lens. This allows you to get higher accuracy and reduces the likelihood of stray light, but the declared 10 microns they still refer to the accuracy of positioning along the Z axis. the probability of getting 10 microns along the XY axes remains purely theoretical.

We will not go deeper into the terminology (the curious can additionally read, for example, GOST 27843-2006 and other technical literature), we denote and summarize that: , starting from the technical parameters of the printer and ending with the properties of photopolymers. You cannot consider 'print quality' as some separate indicator of 3D printer performance in isolation from the material you plan to print, especially since the properties of many inexpensive materials are such that their shrinkage and stray light are greater than the declared parameters of 'print quality' printer.

You cannot consider 'print quality' as some separate indicator of 3D printer performance in isolation from the material you plan to print, especially since the properties of many inexpensive materials are such that their shrinkage and stray light are greater than the declared parameters of 'print quality' printer.

If we form a rating of photopolymer printers that we sell, it should probably look like this:

and high positioning accuracy, has a diode matrix with focusing lenses, but the body of this printer is very convenient, a removable cap allows you to get easy access and at the same time the printer has retained a rigid structure and a metal case. In addition, its control menu is Russified.

2. Anycubic Photon S 3D printer - also has double rails and a diode matrix with lenses, but in our rating it falls to second place due to its plastic case with a hinged lid, which over time has a chance of being torn off during intensive work.