3D printing support material not sticking

3D Print Not Sticking to Bed: 6 Easy Solutions

Jun 12, 2020

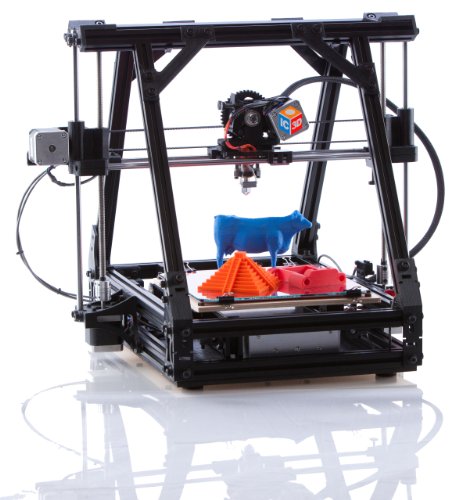

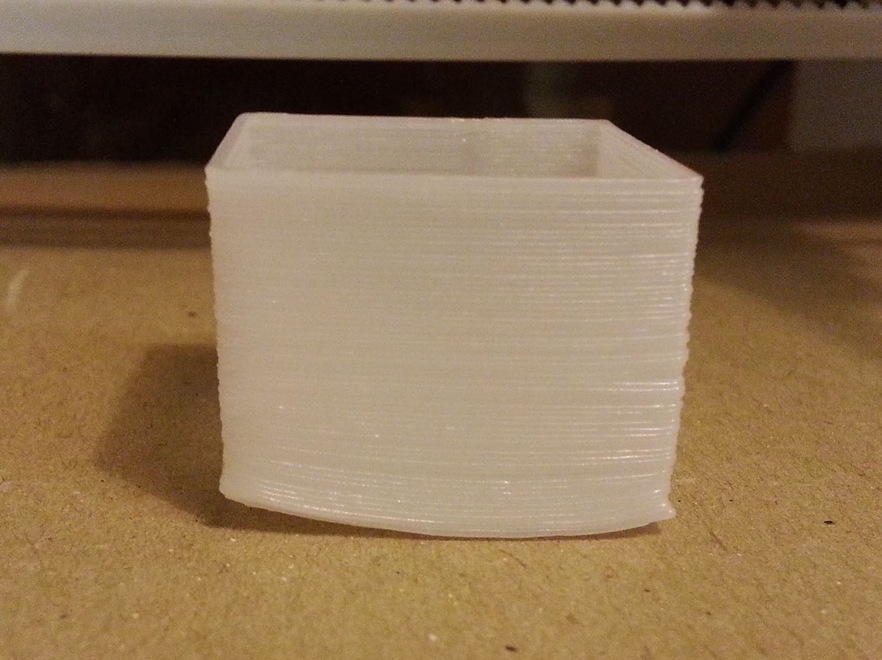

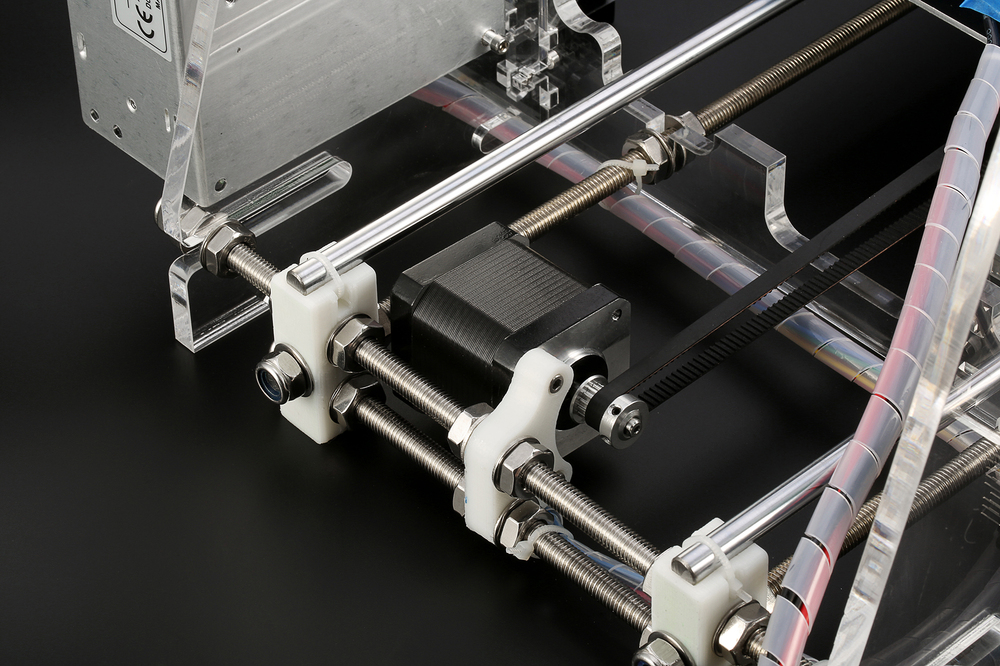

3D print not sticking to bed? It happens. You’ve planned, calibrated, and tested, but your 3D print just won’t stay put. Don’t worry; we’ve compiled the 6 easy solutions to the problem that will most certainly get your parts back to printed perfection.A good first layer adhesion is essential because it sets the foundation for the rest of your print. Unfortunately, first layer bed adhesion is a common 3D printing issue, especially with ABS and PLA. Luckily, there are a few quick solutions you can use to stop this from happening.

