Chocolate extruder 3d printer

ChocoL3D Chocolate 3D Printer Extruder Review – Maker Hacks

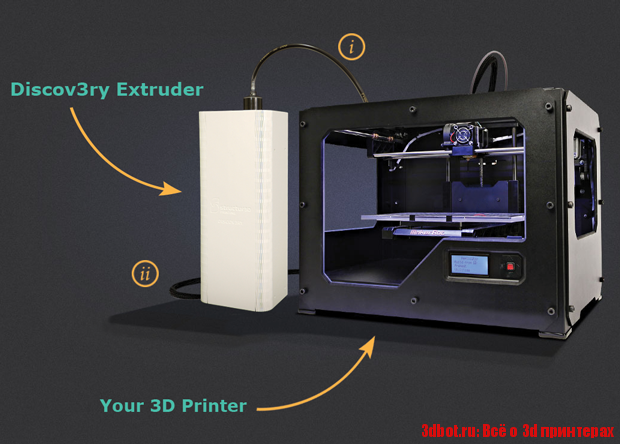

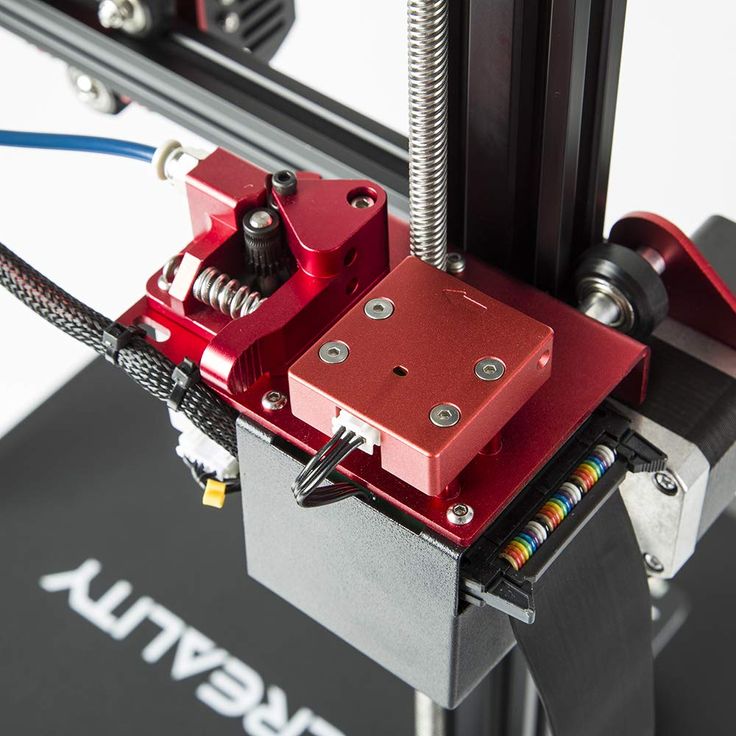

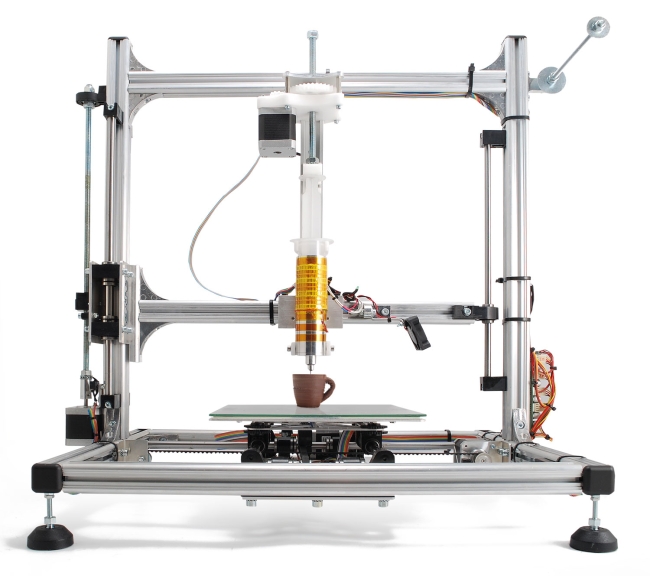

If you are anything like me you’ve thought about what other materials you can 3D print and one of those materials that comes to mind is chocolate. It can be melted down, and formed into amazing ideas by artists, and since it can be melted, extruded and cooled it makes sense for it to be able to be printed. ChocoL3D out of the Ukraine has taken it upon themselves to make a chocolate extruder. The ChocoL3D chocolate 3D printer extruder can be mounted on your 3D printer of choice. ChocoL3D sent me one extruder to test and review.

