Pla material properties for 3d printing

PLA vs ABS vs Nylon

Learn Blog

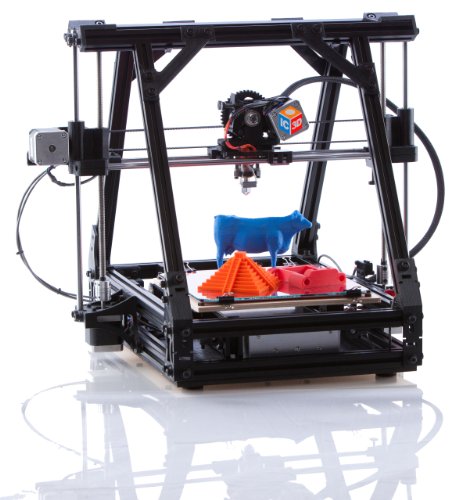

PLA, ABS, and nylon are three of the most popular 3D printing materials. All can be extruded on basic desktop 3D printers and, at around $20 per spool, they are among the most affordable filaments available today. Most people focus on the PLA vs ABS debate, but Nylon is a valuable third entrant with different material properties.

PLA and ABS are both thermoplastics. PLA is stronger and stiffer than ABS, but poor heat-resistance properties means PLA is mostly a hobbyist material. ABS is weaker and less rigid, but also tougher and lighter, making it a better plastic for prototyping applications.

Enter nylon, a flexible plastic that injects a new set of filament properties into the mix, featuring greater chemical resistance and toughness compared to PLA and ABS, but also reduced strength.

This post compares PLA vs ABS and now nylon, and then details how one of these thermoplastics has been augmented to serve a wider range of manufacturing applications. Plus, a bonus exploration of Onyx filament.

U.S. Army Case Study

Read our newest customer success story about a major training base for the U.S. Army.

PLA

PLA is a user-friendly thermoplastic with a higher strength and stiffness than both ABS and nylon. With a low melting temperature and minimal warping, PLA is one of the easiest materials to 3D print successfully. Unfortunately, its low melting point also causes it to lose virtually all stiffness and strength at temperatures above 50 degrees Celsius. In addition, PLA is brittle, leading to parts with poor durability and impact resistance.

Although PLA is the strongest of these three plastics, its poor chemical and heat resistance force it into almost exclusively hobbyist applications.

ABS

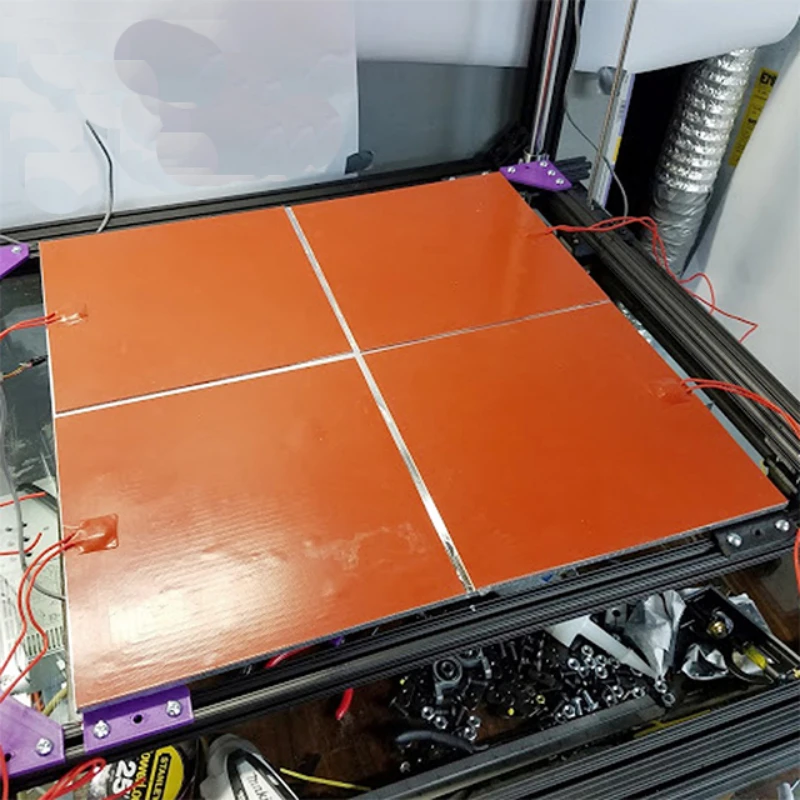

ABS, while weaker and less rigid than PLA, is a tougher, lighter filament more suitable for some applications beyond purely hobbyist. ABS is a bit more durable, is about 25% lighter, and has four times higher impact resistance. ABS does require more effort to print than PLA because it’s more heat resistant and prone to warping. This calls for a heated bed and an extruder that is 40-50 degrees Celsius hotter. ABS, while by no means a heat resistant plastic, has superior heat deflection temperature compared to PLA and nylon.

