Best 3d printer abs filament

The 9 Best ABS Filaments in 2022 (Including From Top Brands Like Flashforge and Inland)

Welcome to the Thomas guide to the best ABS filament 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

Acrylonitrile butadiene styrene filaments, more easily known as ABS filaments, are built for 3D printers. They’re one of several filaments that can be used with these machines and, for several reasons, are one of the more popular options for building creations on a print bed. Experts and amateurs exploring the world of 3D printing will no doubt come across ABS filaments, but when should they be chosen over others, what makes them different, and which are the best?

For consistent quality during the printing process, good ABS filaments are neededImage credit: Shutterstock/asharkyu

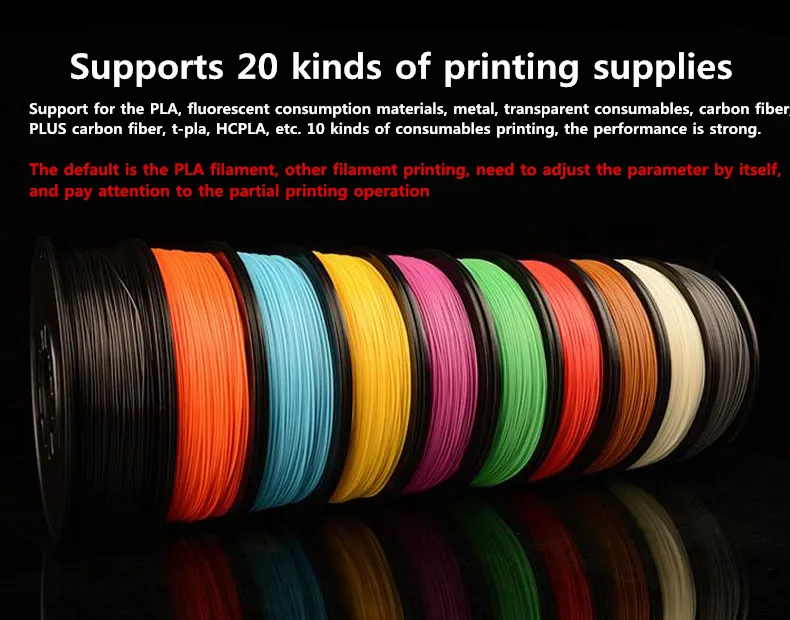

Two top reasons why ABS filaments are popular among professionals and hobbyists is that they’re flexible and simple for most users to figure out. ABS prints out designs that are of decent quality, too. Though there are many options on the market, including carbon fiber, PETG, PLA, nylon, and wood filament choices, ABS filaments are best for products that require resistance to stress, heat, and wear and tear.

Best ABS Filament—Buying Guide

Below, you’ll find a breakdown of what to look for in ABS filaments, including fine details like spool width, temperature range, and adhesion. When browsing sites for ABS material, shoppers will want to consider ABS filament diameter, temperature range, and how well it bonds. All of these will be indicators of a quality filament that will work well with the machine being used.

- Diameter and spool hub hole diameter depends on what the specific 3D printer requires, so be sure to check the recommended spool diameter listed in a printer’s manual. Keep an eye on the mechanical winding done to the spool, too, to prevent annoying tangles.

- The temperature range is the point at which the filament will melt and begin adhering to other layers—too cold, and the first few layers won’t bond; too hot, and the material won’t maintain its properties and could become stringy. 3D printing with ABS requires looking at both extruder temperature and bed temperature in most cases.

- Fantastic layer bonding means that once the design has been printed, it’ll stay together, and its layers won’t separate.

- Good ABS filaments should also stand up well to a manual finishing process, like an acetone vapor treatment. Acetone vapor should smooth the texture of the print and help clean up anything that looks uneven or rough. At the same time, the filament should be strong enough to withstand it while creating a smooth surface finish and not completely melt during an acetone vapor bath.

ABS Filament Brands

Popular 3D printer brands often make filaments on top of 3D printers that are favored among users, including Markforged, MakerBot, Flashforge, and Ultimaker. Which is better comes down to personal preference in most cases as differences are often minute.

Thomas’ Top Picks for the Best ABS Filaments 2022

Shop the best ABS filament brands and options for good dimensional accuracy, and quality 3D printed creations.

Best ABS Filament for Multiple 3D Printer Brands: Inland 1.75mm ABS 3D Printer Filament | Buy Now Best Reliable ABS for 3D Printing: HATCHBOX ABS 3D Printer Filament | Buy Now Best Good Quality ABS Filament for Consistency: SUNLU ABS 3D Printer Filament | Buy Now Best ABS Filament for Beginners: Polymaker ABS Filament | Buy Now Best Filament for Lower Heat Build Platform: Flashforge ABS Pro Filament | Buy Now Best Filaments for Pen 3D Printing: MIKA3D ABS 3D Pen Printer Filament Refill | Buy Now Best Low-Warp ABS Filament for 3D Printing: Reprapper Low Warping ABS 3D Printer Filament | Buy Now Best Thicker Filaments for 3D Printing: Ultimaker 3D Printer Filament, 2. 85mm | Buy Now Best Budget ABS Filament: Amazon Basics ABS 3D Printer Filament | Buy Now

85mm | Buy Now Best Budget ABS Filament: Amazon Basics ABS 3D Printer Filament | Buy Now Scroll down to read more about these top picks for the best ABS filament, according to many happy buyers.

*Prices listed in this article were as shown in US$ on amazon.com (USA) and newark.com as of April 2022

1. Best ABS Filament for Multiple 3D Printer Brands—Inland 1.75mm ABS 3D Printer Filament

Traditional ABS resins can be difficult to work with, and though it’s a popular material, ABS often gets a bad rap for being finicky. Though it’s not expensive, many buyers cast Inland’s vacuum-sealed, silica gel-padded ABS rolls as a high-quality filament.

It’s smooth, sticks well, and isn’t as odorous as other ABS filaments. This option has 13 different color options to meet a variety of project needs, from light blue and purple to yellow and white.

“I have printed several kilometers using many brands of ABS filament, and this is my go-to,” wrote one reviewer. “Inland is remarkably uniform, consistent, and makes very high-quality prints. I have not used any brand that was easier. If you are set up to print ABS, then this is the brand to go with.”

Specifications

Best for: Hardware parts, small models

Filament diameter: 1.75 mm

Print temperature: 464° F to 500° F

BUY NOW:

US$20.99, Amazon2. Best Reliable ABS for 3D Printing—HATCHBOX ABS 3D Printer Filament

Like most ABS filament brands, it takes a bit of time to get any printer set up and functioning properly with the specific needs of this filament from HATCHBOX, but once things are good to go, it prints out models smoothly and efficiently.

This filament is also durable, sticking together from the first layer that’s laid down and staying strong throughout its usage. It’s built for both hobbies and for more functional ABS parts, like creating handles for tools or mounts.

“It is currently my favorite filament and creates amazing prints and is very easy to vapor smooth, and creates a detailed model with a marble-like shine and a smooth texture,” noted a customer. “I have had this filament for nearly a year now, and there have been no issues with the filament cracking or breaking, like several of my other filaments did within the first couple of months.”

