Shapeways 3d printing cost

How much does 3D printing cost?

As a 3d printing company, we always get asked: "how much does it cost to 3d print?".

Our answer has always been "it depends" as there are factors that contribute to the cost of 3d printing. You're looking at anywhere between $3 to $1000(or even more) for the cost to 3d print based on these factors.

So today, we're breaking down each factor for you. If you're 3D printing at home, then those factors are your material, electricity and 3D printer cost. But if you're looking for a 3d printing service or looking into starting a 3D printing business, this guide should help you understand how pricing works when it comes to 3d printing.

Factors that affect the price of 3D printing

Cost of buying and running a 3D printer

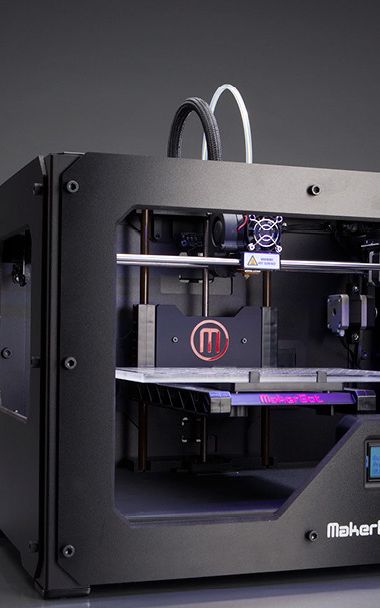

If you're starting a 3D printing business or looking to make money with 3D printing, you might want to consider the price of a 3D printer in calculating the cost to 3D print something. 3D printers can cost anywhere between $200 to $150,000 depending on the technology being used.

Let's say you purchased a $1500 3D Printer that you plan to use 8 hrs / day for 2 years. We're going to ignore repair cost, electricity, etc. for the sake of simplicity.

8 x 365 x 2 = 5840 total hours

$1500 / 5840 hrs = ~ $0.21/hr

So if your 3D model would take about 4 hours to 3D print, then you need to charge $0.84 on top of your price to account for your machine upkeep.

In a way, the time it takes to 3D print also adds to the cost of 3D printing.

3D Model

3D model of a dinosaur trophy"Send us the 3D model" is the second thing we tell our clients after telling them "it depends". Without the 3D model, it's tough to come up with an accurate quote for a 3D print even for seasoned veterans.

The 3D model gives us essential information that can help us quote a 3d print.

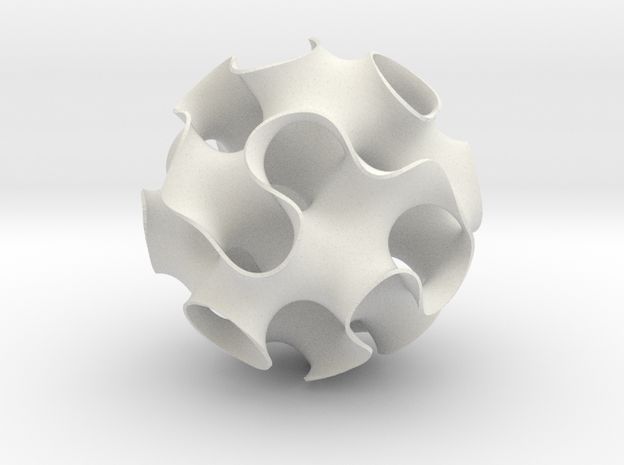

Model volume

With the 3d model on hand, we can calculate the total volume of the model, including the generated supports. The total volume lets us know how much material is needed to 3d print your file.

The total volume lets us know how much material is needed to 3d print your file.

In short, the larger the volume, the higher the cost. There are ways to reduce the cost of 3D printing, and one of them is to hollow your model.

A 3ft model can have less volume than a 1ft model if the 1ft model is solid on the inside, while the 3ft model is hollow.

That is why coming up with an estimate price of 3d printing without the 3d model is not easy.

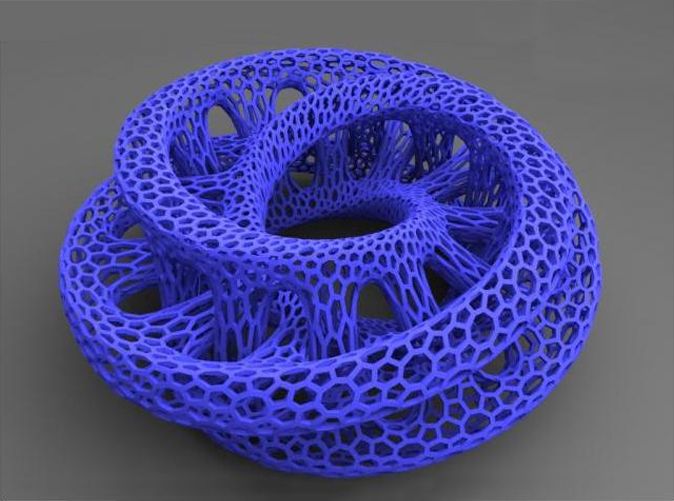

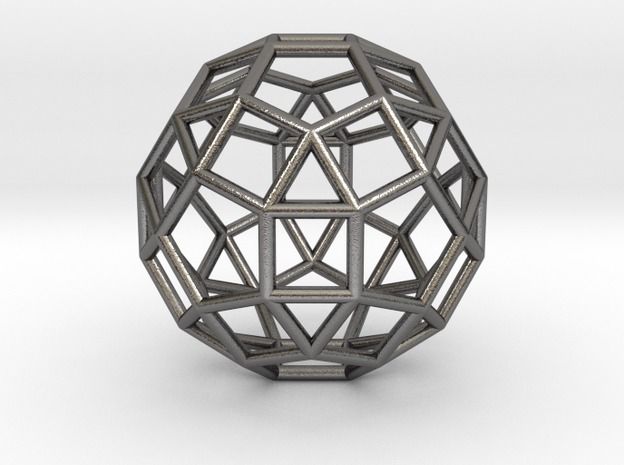

Complexity

Not all 3d models are created equal. Some are 3d print-ready, while some are just plain crazy. 3d printing takes preparation and planning. For some 3d printing services, everything is automated, which can make transactions faster. For simple products, this can be the right solution.

