Dynamism 3d printing

How The Crisis Affected Dynamism, And Other Thoughts On 3D Printing's Future « Fabbaloo

Recently I had a chance to speak with Doug Krone, the CEO of Dynamism, about the latest crisis developments.

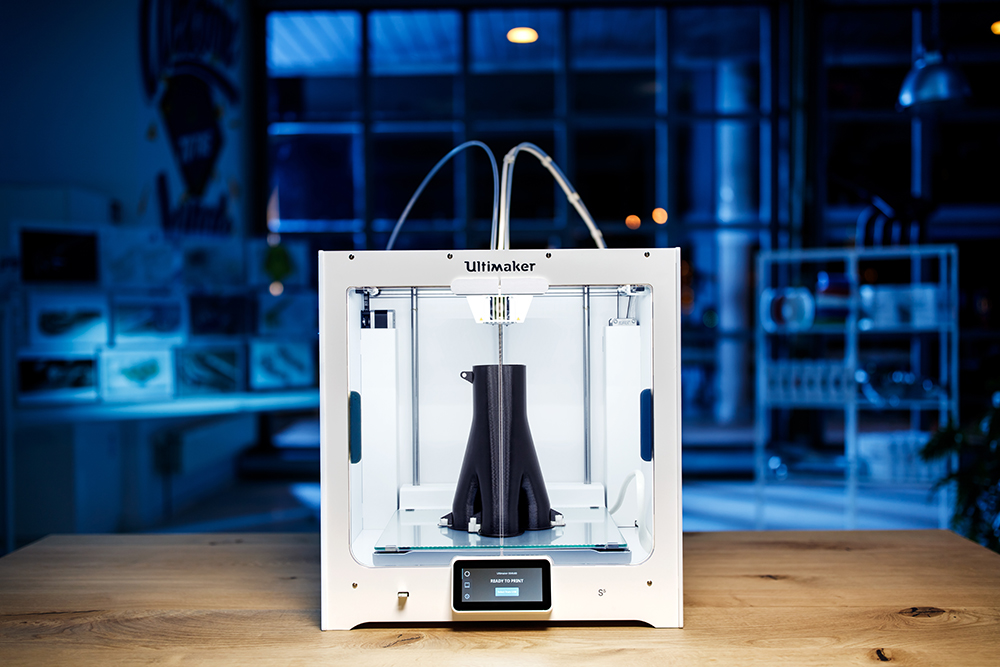

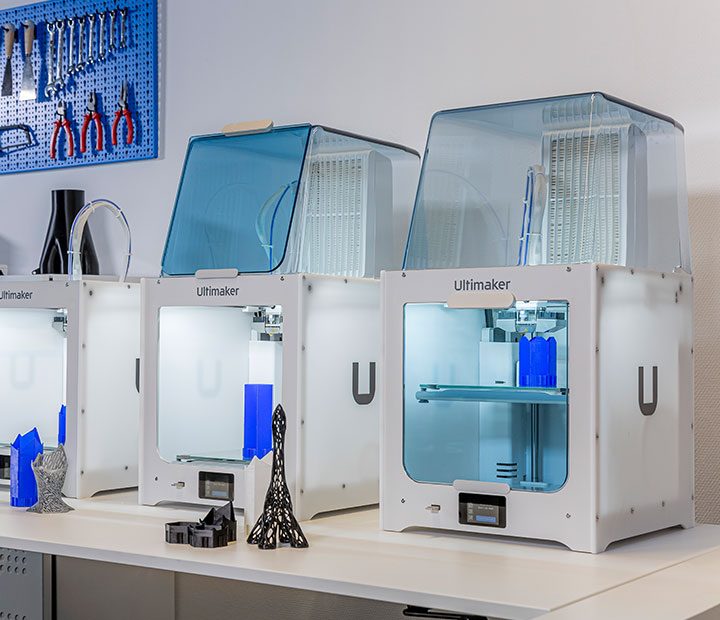

Dynamism is a Chicago-based operation that resells 3D printers, materials, 3D scanners, laser cutters, accessories and more. They focus on the professional and lighter industrial market, as they provide gear from a number of notable vendors in the space, including Ultimaker, Rize, BigRep, Desktop Metal, Raise3D, INTAMSYS and many others.