Specifications

Best for: Functional parts and models

Filament diameter: 1.75 mm

Print temperature: 410° F to 464° F

BUY NOW:

US$21.47, Amazon3. Best Filament for Consistency—SUNLU ABS 3D Printer Filament

ABS is great for 3D printer operators looking for a heat-resistant material that can withstand stress, and SUNLU’s is no exception.

It works with multiple models of printers to create smooth models, and as a small perk, the vacuum-sealed bag comes with an easy-to-find filament end to prevent tangles. Other shoppers have noted this adheres well enough on a heated bed to avoid needing a glue stick or masking tape, too.

“I have an order for 200 printed units, [and] I switched to this brand due to a recommendation on YouTube,” explained a buyer. “I had to raise my nozzle temperature to 250° C, and the bed at 100° C, and I am just churning out the units six at a time with no clogs or issues of any kind… The quality is there, and everything is very consistent. This is the best I have ever run with ABS.”

Specifications

Best for: Adaptors, busts, models, and hardware parts

Filament diameter: 1.75 mm

Print temperature: 446° F to 464° F

BUY NOW:

US$21. 99, Amazon

99, Amazon 4. Best ABS Filament for Beginners—Polymaker Polylite ABS Filament

ABS 3D printing often leaves users with a bad impression when they first try it out—even with a popular filament brand.

This Polymaker option is worth a shot, especially for newbies, according to numerous reviewers. It’s low on odor due to its significantly lower volatile content, which is normally a frequent complaint of experts and enthusiasts who rely on ABS.

“If you’re a first-time ABS printer, I strongly suggest you try this filament,” remarked a customer. “It is super easy to use and work with. I don't even use an enclosure when I'm just printing a few items. I use a Prusa MK3S and a Creality Cr10s Pro v2, and both work well with just the generic ABS settings.”

Specifications

Best for: Beginners, users sensitive to smells, and for making holders, hardware, and mounts

Filament diameter: 1. 75mm

75mm

Print bed temperature: 473° F to 509° F

BUY NOW:

US$21.99, Amazon5. Best Filament for Lower Heated Build Platform—Flashforge ABS Pro Filament

More popular for its PLA filament options, printing ABS models is also doable with Flashforge’s ABS filaments. Hailing from the Pro line, the filaments in this spool set are equipped to create better dimensional accuracy and prevent shrinkage.

It won’t produce the same smell as traditional options, either. However, this one isn’t as resistant to high temperatures and requires a lower heated bed and extruder temperature.

That being said, a higher melt temperature isn’t needed for this filament to have good layer bonding. “I have used several different types of ABS filament, and this one is right up there with all the good ones,” explained one customer. “Printed nicely, and odor was no more than usual. ”

”

Specifications

Best for: Household items and LEGOs

Filament diameter: 1.75 mm

Print temperature: 176° F to 212° F platform temperature

BUY NOW:

US$21.99, Amazon6. Best Filaments for Pen 3D Printing—MIKA3D ABS 3D Pen Printer Filament Refill

ABS print models can come from 3D printing pens, too, and don’t require an enclosed print chamber. These machines are better used for hobby projects, and for such, this set of multi-colored filaments from MIKA3D is great and made specifically for MYNT3D and SCRIB3D pens.

Though they’re built for pens and create well-made models, they’re even usable for extra-small 3D printer projects.

“I just purchased a 3D pen; we have a 3D printer, but I wanted to build manually,” described a customer. “This came vacuum sealed and packed in a way that they were not directly stacked on top of each other. It works well in my pen, and it doesn't jam.”

“This came vacuum sealed and packed in a way that they were not directly stacked on top of each other. It works well in my pen, and it doesn't jam.”

Specifications

Best for: 3D pens and figurines

Diameter: 1.75 mm

Print temperature: 410° F to 464° F

BUY NOW:

US$12.99, Amazon7. Best Low-Warp ABS Filament for 3D Printing—RepRapper Low Warping ABS 3D Printer Filament

The surface finish of a printed product can be tough to nail down. Excess moisture or the incorrect temperature can be a cause for concern during a strict manual examination—causing warping, roughness, or stringy texture.

RepRapper’s filaments are great for printers who are concerned with warping in particular and made for less manual finishing process time and effort. The brand recommends low cooling fan levels for proper first-layer adhesion and an overall strong structure.

“I'm printing on a thick, smooth PEI sheet,” wrote one reviewer who was initially skeptical about buying this filament as it seemed a little too economical to be any good. “Bed at 100, nozzle at 260, 20% fan, and it's printing like an absolute dream. The bed and layer adhesion are both rock solid. The surfaces and bridges are gorgeous. Still tinkering with the support settings, but it's going well.”

Specifications

Best for: Printer mechanical parts, hardware, models

Filament diameter: 1.75 mm

Print temperature: 446° F to 500° F

BUY NOW:

US$23.99, Amazon8. Best Thicker Filaments for 3D Printing—Ultimaker 3D Printer Filament, 2.85mm

The Ultimaker ABS filament spools are on the top end of the ABS options from the printer and filament manufacturer.

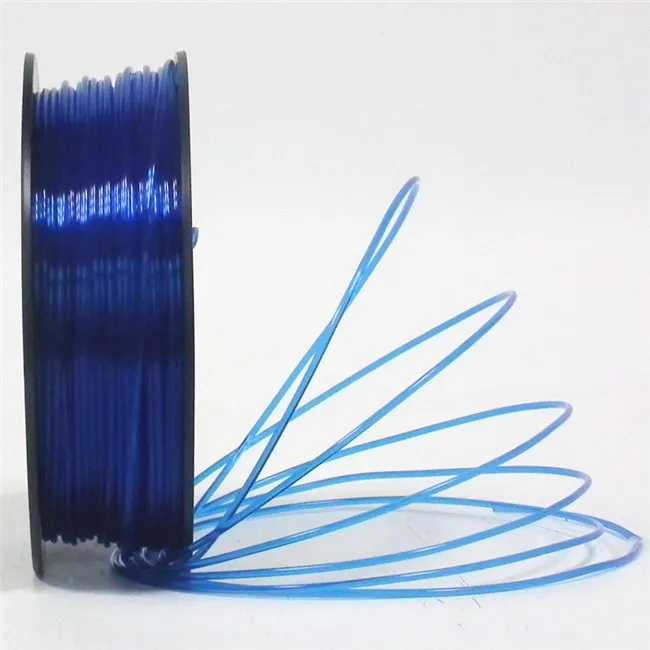

This black tone is perfect for having in any collection of filaments, though it can be found in multiple other hues. It’s a thicker filament at 2.85mm in diameter and is made for sticking to the bed well without pulling apart when it's time to remove the final product.

The Ultimaker ABS filaments also aren’t exclusive to Ultimaker printers as long as the machine uses fused deposition modeling (FDM) tech.

Specifications

Best for: Models, prototypes, end hardware

Diameter: 2.85 mm

Print temperature: 437° F to 473° F

BUY NOW:

US$49.99, Newark9. Best Budget ABS Filament—Amazon Basics ABS 3D Printer Filament

The best ABS filament brands are fairly well-known, but for a no-nonsense spool, Amazon Basics’ version does the trick nicely.

Even at such a low price, this is a decent filament for making products where ABS reigns supreme over other materials. The product description states that it’s built to avoid jamming, though it’s notably thinner than some other ABS options on the market.