But what about complex parts and architectural models? We found that even with the most sophisticated algorithm, you still need some human guidance when it comes to 3d printing these type of projects.

A quick story, a client sent us a 3d model of an actual stadium. They wanted a 3d printed version of this. As we inspected the file, we saw that the model had multiple problems. There were loose joints, the walls were too thin, and there were 3d models inside the stadium itself.

They wanted a 3d printed version of this. As we inspected the file, we saw that the model had multiple problems. There were loose joints, the walls were too thin, and there were 3d models inside the stadium itself.

If we just 3d printed it right away, it would have cost us thousands of dollars on wasted material!

Take this into consideration. Are you willing to risk having your 3d model printed as is? Or do you want to make sure that the final print exceeds your expectations?

Type of material

The materials that you choose matters when it comes to the cost of 3d printing. There are tons to choose from so we are going to focus on the popular ones, thermoplastics and resin.

Thermoplastics: Filaments and Powder

Cost: $

Even if you are new to 3d printing, you have probably heard of "ABS" or "PLA". That's because these two are the most widely used 3d printing material out there. Hobbyists love these thermoplastics as they are cheap. These filaments can cost between $20 to $70 per kg.[1]

These filaments can cost between $20 to $70 per kg.[1]

Although they are cheap, getting a high-quality 3d print out of them is not easy. It will take hours of post-processing time to get smooth finishing from these prints. (More on that later.) In addition to that, 3d printing complex 3d models are nearly impossible using this type of material.

Thermosets: Resin

Cost: $$$

Resin is, in our opinion, the best 3d printing material out there. It's versatile for almost any complex project, and it would give you the best quality 3d print. But at the same time, resin material can get quite costly. Standard resin, on average, cost $50 per litre, and some resin materials can go up to $300 per litre. Luckily, 3d printing companies usually have access to discounted prices for this type of material.

Want to find out how much your 3D model will cost?

Use our instant quoting system to calculate how much it will cost to 3D print something.

GET 3D PRINTING COST

No signup required.

Post-processing

Most don't realize that 3d printing is not an instant process. Drop your file, print, and it's ready. (We hope it was).

After 3d printing, the resulting print needs to be cured, cleaned and polished before you can consider them useable. That is if the 3d printing service company cares about the quality of their product.

Polishing

Imagine polishing the one on the left to make it smooth? Photo courtesy of Formlabs.For filaments, don't even waste your time. As someone who spent hours removing supports, we don't want to you put you through that hell. If you value your time, the amount of time you will spend sanding these prints would cost a lot. And even then, the quality wouldn't be on par compared to resin.

For resin, it's simpler. Once the pieces are UV cured, we can polish it by hand or using a sandblaster.

Again, the 3d model matters as it could affect post-processing. Some models are so complex that the generated supports are very hard to clean. It would take some expertise and a lot of patience for someone to clean these prints.

Some models are so complex that the generated supports are very hard to clean. It would take some expertise and a lot of patience for someone to clean these prints.

Finishing

At PrintAWorld, the projects that we work on usually require more than just 3d printing. Our clients would ask for their 3d print to have a gold finishing, chrome or even an exact Pantone color. With current 3d printing technology, this is impossible to accomplish. So we offer metal plating and painting on top of our 3d printing services.

Profit margin

For 3D printing companies to stay in business, they need to add a profit margins on top of the 3D printing cost. Profit margins for a 3D printing business can be somewhere between 50% - 90% of material cost. We're using material cost as a basis for the sake of simplicity. But profit margins are actually much lower once you start including labor and overhead costs.

There is also a base price (or a minimum fee) that gets added if if the cost of 3D printing is less than a certain amount. It wouldn't make sense for a company to 3D print something for you for a print that costs $3. Even in a highly automated 3D printing service, there's still some labor involved. Either you add more quantity or pay the base price which is around $30-$90.

It wouldn't make sense for a company to 3D print something for you for a print that costs $3. Even in a highly automated 3D printing service, there's still some labor involved. Either you add more quantity or pay the base price which is around $30-$90.

3D printing service price comparison

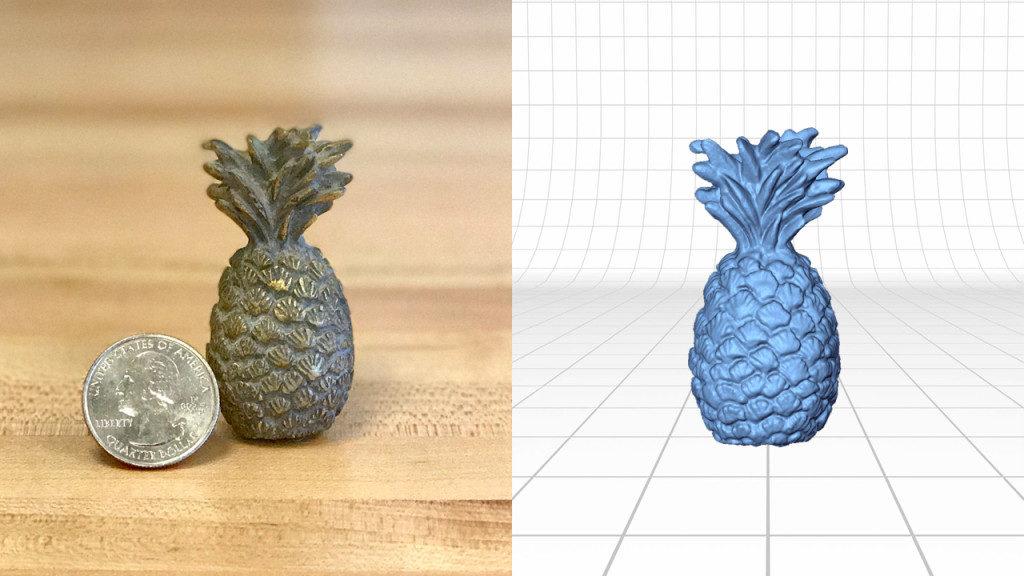

Now that we know what factors affect the price of 3D printing, let's see how much it would cost to 3D print this popular WallStreeBets mascot by ChaosCoreTech.

