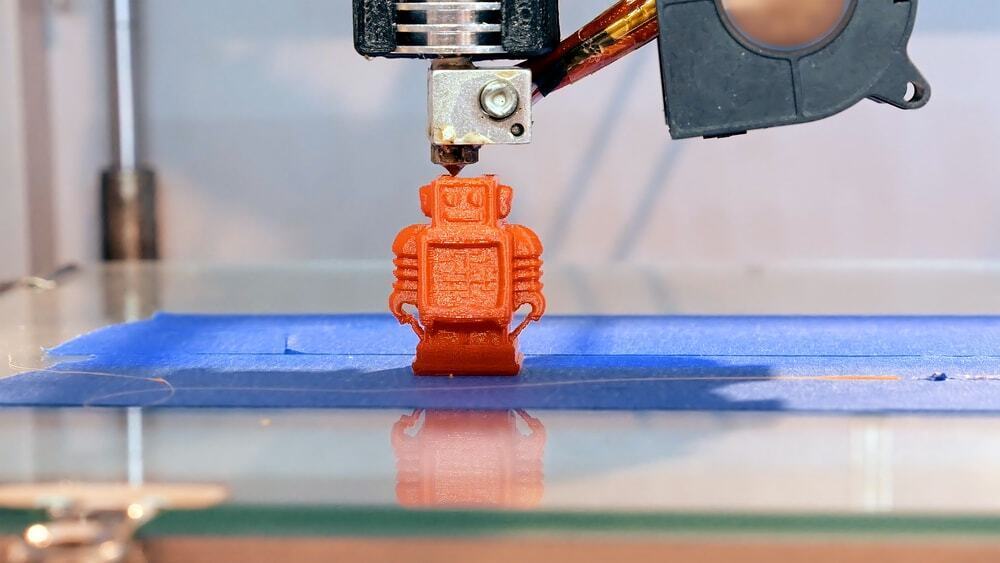

Best 3d printing materials

Ultimate Materials Guide - Tips for 3D Printing with PETG

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage. There are several variations of this material in the market including PETG, PETE, and PETT. The tips in this article will apply to all of these PET-based filaments.

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

Hardware Requirements

Before 3D printing with PET / PETG make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 75-90 °C

Heated Bed Recommended

Enclosure Not Required

Build Surface

Glue Stick

Painter’s tape

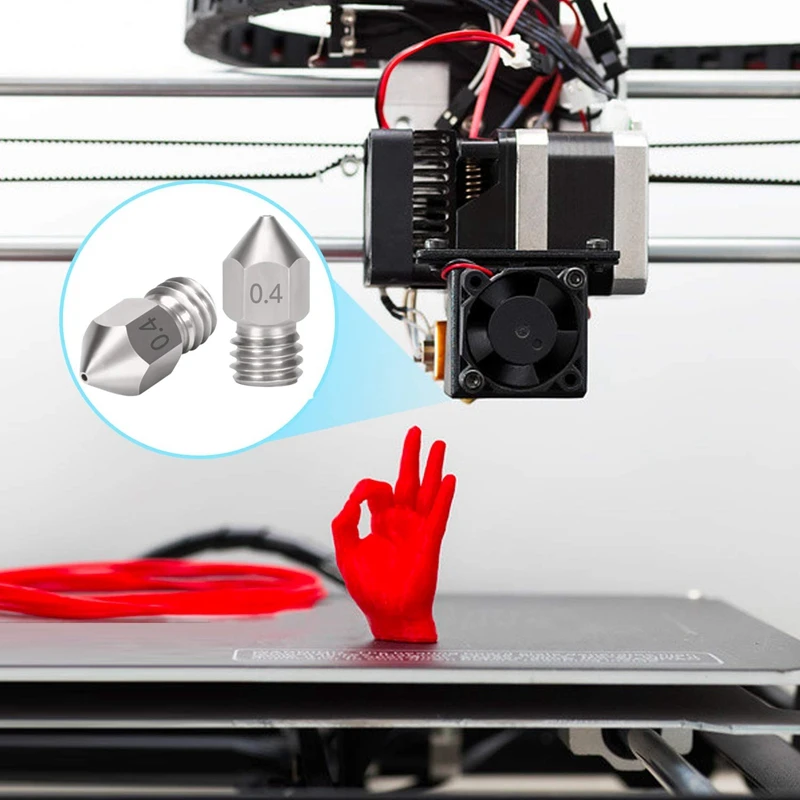

Extruder

Temperature: 230-250 °C

No special hot-end required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PET / PETG such as stringing, oozing, and poor bed adhesion.

Invest In a Good Build Surface

Some 3D printers come with a glass bed or blue painter’s tape installed on the bed. Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Calibrate Retraction Settings to Reduce Stringing

One of the few common issues that we see with PETG is stringing. These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model.

These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Optimize Extruder Settings to Prevent Blobs and Zits

When 3D printing at higher temperatures associated with PETG, you may notice small blobs or zits on the surface of your model. These print defects typically occur at the beginning or end of each segment, where the extruder has to suddenly start or stop extruding plastic. There are several ways to eliminate these print defects such as enabling “Extra Restart Distance” or “Coasting” options located in the Extruder tab. Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Pro-Tips

- The glossy surface of PETG is especially useful when using rafts. The part separates easily from the raft and maintains a clean surface finish.

- Try disabling your part cooling fan for the first few layers of the print to prevent warping. This trick especially works well for larger prints.

Get Started with PET / PETG

Now that you are ready to start printing with PET / PETG, here are a few ideas to help you get started – from common applications to popular filament brands.

