Why 3d printing is overhyped

Is 3D Printing Overhyped? What You Need To Know – Printing It 3D

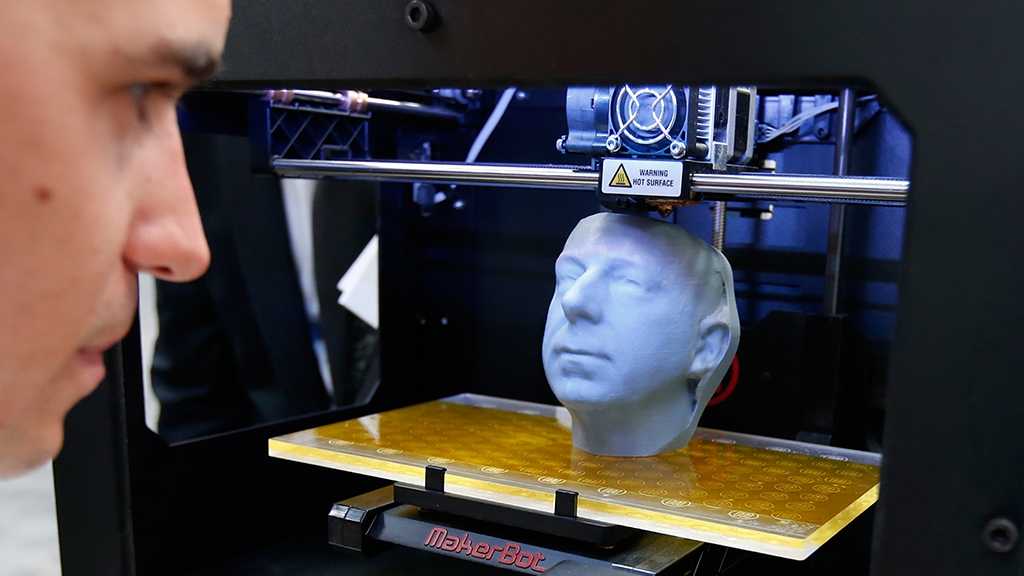

3D printing was introduced in the mid-1980s, but it became popular in 2010 when small 3D printers were first manufactured for home use. At the time, 3D printing was expected to be a revolution. People would start printing whatever they needed, making the 3D printer a must-have item in the home.

3D printing was overhyped because the original printers were too slow and expensive for the average consumer. They also had limitations on the shapes and items they could make. This led many to believe that 3D printing was sold as a revolution prematurely.

The prospect of 3D printing raised people’s expectations, and unfortunately, it turned out to be a disappointment. However, considering the advancement in technology and success of some 3D printers, you’ll understand why manufacturers have integrated 3D printing for easy and faster prototyping. Keep reading to learn more about how the 3D printing industry was overhyped.

What Aspects of 3D Printing Were Overhyped?

When 3D printers were made available in small sizes, the manufacturers compared them to microwaves and other household appliances. Buyers were made to believe that the 3D printer would disrupt manufacturing since people could make whatever they needed from their homes. It was not to be.

Usability and simplicity are aspects of 3D printing that were overhyped. Unfortunately, the application process is much more complex, and consumers need basic knowledge in 3D modeling and printer setup. They also need to know the best material to use and understand G-code.

The cheapest 3D printers have a steep learning curve. What’s seen as marketing hype is a shortcoming in the technology and the oversimplification of the printer, which made it harder to operate. Undoubtedly, 3D printing will eventually overcome its shortcomings.

Has 3D Printing Lived Up to Its Expectations?

Although 3D printing has faced some hiccups, it has been taken up by some of the large manufacturing industry players because they have seen its benefits. Once you forget the ups and downs of the 3D hype, you’ll find that the technology is very helpful.

Once you forget the ups and downs of the 3D hype, you’ll find that the technology is very helpful.

