7Tech 3d printing pen instructions

7TECH 3D Printing Pen - 3D Pen Hub

2nd Generation 3D Printing Drawing Pen With Temperature Control LCD + 3x 1.75mm ABS Filament + EU...

2nd Generation 3D Printing Drawing Pen With Temperature Control LCD + 3x 1.75mm ABS Filament + EU...

$22.99

in stock

Buy Now

Banggood.com

- Description

- Additional information

- Accessories ????

- Videos

- Price History

- Price Alert ????

Popular mid-priced molten plastic pen supporting ABS and PLA plastics. Lots of good reviews, a few bad ones.

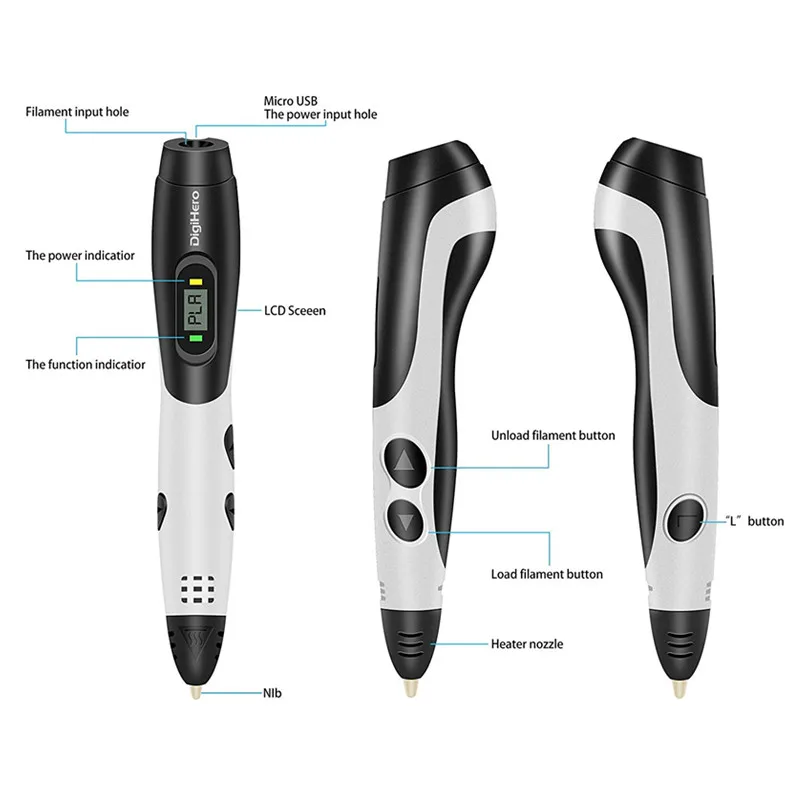

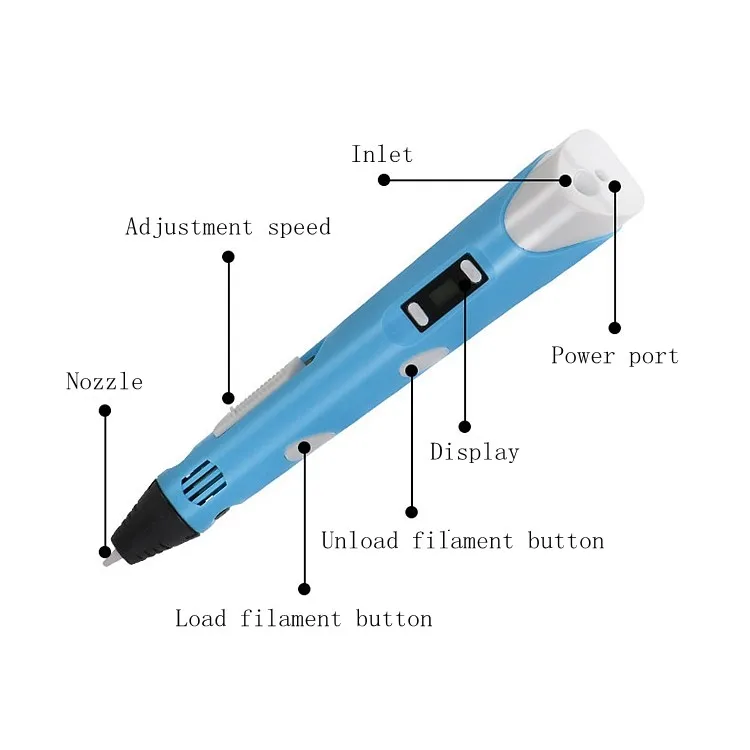

Controls:

- temperature (with display)

- speed (continuous slider)

(Might be a rebranded cheaper chinese version, but the 7Tech brand seems to provide good customer support, return policy, and quality control and actually tests the products before shipping them – hence the leftover “testing filament” you can find inside.)