The improved durability over PLA lends ABS to some more practical applications, such as prototyping and low-stress end-use parts.

Check out our Composites Design Guide

Nylon

Nylon is a flexible, durable plastic with less strength and stiffness than both PLA and ABS. Its malleability lends it much more toughness than the other two, however, with an impact resistance ten times that of ABS. Nylon also boasts a good chemical resistance, which opens the possibility to more industrial applications. As with ABS, nylon requires extra care to print; it needs to be extruded at high temperatures and, due to its tendency to soak up moisture from the air, must be kept in a dry box.

Nylon also boasts a good chemical resistance, which opens the possibility to more industrial applications. As with ABS, nylon requires extra care to print; it needs to be extruded at high temperatures and, due to its tendency to soak up moisture from the air, must be kept in a dry box.

Nylon is tougher and more resistant to chemicals than ABS and PLA, but its low strength and stiffness keep it from being widely used in the manufacturing industry. As a result, advancements in 3D printing materials has introduced nylon-fiber mixtures, opening the door to accessible industrial 3D printing.

Filled Nylon and Onyx

Filled nylon is a mixture of nylon with small particles of a stronger material such as fiberglass or carbon fiber. These mixtures preserve the favorable properties of nylon while adding considerable strength and stiffness. Markforged’s Onyx filament is an example of one of these mixtures, combining nylon with chopped carbon fiber in order to improve key properties of the material. Onyx is 1.4 times stronger and stiffer than ABS and can be reinforced with any continuous fiber. The development of 3D printed continuous fibers has enabled a new category of stronger 3D printed parts.

Onyx is 1.4 times stronger and stiffer than ABS and can be reinforced with any continuous fiber. The development of 3D printed continuous fibers has enabled a new category of stronger 3D printed parts.

With high strength and stiffness, excellent durability, and good chemical resistance, filled nylons such as Onyx are some of the few 3D printed thermoplastics tough enough for the factory floor. Nylon mixtures are suitable for fixtures, jigs, functional prototypes, and even end use parts.

PLA vs ABS vs Nylon: Making a Decision

PLA, ABS, and nylon are great beginner thermoplastics due to their low price point and general ease of printing. If you are looking to begin 3D printing for industrial use cases, however, filled nylons offer the superior material properties needed to withstand manufacturing environments.

To learn more about Markforged's continuous fibers, check out our blog post where we compare fiberglass with carbon fiber!

Read our 3D Printer Buyer's Guide

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

required required requiredSubmit

Thanks!

3D printing with PLA vs. ABS: What's the difference?

PLA and ABS are two essential materials for 3D printing with FDM. They are also two of the most popular materials on our platform. This comparison will help you choose which material to use for your 3D-printed custom parts.

This comparison will help you choose which material to use for your 3D-printed custom parts.

