What is dlp 3d printing

Guide to Resin 3D Printers

There are many 3D printing processes on the market. Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

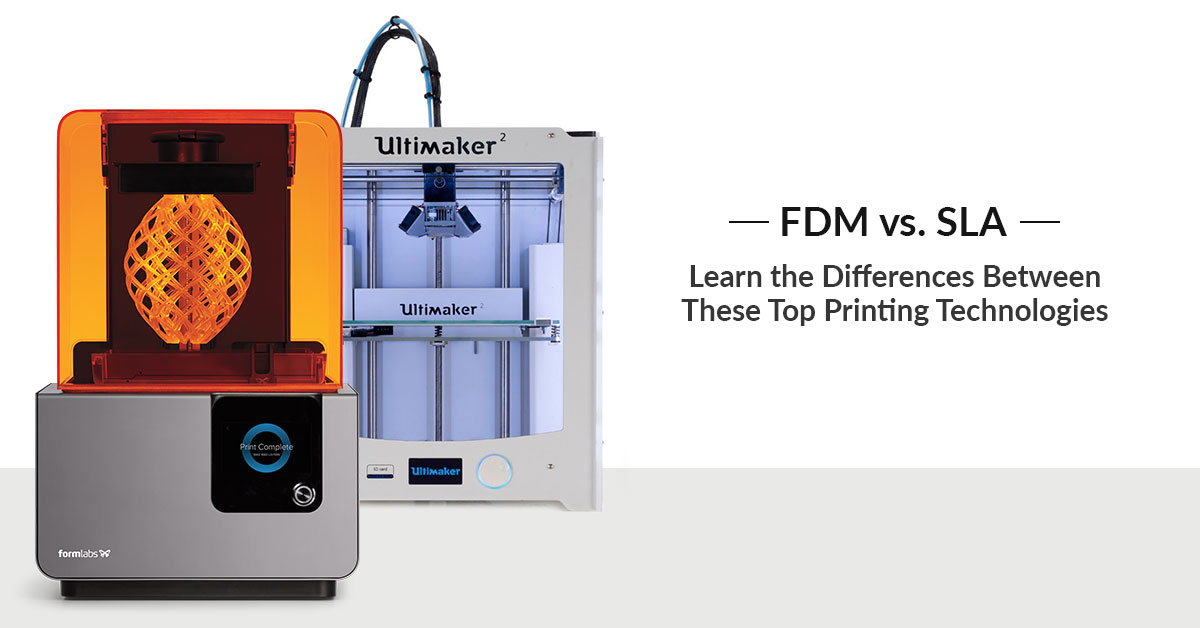

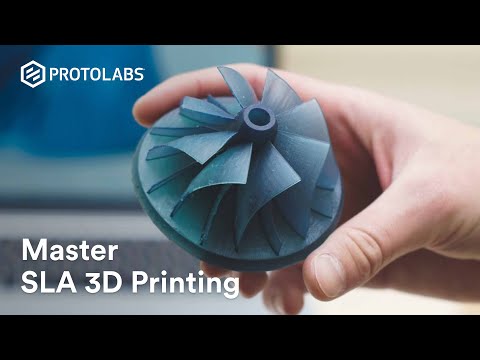

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for resin 3D printing. Resin printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish.

While these technologies were once complex and cost-prohibitive, today’s small-format desktop SLA and DLP resin 3D printers produce industrial-quality parts at an affordable price point and with unmatched versatility thanks to a wide range of materials.

Both processes work by selectively exposing liquid resin to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. While very similar in principle, the two technologies can produce significantly varying outputs.

In this in-depth guide, we walk through the details of the two resin 3D printing processes and explore how they compare in terms of resolution, accuracy, build volume, speed, workflow, and more.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Desktop SLA 3D printers contain a resin tank with a transparent base and non-stick surface, which serves as a substrate for the liquid resin to cure against, allowing for the gentle detachment of newly-formed layers.

The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or the last completed layer, and the bottom of the tank. A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

The cured layer then gets separated from the bottom of the tank and the build platform moves up to let fresh resin flow beneath. The process repeats until the print is complete.

Low Force Stereolithography (LFS) technology, used by the Form 3+ and Form 3L, is the next phase in SLA 3D printing.

In LFS 3D printers, the optics are enclosed in a Light Processing Unit (LPU). Within the LPU, a galvanometer positions the high-density laser beam in the Y direction, passes it through a spatial filter, and directs it to a fold mirror and parabolic mirror to consistently deliver the beam perpendicular to the build plane and ensure accurate, repeatable prints.

As the LPU moves in the X direction, the printed part is gently peeled away from the flexible bottom of the tank, which drastically reduces the forces exerted on parts during the print process.

LFS 3D printing drastically reduces the forces exerted on parts during the print process, using a flexible tank and linear illumination to deliver incredible surface quality and print accuracy.

This advanced form of stereolithography delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, and the process opens up a wide range of possibilities for future development of advanced, production-ready materials.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