For this test we will be using SLA 3D printing.

We modified the file so we can stress test the on-demand 3D printing services that offer SLA printing.

Scaled it up to 152mm or ~6" high

We hollowed the 3D model. Meaning, the insides are empty.

This makes it use less material, making it cheaper.

Speed up the 3D printing time for SLA, which should lower the cost.

3DHubs

Price: $537

3DHubs won't even allow you to print this in resin as it's bigger than what their manufacturers can print.

i.materialise

Price: $211.17

Cheaper than 3DHubs but they won't clean the supports for you at this price. If you need it cleaned, you need to pay extra.

Shapeways

Price: $2061.56

We're not sure why it's this expensive. They might have miscalculated the model volume which made it seem that this piece would require half a liter of resin to print. But, either way, Shapeways is the most expensive one out of this group.

Most Affordable

PrintAWorld

Price: $136.32

Disclaimer. This is our 3D printing company. For SLA 3D printing, we are definitely the cheapest compared to the others in this group. Removing the supports and polishing is even included in the service.

Try it out

Why are 3D printing services expensive?

3D printing services are expensive because we have to account for factors mentioned beforehand such as labor, post processing and overhead costs. We also have to account the industrial 3D printers that they use, which cost at least $100,000 and upwards. Plus, they have to add profit margin on top of that cost.

We also have to account the industrial 3D printers that they use, which cost at least $100,000 and upwards. Plus, they have to add profit margin on top of that cost.

This begs the question, is it better to buy a 3D printer instead?

Should you buy a 3D printer or hire a 3D printing service?

3D printing services can sometimes cost more than an entry level 3D printer. So you might be wondering if it's better to buy a 3D printer instead.

Here's our thoughts on that:

If cost is a problem for you and you're only 3D printing for fun, then buying a 3D printer might be the better investment in the long run.

If your time is more valuable for you, then hiring a 3D printing service would be the better option. You'll have access to large scale 3D printers and capabilities that is impossible to achieve with DIY 3D printing.

Best Budget 3D Printer

Anycubic Photon Mono

The Photon Mono is the best LCD 3D printer that we've gotten our hands on. We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

$229.00 from Anycubic

Commisions earned

In Summary

Multiple factors affect the price of a 3d printing service. If you add in all these variables, you're looking at anywhere between $30 to $15,000 for the cost of 3d printing. The price can even be lower or higher, depending on the scale of your project.

How much does 3D printing cost?

As a 3d printing company, we always get asked: "how much does it cost to 3d print?".

Our answer has always been "it depends" as there are factors that contribute to the cost of 3d printing. You're looking at anywhere between $3 to $1000(or even more) for the cost to 3d print based on these factors.

So today, we're breaking down each factor for you. If you're 3D printing at home, then those factors are your material, electricity and 3D printer cost. But if you're looking for a 3d printing service or looking into starting a 3D printing business, this guide should help you understand how pricing works when it comes to 3d printing.

Factors that affect the price of 3D printing

Cost of buying and running a 3D printer

If you're starting a 3D printing business or looking to make money with 3D printing, you might want to consider the price of a 3D printer in calculating the cost to 3D print something. 3D printers can cost anywhere between $200 to $150,000 depending on the technology being used.

Let's say you purchased a $1500 3D Printer that you plan to use 8 hrs / day for 2 years. We're going to ignore repair cost, electricity, etc. for the sake of simplicity.

8 x 365 x 2 = 5840 total hours

$1500 / 5840 hrs = ~ $0. 21/hr

21/hr

So if your 3D model would take about 4 hours to 3D print, then you need to charge $0.84 on top of your price to account for your machine upkeep.

In a way, the time it takes to 3D print also adds to the cost of 3D printing.

3D Model

3D model of a dinosaur trophy"Send us the 3D model" is the second thing we tell our clients after telling them "it depends". Without the 3D model, it's tough to come up with an accurate quote for a 3D print even for seasoned veterans.

The 3D model gives us essential information that can help us quote a 3d print.

Model volume

With the 3d model on hand, we can calculate the total volume of the model, including the generated supports. The total volume lets us know how much material is needed to 3d print your file.

In short, the larger the volume, the higher the cost. There are ways to reduce the cost of 3D printing, and one of them is to hollow your model.

A 3ft model can have less volume than a 1ft model if the 1ft model is solid on the inside, while the 3ft model is hollow.

That is why coming up with an estimate price of 3d printing without the 3d model is not easy.

Complexity

Not all 3d models are created equal. Some are 3d print-ready, while some are just plain crazy. 3d printing takes preparation and planning. For some 3d printing services, everything is automated, which can make transactions faster. For simple products, this can be the right solution.

But what about complex parts and architectural models? We found that even with the most sophisticated algorithm, you still need some human guidance when it comes to 3d printing these type of projects.

A quick story, a client sent us a 3d model of an actual stadium. They wanted a 3d printed version of this. As we inspected the file, we saw that the model had multiple problems. There were loose joints, the walls were too thin, and there were 3d models inside the stadium itself.

If we just 3d printed it right away, it would have cost us thousands of dollars on wasted material!

Take this into consideration. Are you willing to risk having your 3d model printed as is? Or do you want to make sure that the final print exceeds your expectations?

Are you willing to risk having your 3d model printed as is? Or do you want to make sure that the final print exceeds your expectations?

Type of material

The materials that you choose matters when it comes to the cost of 3d printing. There are tons to choose from so we are going to focus on the popular ones, thermoplastics and resin.