Unboxing

The package arrived and the box itself is a work of art, it is wooden with a slide out cover. All the components were nicely organized and packaged inside the wooden box with ribbons to help remove the items from the firm grip of the foam.

Inside the box you have the extruder components, vat, variety of nozzles, stepper motor, heater cartridge, thermistor, and screws. I planned to install this on an Ender 3 and was provide an STL from the company to print a mount.

All the components feels like they’ve been made very well with the fit and feel feeling great. From the manufacturer’s website, it says ” Extruder and tank are made from aluminium and plated with titanium nitride (TiN) to prevent oxidation and ensure food safety. Gears are made in Polyoxymethylene (POM).”. The nozzles are made of stainless steel.

Assembly

Assembly was fairly straight forward if you’ve ever taken apart your printer, or installed a different hot end or extruder. With the old hot end and extruder assembly removed and unplugged from the control board I installed the adapter that was provided by ChocoL3D onto the X carriage. They provide a variety adapters for different printers on their website support page. I then followed their assembly instructions to complete the hardware installation.

I connected the heater cartridge and thermistor to the Ender-3 control board and moved the existing extruder stepper motor cable over to the new chocolate extruder stepper motor. Mechanically I was ready.

Mechanically I was ready.

Slicing for Chocolate

Slicer settings for chocolate as a material will be fairly different and luckily they have a setup tutorial video on their website. I was able to make the adjustments needed in Simplify3D by watching their video as I do not use Cura.

Chocolate

The other complex piece to printing chocolate is the chocolate itself. There is a difference in what ChocoL3D calls natural and unnatural chocolate. There are cacao fats in natural chocolate, and vegetable fats, such as palm oil in glazes or unnatural chocolate as per ChocoL3D. I saw another review on YouTube with the reviewer having more success with unnatural chocolate so I went ahead and found some chocolate chips, based on palm oil, for $7 Kg on Amazon.

Printing

I watched the videos, bought the chocolate, and setup the slicer and it was time to start printing. I started with a mustache and while it did print it needed some tuning. The top layer left something to be desired. That being said, failures aren’t always failures when printing with chocolate. This “failed” mustache tasted just fine 🙂 .

The top layer left something to be desired. That being said, failures aren’t always failures when printing with chocolate. This “failed” mustache tasted just fine 🙂 .

Next I tried this hammer. I increased the flow a little bit. and I was really happy with the result. My daughter certainly enjoyed eating it.

I followed up with a variety of prints trying different settings. On simple bulky shapes like the hammer things were pretty good. I did have trouble with more complex prints, generally relating to cooling of the chocolate.

The chocolate bunny ears just didn’t seem to cool enough even with really slow layer times to allow it to cool more. Same applied with the unicorn, and top of the emoji (with edible supports!). I was playing with slowing down the layers on short layers and you can see a big difference on the following vase. The first was my initial settings, and the second was extending the layer length time in S3D.

I did print a blower fan duct and added a fan but I got mixed results. Sometimes the fan itself seemed to cool the nozzle to much and clog it. Since we are printing at a temperature of 37C for this chocolate, it doesn’t take much for a fan to cool the nozzle too much and solidify the chocolate. I ended up turning the fan off again just to complete a print and make sure everything else was working as required for this attempt at a chocolate lightsaber:

A couple more completed prints:

Final Thoughts

Using my 3D printer to print edible chocolate has been a really cool exercise. It is not as easy as printing with normal filament and with the community for this not being very large, you are in relatively uncharted waters. Luckily, ChocoL3D was really responsive to me on Facebook anytime I had a question. It needs some fine tuning to get there but some of the prints that ChocoL3D showcase on their website really show how capable this extruder is.

I think that this type of extrusion system is well made and worth it for someone who doesn’t mind tinkering and really wants to print in chocolate. At between $250-$350 USD, depending on wait times, for the ChocoL3D chocolate 3d printer extruder kit alone, it’s not a cheap system, however it truly does feel like a quality product made in small batches. I plan to continue to use this extruder and see how far I can take it. The print I’ve given to friends and family have truly been some conversation starters…