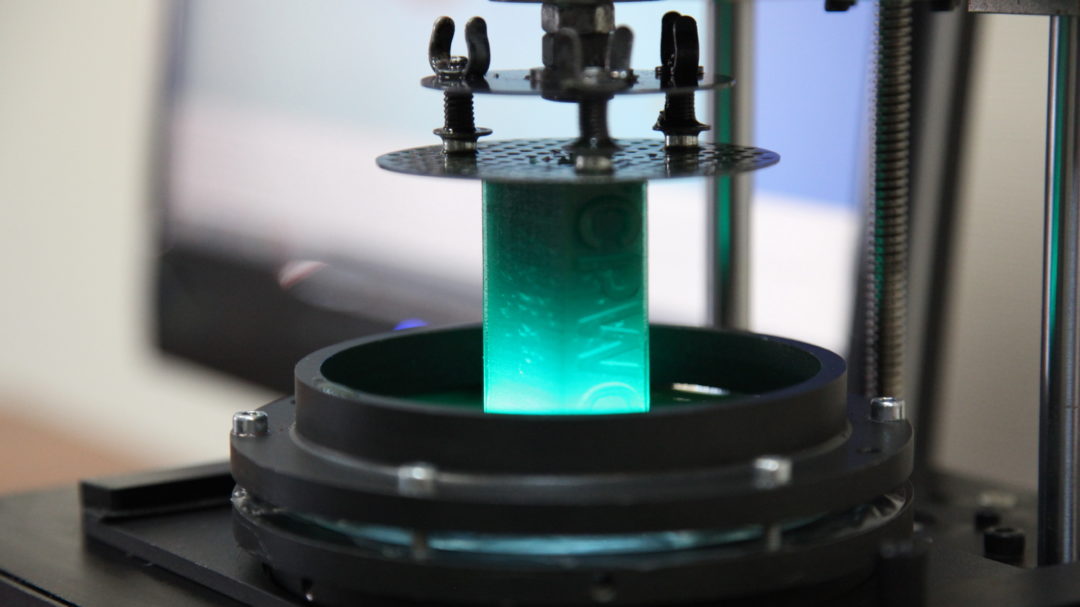

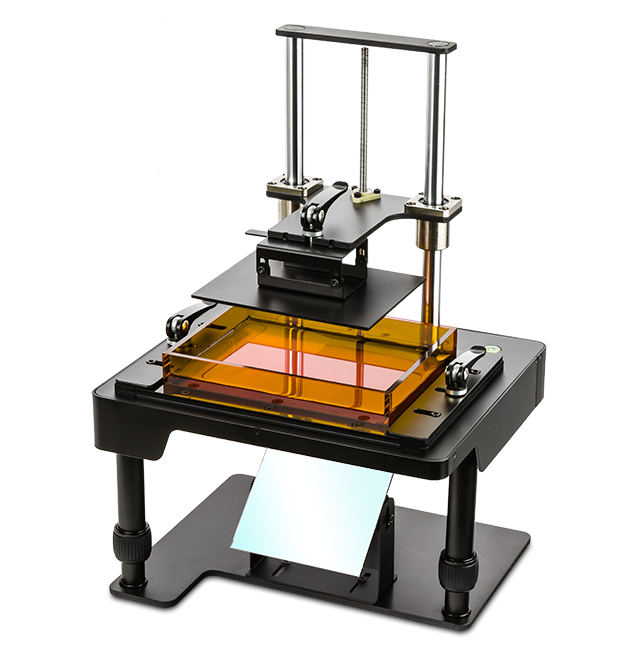

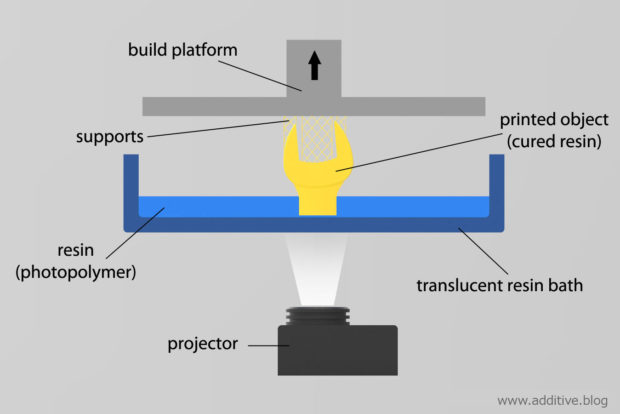

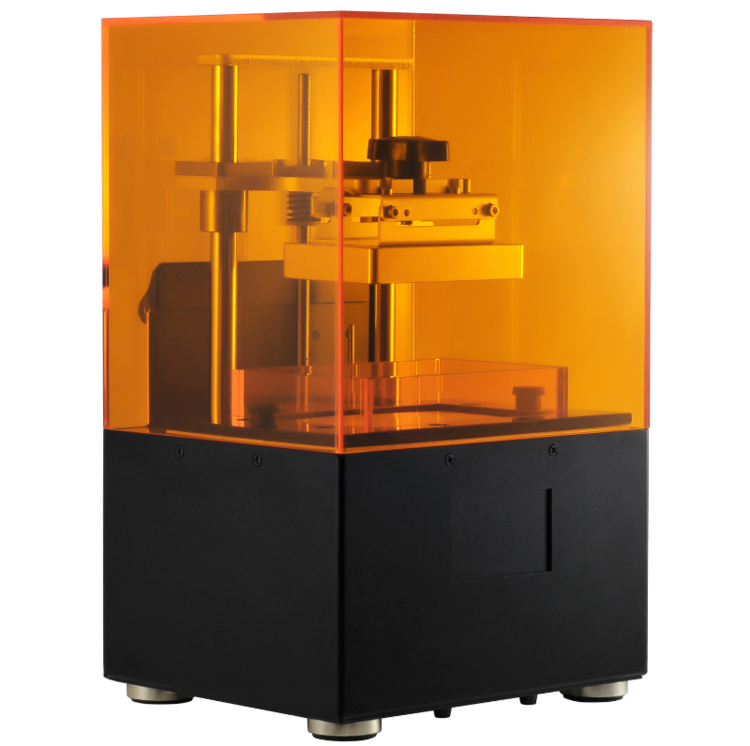

Just like their SLA counterparts, desktop DLP 3D printers are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer.

The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

The light is reflected on a Digital Micromirror Device (DMD), a dynamic mask consisting of microscopic-size mirrors laid out in a matrix on a semiconductor chip. Rapidly toggling these tiny mirrors between lens(es) that direct the light towards the bottom of the tank or a heat sink defines the coordinates where the liquid resin cures within the given layer.

Because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a three-dimensional layer formed from small rectangular cubes called voxels.

Resolution shows up more often than any other value in 3D printer spec sheets, but it’s also a common ground for confusion. The basic units of the SLA and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

In 3D printing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the third vertical Z dimension that makes 3D printing.

Z resolution is defined by the layer thicknesses a 3D printer can produce. Resin 3D printers like SLA and DLP offer some of the finest Z resolutions—thinnest layers—of all 3D printing processes and users can normally choose from a range of layer height options between 25-300 microns, allowing designers to strike a balance between detail and speed.