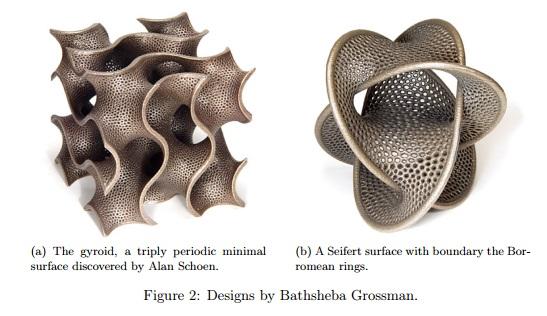

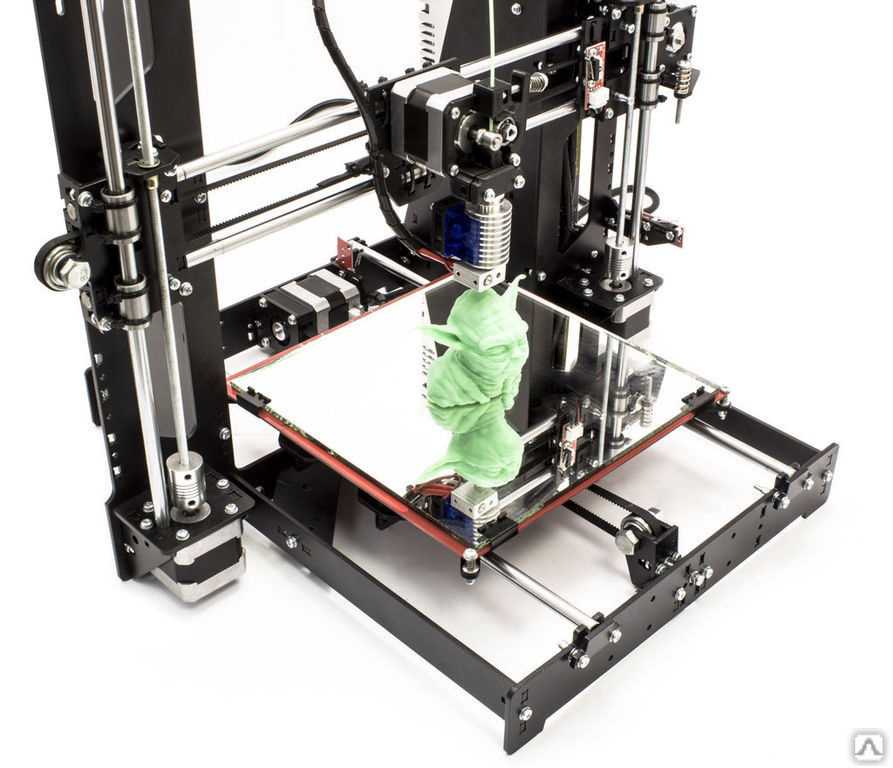

3D printing has lived up to its expectations since it has made prototyping easy. Most companies have introduced 3D printing in their manufacturing process, and prototyping is now done in-house and at a cheaper rate. 3D printers also print unique shapes traditionally created using many small pieces.

Industrial 3D printing has certainly lived up to its expectations and even surpassed them. Companies like General Motors have invested heavily in 3D printing and significantly dropped their production costs. 3D printers for home use may still have a long way to go, but people who have mastered the art of 3D printing know that with the right printer and knowledge, 3D printing has lived up to the hype.

To learn more about the hype behind 3D printing, check out this YouTube video:

Advantages of 3D Printing

3D printing has several advantages, which back the belief that 3D printing is revolutionary. It may not have been a disappointment in many ways, but there’s no doubt, 3D printing has its advantages. These are:

- 3D printing helps bad ideas fail much faster. Instead of mass-producing a product only to discover the market isn’t enthusiastic about it, most companies have opted to create 3D models to test consumer response. This saves on cost, but more importantly, bad ideas fail faster instead of failing slowly.

- 3D printing reduces human error. 3D prints have accurate dimensions, which allow the upper layers to fit accurately. This is why 3D printers can create odd, unconventional shapes and patterns, which are impossible to manufacture as one solid piece.

For example, General Electrics started using 3D printed fuel nozzles for their jet engines. These nozzles were traditionally made up of 20 assembled parts. Today, the nozzle is one solid unit.

For example, General Electrics started using 3D printed fuel nozzles for their jet engines. These nozzles were traditionally made up of 20 assembled parts. Today, the nozzle is one solid unit. - It is a lifeline for businesses in isolation. Instead of waiting for the delivery of important spare parts, such businesses make what they need using the 3D printer. For example, Made In Space created gravity-independent 3D printers, which astronauts use to print whatever they need, instead of carrying spare parts to the space station.

- It saves time. 3D printing has made it easier for companies to build prototypes within a short time and determine if the design is to be changed or not.

- 3D printing enables printing on demand. Instead of stocking items that occupy space but are rarely used, 3D printing allows manufacturers to print what they need when they need it.

- 3D printing is accessible.