Common Applications

- Water proof applications

- Snap fit components

- Planter Pot

Sample Projects

- Self-watering Planter

- Water Bottle

- Snap Fit Parts

Popular Brands

- ColorFabb PETG

- eSun PETG

- E3D Spoolworks Edge

- Hatchbox PETG

- HobbyKing PETG

Ultimate Materials Guide - 3D Printing Flexible Filament

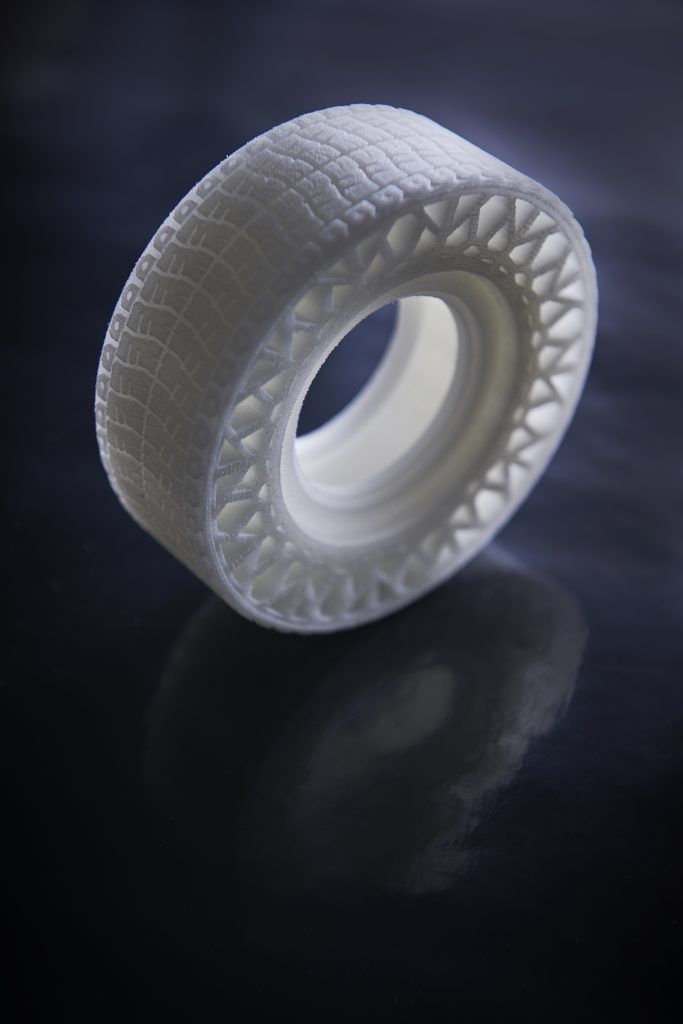

Overview

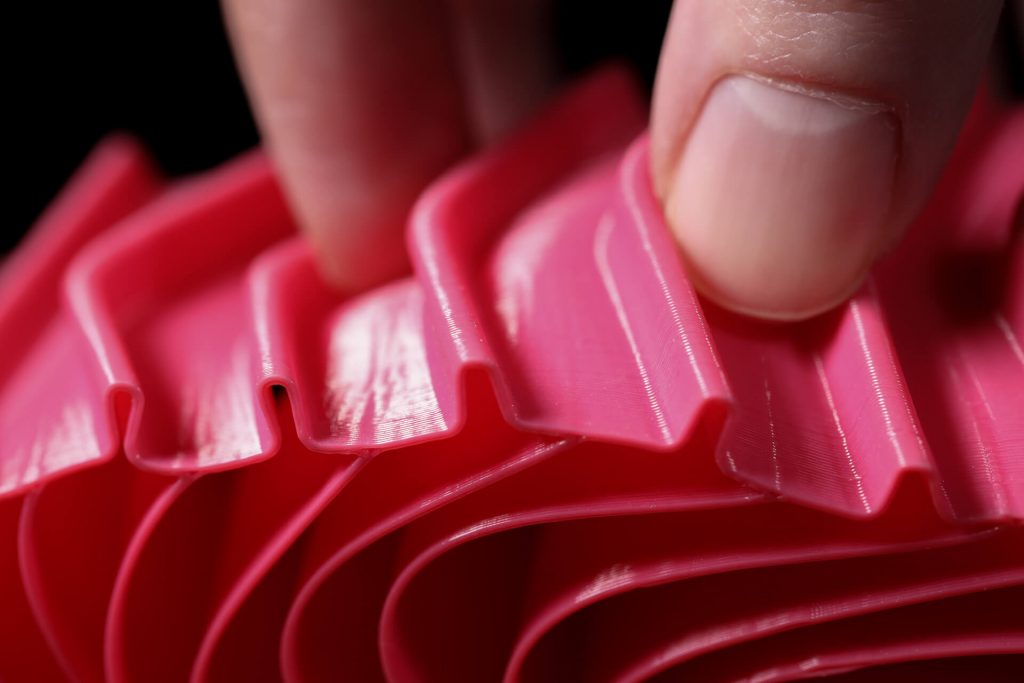

Flexible filaments are made of Thermoplastic Elastomers (TPE) which are a blend of hard plastic and rubber. As the name suggests, this material is elastic in nature allowing the plastic to be stretched and flexed easily. There are several types of TPE, with Thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. In many cases, these terms are used interchangeably, along with popular brand names such as Ninjaflex. The degree of elasticity in the plastic depends on the type of TPE and the chemical formulation used by the manufacturer. For example, some filaments can be partially flexible like a car tire but others can be elastic and fully flexible like a rubber band. This guide will cover tips to help you with both of these variations of flexible filaments.

As the name suggests, this material is elastic in nature allowing the plastic to be stretched and flexed easily. There are several types of TPE, with Thermoplastic polyurethane (TPU) being the most commonly used among 3D printing filaments. In many cases, these terms are used interchangeably, along with popular brand names such as Ninjaflex. The degree of elasticity in the plastic depends on the type of TPE and the chemical formulation used by the manufacturer. For example, some filaments can be partially flexible like a car tire but others can be elastic and fully flexible like a rubber band. This guide will cover tips to help you with both of these variations of flexible filaments.

- Flexible and soft

- Excellent vibration dampening

- Long shelf life

- Good impact resistance

- Difficult to print

- Poor bridging characteristics

- Possibility of blobs and stringing

- May not work well on Bowden extruders

Hardware Requirements

Before 3D printing with flexible filaments, make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure Not Required

Build Surface

PEI

Painter’s Tape

Extruder

Temperature: 225-245 °C

Direct Drive Extruder Recommended

Cooling

Part Cooling Fan Required

Best Practices

Flexible filaments come with many unique challenges that you want to be aware of. These tips will help you reduce the chances of common 3D printing issues such as clogging, kinking, and stringing.

Use Direct Drive Extruders

While some partially flexible filaments work fine with Bowden Extruders, most fully flexible filaments require a Direct Drive extruder for best results. The distance between the drive gear and the melt zone of the hot-end needs to be as short as possible to efficiently feed the filament into the nozzle. Additionally, the pathway through which the filament travels into the melt zone should have tight tolerances to prevent the filament from kinking or coiling inside. For these reasons, it is typically much easier to print flexible filaments with a Direct Drive extruder versus a Bowden extruder. If you are unsure about your 3D printer’s capabilities, you may want to check with the manufacturer to see if the extruder has been approved for use with flexible filaments.

For these reasons, it is typically much easier to print flexible filaments with a Direct Drive extruder versus a Bowden extruder. If you are unsure about your 3D printer’s capabilities, you may want to check with the manufacturer to see if the extruder has been approved for use with flexible filaments.

Use Slow and Consistent Feed Rates

Flexible filaments typically print best using a slow and consistent feed rate. Because the material is elastic, it can be very difficult to control sudden changes in the print speed. Higher print speeds can cause the filament to compress and will most likely result in a jam. Slow and steady is the best approach. Simplify3D provides all of your feed rate settings on the Speeds tab of your process settings so that you can easily configure these values. Finding the optimal print speed for your material can take several attempts based on trial and error. We have seen that speeds of 1200 mm/min (20 mm/s) can be a good starting point for most materials.