In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer. This depends on the resolution of the projector, the most common being full HD (1080p), and its distance from the optical window. As a result, most desktop DLP 3D printers have a fixed XY resolution, generally between 35 to 100 microns.

For SLA 3D printers, XY resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

However, resolution in itself is often just a vanity metric. It offers some indication, but it doesn’t necessarily correlate directly with accuracy, precision, and print quality.

Learn more about resolution in 3D printing in our in-depth guide.

Because 3D printing is an additive process, each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, defined as the repeatability of the accuracy of each layer. Accuracy and precision depend on many different factors: 3D printing process, materials, software settings, post-processing, and more.

In general, both SLA and DLP resin 3D printers are among the most accurate and precise 3D printing processes. Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

For example, entry-level SLA or DLP printers might use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers will try to get the best performance possible out of these parts. Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Accuracy and precision are crucial for parts like dental splints (left) and surgical guides (right).

Calibration is also crucial. With DLP projectors, manufacturers need to deal with the non-uniform light distribution on the build plane and optical distortion of the lenses—meaning that pixels in the middle are not the same size or shape as pixels on the edges. SLA 3D printers use the same light source for every part of the print, which means it’s uniform by definition, but they still require extensive calibration to account for distortions.

Even a 3D printer with the highest quality components and degree of calibration can produce widely varying results depending on the material. Different resins require optimized material settings to perform as intended, which might not be available for off-the-shelf materials or resins that are not thoroughly tested with a specific 3D printer model.

The takeaway? Accuracy and precision are almost impossible to understand from the technical specifications alone. Ultimately, the best way to evaluate a 3D printer is to inspect real parts or ask the manufacturer to create a test print of one of your own designs.

With DLP 3D printers, there’s a direct trade-off between resolution and build volume. The resolution depends on the projector, which defines the number of pixels/voxels available. If one moves the projector closer to the optical window, the pixels get smaller, which increases the resolution, but limits the available build area.

Some manufacturers stack multiple projectors next to each other or use a high-definition 4K projector to increase the build volume, but this leads to substantially higher costs that often price these machines out of the desktop market.

As a result, DLP 3D printers are generally optimized for specific use cases. Some have a smaller build volume and offer high resolution to produce small, detailed pieces like jewelry, while others can produce bigger parts but at a lower resolution.

The stereolithography process is inherently more scalable, since an SLA 3D printer’s build volume is completely independent of the resolution of the print. A single print can be any size and any resolution at any location within the build area. This makes it possible to 3D print large parts at high resolution or a large batch of detailed small parts to increase throughput with the same machine.

The other main barrier to increasing build volume in both SLA and DLP 3D printers is the peel force. When printing larger parts, the forces exerted on the parts increase exponentially as a cured layer separates from the tank.

In LFS 3D printing, the flexible film at the base of the resin tank gently peels away as the build platform pulls the part up, significantly reducing the stress on the part. This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

The Form 3L is the first affordable large format SLA 3D printer with a build volume of 30 cm x 33. 5 cm x 20 cm.

5 cm x 20 cm.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

SLA and DLP resin 3D printers both known for creating parts with the smoothest surface finish of all 3D printing processes. When we describe the differences, in most cases these are only visible on tiny parts or highly detailed models.

Because objects are made of layers in 3D printing, 3D prints often have visible, horizontal layer lines. However, because DLP renders images using rectangular voxels, there is also an effect of vertical voxel lines.

DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines. In this image, see the vertical voxel lines as they appear naturally on the left, and then outlined to more easily identify on the right.

Because the unit is rectangular, voxels also have an effect on curved edges. Think of building a round shape out of LEGO bricks—the edges will appear stepped on both the Z axis and the X-Y plane.

The rectangular shape of voxels makes curved edges appear stepped. Removing the appearance of voxel and layer lines requires post-processing, such as sanding.

In LFS 3D printing, layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA and DLP resin 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

But once again, it’s worth considering the trade-off between resolution and build volume for DLP printers. A small DLP 3D printer can print a small part or a (small) batch of smaller parts fast, at high resolution, but the build volume limits the part size and the throughput. A different machine with a larger build volume can print larger parts or a batch of smaller parts faster, but at a lower resolution than SLA.

SLA 3D printers can produce all of these options in one machine and offer the user the freedom to decide whether she wants to optimize for resolution, speed, or throughput.

SLA 3D printers offer a larger build volume, allowing users to batch parts and print overnight to increase throughput.

Speed can also depend on the material choice. Printing four times faster than Formlabs standard materials, Draft Resin fast-printing resin that is ideal for initial prototypes, rapid iterations, as well as dental and orthodontic models. From fast print initiation speeds to minimal support removal, wash, and cure times, Draft Resin has an optimized workflow to truly maximize efficiency.

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Just like with accuracy and precision, the workflow and available materials differ more from machine to machine than technology to technology.

Most SLA and DLP 3D printers are “plug and play,” with easily swappable build platforms and resin tanks. Some more advanced models also come with a cartridge system to automatically refill the tank with liquid resin, which requires less attention and facilitates printing overnight.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs SLA 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time. Luckily, the software can be easy to download and test before purchasing a 3D printer.

Resin 3D printers offer a variety of materials for a wide range of applications.

One of the most significant benefits of resin 3D printing is the variety of materials that make it possible to create parts for diverse applications. Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

However, the range of supported material options depend on the 3D printer model, so we recommend inquiring with the manufacturer before purchase.

Parts printed with both SLA and DLP technologies require post-processing after printing. First, the parts need to be washed in a solvent to remove excess resin. Some functional materials like engineering or biocompatible parts also require post-curing. For SLA 3D printers, Formlabs offers solutions to automate these steps, saving time and effort.

At last, 3D printed parts printed on supports require these structures to be removed, a manual process that is similar for both SLA and DLP 3D printers. LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

After sorting out the differences in technology and outcomes, we hope it’s much easier to select a resin 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the quality firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

What is DLP 3D Printing?

3D printing processes continually improve and have evolved beyond just SLA (stereolithography) and the widely-used FDM (fused deposition modeling). There has been progress in accuracy, feature complexity, and supporting software in recent years for all types of 3D printing. The most significant advancements have come with the introduction of DLP (digital light processing). The capabilities of DLP printers allow for faster manufacturing of products like dental appliances, medical devices, and footwear and enable improvements in design and quality. DLP offers faster production speed, better surface finish, and isotropic material properties.

