Colour changing 3d printer filament

Color Changing Filaments | How it Works & Best Options

- Author

- Recent Posts

Martin

Besides many test devices, Martin now has his fourth own 3D printer running and prints as a hobby for friends, family and himself. He is happy to share his experience with each new article.

Latest posts by Martin (see all)

Disclosure: Links marked with * are Affiliate Links. I earn from qualifying purchases if you decide to make a purchase through these links – at no additional cost for you!

Color-changing filaments* enjoy great popularity today. As the name suggests, these change color under certain conditions.

For example, UV light can cause a green material to turn red. This gives you more options when designing print models. However, before you decide on such a filament, you should familiarize yourself with its properties. This will ensure that you make a good and, above all, long-term investment.

These are our recommendations for color changing filaments:

- AMOLEN PLA*

- C3D ZHUOPU PLA*

- Zi-Rui Tri Color*

- iSANMATE PLA+*

- colorFabb*

- LAY Filaments*

- Form Futura*

This article tells you about the most important features of color-changing filaments. You will learn what to look for when buying them.

Table of Contents:

- 1 Color Changing Filaments – Basics

- 1.1 Advantages

- 1.2 What should I pay attention to when using color-changing filaments?

- 1.3 What costs can be expected?

- 2 Best Color Changing Filaments

- 2.1 AMOLEN

- 2.2 CC3D ZHUOPU

- 2.3 Zi-Rui Tri Color

- 2.

4 iSANMATE PLA+

4 iSANMATE PLA+ - 2.5 colorFabb

- 2.6 LAY Filaments

- 2.7 Form Futura

- 3 Are Color-Changing Filaments the Right Choice for Me?

- 4 Further Iinformation

- 4.1 The filament must always be matched to the 3D printer

- 4.2 The slicer software is what matters

- 4.3 Be cautious about this before using the printer for the first time

- 5 Related Questions

- 5.1 What expenses can be expected for filaments?

- 5.2 Where can you buy filaments?

- 6 Conclusion – Create Variety in 3D Printing with Color-Changing Filaments

Color Changing Filaments – Basics

Color-changing filaments* consist of normal PLA*, whereby the material additionally has color-changing elements. In most cases, a change in temperature causes it to change color. This material is also available in different thicknesses. This has the advantage that you can buy a filament that fits perfectly to you and your model.

This type of material can not only change color. There are also products that become transparent at a certain temperature. This allows the material to create exciting effects.

Often it is enough to expose the model to direct sunlight to bring about the desired change. In the cool season, however, it is sometimes necessary to actively heat the product. In this case, however, be sure to take into account the melting point of the filament. Otherwise, deformations may occur on the model.

Advantages

With these filaments, you have the possibility to design your model in a varied way. As a result, it is guaranteed to attract everyone’s attention. It reacts not only to heat, but also to other environmental factors such as light. The type of product is indicated in the product description.

A big advantage of color-changing filaments is that they are easy to process. So you don’t need an expensive printer to get nice results.

What should I pay attention to when using color-changing filaments?