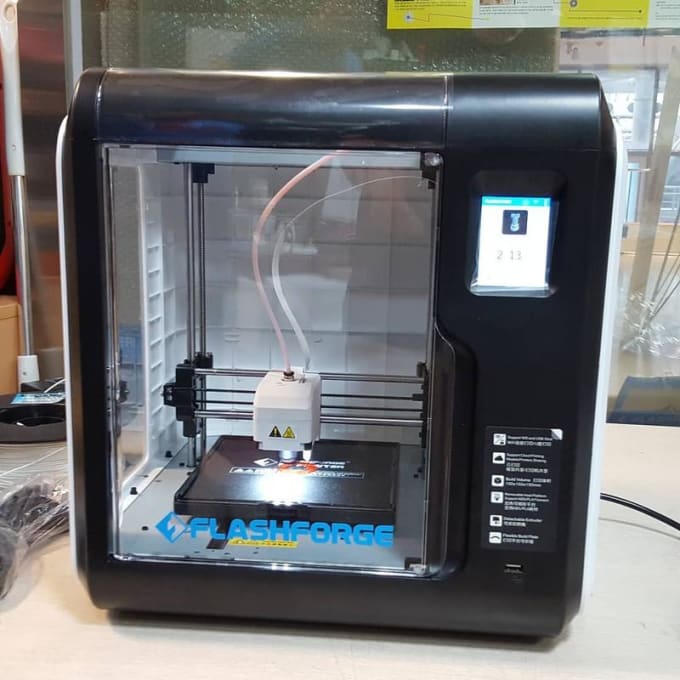

3D printers are more readily available. There are different types of printers, each with unique features to meet the range of demands in 3D printing.

3D printers are more readily available. There are different types of printers, each with unique features to meet the range of demands in 3D printing.

Challenges of 3D Printing

3D printing has its fair share of challenges, and some people have used these shortcomings to disregard 3D printing. Some of the challenges of 3D printing are:

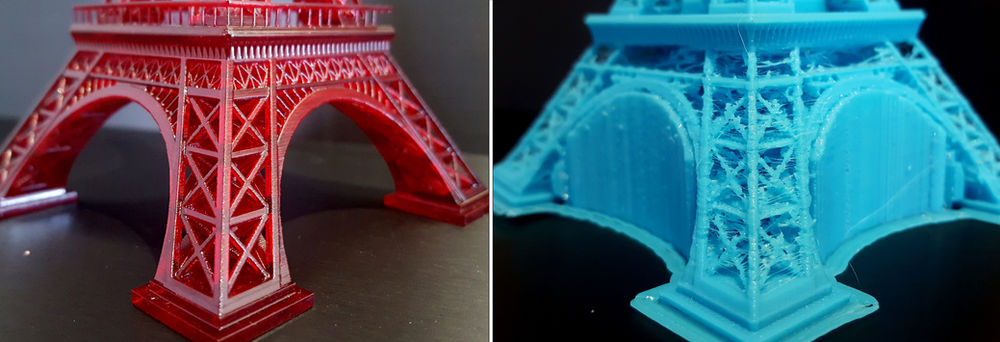

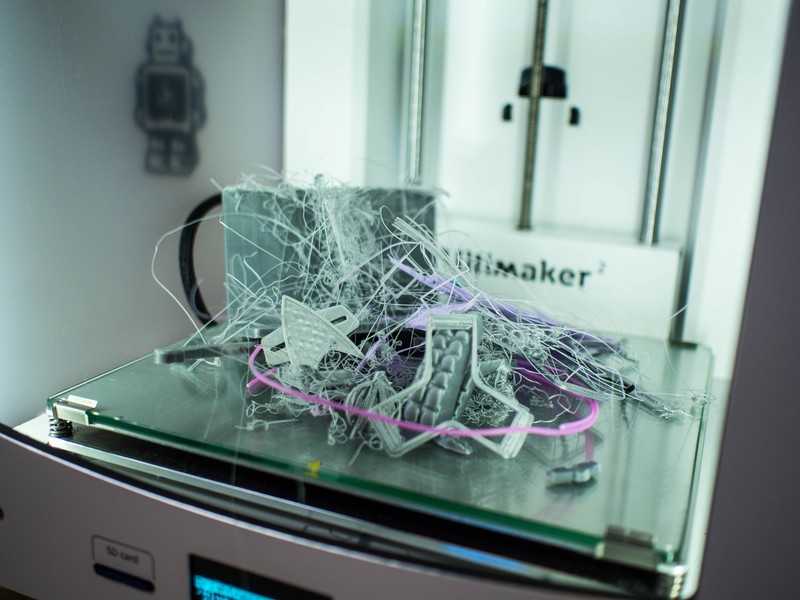

- It’s slow. Printing a small model can take hours. Speeding the printer causes it to start stringing, so you have no choice but to let it work slowly, hopefully with positive results.

- It has limited material. You don’t have much choice in the material you use. Some printers use filaments of a specific diameter, so you have no choice but to use that. Some filaments are used on specific 3D printers because they require the hot end and the bed to be set at a specific temperature. This limits creativity.

- 3D printing is unregulated. Globally, regulators impose conditions for testing parts, especially aerospace and automobile industries.

Unfortunately, there’s no established mechanism to test 3D printed items.

Unfortunately, there’s no established mechanism to test 3D printed items. - The design requires special software. Unfortunately, you can’t just go to your 3D printer, click a button, and then it starts printing. You need to have software which you’ll use to create a design before printing. This is a little difficult for beginners and even seasoned professionals in 3D printing, who sometimes encounter challenges when using the software.