Thermoplastics: Filaments and Powder

Cost: $

Even if you are new to 3d printing, you have probably heard of "ABS" or "PLA". That's because these two are the most widely used 3d printing material out there. Hobbyists love these thermoplastics as they are cheap. These filaments can cost between $20 to $70 per kg.[1]

Although they are cheap, getting a high-quality 3d print out of them is not easy. It will take hours of post-processing time to get smooth finishing from these prints. (More on that later.) In addition to that, 3d printing complex 3d models are nearly impossible using this type of material.

Thermosets: Resin

Cost: $$$

Resin is, in our opinion, the best 3d printing material out there. It's versatile for almost any complex project, and it would give you the best quality 3d print. But at the same time, resin material can get quite costly. Standard resin, on average, cost $50 per litre, and some resin materials can go up to $300 per litre. Luckily, 3d printing companies usually have access to discounted prices for this type of material.

Want to find out how much your 3D model will cost?

Use our instant quoting system to calculate how much it will cost to 3D print something.

GET 3D PRINTING COST

No signup required.

Post-processing

Most don't realize that 3d printing is not an instant process. Drop your file, print, and it's ready. (We hope it was).

After 3d printing, the resulting print needs to be cured, cleaned and polished before you can consider them useable. That is if the 3d printing service company cares about the quality of their product.

Polishing

Imagine polishing the one on the left to make it smooth? Photo courtesy of Formlabs.For filaments, don't even waste your time. As someone who spent hours removing supports, we don't want to you put you through that hell. If you value your time, the amount of time you will spend sanding these prints would cost a lot. And even then, the quality wouldn't be on par compared to resin.

For resin, it's simpler. Once the pieces are UV cured, we can polish it by hand or using a sandblaster.

Again, the 3d model matters as it could affect post-processing. Some models are so complex that the generated supports are very hard to clean. It would take some expertise and a lot of patience for someone to clean these prints.

Finishing

At PrintAWorld, the projects that we work on usually require more than just 3d printing. Our clients would ask for their 3d print to have a gold finishing, chrome or even an exact Pantone color. With current 3d printing technology, this is impossible to accomplish. So we offer metal plating and painting on top of our 3d printing services.

So we offer metal plating and painting on top of our 3d printing services.

Profit margin

For 3D printing companies to stay in business, they need to add a profit margins on top of the 3D printing cost. Profit margins for a 3D printing business can be somewhere between 50% - 90% of material cost. We're using material cost as a basis for the sake of simplicity. But profit margins are actually much lower once you start including labor and overhead costs.

There is also a base price (or a minimum fee) that gets added if if the cost of 3D printing is less than a certain amount. It wouldn't make sense for a company to 3D print something for you for a print that costs $3. Even in a highly automated 3D printing service, there's still some labor involved. Either you add more quantity or pay the base price which is around $30-$90.

3DHubs has a minimum order of $90. It would be wiser if you order multiple quantities of your part to lessen the cost.3D printing service price comparison

Now that we know what factors affect the price of 3D printing, let's see how much it would cost to 3D print this popular WallStreeBets mascot by ChaosCoreTech.

For this test we will be using SLA 3D printing.

We modified the file so we can stress test the on-demand 3D printing services that offer SLA printing.

Scaled it up to 152mm or ~6" high

We hollowed the 3D model. Meaning, the insides are empty.

This makes it use less material, making it cheaper.

Speed up the 3D printing time for SLA, which should lower the cost.

3DHubs

Price: $537

3DHubs won't even allow you to print this in resin as it's bigger than what their manufacturers can print.

i.materialise

Price: $211.17

Cheaper than 3DHubs but they won't clean the supports for you at this price. If you need it cleaned, you need to pay extra.

Shapeways

Price: $2061.56

We're not sure why it's this expensive. They might have miscalculated the model volume which made it seem that this piece would require half a liter of resin to print.

But, either way, Shapeways is the most expensive one out of this group.

But, either way, Shapeways is the most expensive one out of this group.Most Affordable

PrintAWorld

Price: $136.32

Disclaimer. This is our 3D printing company. For SLA 3D printing, we are definitely the cheapest compared to the others in this group. Removing the supports and polishing is even included in the service.

Try it out

Why are 3D printing services expensive?

3D printing services are expensive because we have to account for factors mentioned beforehand such as labor, post processing and overhead costs. We also have to account the industrial 3D printers that they use, which cost at least $100,000 and upwards. Plus, they have to add profit margin on top of that cost.

This begs the question, is it better to buy a 3D printer instead?

Should you buy a 3D printer or hire a 3D printing service?

3D printing services can sometimes cost more than an entry level 3D printer. So you might be wondering if it's better to buy a 3D printer instead.

Here's our thoughts on that:

If cost is a problem for you and you're only 3D printing for fun, then buying a 3D printer might be the better investment in the long run.

If your time is more valuable for you, then hiring a 3D printing service would be the better option. You'll have access to large scale 3D printers and capabilities that is impossible to achieve with DIY 3D printing.

Best Budget 3D Printer

Anycubic Photon Mono

The Photon Mono is the best LCD 3D printer that we've gotten our hands on. We own 8 of these machines and use it as part of our manufacturing process. It's cheap but the print quality is almost the same as the ones that we get from our Formlabs 3. If you're looking to buy your first 3D printer, we recommend going for a resin 3D printer like this one instead of buying an FDM printer.

$229.00 from Anycubic

Commisions earned

In Summary

Multiple factors affect the price of a 3d printing service. If you add in all these variables, you're looking at anywhere between $30 to $15,000 for the cost of 3d printing. The price can even be lower or higher, depending on the scale of your project.

If you add in all these variables, you're looking at anywhere between $30 to $15,000 for the cost of 3d printing. The price can even be lower or higher, depending on the scale of your project.

Review of leading companies in the field of 3D printing services / Habr

I got the impression that in Russia there is a stereotype that there are only two ways to make money on 3D printers:

1) Become a dealer of an international company / set up the production of your own 3d printers

2) buy several 3d printers and take orders from architects/doctors/military

0007 designer people are lower than they seem, and the future, which is unevenly distributed / distributed not quite in Russia, is already here.