The most significant advancements have come with the introduction of DLP (digital light processing). The capabilities of DLP printers allow for faster manufacturing of products like dental appliances, medical devices, and footwear and enable improvements in design and quality. DLP offers faster production speed, better surface finish, and isotropic material properties.

What is DLP 3D Printing?

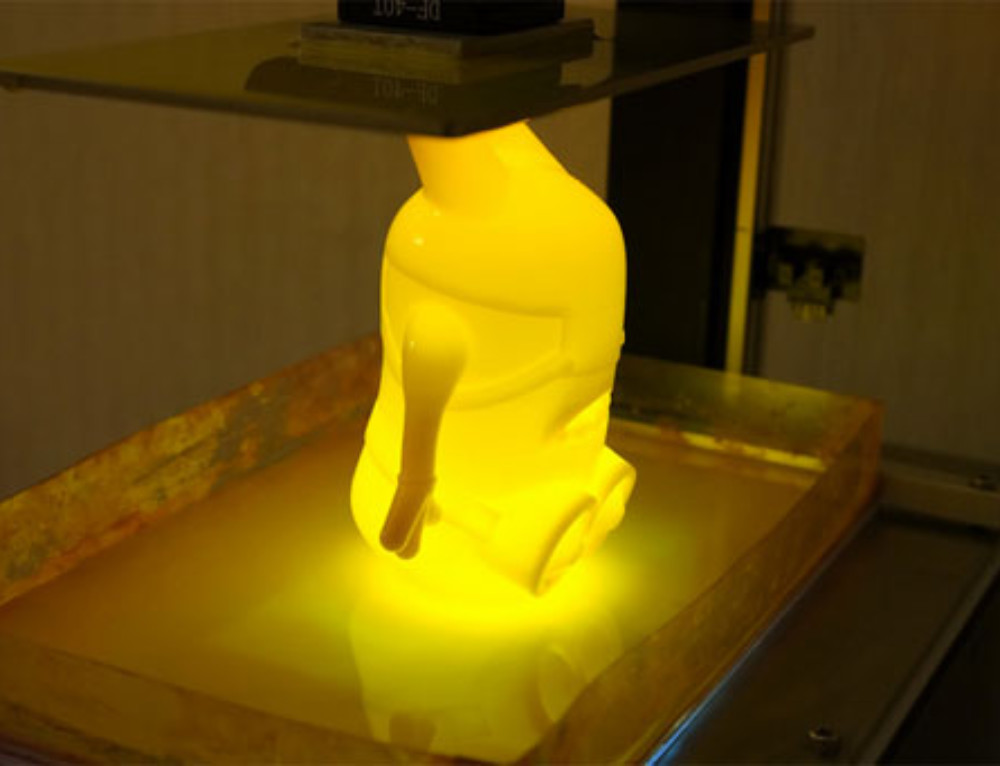

DLP 3D printers fabricate products on a build platform above a vat of photosensitive resin. A DLP chip projects a cross-sectional image of a print layer onto the resin, hardening the exposed material. The platform slowly rises vertically from the resin vat and builds each layer. All points in each layer cure simultaneously, resulting in a much faster layer printing than traditional printing methods using tracing. Once printing is complete, support structures are removed — if any, and the part is washed and cured.

Benefits of Advanced DLP 3D Printing Solutions

DLP 3D printing solutions are advancing faster than other 3D printing technologies because leading companies are taking a holistic approach – 3D printing machines, software, and materials. The following benefits are why companies see DLP as the better choice to produce their products.

The following benefits are why companies see DLP as the better choice to produce their products.

Smooth Surface Finish with Digital Polishing™

DLP 3D printers can achieve the smoothest surface finish of all 3D printing processes with Digital Polishing™, an advanced printing technique that combines 3D printing software and material that is tuned to the machine. DLP printers produce features as fine as .05 mm with no lines and can support a variety of surface finishes with more complex geometries.

Reducing Post-Processing

DLP 3D printers require significantly less post-processing than other 3D printers. DLP prints highly accurate products that require washing and curing steps and eliminates excessive polishing and machining for high-performance parts. It also requires only minimal removal of support structures.

High Throughput with Rapid Speed and Large Area Printing

DLP cures all layers simultaneously, resulting in faster printing than area tracing processes. Concurrent curing allows for faster printing of both small and large batches. DLP 3D printers, when compared to standard 3D printers, produce large, dense parts quicker.

Concurrent curing allows for faster printing of both small and large batches. DLP 3D printers, when compared to standard 3D printers, produce large, dense parts quicker.

Elastic Printing

There is now a wide range of materials supported by DLP printers. Advanced DLP 3D printing solutions can print high viscosity elastic resins, creating products that can surpass equivalent ones made with traditional manufacturing materials like foam.

Clear or Transparent Printing

Printing clear parts have been a challenge for additive manufacturing. With a holistic approach, DLP 3D printing can easily print clear or colored transparent parts. For dental, clear printing simplifies aligner production to just scanning a patient’s mouth and directly printing a clear aligner, eliminating intermediate steps for thermoforming.

Directly Printing Colored Parts

Many companies that leverage 3D printing use the default resin color or dye the part to the desired color. DLP 3D printing is transforming the consumer industry by directly printing colored products. For example, an eyewear company is scanning patient faces and using DLP 3D printing to rapidly produce custom eyewear frames in a wide range of colors, including transparent colored frames. Leading footwear companies are directly printing footwear products or parts in a specific color.

For example, an eyewear company is scanning patient faces and using DLP 3D printing to rapidly produce custom eyewear frames in a wide range of colors, including transparent colored frames. Leading footwear companies are directly printing footwear products or parts in a specific color.