Conclusion

3D printing may appear to have been overhyped, but it’s also possible that it hasn’t reached its potential. It took half a century for computers to go mainstream. The 3D printing technology has been revolutionary in many ways, and once perfected, will meet the high standards imposed on it a decade ago.

3D Printers are Overrated | Machine Design

You know when a product comes out and we think it’s awesome? Then years later, something comes out to replace it, and we look back at the first thing like, “What a pile. ” Well, I’m almost to that point vis-à-vis 3D printers, even though there’s nothing to replace them.

” Well, I’m almost to that point vis-à-vis 3D printers, even though there’s nothing to replace them.

You’re probably groaning by now, but hear me out. Yes, prices for the maker/desktop/DIY category of machines have dropped, the quality of their output has increased, and promotional materials abound with printers creating beautiful and delicate objets d’art.

But like the movie montage where the kids clean up the house before their parents get home, they are glossing over the details. What isn’t shown is the effort, the sweat, the tinkering, the trial and error, and the screaming to the gods themselves to please, please let it work this time.

3D printers may be great, but do they really live up to the hype?

Let’s address the obstacles that keep these devices from truly being the miracle that people have been gushing about for the last 15 years or so.

Warping. 3D printers are extremely sensitive to temperature and temperature changes. Anyone who has any experience at all with them is familiar with this. This goes doubly so for users of unenclosed printers. If you don’t know what I’m talking about, go start a print and then halfway through, swing the closest door wide open. Successful prints shouldn’t be so sensitive.

Anyone who has any experience at all with them is familiar with this. This goes doubly so for users of unenclosed printers. If you don’t know what I’m talking about, go start a print and then halfway through, swing the closest door wide open. Successful prints shouldn’t be so sensitive.

Porosity. 3D-printed parts are full of tiny holes. Even when you print with a 100% fill, it will leak. This prevents 3D-printed parts from being used in a vast range of applications.

Prints not sticking to the bed. Hairspray and masking tape are far from ideal solutions. Reapplying treatments or specialty surfaces is too much like inking the letters on a manual printing press. There is no equivalent operation necessary before you print out your great aunt’s Bundt cake recipe on your inkjet. I don’t think we should have to do that with our 3D printers, either.

Masking tape and hairspray. Ad-hoc solutions to a problem that shouldn’t exist.

Prints that won’t come off the bed. The reverse of the previous issue is prints that won’t unstick from the bed. We shouldn’t have to push and pry on the print to the extent that it shakes the entire machine and misaligns the bed.

Prints that won’t get out of the way for the next print. I want to set a queue and go do something else. Babysitting a printer is contrary to one of the supposed advantages of a 3D printer. We need some sort of changeover mechanism.

Printers are slow. For models of any substantial size, we’re talking really slow. We get to wait hours or sometimes days to see if the print came out correctly.

3D printing takes a long time. A really long time.

Way too manual. We need 3D printers that are at the level of at least a black-and-white laser printer. You know—you just occasionally feed it paper and toner. Of course, 3D printers aren’t even close to the same level of convenience and reliability. They’re more like MP3 players that get songs loaded onto them via Morse code. Oh, and the Morse code tapper thing costs extra.

They’re more like MP3 players that get songs loaded onto them via Morse code. Oh, and the Morse code tapper thing costs extra.

Software. A decent selection of software is available, and we’ve all seen the impressive results. The problem is that the software, if it’s user accessible, requires a lot of tuning. Adjusting variables and trying to correlate cause with effect can be maddening. Sometimes it makes you feel like the Sisyphus of 3D printing: forever working toward a goal and never reaching it.

By now many readers are probably bursting with indignation. They can point to a slew of machines that are hands off and can create very high-quality prints. Yes, those machines exist, and they can probably fulfill a lot of the demands I have made. But you know what else they are? Big and super-expensive. Truly high-quality machines are often priced out of the range of many corporate entities, so how are we—the makers and inventors of this world—supposed to get our hands on them?

Two possible exceptions are the Tiertime UP-BOX and Afinia H series of printers. These machines are the most fire-and-forget maker range printers I have seen to date. Yet good as they are, they still are far from what I think needs to be seen in the industry. Also, their software has the hood welded on, leaving very few user-accessible adjustments.

These machines are the most fire-and-forget maker range printers I have seen to date. Yet good as they are, they still are far from what I think needs to be seen in the industry. Also, their software has the hood welded on, leaving very few user-accessible adjustments.

The Afinia H800 comes with preconfigured software that yields fairly consistent and impressive results.

We don’t need nano-assembling 3D printers like the ones that the artificial intelligence Rei Toei jumped out of in William Gibson’s 1999 novel All Tomorrow’s Parties. Nor am I saying that 3D printers are useless. Quite the contrary: I love 3D printers. I own several and have been professionally tasked to use many others. It’s just that my experiences with this technology made me realize that it’s time for the lower-priced desktop machines to reach the next level in sophistication.