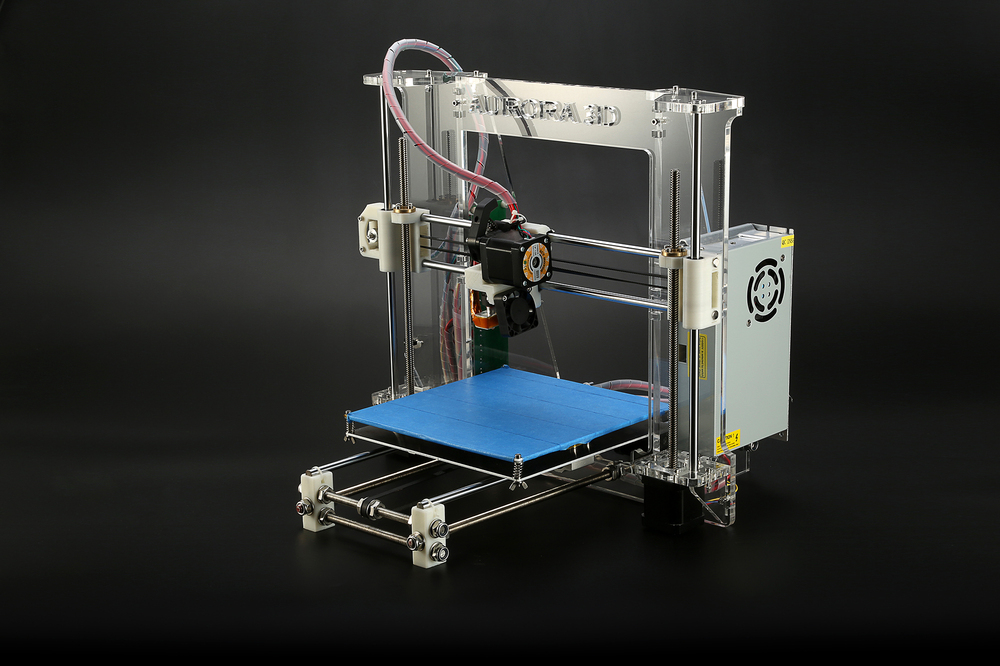

PLA and ABS are the two most common materials for prototyping (desktop) FDM 3D printing (aside from, perhaps, PETG). As thermoplastics, both filaments enter a soft and moldable state when heated, returning to a solid-state when cooled. FDM printers melt and extrude PLA and ABS filament through a nozzle to build up parts layer by layer.

While both materials are used for FDM, they have key differences that make each more optimal for different applications. In this article, we’ll cover the main differences between these commonly used materials.

We also have this handy Youtube explainer video that covers the differences between PLA and ABS filaments.

Want to compare pricing for PLA and ABS?

Upload your CAD file to the quote builder

What are PLA and ABS filaments?

PLA (Polylactic Acid) is a thermoplastic derived from renewable sources such as cornstarch or sugarcane. Biodegradable under the right conditions, PLA is one of the most popular bioplastics and is perfect for a variety of applications ranging from plastic cups to medical implants. It’s easy to print with and has a higher stiffness than ABS and materials like nylon. While PLA is stronger than ABS and nylon, it’s not very heat or chemical resistant.

Biodegradable under the right conditions, PLA is one of the most popular bioplastics and is perfect for a variety of applications ranging from plastic cups to medical implants. It’s easy to print with and has a higher stiffness than ABS and materials like nylon. While PLA is stronger than ABS and nylon, it’s not very heat or chemical resistant.

ABS (Acrylonitrile Butadiene Styrene) is another common thermoplastic, also popular in the injection molding industry. ABS has superior mechanical properties to PLA, as well as being more durable and lighter, though it’s harder to print with. This material is better able to deflect heat than PLA and nylon, but it’s absolutely not completely heat resistant. Prevalent applications of ABS include LEGO bricks, electronic housings and automotive bumper parts.

What’s the difference between PLA and ABS?

PLA and ABS differ in several ways, including their unique tensile strength, density and ideal applications. The table below compares the key material properties of PLA and ABS filaments.

| Properties* | ABS | PLA |

|---|---|---|

| Tensile Strength** | 27 MPa | 37 MPa |

| Elongation | 3.5 - 50% | 6% |

| Flexural Modulus | 2.1 - 7.6 GPa | 4 GPa |

| Density | 1.0 - 1.4 g/cm3 | 1.3 g/cm3 |

| Melting Point | 200 ℃ | 173 ℃ |

| Biodegradable | No | Yes, under the correct conditions |

| Glass Transition Temperature | 105 ℃ | 60 ℃ |

Spool Price*** (1kg, 1. 75mm, black) 75mm, black) | $USD 21.99 | $USD 22.99 |

| Common Products | LEGO, electronic housings | Cups, plastic bags, cutlery |

What is the part accuracy of PLA and ABS?

In general, the tolerances and accuracy of FDM printed components depend on printer calibration and model complexity. However, you can use PLA and ABS to create dimensionally accurate parts with printing details of 0.8 mm and minimum features of 1.2 mm. For connecting or interlocking parts, we recommend a tolerance of 0.5 mm and a minimum wall thickness of 1-2 mm. This will ensure that your part has adequate strength across all wall elements.

Thanks to its lower printing temperature, PLA is easier to print with and less likely to warp (when properly cooled). You can use PLA to print sharper corners and finer features than with ABS.

Want to improve your 3D printing design skills?