Recently we wrote of their experiment with a remote controlled virtual showroom, where they display 3D printers to the public via robot.

Speaking to me from Japan, which is an unusual location for someone whose company is based in Chicago, Krone explained the origin story of Dynamism.

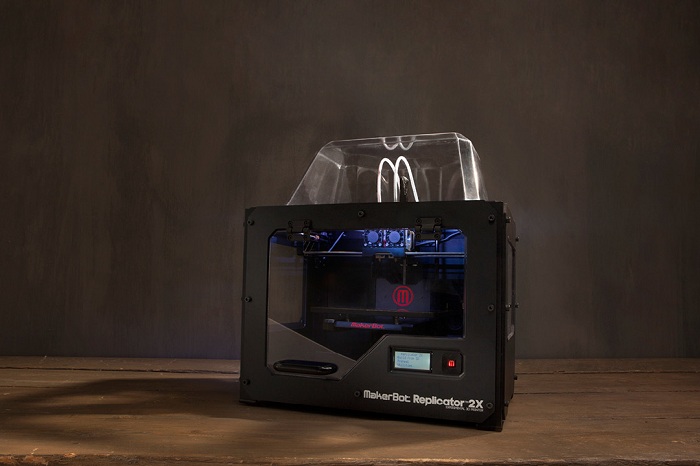

Evidently they were selling various high-tech goods in 2009, and were directed to see some folks making a 3D printer in New York City. It turned out the company was MakerBot and the person they met was none other than Bre Pettis. They switched gears and began selling 3D printers, and eventually grew into the large operation they are today.

Krone takes a long-term view of the progression of 3D printing, thinking of parallels between the 3D printing and manufacturing industries and other markets, where new players clashed with larger traditional entities. Krone believes the same thing is playing out in our space, with may operations coming and going.

Krone believes many existing players in manufacturing think of 3D printing technology as poor quality, “not real”. In a sense they are correct, but that’s not going to be true in the long term. Eventually the quality will meet and exceed some traditional methods, and for makers and users of those technologies, it may be too late.

Krone says, “those that remain will be mega-powers”, and I think he could be right. But then, who might those powers be?

The future, says, Krone, will not be a total dependence on traditional manufacturing as it mostly is today and in the past, but rather will be a hybrid of traditional and 3D printing technologies.

3D Printing As Secondary Source

One concept that Krone (and I) have been thinking about is how 3D printing has been a bright light during the crisis, and how that may change things in the future.