- Brand: 7TECH

- Technology: Molten Plastic

- Filament size: 1.75 mm

- Filament type: ABS, PLA

- Display: YES

- Wireless: NO

Manufacturer’s detailed description:

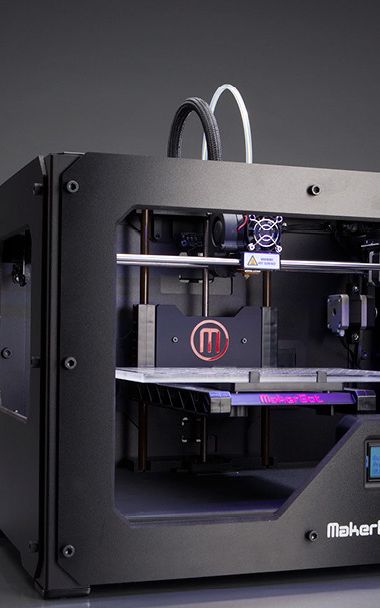

√3D Printing Pen uses the latest developed technology in 3D printing. This technology FDM (fused deposition modeling) is adapted by leading 3D printers like Makerbot, 3D system, and Afinia.

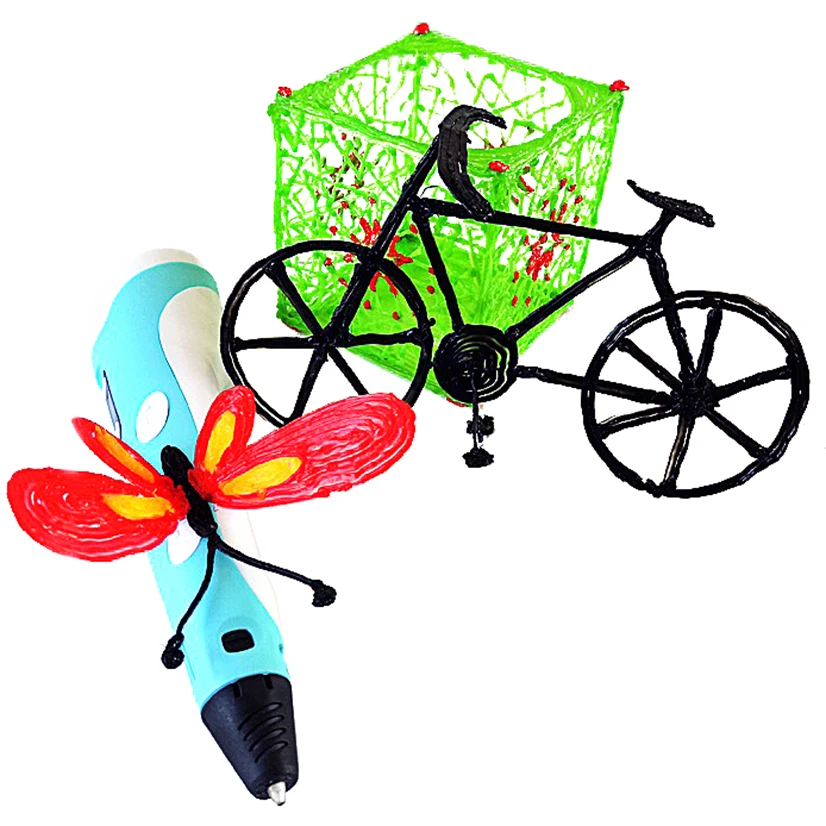

√3D pen is a great tool for anyone interested in 3D creation – from the newbie to expert, The only limitation of 3D drawing is your imagination!

The 7TECH 3D Printing Pen(2nd Edition)Package includes following:

√ 1x Blue 3D Printing Pen

√ 1x 110-240V USA Power Adapter

√ 3x 1. 75mm ABS or PLA Filament with random colors, 10 gram per loop

75mm ABS or PLA Filament with random colors, 10 gram per loop

√ 1x Operation instruction manual

√ 1x Spatula to protect your finger from hot nozzle

Product Features:

√ Intelligence auto standby mode after 5 minutes idling

√ Nozzle diameter: 0.7mm

√ Power input: 12V 3A

√ Heating temperature: 160 to 230 degree adjustable

√ With advanced thermal control, filaments jamming detection, and super silence design

√ The slender pen body suits hands use

√ The speed can be changed by single finger

√ Plastic heats up and then cools to a solid shape

√ A wonderful gift for creative children and adults

Safety and Warning Instruction

1. This 3d pen is suitable for children above 8 years old and adult; Children should use it under the guardian of adult.

2. The nozzle and surrounding area can reach a 230 degree high temperature; keep your bare hands away from the nozzle.

Notice:

Buy authentic 3D Pen in 7TECHMALL to enjoy one year premium asurance. ,

,

Fraud pen from other sellers are not entitled to asurance; All 7TECH pen will gone thru strict QC and there will be testing filament inside pen body.