Download our free 3D printing design rules poster

How strong are PLA and ABS parts?

PLA and ABS have similar tensile strengths, making them solid options for many prototyping applications. Designers and engineers often prefer ABS due to its improved ductility over PLA. ABS has higher flexural strength and better elongation before breaking than PLA, which means that ABS can also be used for end-use applications. PLA, on the other hand, is more popular for rapid prototyping when the form is more critical than the function.

Designers and engineers often prefer ABS due to its improved ductility over PLA. ABS has higher flexural strength and better elongation before breaking than PLA, which means that ABS can also be used for end-use applications. PLA, on the other hand, is more popular for rapid prototyping when the form is more critical than the function.

Overall, PLA is a good option for your custom parts if you don’t plan on putting them under a lot of physical stress (or UV radiation and high temperatures). ABS is more fitting for industrial applications and can weather physical strain better than PLA.

How fast can you print with PLA and ABS?

Both PLA and ABS print at nearly identical speeds. This means that you don’t have to change speed settings on your FDM machines when switching between materials. For PLA, printing at 60 mm/s is pretty standard, though some operators have printed at over 150 mm/s, so the standard speed is by no means a limit. You can also print ABS at the same speed, but between 40-60 mm/s is a bit more accurate for this material.

Surface finishes and post-processing for PLA and ABS

Whether you produce parts using PLA or ABS, FDM-printed components will always have visible layers. Using PLA often results in a glossier finish, while ABS typically prints in a matte finish. To smooth an ABS-printed part and give it a glossy finish, you can use acetone in post-processing. Sanding and additional machining are viable post-processing options for parts printed in ABS. You can also sand and machine PLA, though greater care is required.

If aesthetic quality is critical, then we recommend using SLA 3D printing to produce your custom parts.

Want to explore all the options for FDM post-processing?

Learn more

How heat resistant are PLA and ABS?

For applications requiring higher temperatures, ABS (glass transition temperature of 105°C) is preferable over PLA (glass transition temperature of 60°C). PLA can rapidly lose its structural integrity and can begin to droop and deform as it approaches 60°C, especially if it's supporting a heavier load.

Are PLA and ABs biodegradable?

PLA is stable in general atmospheric conditions, though it will biodegrade within 50 days in industrial composters and 48 months in water. While ABS is not biodegradable, you can recycle it. This being the case, manufacturers tend to use PLA to produce items related to food service, though we absolutely recommend you get safety confirmation from filament manufacturers.

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quotePLA plastic for 3D printing

- 1 Plastic composition

- 2 PLA safety

- 3 PLA Specifications

- 4 Advantages of PLA in 3D printing

- 5 Navigation

PLA-plastic (polylactide, PLA) - is a biodegradable, biocompatible, thermoplastic aliphatic polyester, the structural unit of which is lactic acid.

PLA is made from corn or sugar cane.

Potato and corn starch, soy protein, cassava tubers, cellulose are also used as raw materials.

Today, polylactide is actively used as a consumable for printing on 3D printers.

Natural raw materials in the composition of PLA-plastic allows using it for various purposes without a threat to human health.

The production of PLA plastic significantly reduces carbon dioxide emissions into the atmosphere compared to the production of "petroleum" polymers. The use of fossil resources is reduced by a third, the use of solvents is not required at all.