Under the cut you will find a brief overview of the three giants of the European and American 3d printing industry, which do not specialize in the production of their own 3d printers, but develop communities, create a "marketplace", act as platforms for startups, designers, etc. After the review of the "big three" follows a review of the most interesting projects created around these giants.

After the review of the "big three" follows a review of the most interesting projects created around these giants.

Some projects are commented by Konstantin Ivanov (consst), who attended European (3DPrintShow) and American (Inside 3D Printing) conferences.

Three giants in 3D printing marketplaces from USA and Europe

www.shapeways.com

en.wikipedia.org/wiki/Shapeways

The company, organized in 2007 in the Netherlands (originates from the Philips business incubator), but is headquartered in New York. The company employs 90 people. At the moment, it has attracted about $40 million in investments. It has two full-fledged productions in the Netherlands and in New York. The number of ordered products has exceeded one million.

Konstantin: “World and US market leader Shapeways. Successfully located its head office in Queens, NY, becoming a Mecca among the creative people. For a pretty decent history of its existence, Shapeways has gathered a huge community of designers, at the end of 2013 - 300,000 people.Of course, the number of active and prolific designers is much smaller, but the total number and products on the marketplace cannot fail to impress.

With each of the active designers, Shapeways community managers (they are usually called community managers, which is rather rare in Russia so far) work a lot, communicate, and help resolve any issues: high-quality photography of products, placement on the marketplace, correction of 3d models. In general, the community is the heart of Shapeways.

A huge knowledge base they have collected on the forum and in the Tutorials sections of the site allows you to find the answer to almost any question that arises when working with 3d models for printing. Storehouse of knowledge.

Some of the people from Shapeways (former community managers, production managers) are already creating their own separate businesses in the field of 3d printing. Shapeways encourages and develops an entrepreneurial culture.

However, competitors really, really dislike Shapeways for dumping the market.

Indeed, their prices for 3d printing from many different materials are almost always lower than competitors from Europe. They can afford it, with so many investments involved)

Shapeways have created and are developing an excellent powerful API for developers of various online 3d model customizers, which can also be made through them. As a result, in addition to the marketplace, they work as a production and API, which is very convenient.

They completely stopped delivering to Russia since last year, citing problems at customs. By the way, I must say that the experience of ordering 3D printing from them in NY is also not ideal: they missed the delivery time for samples, I had to write to support, but the issue was quickly resolved.”

A few videos and articles in English for a deeper understanding

Video about the company. Keanu Reeves is there too.

Number of unique pieces made from 2008 to 2013

Founder Peter Weijmarshausen

Forbes article (10/10/2011)

Wired article by Bruce Sterling (10/3/2011)

BusinessInsider article (12/19/2012)

Another performance by Peter Weijmarshausen

www. sculpteo.com

sculpteo.com

en.wikipedia.org/wiki/Sculpteo

French startup launched in 2009. Raised several million investments, has a small fleet of its equipment

Strengths: a very interesting online service, with the ability to not only analyze your model, but also prepare it online for printing. There is a mobile application 3DPcase

Konstantin: “Guys from France who started after Shapeways hit the market. Small team, own small production (industrial 3d printers) in Paris.Like many other players in the market, part of their production capacity is outsourced. This is quite logical, since to control a huge production, including from metals, ceramics, etc. - Pretty messy story.

Quite often you can meet them at exhibitions. The last time, while talking with them at 3DPrintShow in London and Inside3DPrinting in New York, the guys shared their opinion on the pace of market development in Europe and the USA and a little more about competition in Europe, where Shapeways is also actively going.

The main focus of Sculpteo's development is applications, their own online software for calculating, correcting and even preparing 3d models for printing. This is very impressive, none of the competitors do this. For comparison, Shapeways uses only half of its software, the second part is Netfabb's software.

Sculpteo is great for those who already know how to work with 3d models in many ways and use 3d printing for prototyping.

The team is also developing its API. Delivery to Russia, according to the director of the company Clement, they do, but in fact this is not possible.”

More about Sculpteo

Founder éric Carreel

en.wikipedia.org/wiki/eric_carreel

performance éric

222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222EALLOSENOBUFFFFFFFFF -to-print-in-3d-just-grab-your-ios-device-and-the-sculpteo-app

i. materialise.com

materialise.com

en.wikipedia.org/wiki/Materialise_NV

Belgian company founded in 1990 (sic!)

Creators of the "Mammoth-like stereolithographic machine" (print area 2 meters x 0.7 meters x 0.8 meters)

Once they kept their blog on Habré, with some quite useful articles, for example, the translation of the article about the “Industrial Revolution” 1, 2, 3, 4, 5.

Konstantin: has an office both in Belgium and, for example, in Ukraine. The main activity is prototyping of industrial, engineering, medical, aviation, etc. products.However, the company also has its own consumer direction, which was named i.Materialise. The marketplace and community are also being developed. If you look closely, they very much follow the example of their American colleagues, up to copying interface elements, which is quite logical - the usability in Shapeways is really very good.

Recently launched the so-called Boutiques, separate shops for selected designers.

Continue their movement to the consumer segment.

A number of important advantages: its large production with the most experienced staff and a large number of different technologies, printers and post-processing. Completely own software that works well with models (but no better than Sculpteo does). And, of course, the API, which they are actively developing and connecting more and more partners to it.

I also offer a white label option for companies that don't want their customers to know exactly where their products are made.”