Side-note: It looks identical with the V2 model of the Scribbler family, and also with other pens priced in the $20 to $80 range (same casing design, probably different electronics inside though).

Accessories ????

Craft Case for Create , Soyan 3D Printing Pen , Samto 3D , 7TECH 3D , Scribbler 3D and Other 3D...

Craft Case for Create , Soyan 3D Printing Pen , Samto 3D , 7TECH 3D , Scribbler 3D and Other 3D...

$19.99

in stock

2 new from $19.99

1 used from $14.99

as of October 7, 2022 7:17 am

Buy Now

Amazon.com

Mika3D 12 in 1 Bright Shine 3D Printer Silk PLA Filament Bundle, Most Popular Colors Pack, 1.75mm...

Mika3D 12 in 1 Bright Shine 3D Printer Silk PLA Filament Bundle, Most Popular Colors Pack, 1.75mm...

$149.99

$199.99

in stock

as of October 7, 2022 7:17 am

Buy Now

Amazon.com

Tecboss 3D Pen/3D Printer Filament, 1.75mm PLA Filament Pack of 20 Different...

Tecboss 3D Pen/3D Printer Filament, 1.75mm PLA Filament Pack of 20 Different. ..

..

$12.99

$14.99

out of stock

as of October 7, 2022 7:17 am

Buy Now

Amazon.com

TECBOSS 3D Pen Mat, 3D Printing Pen Pad Silicone Template with Bonus 3 Patterns Mat 2 Finger...

TECBOSS 3D Pen Mat, 3D Printing Pen Pad Silicone Template with Bonus 3 Patterns Mat 2 Finger...

$5.49

out of stock

3 new from $5.00

as of October 7, 2022 7:17 am

Buy Now

Amazon.com

7TECH 3D Pen Mat Silicone Design Mat with 280 Stencils eBook and 2 Silicone Finger Caps Great 3D...

7TECH 3D Pen Mat Silicone Design Mat with 280 Stencils eBook and 2 Silicone Finger Caps Great 3D...

out of stock

as of October 7, 2022 7:17 am

Buy Now

Amazon.com

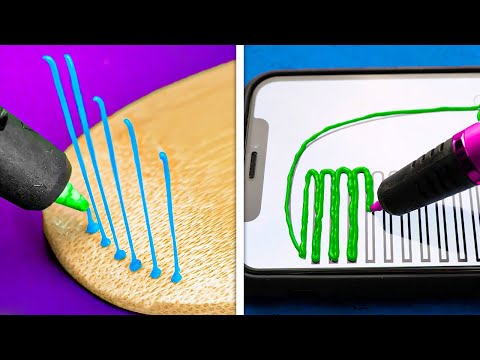

Videos

Testing the 7Tech 3D Pen

In this review, I put the 7Tech 3D pen through it's paces, and build a funky planet. Get the 7Tech Pen here : http://bit.ly/7Tech4D Watch my newer video to find out ...

7TECH 3D Drawing Pen review #awesomepen #7tech4ddrawingpen

This is a review I did of the 7TECH 3D Drawing Pen. I received the pen at a discounted price to provide my unbiased opinion and review of the pen. I think it's ...

Price History

Price History for Craft Case for Create , Soyan 3D Printing Pen , Samto 3D , 7TECH 3D , Scribbler 3D and Other 3D...

Statistics

| Current Price | $19.99 | October 7, 2022 |

| Highest Price | $19. 99 99 | March 26, 2022 |

| Lowest Price | $19.99 | March 26, 2022 |

Since March 26, 2022

Last price changes

| $19.99 | March 26, 2022 |

Price Alert ????

Create Your Free Price Drop Alert!

Set Alert for Craft Case for Create , Soyan 3D Printing Pen , Samto 3D , 7TECH 3D , Scribbler 3D and Other 3D... - $19.99

Reviews of the 7Tech 3D Drawing Pen 2022 (Specs & Price)

Looking for that 3D pen that everyoneís talking about? Well, look no further.

When you buy the 7tech 3D pen, you will get a package containing:

- One blue 3D printing pen

- 110-240 power adopter

- A 3 x 1.75 Multicolored A.B.S filament (10g per loop)

- An easy to comprehend manual user guide

These items may not mean a lot if you have bought other 3D pens in the past. That is until you see what the 7tech 3D pen has.