Reduce Resistance from the Filament Spool

A few tweaks to your material spool can also make a big difference with flexible materials. Typically, your extruder will pull the filament into the nozzle, forcing the filament spool mounted on your printer to unwind a bit of plastic in the process. However, because flexible materials are elastic, this will stretch the filament out as it is being pulled in and can actually result in under-extrusion. Try mounting the spool above your printer so that the filament unwinds in a downward direction which can reduce the resistance. It can also be incredibly helpful to mount the spool’s hub on a bearing to allow the spool to spin as freely as possible.

Tune Your Retraction Settings

The elastic nature of flexible filament makes it sensitive to quick movements such as retractions. In order to successfully print the filament, you will need to optimize your retraction settings to reduce these movements. While you are first starting with this material, we would recommend disabling retraction completely. You can make this change in Simplify3D on the Extruders tab of your process settings. With retraction disabled, you can focus on finding the perfect speed and extrusion rates that allow you to reliably print your models. After you are more confident in these settings, you may wish to add a very small amount of retraction with a slower retraction speed to help with any potential oozing from the hot-end. Simplify3D also includes a unique option called Coasting, which will automatically help lower the pressure in the nozzle when you approach the end of a segment, which can significantly reduce blobs and stringing with these materials. If you want more information about other options that can help reduce hairs and stringing on your prints, we have an entire section on our Print Quality Guide dedicated to that issue: How to Reduce Stringing and Oozing.

You can make this change in Simplify3D on the Extruders tab of your process settings. With retraction disabled, you can focus on finding the perfect speed and extrusion rates that allow you to reliably print your models. After you are more confident in these settings, you may wish to add a very small amount of retraction with a slower retraction speed to help with any potential oozing from the hot-end. Simplify3D also includes a unique option called Coasting, which will automatically help lower the pressure in the nozzle when you approach the end of a segment, which can significantly reduce blobs and stringing with these materials. If you want more information about other options that can help reduce hairs and stringing on your prints, we have an entire section on our Print Quality Guide dedicated to that issue: How to Reduce Stringing and Oozing.

Optimize Your Travel Movements

Retractions can be particularly troublesome for flexible materials, so it is typically best to minimize the number of retractions required for your print. Simplify3D has a great feature that was built specifically for this situation. Instead of moving in a straight line from point A to B, the software will actually choose a completely new path when moving between these points, with the goal of staying within the interior of your object so that there won’t be any oozing or stringing. With this unique feature enabled, you can greatly reduce the amount of retractions required for your print and significantly improve your print quality. To use this feature, click on the Advanced tab of your process settings, and enable the “Avoid crossing outline for travel movement” option.

Simplify3D has a great feature that was built specifically for this situation. Instead of moving in a straight line from point A to B, the software will actually choose a completely new path when moving between these points, with the goal of staying within the interior of your object so that there won’t be any oozing or stringing. With this unique feature enabled, you can greatly reduce the amount of retractions required for your print and significantly improve your print quality. To use this feature, click on the Advanced tab of your process settings, and enable the “Avoid crossing outline for travel movement” option.

Pro-Tips

- Optimize the feed rate by printing at lower layer heights in the 0.1mm – 0.2mm range. The lower layer height requires less plastic, so it allows your extruder to use a lower feed-rate, relieving the burden on the filament.

- Try to avoid using rafts with flexible materials, as the base layers of the raft have higher extrusion rates which may create issues.

- If you are designing a flexible part that needs to fit on top of another object, try using a negative tolerance between the parts so that the flexible part will need to stretch to fit over the other object snugly.

Get Started with Flexible Filaments

Now that you’re ready to start printing with flexible materials, we have a few tips to help you get started. View some typical applications below, try out a few of our sample projects, or choose a popular filament brand to purchase for your next project.

Common Applications

- Vibration dampening

- Grip Sleeves

- Phone cases

Sample Projects

- RC Car Tire

- Phone case

- Bike Handle

Popular Brands

- NinjaTek Ninjaflex, Armadillo, Cheetah

- Polymaker PolyFlex

- eSun TPE

- Sainsmart Flexible TPU

Selection of materials for 3D printing. Part 1.

Hello fellow printers!

In touch 3DMindex.

I am a frequent user of the portal 3DToday.ru , and every time I see another article called “another technological plastic” I get a slight shiver. In the period from 2019 to 2020, so many materials were published that it will be very difficult for even an experienced user to figure out why and for what this or that material is needed.

In my article tetralogy, I decided to make a detailed review of the materials presented by various manufacturers, excluding those that do not deserve special attention. I will make my own rating, according to which I will recommend this or that material from key manufacturers for purchase, and I will tell you about the experience of using them on various 3D printers. The following material manufacturers were chosen by me: Filamentarno, REC, PrintProduct, BestFilament and FD Plast (as the most popular manufacturer among garage craftsmen)

Equipment I work on : Hercules Strong . In my work, I came across many printers, such printers as Ultimaker S2 , Up Mini , Picaso Designer ( Different versions ), Magnum Create , Zenith , Raise N2 , VolgoBot version A4 PRO, and others.

I searched for information bit by bit from different sites, and seasoned them with a little touch of subjective opinion, and also tried to combine everything in my (several) articles.

Let's start:

In this article I will talk about the most famous materials from which everyone begins to get acquainted with the 3D industry. I’ll tell you what to expect and what to fear when working with this or that material, indirectly go through the print parameters, talk about the technical characteristics, application, touch on the economic component when working with a certain material, list some features and sum up my “TOP manufacturers” for production materials and printers( in the high price category ) when working with these materials.

#1 ABS

ABS High impact engineering thermoplastic resin. In 3D printing is the most one of the most popular material.

Print options:

- Extrusion temperature - 210-245°C

- Table temperature - 90-120°C

- Interlayer cohesion - medium

- Table adhesion - medium

This is one of those materials that must be printed in a closed chamber. Fortunately, all modern manufacturers equip printers with a closed case (with the exception of Magnum 'a). In this regard, the printing becomes less toxic, and also (which is no less important) there is a better sintering of the layers (cohesion). For the better, I can note the company Volgobot , they developed an active thermostatic chamber in the PRO version on their printer. In other words, in addition to a heated table (up to 150°C), they have a heating element with a convection fan, thanks to which a single temperature is maintained throughout the entire print volume. According to the manufacturer, the temperature difference in the chamber varies by ± 2°C at 100°C. With this thermal chamber, new frontiers can be opened for use ABS plastic. For example, you can put a model with 100% infill on the entire print area, and their print area is about 297/210/200mm. How does Picaso behave when printed? So in terms of print quality ABS ’om ( as well as other materials ), they are objectively the first in Russia in this parameter, but the issue of stable operation is acute for them.