A little video about Materialise

Videos with TED (in English)

How the largest stereolithographic machine

How to earn 3D printing

Aggregators:

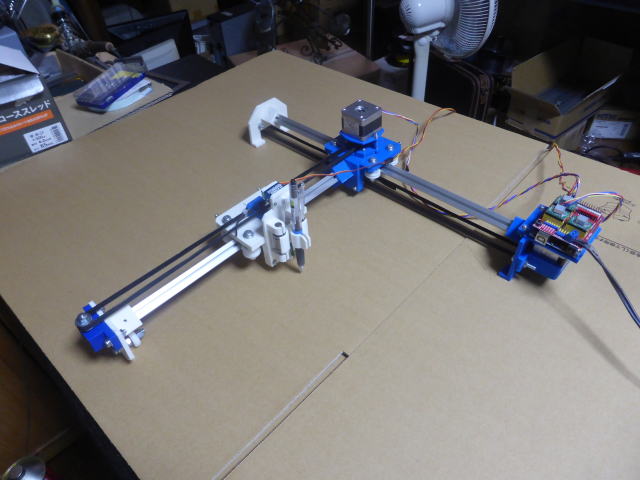

3DHubs.com - allow owners to register their 3d printer in the database. Thus, it becomes possible for any person to find either the nearest 3d printer, or exactly the printer that is needed (all over the world).

Plus, they can collect useful statistics and publish monthly trend reports. They take a commission of 15-20%

Konstantin: “One of the investors from a London fund introduced me to the founders of a fairly recent startup 3dhubs, who also invested in the company. Brian and Bram came up with and are making a great international story that actually makes life easier for those who need to print something “close to home”.The service works all over the world and even a little in Russia. The guys are attentive to the customer service inside, help each client if one of the hub owners has problems with printing. Very comfortably.

Coming to each new city or to an exhibition, they do the so-called unlock of the city and open new hubs with printers there. This was also the case at the exhibition in London last year.”

makeXYZ.com

Texas Entrepreneurs Project. Allows you to search for 3d printers and 3d designers. Received investment from Intel.

Received investment from Intel.

Standing on the shoulders of giants

www.sols.co

Allows you to create personalized insoles.

Konstantin: “A great example of how, growing inside a small start-up company, Sols founder Kegan Schouwenburg caught the entrepreneurial spirit and started her own project to produce custom 3D printed orthopedic insoles!Kegan was one of the people who did the entire production of Shapeways from scratch, which is truly a huge job.

Her company has now raised about $8 million in funding from the same investors who invested in Shapeways and is actively building its business. At the same time, he uses polyamide (nylon) for the manufacture of the base for the insoles and makes all samples using Shapeways. Proper collaboration and collaboration.”

mixeelabs.com

An online application that allows you to create figurines ($25), molecules, key chains for dogs, cufflinks and wallets for cards.

Konstantin: “Second success story in the 3d printing business, also from a former Shapeways employee. Nancy Yi Liang is the founder of product customizer Mixeelabs, who makes money from his brainchild and lives in New York.In our last meeting with her, she told how well things are going with the sale of her products from the site (80% of sales), a little worse from the Shapeaways marketplace (20% of sales), but at the same time, the very first viral effect gave her the same Sad Keanu, which she invented and distributed perfectly everywhere.

Her project is a great example of how, having come up with an interesting and quite viral thing, you can earn money on it in the long run.”

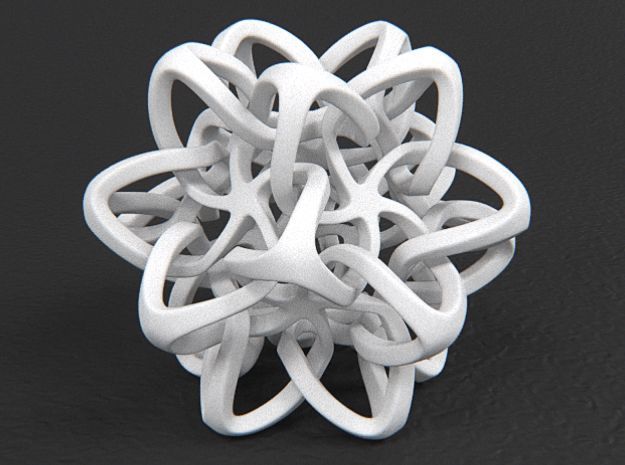

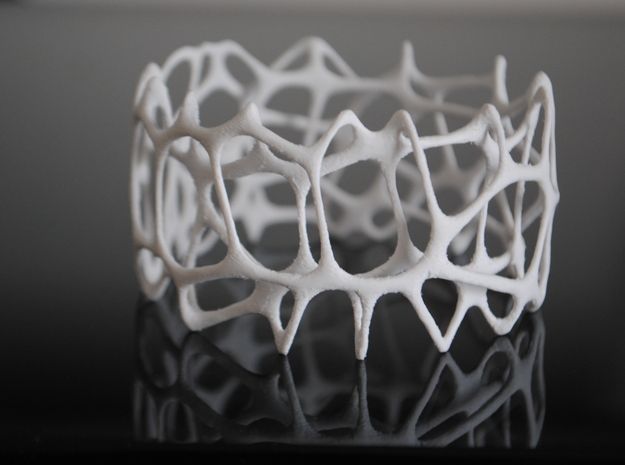

joshharker.com

Joshua Harker — Artist, sculptor, musician, digital adventurer, imagination architect, troublemaker

Konstantin: later he went into business, opened his own company, developed his own unique and recognizable style (which was later copied by many others) and showed how to effectively apply new design approaches to 3d printing.

I could not resist and decided that the worse we are, we will make one for ourselves. Here is the result:

www.minetoys.com

For all Minecraft fans. Prints your character from the game.

www.twikit.com

The service allows you to customize gifts and jewelry made of plastic and metal.

