Best 3d printer board 2023

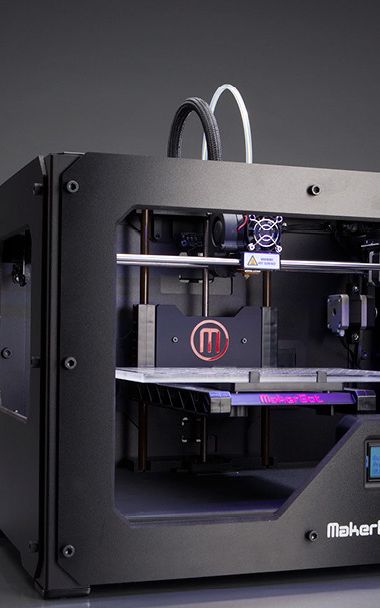

Best 3D Printer for 2022

In the last few years, 3D printing has crossed a rubicon into the mainstream consciousness. Schools and libraries often have 3D printers, and the barrier to entry for hobbyists is lower than ever, with inexpensive machines offering excellent out-of-the-box results.

Because 3D printing technology has come a long way in recent years, I've doubled down on being creative and gotten into 3D scanning and laser cutting as well, which lets you sculpt real-world designs from leather and wood. Advanced printers are also using resin machines that create amazingly detailed prints.

Current 3D printers, which range from affordable (under $300) to high-end (over $4,000), are great gifts for a creative person in your life. Even better, they're great for you to craft your own personalized designs if you're looking to open an Etsy shop or something similar.

These models by Fotis Mint are extremely detailed.

James Bricknell/CNETWe've taken a deep dive into many of the best 3D printers available today. This list includes both small and large 3D printers, with attention paid to print speed, the size of the build plate, the cost of PLA filament, the kind of print head included and other important details. And once you've decided to take the plunge into additive manufacturing -- that's what 3D printing essentially is -- there's an FAQ below.

Our top picks

Dan Ackerman/CNET

Creality Ender-3 S1

Best step-up starter printer

I'd avoided Ender-3 printers for a long while, because they came in kit form and required many hours of assembly, setup and fine-tuning to use. For just a little more than the kit versions, the newer Ender-3 S1 comes nearly fully preassembled, and with high-end features like a direct drive extruder and self-leveling bed.

Print quality even out-of-the-box was excellent, although a lot of that comes down to having good models to work from. I'd love it to have a touchscreen and Wi-Fi, but apart form those missing features, this is a great way to get polished results from a $400 3D printer.

I'd love it to have a touchscreen and Wi-Fi, but apart form those missing features, this is a great way to get polished results from a $400 3D printer.

Read our Creality Ender-3 S1 review.

$399 at Amazon

Dan Ackerman/CNET

Anycubic Vyper

Best for out-of-the-box printing

The Anycubic Vyper FDM printer attempts to be both an affordable 3D printer and easy to use. It's a tricky needle to thread. Plenty of 3D printers offer automatic bed leveling and calibration to make sure prints come out even and firmly anchored to the print bed. This, however, is the first time I've seen a 3D printer run its bed leveling once, with zero manual input from me, and be totally good to go. I printed a 3D test file from the included SD card within minutes of powering on, and I've never seen a first print from a 3D printer come out so perfectly.

Read our Anycubic Vyper review.

$319 at Anycubic

$490 at Amazon

Anycubic

Anycubic Kobra Max

Best to make big projects easily

The Anycubic Kobra Max earned a 9 out of 10 in our recent review, in large part because it's one of the most enjoyable printers I've used in years. The build area is large enough to print entire helmets for cosplay, and the auto-bed-leveling system makes setting the machine up a breeze. The Kobra Max is the best choice for a large build area printer, bar none. --James Bricknell

Read our Anycubic Kobra review.

$549 at Anycubic

Entry-level 3D printers

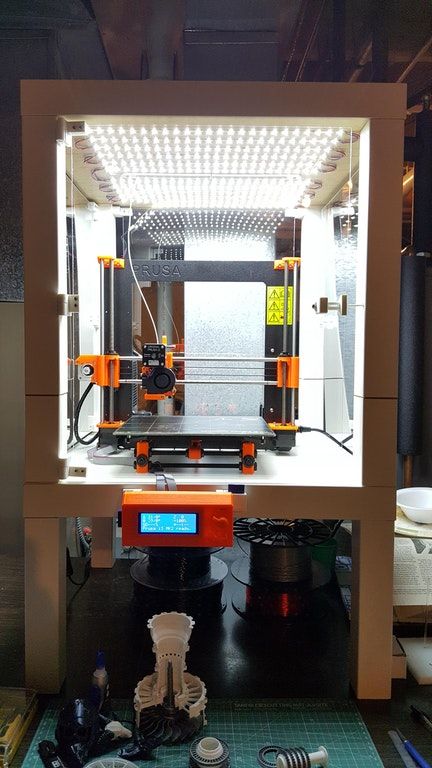

Prusa Research

Prusa Mini Plus

Small but mighty

The Mini Plus is one of the best small-footprint printers you can buy. It has everything you would expect from a Prusa machine: Auto bed leveling, crash detection and great print quality, all for under $450. Building it with my son gave us a lot of good insights into how a 3D printer works, and potentially how to fix one.

Building it with my son gave us a lot of good insights into how a 3D printer works, and potentially how to fix one.

$429 at Prusa Research

Sarah Tew/CNET

Anycubic Mono

Best inexpensive resin 3D printer

Resin printers are the next step up in rapid prototyping design technology when you want your printing to look as high quality as possible. Just be warned: The liquid resin is harder to work with, and it requires both good ventilation and a portable UV light to properly cure. This model is extremely popular with board game hobbyists who want to print pro-looking miniatures, and sometimes you'll see it fall in price. Note that you can save $20 at Amazon by activating the instant coupon on the product page.