“New to 3D printing and wanted to test out ABS after PETG and PLA,” explained a customer. “I have a Prusa MK3S, and this filament was one of the best I’ve printed with… Stuck to bed almost too well, and the quality of print was absolutely perfect. I was shocked. Didn’t do anything but slice in the Prusa slicer and sent to printer. Came back four hours later, and BAM, it was epic.”

Specifications

Best for: Models, cell phone cases, small hardware pieces

Diameter: 1.75 mm

Print temperature: 455° F max

BUY NOW:

US$20.47, AmazonThe Best ABS Filaments—Summary

3D printing ABS models and parts with good dimensional accuracy and little need for glue or ABS slurry requires great ABS 3D printing filaments. Ones protected from excess moisture are doubly as important (though this can be prevented through using a filament dryer). The best ABS filament brands listed above will help make ABS 3D printing easier.

Ones protected from excess moisture are doubly as important (though this can be prevented through using a filament dryer). The best ABS filament brands listed above will help make ABS 3D printing easier.

Printers running on lower temp settings will function well with FlashForge’s spools (US$21.99, Amazon). For reliable 3D printing, HATCHBOX ABS filament rolls (US$21.47, Amazon) make the cut. A great runner-up from one of the best ABS filament brands is the Push Plastic ABS filament ($39, Amazon). Push Plastic ABS is high quality and prints out clean designs.

We hope our review of the best ABS filaments from the best ABS filament brands like Flashforge, Polymaker, SUNLU, Push Plastic, and HATCHBOX ABS has been helpful. For more suppliers of related products, including 3D printer filaments, bioplastic 3D printer filaments, and metal 3D printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

Sources

- https://www.machinedesign.com/buyers-journey/consideration/article/21835444/whats-the-difference-between-pla-abs-and-nylon

- https://www.imaginethat-3d.com/how-to-succeed-when-printing-with-abs

Other 3D Printing Articles

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- All About Multi Jet Modeling (MJM) 3D Printing

- All About Stereolithography 3D Printing

- All About Direct Energy Deposition 3D Printing

Other Best Product Articles

- The Best Commercial Backpack Vacuum

- Best Mouse for Solidworks Users

- Best Monitor for AutoCAD

- The Best Garden Hose Reel

- The Best Commercial Cotton Candy Machine

- The Best Commercial Drones

- The Best Commercial Hedge Trimmer

- The Best Commercial Meat Slicer

- The Best Commercial Chainsaw

- The Best Wheelbarrow

- The Best Commercial Ice Cream Machine

- The Best Commercial Pizza Oven

- The Best Commercial Deep Fryer

- The Best Commercial Mop

- The Best Arduino Starter Kit for Beginners and IoT Projects

- The Best Mig Welders

- The Best Pipe Wrench

- The Best Single Stage Automotive Paint

- The Best Drywall Knife

- The Best Heat Gun For Removing Paint

- The Best Polycarbonate Filament in 2022

- The Best Reel Mowers

- The Best Mulching Lawn Mowers

- The Best Expandable Garden Hose

- The Best Automatic Center Punch

- The Best Rotary Laser

- The Best Two Wheel Wheelbarrow

More from Electrical & Power Generation

Best ABS Filament: Top Brands & 3D Printing Guide

Known for its great mechanical properties, ability to withstand high temperatures, and low cost, ABS filament is a favorite among makers and prototypers who want to create durable parts that hold up over time. It’s also probably the first commonly used filament, having been used in FDM 3D printing for decades, and is now one of the two most used filaments along with PLA.

It’s also probably the first commonly used filament, having been used in FDM 3D printing for decades, and is now one of the two most used filaments along with PLA.

- This article explains ABS filament. For 3D printers, read the best ABS 3D printers

Not all ABS filament is created equal, though. In this guide, we’ll be shepherding you towards the best ABS filament brands currently available, along with sharing top tidbits to help you avoid the most common pitfalls and create quality ABS prints.

What is ABS

To give it its full, non-acronym name, acrylonitrile butadiene styrene is a widely-used petroleum-based thermoplastic polymer that ranks alongside PLA and PETG as the most popular filament type for 3D printing.

As the name implies, ABS is composed of roughly:

- A quarter acrylonitrile

- A quarter butadiene

- Half styrene

ABS material properties are particularly conducive to 3D printing applications. The filament has a high-temperature sensitivity, meaning it can withstand high temperatures and has a higher melting point than PLA. This resistance also extends to chemicals and impact.

This resistance also extends to chemicals and impact.

If you’re wondering how strong is ABS, its durability and high structural strength are noteworthy. The filament also offers a decent degree of flexibility for a stiff material with higher elongation properties than PLA.

On the flip side, ABS is sensitive to colder temperatures and tends to degrade as the temperature drops. Working with ABS is far more complicated than PLA and requires the right thermal environment, notably the proper heat settings on the nozzle, heat bed, and the enclosed print chamber.

ABS melting point & printing parameters

ABS, the shortened name for Acrylonitrile Butadiene Styrene, is printed with an extruder temperature of around 230C, certainly within the 220-250C range. You also need to use a heated bed when printing ABS, at around 110C, as ABS has a glass transition temperature of around 105C. Some however choose slightly lower temperatures. Without a heated bed, ABS prints will warp heavily, rendering them unusable.

These temperatures can vary slightly however depending on the blend and type of ABS used. If you notice any oozing while printing, this is a sign that your extruder temperature is too high, and if layers look blotchy and rough, this is a sign that the extruder temperature is not high enough.

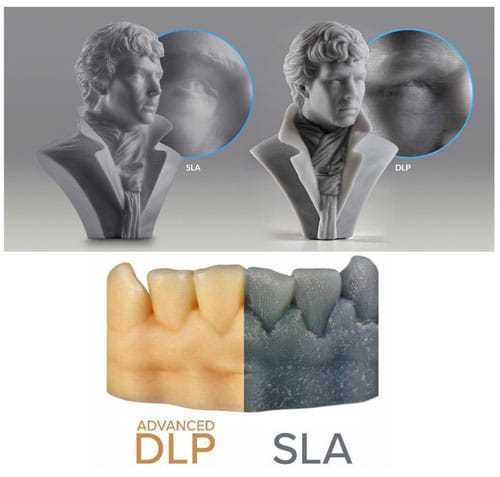

Generally, you should not use a cooling fan with ABS, unlike with PLA where a fan can be crucial. However, with miniature prints in ABS, and prints with delicate overhangs, a cooling fan is sometimes used.You can also polish ABS prints using acetone, giving parts a glossy look. An example is shown above.

You will almost certainly also need an enclosed chamber, as otherwise you will see far more warping and curving at the bottom of your part, and cracking in the midsection. Some believe that good results can still be gained with an open print area if you use a good build surface on a glass print bed, and you will generally be fine if you print small parts, though overall with ABS printing an enclosure is definitely your best bet and we highly recommend using one.

How much does ABS cost?

Good quality ABS filament usually starts at around $20 per kilo, though some variants can cost more. For everyday printing, standard $20 ABS spools are fine.

Some makers prefer to save money and increase color options by buying ABS pellets in bulk, and dying and extruding the pellets into filament themselves. The pellets cost less per kilo, around $10-12, and can be cheaply dyed into smaller sets of custom filament.