In this video and article, we’ll review 6 ways to fix a 3D print not sticking to the bed.

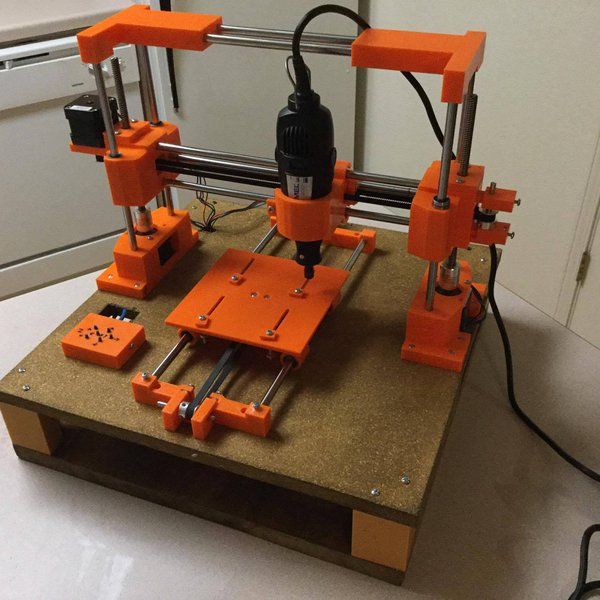

1. Bed LevelingIf your printer has an adjustable bed and you’re having issues with sticking, check to make sure your bed level is flat.

An uneven bed could mean that one side is closer to the nozzle while the other side is too far, creating a difficult print environment. Additionally, if your bed is uneven it can result in your print warping or breaking.

The process for leveling your bed depends on your printer. For example, BCN3D printers are equipped with automatic bed leveling, but you also have the option to manually level your bed. Alternatively, if your 3D printer does not have auto-leveling, you will need to level it yourself.

2. Nozzle to Bed DistanceThere is a certain sweet spot between the bed and the nozzle. It’s like Goldilocks’ porridge – not too close, and not too far, but just right.

- If your 3D print is not sticking to the bed, check the distance between the bedplate and the nozzle.

- If the nozzle is too close to the bed, then the filament will not be able to come out, or the extruder could damage or drag the previously printed layer.

- On the other hand, if the nozzle is too far the filament will not properly place on the bed and will not be able to adhere.

You will have to experiment to see what works best for the filament you are printing. Ideally, the nozzle should be close enough to the bed so that the filament is slightly squished onto the bed’s surface. This allows the filament to get a bit of grip onto the bed.

Learn all you need to know about fiber-filled materials for FFF 3D printing!

3. Nozzle SpeedNozzle speed can also play an important role in your 3D print not sticking to bed. Similar to nozzle distance, you must find a certain sweet spot for the nozzle speed, especially when printing the first few layers.

Slowing down the nozzle’s speed gives the plastic more time to bond to the bed and get a better grip. If you print too quickly, the filament may not stick to the bed because the plastic cools off too quickly. After you have laid down your first few layers and feel confident in your print’s bed adhesion, you can resume the nozzle to a normal speed.

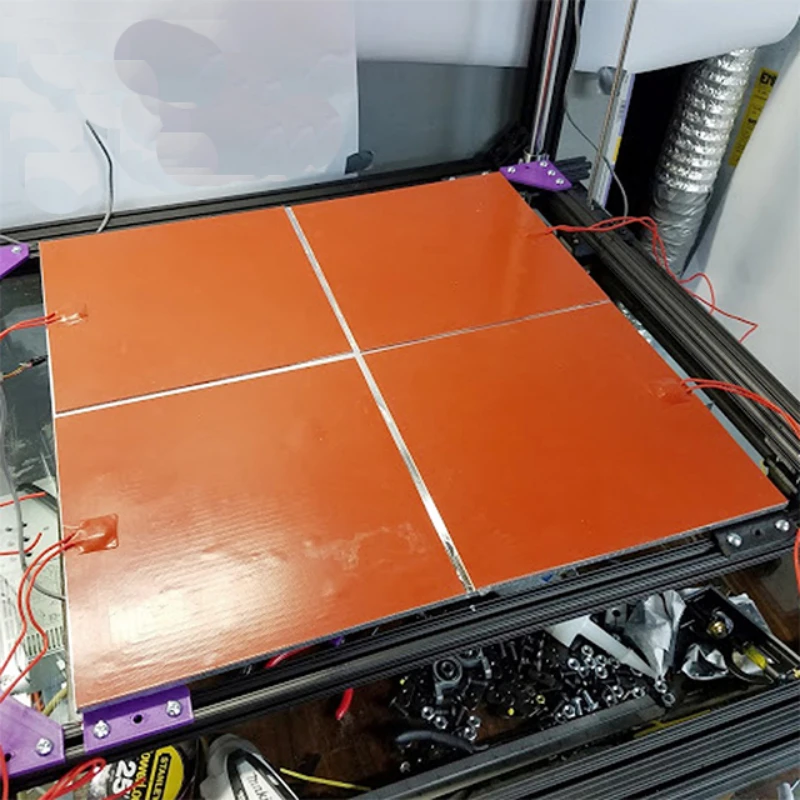

The final thing you can look at is the temperature of your bed. If you are using a heated bed on your prints, double-check that you are using the proper temperature for your specific filament. Different 3D printing materials require different bed temperatures.