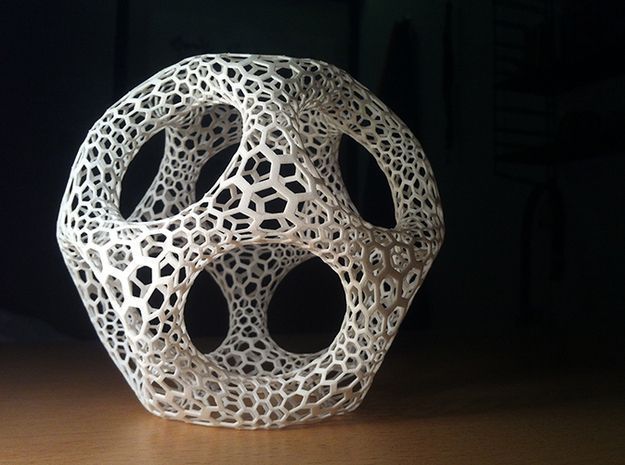

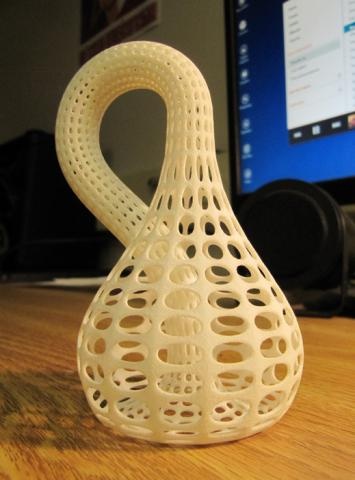

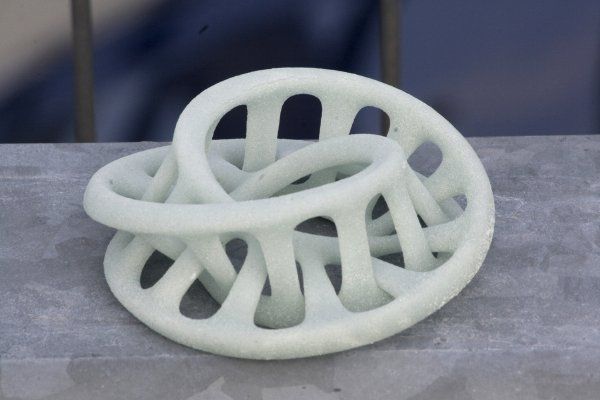

n-e-r-v-o-u-s.com

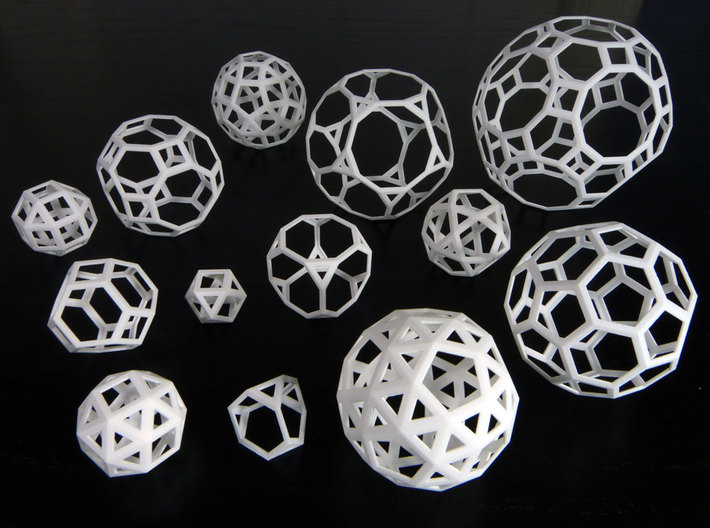

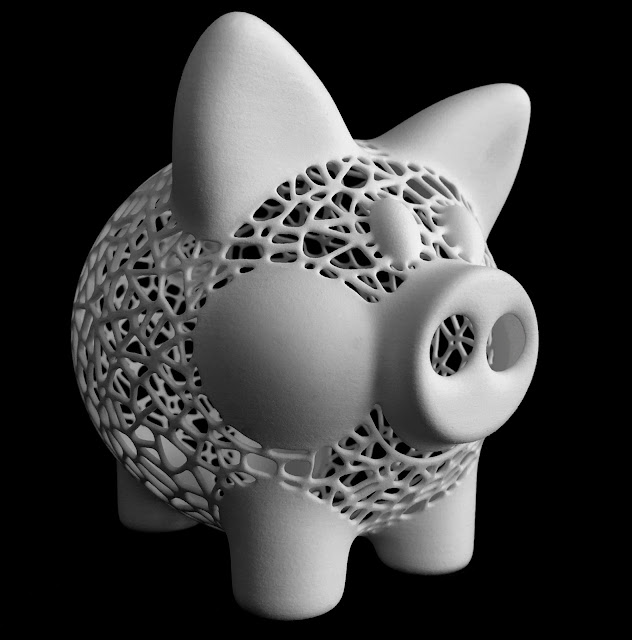

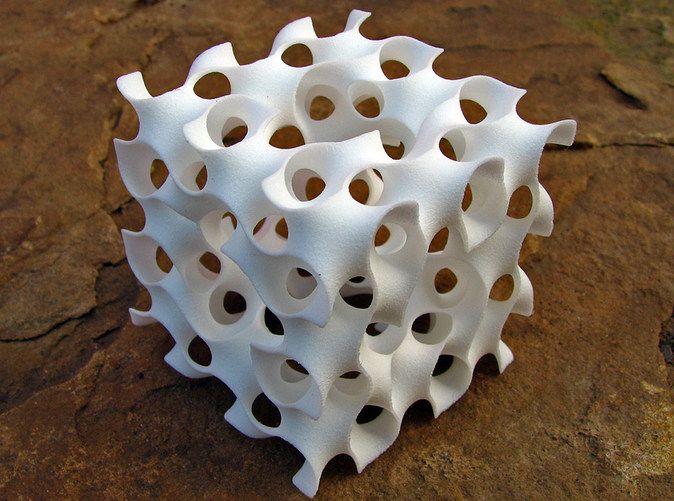

Konstantin: “Nervous are practically gods in 3d printable design, they come up with new shapes and structures and constantly impress.

In addition to the beautiful futuristic design, they came up with an incredible online thing that creates amazing kinetic structures right in the browser, right in front of you. All this is flexible and allows you to actually make wearable objects made using 3D printing.