ABS Properties / 3D Printing Characteristics

- Strong, tough, and durable

- Heat, electricity, and chemical resistant

- Less brittle and more flexible than PLA

- Scratch Resistant

- Suitable for machining, post-processing, and acetone vapor smoothing

- Readily-available and low cost

Best ABS Filament 2022: Top Brands

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Hatchbox – overall best ABS 3D printer filament

- Available on Amazon here

Hatchbox offers a high-quality, no-nonsense ABS filament that offers excellent value for the asking price. Print results are fantastic, although, as with all ABS, the correct temperature settings are needed; this is par for the course.

Print results are fantastic, although, as with all ABS, the correct temperature settings are needed; this is par for the course.

Hatchbox has put in the work to make its filament universally compatible with most ABS printers. Spools arrive in resealable bags, which work great as a temporary air-tight storage option.

Hatchbox ABS ships in 1kg spools in either 1.75 mm or 2.85 mm diameters. The recommended temperatures for the nozzle and bed are 210°C to 240°C, and 55°C to 85°C, respectively. Hatchbox is available in a range of colors, including gold, black, transparent black, yellow, red, blue, and white. One spool of Hatchbox ABS filament sets you back an affordable $20 to $22.

eSun

- Available on Amazon here

eSun proposes what it calls ABS+, an improved and upgraded variant of ABS designed to reduce curling, warping, and cracking during the printing process, while still maintaining the toughness and durability of the thermoplastic. eSun says ABS+ also enhances layer bonding and delivers a smooth surface finish.

eSun’s ABS+ is available in both 1kg and 3kg spools in 1.75 mm and 2.85 mm diameters. The recommended extrusion temperature is 220°C to 260°C, and the ideal bed temperature sits between 90°C and 110°C. You can generally pick up a 1kg spool of eSun ABS+ for around $20 to $25.

There are around 20 colors available, emphasizing tones that pop, perfect for projects that require a distinct color scheme. eSun packages ABS+ in a sealed vacuum bag for easy moisture-free storage when not in use.

Polymaker – best low-cost ABS filament

- Available on Amazon here

Manufactured by Polymaker, PolyLite ABS is another strong pick for those that don’t want to compromise on quality and depend on reliable print results. Polymaker uses a bespoke bulk-polymerized ABS resin, which reduces the volatile content of the filament compared to your garden variety ABS resins. An added benefit of Polymaker’s resin is minimal odors during the printing process. Spools also land on your doorstep with a resealable vacuum bag.

Polymaker’s PolyLite ABS filament is available in 1kg spools, either in 1.75 or 2.85 mm diameters. Quite a few colors are on offer, including black, white, red, yellow, purple, orange, and a rather fetching teal.

Polymaker recommends a nozzle temperature of 245˚C to 265˚C and a bed temperature from 90˚C to 100˚C alongside the use of PEI sheets or adhesive such as an ABS slurry. Expect to pay around $20 to $30 per spool depending on the point of purchase.

Gizmo Dorks

- Available on Amazon here

Unusual name aside, Gizmo Dorks specializes in ABS filament that trudges off the beaten path. You’ll find ABS curiosities such as heat-activated, glow in the dark, fluorescent, and even conductive variants to get those 3D printing creative juices flowing.

Gizmo Dorks have no less than 30 different color options, including 9 specialty colors that produce those unique effects mentioned above. Gizmo Dorks ABS is available in either 1.75 or 2.85 mm diameter 1kg spools and is compatible with most 3D printers under the sun.

Gizmo Dorks say a nozzle temperature of 230°C to 250°C and a print bed tuned to 110°C should see its ABS thrive. You can snap up a spool of Gizmo Dorks for around $20 to $23 per kilo.

Sunlu

- Available on Amazon here

For the price, Sunlu ABS is a quality filament that easily rubs shoulders with the best ABS filament brands out there. You’re buying a high purity ABS with next to no discernible odors.

The spool holders are excellent, too, designed to ease filament loading with just the right flexibility and spooled to avoid tangling. Sunlu ABS arrives in a sealed vacuum pack and boasts compatibility with all your big-name 3D printer brands from MakerBot to Flash Forge, by way of Ultimaker.

You can buy Sunlu ABS in 1kg spools and 1.75 mm diameter. Color options cover your standard black and white jumping to more exotic peach, neon yellow, and pink for a total of 25 different options. Sunlu suggests cranking up your nozzle temperature to 230°C-270°C and dialing the printed bed to 80°C to 120°C for the best results. Prices start at around $20.

Prices start at around $20.

MatterHackers – high-quality ABS filament

- Available at Matterhackers here

Aimed at both hobby makers and professional applications, MatterHackers ABS’ offering breaks down into two leading types. The Build Series ABS works for everyday 3D printing, balancing quality and cost. On the other hand, PRO Series ABS is MatterHacker’s Premium option designed for precision prototyping and intricate parts, with top-tier material properties, meticulous testing, and what MatterHackers calls a ‘precisely detailed chemical blueprint.’

MatterHackers offers a wide selection of colors with multiple shades of green, blue, and red, along with staples like black, white, and gray. Spools ship weighing 1kg with both 1.75 mm and 2.85 mm diameters available. MatterHackers pinpoints a 235°C extrusion temperature and 80°C to 110°C bed temperature as the best settings for its ABS filament.

MatterHackers Pro Series ABS costs more than most of the other best ABS filament brands, anywhere from $42 to $52, depending on whether MatterHackers weaves in a lighting discount or not. The Build Series is priced at a far more affordable $20 per spool.

The Build Series is priced at a far more affordable $20 per spool.

Overture

- Available on Amazon here

Made from a specialty bulk-polymerized ABS resin similar to Polymaker’s plastic, Overture ABS doesn’t hit the wallet hard but still delivers outstanding print quality with low warping and minimal odors thrown in for good measure. A spool costs around $20.

Overture ABS reaches retailers in 1kg spools with a 1.75 mm diameter in a limited selection of white, black, red, gray, and blue. A vacuum-sealed pack helps keep the ABS moisture-free. And, for the environmentally conscious, Overture is slowly transitioning to reinforced cardboard spools.

To get the best results, you’ll need to fire up your printer’s nozzle to between 245°C and 265°C and set the bed to hit between 80°C and 100°C. Overture also recommends using glue or sheets to help first layer adhesion.

IC3D

- Available on Amazon here

IC3D ABS is another all-around, no-frills filament brand well worth considering. There’s little in the way of unique features here, but IC3D filament is reliable and consistent, ticking off all the material properties you’d expect – strong, durable, and tough.

There’s little in the way of unique features here, but IC3D filament is reliable and consistent, ticking off all the material properties you’d expect – strong, durable, and tough.

You can find IC3D ABS filament in 1.75 and 2.85 mm diameter in 1kg, 2.27kg, and 10kg spools. The color range isn’t quite as comprehensive as the other best ABS filament brands on our list, but there’s enough there to cover most projects with your standard black, white, green, blue, and so on, as well as a unique lime green.

IC3D filament’s cost ranges from $30 to $200. IC3D advises tuning the nozzle temperature to 220°C to 260°C and the bed temperature to 110°C for the smoothest results.

ABS Filament Benefits

- Low cost: one of the cheapest filaments around, along with PLA. It is also one of the strongest materials available for such a low price.