It may also help to slightly increase the bed’s temperature by just a few degrees to help the first layer stick. After the print has established a good grip, you can then lower the temperature to maintain a normal heat.

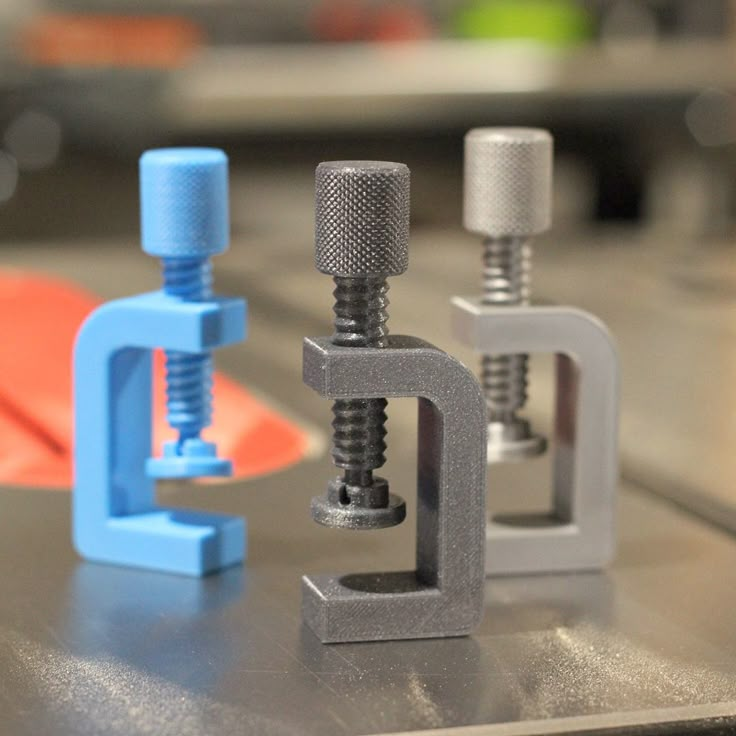

5. AdhesivesIf you’ve double and triple-checked all of your bed and nozzle settings and you still have bed adhesion problems, then it’s time to bring in some backup tools so that the print keeps sticking to bed. If you still cannot get your 3D print to stick to the bed, use an adhesive right on the bed where the filament will land.

There are a few different options you can consider, including:

- Glue sticks,

- Painters tape,

- Hairspray,

- Or 3D printing specific adhesives like Magigoo.

Using an adhesive specifically designed for 3D printing ensures that you will be able to properly wash off the adhesive from your print once it is finished.

This common practice is both quick and cost-effective and can save you a lot of headaches. You only have to apply a thin layer to the bed. Different filaments will adhere to different adhesives, so experiment to see what works best for you.