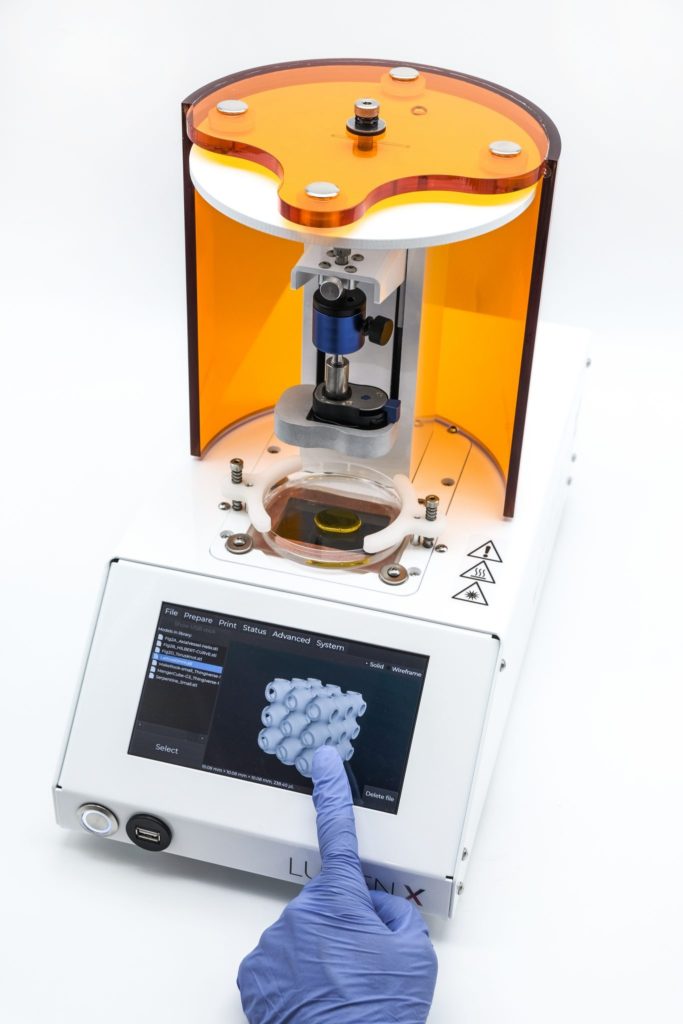

DLP Printers with LEAP™ Technology

All LuxCreo DLP 3D printers utilize LuxCreo’s patented LEAP™ (Light Enabled Additive Production) technology. LEAP™ technology incorporates software, resin tuning, and materials for even better surface finish, accuracy, and performance than other DLP 3D printers. LEAP™ technology also allows LuxCreo’s DLP 3D printers to print fully clear parts with post-processing requiring only washing and curing steps without reducing layer thickness. LuxCreo’s DLP 3D printers allow for 90% material and labor savings to reduce excessive machining, post-processing, and material waste. Additionally, DLP 3D printers with LEAP™ technology print elastic materials better than other DLP 3D printers for smoother, more accurate, and translucent parts.

DLP Vs. FDM and SLA

The benefits and drawbacks of DLP are often discussed in comparison to fused deposition modeling (FDM) and stereolithography (SLA).

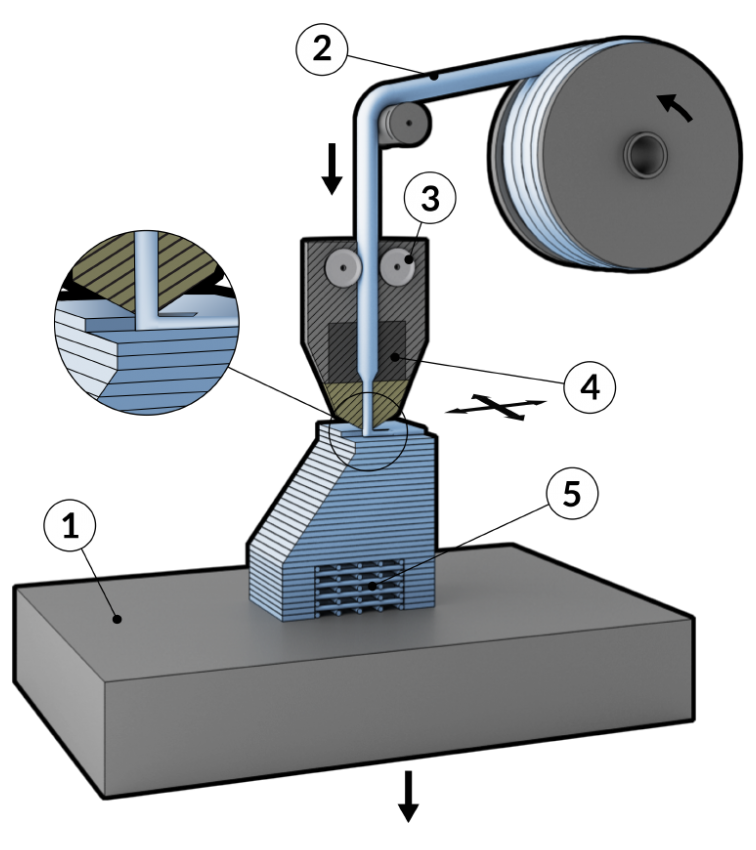

Fused Deposition Modeling (FDM)

An FDM 3D printer extrudes a thermoplastic filament through an aperture while tracing the part’s structure on a horizontal platform. As the printer head traces the cross-section, the filament is heated, melting and depositing the material. The deposited material quickly cools and hardens. The market considers FDM line-by-line tracing the slowest process and requires significant post-processing, such as sanding, to deliver the final part.

Stereolithography (SLA)

In stereolithography, a laser scans over a wet bath of thermosetting resin to form a layer of hardened material. Within the resin bath, a platform moves down by one layer thickness, and the laser scans over the material again to create the next layer. As this process continues, the hardened resin forms a part.