- Great mechanical properties: being so strong, durable, scratch-resistant, and resistant to high temperatures and electrics, ABS is perfect for industrial 3D printing.

So many electrical parts are made with ABS casings, as well as plastic parts that need to be able to handle day-to-day wear without being ground down.

So many electrical parts are made with ABS casings, as well as plastic parts that need to be able to handle day-to-day wear without being ground down. - Less printing errors: unlike PLA, ABS is less prone to oozing and stringing, making it easier to print parts with good surface finishes.

- Easy post-processing: ABS is commonly polished with acetone for a radiant finish, as well as filed or painted using acrylic paints.

- Many colors and blends: like PLA, ABS has a wide range of colors and variants that will suit any kind of 3D printing project you have.

Which 3D Printers Are Good For ABS?

We have an article on the best ABS 3D printers here.

Disadvantages of ABS filament

- Bad warping and curling: especially on long, thin parts. As a result, brims and rafts are commonly used, as well as a 3D printer with an enclosure to carefully regulate temperatures.

- Strong smell & fumes: Print with a window open or filtration system, though there is no evidence these fumes are harmful except at extremely high temperatures that you will never reach 3D printing.

- Not biodegradable or renewable: unlike PLA, ABS is made from petroleum-based compounds and cannot be reused, and does not degrade.

How to get the best results from ABS 3D printing:

- Control warping: use a proper build surface, such as PEI or PET sheets, or Kapton tape with ABS mix, and a heated bed at a hot enough temperature. Using a build surface transfers some heat to the first few layers of the part, helping the layers most likely to curl and warp. You can also change the settings in your 3D slicer to print the first few layers at a higher extruder temperature to ease them in, before turning it back down afterwards.

- Use brims and rafts: when printing large parts, or delicate parts, you may find that you will still have trouble getting these parts to properly adhere to the bed. Adding a brim or raft helps.

Brims add several rings of ABS around your model on the first few layers to create extra surface area to hold down the edges of the part, and rafts are a separate plastic structure under your print which can be removed after the print has been completed.

Brims add several rings of ABS around your model on the first few layers to create extra surface area to hold down the edges of the part, and rafts are a separate plastic structure under your print which can be removed after the print has been completed. - Print in well ventilated area: some printers have HEPA filters now, but still consider opening a window or fan when printing to direct fumes outside.

- Proper Bed Adhesion: Like working PLA, correct bed adhesion is the first step to creating a quality ABS print. We recommend using products with adhesive qualities like hair spray, glue, PEI sheets, or tape if the printer struggles with adhesion and layer separation. A quick wipe down of the build platform before triggering a print also does wonders to promote strong first layer adhesion.

- Proper Cooling: ABS contracts and shrinks when cooled, which can throw up a mire of unwanted issues, including warping and curling.

To avoid this, try to manage the rate ABS cools by fine-tuning the temperature settings of your printer’s nozzle and heat bed. A nozzle temperature of 230°C and a heated bed dialed to 110°C are great starting points. From there, amend the settings by a few degrees up or down at a time until you settle on a happy thermal middle ground.

To avoid this, try to manage the rate ABS cools by fine-tuning the temperature settings of your printer’s nozzle and heat bed. A nozzle temperature of 230°C and a heated bed dialed to 110°C are great starting points. From there, amend the settings by a few degrees up or down at a time until you settle on a happy thermal middle ground.

How to Store ABS

ABS is slightly hydroscopic, meaning it absorbs small amounts of moisture and water from the air. Over time, this gradually worsens the filament’s printing properties as it becomes more brittle and can bubble. The effects are not huge, and take a while to develop, but still lead to some degradation of filament.

Therefore, it is best to keep your ABS filament in a filament container to keep the air out. We recommend our choices for high quality filament containers below:

- Polymaker PolyBox II filament container

- Printdry Vacuum Sealed Filament Storage containers

If your ABS filament has been left in the open for some time, you can dry it to regain optimum print characteristics and remove the excess moisture. We recommend the following filament dryer:

We recommend the following filament dryer:

- PrintDry Filament Drying System

ABS Applications

Outside of 3D printing, ABS is commonly used to create plastic toys and action figures, and is the plastic used in Lego. ABS is also used in the casings of electronics and other products like clocks, and in pipes. In fact, the timer I use to complete one-hour work sprints is made from ABS.

Within 3D printing, ABS is often used in rapid prototyping for parts or products that need to be able to withstand high heats, strong impacts and other forms of wear and tear. ABS parts are tougher than PLA, and tend to be used in more industrial settings.

Others include:

Hobbyists and Home Applications – parts subjected to weathering, friction, and stress such as outdoor household items, parts for hobby RC cars, brackets, gears, heavy-duty toys, heavily used covers, and homemade musical instruments.

Small Business Applications – rapid prototyping and small-batch real-world and mechanical parts.

Manufacturing – mass production toys such as Lego blocks, casings and shells for home and cooking appliances, automotive parts like dashboards and bumpers, phone cases, protective equipment, drainage piping, monitors, and much more.

Schools and Education – bringing to life classroom subjects such as design, engineering, robotics, technology, and mechanics.

Medical – prosthetics, diagnostic equipment casing, and drug-delivery systems.

ABS 3D Printer Filament FAQs

How Hygroscopic Is ABS?

Although not as sensitive to moisture as other filaments like PETG, ABS is still relatively hygroscopic and naturally absorbs moisture in the air over time if left out in the open. ABS’ hygroscopic properties are more bark than bite and easily avoided with proper storage in a sealed, air-tight container.

How Should You Store ABS Filament?

When not in use, ABS should be stored in an air-tight container to prevent pesky moisture from creeping into the filament, which can lead to bubbling and diminish the material’s durability. For more, check out our section above on properly storing the best ABS filament brands.

Does ABS Print Better Than PLA?

There’s no straight yes or no answer to whether ABS or PLA print better. It comes down to your aims, the printed part, and your printer’s strengths and weaknesses. ABS and PLA’s different properties may be better depending on the specific use case. For parts not subject to wear and tear, such as decorative models and figurines, PLA is a better option. If you need strength and durability, ABS takes the lead.

Is ABS Good For 3D Printing?

ABS wouldn’t be among the most popular filament types if it weren’t suitable for 3D printing. A more challenging printing process than PLA aside, ABS is a versatile material with a slew of applications and desirable material properties.

A more challenging printing process than PLA aside, ABS is a versatile material with a slew of applications and desirable material properties.

If you want to find out more about 3D printing:

- View our complete guide to 3D printer filaments

- View our recommendations for the best FDM 3D printers

- Read our complete best 3D printer buyer’s guide

- View our feature story on how much a 3D printer costs to buy and maintain

- How to acetone smooth ABS

Other ABS and filament articles include:

- The best ABS 3D printers

- ASA vs ABS filament compared

- Complete guide to PETG filament

- Complete guide to PLA filament

- Complete guide to TPU filament

- PLA, ABS, and PETG shrinkage: Everything you need to know

Best 3D Printer Filaments (Review 2021)

Once you've chosen your 3D printer, you need to choose the type of filament intended for your project. Filament is a raw material used in 3D printers that will be heated to a high temperature to turn it into a semi-solid state. At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto a plate.

