Reverse engineering 3d laser scanner

3D Scanners for Reverse Engineering

Hi everyone! This is Top 3D Shop, and in the following review, we will talk about reverse engineering, the considerations when choosing 3D equipment for it, and related case studies.

Read on to learn more.

What is reverse engineering?

Source: 3daeroscan.com

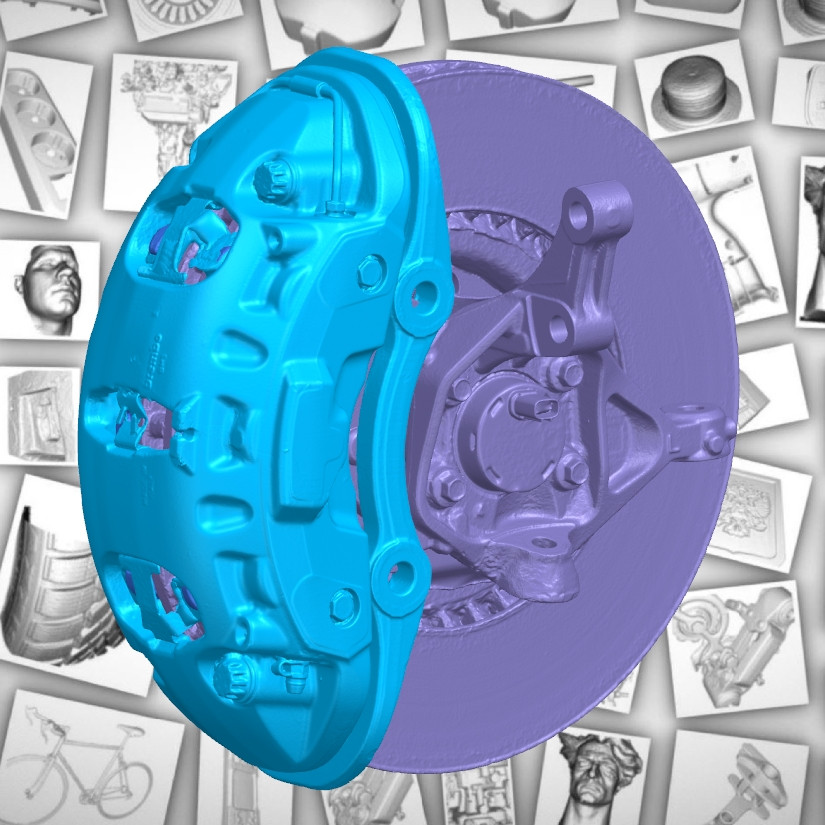

Reverse engineering, also known as back engineering, is the process of creating a project of parts or products with no drawings or documentation. By creating a digital CAD model using 3D scanning, these parts can be modified and optimized to extend their lifetime or add new functions. This method is used in many industries, including the production of military equipment or spacecraft.

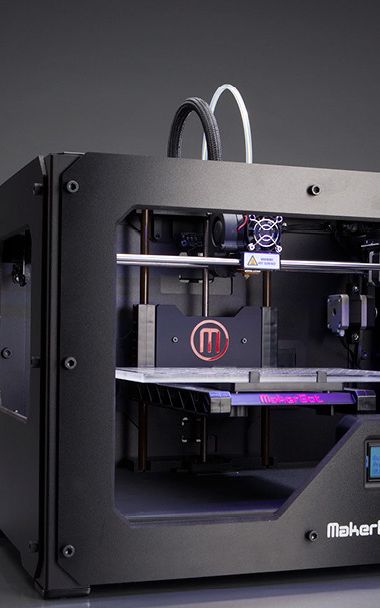

With the growing popularity of 3D printing, reverse engineering is gaining ever-increasing attention. This is due to the fact that the reproduction of an object or design using digital modeling and 3D printing is more accessible to ordinary users than other production processes.

The ICON company uses a variety of 3D scanners to reverse engineer vintage car parts.