Fortunately, all modern manufacturers equip printers with a closed case (with the exception of Magnum 'a). In this regard, the printing becomes less toxic, and also (which is no less important) there is a better sintering of the layers (cohesion). For the better, I can note the company Volgobot , they developed an active thermostatic chamber in the PRO version on their printer. In other words, in addition to a heated table (up to 150°C), they have a heating element with a convection fan, thanks to which a single temperature is maintained throughout the entire print volume. According to the manufacturer, the temperature difference in the chamber varies by ± 2°C at 100°C. With this thermal chamber, new frontiers can be opened for use ABS plastic. For example, you can put a model with 100% infill on the entire print area, and their print area is about 297/210/200mm. How does Picaso behave when printed? So in terms of print quality ABS ’om ( as well as other materials ), they are objectively the first in Russia in this parameter, but the issue of stable operation is acute for them.![]() I know that they are very worried about this, and this is their key merit, but my friends and I who work with this printer have malfunctions, in general, the issue of malfunctions can be attributed to any technique, but once it happened like this that Picaso did not work out of the box yet ( this happens sometimes in case of careless transportation, and applies to all manufacturers of 3D printers ), but fast ( like-nowhere ) and qualified ( especially ) technical support helped to solve this and not only problems, thanks to them for that. As for other manufacturers, some print “good”, and some “satisfactory”, the question is more about how much manufacturers sell their goods for, and which goods are worth their money and which are not.

I know that they are very worried about this, and this is their key merit, but my friends and I who work with this printer have malfunctions, in general, the issue of malfunctions can be attributed to any technique, but once it happened like this that Picaso did not work out of the box yet ( this happens sometimes in case of careless transportation, and applies to all manufacturers of 3D printers ), but fast ( like-nowhere ) and qualified ( especially ) technical support helped to solve this and not only problems, thanks to them for that. As for other manufacturers, some print “good”, and some “satisfactory”, the question is more about how much manufacturers sell their goods for, and which goods are worth their money and which are not.

Specifications:

- Melting point - 175-210°C

- Softening point - 100°C

- Operating temperature -40+80°C

- Hardness (Rockwell) - R105-R110

- Elongation at break - 6%

- Bending strength - 41 MPa

- Tensile strength - 22 MPa

- Tensile modulus - 1.

6 GPa

6 GPa - Flexural modulus - 2.1 GPa

- Density - 1.1 g/cm³

- Shrinkage in the manufacture of products - up to 0.8%

- Moisture absorption - 0.45%

Application:

This material is found everywhere in our lives. It is widely used in industry, large car parts (dashboards, radiator grilles), cases of large household appliances, sports equipment, plumbing products are made from it. In 3D printing, it was the first polymer used. Unfortunately, in this area it is not as easy to handle as we would like. Due to the specifics of the technology, it is difficult to make large objects from it due to shrinkage, detachment and delamination of the model occur. A closed print chamber partially solves this problem, in order to almost completely get rid of it, it is necessary to have a thermostatic chamber.

Pros:

- Good combination of strength and elasticity makes it suitable for mechanical applications.

- A wide range of temperatures used allows the use of products from it for technical purposes.

- Ease of machining, combined with chemical smoothing of the surface with inexpensive solvents such as acetone, allows you to make decorative items or cases with a high surface quality.

Cons:

- Does not tolerate UV radiation well, turns yellow in sunlight, which limits the use of unpainted surfaces outdoors

- Does not like drafts when printing, which limits the use of cheap printers with an open case.

- Due to relatively high shrinkage it is prone to delamination (separation), requires a heated bed, without it there are problems with the first layer sticking to the bed.

- During the printing process, an unpleasant odor may form, it is better to print in a ventilated room, or to equip the printer with a special exhaust ventilation system, with output outside the apartment.

Economic component:

Here is a table with manufacturers, with current prices for January 21. Since manufacturers sell coils in different weights, I decided to find the cost of the material per gram of the product by the ratio of price to weight. The result is presented in column “ ₽/M ”. The column “ Quality ” is absolutely subjective, because I gave points in it absolutely arbitrarily, based on the experience of working with material from one or another representative, but in general, the quality of today's production mastodons is ± on the same level, and the problems I have with printing can be related to the storage conditions of materials. Column “ Recommendation ” - is the ratio of “ Quality ” to “ ₽/M ”, it is needed in order to reduce these values to a common denominator, the higher the score in it, the more I recommend the material from this manufacturer.

Since manufacturers sell coils in different weights, I decided to find the cost of the material per gram of the product by the ratio of price to weight. The result is presented in column “ ₽/M ”. The column “ Quality ” is absolutely subjective, because I gave points in it absolutely arbitrarily, based on the experience of working with material from one or another representative, but in general, the quality of today's production mastodons is ± on the same level, and the problems I have with printing can be related to the storage conditions of materials. Column “ Recommendation ” - is the ratio of “ Quality ” to “ ₽/M ”, it is needed in order to reduce these values to a common denominator, the higher the score in it, the more I recommend the material from this manufacturer.

What is the result?

1st place - FD Plast (Recommended for test printing)

2nd place - Filamentarno (I highly recommend)

3rd place - PrintProduct

4th place - Bestfilament

5th place - REC

To my surprise, FD Plast has the first place in this championship, and REC is outsiders. What are the reasons? Of course in price. About 5 years ago, REC was the top quality with corresponding prices, but over the past couple of years, other manufacturers have pulled up in this parameter, but the prices are kept lower than REC, hence the connection. Maybe after this article, REC will stop slightly jacking up prices for their material, and will be more accessible to ordinary buyers.

What are the reasons? Of course in price. About 5 years ago, REC was the top quality with corresponding prices, but over the past couple of years, other manufacturers have pulled up in this parameter, but the prices are kept lower than REC, hence the connection. Maybe after this article, REC will stop slightly jacking up prices for their material, and will be more accessible to ordinary buyers.

As for FD Plast, in my opinion, their material is suitable for test or home printing, but if you have a serious large-scale project and tight deadlines, then it is better to contact trusted manufacturers. It will turn out more expensive, but spend less time and nerves in case the seal fails.

It is also worth noting that there are many brands and composites based on ABS, and therefore the prices for the material can vary so much, unfortunately, the manufacturer does not offer a technological map for the material, which is why it is impossible to fully find the answer to Question: Why is it so expensive?

If you order 3D printing from various companies, then on average in the provinces the price for printing with this plastic is from 10 to 30 rubles per gram, if you order from top3Dshop, then the price for ABS is 45 rubles per gram.

In general, using this plastic is quite a profitable business if you are going to fulfill orders for 3D printing.

Top ABS 3D Printer:

1 Place - Picaso

2 Place - Hercules (slightly not up to Picaso in quality, I think the price tag for equipment is too high, I took it myself solely from the recommendations of comrades and a large (high) print area. )

3rd place - Volgobot (the quality is comparable to Hercules strong, but the price tag is lower, I put it in 3rd place due to the fact that the company is not as large as direct competitors, although it has its own development vector, and their thermal chamber works wonders with ABS, however this is not their only worthy development, they have a configurator with a large list of options in which you can assemble a printer for your tasks, however, you should contact the manufacturer for all the details. but the guys try and keep in touch with all their customers. )

)

All other printers have approximately the same level of printing with ABS, fortunately for 5-8 years of existence of companies, all ± have learned to work with this material.