Filament is a raw material used in 3D printers that will be heated to a high temperature to turn it into a semi-solid state. At this point, the printer can easily create the appropriate design layers and print the entire 3D CAD model onto a plate.

However, as you research the various 3D printer filaments, you will hear of numerous materials that can only make it harder to choose the right one for you. This is especially true for people who are just starting to explore the world of the 3D printing process.

While most of us are not new to PLA and ABS, there are other fiber materials you should be aware of such as HIPS, PET, PETG, TPE, TPU, TPC and a few others. And to get a better idea of them, here are some of the more typical types of 3D printer filaments available on the market.

3D Printer Filament Types

PLA Filament

Polylactic acid (PLA) reigns supreme in the industrial 3D printing world. 3D printing with PLA is so easy. It has a lower plate temperature, so it doesn't need a heating bed and therefore has fewer warping issues.

It has a lower plate temperature, so it doesn't need a heating bed and therefore has fewer warping issues.

It is widely used in prototyping, such as printing low-wear toys, prototype parts and containers. Please note that it cannot be used for anything that has a temperature rating of 60°C or higher as it warps at 60°C. For all other purposes, PLA is suitable for a general 3D printer.

ABS Filament

ABS (also known as Acrylonitrile Butadiene Styrene) is the second most popular 3D printing filament. In general, ABS withstands high loads and high temperatures. Thus, it is suitable for most applications. It is great for items that are frequently handled, dropped or heated. For example, mobile phone cases, high-wear items, automotive trim parts, and electronic houses.

Nylon filament

Nylon is the preferred family of synthetic polymers for many industries, professional 3D printing being one of them. As for other forms of filament, they have better performance, efficiency, versatility and durability. Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

As for other forms of filament, they have better performance, efficiency, versatility and durability. Given the strength and versatility of nylon, this type of 3D printer filament can be used to make loops, buckles or gears, as well as working prototypes.

PET (G) thread

The most widely used plastic in the world is polyethylene terephthalate (PET). It is best known as water bottle thread, but it is also used in clothing fibers as well as food containers. Although PET is commonly used in 3D printing, its modified version PETG is becoming more common.

The G in PET stands for glycol, resulting in a more transparent filament that is less prone to cracking and easier to use. PETG is versatile but surpasses many forms of 3D printer filament in its strength and inability to reach high temperatures or withstand strong impacts. The fulfillment of the following conditions makes it an excellent choice for 3D printing filament for practical parts such as mechanical parts, printer parts, and protective materials.

TPE, TPU, TPC filament

Thermoplastic polyurethane (TPE) is a flexible and durable plastic similar to rubber. In addition, TPE is mainly used for the production of auto parts and household appliances.

TPU (Thermoplastic Polyester E) is a special form of TPE that is very common among high end 3D printers. Compared to conventional TPE, TPU is significantly more flexible, hence allowing more control during printing.

What's more, TPC (Thermoplastic Copolyester) is also another form of TPE that is not as widely used as TPU. The key advantage of TPC over TPE is its greater resistance to chemical and UV attack, as well as heat (up to 150°C).

If you need to create items that require a lot of wear, use TPE or TPU because these filaments use 3D printed filaments that are vulnerable to deformation. Products such as toys, mobile phone cases, or wearable items such as wristbands can be some examples of its application. On the other hand, TPC performs well for comparable applications, but outperforms it in harsher environments, including outdoors.

On the other hand, TPC performs well for comparable applications, but outperforms it in harsher environments, including outdoors.

Wood filament

Technically not wood because it contains wood fiber in enhanced PLA. Generally speaking, wood products are valued for their natural beauty rather than their practical utility. When printing items for tables, tables or shelves, it is recommended to use wood 3D printing media. Any of the application examples include chalices, figurines, and trophies. What's more, it's a truly innovative application for 3D printers, which are often used to model real buildings, structures, or trees.

Metal thread

Like wood thread, it is not 100% metal. Specifically, it is composed of metal powder, and one of the following materials is PLA or ABS. However, the effects also have a metal-like aesthetic appeal. Metal Infused can be printed for both decorative and practical purposes. Figures, prototypes, toys, including tokens, can be 3D printed from metal and give them a great look. You can also use metallic 3D printer filament to make parts such as tools or finishing components in light applications.

You can also use metallic 3D printer filament to make parts such as tools or finishing components in light applications.

Biodegradable (biophila) filament

This biodegradable 3D printer filament aims to reduce the impact of all plastic waste into the atmosphere. Although biodegradable 3D filament was originally environmentally friendly, it can still produce quality printed products. Choose this biophile if you don't have special requirements for strength, versatility or endurance. For projects that require prototyping, you can also benefit from these flawless fiber prints that can be biodegraded responsibly.

Conductive thread

This is a kind of three-dimensional material with conductive carbon particles in it. It is ideal for Arduino-based open source businesses. You'll want to look into this filament if you want to make circuits, LEDs, sensors, and other low voltage projects.

Magnetic filament

PLA magnetic iron filament is as magnetic as the name suggests. This one-of-a-kind filament is made from PLA material impregnated with powdered iron. It is ideal for making fridge magnets and other custom-made decorative items. Also, it can be used to create multiple DIY structures, sensors, educational resources, etc.0003

This one-of-a-kind filament is made from PLA material impregnated with powdered iron. It is ideal for making fridge magnets and other custom-made decorative items. Also, it can be used to create multiple DIY structures, sensors, educational resources, etc.0003

Top Five 3D Printer Filaments

Access to a 3D printer creates a whole new world of creative printing. There are several purposes and hobbies that 3D printing serves, but they all rely on the same raw material - 3D printer filament.

While unique materials are recommended for durable and impressive models, you need to select the right material for your 3D image. need printer. You also need to consider the quality and attributes of the thread. That being said, finding the right 3D filament is no picnic.

As such, we sought the advice of tech experts and 3D printer enthusiasts to find the most popular 3D printing filaments on the market. And to give you a clearer idea of their main features and specifications, we have done a detailed analysis to better understand which filament you should pair with your 3D printer. Also, don't forget to click on the buttons below to get the best deals on Amazon!

Also, don't forget to click on the buttons below to get the best deals on Amazon!

Best ABS 3D Printers 2022: Cheap and Premium

Contents

- Want to try your hand at ABS 3D printing but don't know where to start?

- What is ABS?

- Best ABS 3D printers of 2022

- FlashForge Adventurer 3 is the best choice for beginners and casual crafters

- Creality CR-200B

- Qidi Tech X-Plus

- FlashForge Creator Pro 2

- CR-5 Creality Dremel 3D45 - Best ABS 3D Printer for Schools

- Ultimaker S3

- Buyer's Guide - What to Consider When Buying an ABS 3D Printer

- Essential 3D Printer Specifications for ABS Printing

- ABS 3D Printer Upgrade to Help You Print Better Parts

Want to try ABS 3D printing but don't know where to start?

We've put together a comprehensive guide featuring the best ABS 3D printers under the sun. Here you'll find budget options, pro-class workhorses, and everything in between, with the guarantee that each one is money well spent.

Not every printer has what it takes to produce quality prints, but as is increasingly the case in 3D printing, there are quite a few options. Now you do not need to look for a lone suitable printer, but you need to choose the right one from a sea of potential candidates. We will help you separate the wheat from the chaff and settle for the best.