A chocolate extruder for your 3D printer

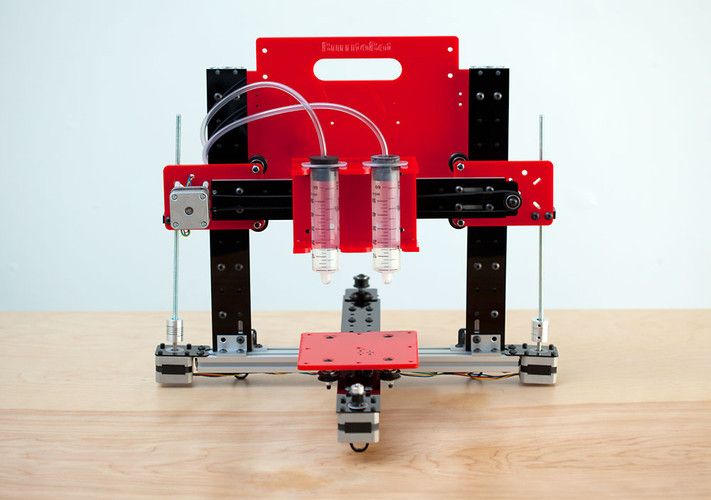

Cakewalk 3d is the kit that turns a personal 3D printer into a food 3D printer. For chocolate lovers, we explain how to do it step by step!

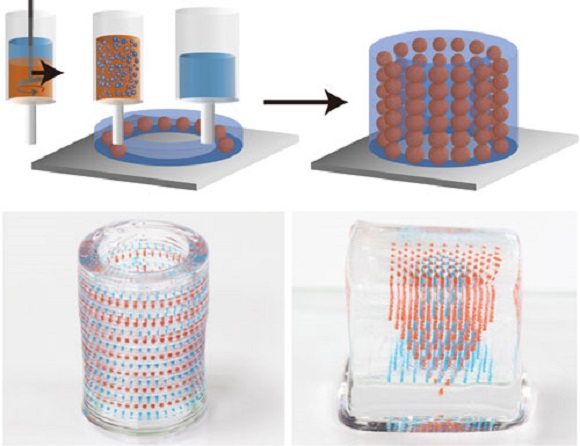

No one knows how difficult it is to become a master chocolatier and master the art of pastry making. Just try making chocolate designs on cakes. You have probably realized how difficult it is to make precise and complex designs. To remedy this, Digital Pastry has developed a kit extruder that allows you to extrude chocolate with your 3D printer. The principle is simple, you install the extruder kit on your 3D printer and then you put the material in it and launch your printing.

The principle is simple, you install the extruder kit on your 3D printer and then you put the material in it and launch your printing.

How to use the Chocolate extruder?

First of all, you have to prepare your 3D printer as you would for a plastic print. Obviously, to print chocolate you need to use the Cakewalk 3d. Install the device on your 3D printer and let your imagination and your greed express itself!

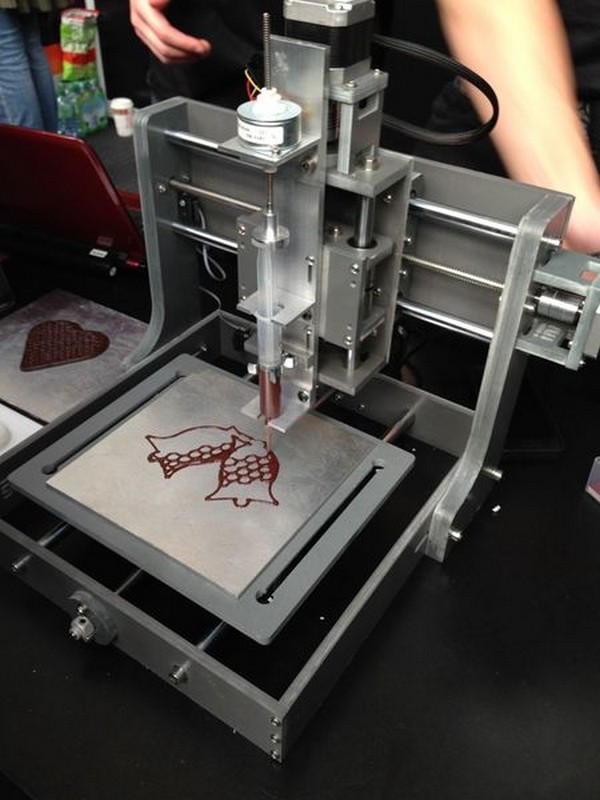

Example of 3d printing with dark chocolateCakewalk 3d Kit Components

- One 17 x 5.5 cm aluminium cylinder

- worm screw

- top sealing cap

- cone in which the nozzle is fixed

- 1 mm nozzle in food grade stainless steel

As an option you can also purchase an additional kit that contains the mechanical parts for easy assembly:

- Nema 17 engine

- coupler

- flange bearing

- the necessary screws and bolts for the assembly

On your side, you must make some parts on your 3D printer (prints without support).