The chart below highlights the benefits and drawbacks of each 3D printing process:

| DLP | SLA | FDM | |

| Build Volume | Supports fast layer by layer printing with small and medium build volumes. Larger build volumes are becoming possible with multiple projectors. | Supports small and large build volumes but is slow due to the tracing process and extrusion limitations. | Supports small and large build volumes but is slow due to the tracing process and extrusion limitations. |

| Surface Finish | DLP printers produce highly accurate, complex geometries with a variety of surface textures. New LuxCreo LEAP DLP innovation enables Digital Polishing™, eliminating polishing steps required to achieve transparent parts. | A laser traces outside contours giving excellent detail. The size of the laser spot determines the minimum feature size. This size is in the range of .03 mm to .15 mm. However, spot beams are as large as .08 mm, and surfaces require extensive polishing for transparency. This size is in the range of .03 mm to .15 mm. However, spot beams are as large as .08 mm, and surfaces require extensive polishing for transparency. | FDM requires significant post-processing, including CNC machining and chemical vapor smoothing, to remove out layer lines and drill out support structures to achieve smooth hole features. It is limited to simplified models and geometries. |

| Accuracy | DLP is comparable to SLA in deposition accuracy achieving 0.02mm (xy) and 0.01 (z) accuracy. | SLA is comparable to DLP in deposition accuracy. However, spot beam angle and size limit feature size. | FDM has lower accuracy depending on nozzle aperture size and printer design quality. |

| Speed | Fast; DLP generally prints faster, curing an entire layer at once, eliminating the time needed to scan the part’s interior, as seen in SLA printing. More parts in a batch and part complexity do not require more time. DLP can print in minutes for what takes SLA and FDM hours and days. DLP can print in minutes for what takes SLA and FDM hours and days. | Slow, high-resolution laser point that creates the fine exterior faces now becomes the limiting factor in curing the interior fill areas. More parts in a batch take more time. | Slow; large parts can take days to print. Batch printing time slows for full batches having to trace each part cross-section in series. A 190 x 120 x 380 solid box will print in 133 hours, up to .3 cm per hour on FDM printing (printer dependent). |

| Post-Processing | Advanced DLP solutions are now reducing post-processing workflow steps. New LuxCreo LEAP DLP innovation enables Digital Polishing™, eliminating polishing steps required to achieve transparent parts. | Continues to require significant post-processing steps to achieve clarity and smooth surfaces. | Requires significant post-processing (i.e., support removal, tumbling, vapor smoothing, and machining) to remove support structure, achieve dimensional accuracy, and ensure surface finish comparable to DLP. |

| Materials | High-performance resins printed on production-grade DLP printers are leading the 3D printing space in elastic and dental applications outperforming SLA, FDM, SLS, and traditionally manufactured materials. | SLA resins options are extensive; however, the slow high, intensity laser tracing process limits final product performance. | Primary materials include thermoplastics with various properties from rubbery to rigid, including TPUs, ABS, and polycarbonate. |

Each printing process offers unique advantages suited to specific product applications. Understanding the advantages and limitations will help companies better decide if DLP 3D printers will support their manufacturing process.

Choosing a 3D Printing Partner

With the right 3D printing technology partner, companies can determine the best materials, processes, and designs to ensure optimum 3D printing yields. Whether using in-house 3D printing processes or outsourcing for easier scalability, working with a leading 3D printing company can help enhance and fine-tune the process.

Advanced companies like LuxCreo offer smart-factory access to cloud-connected DLP 3D printers for on-demand production and market flexibility without the steep initial costs of traditional manufacturing. Smart factories offer a fast, low-risk option for low or high-volume manufacturing, prototyping, and full-scale production.

LuxCreo’s DLP 3D printers with patented LEAP™ (Light Enabled Additive Production) process offer the ideal 3D printing process to help you scale. We offer smart factory-connected 3D printers, high-performance materials, and on-demand Smart Factory production service for low and high-volume manufacturing and rapid prototyping applications. For more information on how our services can improve manufacturing, visit our contact us page or call (650) 336-0888.

DLP 3D printing | Description and features of the technique

What is DLP 3D printing?

DLP 3D printing is an additive manufacturing technique that uses liquid photopolymer resins to build objects that are cured by light waves. “Yes, this is an SLA print!” - exclaim those who are already familiar with the methods of additive manufacturing. Indeed, the principle of operation of these two technologies is almost identical. However, the curing of the object in DLP printing occurs under the influence of a different light source.

In general, DLP 3D printing can be described as a direct analogue of SLA 3D printing, even surpassing it in some aspects. For example, the print speed in DLP 3D printers is an order of magnitude higher than in SLA devices. And the difference in fidelity varies depending on the specific equipment and consumable, and is generally small. Now let's move on to the technical aspects and talk about the principle of operation of DLP technology.

Technology Description

As with all 3D printing technologies, the first step in manufacturing a physical object is to create a 3D digital model of it. We will not delve into the details of this stage, you can read more about 3D modeling for 3D printing here. The finished 3D model is loaded into a slicer program designed to set print settings and “cut” the model into layers. This step also generates supporting structures under the overhanging elements of the object. The received settings are saved, the model is converted into a control code for a 3D printer. Now you can start printing.