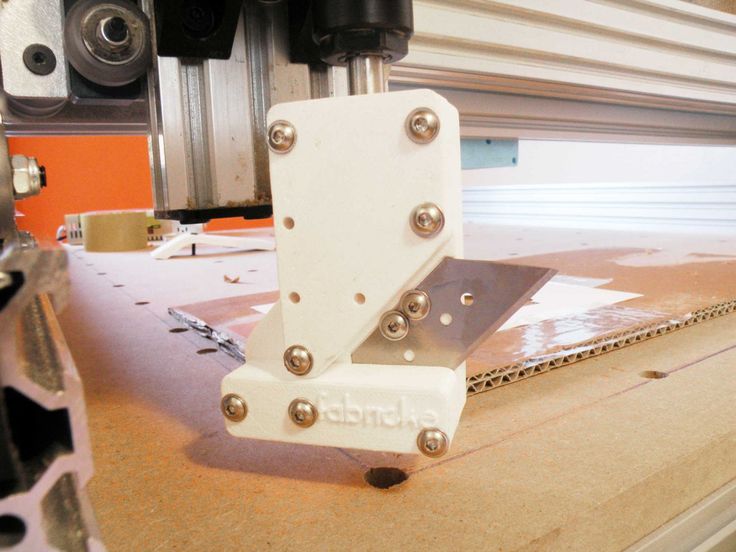

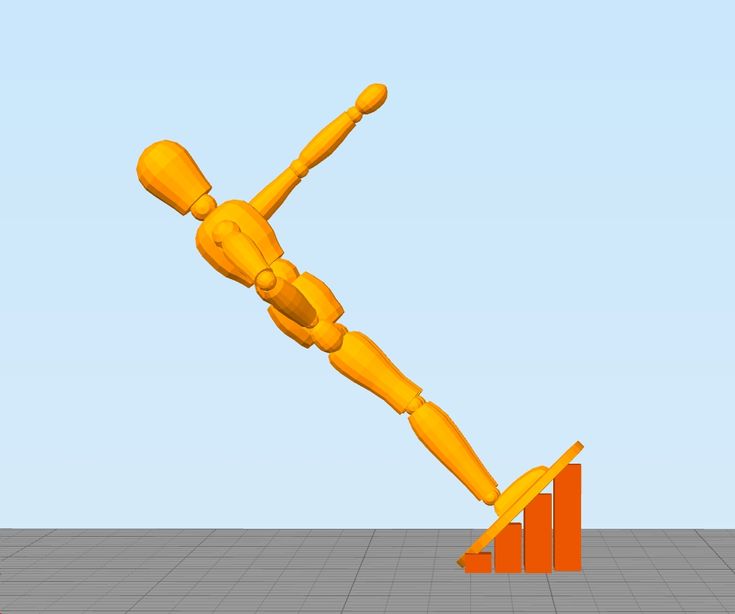

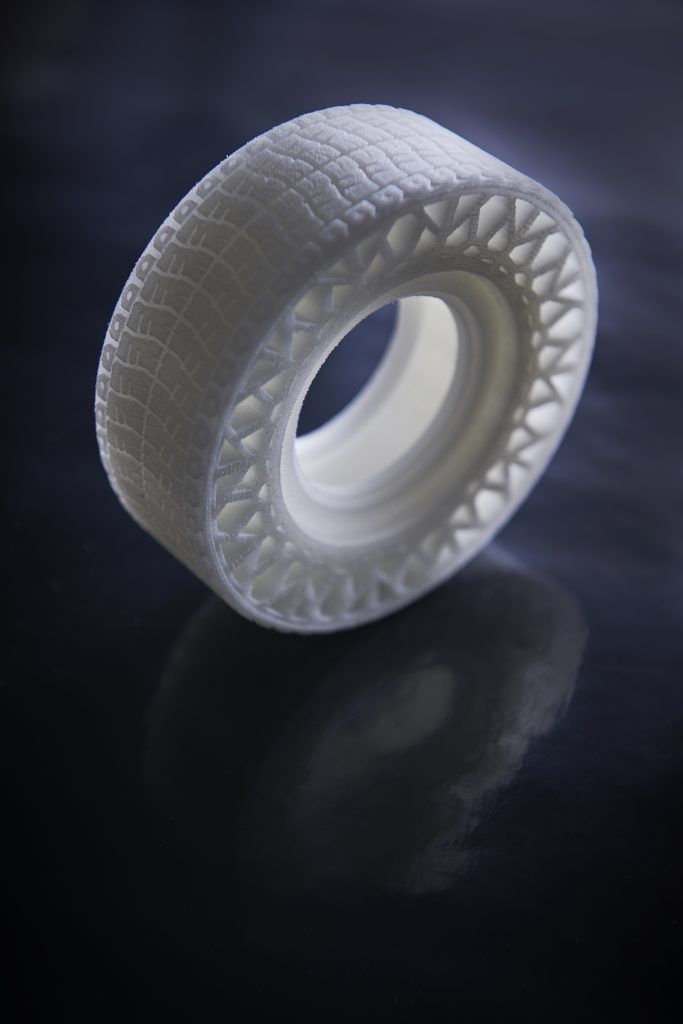

6. Brims and RaftsIf you don’t want to use adhesives but the 3D print not sticking to bed remains a problem, then printing a brim or raft might be your best option.

- A brim is a layer of filament that surrounds the print and attaches to the first layer of your printed object. It is similar to a hat’s brim. It does not sit under the part, but just simply adds an extra layer around it.

- A raft, on the other hand, is a thin layer of filament that is laid down before the rest of your print.

This creates a flat filament base for the rest of your print to build upon. Both rafts and brims are removed from the final object once it is done printing.

This creates a flat filament base for the rest of your print to build upon. Both rafts and brims are removed from the final object once it is done printing.

These are especially useful when creating very small prints or prints that need more support in their first few layers. For instance, both will help to anchor the print and allow it to adhere better.

3D print not sticking to bed: Final ThoughtsNon-optimal first layer adhesion is a common problem in 3D printing, especially with PLA and ABS. But, luckily it has a few different solutions available. If you are really struggling with 3D print not sticking to bed, don’t be afraid to try a combination of a few of them to get your print to stick.

Not Sticking to the Bed

Not Sticking to the Bed

It is very important that the first layer of your print is strongly connected to the printer’s build platform so that the remainder of your part can be built on this foundation. If the first layer is not sticking to the build platform, it will create problems later on. There are many different ways to cope with these first layer adhesion problems, so we will examine several typical causes below and explain how to address each one.

If the first layer is not sticking to the build platform, it will create problems later on. There are many different ways to cope with these first layer adhesion problems, so we will examine several typical causes below and explain how to address each one.

Common Solutions

Build platform is not level

Many printers include an adjustable bed with several screws or knobs that control the position of the bed. If your printer has an adjustable bed and you’re having trouble getting your first layer to stick to the bed, the first thing you will want to verify is that your printer’s bed is flat and level. If the bed is not level, one side of your bed may be too close to the nozzle, while the other side is too far away. Achieving a perfect first layer requires a level print bed. Simplify3D already includes a useful bed leveling wizard that you guide you through the bed leveling process. You can find this wizard by going to Tools > Bed Leveling Wizard, and following the on-screen instructions.

Nozzle starts too far away from bed

Once your bed has been properly leveled, you still need to make sure that the nozzle is starting at the correct height relative to the build platform. Your goal is to locate your extruder the perfect distance away from the build plate — not too far and not too close. For good adhesion to the build plate, you want your filament to be slightly squished against the build plate. While you can adjust these settings by modifying the hardware, it is typically much easier (and much more precise!) to make these changes from Simplify3D. To do this, click “Edit Process Settings” to open your process settings and then go to the G-Code tab. You can use the Z-Axis global G-Code Offset to make very fine adjustments to your nozzle position. For example, if you enter -0.05mm for the Z-axis G-Code offset, the nozzle will begin printing 0.05mm closer to your build platform. Be careful to only make small adjustments to this setting. Each layer of your part is usually only around 0. 2mm thick, so a small adjustment goes a long way!