$189 at Anycubic

$250 at Amazon

Dan Ackerman/CNET

Monoprice Mini Delta V2

Best for tiny desks

I had high hopes for this dirt-cheap 3D printer with a tiny footprint. It's usually under $200 and requires no additional assembly. And I do like it, but it's for a specific audience. This is not the great low-cost entry-level printer I was hoping for. It required some tweaking and troubleshooting to get up and running. The included microSD card was so cheap and corrupted it never worked, the built-in Wi-Fi was never able to connect to my network, and the machine's arms got caught on some poorly installed plastic wire covers (I just ripped the paper-thin covers off).

It's usually under $200 and requires no additional assembly. And I do like it, but it's for a specific audience. This is not the great low-cost entry-level printer I was hoping for. It required some tweaking and troubleshooting to get up and running. The included microSD card was so cheap and corrupted it never worked, the built-in Wi-Fi was never able to connect to my network, and the machine's arms got caught on some poorly installed plastic wire covers (I just ripped the paper-thin covers off).

But once I had all the problems ironed out, it was a reliable little machine for quick jobs. It would make a great second 3D printer, or if you need to fit one into a small space. I especially liked the auto-leveling, which worked well, and the color touchscreen, which is a feature that often gets chopped from low-cost models. If you're willing to put a little effort into getting it set up correctly, it's a great printer for the price.

$175 at Amazon

Midrange 3D printers

Anycubic

Anycubic Photon Mono X

Best for mass-produced gaming minis

Standard resin printers are fine if you want to print small items or miniatures. For more oversized cosplay items, practical models or collections of gaming miniatures, you're going to need a bigger build area.

For more oversized cosplay items, practical models or collections of gaming miniatures, you're going to need a bigger build area.

Enter the Anycubic Mono X, a resin printer that solves that issue by having a build plate nearly three times bigger than the standard Anycubic models. For example, I managed to print the entire blade of a Dune Crysknife, something that would have needed to be split into three parts if it wasn't for the extra build volume.

The Mono X also prints at insane speeds. Because resin prints the entire layer in one shot, they tend to be quicker than traditional FDM printers in the first place, but the Mono X takes this to the extreme with layers printing in as little as 1 second. It's incredible to watch. --James Bricknell

It's still cheaper to shop at Anycubic directly, but you can save $110 at Amazon by activating the instant coupon on the product page.

$349 at Anycubic

$660 at Amazon

James Bricknell/CNET

Flashforge Adventurer 4

Best 3D printer for ease of use

The Flashforge Adventurer 3 has long been one of CNET's favorite midprice 3D printers. The updated Adventurer 4 brings a handful of iterative improvements that make for a winning evolution. The Adventurer 4 is a fully enclosed unit, which helps control the temperature and block drafts. The build area is 220 by 200 by 250mm, and it has a system for easily swapping out nozzles -- all good features to have in a mid-level to high-end printer.

The updated Adventurer 4 brings a handful of iterative improvements that make for a winning evolution. The Adventurer 4 is a fully enclosed unit, which helps control the temperature and block drafts. The build area is 220 by 200 by 250mm, and it has a system for easily swapping out nozzles -- all good features to have in a mid-level to high-end printer.

$849 at Amazon

High-end and professional 3D printers

Creality

Creality CR-30

Best for small biz or pro cosplayers

A word of warning; the CR-30 is not for the beginners out there. It is a complicated machine, and you will need some 3D-printing knowledge to really get the hang of it. It's also a very different beast, and instead of printing on a static-sized build plate, it uses a conveyor belt to create an "endless Z-axis." That lets you print very long things or lots of things over and over again.

If you are a cosplayer looking to make weapons or large armor pieces, the CR-30 gives you a lot of room to create. I've managed to print Squall's Gunblade from Final Fantasy VIII as well as the Whisper of the Worm from Destiny 2 (both were printed in two halves and attached together). It's great for small businesses looking to mass-produce small parts, and with just two CR-30s you could create a small empire on Etsy or Shopify. --James Bricknell

$1,100 at Crealty

$1,100 at Amazon

Sarah Tew/CNET

Glowforge 3D Laser Cutter

Best for woodworkers

I can't begin to tell you how much I love the Glowforge. Laser cutters can create projects from wood, leather, lucite and other materials, making it an interesting creation alternative to filament-based 3D printers. Even better, what would take a 3D printer hours to do takes just minutes in the Glowforge.

With it, I've created laser-etched LED lights, birch wood tool caddies, and even a three-tier box for my Nespresso sleeves. There's a robust community of makers creating and sharing files, but pretty much any line drawing you can create in something like Adobe Illustrator can be turned into a project.

The software is all cloud-based, which adds a layer of complication (you need internet service to use it), but the ability to create amazing gifts and more from simple 0.125-inch or 0.25-inch cheap plywood is pretty empowering.

See some of my laser cutter projects (and download my SVG files) here.

$3,995 at Glowforge (Glowforge Basic)

$4,995 at Glowforge (Glowforge Plus)

3D Scanners

Revopoint

Revopoint Pop 2

Incredible details

While the software has a pretty steep learning curve, the end result is extremely detailed. I've really enjoyed using the handheld version to scan larger models while the included turntable makes scanning smaller objects a breeze. If you are looking for a professional-grade scanner and can spend some time on the software, the Pop 2 is a great choice.

I've really enjoyed using the handheld version to scan larger models while the included turntable makes scanning smaller objects a breeze. If you are looking for a professional-grade scanner and can spend some time on the software, the Pop 2 is a great choice.

$800 at Amazon

Sarah Tew/CNET

SOL Desktop Laser 3D Scanner

Best 3D scanner for easy replicas

Recreate pretty much anything by putting it on this 3D scanner, where a rotating base and built-in camera create a 360-degree copy, which is then editable in any 3D program and printable on your 3D printer. Simply scan the object, import the scan into your slicing software for cleanup, and print. The included software alerts you of next steps in the printing process with either sound or texts. Scan quality and print resolution are great, and setup is easy, although you might want to clean up your 3D model a bit in a 3D software app after.