That is until you see what the 7tech 3D pen has.

The pen has a filament jamming detection. So, unlike most 3D pens, you wonít have any frustrations unclogging the pen. It is also super silent, has an advanced thermal control, and a control to manage the extrusion speed.

In this Guide

Overview of 7Tech 3D Drawing Pen Ver. 2015

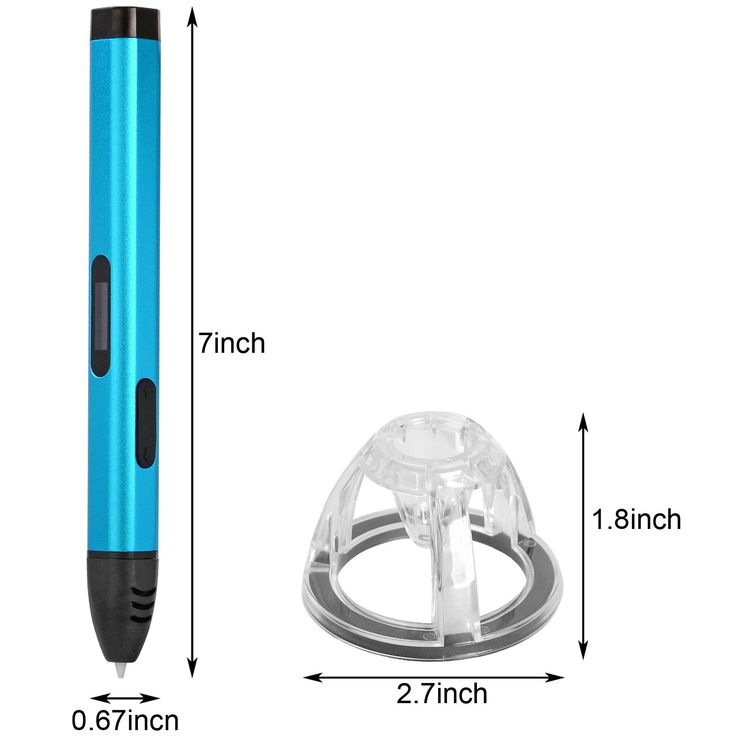

- Model Name: 7TECH 3D Printing Pen with LCD Screen Ver. 2015 (Second Edition)

- Nozzle diameter: 0.7mm

- Heating temperature: 160-230 degree adjustable

- Power input: 12V 3A

- Colors: Currently only light Blue

- 7tech 3D Pen Price:[amazon_link asins=’B00S4CJWVE’ template=’PriceLink’ store=’3dnet02-20′ marketplace=’US’ link_id=’51b352ec-1a4d-11e7-b3ba-5dfe20c6fe8d’]

Click Here to Buy the 7TECH 3D Pen

Whatís in the Box?There are a number of accessories that come in the box. These include:

These include:

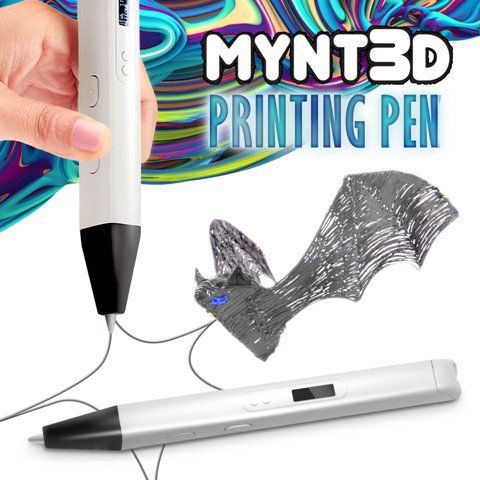

3D Printing Pen

The main accessory in the box is the 7Tech 3D pen. The pen is blue in color and looks like a standard glue pen. The pen is fitted with an LCD display on which you can select different settings such as flow speed, temperature, and others. The pen feels somewhat like a standard glue pen and weighs a mere 65gm. The ergonomics of the pen allow you to create 3D objects in a comfortable writing position.

Power Cable

The box comes with a standard 110-240 volts power adapter. You can power the pen by fitting the cable in any standard power socket.

ABS Filament

ABS filament refers to a thin type of plastic wire that is used in 3D pens. The filament is inserted in the pen and then melts when the pen is heated. On melting, the filament turns to molten plastic, which is used to create the 3D objects.

The filament comes in different colors. In the 7tech box, there are three color filaments to get started with. You can think of the filament as the refill ink for a pen.

You can think of the filament as the refill ink for a pen.