- a 27×300mm support piece which is also the backbone of the whole extrusion unit

- rings for holding the cartridge made up of the elements of the kit

We offer an optional heat mat that we recommend you use to maintain the temperature of the chocolate.

To assemble the Cakewalk 3d Food Extruder go to the assembly instructions pages.

Which chocolate to use?

No need to look for a sophisticated chocolate. For example, the classic Nestlé Dessert bar works very well. However, you should avoid chocolates with chunks, you should melt the chocolate and check that the mixture is very smooth before using it. If you want to temper your chocolate before pouring it into the extruder, and you don’t know how to do it, go watch Chef Francisco Migoya’s video. Please note that it is sometimes more complex to print with tempered chocolate than with purely melted chocolate.

How to use the heated mattress?

The purpose of a heating mat is to control the temperature in the cartridge. This prevents the chocolate from solidifying during printing. The heating mat can be wedged under the holding rings thanks to its flexibility.

This prevents the chocolate from solidifying during printing. The heating mat can be wedged under the holding rings thanks to its flexibility.

To operate the heating mat connect the two wires to those controlling your fan. The temperature is set with the % of ventilation in your slicer so that it is reflected in your Gcode. For some models of 3D printers, you must connect it in place of the resistor of your plastic extruder. However, be careful never to raise the temperature above 40° Celsius, as the properties of the chocolate would change too much.

How to prepare your 3d file for the chocolate extruder?

The best thing about Cakewalk3d is the ability to model baked goods directly on your computer. Cakewalk3d allows you to make sweet and savory products with decorations and shapes that are also particularly challenging. To model your pastry in 3D, use your CAD software and then your favorite slicer. Once in the slicer, you have several choices. You can use the profiles available on our site or create your own. Also, remember to take a 3D model without a support.

Also, remember to take a 3D model without a support.

As seen previously you should not exceed 40° Celsius to print chocolate. However, you must take into account the cooling speed of the chocolate. Indeed, depositing a layer of melted chocolate (it’s hot) on a lower layer not yet solidified can deform the object. A layer should be applied only when the layer below is cool enough to support the weight of the new layer and its heat. This is best done with a relatively small amount of chocolate, using our 1 mm diameter socket.

To adjust the slicer go to the settings and set the nozzle diameter to 1mm, the layer height to 0.8mm and if necessary the temperature of the mat not exceeding 35° Celsius. As with 3D printing with plastic, it will take several tries to get the best results.

Precautions for use

It is important to note that the cooling time for chocolate 3D prints is longer than for plastic prints. The configuration parameters are obviously not the same, and depend on the shape of the object, the type and the chocolate used. Please also take into account the ambient temperature, to avoid problems with the printer.

Please also take into account the ambient temperature, to avoid problems with the printer.

Configuration files

The slicing parameters are available on this page. However, be careful, all 3D printers are slightly different from each other and it is not impossible that the settings change slightly.

The store

Our store is not open yet, but you can order a Cakewalk 3d here.

If you want to know more about how Cakewalk 3d works, please read our Frequently Asked Questions.

You may also want to see

- 3D delicacy at VivaTech 2022

Meet us at the VivaTech stand from 15 to 18 June 2022 for its sixth edition… La Pâtisserie Numérique, winner of the Fast Forward Agrifood acceleration program and of the VivaTech Innovative Challenge 2020, will be present on the booth F60 of the VivaTechnology show from 15 to 18 June 2022 in Hall 1 at […]

- La Patisserie Numerique joins Agrifood

La Patisserie Numerique joins the Fast Forward Agrifood program! We are pleased to announce that we are now one of the six young winning companies to join the Fast Forward Agrifood acceleration program! Dedicated to innovative start-ups in the agricultural and agri-food sectors in the Normandy region, the Fast Forward Agrifood program offers winning companies […]

- 3d Printing + delicacy : join us, we’re hiring!

New hiring in sight! If you’re a foodie and a pro at additive manufacturing, then we’ll tell you about the great profiles we’re looking for and how to join us.

At the Digital Patisserie, we like to work as a team and pool our skills. Indeed, our ambition is to revolutionize gastronomy with digital manufacturing […]

At the Digital Patisserie, we like to work as a team and pool our skills. Indeed, our ambition is to revolutionize gastronomy with digital manufacturing […] - How can 3D food printing impact the food industry?