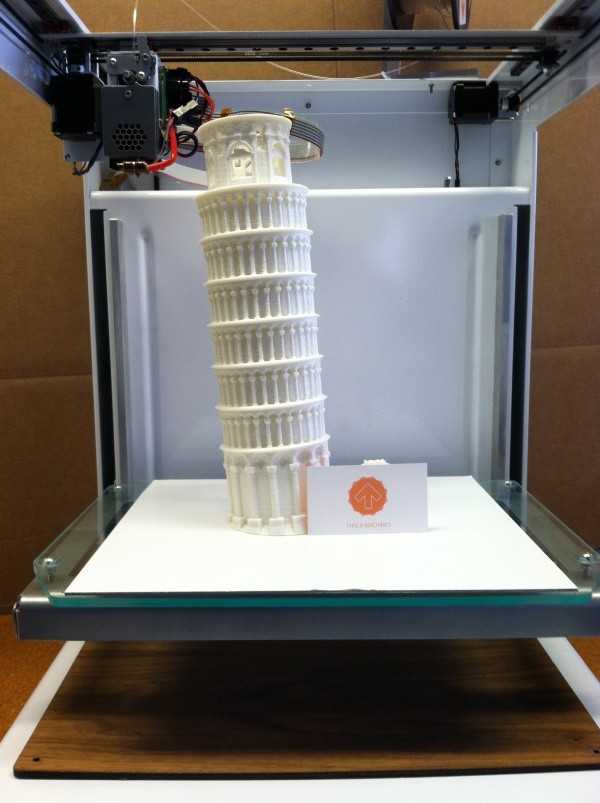

During the crisis the need for supplies was so great that in desperation buyers turned to 3D printing companies to help produce needed items. This was entirely possible because 3D printers are, in a sense, generic manufacturing devices that require only a 3D design and a suitable material to produce products. This is quite different from traditional manufacturing that is more efficient, but takes quite a while to set up.

In many cases, 3D printing was able to step up and provide near-immediate production when needed. People now know this to be true, and that could change things in the future.

Specifically, Krone believes that 3D printing will from now forward be considered a kind of “secondary source” for in-demand products. This could manifest in different ways, but Krone had two excellent concepts in mind.

One was for governments to recognize and implement means to leverage 3D printing in emergencies. Today this is happening mostly informally or independently, but this could be made more formal if governments were more deeply involved.

Another very interesting idea from Krone was the notion of hospitals launching their own emergency production infrastructure. One can imagine a kind of production makerspace attached to institutions that can, at a moment’s notice, begin production of various items as required. I think Krone is on to something here, and this could become a big market for professional and industrial 3D printers in the future.

The State Of 3D Print Reselling

But what about Dynamism itself? Has the market collapsed? I asked Krone his thoughts on this question.

He told me that “sales are way up”, and in fact he’s actually hired two people during the lockdown period. That’s good news, and it also indicates that people are making so much use of their 3D printers that they need more of them.

Krone also said that things haven’t been easy, as they’ve had some supply chain disruption and backlogs. Many consumables come from China, especially thermoplastic pellets, which are used to produce 3D printer filament.

Those things, like the crisis, will eventually pass.

Via Dynamism

Dynamism / Dynamism - 3D Printing Solutions including hardware, software, and...

Dynamism / Dynamism - 3D Printing Solutions including hardware, software, and...Dynamism is the leader in 3D printing advisory, hardware, software, and training. Talk to us about your 3D printing goals, and rely on us for best-of-class 3D printing solutions and support.

dynamism.com was registered 10 years 3 months ago. It is a sub-domain of com. It has a global Alexa ranking #471,661 and ranked 137029th in United States. dynamism.com receives about 2,765 unique visitors and 8,295 page views per day which should earn about $ 25.00/day from advertising revenue.Estimated site value is $ 9,000. 00. According to SiteAdvisor, dynamism.com is safe to visit.Its web server is located in United States, with IP address 207.150.195.117.

00. According to SiteAdvisor, dynamism.com is safe to visit.Its web server is located in United States, with IP address 207.150.195.117.

| Title: | Dynamism - 3D Printing Solutions including hardware, software, and training.... |

| Keywords: | ultimaker, formlabs, desktop metal, lulzbot, makergear, zmorph, einscan, 3d printer, scanner, filament, education |

| Alexa Rank: | #471,661 |

| Daily Revenue: | $ 25.00 | Daily visitors: | 2,765 | Daily Pageviews: | 8,295 | Google Analytics: | UA-722595-1 |

| Created: | 2012-06-20 |

| Updated: | 2020-06-21 |

| Registrar: | GoDaddy. com, LLC com, LLC |

| IP Address: | 207.150.195.117 |

| Host Location: | Texas, Austin, United States, 78702 |

| Global Rank | 471,661 |

| Delta | 57390 |

| Reach Rank | 452175 |

| Country | United States |

| Rank in Country | 137029 |

- Traffic Rank

- Search %

| Host | Type | TTL | Extra |

|---|---|---|---|

| dynamism.com | A | 7200 | IP: 207.150.195.117 |

| dynamism.com | NS | 7200 | Target: ns24.worldnic.com |

dynamism. com com | NS | 7200 | Target: ns23.worldnic.com |

| dynamism.com | SOA | 3600 | MNAME: NS23.WORLDNIC.com RNAME: namehost.WORLDNIC.com Serial: 120012916 Refresh: 10800 Retry: 3600 Expire: 604800 |