Introduction Manual

You need to go through the manual to learn how to operate the pen. The manual is available in every box and is especially useful for new beginners. You should also check the safety instructions indicated in the 7tech 3D pen instructions manual. For example, the pen has a powerful heating element that can get the nozzle to reach temperatures of up to 230∞C.

Design of the 7Tech 3D Drawing Pen

If you are interested in 3D printing, the only tool you need is the best 3D pen. However, choosing the right pen is challenging as new 3D pens enter the market and the old ones get improved.

The 7TECH 3D Drawing Pen Ver. 2015 is one of the best 3D pens in the market. The pen is designed with the end-user in mind and uses fused deposition modeling like is used in 3D printers.

Features of 7Tech 3D Drawing Pen

While the 7Tech 3D printing pen is compact and small, it has a host of features that make it an ideal pen for beginners and experienced artists. Below is an overview of the features of the pen.

Below is an overview of the features of the pen.

Temperature Control

The pen can use different types of plastic filaments. These filaments have different melting points. You can adjust the temperature to reach the melting point of the filament you are using.

Speed Control

You can control the speed of the 7Tech 3D Printing Pen using your finger. The one-finger speed control allows you to slow down or increase the speed of the flow of molten plastic.

If you are creating intricate designs, slow down the speed to have more time to maneuver the pen. On the flip side, if you want to quickly complete hours of repetitive work, speed up the flow of the molten plastic.

Jam Detection and Unclogging Mechanism

3D printing pens can get clogged, just like is the case with traditional printers. The good news is that the 7tech 3D pen has jam detection mechanisms. When there is a jam, an error message is automatically displayed on the LCD display. To unclog the jam, simply reverse the motion of the filament by using the speed button.

To unclog the jam, simply reverse the motion of the filament by using the speed button.

Auto Standby Mode

To save power and ensure the heating element stays durable, there is an auto-standby mode. With this feature, the heating element of the pen automatically switches off after 5 minutes of inactivity.

Dual Filament Operations

There are two types of filaments for 3D pens in the market. These pens only work with specific filaments. The 7Tech 3D Pen works with both 1.75mm PLA and ABS filaments. With this pen, you can buy any filament you want, depending on your budget.

Silent Operation

One of the disadvantages of buying cheap 3D pens is that they can be noisy when you are using them. The noise can distract your creative process. The 7Tech 3D pen does not vibrate nor produce noise, even when in use for hours.

Safety Features

You can use the 7tech pen at home or in the office without worrying about interruptions. The pen has an auto-standby mode which enables it to temporarily shut off when you leave it idle for more than 5 minutes.

The pen has an auto-standby mode which enables it to temporarily shut off when you leave it idle for more than 5 minutes.

Accessories

This pen sports an LCD screen for better doodling experience, a 0.7mm nozzle diameter, and an aluminum spatula to help protect your fingers from the hot nozzle. You also donít have to worry about setting up the pen or using it as it comes with a comprehensive operational manual guide.

Check More Features of the Pen at Amazon

Pros of the 7Tech 3D Pen

Durable

3D Model Created with 7Tech 3D PenThe 7Tech 3D pen is built with sturdy materials that last long. The pen will remain in good condition even after long use.

Versatile

The penís temperature control and adjustable speed allow you to select custom settings for the design work you are doing. Moreover, you can regulate the flow of molten plastic at any time using the one-finger speed control.

Comfortable

The ergonomic design and lightweight construction of the pen allow for a comfortable writing position. You can draw for hours without experiencing any fatigue or soreness.

You can draw for hours without experiencing any fatigue or soreness.

Child-Friendly

Features like the jam unclogging mechanism and LCD display make it easy for kids to use the pen. Moreover, the auto-standby feature ensures the device is safe since kids can forget to turn it off.

Check this video of how the 7tech 3D pen works:

Cons of the 7Tech 3D Pen

I personally loved my experience with using this pen. Clearly, many other users also love the pen from the reviews on Amazon. However, there are a few concerns some customers had with the pen. These include:

- Although the pen comes with 3 filament strands of 3 colors (pink, blue and white), these are never enough. You should, therefore, add an extra filament package with other colors when making your order.

- The pen nozzle can get extremely hot. It heats up to 240 degrees. Therefore, be careful when using the pen where there are children who can easily touch it.

- Children below 8 years should not use the pen due to the burning hazard. Children above 8 years should only use the pen under adult supervision.

Read More Customer Reviews on Amazon

Pros

Slim and lightweight, hence easy and comfortable to use.

Has aluminum spatula that protects your fingers from the hot nozzle

Easy to operate for both newbies and experts

Advanced clogging technology that prevents it from jamming

One-year premium quality guarantee.

Cons

Only has 3 filament strands of 3 colors, which are not enough.