$614 at Amazon

3D printing FAQs

What material should I use to print with?

Most home 3D printers use PLA or ABS plastic. Professional printers can use all sorts of materials, from metal to organic filament. Some printers use a liquid resin, which is much more difficult to handle. As a beginner, use PLA. It's nontoxic, made mostly of cornstarch and sugarcane, handles easily and is inexpensive. However, it's more sensitive to heat, so don't leave your 3D prints on the dashboard of a car on a hot day.

Which brand of PLA is best?

Generally speaking, Hatchbox has never let me down and runs about $25 for a full 1kg spool on Amazon. Some of the printers I tested only accommodate narrower 0.5kg spools. In those cases, I sometimes used a larger Hatchbox roll with a separate spool-holder. Other times, I had good luck with AIO Robotics 0.5kg spools, which are a little more expensive, at $14 for 0.5kg. Amazon Basics and Monoprice can also be good, but for any brand, weird colors like metallic or glow-in-the-dark filament can be hit-or-miss. Note that a 1kg roll prints a lot of stuff.

Note that a 1kg roll prints a lot of stuff.

What settings should I use?

Most 3D printers include or link to recommended software, which can handle converting 3D STL or other files into formats supported by the printer. Stick with the suggested presets to start, with one exception. I've started adding a raft, or bottom layer of filament, to nearly everything I print. It has cut down dramatically on prints that don't adhere to the bed properly, which is a common issue. If you continue to have problems, rub a standard glue stick on the print bed right before printing.

What are supports?

Your 3D models probably need some help to print properly, as these printers don't do well with big overhangs -- for example, an arm sticking out from a figure. Your 3D printer software can usually automatically calculate and add supports, meaning little stands that hold up all those sticking-out parts of the model. After the print is done, clip the supports off with micro cutters and file down any nubs or rough edges with hobby files.

Where do I find things to print?

Thingiverse.com is a huge online repository of 3D files for anything and everything you can think of. Pokemon chess set? It's there. Dyson vacuum wall mount? You bet.

When you're ready to create your own designs, there are a ton of software packages to choose from, but it's easiest to start with the browser-based free TinkerCad app from Autodesk.

Crazy things I've made on a 3D printer

+15 more See all photosMore creative recommendations

- Best 3D Printer Filament

- Best Budget 3D Printer

- Best Laptops, Desktops and Tablets for Designers and Creatives in 2022

- Best Vlogging Camera for 2022

- The Best 3D Printer Resin

Best Budget 3D Printer 2022: 6 Great Printers at a Price You'll Love

It costs less than ever to get into 3D printing, with printers available for under $200. The catch is that these budget machines usually require some tweaking to get right. You'll save money, but it's a rough and tumble way to get started.

The catch is that these budget machines usually require some tweaking to get right. You'll save money, but it's a rough and tumble way to get started.

3D printing -- or additive manufacturing to give it its scientific name -- has been around a long time now. It's a fun way to create models that can be practical, or just for fun. You can print giant pieces of cosplay armor, or small statues to give as gifts. You can even buy a few printers, open your own Etsy store and make yourself a tidy profit.

These budget 3D printers all cost under $500 (though prices can drift a bit month to month), and some are better suited to beginners than others. Our list of picks for best 3D printer overall covers a much wider range of choices, but these are excellent for getting started or for buying several at once!

Dan Ackerman/CNET

Anycubic Vyper

Our top pick

The Anycubic Vyper is easily the best budget 3D printer available now. Unlike a lot of other low-cost printers, the Vyper includes high-end features that make the entire experience better. There's a filament run-out sensor and a power loss detector. The automatic bed leveling helps produce a worry-free finished product.

Unlike a lot of other low-cost printers, the Vyper includes high-end features that make the entire experience better. There's a filament run-out sensor and a power loss detector. The automatic bed leveling helps produce a worry-free finished product.

$430 at Amazon

Creality

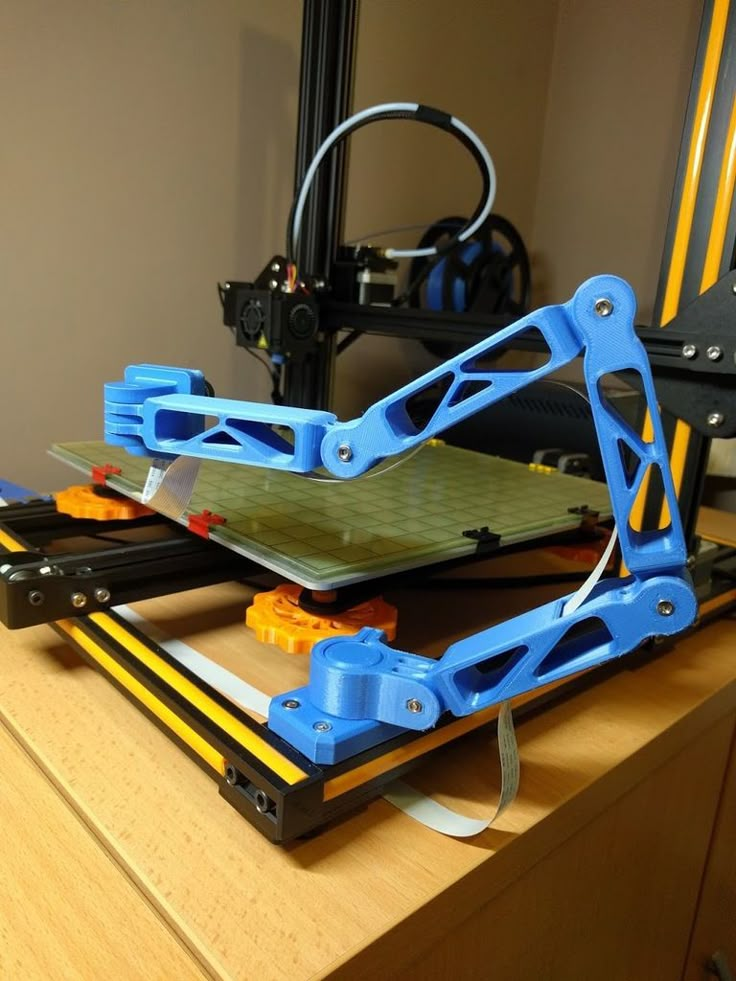

Creality Ender 3

Community favorite

The Ender 3 is one of the bestselling 3D printers of all time. Its under-$200 price removes a huge barrier to entry for anyone looking to spend as little as possible for their first machine.