2mm thick, so a small adjustment goes a long way!

First layer is printing too fast

As you extrude the first layer of plastic on top of the build platform, you want to make sure that plastic can properly bond to the surface before starting the next layer. If you print the first layer too fast, the plastic may not have time to bond to the build platform. For this reason, it is typically very useful to print the first layer at a slower speed so that the plastic has time to bond to the bed. Simplify3D provides a setting for this exact feature. If you click on “Edit Process Settings” and go to the Layer tab, you will see a setting labeled “First Layer Speed”. For example, if you set a first layer speed of 50%, it means that your first layer will print 50% slower than the rest of your part. If you feel that your printer is moving too fast on the first layer, try reducing this setting.

Temperature or cooling settings

Plastic tends to shrink as it cools from a warm temperature to a cool temperature. To provide a useful example, imagine a 100mm wide part that is being printed with ABS plastic. If the extruder was printing this plastic at 230 degrees Celsius, but it was being deposited onto a cold build platform, it is likely that the plastic would quickly cool down after leaving the hot nozzle. Some printers also include cooling fans that speed up this cooling process when they are being used. If this ABS part cooled down to a room temperature of 30C, the 100mm wide part would shrink by almost 1.5mm! Unfortunately, the build platform on your printer is not going to shrink this much, since it is typically kept at a fairly constant temperature. Because of this fact, the plastic will tend to separate from the build platform as it cools. This is an important fact to keep in mind as you print your first layer. If you notice that the layer seems to stick initially, but later separates from the print bed as it cools, it is possible that your temperature and cooling settings are to blame.

To provide a useful example, imagine a 100mm wide part that is being printed with ABS plastic. If the extruder was printing this plastic at 230 degrees Celsius, but it was being deposited onto a cold build platform, it is likely that the plastic would quickly cool down after leaving the hot nozzle. Some printers also include cooling fans that speed up this cooling process when they are being used. If this ABS part cooled down to a room temperature of 30C, the 100mm wide part would shrink by almost 1.5mm! Unfortunately, the build platform on your printer is not going to shrink this much, since it is typically kept at a fairly constant temperature. Because of this fact, the plastic will tend to separate from the build platform as it cools. This is an important fact to keep in mind as you print your first layer. If you notice that the layer seems to stick initially, but later separates from the print bed as it cools, it is possible that your temperature and cooling settings are to blame.

Many printers that are intended to print high-temperature materials like ABS include a heated bed to help combat these problems. If the bed is heated to maintain a temperature of 110C for the entire print, it will keep the first layer warm so that it does not shrink. So if your printer has a heated bed, you may want to try heating the bed to prevent the first layer from cooling. As a general starting point, PLA tends to adhere well to a bed that is heated to 60-70C, while ABS generally works better if the bed is heated to 100-120C. You can adjust these settings in Simplify3D by clicking on “Edit Process Settings” and then selecting the Temperature tab. Choose your heated build platform from the list on the left-hand side and then edit the temperature setpoint for the first layer. You can just double-click on the value to change it.

If your printer has a cooling fan, you may also want to try disabling that cooling fan for the first few layers of your printer so that the initial layers do not cool down too quickly. You can do this by clicking “Edit Process Settings” and going to the Cooling tab. You can adjust the fan speed setpoints on the left-hand side. For example, you may want the first layer to start with the fan disabled and then turn on the fan to full power once you reach the 5th layer. In that case, you will need to add two setpoints into that list: Layer 1 at 0% fan speed, and Layer 5 at 100% fan speed. If you are using ABS plastic, it is common to disable the cooling fan for the entire print, so entering a single setpoint would suffice (Layer 1 at 0% fan speed). If you are working in a breezy environment, you may also want to try to insulate your printer to keep the wind away from your part.

You can do this by clicking “Edit Process Settings” and going to the Cooling tab. You can adjust the fan speed setpoints on the left-hand side. For example, you may want the first layer to start with the fan disabled and then turn on the fan to full power once you reach the 5th layer. In that case, you will need to add two setpoints into that list: Layer 1 at 0% fan speed, and Layer 5 at 100% fan speed. If you are using ABS plastic, it is common to disable the cooling fan for the entire print, so entering a single setpoint would suffice (Layer 1 at 0% fan speed). If you are working in a breezy environment, you may also want to try to insulate your printer to keep the wind away from your part.

The build platform surface (tape, glues, and materials)

Different plastics tend to adhere better to different materials. For this reason, many printers include a special build platform material that is optimized for their materials. For example, several printers use a BuildTak sheet on the top of their bed that tends to stick very well to PLA. Other manufacturers opt for a heat treated glass bed such as Borosilicate glass, which tends to work very well for ABS when heated. If you are going to print directly onto these surfaces, it is always a good idea to make sure that your build platform is free of dust, grease, or oils before starting the print. Cleaning your print bed with some water or isopropyl rubbing alcohol can make a big difference.