Source: 3dreveng.com

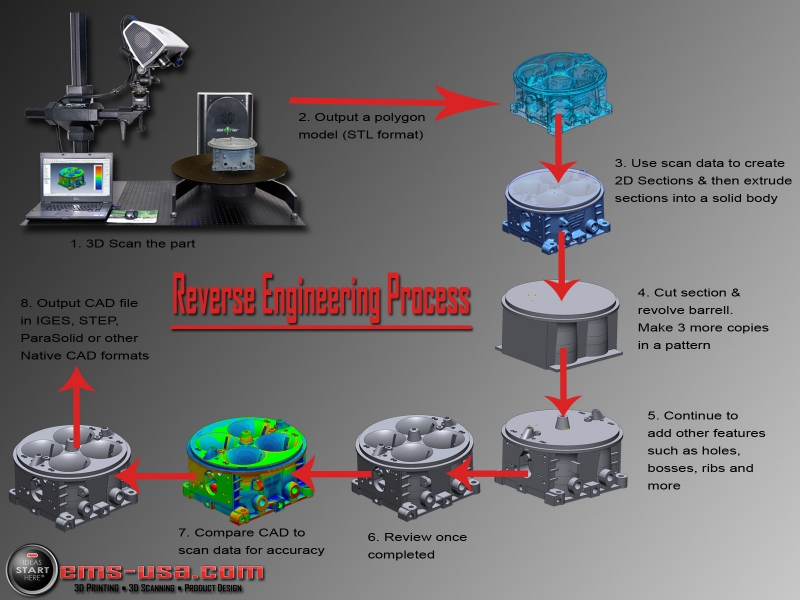

The process of reverse engineering involves three tasks: obtaining a sufficiently accurate digital impression of a part, converting the resulting image into a solid 3D model in specialized software, and subsequent digital processing of the model to eliminate artifacts, convert the format, and make some modifications so that the model design is suitable for the product launch.

Therefore, it is necessary to choose the right 3D scanner to obtain the primary data that best suits the existing task. For example, it is completely pointless to scan a piece of jewelry with a time-of-flight scanner for large objects, and vice versa: the very high accuracy of a desktop or handheld scanner is redundant when scanning, for instance, a sea vessel.

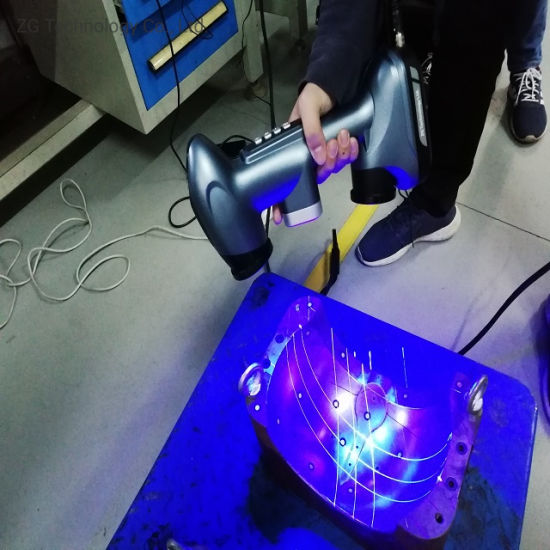

NeoMetrix Technologies uses the Creaform HandySCAN 700 3D scanner for reverse engineering and metrological control of various objects.