Its popularity means there is a huge community of people to help you get it set up and working -- it's not exactly plug-and-play -- and you may need to spend a fair amount of time tweaking the Ender 3 to get it to print as well.

$189 at Amazon

Prusa Research

Prusa Mini Plus

Small but mighty

The Mini Plus is one of the best small-footprint printers you can buy. It has everything you would expect from a Prusa machine: Auto bed leveling, crash detection and great print quality, all for under $450. Building it with my son gave us a lot of good insights into how a 3D printer works, and potentially how to fix one.

It has everything you would expect from a Prusa machine: Auto bed leveling, crash detection and great print quality, all for under $450. Building it with my son gave us a lot of good insights into how a 3D printer works, and potentially how to fix one.

$429 at Prusa Research

James Bricknell/CNET

Elegoo Neptune 2

Keep it simple

The Elegoo is one of my favorite ultra-cheap printers. When testing it, I kept expecting it to fail and it just didn't. It produced amazing results for the price, and continues to do so every time I use it. It doesn't have auto bed leveling, but the Elegoo was easy to set up. And because it's based on the popular Ender 3, it has a lot of mods available to make it even better.

$180 at Amazon

Dan Ackerman/CNET

Creality Ender 3 S1

Direct drive with advanced features

As Dan Ackerman said in his review of the Creality Ender 3 S1 "At $399, the S1 version of the Ender-3 is about $100 more than older versions but includes so many upgrades and quality of life features that it qualifies as a great beginner-friendly, plug-and-play printer. "

"

It's also a great budget-friendly Direct Drive printer, making it easier to use for materials such as TPU.

$400 at Amazon

Resin 3D printers for beginners

Most beginner printers use plastic filament to create models, but there are plenty of affordable resin 3D printers, too. Liquid resin is a little more difficult to use than standard 3D printing material, and requires safety equipment. But it also produces amazingly detailed results.

Elegoo

Elegoo Mars 3

The best starter resin printer

This small resin printer is Elegoo's latest model in its popular Mars line. Because of the 4K monochrome LCD (these printers use light from an LCD to cure liquid resin) it can print much faster than older printers. The level of detail on models is something that standard 3D printing simply can't reproduce. At this price, the Elegoo Mars 3 is the best resin printer for the money.

$255 at Amazon

James Bricknell/CNET

Anycubic Mono X

When you need it bigger

This is expensive for a budget printer, but well worth it if you want a large enough print area to make something special. I have been using this as my main resin printer and it can handle anything I throw at it, from a D&D miniature army to highly detailed sculptures.

$500 at Matterhackers

$450 at Amazon

James Bricknell/CNETFrequently asked questions

What material should I use to print with?

Most home 3D printers use PLA or ABS plastic. Professional printers can use all sorts of materials, from metal to organic filament. Some printers use a liquid resin, which is much more difficult to handle but offers sharper details. As a beginner, use PLA. It's non-toxic, made mostly of cornstarch and sugarcane, handles easily, and is inexpensive. However, it's more sensitive to heat, so don't leave your 3D prints on the dashboard of a car on a hot day.

As a beginner, use PLA. It's non-toxic, made mostly of cornstarch and sugarcane, handles easily, and is inexpensive. However, it's more sensitive to heat, so don't leave your 3D prints on the dashboard of a car on a hot day.

What settings should I use?

Most 3D printers include or link to recommended software, which can handle converting 3D STL or other files into formats supported by the printer. Stick with the suggested presets to start, with one exception. I've started adding a raft, or bottom layer of filament, to nearly everything I print. It has cut down dramatically on prints that don't adhere to the bed properly, which is a common issue. If you continue to have problems, rub a standard glue stick on the print bed right before printing.

What are supports?

Your 3D models probably need some help to print properly, as these printers don't do well with big overhangs -- for example, an arm sticking out from a figure. Your 3D printer software can usually automatically calculate and add supports, meaning little stands that hold up all those sticking-out parts of the model. After the print is done, clip the supports off with micro cutters and file down any nubs or rough edges with hobby files.

After the print is done, clip the supports off with micro cutters and file down any nubs or rough edges with hobby files.

How we test

Testing 3D printers is an in-depth process. Printers often don't use the same materials, or even the same process to create models. I test SLA, 3D printers that use resin and light to print, and FDM, printers that melt plastic onto a plate. Each has a unique methodology. Core qualifiers I look at include:

- Hardware quality

- Ease of setup

- Bundled software

- Appearance and accuracy of prints

- Repairability

- Company and community support

A key test print, representing the (now old) CNET logo, is used to assess how a printer bridges gaps, creates accurate shapes and deals with overhangs. It even has little towers to help measure how well the 3D printer deals with temperature ranges.

James Bricknell/CNETTesting resin requires different criteria so I use the Amerilabs standard test -- printing out a small resin model that looks like a tiny town. This helps determine how accurate the printer is, how it deals with small parts and how well the UV exposure works at different points in the model.

This helps determine how accurate the printer is, how it deals with small parts and how well the UV exposure works at different points in the model.

Many other anecdotal test prints, using different 3D models, are also run on each printer.

For the other criteria, I research the company to see how well it responds to support queries from customers and how easy it is to order replacement parts and install them yourself. Kits (printers that come only semi-assembled) are judged by how long, and how difficult, the assembly process is.