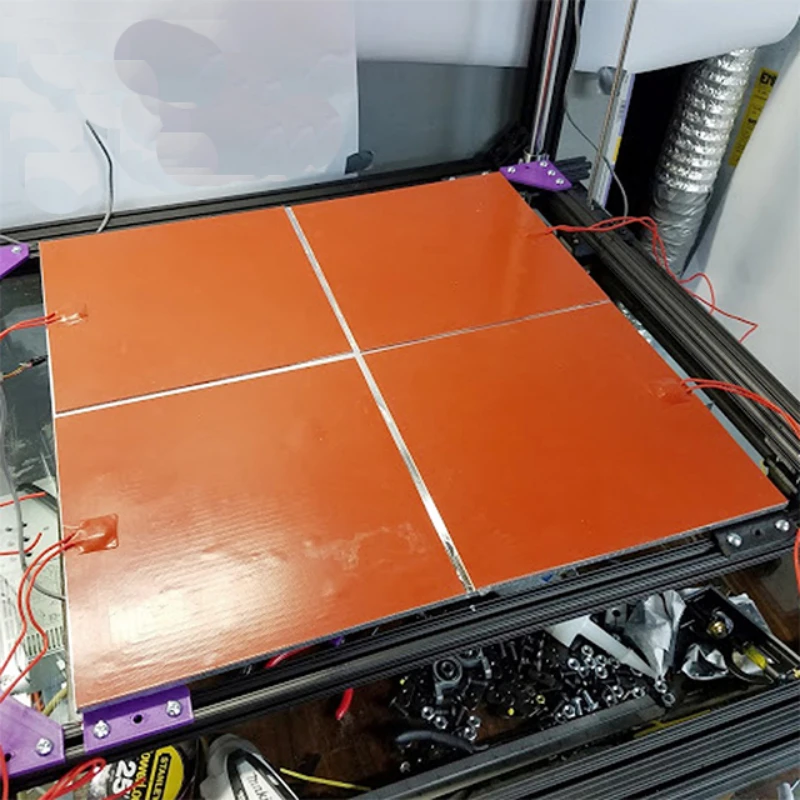

A color-changing filament with PLA as the base material is easy to print. So you can process it without a heated print bed, which makes the material suitable even for cheaper devices.

So you can process it without a heated print bed, which makes the material suitable even for cheaper devices.

The ideal extruder temperature is 205°C – however, you usually have a margin of 15°C here. The choice of temperature always depends on the type of model.

However, you should always keep in mind that the material has limited mechanical properties. So if you want to print a model that is particularly flexible, you are better off with another alternative. Also keep in mind that color-changing PLA is easily porous and should not come into contact with food.

However, you can coat your printed object with a food-safe coating afterwards to still use it for this purpose.

Related Post:

Guide: Food Safe Coatings for 3D Printing

Meanwhile, filament that is capable of changing color is also available in the form of ABS*. In this case, you have a little more options in the design of your final product. Also, the material can come into contact with food. However, in this case, you should definitely go for a 3D printer with a heated print bed.

However, in this case, you should definitely go for a 3D printer with a heated print bed.

What costs can be expected?

In most cases, you have to accept somewhat higher expenses when buying the color-changing filaments than when buying pure PLA. This is because they simply cost more due to their unique properties.

The price for the color-changing filament is usually between 15 and 45 dollars. So even if you place a large order, you don’t have to expect too high expenses. In order to make a well-considered decision and at the same time save yourself from having to buy new filament in the near future, you should take a close look at the product description of the retailer in question.

Best Color Changing Filaments

In terms of color-changing filaments, you now have a wide selection of brands and product variants. This means that you can find the right article for every taste and every area of application. The following manufacturers have proven themselves in this area:

AMOLEN

The AMOLEN PLA* changes its color depending on the applied temperature. Below 30 °C it is very dark and becomes redder and lighter with heat.

Below 30 °C it is very dark and becomes redder and lighter with heat.

Check Price at:

Amazon*

The effect is beautiful to watch during printing alone. And afterwards you can easily provoke the effect with a hair dryer (but make sure that the filament doesn’t get too hot).

@kijaidesign on reddit shared an awesome time-lapse video with this filament. There you can see the filament in action before you consider buying it.

CC3D ZHUOPU

Another great color-changing PLA is from CC3D ZHUOPU*. It also changes its color according to the surrounding temperature. It is available in three different colors.