| dynamism.com | MX | 7200 | Priority: 10 Target: mailx3.newtekwebhosting.com |

| dynamism.com | TXT | 3600 | TXT: v=spf1 ip4:63.134.207.1/24 include:mailsenders.netsuite.com +a +mx ~all |

HTTP/1.1 200 OK

Content-Encoding: gzip

Connection: keep-alive

X-Powered-By: Undertow/1

X-Powered-By: JSP/2. 3

3

X-Powered-By: JSP/2.3

Server: WildFly/11

Transfer-Encoding: chunked

Content-Type: text/html;charset=UTF-8

Date: Sat, 25 Jul 2020 11:58:18 GMT

| Domain | Rank |

| triamudom.ac.th | #471,667 |

| shinshilka.ua | #471,668 |

| katrinaleechambers.com | #471,669 |

| thegunsafes.net | #471,670 |

| oyunlar.com | #471,671 |

| fui.edu.pk | #471,677 |

| 1ml.com | #471,677 |

| stylekadin.com | #471,678 |

| mygamesrus.ru | #471,679 |

| upstateelevator.com | #471,685 |

- dynamism.com1 second ago

- buro-os.com2 seconds ago

- warrentricomi.com5 seconds ago

- theetiquettefactory.com6 seconds ago

- kyoufuku.com6 seconds ago

- moto.

it10 seconds ago

it10 seconds ago - kybikifishka.ru10 seconds ago

- hdmoviezroot.in12 seconds ago

- fdi.gov.cn12 seconds ago

- dizajn-gostinoj.com13 seconds ago

- if-cdn.com14 seconds ago

- schroederpage.blogspot.com14 seconds ago

- kinokor.kz14 seconds ago

- mydirtyhobby.to15 seconds ago

- ainab.info15 seconds ago

3D printing in the creation of modern implants

Implementation stories

Medicine

Author: Semyon Popadyuk

Author: Semyon Popadyuk

Cooperation for the best result | Implants that stimulate bone growth | Application possibilities for 3D printed implants | Model for the future