I look forward to the day that using these machines isn’t a hobby unto itself. We don’t need another hobby. We need a reliable tool to complement our efforts, not hinder them. All the time you spend mother henning around your 3D printer is time not spent on your projects.

We need a reliable tool to complement our efforts, not hinder them. All the time you spend mother henning around your 3D printer is time not spent on your projects.

That next level exists. It just needs to be priced right so that it is within reach of the individual. To borrow a phrase from the aforementioned William Gibson, “The future is already here—it's just not very evenly distributed.”

Advantages and disadvantages of 3D printing. All subtleties and nuances in one post

Introduction.

The invention of 3D printing has revolutionized manufacturing and product development.

3D printing, also called additive manufacturing, entails combining multiple layers of material one after the other until you create a 3D printed model.

It has become so popular among many manufacturers due to its innovative features that far outstrip those of traditional production.

However, like any other manufacturing method, 3D printing has many drawbacks.

Therefore, in this article, we will tell you about the advantages and disadvantages of 3D printing so that you can learn more about this groundbreaking technology.

Benefits of 3D printing.

The reason 3D printing has become so popular is because of its advantages over traditional manufacturing methods. Here we look at the most significant benefits of 3D printing.

This is available.

3D printers are more affordable than ever. One of the most popular Creality Ender 3 V2 models is available for just $300.

In addition to the bestseller Ender 3 V2, we have a selection of kits for building 3D printers in our catalog, and all of them amaze with their price-quality ratio.

Only 5 years ago it was impossible to buy ready-made equipment at such a low price.

3D printing is a one-step manufacturing process, so it not only saves you the cost of using different manufacturing processes and machines, but also saves you valuable time.

3D printers don't need constant supervision as they can perform certain tasks once set up; so you don't have to be around all the time.

For example, they can be left to work at night without resorting to an expensive night shift to watch them.

In addition, 3D printing saves on overall material costs by using only the material needed to produce a particular part with no or minimal wastage.

Buying 3D printing equipment can be expensive if you only need to make one part, so it may be cheaper to outsource the project to a 3D printing service company.

3D4U engineers have hands-on experience in providing custom 3D printing services. You can contact us in any convenient way and we will provide you with support, both in choosing equipment and consumables, and in printing your products.

Rapid prototyping.

Using 3D printing equipment, you can create prototypes in a couple of hours. This greatly speeds up the design process, meaning you can get parts within hours and be ready for your next project.

In addition, you can quickly and cheaply create a new prototype with each design modification, as opposed to the costly and time-consuming prototyping process with traditional methods.

Strong and lightweight parts.

Plastic is the main material used in 3D printing, although there are a number of materials available for 3D printing.

3D printing makes it possible to create complex organic shapes that are much lighter than traditionally created parts.

In the aerospace and automotive industries this is a vital factor as the use of lightweight materials helps improve fuel efficiency.

3D printed parts can be made from custom-made materials that have special characteristics such as water repellency, higher strength, and heat resistance.

Plastics such as PLA can be combined with metals or even wood for unique finishes and properties.

3D printing technology is environmentally friendly.

The use of 3D printing technology reduces the amount of waste generated during the production process.

What's more, this technology helps to improve the environment even further, as lightweight 3D printed models can make cars or planes significantly more fuel efficient.

You can 3D print with materials that are either recycled or made from plant-based organic materials.

Easy access.

The use of 3D printing equipment has increased in recent years due to greater availability.

Finding a local 3D printing service provider is now easier than ever.

3D printing has become a popular hobby due to its low cost and easy access.

Many people have integrated 3D printing into their hobbies such as games, fan art or cosplay.

For people who can't afford to buy a 3D printer, there are many so-called manufacturing facilities where sharing a 3D printer is free or inexpensive.

Manufacturers are also turning to 3D printing to save on shipping costs. With most of the traditional manufacturing methods used overseas in countries such as China, 3D printed parts can be made closer to where they are needed for fast response.

Waste reduction.

3D printing uses only the required material to make certain parts, as it is an additive manufacturing process.

This is different from traditional processing, in which huge masses of non-recyclable materials are cut to form three-dimensional parts.

The total cost of 3D printing is therefore lower because less material is used and you only pay for what you need.

Improvements in the medical sector.

3D printing has revolutionized the medical sector as it is now possible to print human body organs such as the heart, kidneys and liver.

Printing prostheses or hearing aids is no longer a novelty.

In addition, more research is being done into how 3D printing technology can further help the healthcare sector.

Print on request.

Unlike subtractive manufacturing, 3D printing technology does not take up much inventory space as parts can only be printed when ordered or needed.

Not only will you save on costs, but you will also save space as you only print in bulk when needed.

All 3D design files are stored in a virtual library, from where you can then print them with a 3D model as an STL or CAD file.