Purpe Blue to Pink*Amazon*

Green to Yellow*Amazon*

Orange to Yellow*Amazon*

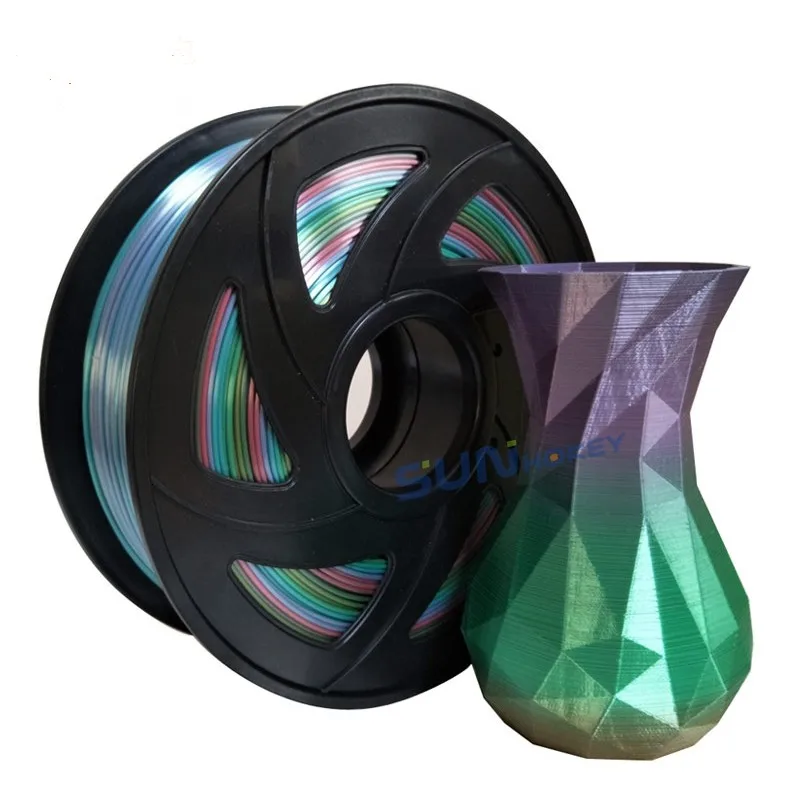

Zi-Rui Tri Color

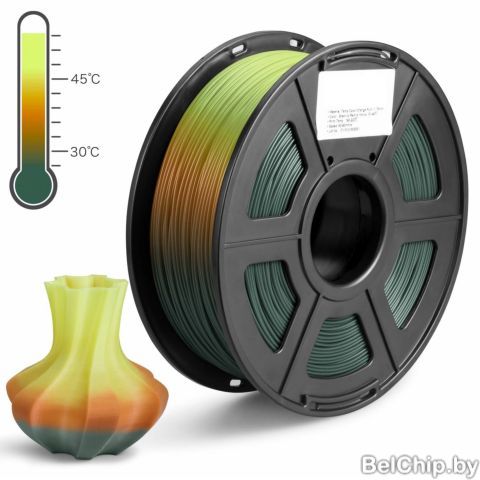

The Zi-Rui Tri Color Filament* is especially interesting because it changes between three colors – pine green, light orange to yellow.

Check Price at:

Amazon*

The two temperature points are 31 °C and 45 °C. You have to watch out for direct sunlight though because it is not entirely UV-resistant.

iSANMATE PLA+

The iSANMATE PLA+ color-changing filament* changes from Green to Yellow. The effect is quite extreme and will catch your attention.

iSANMATE PLA+*Check Price at:

Amazon*

It changes its color around the 33 °C mark. Under this temperature it is green and above it, it becomes yellow. The quality of this filament is quite remarkable too because it is almost like printing with normal PLA!

colorFabb

This company not only produces color-changing filaments* but also makes glow-in-the-dark materials*. This way you can achieve a particularly interesting effect with your model. The filament is also available in different diameters.

The filament is also available in different diameters.

Check Price at:

Amazon*

LAY Filaments

LAY Filaments is a somewhat cheaper alternative. The manufacturer specializes in filaments with reflective properties*. These can be used not only in the private sector but also in the form of traffic signs.

Lay Filaments Reflect-o-Lay Reflective 3D Printing Filament*Check Price at:

Amazon*

Here, too, you can choose between products with different diameters. So you will find the right material for every application.

Form Futura

Form Futura is also a comparatively expensive supplier. However, its products meet the latest standards. The manufacturer specializes in thermal filaments*. Specifically, this means that these materials change color above a certain temperature.

Check Price at:

Amazon*

It is best to test the material before you place a large order, as it is already quite expensive compared to conventional filaments. This way you can see if the financial investment is worth it for you.

Are Color-Changing Filaments the Right Choice for Me?

You need to know for yourself whether you should buy color-changing filaments. Consider in advance how you want to use the model and what properties it should have. This will enable you to make a good choice with regard to the material.

Also, familiarize yourself with the most important characteristics of the filament. If in doubt, ask an expert for advice. He or she can give you an overview of the most important characteristics of the material and tips regarding your purchase.

Color-changing filaments are used today not only in the private sector. The dynamic properties of the material are also appreciated in the professional context. Thanks to the large product variety, the right product can be found for just about every sector.

Thanks to the large product variety, the right product can be found for just about every sector.