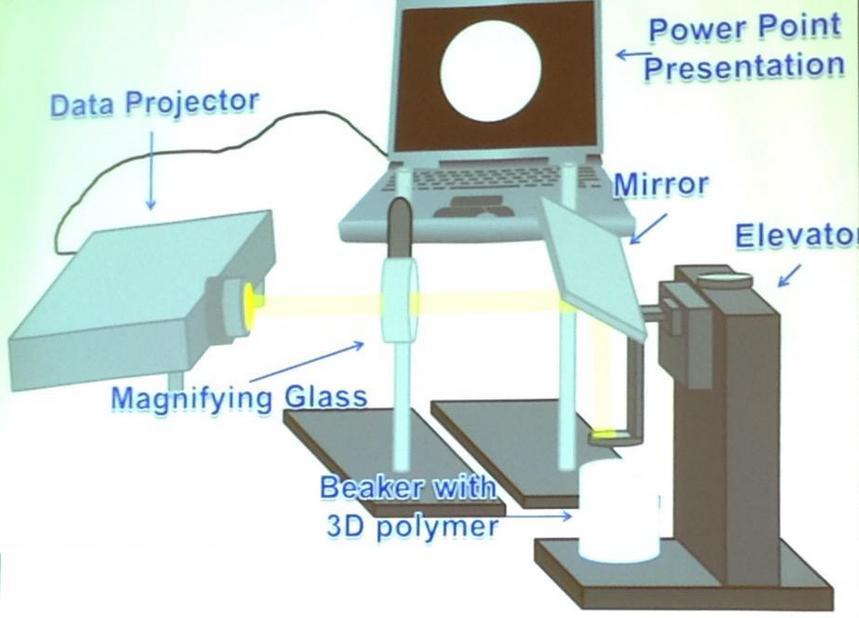

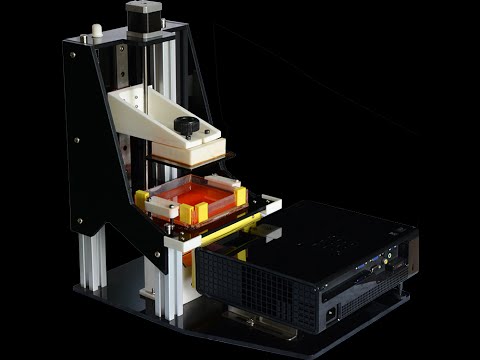

Above we mentioned the similarities between DLP and SLA 3D printing. It's time to talk about their difference and how DLP printers work. Instead of a laser machine (as in SLA), DLP 3D printing works with a special projector as a light source. This technique is not new: you can also find such DLP projectors in other, more common devices, for example, in TVs. Here they are also used for curing liquid consumables - photopolymer resins.

As in SLA printing, there are two options for DLP 3D printing devices: in one, the object is built from the bottom up (the working platform goes down), and vice versa (the working platform goes up). In our article, we will consider DLP 3D printing using both types of devices as an example.

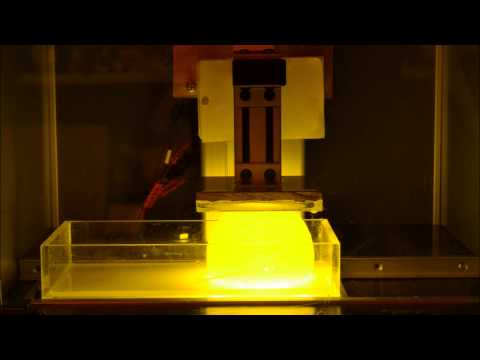

Reverse DLP 3D printing

So, a special container of a 3D printer is filled with photopolymer resin to a certain level. The building platform is lowered into the container so that the gap between it and the bottom is equal to the height of one layer. Under the tank is a DLP projector. Light corresponding to the section of the first layer of the model is projected onto the platform. After its curing, the platform rises and the illumination of the second layer begins.

So, step by step, a physical object is created. Upon completion of printing, the platform rises above the level of the photopolymer, the product is removed and cleaned of the remnants of the consumable. After that, it is necessary to perform the final illumination in a UV lamp for complete curing of the material.

After that, it is necessary to perform the final illumination in a UV lamp for complete curing of the material.

Direct DLP 3D printing

Unlike reverse printing, the DLP projector is located on top, above the resin tank. In this case, the working platform is located directly in it. To build the first layer, the platform rises so that the gap between it and the surface of the consumable corresponds to the height of the first layer.

The cross section of the first layer is projected onto the platform, curing the photopolymer, after which the platform is lowered down to the height of one layer. These steps are repeated until the complete construction of the product. Further actions are identical to those described in the previous paragraph: the object is removed, cleaned of consumables and subjected to additional illumination.

Benefits

Why is DLP 3D printing so interesting? What features of it help this technique to gain more and more popularity every day? Let's watch:

- Faster print speed than SLA 3 D printers.

In contrast to laser stereolithography, DLP 3D printing projects a whole layer onto the photopolymer at once, and does not gradually pass through its sections with a laser. Due to this, the speed of creating products increases several times;

In contrast to laser stereolithography, DLP 3D printing projects a whole layer onto the photopolymer at once, and does not gradually pass through its sections with a laser. Due to this, the speed of creating products increases several times; - High print precision. In terms of the accuracy of the created objects, DLP 3D printing is in no way inferior to SLA 3D printing: the layer height in this technique can reach 15 microns! However, it all depends on the type of 3D printer and the specific material;

- Large selection of consumables. As for photopolymers, their range in the 3D printing market is so wide today that it is sometimes difficult to decide. Moreover, often DLP 3D printers can work with the same consumables as SLA printers;

- Affordable equipment price. DLP projectors are much cheaper than laser systems, which affects the cost of 3D printers for DLP printing for the better. Technology is developing rapidly and many today are opting for digital LED projection.

Among the shortcomings, it is worth highlighting only the rather high cost of consumables.

Applicable materials

DLP 3D printing works with liquid photopolymer resins (much the same as SLA 3D printing). Some consumables are even suitable for both methods. It depends on the wavelength of illumination and consumables. However, even specifically for digital LED projection, excellent professional lines of photopolymer resins have been developed.

So, today in the 3D printing market you can find flexible and rigid materials, transparent photopolymers and resins of a wide variety of colors. Consumables for specific applications are also available. For example, dental photopolymers with various properties, as well as burnable materials for the manufacture of jewelry master models.

Equipment

Even today, some DLP 3D printers can compete directly with SLA printing equipment. Our store presents a variety of devices, both professional and budget class, for DLP 3D printing. Some of them are listed below:

Some of them are listed below:

- WANHAO DUPLICATOR 7

- M-ONE

- WANHAO DUPLICATOR D7 PLUS

- B9CREATOR

- TITAN1

All 3D printers available for order. For additional questions, write to us by e-mail, or call the numbers listed in the "Our Contacts" section.

What is DLP 3D printing for?

We have figured out how the technology works. Now consider the scope of 3D printing DLP:

- Jewelery;

- Dentistry;

- Art and design;

- Souvenir products.

In general, DLP 3D printing is suitable for any area where high precision and detail of the created products is important. With equal success, this method is used in architectural prototyping, as well as for small-scale production of small-sized products.

Back to Home

DLP 3D Printing Technology - Features and Benefits

Documentation

SISMA-DLP 3D. pdf

pdf

DLP 3D (DIGITAL LIGHT PROCESSING) technology is one of the additive manufacturing methods that uses liquid photopolymer resins as a working material, which harden as a result of exposure to light emitted by digital LED projectors (DLP).