What is ABS?

ABS Filament, or Acrylonitrile Butadiene Styrene, along with PLA, is one of the most popular filaments used in 3D printing. Manufacturers favor ABS for its strength over PLA, which tends to be more brittle and less flexible. Due to its high melting point, ABS is more tolerant of high temperature environments and is valued by manufacturers for its impact and chemical resistance.

This makes ABS a favorite in manufacturing, including injection molding, for applications as wide as plastic toys such as the ubiquitous Lego block, car dashboards, and the plastic cases of countless household appliances.

However, ABS is known to be difficult to tame and difficult to work with. This thermoplastic requires a relatively high and stable temperature to melt, unlike PLA, which becomes malleable at a relatively lower temperature.

Other problems arise as a result, such as the tendency of ABS to buckle, a symptom of the heat contraction that ABS is susceptible to due to its rapid setting properties. In other words, ABS shrinks as it cools. Controlling the rate at which the filament loses temperature is essential to avoid problems.

Best ABS 3D Printers of 2022

FlashForge Adventurer 3 is the best choice for beginners and casual DIYers

- Price: Available at Flashforge 9 Official Store0078

- Assembly volume: 150 x 150 x 150 mm

- Maximum extruder temperature: 240°C

The FlashForge Adventurer 3 printer pretty much meets the requirements for beginners. This ABS 3D printer is replete with features that take the first hassle out of 3D printing. With a simple and intuitive touch screen and detachable flexible build platform, FlashForge Adventurer 3 eliminates many of the usual initial hurdles.

With a simple and intuitive touch screen and detachable flexible build platform, FlashForge Adventurer 3 eliminates many of the usual initial hurdles.

Simplicity extends to more practical aspects: calibration, automatic filament loading and an easy-to-remove nozzle. Plus, there's pure convenience with Wi-Fi connectivity and a handy built-in camera for cloud-based fingerprint monitoring.

With this focus on ease-of-use, FlashForge could have bypassed the complex printing of ABS, but the FlashForge Adventurer 3 is well equipped to handle this tricky thermoplastic.

The printer features a fully enclosed chamber which, combined with an extruder capable of reaching 240°C in less than a minute and a heated bed reaching 100°C, gives you everything you need for successful ABS printing. Although the print quality is not outstanding, it is stable enough to produce quite adequate detail for decorative or domestic purposes.

FlashForge Adventurer 3 is not a machine for professional or experienced printers. We could point to the cramped dimensions of 150 x 150 x 150mm, minimal slicer compatibility, or a filament chamber that only holds FlashForge filament, but ultimately that's not the intended audience.

We could point to the cramped dimensions of 150 x 150 x 150mm, minimal slicer compatibility, or a filament chamber that only holds FlashForge filament, but ultimately that's not the intended audience.

Whether you're a beginner or educator looking for an affordable ABS-enabled printer that won't overwhelm you with options or advanced features, the FlashForge Adventurer 3 is a compact and reliable machine.

Creality CR-200B

- Price: Available at the official Creality store

- Assembly volume: 200 x 200 x 200 mm

- Maximum extruder temperature: 260°C

You've probably heard of the Creality Ender and CR series. But much less attention in Creality's marketing promotions is given to the Creality CR-200B. A sharp, fully enclosed printer designed from the ground up for user convenience, the Creality CR-200B is designed for manufacturers looking to print with high temperature media on a tight budget. This is one of the best ABS 3D printer for beginners.

Despite being cheap, the Creality CR-200B has a well-thought-out set of features, in particular for working with ABS. The closed design joins forces with an extruder with a temperature limit of 260°C and a heated layer of carborundum glass that can maintain a temperature of 100°C. The Creality CR-200B provides optimal conditions for ABS printing and, more importantly, slow cooling to avoid warping and other problems.

When tested, the print quality of the Creality CR-200B is predictable, though the results don't compare to printers twice the price. For hobby projects, prints are more than welcome, whether you're creating decorative pieces or basic functional pieces to make life around the house easier.

Featuring a 4.3-inch touch screen, intelligent thread runout sensor, internal LED lighting and a fully assembled package, the Creality CR-200B is easy to start and use for beginners. If aesthetics are important, the Creality CR-200B's contoured edges and clean black and white design are easy on the eyes.

There's no getting around the fact that the Creality CR-200B's 200 x 200 x 200mm footprint isn't that big, even by budget standards. With the exception of the limited capacity for large prints and manual bed leveling, we are confident that cost-conscious manufacturers looking for a reliable ABS printer will have no problem working and honing their skills with the Creality CR-200B.

Qidi Tech X-Plus

- Price: Check Price

- Building volume: 270 x 200 x 200 mm

- Maximum extruder temperature: 300°C

The Qidi Tech X-Plus extruder meets all the temperature requirements for making quality ABS, but with an interesting twist. Instead of a single extruder that can change temperature, Qidi Tech has made the bold choice of two interchangeable extruders. Elegant yet practical at the same time.

Each is focused on providing the best thermal conditions when using either high temperature filaments such as ABS or 3D printing base materials such as PLA and PETG. One of the two extruders reaches temperatures of up to 300°C, far exceeding the basic requirements for ABS. Nylon and PC also pair well with the Qidi Tech X-Plus.

One of the two extruders reaches temperatures of up to 300°C, far exceeding the basic requirements for ABS. Nylon and PC also pair well with the Qidi Tech X-Plus.

Qidi Tech X-Plus's ABS printing capabilities are expanding, making it one of the best 3D printers for ABS printing. It features a double sided reversible heated bed with one side configured for ABS printing. In addition, Qidi Tech X-Plus has a fully enclosed chamber and air filtration system to meet another temperature requirement for ABS printing and deal with toxic fumes in the process.

One would expect all of these functions to have trade-offs. Fortunately, this is not the case in this case. The Qidi Tech X-Plus features a touch screen, plenty of connectivity options including Wi-Fi, and best of all, effortless bed leveling. It will appeal to both beginners who are looking for an easy path to ABS printing and semi-professionals who value efficiency.

To top it off, the Qidi Tech X-Plus has a working volume of 270 x 200 x 200 mm. Not quite small and not quite large, it is suitable for many tasks, but if you plan to print large quantities, it is better to choose a more powerful alternative.

Not quite small and not quite large, it is suitable for many tasks, but if you plan to print large quantities, it is better to choose a more powerful alternative.

FlashForge Creator Pro 2

- Price: Available in Flashforge official store

- Assembly volume: 200 x 148 x 150 mm

- Maximum extruder temperature: 240°C

FlashForge Creator Pro 2 has all the necessary features for ABS printing. The printer has a closed chamber, a 240°C extruder and a 120°C heated bed, but it stands out from the crowd thanks to its independent dual extruder setup.

IDEX, as it is called, allows you to print different types of media at the same time. They can work with different colors/filament types for mirror, duplication or multi-color prints. In addition, it can perform independent prints at the same time. This opens up many possibilities for ABS printing, not least for more complex overhang projects requiring dissolvable support structures such as rafts and rims.

Even better, FlashForge keeps the price relatively low for what is usually technology reserved for much more expensive ABS 3D printers. IDEX and inexpensive are usually not synonymous, but in the case of FlashForge Creator Pro 2, they are.