Is 3D food printing a utopia? Will 3D printers be in our kitchens tomorrow? It is rather the first step, but they are already a reality. Projects led by recognized scientists and other enthusiasts have already seen the light of day and the results are amazing. Let’s take stock of what’s really happening… The road […]

- Special offer: The Mutant™ with our partner’s WhamBam

The Mutant™: adapter for Cakewalk 3d The MUTANT™ is The Universal Tool Swapping System. It allows you to transform your FDM printer into so much more! The MUTANT™ gives you the ability to change your hot end on the fly, mount various hot ends, and other tools such as: laser cutters, pen plotters, food plungers, […]

Meet the chocolate extruder. Review

Reviews

Subscribe to the author

Subscribe

Don't want

82

Greetings to all fans of fdm technology. The time has come when I nevertheless decided to open some of the technical information on the extruder for printing with chocolate.

The time has come when I nevertheless decided to open some of the technical information on the extruder for printing with chocolate.

But first, a little background:

The first time I heard about 3D printers was in 2013 and I immediately got excited about buying it. But after analyzing their capabilities and comparing them with the price of these devices, I realized that it’s not worth buying yet. The second reason was the lack of free time, because I worked as a manager of a Japanese construction equipment repair company (excavators, loaders, rollers, amphibians, etc...). The main work occupied almost all of my time because, firstly, it was interesting to me, and secondly, even now in the public domain it is not possible to find sufficient necessary literature and information for a full-fledged study. In this regard, I had to independently seek out information, by trial and error to learn complex mechanical and hydraulic circuits and devices.

In March 2017, I realized that the flow of new information had stopped (I learned everything I needed to work, but there were no new techniques and new tasks). And since I learned everything, it became not interesting to perform the same actions. There were no growth prospects for 2017 in the company, and that is why I left my job in search of new knowledge and aspirations.

And since I learned everything, it became not interesting to perform the same actions. There were no growth prospects for 2017 in the company, and that is why I left my job in search of new knowledge and aspirations.

After leaving work, I decided that everything needed to be changed globally, and not locally, and taking my family, I moved from Kharkov to Odessa.

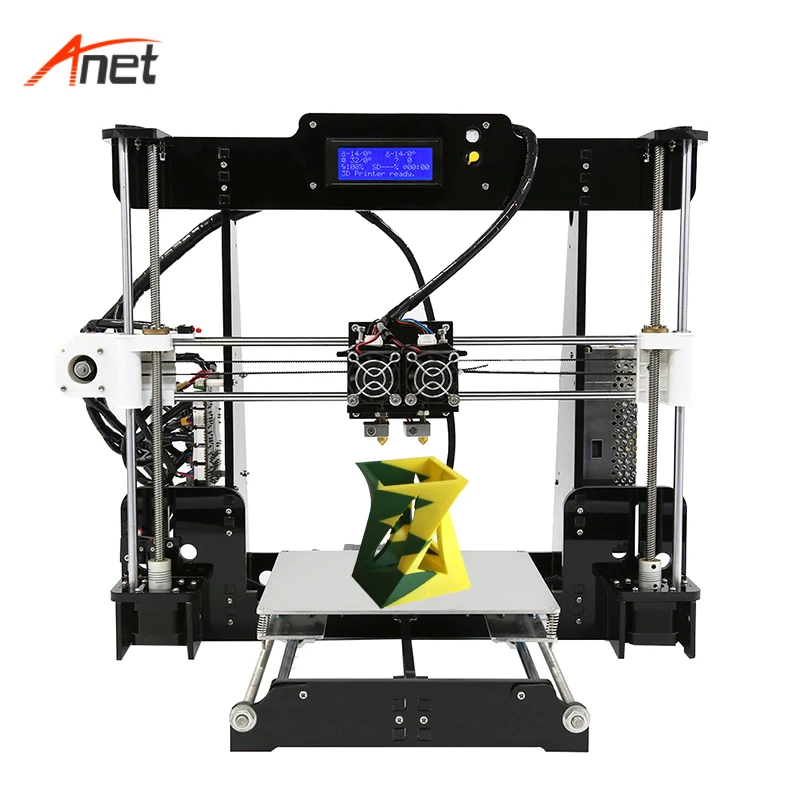

And then, by chance, almost a neighbor was selling his Anet A8 for ridiculous money. He bought it, but could not give the fret. Naturally, I bought a printer from him and dealt with 3D printing with plastic. I printed more with ABS and even managed to find clients for various details of scenery for quest rooms and similar things. Having studied your printer inside and out again, it's time to move on.