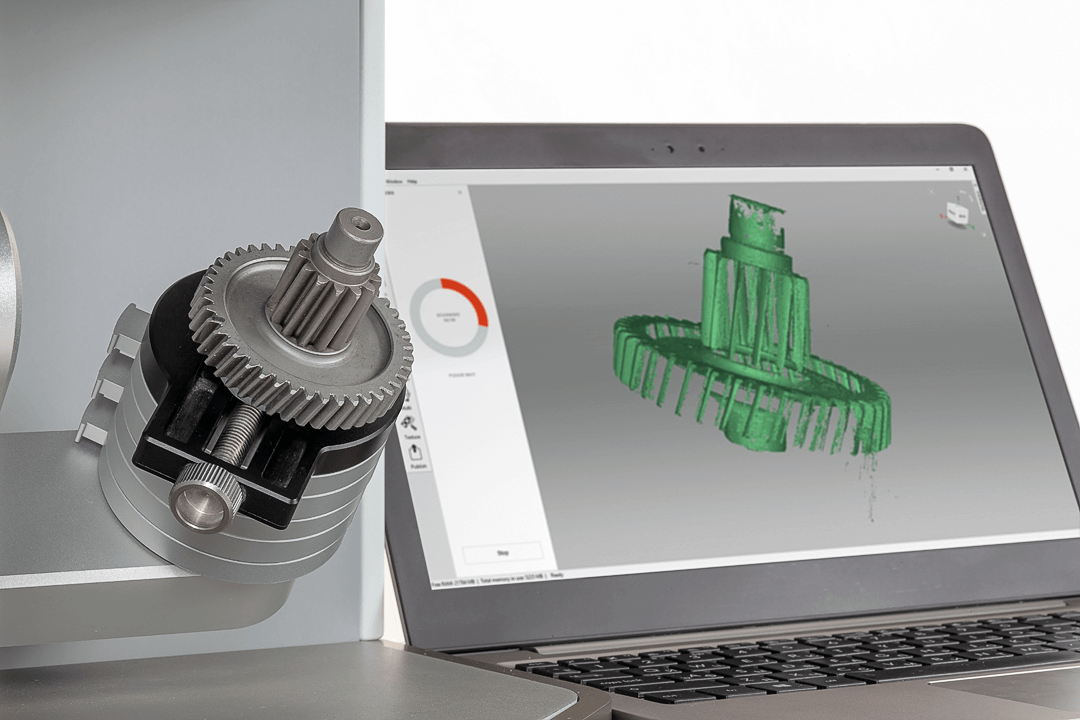

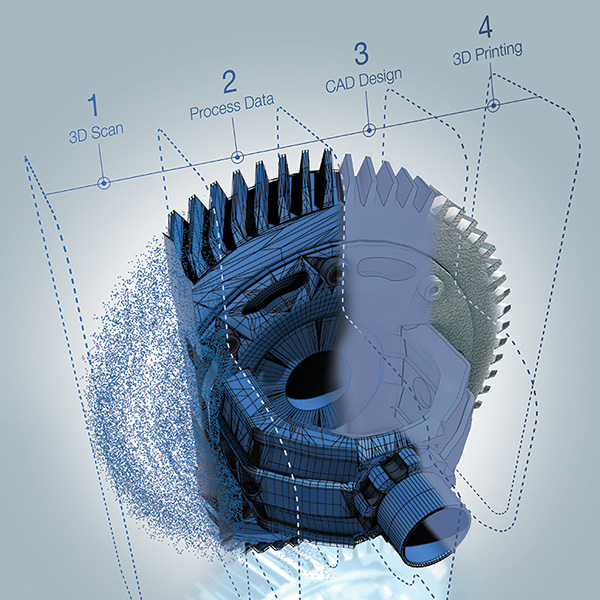

Stages of reverse engineering

Source: 3dcaptura.cz

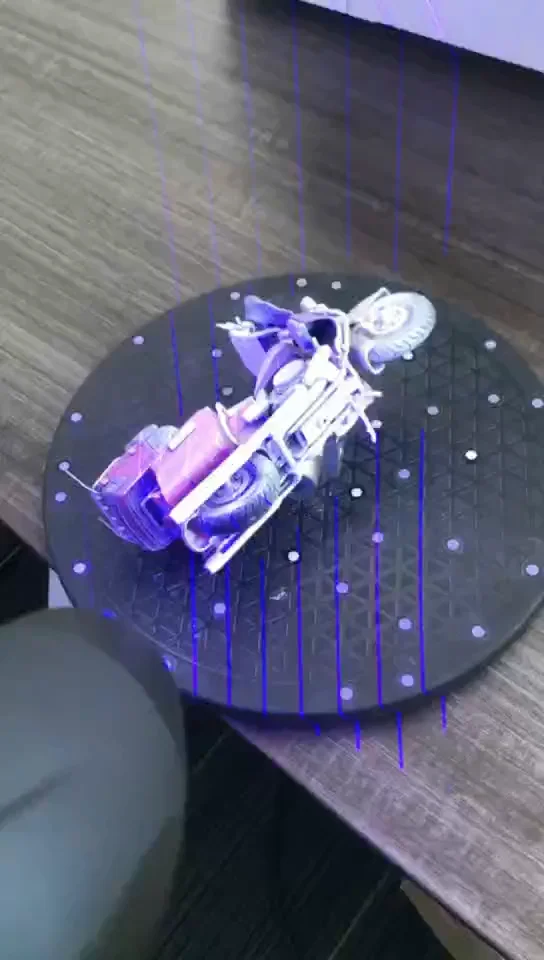

1. Prepare the object for scanning, apply markers if necessary. Note that glossy surfaces impede the work of 3D scanners, and reflective or transparent ones are nearly impossible to scan without a matte finish, so spray a temporary matte powder on the object to improve scanning accuracy.