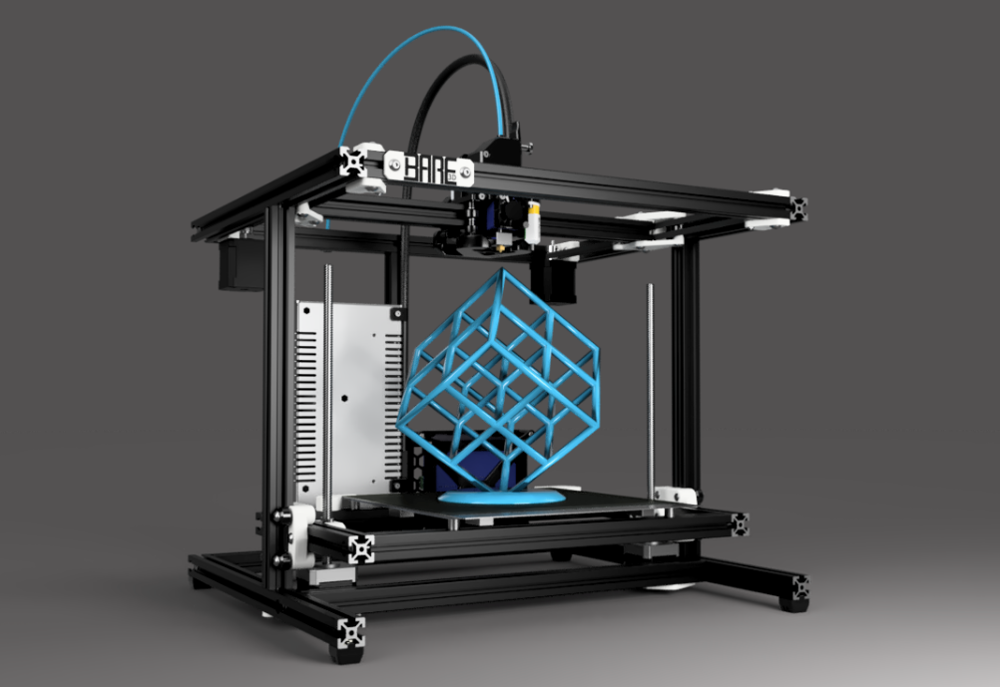

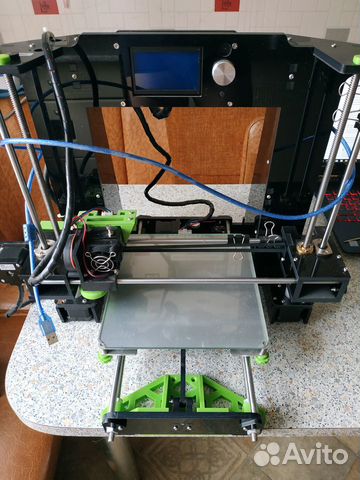

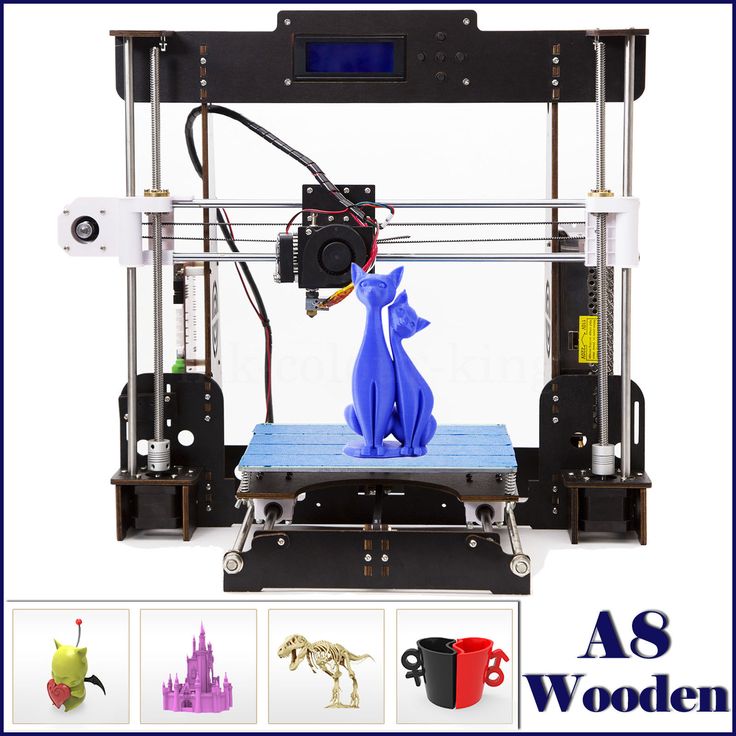

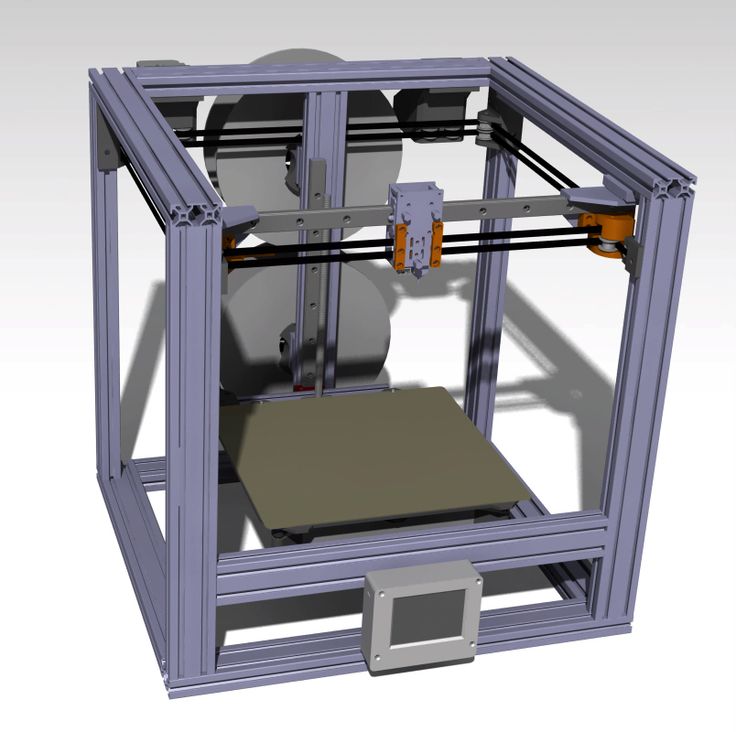

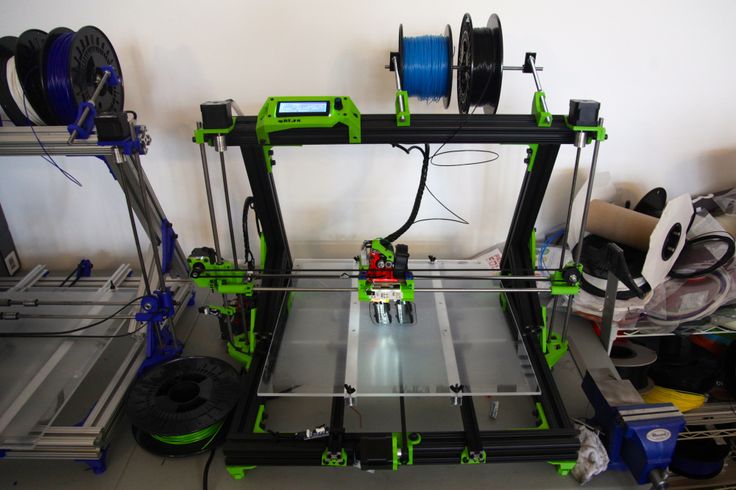

Board for a 3D printer: choosing a control motherboard

When buying or assembling a 3D printer with your own hands, special attention should be paid to the device's motherboard. Since this component is responsible for printing products in general. Consider what functions the motherboard performs, what types of this component exist, and what parameters you need to pay attention to when choosing it.

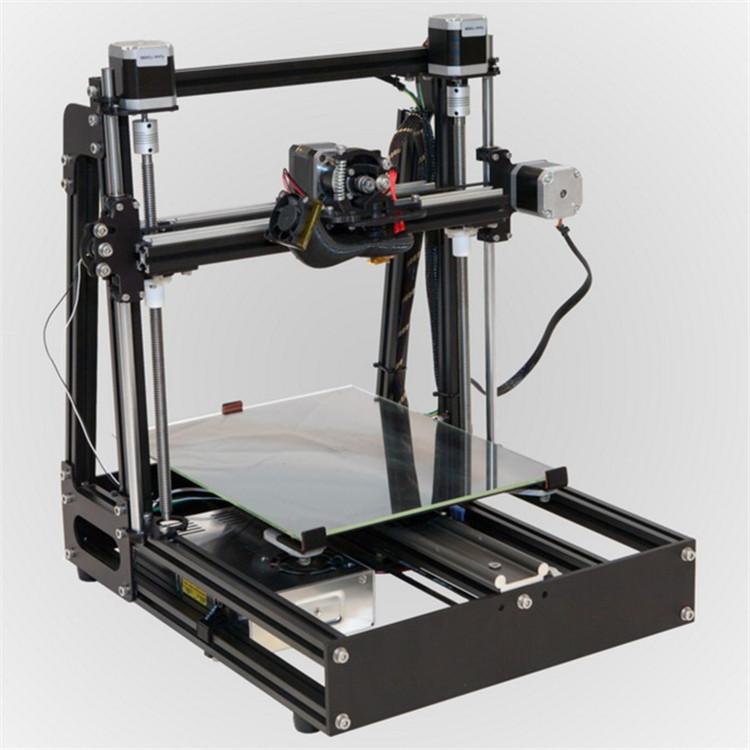

3D printer motherboard

The controller motherboard is the main control element for the extruder, motor, sensor and heated filament bed in any 3D printer.

Motherboard is executing user-specified commands. After the internal set of microchip elements converts electrical impulses into mechanical movements of stepper motors. As a result, a three-dimensional computer model will be printed layer by layer on the working surface of a 3D printer.

Choosing a control board

Among the most popular motherboards for 3D printers, there are five models:

- Arduino Mega 2560 + Ramps 1.4.

- Melzi.

- Lerdge X.

- Duet.

- Rumba.

Let's take a closer look at the features, pros and cons of each board.