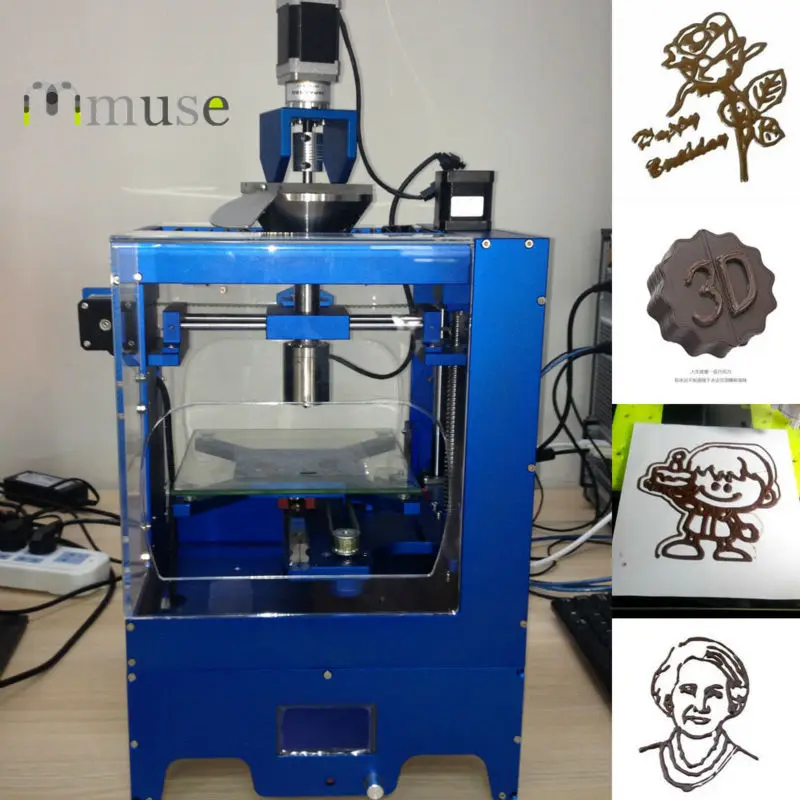

Having studied the field of fdm technologies, I liked the idea of printing with chocolate. I even thought of opening a cafe with 3D printed chocolate figures. But the concept should be simple and fast - a person comes, places an order and receives a finished product in a maximum of 20 minutes. For example, a child can order his favorite cartoon character, or just the name of the one or the one with whom he came. Well, everything in this spirit.

For example, a child can order his favorite cartoon character, or just the name of the one or the one with whom he came. Well, everything in this spirit.

I figured out the money only for 3D printers (which cost from $ 2k) is not weak. They don't give you that kind of speed. As a result, I decided to make my own extruder for printing chocolate, the main criterion of which should be the superiority of those already on the market in: price, print speed, simplicity, print resolution.

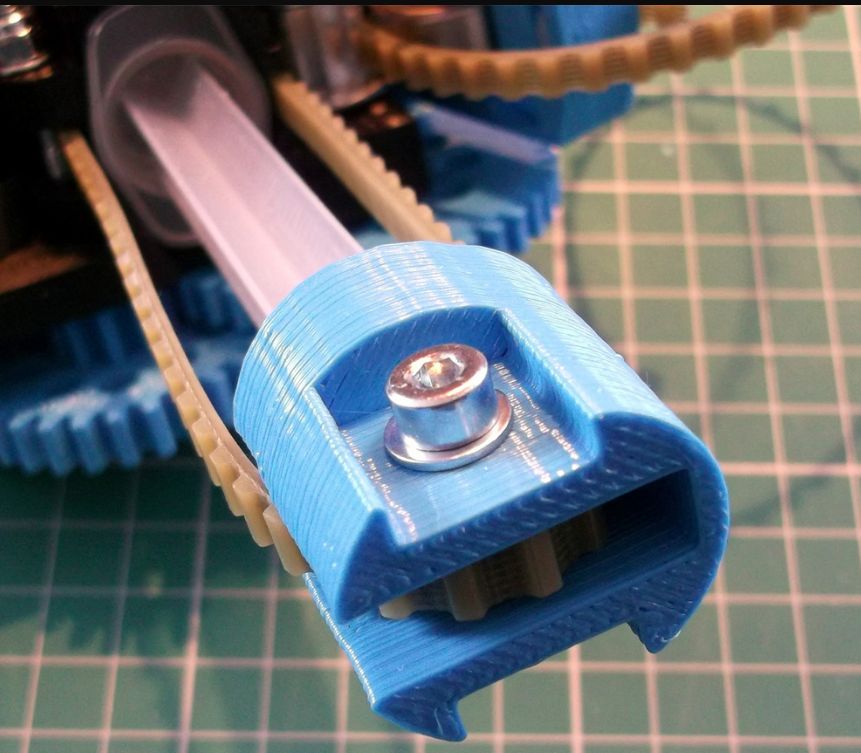

This is where the experience and knowledge gained in my last job came in handy. The extruder was based on a gear-type pump. Nothing is given to us in this life just like that))

The first drawings and sketches appeared in October 2017.