2. Use a 3D scanner to capture important areas of the part. You may need to orient and rescan your object several times if it has holes or deep grooves.

3. Adjust and optimize the resulting polygonal mesh. Some scanners create very large files, making it difficult to post-process and print an object. Remove artifacts, check the surface stitch.

4. Import the mesh into CAD software equipped with reverse engineering tools.

Import the mesh into CAD software equipped with reverse engineering tools.

5. Convert polygons to solids.

6. If necessary, add new objects to the resulting 3D model or delete unnecessary ones.

7. Use 3D printers or CNC machines to produce a new part according to the created model.

Reverse engineering of automotive parts with a Creaform 3D scanner using the VXmodel and Autodesk Inventor software

Case studies

Reverse engineering of an impeller

Source: 3d-scantech.com

An equipment manufacturer needed to optimize the production of impellers and eliminate manufacturing variances. It proved impossible to obtain accurate data of a part with holes, dead angles, and geometrically complex surfaces by traditional means. The impeller has narrow gaps between the vanes, which prevents measurement with a probe, so it was decided to employ 3D laser scanning and process the results using reverse engineering methods for comparison with the original digital model.

Source: 3d-scantech.com

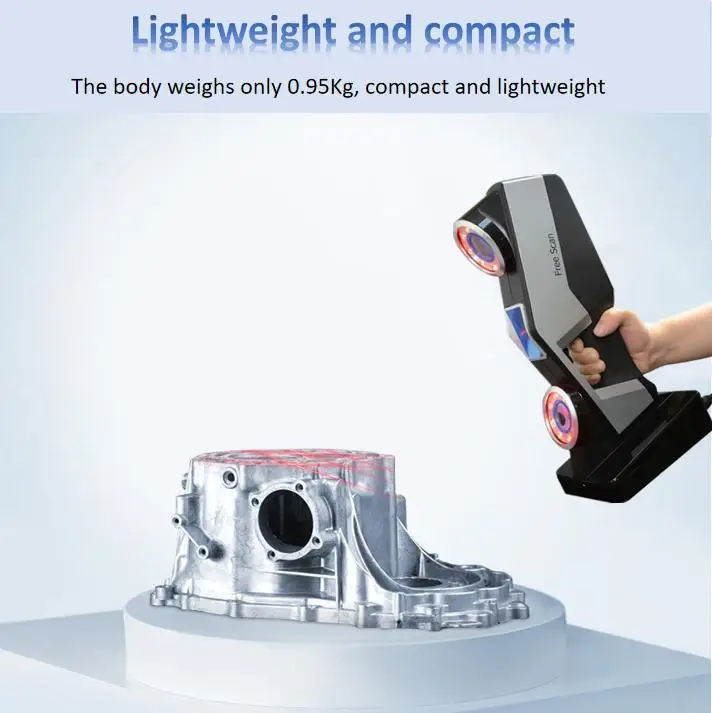

3D scanning was performed by means of the ScanTech PRINCE high-precision 3D scanner with red and blue laser scanning modes. The device has a resolution of 0.020 mm and can quickly switch between modes. It is capable of scanning deep holes with a single red laser line and capturing the smallest details. In addition, the scanner is insensitive to ambient light.

Source: 3d-scantech.com

A full detailed model of the impeller housing with vanes was obtained using the 3D scanner.

Source: 3d-scantech.com

A complete digital model was created for analysis.