Worth mentioning: Ultimaker / Raise Pro 2 I am not satisfied, and the price tag is also not small)

#2 PLA

PLA-plastic (polylactide, PLA) is a biodegradable thermoplastic aliphatic polyester, the structural unit of which is lactic acid. PLA is made from corn, sugar cane, potato or corn starch, and cellulose. It is one of the most popular materials for 3D printing. Due to its natural raw materials in the composition of the polymer, it can be used for various purposes without a threat to humans.

Print options:

- Extrusion temperature - 190-230°C

- Table temperature - 20-60°C

- Interlayer cohesion - good

- Table adhesion - good

- It is essential to dry the filament spool before use for more stable printing.

Specifications:

- Melting point - 175-180°C

- Softening point - 50°C

- Product operating temperature -20+40°C

- Hardness (Rockwell) - R70-R90

- Elongation at break - 3.8%

- Bending strength - 55.3 MPa

- Tensile strength - 57.8 MPa

- Tensile modulus - 3.3 GPa

- Flexural modulus - 2.3 GPa

- Density - 1.23-1.25 g/cm³

- Manufacturing shrinkage - no

- Moisture absorption - 0.2-0.4%

Application:

PLA plastic shows itself excellently in mock-up workshops and in creating master models that are not designed to bear long-term mechanical loads. With it, models with careful detail are obtained, and are also used when working with children.

Pros:

- Does not shrink during printing, which allows you to get an exact match of the dimensions of the printed product to the simulated one.

- Does not require a heated bed and is not afraid of drafts when printing, which means it can be used for printing on the cheapest Chinese printer with an open case.

- Non-toxic. During printing, it smells pleasant and slightly, which allows you to print it in the apartment without using a special hood.

- Hard, durable and slippery, wide range of applications.

- Produced from natural ingredients, can be used in food contact.

- Biodegradable, this plastic does not harm the environment when disposed of.

Cons:

- Exposure to air and ultraviolet light, like any natural material, becomes more brittle over time, so it is not recommended for long-term use at high physical exertion or use without a protective coating in the open air.

- Low softening temperature (50°C) - in the inside of a car left in the sun on a hot day, easily softens and loses its shape.

- Narrow temperature range (-20 to +40°C).

- The high hardness of the plastic makes it difficult to machine.

- Due to the high content of residual monomers, plastics from some manufacturers are prone to plugging in all-metal hot ends.

Economic component:

PLA prices are slightly higher, and therefore our TOP has shifted slightly:

1st place - Filamentarno (Recommended)

2 Place - FD Plast (Worth a try for a test print)

3rd place - PrintProduct

4th place - REC

5th place - BestFilament

PLA is a material that absorbs a lot of moisture, due to which its characteristics drop significantly, and the already fragile material becomes almost glassy. FD Plast once again takes its price, bypassing its competitors by 1.5, or even almost 2 times, but I suffered a lot with it, it draws moisture from the air, probably as much as silica gel from shoes.

If you order 3D printing from various companies, then on average in the provinces the price for printing with this plastic is from 10 to 20 rubles per gram, if you order from top3Dshop, then the price for PLA is 35 rubles per gram.

Based on the issue of profit, the use of this plastic brings less money per 1 gram of material, but due to its features, there are much fewer problems in printing with this plastic than with the same ABS.

Top 3D printers for PLA:

1st place - Picaso (In the past, they had problems printing this material, the extruder often clogged, but as far as I know this problem has been fixed)

2nd place - All remaining manufacturers. (As of January 21, all manufacturers have learned to produce approximately the same print quality for PLA, in principle, this is one of the easiest materials to work with, and I don’t see much point in crucifying, put more airflow and print on health)

Worthy of mention: Raise PRO 2 (this is perhaps one of the worst printers for PLA printing, I tried to print on it in one CMIT, and from the stuffy room the extruders clogged literally on every print, in general, it also depends on the material manufacturer, but one and the same coil on different printers showed itself in completely different ways, and therefore I highly do not recommend printing with PLA plastic on this printer)

#3 PET-G

PETG (polyethylene tereflatate glycol, PETG) highly impact resistant plastic, due to glycol modification it does not crystallize, making deep drawing thermoforming more possible. At the moment, plastic is actively gaining popularity, all because it combines the positive qualities of many other polymers.

At the moment, plastic is actively gaining popularity, all because it combines the positive qualities of many other polymers.

For some manufacturers you will not find such material as PET in the catalog, this is due to the fact that marketers probably decided to rename this material, and therefore Filamentarno has Prototyper as an analogue of PET, and RELAX for REC.

Print options:

- Extrusion temperature - 215-245°C

- Table temperature - 20-80°C

- Interlayer cohesion - very high

- Table Adhesion - Medium

Specifications:

- Extrusion temperature - 215-245°C

- Table temperature - 20-80°C

- Interlayer cohesion - very high

- Table Adhesion - Medium

- Specifications

- Melting point - 222-225°C

- Softening point - 80°C

- Operating temperature -40+70°C

- Hardness (Rockwell) - R106

- Elongation at break - 50%

- Bending strength - 76.

1 MPa

1 MPa - Tensile strength - 36.5 MPa

- Tensile modulus - 2.6 GPa

- Flexural modulus - 1.12 GPa

- Density - 1.3 g/cm³

- Manufacturing shrinkage - no

- Moisture absorption - 0.12%

Application:

In everyday life PET is used to make plastic bottles, due to its chemical neutrality it is used in the food industry. By itself, PET-G is similar to PET material. In 3D printing, it has proven itself as a versatile material that can be used both in technical parts bearing low loads and in prototyping.

Pros:

- Odorless Printing - Allows you to print at home without the need for an optional exhaust fan.

- No shrinkage for high dimensional accuracy.

- Very strong sintering between layers - can print thin-walled products with high strength.

- UV resistant - printed designs can be used outdoors.

- Wide operating temperature range.

- Printing does not require a closed chamber.

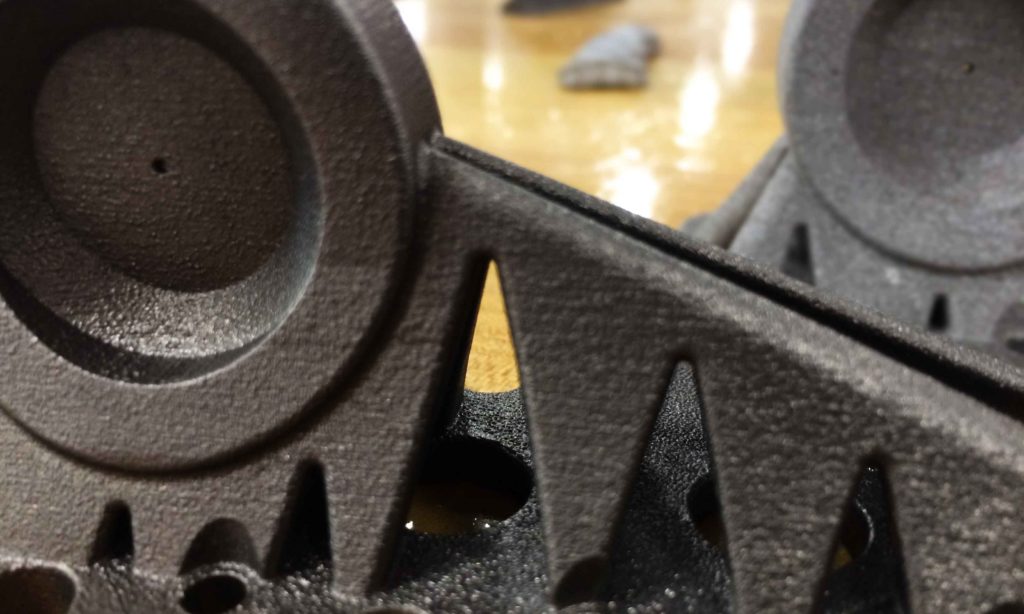

- Good slip and impact resistance - can print gears, bushings and other machine parts.