Quality and consistency.

Old production methods are usually characterized by poor design, which can lead to poor quality prototypes.

This means that the quality of the product cannot be guaranteed.

However, this is not the case when 3D printing technology is used, since the assembly of the product is carried out in a strict step-by-step process, which ensures outstanding product design and quality.

3D printing technology also allows for greater consistency than traditional manufacturing, while still producing consistently high quality parts.

This is possible because errors are detected immediately, helping to reduce the overall number of wasted materials and defective parts.

Therefore, this technology ensures that parts in a batch are not defective or incompatible when compared to other parts.

Open design and product testing.

The visual appearance of a product, either virtually or on screen, cannot be compared to the actual feel of a prototype that you can experience with 3D printing technology.

In this way, you can physically touch and feel the product prototype and check if there are any flaws in its design.

In case of an error, you can edit the CAD file and print a new version later.

A physical prototype is invaluable for demonstrating a product to clients or executives who would otherwise find it difficult to validate a product based on a 3D CAD model.

This is one of the main applications of 3D printing in the industry, and it's worth remembering that 3D printing was originally called "rapid prototyping" for this very reason!

Faster production.

Unlike traditional production methods such as CNC machining and injection molding, 3D printing is significantly faster.

This is because this technology allows you to quickly test designs and ideas, from prototype to final product.

Therefore, this allows you to spend more time in the market and attract customers before your competitors have finished producing their final products.

Endless geometry and shapes.

Conventional manufacturing methods rely on cutting and shaping techniques to create the desired shapes, which is not only difficult but also expensive.

Luckily, you won't have this problem with 3D printing technologies, and all you need is the right supports.

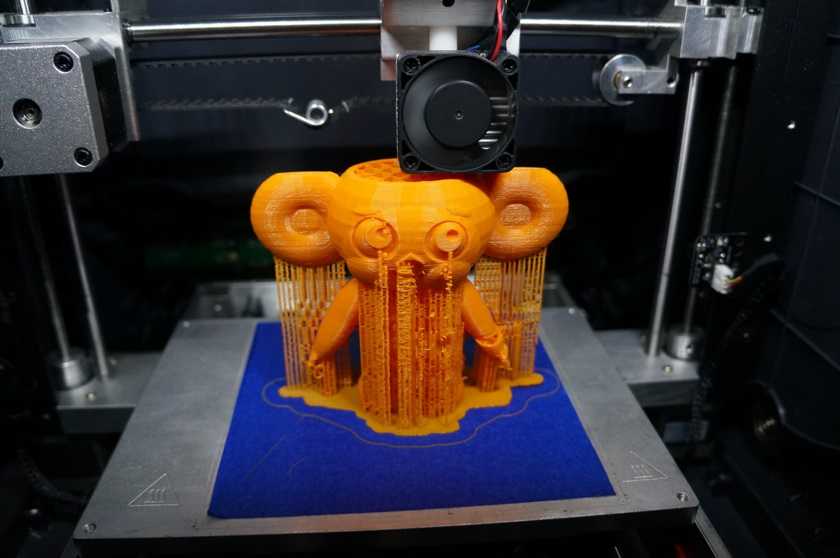

You can create supports yourself or automatically using the software.

3D printing allows you to create hollow shapes without holes, have extreme undercuts that are impossible with any other production method.

Disadvantages of 3D printing.

Of course, everything will always have its drawbacks! While there are many advantages to 3D printing, there are also disadvantages. Here are the main ones.

Limited build size.

The size of the camera built into 3D printers is usually relatively small, which limits the size of the parts you can print.

Therefore, any larger item must be printed piece by piece and then assembled after production.

This increases the time it takes to print because the 3D printer needs to print more parts before you can go ahead and manually join the parts.

The designer must decide where to place these breaks so that they do not weaken the surface and ruin the finish of the final piece.

Structure Detail.

In 3D printing, parts are usually created one layer after another, which is why it is also called additive manufacturing. This means that although the layers are firmly held together, they are susceptible to splitting when subjected to loads at certain orientations or stresses.

This is a problem that is often encountered in products created using fused deposition modeling. In addition, Multijet and Polyjet parts tend to be more fragile.

In this regard, it may be better to use injection molding in the manufacture of homogeneous parts, since they are stronger and less likely to fail when the structure is loaded.

Loss of jobs in the manufacturing sector.

The use of 3D printing allows you to create prototypes and product designs within hours with one simple step.

Most subtractive manufacturing steps are eliminated and this helps save on labor costs as fewer people need to be hired to complete the manufacturing process.

Ultimately, this leads to a reduction in manufacturing jobs, which can be especially detrimental in countries where the majority of citizens depend on low-skill jobs.

Of course, operators and manufacturers of 3D printers are required, which partially compensates for these losses.

3D printing technology is not very user friendly.