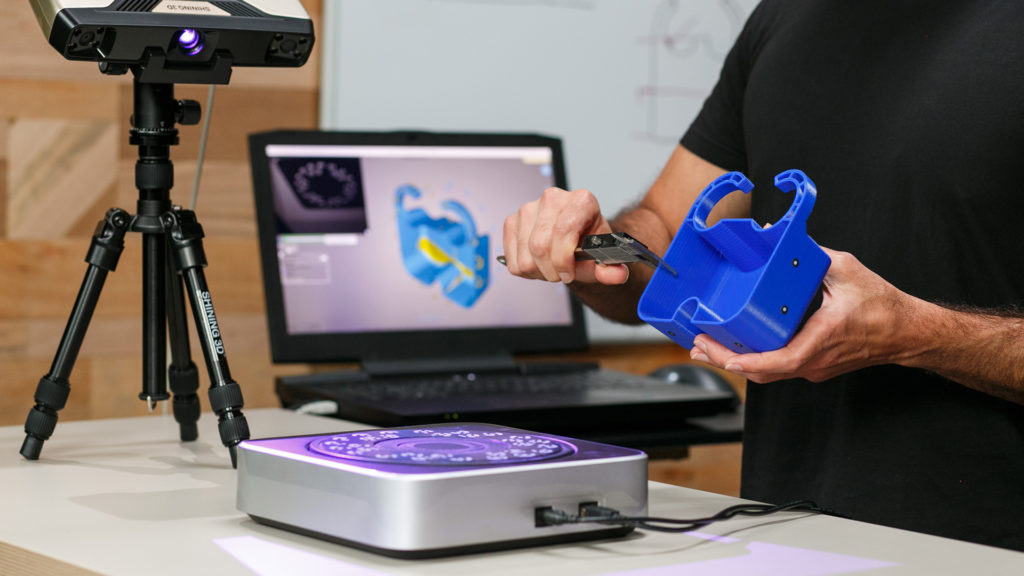

Creating an audio speaker cart using reverse engineering

Source: shining3d.com

To participate in a sports and dance event called Colorguard, a captain had to do something for her team. She decided to create a cart for a heavy speaker that girls use to play music during training and performance. The speaker was to be easily removed from the cart if necessary. Besides, one of its handles needed restoration.

The speaker was to be easily removed from the cart if necessary. Besides, one of its handles needed restoration.

The speaker has three identical handles attached with screws. To replace the broken handle with a new one, the EinScan-SP was used to scan one of the remaining handles. Since the handle was very dark, it was dusted with a thin layer of baby powder so that the scanner could correctly recognize the surface. The EinScan-SP has the function of automatically stitching images when the object is rotated on the turntable and in different positions of the object. The program selects certain points from several scans and connects them. This allows users to scan not only the sides but also the top and bottom of the object.

Source: shining3d.com

To clean up the resulting image from artifacts and eliminate any damage on the handle, the Deform: Smooth tool in the free Autodesk Meshmixer utility was used. Using the Edit: Erase and Fill tools, the existing manufacturer's logo was removed, with the event logo added. Meshmixer was also used to make sure the screw holes were cylindrical. Processing the resulting STL file in Meshlab simplified the model and reduced the file size from 26 to 2.4 Mb.

Meshmixer was also used to make sure the screw holes were cylindrical. Processing the resulting STL file in Meshlab simplified the model and reduced the file size from 26 to 2.4 Mb.

Source: shining3d.com

The handle was printed using the Afinia H+1 3D printer with a TPU extruder and NinjaTek's Cheetah flexible filament. For greater rigidity, 80% filling was used. The resulting handle turned out both durable and pleasant to touch.

Source: shining3d.com

After examination, it was decided to use the speaker mount holes as attachment points to the cart. Measurements with a caliper would have taken plenty of time, it was more efficient to use the Shining 3D EinScan Pro 2X Plus portable 3D scanner. Markers were applied for better surface capture.

Source: shining3d.com

Although the EinScan Pro 2X Plus comes with the Solid Edge software (a complete CAD package with reverse engineering capabilities), it was decided to use Autodesk Fusion 360 because the user was more comfortable with it.

Source: shining3d.com

The resulting 3D model was too large to be printed in one piece, so it was split into two parts. It was printed with black PLA.

Source: shining3d.com

The print path was optimized to increase the strength of the cylinder and walls.

Source: shining3d.com

The cart handle was made of acetone-welded ABS plastic, and a piece of chipboard was used to make the base plate.