The first test model was assembled in December of the same year.

This was followed by a number of modifications, and as a result, the nth version is now in production, which, as I think, can be brought to the market.

Now a few words about the extruder itself:

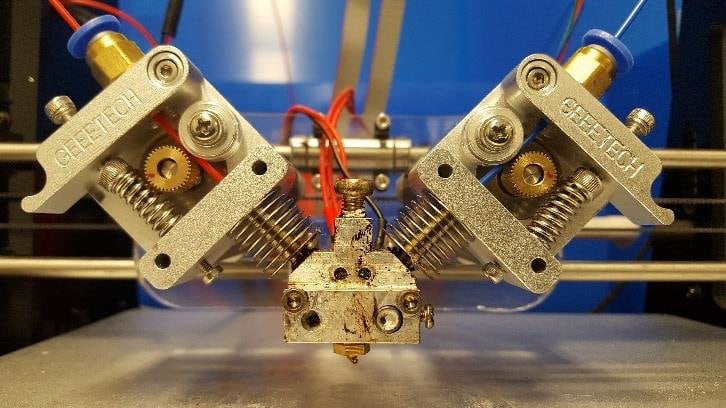

Here are the main components of my extruder. He received the name ChocoL3D.

He received the name ChocoL3D.

Here's a 3D video of assembly and disassembly:

How it works:

Body made of aluminum with Teflon coating. Aluminum itself is a food grade alloy, especially at temperatures below 40 degrees Celsius. But the final version (which is currently in production will be Teflon coated.)

Aluminum is a good conductor of heat, so the heater is placed in the case, and the glass of chocolate is heated passively and the temperature is distributed evenly. Also, during the printing process, solid chocolate is loaded into the glass and melts there on its own. There is no need to first melt the chocolate and then load it into the extruder.

The stepper motor drives the drive gear, which in turn drives the driven gear and the chocolate mass is forced into the outlet nozzle.

It's simple.

I post examples of work on the social network and ask those who are interested to subscribe

- Youtube - https://www.youtube.com/channel/UCBQSM-Y81Q-nBuJgoYlmAFQ

- Instagram - https://www.instagram. com/chocol3d/

- Vkontakte - https://vk.com/chocol3d

- We are also working on the site - https://twinshadoww.wixsite.com/chocol3d

The approximate cost of a fully finished kit cost around $ 350

Unfortunately, at the moment I do not have the funds to produce a batch and sell finished devices . But I am ready to discuss all questions in private messages or by mail. Write.

Happy printing everyone!

Well, a couple of examples of work.

*all made of chocolate icing

Subscribe to the author

Subscribe

Don't want

82

More interesting articles

nemoi13

Loading

03. 10.2022

10.2022

1648

6

Subscribe author

Subscribe

Don't want

The Anet ET4 Pro is a 3D printer that I definitely wouldn't recommend to beginners. Before he started p...

Read more

four

Subscribe author

Subscribe

Don't want

This year, Raise3D released the MetalFuse metal 3D printing system, consisting of a 3D printer...

Read more

nk.xcfg

Loading

05/10/2016

38210

117

Subscribe to the author

Subscribe

Don't want

“A good tester doesn't even launch the app. ” (heard at work) Based on real...

” (heard at work) Based on real...

Read more

3D food printer from Moscow scientists prints chocolate, cakes and even nuggets

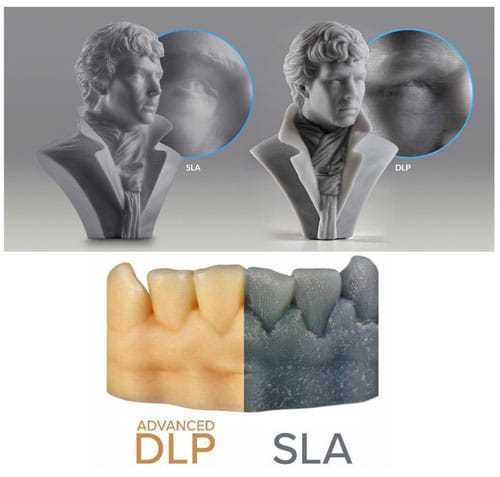

A 3D food printer with a system of "smart" recipes that prints food products with specified properties was created by scientists from the Moscow State University of Food Production (MGUPP). The new device consists of 99% domestic components and can be used to design vending machines that print products according to the client's order. The 3D printer already prints with dough and chocolate, and in the future it will be able to produce even meat products - nuggets, for example, have already been successfully obtained.

chocolate chess

One of the goals of developing a 3D food printer was to create food rich in vitamins, micronutrients and antioxidants that would be a healthy alternative to traditional meals.