Further Iinformation

The filament must always be matched to the 3D printer

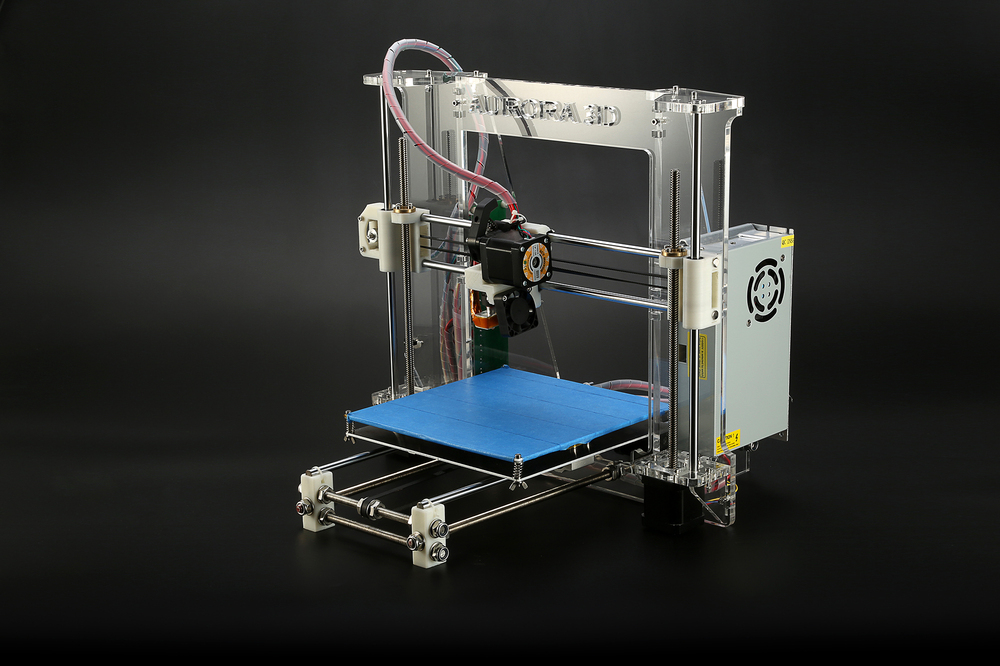

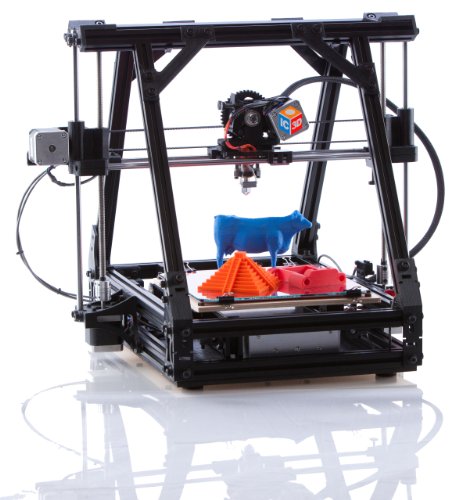

If you already own a 3D printer, you should make sure that the device can process the filament before buying it. Check the instruction manual for your model on the one hand and the properties of the filament on the other. This way you can see if your machine is capable of processing the material. You should not have any problems with PLA on any machine. Because this product makes only low demands on your printer. So you have the possibility to process color-changing filaments even with a cheaper model.

However, if you don’t have a 3D printer yet and are planning to buy one, you should rather look for a versatile device. In this case, you almost don’t have to make any compromises when it comes to printing your models. Pay particular attention to the temperature range and the speed settings. This allows you to counteract errors such as stringing when processing the filaments. However, you also have to expect higher expenses with such a model. A 3D printer that has versatile features and delivers accurate results usually costs more than 500 dollars. Beginners’ models, on the other hand, are available for around 200 dollars.

This allows you to counteract errors such as stringing when processing the filaments. However, you also have to expect higher expenses with such a model. A 3D printer that has versatile features and delivers accurate results usually costs more than 500 dollars. Beginners’ models, on the other hand, are available for around 200 dollars.

Related Posts:

- Best 3D Printers under $300

- Best 3D printers under $500

- Best 3D printers under $1000

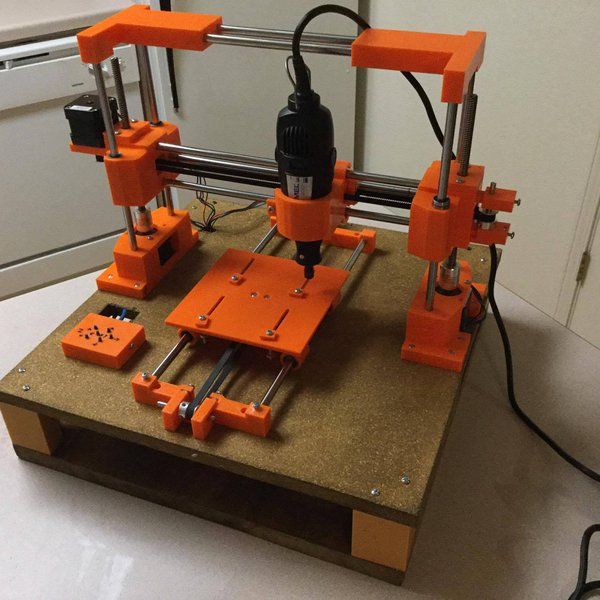

You can save money by assembling your 3D printer yourself. Special kits* are now available for this purpose. These come with instructions so that you can quickly find your way around this process, even if you are a novice. However, always proceed step by step when constructing your printer. In this way, you can avoid mistakes.

Related Post:

How to Build a 3D Printer at Home: Kit or DIY?

The slicer software is what matters

Not only the printer and filament determine the quality of the result. The slicer software also plays an important role in this context. This is the program in which you enter the specifications for 3D printing. The software is ideally designed so that you can easily find your way around. In addition, all settings should be easy to make. This will ultimately save you a lot of time and effort.

The slicer software also plays an important role in this context. This is the program in which you enter the specifications for 3D printing. The software is ideally designed so that you can easily find your way around. In addition, all settings should be easy to make. This will ultimately save you a lot of time and effort.

Meanwhile, there are programs that are specially tailored to individual printer models. This ensures intuitive handling of the device.

High-quality software also shows you potential problem areas in 3D printing. With it, you can see in advance whether your model has pores or holes. That way, you don’t have to deal with misprints.

Be cautious about this before using the printer for the first time

When you buy a 3D printer, you usually have to assemble it and connect it correctly before you can use it. Follow the manufacturer’s operating instructions in this regard. Follow the step-by-step procedure to ensure that you avoid mistakes.

Also, familiarize yourself with the features of the device. Pay particular attention to the equipment. This way you know which filaments you can process with your 3D printer.

Pay particular attention to the equipment. This way you know which filaments you can process with your 3D printer.

Keep in mind that some models can also be expanded. You can equip them with a heated print bed afterwards. This gives you the option of processing even more filaments with the same printer.

Before you start a large print, you should run a test print. This will also help you to identify any errors in good time. By doing this, you avoid wasting materials and incurring high costs. This is particularly advantageous if you are using expensive color-changing filament.

Related Questions

What expenses can be expected for filaments?

The cost of filament depends on the type of product you are purchasing. The cheapest variants include ABS* and PLA*. Here you can buy spools for a price in the single-digit range. However, if it’s a color-changing filament, the cost is naturally a bit higher. However, even in this case, your expenses will be kept within limits.

It’s a different story when you turn to TPU* and TPE* products. These are the most expensive materials. However, this is due to their numerous positive properties. For example, models made of these filaments are not only flexible, but they also have a high resistance. So the extra expense, in this case, can be well worth it. The cost per spool is usually over 35 dollars.

PETG* is also more expensive. This filament is also flexible. It also has a high degree of transparency. It also has the advantage that – unlike PLA – it can come into contact with food without hesitation. For this reason, products made from this filament are often used in the medical sector as well as in industry. A spool of PETG usually costs between 25 and 30 dollars.

If you want to save money when buying filaments, you should compare several retailers with each other. This is because the costs can vary from supplier to supplier. You are particularly flexible in this regard when you search for the product online. Here, you usually have a particularly large selection of sellers at your disposal. Therefore, never go for the first store that comes along. Look at it carefully. It is important that the provider is transparent in terms of pricing – in addition, each item in its range should be provided with a detailed description. In this context, a right of exchange and return also proves to be practical. With this, you avoid buying a pig in a poke.

Here, you usually have a particularly large selection of sellers at your disposal. Therefore, never go for the first store that comes along. Look at it carefully. It is important that the provider is transparent in terms of pricing – in addition, each item in its range should be provided with a detailed description. In this context, a right of exchange and return also proves to be practical. With this, you avoid buying a pig in a poke.

Where can you buy filaments?

If you want to buy these products, it’s best to go online. You’ll find a wide selection of variants* here, with the right item for almost every need.

However, you can easily lose track of the large product range. To avoid this scenario, you should narrow down your search in advance. Be clear about which properties the filament should have. You can also think about the price and set a possible limit here. This way, you can narrow down your selection and make a decision more easily.

In the meantime, you have the option online to take advantage of a non-binding consultation at any time. The majority of online stores provide you with their own customer service. You can have all your questions answered by expert employees and clear up any uncertainties.