What is DLP 3D printing?

This technology first appeared in the 80s of the last century. It was developed by Texas Instruments, which at that time was the world leader in the field of microelectronics. Larry Hornbeck pioneered digital light processing. He used digital mirrors placed in a semiconductor chip matrix. Each such mirror was a pixel in the picture and the minimum element to display. Gradually, the technique was improved, developed, opening up new horizons for application. And modern printers allow you to print three-dimensional products ranging in size from 2 mm to 650x650x450 mm with a minimum wall thickness of 0.8 mm.

At its core, the technology is very similar to laser stereolithography (SLA), but in application it turns out to be cheaper. There are no expensive laser emitters here, which made it possible to significantly reduce the cost of production. Also, this technology, unlike SLA, has a higher print speed while maintaining the maximum fidelity of the original image.

There are no expensive laser emitters here, which made it possible to significantly reduce the cost of production. Also, this technology, unlike SLA, has a higher print speed while maintaining the maximum fidelity of the original image.

Technology description

The principal device and operation of printers based on the DLP 3D printing technique is quite simple. The printer operates under the control of a specialized software package. The first stage of printing is the creation of a three-dimensional model of the future product. The finished layout is loaded into a program that automatically splits the object intended for printing into layers of a given thickness, up to several microns.

DLP 3D technology can be:

- Reverse. Liquid photopolymer compound is poured into the transparent bottom tray of the printer. The working table moves into this container, retreating from its bottom to the thickness of the very first layer of the future object.

Under the bath there is a device that projects an image of the first layer onto the bottom through a focusing lens. Under the influence of an ultraviolet light source, the working part of the material instantly hardens. After that, the table automatically rises to the next layer.

Under the bath there is a device that projects an image of the first layer onto the bottom through a focusing lens. Under the influence of an ultraviolet light source, the working part of the material instantly hardens. After that, the table automatically rises to the next layer. - Straight. The essence of direct printing is very similar to reverse printing, but the difference is that the DLP projector is located not under the bath with a photopolymer composition, but above it. And the first layer begins to be built not from the bottom of the bath, but from the surface of the material. It turns out that during operation, the platform will sink layer by layer.

All these steps (table movement, digital LED projection, UV radiation) are repeated one after another. The new layer is firmly connected to the previous one. At the same time, there are no seams and visible transitions. Gradually, layer by layer, a printed object is obtained.

Mandatory condition - the depth of the bath and the layer of poured photopolymer must correspond to the dimensions of the future product.

To understand the difference between the technological processes of laser stereolithography and digital LED printing, let's dwell on the features of SLA. Here, the working unit is not a projector, but a laser beam. It does not project a layer, but, having a minimum thickness, exactly repeats the shape of the model, passes through every point of the future object, polymerizing the liquid material. The result is a product identical to the computer model.

Advantages and disadvantages of DLP 3D printing

DLP technology in 3D printing is gradually gaining momentum in popularity due to the presence of a number of impressive advantages:

- High print speed. Here, work is being done not with every point of the object, but with its layer, which already contains hundreds, or even thousands of such points. This makes printing very fast.

- Decent accuracy. The minimum thickness of the working layer is 15 microns, which means that even the smallest elements from the computer model will be identically transferred to the printed object.

- Large selection of print materials. DLP printers work with the same materials as SLA. The modern market offers large-scale lines of photopolymer resins that mimic any material, from superhard plastics to rubber. All of them are presented in a large variety of colors.

- Low cost printer. Digital LED projection units are much cheaper than laser printers.

- Many consumers believe that the accuracy of DLP printing is much lower than SLA and attribute this to the shortcomings of the technology. But not everything is so clear-cut here. It should be understood that the accuracy of LED digital printing depends on the quality of the photopolymer used and the printer itself, and the ambient temperature. So, the best material will be a composition that includes pigments and light blockers. They will prevent the dispersion of the flow and, accordingly, the polymerization of the material adjacent to the model.

It is also important to monitor the temperature of the polymer in the pan. The printer itself will generate a lot of heat during operation, which can lead to unwanted polymerization of the composition. To prevent this from happening, you should lower the temperature in the room. But the lack of heat is not the best solution, because the emitted portion of ultraviolet radiation may not be enough to completely harden the material. This problem in many printers is solved by the presence of the option of automatic heating of the photopolymer. Print quality is also affected by the accuracy of the printer itself. It is directly related to the resolution of the LED projector.

The printer itself will generate a lot of heat during operation, which can lead to unwanted polymerization of the composition. To prevent this from happening, you should lower the temperature in the room. But the lack of heat is not the best solution, because the emitted portion of ultraviolet radiation may not be enough to completely harden the material. This problem in many printers is solved by the presence of the option of automatic heating of the photopolymer. Print quality is also affected by the accuracy of the printer itself. It is directly related to the resolution of the LED projector.

Good material + high-quality printer + adherence to technology - and the print accuracy will not be inferior to laser stereolithography. And the only conditional drawback of this technology will be reduced to zero.

DLP 3D application

Despite the fact that the DLP 3D printer appeared relatively recently, it has found wide application in many areas of science, production, and technology. This technology is used in the manufacture of master copies and models for casting and functional testing prototypes. With its help they print:

This technology is used in the manufacture of master copies and models for casting and functional testing prototypes. With its help they print:

- veneers, teeth for prosthetics, crowns and other dental products;

- jewelry, including designer products;

- elements of complex spatial configurations of small volumes;

- toys, decorative items, souvenirs;

- medical products;

- elements for sensory, measuring devices, "smart" lighting systems;

- matrices for the production of silicone molds and other products that require high detail.

This 3D printing technology is also widely used in various industries - due to its high quality, ease of use, waste-free production.

DLP 3D equipment manufacturers

One of the leading manufacturers of DLP 3D printers is the Italian company SISMA S.p.A. The history of the company has more than half a century, the main specialization has always been the development and production of high-precision equipment (previously for metal processing, and now for additive manufacturing).