- Non-toxic, can be printed on articles intended for contact with food.

Cons:

- High fluidity requires careful adjustment of the retracts.

- High printing temperature quickly disables the fluoroplastic insert in the hot end and makes you think about switching to all-metal thermal barriers.

- Strength and softening point lower than ABS.

- A fairly versatile material, good print behavior but not outstanding performance.

Economic component:

1st place - FD Plast

2nd place - Filamentarno

3rd place - BestFilament

4th place - PrintProduct

5th place - REC

Surprisingly, the PET-G rating is, in my opinion, the most honest. Due to the fact that PET is more stable in terms of storage and printing material, there was a large increase in points in the “Quality” column. REC is again an outsider, once again I repeat that this is due to the high cost of the material, and it hurts me to see this company at the end of the top.

REC is again an outsider, once again I repeat that this is due to the high cost of the material, and it hurts me to see this company at the end of the top.

If you order 3D printing from various companies, then on average in the provinces the price for printing with this plastic is from 15 to 35 rubles per gram, if you order from top3Dshop, then the price for PET-G is about 40 rubles per gram (I did not find the exact price ).

Based on the issue of profit, the use of this plastic brings less money per 1 gram of material, but due to its features, there are much fewer problems in using this plastic than with the same ABS.

Top 3D printers for PET-G:

NOT top by PLA)

#4 HIPS

HIPS (High Strength Polystyrene) is a fairly soft plastic designed to be used with ABS to support dual extruder 3D printing. This was facilitated by its following properties: the same extrusion temperature as ABS, low sintering with ABS, the presence of a solvent (D-Limonene), which dissolves HIPS and does not dissolve ABS. Some manufacturers do not have this material in their catalog, in fact, I do not see its widespread use at the present time, and therefore it is not a pity.

Some manufacturers do not have this material in their catalog, in fact, I do not see its widespread use at the present time, and therefore it is not a pity.

Print options:

- Extrusion temperature - 210-245°C

- Table temperature - 90-120°C

- Interlayer cohesion - medium

- Table Adhesion - Medium

Do not start work without drying the coil!

Specifications:

- Extrusion Temperature - 210-245°C

- Table temperature - 90-120°C

- Interlayer cohesion - medium

- Table Adhesion - Medium

- Do not start work without drying the coil!

- Specifications:

- Melting point - 175-210°C

- Softening point - 97°C

- Operating temperature -40+70°C

- Hardness (Rockwell) - L79

- Elongation at break - 64%

- Bending strength - 37.6 MPa

- Tensile strength - 16.

4 MPa

4 MPa - Tensile modulus - 0.93 GPa

- Flexural modulus - 1.35 GPa

- Density - 1.05 g/cm³

- Manufacturing shrinkage - 0.4%

- Moisture absorption - 1%

Pros:

- Less shrinkage than ABS, making it suitable for precision printing.

- Lighter density than PLA, allowing for prints where lightness is required.

- Softness of the surface, which guarantees ease of machining.

- A matte finish that gives a smooth effect to garments.

- Almost same softening point as ABS, making it suitable for outdoor use.

Cons:

- Like ABS, it requires a heated platform and is prone to delamination, although to a lesser extent.

- Lower bending strength than ABS and, as a result, more brittle products.

- Poor UV resistance, which limits the use of products in sunlight.

- All this makes it possible to use this plastic for the production of furniture decor and interior decorations.

Application: once this material appeared it was used to print supports on 2 extruder printers, the supports themselves were dissolved in limonene. To date, this is no longer so relevant, due to the appearance of such material as PVA, the material itself is completely unnecessary today. The material itself is quite stable, although it requires careful drying.

Economic component:

1st Place - FD Plast

2nd place - Bestfilament

3rd place - REC

As far as buying recommendations, it can be safely replaced with PVA, in general I consider HIPS already out of fashion, so I doubt that anyone spends it in large quantities.

Top 3D Printers for HIPS:

1 Place - Hercules / Volgobot

2nd place - Picaso (Picaso dropped to second place due to the fact that slippage occurs when printing with HIPS, it is quite possible that they got rid of this problem on new printers, but in 2019 it was like that)

№5 SBS

SBS (styrene butadiene styrene) is another relatively new player in the 3D printing plastics market. It is characterized by low toxicity and shrinkage, as well as high strength. Its main advantage is its transparency. Products printed with this plastic and treated with a solvent acquire the transparency of colored glass.

It is characterized by low toxicity and shrinkage, as well as high strength. Its main advantage is its transparency. Products printed with this plastic and treated with a solvent acquire the transparency of colored glass.

This material has different names for different manufacturers, for example, BestFilament calls it WATSON, and some manufacturers do not have it at all.

Print options:

- Extrusion temperature - 220-240°C

- Table temperature - 70-90°C

- Interlayer cohesion - low

- Table Adhesion - Medium

Specifications:

- Melting point - 190-210°C

- Softening point - 76°C

- Operating temperature - -80+65°C

- Hardness (Rockwell) - R118

- Elongation at break - 250%

- Bending strength - 36 MPa

- Tensile strength - 34 MPa

- Tensile modulus - 1.35 GPa

- Flexural modulus - 1.

45 GPa

45 GPa - Density - 1.01 g/cm³

- Shrinkage in the manufacture of products - 0.2

- Moisture absorption - 0.07%

Pros:

- Relatively low shrinkage, allowing printing in open case printers.

- High adhesion to the table.

- Potential for food contact.

- Impact resistant.

- Beautiful colors for creating unique decor items.

- Transparency after processing, can be used in luminaires.

- Wide operating temperature range, frost resistance.

- Easy post-processing by both chemical and mechanical methods.

Cons:

- Poor intercoat cohesion, requires large orifice nozzles or 100% coverage.

- Relatively high print temperature, similar to PETG.

- Applications: Most often used in decorative elements and creating custom lamps.