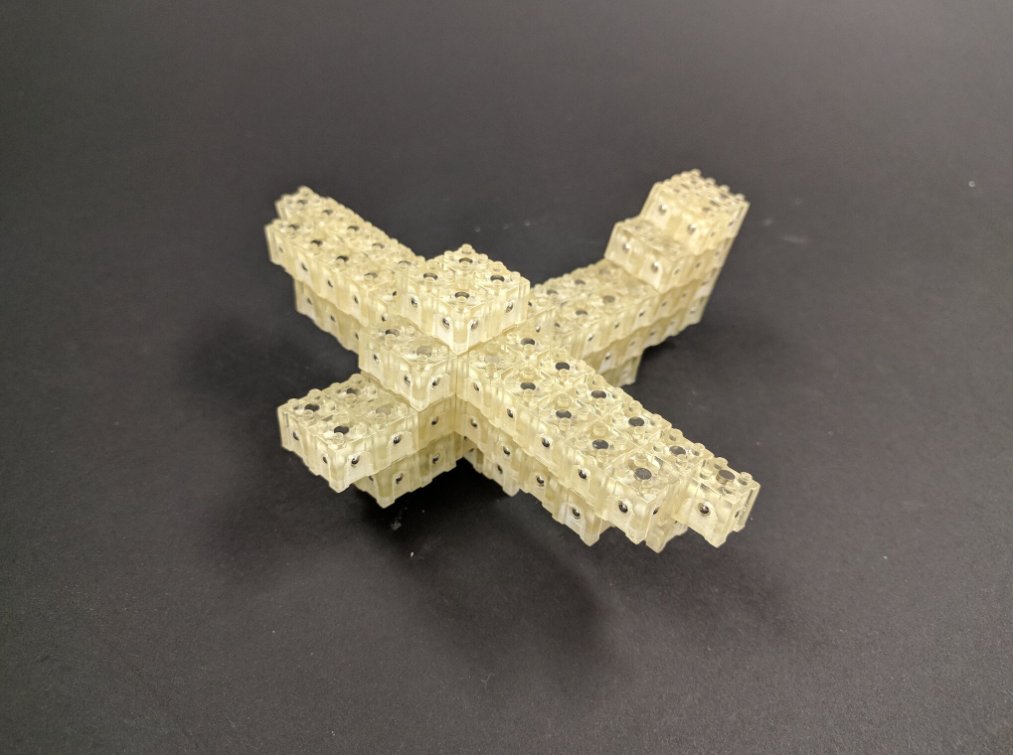

Spinal implant manufacturer K2M expands its capabilities through a strategic 3D printing partnership with 3D Systems. The specialists of the two companies will jointly develop innovative implants for the treatment of diseases of the spine and explore new ways to create customized implants.

Effective partnerships arise when each party brings something unique to the project, making the result of cooperation become something more than the totality of the introduced elements. The partnership between K2M and 3D Systems is an ideal example of such collaboration and is based on the two companies' common goal of improving innovation processes and results.

K2M is a world leader in comprehensive and minimally invasive spinal solutions based on the 3D Total Body Balance™ concept. Surgeons around the world use the company's products to treat the most complex pathologies of the spine.

As part of its desire to expand the range of solutions offered, K2M has attempted to combine its own experience in the treatment of spinal pathologies with the experience accumulated in the industry in the manufacture of high-precision medical devices. 3D Systems was one of the first to join this endeavor.

The company has been one of the leaders in 3D technology for over 30 years and often provides surgeons, healthcare professionals, medical device manufacturers and medical schools with high-precision solutions, including virtual reality surgical simulators, 3D printed anatomical models, Virtual Surgery Planning (VSP®) technology, as well as customized 3D surgical guides, instruments and implants.

iQB Technologies experts recommend the article: Additive technologies in medicine: how to reduce risks to patients' health

Using the 3D Systems ProX DMP 320 printer and proprietary Lamellar 3D Titanium Technology™, K2M manufactures the CASCADIA™ Interbody Systems series of implants with surfaces that combine both porosity and roughness to promote bone growth

Collaboration for a Better Result

The partnership between K2M and 3D Systems is based on the technological developments that the parties share as well as the cultural values they share, according to Jim Ham, director of marketing for the K2M Total Spine Solutions Group.

“We know everything about the spine, and 3D Systems knows everything about 3D printing, but there are a lot of opportunities for synergy in the way we do our business, in our pursuit of innovation, in our shared corporate goals and desire to improve the lives of patients.”

K2M started out as a developer of new technologies and devices for the treatment of spinal deformities. The introduction of 3D printing has allowed the company to expand beyond deformity treatment into the rapidly growing market for products for the treatment of degenerative spinal diseases using minimally invasive procedures.

The introduction of 3D printing has allowed the company to expand beyond deformity treatment into the rapidly growing market for products for the treatment of degenerative spinal diseases using minimally invasive procedures.

“We need the capabilities of 3D printing to further develop our portfolio of degenerative pathologies and minimally invasive procedures, and 3D Systems has provided us with these capabilities,” explained Mr. Ham. “The partnership with 3D Systems has strengthened our leadership position in 3D printed spine products, allowing us to tap into a wider market and fueling our growth over the past few years.”