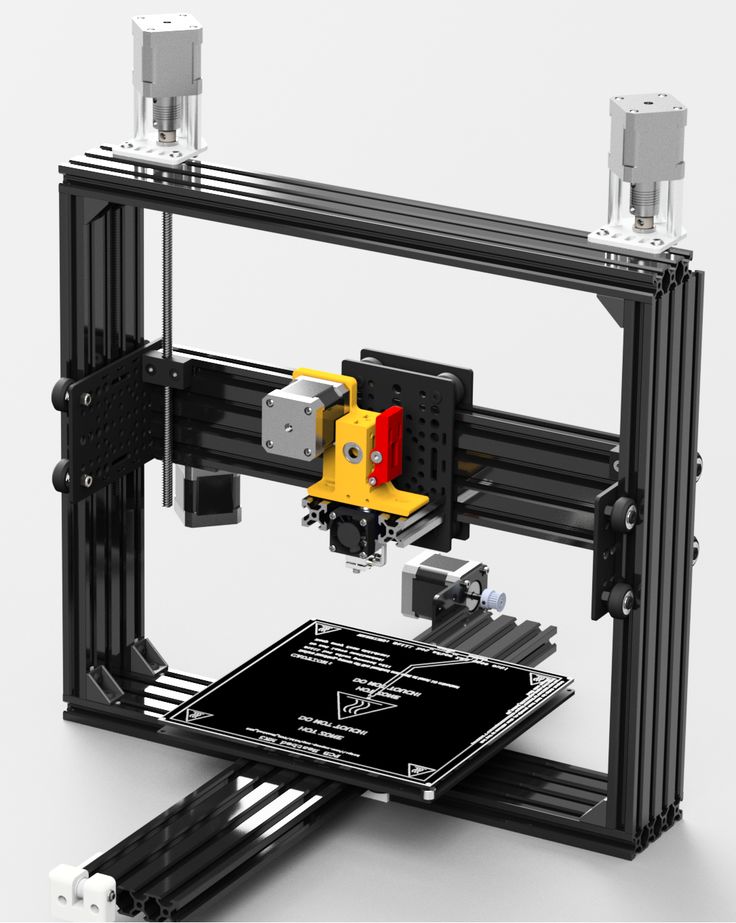

Arduino Mega 2560 + Ramps 1.4

Board with Ramps 1.4 component operates from 5 V. It is equipped with five slots for installing stepper motors. At the same time, three slots allow the motors to control the axes of the printer, and the other two to drive the extruders. In addition, the board contains many additional pins for controlling various elements, such as a table auto-level sensor, axle limit switches, servos, etc.

To control all the printer's built-in electronics, the board contains contact pads into which the Ramps shield component is inserted.

The three main advantages of the board are:

- low price;

- a wide range of interchangeable components that can be replaced in the event of a breakdown;

- additional pins for controlling various printer components.

The board has only one significant drawback - its bulky design.

Melzi

The Melzi motherboard is equipped with four stepper motor controllers, three of which are located on the XYZ axis and one on the extruder. This model is sold already with customized firmware. Therefore, the user only needs to correctly connect the wires to the output connectors.

You can print 3D objects using a memory card via a micro-USB connector or by connecting the card directly to a computer.

The Melzi board is ideal for the beginner building a printer for the first time. Since it does not require additional calibrations and can be used immediately after purchase. However, the motherboard also has significant drawbacks:

Since it does not require additional calibrations and can be used immediately after purchase. However, the motherboard also has significant drawbacks:

- no display can be connected to the board;

- You can reflash the motherboard only through the ISP port, but this will take a lot of time and a layer of special knowledge;

- If the motor controller fails, it cannot be replaced.

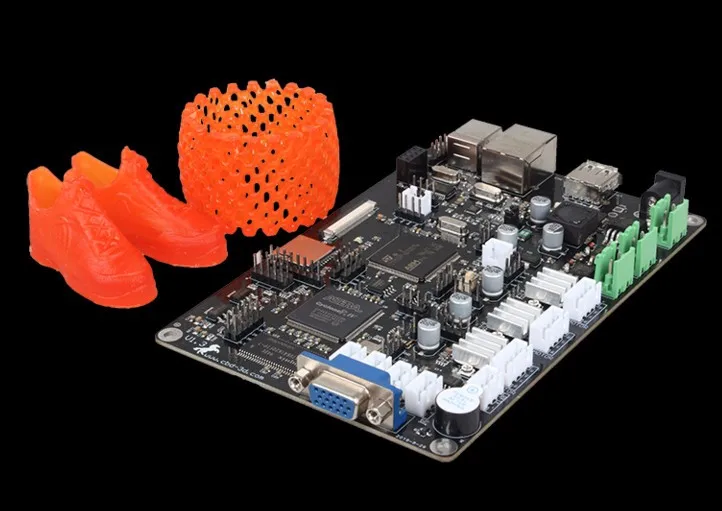

Lerdge X

Lerdge X is a motherboard with a 32-bit STM32F407 chip that allows you to quickly read lines of code. The device is additionally equipped with four drivers and a color display with touch control. The board supports only one extruder and it is not possible to install a second one if necessary.

Before using the board, you need to calibrate it, set the dimensions of the working area, adjust the temperature sensors of the extruder and table, and set the speed parameters of each motor.

You can print files using a flash drive, memory card or via a computer.

Pros of using the Lerdge X board:

- motherboard fits any type of printer;

- board chip supports various kinds of popular slicers;

- built-in display with touch screen.

The disadvantage of using the board is that only one extruder can be used.

Duet

The Duet board is equipped with its own open source firmware, which is available for free to any user on Github.com. The 32-bit Atmel SAM3X8E chip is responsible for the stable operation of the motherboard.

Built-in device drivers allow four extruders to print simultaneously. For more convenient control, the user can install a touch screen with a diagonal of 4.3, 5 and 7 inches.

Pluses of the board:

- free firmware;

- four extruders available at the same time;

- two board configurations to choose from (Ethernet or Wi-Fi).

Duet motherboard cons:

- Before installing the board, it requires full configuration and firmware.

Rumba

The Rumba 8-bit motherboard allows the 3D printer to use three extruders at the same time. However, installing them separately will not work, but you can only install a Diamond Hotend multi-extruder with support for three filaments.

This type of board is based on the Arduino processor. It comes with Marlin firmware installed. If the user needs to reflash the board, then for this you can use the standard mini-USB connector.

Among the advantages of Rumba are:

- the presence of connectors for connecting a display and a slot for a memory card;

- removable motor drivers that can be easily replaced if broken;

- simple flashing if necessary.

The main disadvantage of the motherboard is that for printing with multiple filaments, you will need to purchase an additional multi-extruder.

What to look for when choosing a 3D printer board?

When choosing a motherboard for installation in a 3D printer, the user is advised to pay attention to six device parameters:

- The number of supported extruders. Ideally, there should be four or more. In this case, full color printing will be available.

- Integrated or plug-in drivers. It is desirable that the drivers in the board are removable. Since in the event of a breakdown, they can be easily removed and repaired or replaced in the event of a complete malfunction.

- Number of engines. It is recommended that the board has at least four motors, ideally six.

- Wi-Fi available. The built-in module will allow you not to constantly connect the printer to the computer each time you print.

- Firmware support. It is desirable that the board supports various types of firmware. Both paid and free.