Economic component:

1 Place - FD Plast

2nd place - Filamentarno

3rd place - BestFilament

Top 3D printers for SBS:

1st Place - Picaso

2nd place - VolgoBot

3rd place - Hercules

Conclusion:

As for the article: it turned out to be shorter than I planned, this category of materials did not include such materials as Flex (various modifications), Nylon and other PC At the time of the final editing of the article, I realized that not all printers are capable of printing with these materials, Flex’a needs special extruders capable of printing rubber-like materials, for a PC, the presence of a closed case does not mean success in work, and the material loves temperature very much. Therefore, if the article receives some response, I will talk about “engineering plastics”, composites created on their basis, and also talk about materials that are at the forefront of progress, so my dear reader, adequate criticism is welcome.

Therefore, if the article receives some response, I will talk about “engineering plastics”, composites created on their basis, and also talk about materials that are at the forefront of progress, so my dear reader, adequate criticism is welcome.

As for material manufacturers, a few words about each:

FD Plast : wins in public domain although I don't agree with it because I think their policy of dumping the market is wrong, but the company has many followers who prefer goods from the “cheap and cheerful” category.

Filamentarno: for me personally is the best manufacturer with an adequate price, not a small list of products, and with a constant quality that has never let me down.

Print Product: before switching to Filamentary, he mainly used the products of this company, in the past the company had a colossal list of products, but in the last year they decided to change the vector of development, and relied on materials whose quality can be sufficiently ensured .

REC : in the past, the clear favorite in terms of the quality of the materials provided, now the quality is at the same level, but the price tag bites.

Best filament it seems to me that the quality floats slightly from batch to batch, gaps form on Hercules when printing with ABS plastic.

3D printing materials | A wide variety of materials

Materials for 3D printing! To date, the main materials for printing on a 3D printer are PLA and ABS plastic. Both materials have long established themselves on the market and are used for printing on a 3D printer using layer-by-layer material build-up technology.

ABS (ABS) plastic is a plastic formed during the polymerization of substances such as acrylonitrile (A) with butadiene (B) and styrene (S).

PLA plastic, or biodegradable plastic as it is also called, is an aliphatic polyester with a monomer in the form of lactic acid. The materials for the production of such plastic are rapidly renewable resources - corn or sugar cane, that is, starch or cellulose.

PVA plastic. The well-known PVA glue is transferred from a dry state to a liquid of the desired consistency, then melted using special equipment and formed into PVA threads or special granules that are used for 3D printing.

An even newer material, Nylon, is resistant to a wide range of chemicals and solvents. The materials discussed above are known to everyone who is associated with the 3D technology market.

These are the most commonly used materials. But manufacturers have stepped far ahead, and are already using a wide variety of materials for printing on a 3D printer, for example, clay, resin, seaweed, and more. etc.

Here is a list of the most unexpected and creative materials for 3D printing:

White Resin from Formlabs:

3D Printing Materials

3D printing equipment manufacturer Formlabs introduces a new material - White Resin. The company has recently launched two new 3D printing materials, Clear Resin and Gray Resin. The main feature of the White Resin material is the striking white and opaque color of the material, as well as the exceptional smoothness of the surface of the printed object. In addition, this material is ideal for subsequent staining.

The main feature of the White Resin material is the striking white and opaque color of the material, as well as the exceptional smoothness of the surface of the printed object. In addition, this material is ideal for subsequent staining.

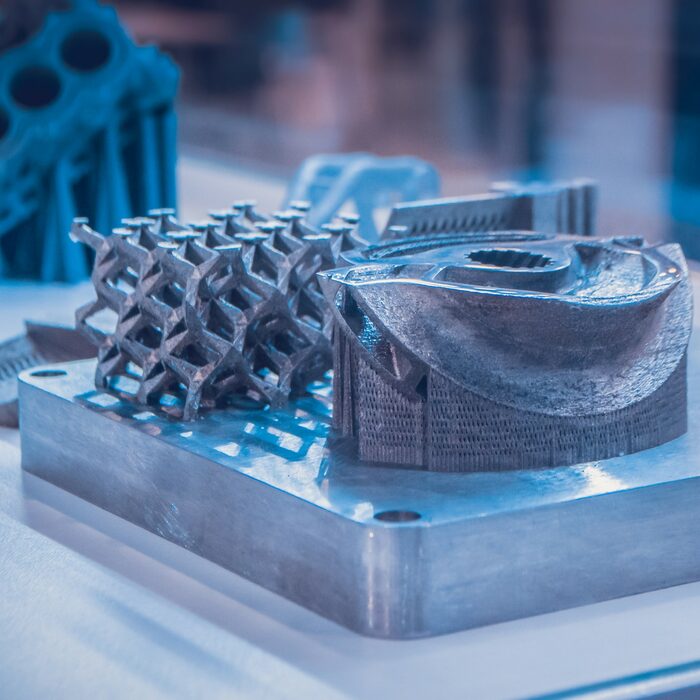

Titanium Powder for 3D Printing Auto Parts:

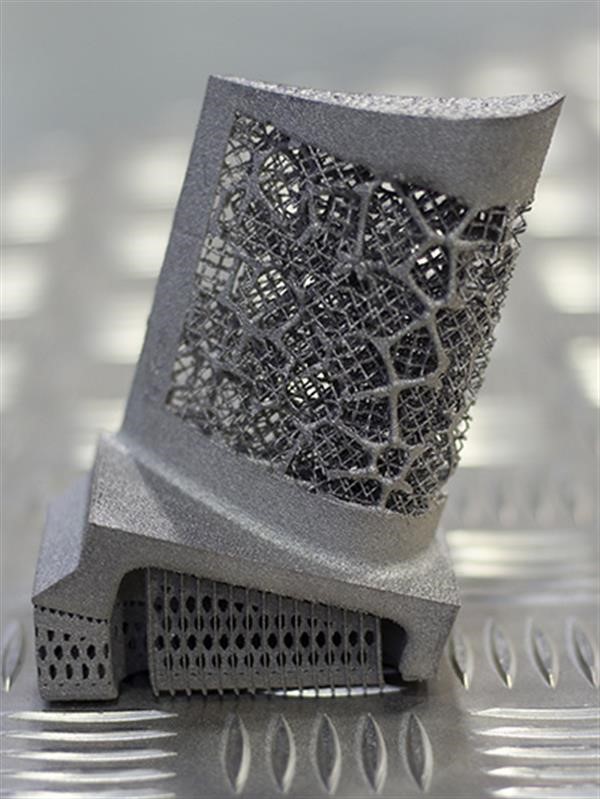

British metalworking company Metalysis has released a new cheap titanium powder that is suitable for 3D printing of auto parts and parts. Until now, the most popular materials for 3D printing have been plastics, due to the high cost of producing titanium powders. But recently, Metalysis has found a new, low-cost way to produce titanium powder, which could become the most sought after in the manufacture of equipment and machinery in the aerospace, defense and automotive industries.

For the production of titanium powder, Metalysis uses rutile, which is electrolyzed directly into titanium powder. This method of obtaining a powder makes it possible to change, if necessary, the size of the powder granules, its purity, morphology and the proportion of the content of alloying elements in the composition.