The pen nozzle can get extremely hot.

Not suitable for children under 8.

Conclusion

When looking for a good 3D pen to purchase, consider the safety and control features. the 7Tech 3D Drawing Pen Ver. 2015 will make your creations come to life. It has an aesthetic aura yet an easy-to-use design that even children can take advantage of.

If you want your 3D objects to be really fine, smooth out rough spots with a silicon spatula or any other item when the plastic is still warm. After this, let the 3D model cool before moving it. If you want a sturdy design, put enough layers of the object you have created.

After this, let the 3D model cool before moving it. If you want a sturdy design, put enough layers of the object you have created.

With all the user-friendly features of the 7Tech 3D Drawing pen make it a masterpiece that you should buy.

Read Amazon Reviews Check Price at Amazon

The second part of the 3D printing guide for beginners. Timeline of 3D printing

The birth of modern 3D printing. 1980-1990

The earliest modern 3D printing technologies first appeared in the late 1980s, at which time they were called Rapid Prototype (RP) technologies - RapydPrototype (RP). This is because processes were originally conceived as a fast and cost-effective way to create prototypes for industrial product development.

Interestingly, the very first patent application for PSU technology was filed by Dr. Kodama in Japan in May 1980. Unfortunately for Dr. Kodama, the full patent specification was not filed until one year after application, which is particularly unfortunate given that he was a patent lawyer.

Hideo Kodama (Hideo Kodama)

In reality, however, 3D printing started in 1986, when the first stereolithography apparatus (SLA) patent was issued. This patent belonged to Charles (Chuck) Hull, who first invented the SLA machine at 1983 year. Hull continued to collaborate with 3D Systems Corporation, one of the largest and most prolific organizations active in the 3D printing sector today.

3D Systems created its first commercial SLA-1 rapid prototyping system in 1987 and, after extensive testing, sold it in 1988. However, despite the fact that SLA technology may claim the first place in the history of 3D printing, it was not the only rapid prototyping technology at this time. At 19In 1987, Carl Deckard, who worked at the University of Texas, applied for a US patent for selective laser sintering (SLS-Selective Laser Sintering). This patent was issued in 1989 and SLS was later licensed from DTM Inc. and subsequently acquired by 3D Systems. Also in 1989, Scott Crump, co-founder of Stratasys Inc. , applied for a patent for FDM-Fused Deposition Modeling technology, which the company still owns today, the technology used today by many entry-level printers. open source level RepRap (Replicating Rapid Prototyper). The FDM patent was issued to Stratasys in 1992 in Europe.

, applied for a patent for FDM-Fused Deposition Modeling technology, which the company still owns today, the technology used today by many entry-level printers. open source level RepRap (Replicating Rapid Prototyper). The FDM patent was issued to Stratasys in 1992 in Europe.

Scott Crump Co-founder of Stratasys

In 1989, Hans Langer founded EOS GmbH in Germany. After playing around with SL technology, EOS shifted its focus to SLS technology. Today, EOS is recognized worldwide for the quality of its products for industrial prototyping. In 1990, EOS sold its first Direct Metal Laser Sintering (DMLS) stereo system in cooperation with Electrolux Finland, which was later acquired by EOS.

Other 3D printing technologies emerging in these years include Ballistic Particle Manufacturing (BPM) originally patented by William Masters, Laminated Object Manufacturing (LOM) patented by Mikhail Feigin, masked stereolithography ( SGS - Solid Ground Curing), patented by Itzhak Pomeranz and three-dimensional printing (3DP), patented by Emanuel Sachs. So in the early nineties, there was an increase in the number of competing companies in the rapid prototyping market, but only three of them have survived to this day - 3D Systems, EOS and Stratasys.

So in the early nineties, there was an increase in the number of competing companies in the rapid prototyping market, but only three of them have survived to this day - 3D Systems, EOS and Stratasys.

Development of various 3D printing technologies. 1990-2000

Throughout the 1990s and into the early 2000s, many new technologies continued to be introduced, but they all remained exclusively focused on industrial production. Through research and development (R&D), more advanced technology has been introduced for specific casting tools. This marked the beginning of a new terminology, namely high-speed machining (RT-Rapid Tooling), rapid casting (Rapid Casting) and rapid production (RM-Rapid Manufacturing).

So in 1996 SandersPrototype (later Solidscape) and ZCorporation were created, in 1997 - Arcam, Objet Geometries - in 1998, in 2000 MCP Technologies introduced the technology of selective laser melting (SLM), in 2002 EnvisionTec was founded, In 2005, ExOne was established as a subsidiary of Extrude Hone Corporation and SciakyInc. introduced its pioneering additive process based on patented electron beam welding technology.

introduced its pioneering additive process based on patented electron beam welding technology.