Other manufacturers opt for a heat treated glass bed such as Borosilicate glass, which tends to work very well for ABS when heated. If you are going to print directly onto these surfaces, it is always a good idea to make sure that your build platform is free of dust, grease, or oils before starting the print. Cleaning your print bed with some water or isopropyl rubbing alcohol can make a big difference.

If your printer does not include a special build platform material to help with adhesion, you still have options! Thankfully, there are several types of tape that stick well to common 3D printing materials. Strips of tape can be applied to the build platform surface and easily removed or replaced if you want to print with a different material. For example, PLA tends to stick well to blue painter’s tape while ABS tends to stick better to Kapton tape (otherwise known as Polyimide film). Many users have also had great success using a temporary glue or spray on the top of their build platforms. Hair spray, glue sticks, and other sticky substances tend to work very well if everything else has failed. Feel free to experiment to see what works best for you!

Hair spray, glue sticks, and other sticky substances tend to work very well if everything else has failed. Feel free to experiment to see what works best for you!

When all else fails: Brims and Rafts

Sometimes you are printing a very small part that simply does not have enough surface area to stick to the build platform surface. Simplify3D includes several options that can help increase this surface area to provide a larger surface to stick to the print bed. One of these options is called a “brim.” The brim adds extra rings around the exterior of your part, similar to how a brim of a hat increases the circumference of the hat. This option can be enabled by going to the “Additions” tab end enabling the “Use Skirt/Brim” option. Simplify3D also allows users to add a raft under their part, which can also be used to provide a larger surface for bed adhesion. If you are interested in these options, please take a look at our Rafts, Skirts, and Brims tutorial which explains things in greater detail.

Related Topics

The model does not stick to the 3D printer table: What should I do?

Adhesion of the model to the working surface of the 3D printer table - ways to increase it

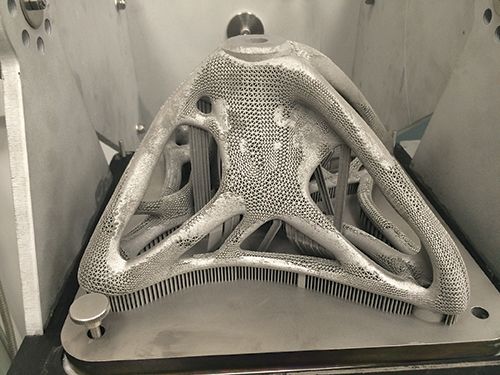

FDM 3D printing technology involves the fulfillment of a number of conditions to obtain the best printing result. One of these necessary conditions is a high adhesion rate, that is, reliable fastening of the lower printed layer of the product to the working platform of the device. In the case where the first layer does not adhere securely to the table, there is a high probability of occurrence of such troubles as deformation of the product. This is especially true of ABS plastic, in relation to the protruding parts of the product and corners.

Every 3D printer needs to be calibrated before printing. In this case, the height of the printed layer along the Z axis will be adjusted. Everyone knows that there should be a gap of about 50-75% of the thickness of the selected layer from the nozzle to the hot layer. Implementing this is very simple. You need to take a regular sheet of A4 office paper. The leaf density index should be 80 mg/m 3 . The nozzle should fit snugly against the table, but the sheet should pass with little effort. In this case, the calibration is considered correct. For those new to 3D printing, there are also videos illustrating proper desktop setup.

Implementing this is very simple. You need to take a regular sheet of A4 office paper. The leaf density index should be 80 mg/m 3 . The nozzle should fit snugly against the table, but the sheet should pass with little effort. In this case, the calibration is considered correct. For those new to 3D printing, there are also videos illustrating proper desktop setup.

3D printers can be supplied with an aluminum or glass work platform, depending on the model. Some 3D printers prefer to print directly on the platform without using any additional tools. But in any case, there are some rules that must be followed.

Rule #1: A smooth surface must be free of dust and grease before printing. For this, isopropyl alcohol is used. If this rule is neglected, then you will definitely encounter deformation of the first printed layer, and, accordingly, the entire product will be of lower quality.

Rule #2: To improve adhesive performance, special products must be used: kapton tape, heat resistant tape, heat mat, ABS solution, garolite, borosilicate glass, 3D printing adhesive, PEI film. The choice is quite wide and you can choose the best option.

The choice is quite wide and you can choose the best option.

Let's take a look at the most popular options for these products in more detail ...

Blue 3D printing tape or heat resistant tape

This is one of the popular options for increasing adhesion. The advantages of this material are convenience, low cost, ease of application, ease of removal of the finished product. The disadvantages include the disposability of this material, although this is not always the case.

The most popular type of heat resistant tape is blue 3D printing tape. Masking tape can be attributed to this category with a stretch.

How to use: Degrease and clean the surface of the platform before using the adhesive. The tape is glued back to back so that there are no defects on the finished product. It is necessary to make pasting the platform as evenly as possible.

Applicability: Heat Resistant Tape is recommended to improve adhesive performance when printing with filaments such as PLA, ABS, Nylon, PETG.

3D Printing Adhesive

This adhesive material is a bottle of clear liquid. The material can be used on both glass and aluminum platforms. It can also be used over masking tape or kapton.

The advantages of 3D printing adhesive are ease of application, low cost, compatibility with most 3D printed materials.

How to use: The adhesive was evenly applied to the degreased platform or material with a foam sponge.

Applicability: 3D printing adhesive is compatible with almost all materials. It is recommended to use it when printing with ABS plastic, ABS+, FLEX, RUBBER, PC, as well as PLA and other materials.