Although FlashForge Creator Pro 2 comes fully assembled and boasts user-friendly features such as a touch screen, bed leveling is done manually. Considered alongside the IDEX system, experienced fabricators or small businesses with technical expertise will find this printer more suitable than beginners looking for an easy first step in ABS 3D printing.

Creality CR-5 Pro

- Price: $1,199 - Available at Creality Official Store here

- Assembly volume: 300 x 224 x 380 mm

- Maximum extruder temperature: 300°C

Striking in appearance with a distinct white body and more than a passing resemblance to the stellar Ultimaker S5, the Creality CR-5 Pro will ask you to dig deep into the coffers, but will justify every penny.

Bowden's precision extruder melts ABS to the ideal 250°C, while the 100°C heated bed provides a warm landing pad. In addition, the chamber is closed, it retains all the heat that ABS relies on.

We can say that these are standard things for an ABS ready printer. But the Creality CR-5 Pro goes further. It features an Ultrabase-like carborundum glass plate with a capacious 300 x 225 x 380mm volume and print quality with a level of smoothness and precision you won't find in budget ABS 3D printers.

It's not easy to define the Creality CR-5 Pro as an industrial or consumer grade printer, as it seems to fit into both categories. But this is the versatility of the printer. The Creality CR-5 Pro can serve both hobbyists with spare cash and small businesses that need a high performance ABS printer.

Dremel 3D45 is the best ABS 3D printer for schools

- Price: $1,999

- Assembly volume: 254 x 152 x 170 mm

- Maximum extruder temperature: 280°C

The Dremel 3D45 is designed to simplify and optimize ABS printing by creating a user-friendly ecosystem that takes care of everything right from the start. For schools and educators who place a high value on safety, ease of use and performance, the Dremel 3D45 is one of the best options currently available.

For schools and educators who place a high value on safety, ease of use and performance, the Dremel 3D45 is one of the best options currently available.

The Dremel 3D45 specification is like a list of ideal requirements for ABS printing: a body, a 280°C all-metal extruder, and a 100°C heated bed. Using Dremel's own ABS filament automatically adjusts to the optimum settings and ensures perfect prints every time. Printing safety and convenience are also ensured by charcoal filters, transparent panels, a touch interface and semi-automatic bed leveling.

The theme of the ecosystem here may seem too restrictive and cramped for lone manufacturers who prefer options and features. Little is left to chance here, which in turn limits the Dremel 3D45's ability to go beyond the narrow hand-printing experience.

Ultimaker S3

- Price: $4,000

- Assembly volume: 230 x 190 x 200 mm

- Maximum extruder temperature: 280°C

Last but not least on our list of the best ABS 3D printers is the Ultimaker S3. Considered a more economical $6,000 counterpart to the Dutch manufacturer's Ultimaker S5, the Ultimaker S3 is a versatile professional 3D printer suitable for prototyping and mass production.

Considered a more economical $6,000 counterpart to the Dutch manufacturer's Ultimaker S5, the Ultimaker S3 is a versatile professional 3D printer suitable for prototyping and mass production.

What makes this printer so competent in ABS printing is the combination of 280°C extruders, 140°C heated bed and elegant body design. The resulting print quality is one of the best of any printer on our list, featuring excellent finishes, crisp, precise edges and fine detail. If you want to work with other types of filament, the Ultimaker S3 handles PLA, PVA, CPE and nylon equally well.

The Ultimaker S3 also features a dual extrusion system, which means you can juggle two types or colors of filament in one print. The printer also comes with interchangeable print cores, each with properties suitable for a specific filament type.

It is worth dwelling on other characteristics. For the price, you get all the user-friendliness you want, including automatic bed leveling, Wi-Fi connectivity, a touch screen, material feed sensor, and more.

Buyer's Guide - Things to Consider When Buying an ABS 3D Printer

Enclosed Chamber

Enclosed Chamber is a mandatory and non-negotiable feature when purchasing an ABS 3D printer. The reason for this is temperature control. ABS shrinks or shrinks as it cools.

If the temperature of the ABS drops too quickly, it can cause unwanted warping and twisting. You want to avoid this by using a case that provides a stable temperature, allowing the ABS to cool down more slowly, in a more controlled manner, minimizing the possibility of problems.

Extruder/nozzle temperature

ABS melts between 220°C and 230°C. If you plan to work with more heat sensitive materials such as nylon, look for printers with a standard extruder and nozzle that can handle temperatures from 220°C to 250°C or more.

Heated bed

Be sure to choose a 3D printer with a heated bed, ideally able to withstand temperatures up to 120°C. However, 100°C is sufficient for ABS. The heated bed ensures that the ABS is applied to the platform hot enough to avoid warping and other problems.

However, 100°C is sufficient for ABS. The heated bed ensures that the ABS is applied to the platform hot enough to avoid warping and other problems.

Budget

The best ABS 3D printers available at various prices. They are distinguished from each other by characteristics. In budget options, you'll find everything you need to confidently print with ABS. However, they often lack high-quality features such as automatic bed leveling, Wi-Fi connectivity, etc.

There is also a direct relationship between price and final print quality. Pay more and the results tend to be better.

If you're just getting started with 3D printing, we recommend choosing an inexpensive option to try your hand at, with the option to upgrade to a more expensive model when you're more confident.

Fans

Fans are great for less heat sensitive materials like PLA, but for ABS printing they can be detrimental. Fans that remove heat from the chamber can make it difficult to maintain the correct thermal environment for ABS printing. We recommend 3D printers with the ability to disable fans.

We recommend 3D printers with the ability to disable fans.

Basic 3D printer specifications required to print with ABS

Despite the higher demands compared to the relatively docile and predictable PLA, ABS can thrive in the right conditions.

Closed chamber

First of all, a stable thermal environment. A closed chamber 3D printer provides this environment by storing heat in the build area and blocking warp-causing cold air that can't ruin the print process.

High Temperature Nozzle

In addition, because ABS is temperature sensitive, it requires an extruder with a nozzle capable of reaching temperatures between 220°C and 250°C, depending on the manufacturer's recommendations. Similarly, ABS is best suited for a heated bed capable of maintaining temperatures between 100°C and 110°C.

Print Surface and Adhesive

In addition to the performance requirements, more detailed steps can be taken to successfully print with ABS. These include working with a clean print surface, using adhesive to ensure the first layer is firmly attached to the build plate, and turning off cooling fans if the printer has one.

These include working with a clean print surface, using adhesive to ensure the first layer is firmly attached to the build plate, and turning off cooling fans if the printer has one.

Ventilation for toxic ABS fumes

Finally, when working with ABS, you will inevitably have to deal with harsh, foul-smelling, toxic fumes. Adequate ventilation in the workspace helps dissipate these fumes, so be sure to open a window. Even better, 3D printers have air filters, ideally HEPA, that help keep fumes under control, getting rid of the most harmful properties.

ABS 3D printer upgrade to help you print better parts

Most ABS 3D printers come with everything you need to get started, but there are always ways to improve the process and improve your printer. Here are the three most common ways to upgrade.

All Metal Hot End

One cost effective upgrade that can extend the life of your 3D printer is to go from a Teflon gasketed hot end to an all metal hot end or Capricorn tube.