Metal plastic for ColorFabb 3D printer:

Materials for 3D printing

BronzeFill and CopperFill are two new filaments from the premium Dutch manufacturer colorFabb. Their key feature is the addition of bronze and copper powder to the plastic, which gives the filament additional rigidity, as well as a pleasant metallic sheen and smoothness. To the touch, the model obtained as a result of printing will very much resemble a metal one.

Bronzefill and CopperFill can be polished to a beautiful metallic sheen just like any other hard bronze and copper items. After polishing, the visible streaks that remain after printing disappear, and the bronze or copper item begins to shine.

Bronze and copper plastic for 3d printing is ideal for metal prototyping and obtaining very durable models in industry, architecture, design and other fields.

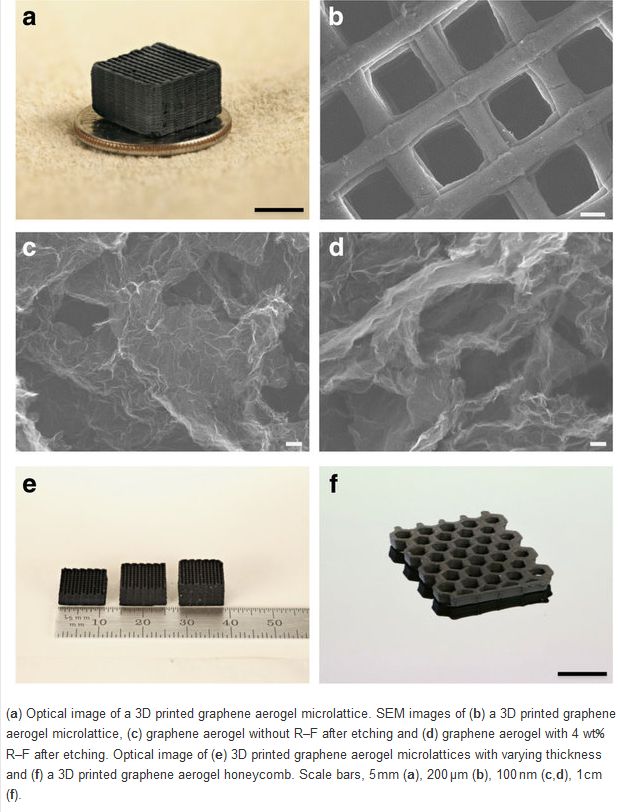

One of the most amazing materials is graphene:

3D printing materials

A 3D printable material with incredible potential for applications in various fields (molecular programming, solar energy, etc. ), it can change the lives of many people. In this regard, the Canadian research company Lomiko Metals Inc. announced the opening of a new special laboratory Graphene 3D Labs Inc., which will focus on the development of high-performance materials based on graphene. Information about the material: graphite or graphene is entirely composed of carbon atoms, but 1 mm of graphite contains about 3 million layers of graphene. Graphite has a three-dimensional crystal structure, while graphene is a two-dimensional crystal 1 atom thick.

), it can change the lives of many people. In this regard, the Canadian research company Lomiko Metals Inc. announced the opening of a new special laboratory Graphene 3D Labs Inc., which will focus on the development of high-performance materials based on graphene. Information about the material: graphite or graphene is entirely composed of carbon atoms, but 1 mm of graphite contains about 3 million layers of graphene. Graphite has a three-dimensional crystal structure, while graphene is a two-dimensional crystal 1 atom thick.

3D Printer Wood Filament:

3D Printing Materials

Dutch 3D printing materials company colorFabb has launched WoodFill wood filament. Wooden threads WoodFill are available in two types - Fine (Delicate) and Coarse (Rough). The main difference between these threads is the quality of processing of wood fibers. WoodFill Fine uses finely ground wood particles, WoodFill Coarse threads are thicker - based on coarsely ground wood particles. Wooden threads allow you to print beautiful and original vases, decorative elements and interior items. Finished objects are highly durable and produced in a short time. WoodFill filaments are made up of 30% pine wood fibers and 70% PLA plastic.

Wooden threads allow you to print beautiful and original vases, decorative elements and interior items. Finished objects are highly durable and produced in a short time. WoodFill filaments are made up of 30% pine wood fibers and 70% PLA plastic.

Seaweed 3D Printer Filament:

3D Printing Materials

Le Fabshop is the first company in the world to introduce SWF filaments - "green" filaments based on seaweed.

New materials from Proto-Pasta:

Recently, scientist Aaron Crum and mechanical engineer Dustin Crum launched the Proto-Pasta project, which developed three new materials for use in a desktop 3D printer: Carbon Fiber Reinforced PLA ( PLA reinforced with carbon fiber), High Temperature PLA (high temperature PLA) and Polycarbonate-ABS (ABS with polycarbonate alloy). Compared to all known types of plastic - ABS and PLA, the presented materials have improved performance characteristics and are affordable. Carbon Fiber Reinforced PLA is more resistant to high temperatures than regular PLA. Polycarbonate-ABS (PC-ABS) is characterized by high elasticity and bending strength.

Polycarbonate-ABS (PC-ABS) is characterized by high elasticity and bending strength.

Rubber material for stereolithography:

Materials for 3D printing

This is a rubber based material ideal for stereolithography printing, the new material has a wide color gamut, allows you to print objects in high resolution, odorless, easy to peel, available from price.

3D printing material based on silk:

3D printing materials

Another 3D printing material was created from raw silk. The raw silk has been sourced from sustainable sources and treated with epoxy. The silk-based material is flexible and highly durable, thin and light, ideal for 3D printing applications.

Polished and Raw Brass as 3D Printing Material:

3D Printing Materials

Shapeways has introduced two new materials to the world at once - Polished Brass and Raw Brass. Polished Brass is a material with a smooth, glossy bright yellow surface. Products printed with its help, then covered with 22 carat gold, are almost indistinguishable from real gold jewelry. Raw Brass is ideal for 3D printing antique or antique-style objects, and is also useful for jewelry prototyping and functional parts.

Products printed with its help, then covered with 22 carat gold, are almost indistinguishable from real gold jewelry. Raw Brass is ideal for 3D printing antique or antique-style objects, and is also useful for jewelry prototyping and functional parts.

Soft Plastic from Shapeways:

3D Printing Materials

Shapeways has developed a new soft plastic called Elasto Plastics for use in summer footwear. Elasto Plastics has a milky white color, the material is very flexible, has an uneven grainy surface and is quite strong.

In our online store ac5ffgxkeg.lceqo.ccwc.finefive.ru there is an excellent analogue of Elasto Plastics - this is a unique flexible plastic from a Ukrainian manufacturer - PLASTAN 9 plastic0003

The second analogue - FlexibelPolyEster (FPE) - is a rubber-like elastic plastic thread designed specifically for printing on a 3D printer

Transparent resin for a 3D printer:

Materials for 3D printing stereolithography, according to the technology of layering transparent resin and strengthening the layers with a special laser.