Photos of works from Nervous System

Octopussy which I myself printed a year ago (report on Habré)

Blokify. com

com

A mobile application that makes it very easy to create a 3d model and send it to print. Convenient for working with children.

Video and a couple of photos

draw

materialize

WhiteClouds.com

»Submit your ideas (even on a napkin). We will bring them to life."

The company does not require its customers to be able to handle a computer: you can send a simple sketch made by hand, and the company's specialists will turn it into a digital three-dimensional model, print it on a 3D printer and send the finished product to the customer. Once, they even sent a cardboard model to the company, asking them to print a copy on a 3d printer, and the order was completed.

Portfolio under the spoiler

A little zombie:

Russian projects

The following picture speaks eloquently about the state of affairs in Russia:

3D Printing Map of the World

parable on the topic

One company once sent a shoe salesman to an African city.

Shortly after arriving in Africa, he wrote to the office:

“You can take me back. Here everyone walks barefoot.

They returned him to his homeland.

Then they sent another shoe seller.

Almost immediately upon arrival, he sends an urgent telegram to the office:

“Send all the shoes you have. Here everyone walks barefoot!

zdravprint.ru

A service for the creation of individual fixators, which are printed on a 3D printer and are designed to replace plaster at certain stages of recovery.

Konstantin: “My good friend Fedor Aptekarev at the last Yandex Startup Camp launched a project to create plaster using 3d printing. With such a cast, the fracture can be endured a little easier.”

What awaits us in the future

Me : Konstantin, while collecting materials for this post, I came across some skeptical statements by very respected people (for example, the director of Epson) about the future of 3d printing, but you, in turn, You have been actively developing this industry in Russia for a year already, holding training seminars, developing a community, holding competitions for designers, planning to launch an API for your project, what is the basis for your confidence that this is worth doing?

Konstantin: Glad you asked. Let's clarify what exactly the head of Epson said. Something like this: “There is no big future for plastic 3D printing at home. We will only make commercial 3D printers.” He talks about building an industrial design printer. Epson itself is going to develop industrial printers. And I completely agree with them.

Let's clarify what exactly the head of Epson said. Something like this: “There is no big future for plastic 3D printing at home. We will only make commercial 3D printers.” He talks about building an industrial design printer. Epson itself is going to develop industrial printers. And I completely agree with them.

My opinion is that industrial 3d printing technologies, which we also use, can really take 3d printing to a new consumer level. Here you need to immediately make a reservation that the head of Epson is talking about home printing, but he only means FDM technology (plastic filament melting), as the most popular home 3d printing technology. At the same time, do not forget that after the end of the patent for SLA technology (stereolithography), for example, a completely “home” Formlabs 1 printer appeared, which gives a very acceptable quality. Yes, of course, it can not be compared with the industrial one.

I'm talking about the fact that rather than home 3d printing, there is no future, but FDM technology. She will live herself. It is suitable for too narrow an application and the quality is very, very low.

She will live herself. It is suitable for too narrow an application and the quality is very, very low.

I am sure that what we are doing now will create (and is already creating it abroad) a new market and new opportunities for consumers and designers, will speed up the solution of many problems and, of course, will become more accessible. Confidence is fully confirmed by the facts, the results of communication with colleagues from abroad and in Russia, and, of course, by the numbers, which are constantly growing.

Me: Konstantin, after talking with the CEO of the world's leading companies and having “visited the future a bit”, what will the world expect in the coming years?

Konstantin: In the very near future, I can say with complete confidence, the following awaits us:

- the widespread integration of the "print on a 3d printer" button into all conceivable and unthinkable applications, programs, games, and so on. We will print both in 3d printing services and for enthusiasts on home 3d printers

- the end of patents for the main industrial 3d printing technologies (SLA (already), SLS, 3DP, DMLS) will lead to a more serious development of smaller and less expensive printers, respectively, the growth of both industrial technologies and quality will also skyrocket

- Google , actively introducing 3D scanners into their phones, will also contribute to the growth of the market, since many people will have the most important thing for the market - a model for printing. And to create it, you only need a phone number

And to create it, you only need a phone number

- finally, the alliance of 3D Systems and Google in the Ara project will give a significant jump in the development of 3d printing speed and it is likely that we will finally see how an entire custom goods production line will finally be made using 3d printing. This is what is called mass customization

P.S.

Model Databases:

Thingiverse.com (free models, project by MakerBot, over 100,000 models downloaded, 21 million downloads)

Threeding.com (paid and free models, project from Bulgaria, plans to release an app for Apple iOS and Android, commission 8.5%)

3DPrintWise.com ()

CGtrader.com (paid models, received investment from Intel. 35,000 3d designers posted over 45,000 3d models)

Anyone who wants to participate in the API test for a 3d printing service - write to me magisterludi or Konstantin consst

3D printing with metal - a fundamental guide

Today, there is no more relevant trend in 3D printing than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

3D metal printing at home

If you want to make objects at home that will look like metal, it is best to pay attention to metallized PLA filaments (Photo: colorFabb)

where to start if you want to print metal objects at home? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metal 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing your home printer for metal 3D printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, sanding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are some examples:

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams of

Industrial metal 3D printing

But what if you want a higher quality result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

If you are not going to start a metal 3D printing business, but still need a professionally 3D printed metal part, it is best to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which are considered the best option for patients today. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045".

However, let's look at what metal 3D printing technologies are. formed layer)

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D-printing process No. 2:

binder Jetting (spraying the binder)

under 3DP-technology EXONE Metal objects are printed due : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3: 9Metal Deposition This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metal 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying the binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation, its registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With few exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D Printing Metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver, and Other Precious Metals

Most preformed layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metal 3D printing. Printers

Do not even hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - metal filament printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

#1 Metal 3D Printing Service: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Extensive technical documentation will help identify design flaws and select the right material for the project.

3D printing metals: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialize is a company that works with industrial customers to prototyp 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their site.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and companies that offer 3D printing services in your area, upload STL files (which are immediately evaluated for defects ) and contact service providers directly to get the job done.