All these organizations joined the ranks of Western companies operating in the world market. Terminology has also evolved with the spread of manufacturing applications, and a common term for all technologies has been adopted - additive manufacturing (AM - Additive Manufacturing). It is noteworthy that at the same time there were many parallel processes in the Eastern Hemisphere, but in the end, all of them did not have a significant impact on the world market.

The mid-2000s began to show signs of diversification in two specific areas of focus that are much more clearly defined today.

First of all, these are top-of-the-line 3D systems, still very expensive equipment that has been directed towards the production of high quality, high tech complex parts. The growth of this field continues to this day, but only now, after years of research and development, the results are becoming more visible when using technologies in the aerospace, automotive, medical and jewelry sectors. Much still remains behind closed doors and/or under non-disclosure agreements.

Much still remains behind closed doors and/or under non-disclosure agreements.

On the other hand, some manufacturers of 3D printing systems are directing their efforts towards the development and promotion of the concept of modellers, as they were called at the time. In particular, these were 3D printers that kept the focus on improving functional prototyping, which were designed specifically as office-friendly, cost-effective systems. This was the prelude to today's desktop printers. However, most of these systems were still being developed for industrial prototyping.

In hindsight, this was indeed the calm before the storm.

Opening 3D printing to the general public 2007 - ...

In the low-price segment, 3D printers are in the middle of the price range today, as price struggles have come along with incremental improvements in materials used, as well as printing speed and accuracy.

In 2007, the market saw the first $10,000 printers from 3D Systems, but they failed to achieve their intended goal. This was partly due to the system itself, partly to market influences. According to many industry insiders, users, and commentators, the holy grail at the time was getting a $5,000 3D printer as the key to opening up 3D printing technology to a wider audience.

This was partly due to the system itself, partly to market influences. According to many industry insiders, users, and commentators, the holy grail at the time was getting a $5,000 3D printer as the key to opening up 3D printing technology to a wider audience.

For most of the year, the world was looking forward to the arrival of the long-awaited Desktop Factory, as many predicted that they would find the Holy Grail. However, the expectations were in vain, as production faltered in anticipation of the release. Desktop Factory, led by Cathy Lewis, was acquired by 3D Sysytems in 2008, and that was it. As it turned out later, 2007 did become a turning point for the opening of 3D printing technology to a wide audience, although at that moment no one realized that the RepRap phenomenon had already taken root. Dr Bowyer conceived the concept of an open source, self-replicating RepRap 3D printer back in 2004. In the years that followed, the seeds gradually germinated, with major contributions from members of his Bath team, especially Vic Oliver and Rhys Jones, who developed the concept of working prototype 3D printers based on deposition modeling technology. In 2007, shoots began to appear, and the promotion of 3D printing to the masses began to gain momentum.

In 2007, shoots began to appear, and the promotion of 3D printing to the masses began to gain momentum.

Adriano Bowyer (left) and Vik Olliver (right)

However, the first commercially available disassembled 3D printer based on the RepRap concept was only put up for sale in January 2009. It was a BfB RapMan 3D printer. MakerBot Industries closely followed this technology, the founders were actively involved in the development of the RepRap printer, until, due to extensive investments, they moved away from the philosophy of open source printers. In 2009, a lot of similar printers appeared, sold in various parts of the world, and this continues to this day. The RepRap phenomenon has spawned a new sector of entry-level commercial 3D printers.

2012 was the year of introducing alternative printing technologies to the entry level market. B9Creator with color LED projection technology (DLP-Digital Light Processing) appeared in June, and Form 1 in December. Both projects were launched with Kickstarter funding and both have been huge successes.

As a result of market divergence, significant shifts at the industry level, and a sharp increase in awareness, 2012 was also the year of the emergence of various media channels. 2013 was a year of significant growth and consolidation in 3D printing technology. One of the most notable events was the acquisition of MakerBot by Stratasys.

There is no denying the impact of 3D printing on the industrial revolution, it shows great potential for future consumers. We can only guess what form this potential will take, still unfolding before us.

3D printing technologies are developing every day, taking their place more and more firmly in many areas of our lives. 3D4U also does not stand still, and today is ready to offer you 3D printing services using FDM / FFF technologies and jewelry printing using DLP technology using the B9 3D printer described aboveCreator. Almost everyone has heard about 3D pens. Many have tried them, many have them. So, perhaps, this gadget will surprise no one. And, probably, if there is a 3D printer at home, then the pen against its background will look very funny. But... Do not rush, a 3D pen can become an indispensable assistant and a very handy tool for any maker. Now, using my example, I will show how easy it is to save a three-dimensional model that took 41 hours to print using a 3D pen.