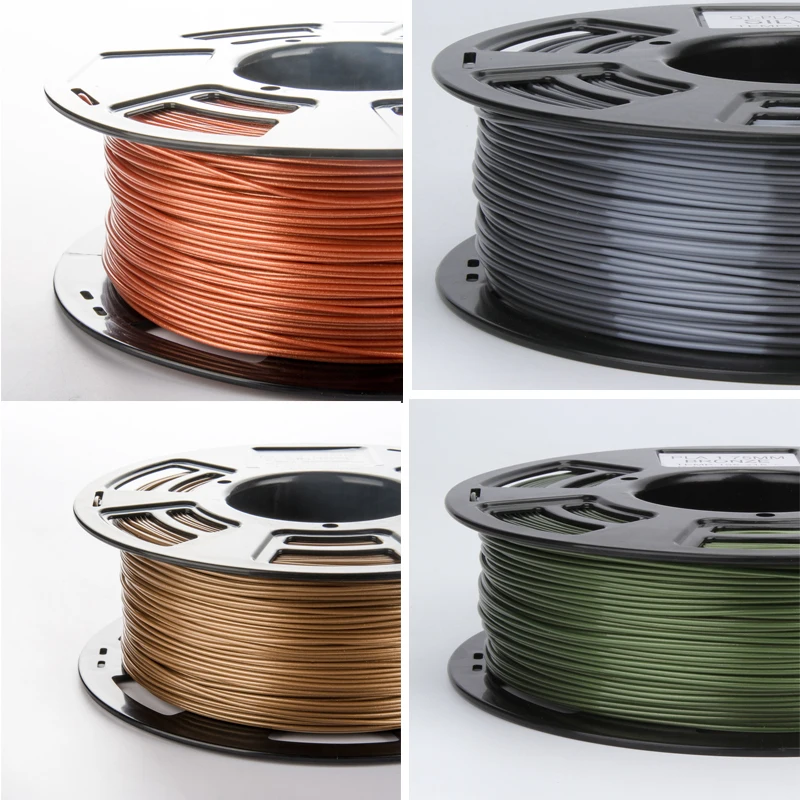

PLA is usually supplied as a thin filament that is wound on a spool.

| Melting point | 173-178°C |

| Softening point | 50°C |

| Hardness (Rockwell) | R70-R90 |

| Elongation at break | 3. 8% 8% |

| Flexural strength | 55.3 MPa |

| Tensile strength | 57.8 MPa |

| Tensile modulus | 3.3 GPa |

| Flexural modulus | 2.3 GPa |

| Glass transition temperature | 60-65°C |

| Density | 1.23-1.25 g/cm³ |

| Minimum wall thickness | 1 mm |

| Print Precision | ± 0.1% |

| Micron size | 0.3 mm |

| Manufacturing shrinkage | no |

| Moisture absorption | 0.5-50% |

- non-toxic;

- wide color palette;

- when printing, no need for a heated platform;

- dimensions are stable;

- is ideal for moving parts and mechanical models;

- excellent sliding of details;

- savings in energy costs due to the low softening temperature of the yarn;

- no need to use Kapton to lubricate the surface for building up the prototype;

- smoothness of the surface of the printed product;

- obtaining more detailed and completely ready-to-use objects.

PLA plastic is ideal for 3D printing objects with great detail

Work with PLA plastic on a 3D printer is carried out using FDM-Fused Deposition Modeling technology. The thread is melted, after which it is delivered through a special nozzle to the surface for work and is deposited. As a result of building a model with molten plastic, an object completely ready for use is created. Products made of PLA plastic are subjected to grinding and drilling, painted with acrylic. However, it is worth remembering that the item made of PLA must be handled with care due to its fragility. Another disadvantage of PLA plastic is its fragility: the material lasts from several months to several years.

PLA is an ideal material for 3D printing prototypes and products that are not expected to be used for a long time. These can be decorative objects, presentation items, and items that require meticulous detailing.

Go to the main page of Encyclopedia of 3D printing

PLA and ABS for 3D printing: what's the difference?

3DPrintStory 3D printing process PLA and ABS for 3D printing: what's the difference?

PLA or ABS: Which one to use and when? The article reveals the difference between these plastics and shows the areas of their use.

Some of the most popular plastics for FDM (Fused Deposition Modeling) 3D printing are ABS and PLA. Both are thermoplastics. This means that they become malleable when heated - so you can shape them and when cooled they will retain their shape. Both materials are made into bars that you can feed into your 3D printer's extruder. The printing process when using ABS and PLA is very similar.

Despite their apparent similarities, ABS and PLA are different. Some 3D printers can only print with PLA plastic at all.

ABS and PLA - brief definitions

PLA (PolyLactic Acid) is a biopolymer, i.e. a biodegradable plastic. It is made from renewable materials such as cornstarch or sugarcane. In addition to 3D printing, PLA is used for packaging, plastic bottles and cups. It is considered to be more environmentally friendly compared to ABS.