The majority of online stores provide you with their own customer service. You can have all your questions answered by expert employees and clear up any uncertainties.

Of course, you also have the choice of going to a specialist dealer near you. You can get personal advice from him. You can also get an impression of the quality of the products on site. This is an advantage especially if you are not yet too familiar with the various properties of the filaments. However, in this case, you also have to make some sacrifices in terms of selection. Furthermore, you have less leeway when it comes to pricing. Ultimately, you have to decide for yourself whether the advantages or disadvantages outweigh the disadvantages.

Conclusion – Create Variety in 3D Printing with Color-Changing Filaments

Color-changing filaments* are suitable for many types of models. But especially if you want to bring a little variety into the game, you should rely on these materials. They change color when the temperature reaches a certain level – you can do this by exposing the filaments to direct sunlight.

They change color when the temperature reaches a certain level – you can do this by exposing the filaments to direct sunlight.

When it comes to printing, the materials prove to be uncomplicated. PLA is their basis, whereby this was provided with color-changing attributes. You can also process models of this type with an inexpensive printer. You don’t need a heated print bed either. Meanwhile, color-changing filaments made of ABS are also available.

If you want to save money when buying color-changing filaments, you should look at several items in advance. Compare their prices with each other so that you can make a well-considered choice. If in doubt, ask your local dealer for advice. With his help, you will find a filament that suits you.

Disclosure: This website is the property of Martin Lütkemeyer and is operated by Martin Lütkemeyer. Martin Lütkemeyer is a member of the Amazon Services LLC and other Affiliate Programs. These are affiliate advertising programs designed to enable websites to earn advertising revenue through advertising and linking to Amazon. com and others. Links marked with * are affiliate links.

com and others. Links marked with * are affiliate links.

Colour Change 3D Print PLA Filaments

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

Filters:

- Special

-

3DJAKE magicPLA Deep Space 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Metallic Emerald 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Juicy Peach 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Frozen Gold 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Sunset Sky 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Parrot 4 Model types- Shimmering colours

- ecoPLA basis

- Made in EU

-

3DJAKE magicPLA Frozen Lavender 4 Model types- Shimmering colours

- ecoPLA base

- Made in EU

-

3DJAKE magicPLA Watermelon 4 Model types- Shimmering colours

- ecoPLA basis

- Made in EU

-

Spectrum PLA Special Thermoactive Red 2 Model types- Colour-changing

- Easy to print

- High-quality

-

R3D PLA Colour Change Blue to Pink- High toughness/strength

- Colour changing effect

- Versatile in use

-

R3D PLA UV Colour Change White to Sky Blue- Changes colour under sunlight

- High UV resistance

- High toughness

-

R3D PLA UV Colour Change Pink to Purple- Changes colour when exposed to sunlight

- High UV resistance

- High toughness

-

R3D PLA UV Colour Change Yellow to Green- Changes colour when exposed to sunlight

- High UV resistance

- High toughness

-

R3D PLA UV Colour Change White to Peach Red- Changes colour when exposed to sunlight

- High UV resistance

- High toughness

-

R3D PLA Colour Change Purple to Red- High toughness/strength

- Colour changing effect

- Versatile in use

All prices incl. VAT.

VAT.