Despite the hype about the potential of 3D printing technology, using 3D printers is not as easy as you might think. Since this is a new technology, trial and error is often required when creating parts on a 3D printer.

Those with previous experience with this technology can correct this problem.

However, until 3D printing becomes widespread, it should be viewed as a technology with a potentially steep learning curve.

Limited materials.

Since 3D printing technology is a recent innovation, the materials needed in the manufacturing process are limited and some are still being developed.

The material of choice for 3D printing is plastic as it melts quickly in layers to make the final item. However, plastic is not the strongest material for all requirements and its strength varies making it not an ideal choice for certain components.

Metal 3D printing is gradually gaining momentum as a viable technology, but at the moment it is quite expensive.

Other specialized materials are also used, including gold and glass, but have yet to be commercialized.

3D printers are expensive.

Of course, we are talking about the industrial sector and industrial 3D printers. At the beginning of the article, we already mentioned that the growth in the production of desktop printers is now at its peak and anyone with an average income can afford to buy a 3D printer. Modern printers for the home are cheaper than laptops, TVs and smartphones.

Modern printers for the home are cheaper than laptops, TVs and smartphones.

Materials and equipment used in industrial 3D printing are expensive, and industrial printers cost hundreds of thousands. Since the initial capital required to use 3D printing technology is prohibitive, many people are unable to enjoy this innovative technology.

Moreover, the materials required to use 3D printing technology can be expensive compared to materials used in traditional manufacturing.

To get around these costs, many companies rent 3D printing equipment or use a third party to gain access to 3D printers from so-called 3D printing shops.

Copyright infringement.

The development of 3D printing technology has led to an increase in counterfeiting cases. This is because now anyone with access to a product blueprint can quickly copy existing products. Because of this, the number of patent infringements has increased, and it is almost impossible to identify a counterfeit product. The development of 3D printing technology has made life difficult for copyright and patent holders to protect the rights to their unique products.

The development of 3D printing technology has made life difficult for copyright and patent holders to protect the rights to their unique products.

As with other industries such as the music industry, this is likely to be an ongoing battle with many innovations and legislative changes to combat it.

Manufacture of hazardous goods.

Making explosives, weapons, knives, and other dangerous weapons is theoretically more accessible thanks to 3D printing technology. This is because it gives people access to a method of producing items in their own homes, which was previously not possible.

This has made it difficult for the relevant security authorities to determine when terrorists and criminals are manufacturing weapons. As 3D printing technology becomes cheaper and more user-friendly, the development and production of unlicensed weapons is expected to increase.

Of course, media reports of 3D printed weapons have been exaggerated, and in fact any weapon made from plastic that melts at 200°C will not be very effective.

In addition, some criminals use 3D printers to create realistic ATM card readers.

Conclusion.

After reading this article, you now know the advantages and disadvantages of 3D printing. So, with that in mind, you can understand why 3D printing has revolutionized manufacturing and gained widespread popularity all over the world.

Similarly, you are also well aware of the disadvantages of 3D printing technology.

Thus, 3D printing technology is an innovation that needs to be appreciated, being aware of its shortcomings and possible solutions.

We found out the dangers of 3D printing. The main myths about technology

Vladislav Kochkurov General Director of the Center for Additive Technologies

The first product was 3D printed in 1983 - it was a small container in the form of a bowl. Now researchers are creating aircraft engines and rockets, jewelry, food, and even houses. Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Now researchers are creating aircraft engines and rockets, jewelry, food, and even houses. Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Read Hi-Tech in

Myth No. 1. 3D printing takes place with little or no human intervention

new product. One gets the false impression that the entire cycle of additive manufacturing consists only of the operation of equipment, and a person hardly participates in this - he only turns on a 3D printer and loads a polymer, metal powder or other material into it.

But the key role in building an object is played by its 3D model. It is a map on which the finished product will be built. The quality and characteristics of the future subject depend on its detailed study. Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

In industrial production, the construction of a 3D model is carried out in AutoCAD computer-aided design systems. The design engineer, in accordance with the terms of reference and using various calculation methods, creates the geometry of the future product. Even if the 3D model already exists and does not need to be built from scratch, AutoCAD programs carry out its topological optimization - redesign for additive manufacturing.

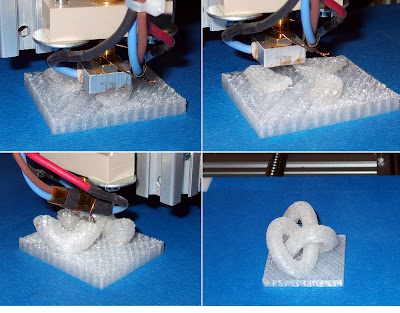

This process aims to eliminate stress raisers and thin-walled features that can cause cracks or other damage during the printing process. Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Further, based on the prepared 3D model, the printer prints on its own, sometimes working for several days in a row. But before that, the equipment needs to be prepared - make sure that the build platform is level and all the mechanisms move as they should. Even the powder in the 3D printer is not just poured, but goes through the stages of incoming control and preparation.