And, probably, if there is a 3D printer at home, then the pen against its background will look very funny. But... Do not rush, a 3D pen can become an indispensable assistant and a very handy tool for any maker. Now, using my example, I will show how easy it is to save a three-dimensional model that took 41 hours to print using a 3D pen.

Let's start by inspecting the gadget.

Everything is standard, the box contains instructions, power supply and the pen itself.

Power supply cable length 1.4 m, should be enough for most outlets near tables.

12 volt, 3 amp power supply.

At idle, it easily gives out the declared volts, I didn’t measure the current, sorry. Let's go straight to the test.

Handle like a handle. Of the interesting - this is the specified nozzle diameter - 0.7 mm. A big plus for me personally is that the pen is omnivorous. You can print both PLA and ABS. There is also a manual temperature control.

Mode selection is intuitive. You just need to press the buttons on the sides of the screen.

Next, press the feed button, you can release it once. Heating starts. Heats up quickly, faster than a 3D printer.

When the desired temperature is reached, the indicator to the left of the screen changes from red to green.

In addition to adjusting the temperature on the handle, there is an adjustment for the plastic feed (speed).

On the other side of the feed adjustment there are 2 buttons - “squeeze out” and “pull out”.

Filled for the first test with a piece of plastic left over from the last print.

On the first delivery, you can see that there was already some plastic in the nozzle. This is good, since the handle was really checked. Some printer manufacturers supply them with a printed figure on the table, the user immediately sees that the device is working and prints as it should.

I had a test plastic right away for a reason, I refilled transparent SBS, it is quite soft and often there are problems with it when printing on a printer. Here, everything immediately went briskly.

A small digression.

I was given a set of plastic along with the pen.

3D palette.

By the way, a very good addition to the 3D pen. In addition to conveniently located plastic in separate pockets, there is a compartment for storing a pen, as well as an envelope with sketches on tracing paper for easy creation of three-dimensional models.

We take a tracing paper and draw glasses along the contour.

When the plastic has cooled, it can be easily removed from the tracing paper. We're filming.

Draw the second bow.

Next, melt the temples to the glasses.

PLA plastic is very pleasant to work with, easy to soften and stick to each other. But there is one drawback, it should not be overheated, it becomes too fluid, but more on that later.

But there is one drawback, it should not be overheated, it becomes too fluid, but more on that later.

Glasses are ready.

Now let's get down to business. I printed a Pinky monster figurine from DOOM 3. Printing did not work right away, the model is very complex with spikes and other details sticking out in all directions. I printed both in 2 extruders with supports from HIPS, and with supports generated in MeshMixer. But when moving to the beginning of the hands, something always fell off and I had to stop printing. Perhaps the plastic is to blame, it is almost a year old and it was stored without a package and a box, just like that.

In general, for the third time I combined printing methods and added supports from HIPS plastic to the model with supports from MeshMixer. In the middle of printing, I saw that my hands were torn off again, but I spat and finished printing to the end, deciding to simply glue the damaged parts.

The parts have been reprinted and now with a 3D pen I can easily glue them to the main model.

With such a seam, glued parts are obtained, but firmly. And the protruding excess plastic can be ground off or cut off with a knife after treatment with dichloromethane.

Saw off the muzzle.

And glue a new, high-quality one.

This is a darned creation of Frankenstein.

Here you can see the comparison of the quality of the old and new muzzle.

Let's move on to the hands. It’s more difficult here, in some places it turned out to be a big gap.

But, in principle, the handle easily copes with wide gaps.

It remains only to process the seams.

I didn't sand or dry sand them. I decided to treat the entire model with methylene chloride, it dissolves both PLA and ABS equally well.

The seams have become smoother, but most importantly, the top layer of plastic has become soft and can be easily cut with a knife, like plasticine. Align all the seams, cutting off the excess, and once again go through the brush with DCM.

Align all the seams, cutting off the excess, and once again go through the brush with DCM.

And here is the result:

Finally, let's look inside the 3D pen.

Remove the black tip and unscrew one single screw.

Here you can see a ceramic nozzle with a heater and a thermistor, a short bowden tube and an extruder on a simple brushed motor. The feed is controlled by the rotation speed of the motor shaft. On the motor there is a small brass gear pushing through plastic, on the other hand, all this is pressed by a small bearing with a flat side. In general, everything is very simple, like Kalash. Yes, and remember, I wrote about the fact that you should not overheat PLA plastic. In the disassembled photo, it is noticeable that there is something red on the back of the heater, where the tube enters it. It's just PLA plastic, I painted it a little in the heating mode for ABS, and it became so liquid that it went in the opposite direction.