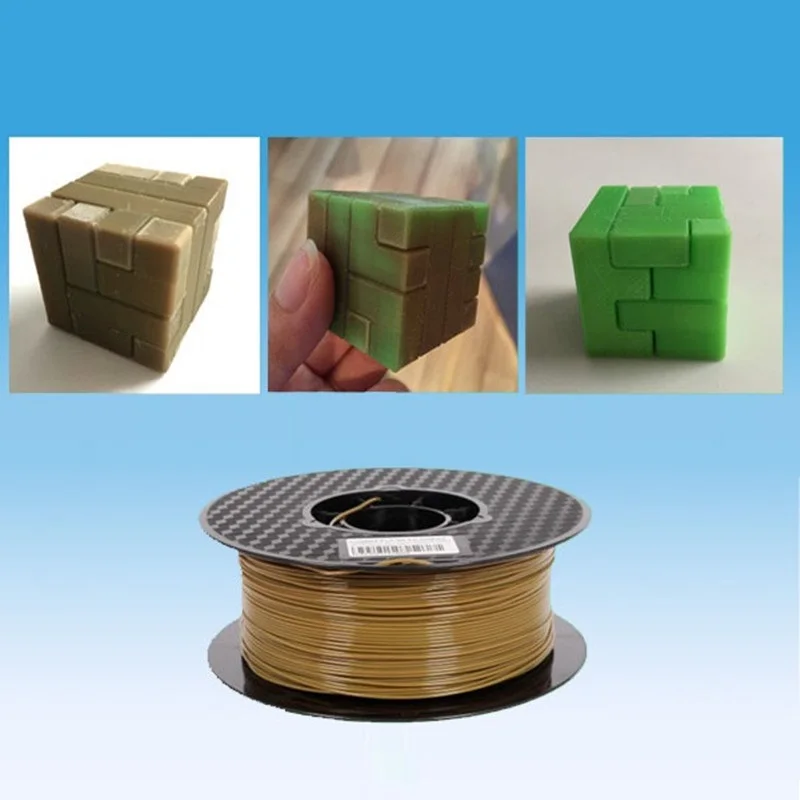

PLA from TOPZEAL that changes color when heated (3d printing)

Hi all! Many people already have 3D printers here, and it’s hard to surprise with an abundance of materials for printing, but there are exotic types of rod, one of which I will test today. This filament in terms of its mechanical characteristics is no different from the classic PLA, but it can change its color when heated above 33°C, so that the color of the model will change even from the heat of the hands. This solution was conceived more as a decorative one, but it can also be used for visual control of the temperature of objects. More details under the cut.

Characteristics

Material: PLA

Rag diameter: 1.75mm

Press temperature: 190-230 ° C

Table temperature: Heating is not required, but for better adhesion, you can warm up to 50 ° C

Color change temperature: from 33°C

Filament weight: 1kg

Length: 343m

Unpacking and appearance

Coils are supplied in 9 yellow bags0004

Inside unmarked cardboard box

Characteristics are indicated on the coil itself

The package is airtight, there is a ziplock on one side for storage after unpacking

Testing

I chose not the best option, you can even say the worst, because. the transition from yellow to white is more difficult to see than from a more saturated blue or pink color. Okay, let's work with what we have. Print settings left as standard, nozzle 200°C degrees, table 60°C

the transition from yellow to white is more difficult to see than from a more saturated blue or pink color. Okay, let's work with what we have. Print settings left as standard, nozzle 200°C degrees, table 60°C

I printed a cube with 100% infill, I thought that the color would start to change in the process

The heat transfer with this filling is not bad and the case did not have time to cool below 33°C

But after a while the upper part became colder and changes became noticeable

After some time, the table cooled down and the cube turned yellow all over

To show the transition process more clearly, I drew and printed a plate 3 mm thick with 100% filling, poured water into a glass with a temperature of about 80 ° C, under such conditions the color change occurs almost instantly

True, in the photo the border looks more blurred, it seems clearer with the eyes

As I wrote under the heading, this type of plastic was conceived as decorative, but it seems to me that it can also fit as a temperature indicator. I will use the cube again as a test subject.

I will use the cube again as a test subject.

The temperature of the table is 40°C, the color stopped changing after 5 minutes, but just in case, I waited for 10

50°C, color creeps back up

60°C, the cube is almost fully warmed up

Yes, on gifs the transition is seen quite badly, I marked with a marker what I saw with my own eyes, then I checked with the thermal imager, it turned out pretty close to the truth, the color changes at a temperature of about 35 ° C

On the same blue plastic, the transition boundary would be much clearer, so you can print a model for a specific radiator or element, put marks on an oblong body after calibration and an individual overheating indicator is ready, here is an example of other colors from the store

I also checked the mechanical properties, it turned out to be quite difficult to break a 3mm plate with your fingers

The edges are practically not deformed after the collapse, the filament is quite elastic and durable

Found in an old review a gif with testing a similar record from FDPlast

Result

Creozone then turned out to be more plastic, although the resistance to fracture showed more fdplast

TOPZEAL filament burns like classic PLA, with a blue flame, without stink and soot

There are practically no traces of burning on the outside

There are dark areas on the bottom that indicate exposure to high temperatures, but this is the norm for pigmented plastic

Results

The price tag seems to be not very large for an exotic type, while in terms of physical properties it surpasses the classic cheap local PLA, it does not stink during printing, it sticks to the table well, the layers also sinter perfectly, so the material itself is not bad, but the color change in Depending on the temperature, it can transform familiar models or even allow you to create something useful, people printed mugs or “covers” for disposable cups, cases for mobile phones online. I printed it, put it on the child's phone, after half an hour the case faded, so you need to rest. It may not be so relevant for devices on the MTK, a break will have to be done every 10 minutes)