“Today, many are deficient in nutrients and micronutrients that can be replenished with elements in chemical form, but eating foods fortified with them contributes to better absorption. The main goal of creating a food printer was the ability to produce personalized functional products using a system of “smart” recipes, which will be like instructions for the printer,” says Aleksey Kuchumov, Vice-Rector for Research and Development of MGUPP.

The main goal of creating a food printer was the ability to produce personalized functional products using a system of “smart” recipes, which will be like instructions for the printer,” says Aleksey Kuchumov, Vice-Rector for Research and Development of MGUPP.

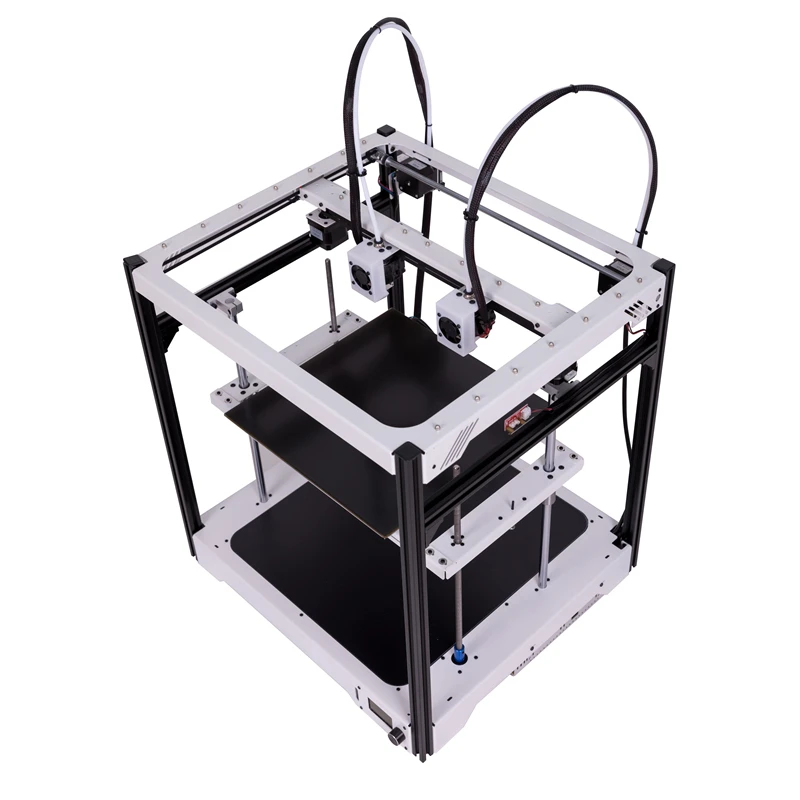

The main difference between the development of MGUPP scientists and existing 3D printers is the units modified for the tasks of the food industry. The unique technology allows you to take a device for printing with plastic and upgrade it for printing with food raw materials.

“We made one unique extruder (a nozzle through which the raw material exits) of a revolving type. Inside it is a drum into which various raw materials are fed, which allows you to speed up the production process and use fewer parts. This is also our innovation - the use of one powerful drum extruder, into which various raw materials are fed under different pressures and temperatures, ”notes Alexey Kuchumov.

The development of MGUPP scientists allows you to make a 3D printer of any size and for any task, as well as increase the print area to one and a half meters, which is 1. 2 meters more than existing analogues.

2 meters more than existing analogues.

3D printer

In addition, the new device provides the ability to produce artificial meat using bioprinting technology. At the same time, the printer performs the function of a freezer - a refrigerator, and with different setting temperatures. It is designed in such a way that the necessary climatic environment will be formed for each type of raw material: its own temperature, its own humidity, etc. Among other things, a laboratory for the production of “cultured” meat is being opened together with 3D Bioprinting Solutions.

“The bioprinter prints a special plant-based substrate, on which live cells taken painlessly from animals are applied. This device prints according to a given digital model, using special nozzles - devices that allow you to print both cellular material and plant fibers. Such meat can be called “ethical”, and it will be in demand on the market,” comments Alexey Kuchumov.