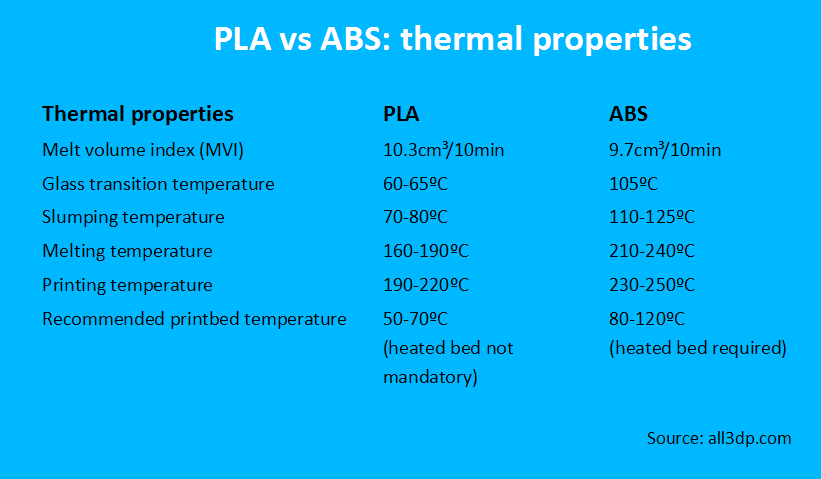

What does each of these characteristics mean?

- Melt flow index characterizes the ease of flow of the molten polymer.

It is measured in the amount of material that passes through a capillary of a certain diameter and length in 10 minutes.

It is measured in the amount of material that passes through a capillary of a certain diameter and length in 10 minutes. - Glass transition temperature - the point at which a hard and brittle material becomes molten or elastic with increasing temperature. This is an important characteristic if you are printing a model that will interact with hot water or drinks: for example, a PLA coffee mug is not a good idea. ABS plastic in this case is also a bad option: see the "Recommended Applications" section below.

- The pour point characterizes the limit of resistance to heat: at temperatures above this, the object will bend. If your 3D printer is equipped with a heated table, the temperature of this table must be below this temperature; otherwise, the object is deformed during 3D printing.

- Melting point (or melting point) - everything is obvious here - the temperature at which the material begins to melt.

- 3D printing temperature - usually higher than the melting temperature, since the plastic must be melted (not just started to melt) when fed through the extruder nozzle.

Mechanical and physical properties

PLA is more brittle and has a higher surface hardness. More prone to breakage during bending. Acetone treatment (to improve surface smoothness) is not possible.

The illustration below shows a key printed in ABS.

When printed at the manufacturer's recommended temperatures, ABS parts will be much harder and more resistant to impact and stress than PLA. That is, ABS is better suited for printing mechanical components and parts and objects with high resistance to aggressive environments. In addition, ABS parts are more flexible and bend rather than break under external pressure. ABS is better malleable, post-processing is easier. Printed models can be sanded, painted. They can be treated with acetone to get a smooth, shiny surface.

Easy to 3D print

In general, PLA is best for beginners to get into 3D printing. ABS plastic is more prone to the standard 3D printing problem of shrinkage (i. e. when the first layers cool too quickly and begin to curl around the edges, causing the model to come off the table at the corners). Printing ABS plastic will require experimentation to find the optimal settings.

e. when the first layers cool too quickly and begin to curl around the edges, causing the model to come off the table at the corners). Printing ABS plastic will require experimentation to find the optimal settings.

PLA has another drawback - it tends to clog the nozzle of the extruder, as it is more sticky and expands more when melted. To avoid clogging the nozzle, it is recommended to follow the manufacturer's instructions. The layers lay down well and are unlikely to be bent around the edges. The printed product is easier to separate from the table than similar ones made of ABS plastic. Heated bed is optional (but can improve print quality if used correctly). The 3D printer doesn't have to be kept in a closed case (but again, using a case can result in better results). To increase the adhesion of the table, it is recommended to use special tape (also known as 3D printing tape).

ABS tends to shrink more than PLA.

Printing with ABS plastic takes place at higher temperatures than PLA, which greatly reduces the chance of nozzle clogging. In addition, less force is required to feed the material into the nozzle. Since ABS shrinks as it cools, the part can come off the table (especially when 3D printing tall models). To avoid this, it is necessary to use a heated table. It is desirable that the printer has a case. Since the grip on the table is worse than that of PLA, various problems can arise. To improve adhesion to the table, it is recommended to use Kapton tape (withstands temperatures up to 400ºC). True, tape is expensive, so there is an alternative option - spray hairspray on the table before printing.

In addition, less force is required to feed the material into the nozzle. Since ABS shrinks as it cools, the part can come off the table (especially when 3D printing tall models). To avoid this, it is necessary to use a heated table. It is desirable that the printer has a case. Since the grip on the table is worse than that of PLA, various problems can arise. To improve adhesion to the table, it is recommended to use Kapton tape (withstands temperatures up to 400ºC). True, tape is expensive, so there is an alternative option - spray hairspray on the table before printing.