ABS solution

This adhesive is a solution of ABS plastic in acetone or ethyl acetate. To prepare such a solution, 15-20 cm of ABS plastic thread and 60-90 ml of ethyl acetate are used. The viscosity of the solution should be intermediate between milk and water, and the mixture should not resemble a resin or paste. This option is the most reliable, allowing to prevent deformation and bending of the corners of the product. But it will be important to maintain the correct consistency of the solution.

This option is the most reliable, allowing to prevent deformation and bending of the corners of the product. But it will be important to maintain the correct consistency of the solution.

How to use: The prepared mortar is applied in a thin and even layer on a degreased working platform.

Applicability: This adhesive will be most effective on ABS plastics, it is also applicable to ABS.

Kapton tape or Kapton

This material is similar to tape in many ways. Kapton tape is a golden translucent material with an adhesive layer. Kapton is made on the basis of a heat-resistant polymer. Thanks to the use of this material, the lower part of the finished product has a smooth and even glossy appearance.

Method of application: Similar to blue adhesive tape - it is necessary to paste over the working platform as evenly and end-to-end as possible, having previously degreased it.

Applicability: It is recommended to use kapton tape when working with the following types of plastics: ABS, PLA

Thermal pad

This material for increasing adhesion is one of the most popular. Its advantage is reusability and versatility. The use of a thermal mat allows you to achieve maximum adhesiveness of the printed product, as well as to protect the working platform itself, its surface from scratches and other damage. Thermal mat is a sheet of polymer. It can be magnetic or sticky.

Its advantage is reusability and versatility. The use of a thermal mat allows you to achieve maximum adhesiveness of the printed product, as well as to protect the working platform itself, its surface from scratches and other damage. Thermal mat is a sheet of polymer. It can be magnetic or sticky.

Method of application: If the mat has an adhesive base, then the platform must be degreased before applying it. The protective film is removed from the mat, and it is evenly glued to the platform. To improve adhesion, the platform can be preheated to about 50 degrees. Calibration of the platform is carried out after gluing the thermal mat.

Applicability: Thermal mats are universal, that is compatible with all types of filaments.

Garolith

Garolith, also known as LE sheet, is a coating based on glass fiber or epoxy resin. There are several varieties of harolith.

How to use: The sheet is applied to the printing platform.

Applicability: Garolite is not a universal material. Its main purpose is to print with nylon thread, that is, it is used to achieve maximum adhesion with Nylon plastic. Sometimes it is possible to add glue to enhance adhesion, although this is usually not required at all.

PEI film

When printing on 3D printers equipped with a heated bed, PEI film is often used. This material is made of polyesterimide. There is a lot of controversy among users regarding the use of this adhesive material. Some argue that it is difficult to remove the finished product from it. Others recommend using glue to improve adhesion. But the film provides good protection against damage to the surface of the platform.

How to use: The film is fixed on the platform with paper binders (simple clips).

Applicability: PEI films are quite versatile. They can be used with filaments such as ABS, PLA, etc.

The print does not stick to the 3D printer bed

It is very important that the first layer of the print is firmly attached to the printer bed so that all other layers use it as a foundation. If the first layer does not adhere to the platform, problems will arise later. There are many different ways to solve this misunderstanding, so we will only point out the most typical causes and explain how to eliminate them.

If the first layer does not adhere to the platform, problems will arise later. There are many different ways to solve this misunderstanding, so we will only point out the most typical causes and explain how to eliminate them.

Print platform not level

Many printers allow you to adjust the print platform using a few screws or knobs. If this is your case and you are having problems with the first layer sticking, the very first thing to do is to make sure your build platform is level and not skewed. If skew occurs, one side of the platform may be too close to the nozzle while the other is too far away. To get the best possible first layer, the print platform should be adjusted accordingly. Most 3D printing software has a setup wizard that guides you through the platform leveling steps. You can usually find it, the Bed Leveling Wizard, somewhere in the Tools menu.

Nozzle starts too far from platform

After you have properly leveled the platform, you must also make sure that the nozzle starts at the correct height from the platform. Your task is to position the extruder at the ideal distance from the print platform: not too far and not too close. In order for the printed object to better adhere to the platform, it is useful that the filament is slightly pressed into it. Of course, you can configure everything directly on the printer, but, as a rule, it is much easier (and much more accurate!) This is done through the program. You can usually find the relevant options in a menu like Edit Process Settings → G-Code. There you can set the global value for the offset of the G-Code along the Z axis, adjusting it extremely accurately. For example, if you set this offset to -0.05mm, the nozzle will print 0.05mm closer to the platform. Do not overdo it, set only very small offsets. Each layer of your object is typically around 0.2mm thick, so "small" offsets should be understood at that scale.

Your task is to position the extruder at the ideal distance from the print platform: not too far and not too close. In order for the printed object to better adhere to the platform, it is useful that the filament is slightly pressed into it. Of course, you can configure everything directly on the printer, but, as a rule, it is much easier (and much more accurate!) This is done through the program. You can usually find the relevant options in a menu like Edit Process Settings → G-Code. There you can set the global value for the offset of the G-Code along the Z axis, adjusting it extremely accurately. For example, if you set this offset to -0.05mm, the nozzle will print 0.05mm closer to the platform. Do not overdo it, set only very small offsets. Each layer of your object is typically around 0.2mm thick, so "small" offsets should be understood at that scale.