Help. Each specific type of board can support one or more types of firmware.

Their number depends on the board manufacturer. For example, Arduino boards support Marlin, Marlin Kimbra, Marlin RichCattell, Repetier-Firmware, Teacup, Aprinter, Sprinter firmware. Arduino Due motherboards can work with Marlin4Due, Marlin Kimbra v4.2.x, Repetier-Firmware, RepRap Firmware. And 32-bit ARM processors are compatible with Smoothie Project and Redeem firmware.

Their number depends on the board manufacturer. For example, Arduino boards support Marlin, Marlin Kimbra, Marlin RichCattell, Repetier-Firmware, Teacup, Aprinter, Sprinter firmware. Arduino Due motherboards can work with Marlin4Due, Marlin Kimbra v4.2.x, Repetier-Firmware, RepRap Firmware. And 32-bit ARM processors are compatible with Smoothie Project and Redeem firmware. - The presence of protection against incorrect inclusion of elements.

In this article, we have listed only the most popular motherboards for 3D printers. However, on the electronics market there are boards for any user requests, the choice of which can be guided by the recommendations presented above.

- March 29, 2021

- 4071

Get expert advice

where to study, where to work, salary

Updated

3D printing engineer is engaged in technical support, work with equipment, software, creation of 3D models. A specialist needs to have deep knowledge of engineering, programming, and mathematics. The profession is referred to the specialties of the future. By the way, the ProfGid career guidance center has recently developed an accurate career guidance test that will tell you which professions suit you, give an opinion about your personality type and intelligence. The profession is suitable for those who are interested in physics and mathematics (see. choosing a profession based on interest in school subjects). 9Ol000

A specialist needs to have deep knowledge of engineering, programming, and mathematics. The profession is referred to the specialties of the future. By the way, the ProfGid career guidance center has recently developed an accurate career guidance test that will tell you which professions suit you, give an opinion about your personality type and intelligence. The profession is suitable for those who are interested in physics and mathematics (see. choosing a profession based on interest in school subjects). 9Ol000

Brief description

The profession of a 3D printing engineer has appeared quite recently, but its value and social significance cannot be underestimated. With the help of 3D printing, unique products used in medicine and industry are already being created today. Mathematicians and engineers are constantly developing more advanced technologies that make it possible to create blanks, anatomical models, souvenirs, houses, prostheses using this type of printing. And printers used for printing with biomaterials make it possible to create human skin, which has become a breakthrough in the treatment of wounds, injuries, and acceleration of the rehabilitation period.

And printers used for printing with biomaterials make it possible to create human skin, which has become a breakthrough in the treatment of wounds, injuries, and acceleration of the rehabilitation period.

Read also:

Full control over 3D printing is carried out by an engineer who is an excellent programmer, technologist, biologist and even a chemist, because the profession forces him to know the composition and properties of different materials well. To work in this area, you must have a technical education, attending IT courses, lectures on modeling will be a plus. A specialist must be able to independently design a 3D model, select the necessary materials, calculate all the risks, and then print, creating products for the field of medicine, aviation, industry, etc.

Occupation specifics

3D printing engineers use different materials for their work, computer programs and industrial 3D printers. Today, medical centers, industrial, aerospace, engineering and other industries need these specialists. There are few specialists, their work cannot be called simple, because the duties of a 3D printing engineer include:

There are few specialists, their work cannot be called simple, because the duties of a 3D printing engineer include:

- selection of new materials, testing;

- using modern software to improve and adjust 3D printer settings;

- preparation of layouts, development of raster images for subsequent printing;

- full print control;

- study of new technologies;

- knowledge of certification rules, requirements that are put forward for 3D models and finished products;

- documentation development, software debugging;

- selection of new equipment, training of other employees;

- equipment maintenance.

Responsibilities vary by location, but a 3D Printing Engineer must be a multi-skilled professional who is ready to quickly learn new technologies at any time and then successfully apply them in practice. Employers put forward strict requirements for engineers, because the wages of such specialists are solid. They must have at least 3 years of practical work experience, the obligatory knowledge of a technical foreign language is important. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

They must have at least 3 years of practical work experience, the obligatory knowledge of a technical foreign language is important. A 3D printing engineer must know the basics of economics and marketing, because his duties include optimizing workflows aimed at reducing the cost and speed of printing.

Read also:

Pluses and minuses

Pluses

- An important profession that will help save millions of lives in the future, improve the environment, and allow the rational use of natural resources.

- 3D printing engineers are unique specialists today.

- Demand in various fields.

- A specialist will have no problems finding work in megacities.

- The salary is stable and high.

- An experienced engineer will be able to open his own production for the manufacture of souvenirs or other products.

- You can study in Russia by enrolling in a technical university.

- Lack of physical activity.

Cons

- Working sedentary, but not monotonous.

- Irregular working hours, because the creation of a large product can last for more than 5 hours.

- The cost of industrial 3D printers is high, so in order to organize your own production, you need to think about starting capital or finding an investor.

- Any mistakes made by a 3D printing engineer are associated with huge financial losses.

- Difficulties in finding work in small towns and villages.

- Work at the computer leads to a decrease in vision.

Important Personal Qualities

A 3D Printing Engineer has a lot of professional knowledge, so he must be an erudite person with an excellent memory. The character of this rare specialist should contain responsibility, curiosity, and creativity. An engineer is obliged to constantly study, a craving for both the exact sciences and linguistics is welcomed, because most of the instructions, books and technical documentation are still being created mainly in foreign languages.

See also:

3D printing engineer training

Universities

-

4 years

220,000 ₽/year

15 budget places

-

4 years

48,500 ₽/year

12 budget places

-

36 200 ₽/year

25 budget places

-

4 years

200,000 ₽/year

25 budget places

See also:

Place of work

3D printing engineers will be able to work in agencies engaged in the production of consumer goods. They are in demand in architectural companies, factories, medical centers and nanolaboratories, clothing design and manufacturing agencies.