Storage conditions

Both plastics (PLA/ABS) absorb moisture from the air. To avoid this, the air is pumped out during packaging. Manufacturers of materials for 3D printing recommend using spools as quickly as possible, as quality begins to suffer over time. Unpacked material should be stored in a dry place.

If PLA is stored for a long time, you may notice bubbles during 3D printing. Doing so may clog the nozzle and degrade the surface quality of the printed product. While wet PLA can be dried under warm air, heat can degrade the material's structure and change thermal properties, which will affect print temperatures.

While wet PLA can be dried under warm air, heat can degrade the material's structure and change thermal properties, which will affect print temperatures.

When printing with damp ABS, bubbles may also occur. If you dry it with warm (but not too much) air, for example, using a food dehydrator, the thermal properties of the plastic will not change.

Vapors and smell

When you 3D print with resins (PLA/ABS), you will smell. The smell depends on the media used and the printing temperature.

PLA smells almost pleasant, some compare this smell to warmed waffles or candy.

ABS smells bad when heated. Some complain of headaches and even nausea due to 3D printing. If you are printing indoors, good ventilation is recommended.

Degradability and durability

PLA is biodegradable - it is made from plant materials. Since it needs a little heat to decompose, you can safely throw it into the trash containers.

ABS does not biodegrade but can be recycled.

Both materials (PLA/ABS) degrade when exposed to sunlight and moisture. ABS is more stable and more chemical resistant than PLA.

What to choose?

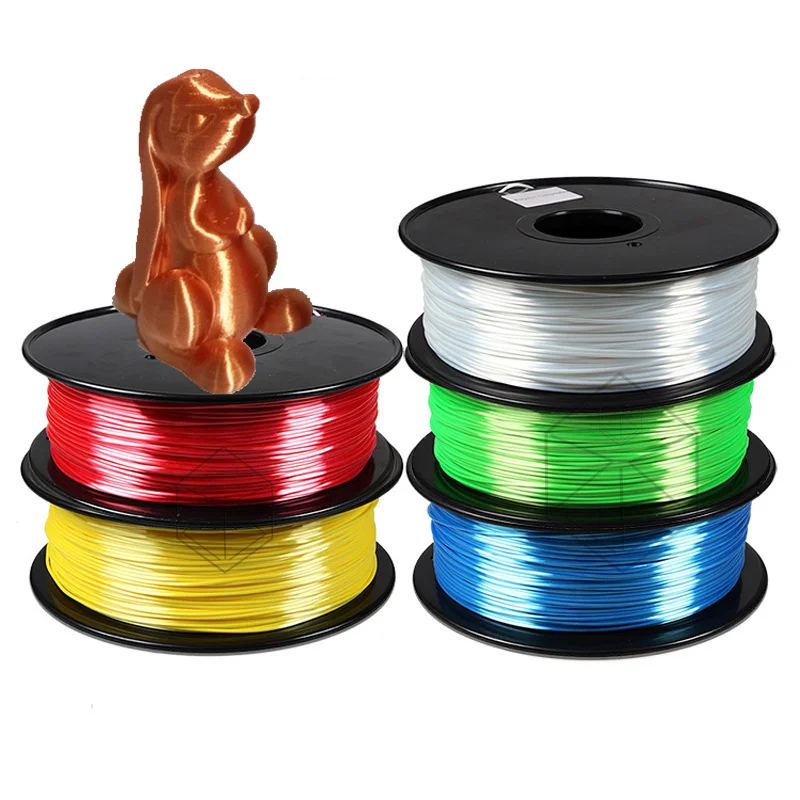

Both materials are available in different colors; there are even translucent materials. Some specialty materials are only available as a mixture based on PLA. This is wood, metal, etc.

The photo below shows ColorFabb's "Bamboofill". The material contains 80% PLA and 20% bamboo sawdust.

Prices for PLA and ABS

Prices are in the same range, but as a rule, PLA plastic is a bit more expensive. Naturally, PLA plastics with impurities of wood or other materials are more expensive.

Recommended applications

PLA is widely used in 3D printing, such as household items, gadgets and toys. It's great if flexibility isn't your primary requirement. In this it is inferior to ABS. On the other hand, it is biocompatible and can be safely used in accessories that interact with the skin.