K2M 3D printed products are manufactured using 3D Metal Printing (DMP) technology developed by 3D Systems. While this technology is new to K2M, it is well established in precision medicine, explained Tim van Kleinenabrugel, director of healthcare business development at 3D Systems in Leuven, Belgium.

“More than a decade of experience and 500,000 manufactured pieces prove that metal 3D printing using a laser beam is very well suited for the manufacture of organically shaped spinal implants with a porous structure,” Van Kleinenbrügel said.

Bone stimulating implants

3D Systems provides design consulting, 3D printing and post-processing services for the FDA-certified K2M CASCADIA family of vertebral implants. In 2016, CASCADIA's rapidly growing product line was recognized by Orthopedics This Week with its annual Spine Technology Award.

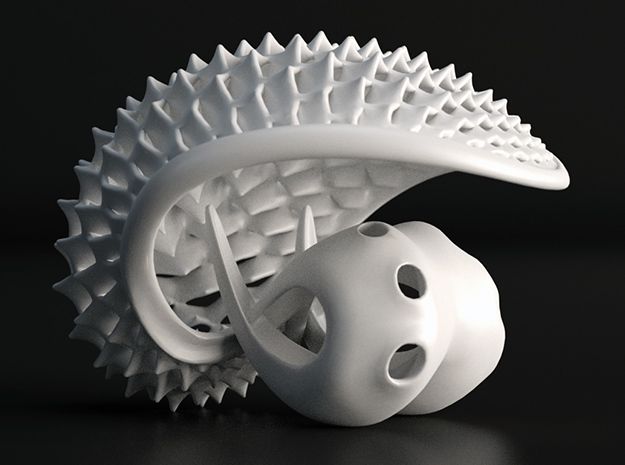

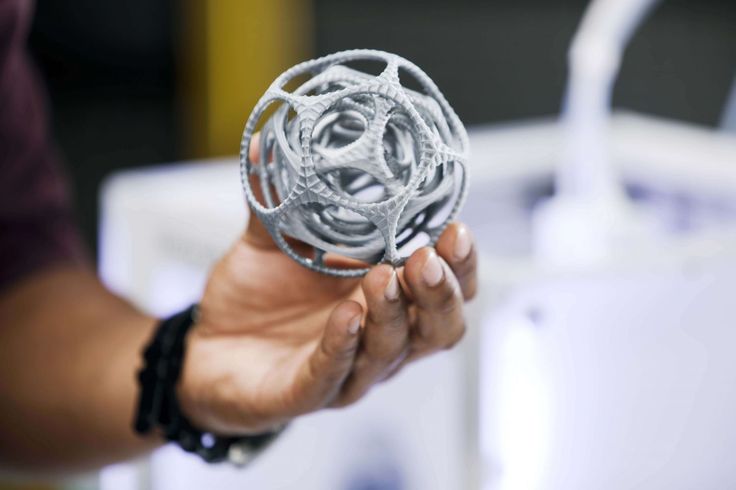

CASCADIA implants are manufactured using ProX DMP 320 printers and K2M's latest Lamellar 3D Titanium Technology™. Using traditional technologies, such products cannot be produced.

Metal 3D printing (DMP) technology is an excellent solution for creating porous structures and natural shapes similar to those used in K2M vertebral implants

Implants are made from titanium powder by selective action of a high-energy laser beam - in this way, porosity and surface roughness are simultaneously achieved, ensuring bone tissue growth. Although the products have the strength of titanium, they transmit X-rays, allowing surgeons to better see how the implant interacts with adjacent body tissues.

K2M products using Lamellar 3D Titanium technology include CASCADIA TL, AN, Lateral, AN Lordotic Oblique and Cervical Interbody Systems implants. The manufacturing process used by 3D Systems to manufacture them includes not only 3D printing, but also post-processing - heat treatment, surface treatment, cleaning and laser marking - that is, everything that is necessary to obtain a finished product.

Tom Morrison, a neurosurgeon at the Polaris Center for Neurosurgery and Spine Surgery in Atlanta, Georgia, has been using CASCADIA Interbody Systems implants for over a year.