The first layer prints out too fast

When you print the first layer of plastic onto the platform, you want this first layer to be well attached to the surface before the second layer is laid on it. If you print the first layer too quickly, the plastic may not have time to attach to the platform. For this reason, it is usually very useful to print the first layer at a lower speed. Most slicers have this option. You can find it approximately in the menu Edit Process Settings → First Layer Speed. For example, if you set this parameter to 50%, then the first layer will print 50% slower than the rest. If you think that this is not enough, try changing it again.

If you print the first layer too quickly, the plastic may not have time to attach to the platform. For this reason, it is usually very useful to print the first layer at a lower speed. Most slicers have this option. You can find it approximately in the menu Edit Process Settings → First Layer Speed. For example, if you set this parameter to 50%, then the first layer will print 50% slower than the rest. If you think that this is not enough, try changing it again.

Temperature or cooling settings

Plastic shrinks as it cools. For clarity, imagine that you are printing an object with ABS plastic that is 100 mm across. If an extruder is printing plastic at 230°C and the plastic is laid out on a cold platform, it will likely cool down fairly quickly when it exits the hot end. Some printers have special cooling fans to speed up this process. If an ABS object is cooled at room temperature of 30°C, a 100mm long rib will shrink by almost 1.5mm! In this case, the print platform does not suffer such linear distortions; in general, it is usually maintained at a constant temperature. Due to these circumstances, the plastic will tend to detach from the platform as it cools. And this is an important point to keep in mind when printing the first layer. If you notice that at first the layer seems to stick to the platform, but then, as it cools, it starts to lag behind, perhaps the reason is precisely in the temperature and cooling settings.

Due to these circumstances, the plastic will tend to detach from the platform as it cools. And this is an important point to keep in mind when printing the first layer. If you notice that at first the layer seems to stick to the platform, but then, as it cools, it starts to lag behind, perhaps the reason is precisely in the temperature and cooling settings.

Many printers that are designed to print on materials at high temperatures (such as ABS) have a heated bed feature to help combat these problems. If the platform is heated to 110°C and maintained at this temperature throughout the printing process, this will ensure that the first layer is heated and will not shrink. So if your printer has a heated bed, you can try turning it on to keep the first layer warm. In general, keep in mind that PLA adheres well when heated to 60-70°C, while ABS works best when heated to 100-120°C. In print management programs, all this is configured. In the corresponding menu, for example, Edit Process Settings → Temperature, you need to select the required platform from the list and specify the temperature of the first layer for it. The temperature value can usually be changed by double-clicking on this parameter.

The temperature value can usually be changed by double-clicking on this parameter.

If your printer has a cooling fan, you can try turning it off while printing the first few layers so they don't cool too quickly. This is also usually found in the Edit Process Settings menu, under the Cooling tab. Here you can set the fan speed for the selected levels. For example, you might want the first layer to print with the fan turned off, but to turn on full power when the fifth layer is reached. Then you will need to set two labels in the corresponding list. Layer 1 is at 0% fan speed, layer 5 is at 100% fan speed. If you are using ABS plastic, then the fan is usually turned off for the duration of the print, so one mark (layer 1 - 0%) will be enough. If you are working in very windy conditions for some reason, you may also need to protect the printer from the wind. When printing bridges and overhanging elements with ABS, it is better to turn on the cooling, so the plastic will cool and harden faster.

Print bed surface (tape, adhesive, other materials)

Different plastics adhere differently to different coatings. Therefore, many printers come with special materials that are proposed to cover the platform for printing. For example, some printers come with a FIXPAD sheet - to which PLA, ABS, HIPS, SBS adhere very well. Other manufacturers offer special self-adhesive films for the 3D printer table. If you're going to be printing directly onto these surfaces, it's always a good idea to make sure they're free of dust, grease, or oil before you start. It is enough to rinse them with water or isopropyl alcohol - and the effect will be very noticeable.

If your printer does not have this special material to increase adhesion to the print platform, you still have a lot of options! There are many different types of tapes to which common 3D printing plastics adhere well. Strips of these tapes are simply glued onto the platform, and then easily removed or replaced as needed if you want to print with other materials. For example, PLA adheres pretty well to blue masking tape, and ABS loves Kapton, which is also known as polyamide film. Many users have had great success working with temporary glue or sprays applied to the platform. It can be hairspray, glue stick, or more tricky sticky substances that will solve the problem if nothing else helps. Just experiment and find what works best for you.

For example, PLA adheres pretty well to blue masking tape, and ABS loves Kapton, which is also known as polyamide film. Many users have had great success working with temporary glue or sprays applied to the platform. It can be hairspray, glue stick, or more tricky sticky substances that will solve the problem if nothing else helps. Just experiment and find what works best for you.

If all else fails, use margins: raft (raft) or brim (brim)

Sometimes you need to print a very small object, the surface of which is simply too tiny to stick to the platform. 3D printing programs often have settings that allow this surface to be enlarged so that there is something to stick to. One of these options is called brim (margins). These margins are extra circles printed around your object, so it looks like a hat with a brim. The option is enabled in the menu Additions → Use Skirt/Brim. Printing programs also sometimes offer to print a “raft” (raft) under the part, which serves the same purpose as the fields.