I printed it, put it on the child's phone, after half an hour the case faded, so you need to rest. It may not be so relevant for devices on the MTK, a break will have to be done every 10 minutes)

Currently in RU warehouse there is a choice of yellow,

and blue

As always, constructive criticism is welcome in the comments. All the best =)

The product was provided for writing a review by the store. The review is published in accordance with clause 18 of the Site Rules.

plastic bottle filament how to make filament production

By making filaments for printing on a 3D printer, the user can significantly save money spent on consumables. Plastic filament for printing can be made from PET bottles. Consider which bottles are suitable for this, the procedure for manufacturing a filament, as well as the advantages and disadvantages of this method.

Plastic filament for printing can be made from PET bottles. Consider which bottles are suitable for this, the procedure for manufacturing a filament, as well as the advantages and disadvantages of this method.

Is it possible to make plastic for a 3D printer from PET bottles?

When making filament for 3D printing, the following types of PET bottles are recommended:

- Blue. Such bottles have the hardest plastic, but when melted, it will be the most fluid of all.

- White and green. The plastic of these bottles is softer than that of the blue ones. In molten form, the material is thicker.

- Brown. These bottles have the softest plastic. When molten, it is highly viscous (similar to ABS filament).

How to make DIY filament and print with plastic bottles?

Preparatory work

The bottle threads must be unraveled into ribbons before starting production.

Soft bottles have a thinner plastic, so it is better to cut them into strips of 10 mm.

Containers with medium hard or harder plastic material can be cut into thin strips, about 7 mm thick.

PET Bottle 3D Printer Filament Tools

To create PET bottle filament, you will need the following tools:

- stationery knife or bottle cutter;

Important! When choosing a bottle cutter, you need to pay attention to the accuracy of cutting plastic. The width of different cut strips should not differ by more than 0.1 mm.

- oven;

- plastic crusher;

- homemade vertical extruder - it has a metal pipe with a drill screw that rotates with a stepper motor, and a nozzle with two heaters from a 3D printer;

- turntable;

- large pelvis;

- cold water.

Step-by-Step Instructions

Production of PET bottle filament for 3D printing is carried out in the following order:

- Cut plastic bottles must be melted in an oven at 180 °C. The melting time depends on the number of bottles.

Help. It takes approximately 40 minutes to melt 10 plastic bottles.

- After melting, the plastic must be completely cool. All excess moisture will evaporate from the material, and it will crystallize. In appearance, the polymer resembles glass.

- The cooled material must be ground in a crusher into a finer fraction.

- The crushed plastic is then fed into the vertical extruder. The rotating screw moves the ground polymer to the bottom of the device to the nozzle with heaters. The plastic starts to melt.

- As the molten PET exits the nozzle, it enters a bowl of cold water placed on the turntable. The rotation of the table will prevent sticking of the material. The thread must be cooled as quickly as possible so that it becomes flexible and transparent. In this case, it can be used for 3D printing.

- Let your homemade filament dry well before printing. Since in the presence of a large amount of moisture, a thread of molten plastic will exit the extruder in the form of foam.

It is recommended to dry the skeins of thread in a closed container with silica gel at a temperature of 50–60 °C. To do this, you can use the oven or simply place the container on the radiator.

It is recommended to dry the skeins of thread in a closed container with silica gel at a temperature of 50–60 °C. To do this, you can use the oven or simply place the container on the radiator.

When using ready-made filament for 3D printing on a printer, there are a few things to consider:

- The product must be printed on a cold table, the temperature of which does not exceed 35 °C. This limitation of the temperature regime is due to the fact that the plastic must quickly cool down to a temperature below 70 ° C. Otherwise, the material may almost completely lose its strength properties.

- Extruder temperature should be around 265°C. But it may differ depending on the printing speed and the type of plastic from which the filament is made.

- If the feed mechanism of the 3D printer is made of brass, then it is better to put a thin-walled rubber hose on the roller. It will not allow the PET thread to slide.

Pros and cons of using bottles to create plastic

The main advantage of recycling PET bottles into plastic filaments for 3D printing is that you can save on the purchase of industrial filaments and recycle unnecessary packaging, which, when taken to landfills, greatly pollutes the environment .