“Lamellar 3D Titanium technology never ceases to amaze me,” says Dr. Morrison. “Porosity and surface roughness are of great importance from a biological point of view, and the results of long-term follow-up of my patients confirm my impressions. I am very enthusiastic about the use of CASCADIA Interbody Systems implants and will be very excited about the new possibilities of using K2M's Lamellar 3D Titanium technology to stimulate bone growth. ”

”

TASK

- Creation of innovative methods for the treatment of diseases of the spine.

SOLUTION

- A global partnership that combines K2M's extensive experience in the creation of spinal implants with 3D Systems' advanced metal 3D printing technologies.

RESULTS

- Manufacturing a rapidly growing line of CASCADIA™ Interbody Systems implants with porous and rough surfaces that promote bone growth.

- Using Virtual Surgery Planning (VSP®) and 3D printing an experimental device for a patient with no other treatment option.

- Enabling development of other areas, such as innovative custom spinal implants.

Application options for 3D printed implants

A recent example of effective collaboration between K2M and 3D Systems is a project in which 3D Systems provided Virtual Surgery Planning (VSP®) and, together with K2M, created an experimental device used in those rare situations where there are no certified alternative treatments for the patient.

The process began when Sean Reynolds, project manager at K2M, spoke about the company's latest developments with Dr. Michael Finn, a neurosurgeon at the University of Colorado who specializes in spine disorders.

A collaboration between K2M and 3D Systems has resulted in a 3D-printed experimental metal implant that could serve as a model for new applications for metal 3D printing.

Dr. Finn had a patient who he thought would be a good candidate for a 3D printed implant. The patient had previously undergone surgery, but the recovery process was slow and the patient suffered from limited mobility. At that time, there were no alternative products on the market that could help the patient. Dr. Finn concluded that removing the implant from the last operation and replacing it with a 3D printed implant would be the best treatment tactic.

“This part of the body is under significant stress, so the patient did not recover well,” Dr. Finn explained. “I thought that a 3D-printed implant would give the patient the best chance of recovery.”

“I thought that a 3D-printed implant would give the patient the best chance of recovery.”

Based on the results of the spine scan and a web consultation with K2M and Dr. Finn, 3D Systems developed a virtual surgical plan. As a result of the cooperation of the three main project participants, the implant design was developed and the type of screws for its fastening was selected.

From Dr. Finn's point of view, the operation was a success, and the collaboration between K2M and 3D Systems is one example of success: “I was impressed by the dynamism of both companies. They really focused on building this product in a timely manner. K2M is able to develop innovative solutions for complex surgical procedures, and 3D Systems has a lot of experience in solving such problems, so this project was not too difficult for them.”

Model for the future

For Sean Reynolds and K2M, the collaboration between the two companies at a critical stage in pre-surgery was an exciting prelude to a promising new line of work - the provision of surgical planning services and the manufacture of customized implants for the treatment of complex degenerative diseases of the spine.

Although experimental devices are rarely used, the approach used in the case described above may in the future become a model for the manufacture of individualized implants for a particular patient. These will be implants approved by the US Food and Drug Administration for production within certain specifications based on the needs of the patient.

“Based on our experience with 3D printing, we believe that in the future, 3D printed customized spinal implants will be widely used in the treatment of not only complex cases, but also degenerative diseases,” said Reynolds. “We are very pleased and excited about the prospects for future collaboration with 3D Systems.”

Translation from English. The original of this material is on the 3D Systems website.

Article published on 04.12.2017, updated on 04.03.2022

Home - Print Group - Zagreb

We create magic

An excellent team of capable people, the best quality of machines and an outstanding place for work provide that in our production process we make a day after day.