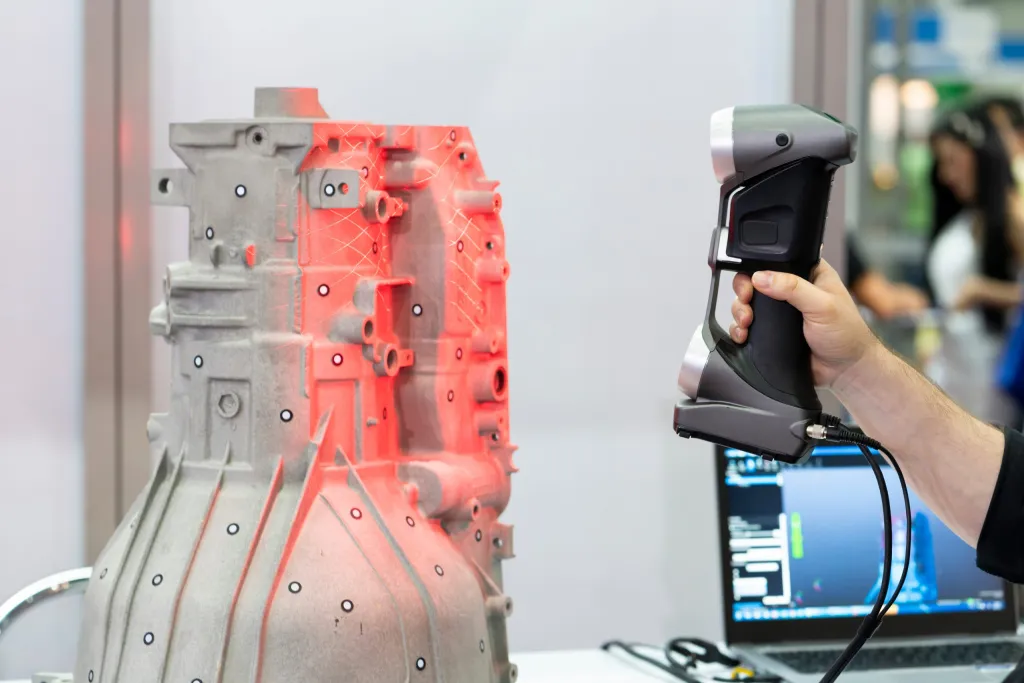

Reverse engineering of stamping dies

Source: metrology.news

Gestamp is an international company engaged in the design, development, and hot stamping manufacture of metal automotive parts for major carmakers. In modern production, there occurs a situation when changes are made to a CAD-designed die directly in production. Manufacturers often forget to reflect such changes in the documentation/original model. As a result, when a die is replaced on account of wear or damage, engineers have to make undocumented changes anew, which leads to errors and an increase in flaws.

Source: metrology.news

This situation can be fixed with the use of reverse engineering. After a die is set and configured, it is scanned and all the changes are recorded in the digital model. The resulting file, which fully corresponds to the scanned surface including the smallest details, is used for reverse engineering of the die. Changes identified using this method are incorporated into the original 3D model of the die.

Source: metrology.news

Gestamp specialists work with the Creaform HandySCAN 3D scanners, appreciating their accuracy, convenience, and compatibility with reverse engineering software.