Another mandatory stage in the production cycle of a product, where human participation is needed, is post-processing.

Myth #2: A finished product comes out of a 3D printer

Many people think of 3D printing as it is shown in films. Robotic installations in a matter of minutes create superhero costumes and print elements of spaceships. Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

Robotic installations in a matter of minutes create superhero costumes and print elements of spaceships. Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

To relieve the internal stress that occurs during the printing process, the product undergoes alternating heating and cooling procedures. This way it achieves full mechanical properties. Then technological supports are cut off - they have already fulfilled their function. Removal of excess powder and surface treatment of the product are carried out using a sandblasting chamber. If it is necessary to achieve absolute smoothness of surfaces, then milling, turning, electrochemical and grinding machines are used. For plastic products, chemical post-treatment with acetone or other solvents is sometimes used.

Myth #3: You can 3D print anything

Innovations in the field of additive technologies appear every year and already surpass our imagination. Synthetic meat steaks, a human heart, and a whole house are already being printed. It seems that the possibilities of additive manufacturing are endless and a 3D printer can do anything. But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

Synthetic meat steaks, a human heart, and a whole house are already being printed. It seems that the possibilities of additive manufacturing are endless and a 3D printer can do anything. But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

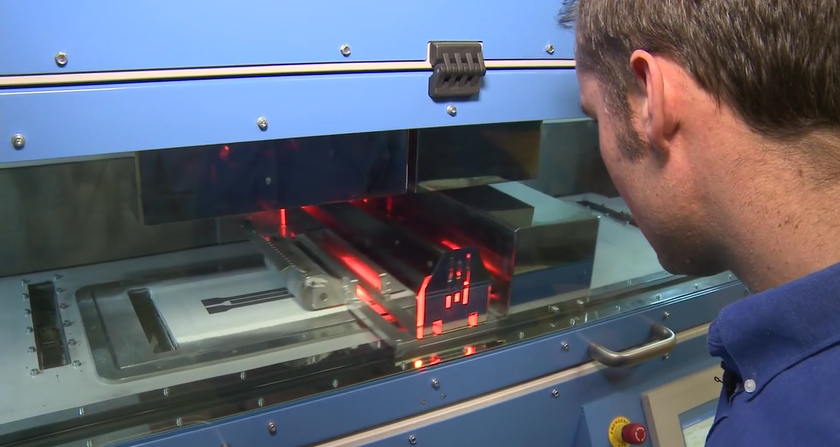

For example, the Center for Additive Technologies has an installation with a build chamber up to half a meter, the largest printer in Russia based on selective laser melting technology. Elements of Russian aircraft engines are already being “grown” there.

“Innovations in the field of additive technologies appear every year” The capabilities of polymer printers are much wider - one of them, listed in the Guinness Book of Records, can create objects up to 30 m long. In 2017, a monolithic boat was printed on it, weighing 2 tons and 7 m long. The smallest object printed on a 3D printer is a ship. Its length is 2-3 times less than the thickness of a human hair - only 30 micrometers (0. 03 mm).

03 mm).

3D printers are already used to create even at home. A construction printer works by analogy with an FDMD printer that prints plastic products, but instead of polymeric materials, cement mixtures are used as “inks”. In size, such a mechanism is much larger. The world's largest 3D printed building has an area of 641 square meters. m. and is located in the UAE.

Other limitations in additive manufacturing are not related to the size of the 3D printer's build chamber, but to the material used. During the printing process, it is in a liquid or molten state, therefore, it should melt normally. Wood, fabric, or paper objects cannot yet be printed, as they will burn before the material can be melted. Although here you can find a loophole: if you mix crushed cellulose fibers with a water-based gel, and then freeze the object, gradually removing water from it, you will get products made of a material similar to wood.

Myth No. 4. Products printed on a 3D printer are worse in quality

Visually, the 3D printing process looks like a layer-by-layer application of material. This may raise the question: how firmly are the layers interconnected?

This may raise the question: how firmly are the layers interconnected?

3D printing can cause several defects, so it is important to follow the workflow. A lot depends on the quality of the materials. In industrial production, all metal powders undergo input control, this process is regulated by standards. Even if the material is certified, it is very important to observe the conditions for proper storage: avoid moisture and dampness, place in a special package. If you do not check the condition of the nozzle, set the temperature or print speed incorrectly, misalignment of layers, overheating, or other defects may occur.

If all the conditions are met, then the product will not be inferior in properties, and often even surpass the analog made by traditional methods. If you compare two aluminum objects under a microscope, the printed product will have a denser structure.

“If all conditions are met, then the product will not be inferior in properties, and often even surpass the analog made by traditional methods” Myth No.

Learn more