LEARN MORE

GET AND KEEP CUSTOMERS' ATTENTION

DO YOU WANT TO SHOW THE PRODUCTS IN YOUR CAMPAIGN IN THE ORIGINAL WAY?! POS DISPLAYS ARE A GREAT WAY TO ATTRACT AND KEEP THE ATTENTION OF CUSTOMERS AND MAKE THE MOST OF SPACE TO PROMOTE THE PRODUCT.

LEARN MORE

WHO WE ARE

DURING 20 YEARS OF EXISTENCE IN THE MARKET, WE HAVE CHANGED ENOUGH. HOWEVER, ALL THIS TIME, WE HAVE CONSTANTLY PROGRESSED AND INCREASED OUR PRODUCTION AND HUMAN RESOURCES.

LEARN MORE

FOR OVER 20 YEARS HELPING SOME OF THE BIGGEST BRANDS IN THE WORLD TO CONNECT WITH AN AUDIENCE. WITH THIS EXPERIENCE AND WHETHER YOU NEED A STORE ADVERTISING CARDBOARD SHELF, RETAIL STORE BRANDING OR OUTDOOR BANNER PRODUCTION, WE HAVE THE RIGHT SOLUTION FOR YOU. STRONG AND PURPOSED WORK IN A STRICTLY CREATIVE SENSE, WITH A COMPLETE PRODUCTION OFFER... WE LITERALLY DEVELOP THE PROJECT FROM THE ORIGINAL CONCEPT TO THE FINAL PRODUCT.

OFFSET

Offset is ideal for printing letterheads, catalogs, flyers and corporate publications, as well as high volume labels, posters, cartons, carton displays or billboards. ..

..

DISCOVER MORE...

POS FLOOR DISPLAYS

Our POS solutions are tailored to be efficient, durable and to meet all your marketing standards.

In manufacturing, we use precise methodology, quality materials and state of the art equipment to provide solutions that will fully meet your needs and requirements.

HC Poster POS - solutions can be applied in the presentation of food products, household chemicals, cosmetics, small electrical appliances and many other products from other business sectors.

Our goal is to provide you with a full range of services so that your presentation and visual communication with current and future clients is at the highest level.

CARDBOARD DISPLAYS WOOD, METAL AND PLASTIC STANDARD SOLUTIONS

We love challenges. We approach each project, finding new design solutions in order to obtain products that satisfy our customers to the maximum, not only in quality and innovation, but also in price.:quality(80)/images.vogel.de/vogelonline/bdb/1443600/1443640/original.jpg)

Look at some of the real business challenges that have been successfully implemented.

LEARN MORE

- DESIGN

- PRODUCTION

- INSTALLATION

Design is more than just meeting your specification.

We would like to be involved in the planning process from the very beginning of an idea. This way, together we can go through the entire process, from concept planning to the finished product that best suits your needs.

We will give you tips to improve your idea. We are confident that, based on our experience and ideas, the final product will exceed all your expectations. Your success is our success!

Regardless of the complexity of the operation, we will do well.

We have over 60 machines, over 210 employees and an optimally designed workspace. Our production facilities include printing, contour cutting, finishing, assembly and installation.

Printing accuracy and quality, large production capacity and highly trained staff ensure that we are safe in any challenge.

We take the installation process of the product as seriously as the manufacturing process.

More than twenty years of experience in product development means so much time in assembling, gluing, stretching, testing...

Tell us what your ideas are, even if they seem impossible to you. We will work to provide you with a solution. We have a wide network of certified specialists throughout Europe and we have confidence in them.

THIS IS NOT MAGIC, BUT WE ARE VERY CLOSE TO IT. A BIG TEAM OF CAPABLE PEOPLE, THE BEST MACHINES AND AN OUTSTANDING WORK SPACE MAKE THAT WE CREATE PERFECTION DAY BY DAY IN OUR PRODUCTION PROCESS.

LEARN MORETECHNOLOGY

LEARN MORE

TEAM

LEARN MORE

From idea to finished product

During the 20 years of existence on the market, we have changed enough. However, all this time, we have been constantly progressing and increasing our production and human resources.