Footwear design using reverse engineering

Source: rangevision.com

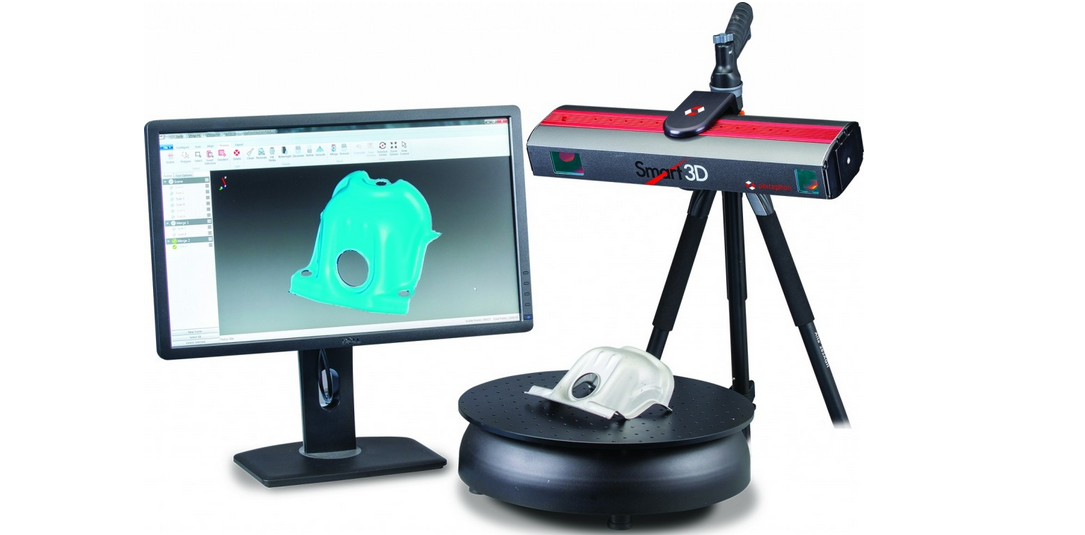

RangeVision specialists investigated the possibility to speed up reverse engineering of objects with a large number of surfaces that change their curvature in accordance with mathematical laws. They used the sole of sports shoes as a test surface with such properties.

Source: rangevision.com

For this, they performed a 3D scan of the sole's geometry using the RangeVision Spectrum high-resolution 3D scanner (adjusted for object sizes from 30 cm to 1 m) and a rotary table. In 25 minutes, the device completed two groups of 8 scans, which were automatically linked into one model by the scanner software. Post-processing in the RangeVision ScanCenter program and obtaining a 3D model in .stl format took another 35 minutes.

Source: rangevision.com

Reverse engineering of the sole was carried out in Geomagic Studio using the NURBS method. First of all, artifacts and digital noise were removed, a coordinate system was created, unnecessary details were cut off, and the boundaries were smoothed.

Source: rangevision.com

After applying the NURBS method to the resulting surface, the final 3D model was created. Reverse engineering using NURBS took 4 hours. The entire task was completed within one working day.

Scanning of different objects, DE-Engineering

Source: rangevision.com

The DE-Engineering company fulfills orders on high-precision 3D digitizing and reverse engineering of various objects, from aircraft to jewelry. The founder Dmitry Epstein maintains a video blog on YouTube, in which he publishes the most interesting works. DE-Engineering uses the RangeVision PRO and Gom Atos 3D scanners.

Source: rangevision.com

3D scanning of large objects, such as the frame of a helicopter or an airplane, has some peculiarities: to save time, markers are glued with strips of masking tape, and scanning is carried out from several points to facilitate stitching of the model.

Source: rangevision.com

For the armoring of two Citroen Jumpy vehicles, DE-Engineering specialists performed 3D scanning of the body and created an accurate model, according to which the metal plates were manufactured. The high precision of reverse engineering made it possible to install the armor without any additional fit. The whole process took seven days — two days for scanning and five days for processing.

The whole process took seven days — two days for scanning and five days for processing.

Source: rangevision.com

DE-Engineering tries to use point cloud processing instead of polygons, which is more convenient from the point of view of model simplification. This allows maximizing the detail of an object in complex geometry areas and reducing it in simple ones. Processing is performed with the Catia software. Replaceable lenses are used to scan jewelry.

3D scanning in reverse engineering of a complex-shaped part, Top 3D Shop

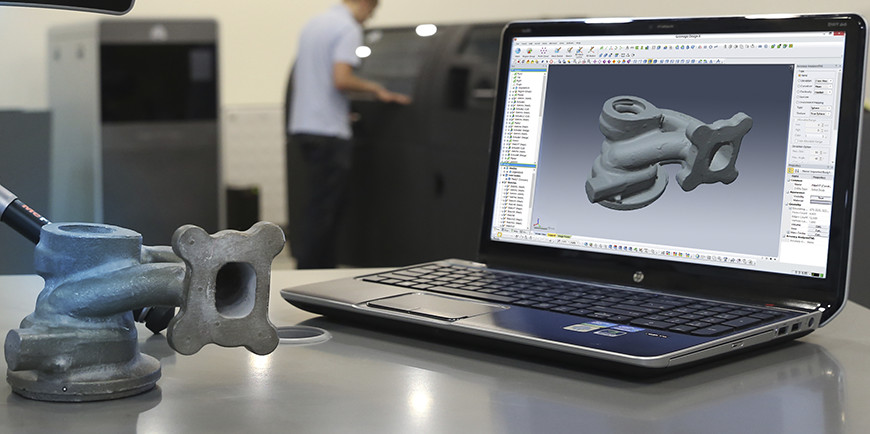

A client contacted Top 3D Shop with a request to restore a broken plastic part of a complex shape.

The part was created by 3D scanning with the RangeVision Pro, reverse engineering, and 3D printing.

Step 1. The length of the part is about 30 cm, so it was impractical to use medium-precision handheld scanners and solutions for large objects. Desktop scanners with a multi-axis table were not suited either, because the object did not fit in length into the half-open scanner camera. Thus, stationary optical or high-precision handheld scanners seemed to be the only options.

Step 2. The object has a geometry of medium complexity. For good scanning of such parts, a scanner accuracy of 40–60+ microns is required.

In the images: solid models of the object with the restored integrity

Step 3. The higher the accuracy of a 3D scanner and the more features it has, the more expensive it is. The customer's budget did not allow the use of GOM, Solutionix, or Scantech scanners, so Top 3D Shop employed the RangeVision Pro, which scans such small objects with an accuracy of 40 microns. Based on the data obtained from 3D scanning, reverse engineering was performed, and the part was prepared for printing.

How to choose a 3D scanner for reverse engineering

First of all, it is necessary to define the size of the scanned objects — this affects the choice of scanning technology and the type of scanner (desktop, handheld, or floor-standing):

- For objects larger than 10 m in any of the coordinate axes, 3D scanners with the usual laser triangulation or structured light technologies are not suitable. Scanning such objects even with a handheld scanner will take a lot of time, and the accuracy of data decreases. This problem is partially solved by photogrammetry. Therefore, for very large objects (airplanes, ships, buildings), it is most effective to use time-of-flight (ToF) scanners.

- For objects larger than 50 cm but less than 3 m, it is recommended to use handheld scanners — optical or laser ones.

- For objects from 10 to 50 cm, stationary desktop or portable floor-standing 3D scanners suit best (both optical and laser). Optical desktop and floor-standing scanners are more affordable than laser ones.

Some handheld laser scanners can be used for tasks requiring high scanning speed.

Some handheld laser scanners can be used for tasks requiring high scanning speed. - Desktop high-precision optical scanners are best for small objects. Scanners of this type can be divided into two groups: dental and versatile.

Dental scanners feature immensely high precision, high resolution, and rotary tables with the ability to attach an occluder and impression stands.

Versatile scanners are usually equipped with a multi-axis rotary table, or the scanner itself is fixed on axes with several degrees of freedom. This design allows for autonomous scanning of most of the object's surface. These scanners have a good scanning depth to correctly capture grooves.

For objects with a size of 10–50 cm, laser handheld scanners are better suited if at least one of the following conditions is met:

- 3D scanning is planned to be used very often;

- the object to be scanned cannot be transported to the workshop; for example, it is a non-removable part of a massive mechanism, or transportation is impossible for other reasons;

- there is not enough room to place a stationary scanner;

- the surface of an object is difficult to scan with optics — it is black or highly reflective.

After defining the size of scanned objects, it is important to find out the required scanning accuracy and the measurement tolerance and see whether a metrological scanner is needed.

Reverse engineering of car parts at Jay Leno's Garage using the Faro Quantum ScanArm HD 3D laser scanner and the Stratasys Dimension 1200es 3D printer

Software for modeling and reverse engineering

Software for creating polygon models

Source: all3dp.com

To create point clouds and polygon models, it is usual to employ the proprietary software of a 3D scanner. Some 3D scanning and reverse engineering software products can also work directly with the most popular scanners.

Software for converting polygon models into solid ones

Geomagic Essentials

Source: einscan.com

Geomagic Essentials is a program that extracts all the necessary elements of a scanned part for direct use in a CAD package. This software is designed to work with scans made by the Shining 3D EinScan Pro 2X (a joint product of 3D Systems and Shining 3D), which automatically processes and transfers the received data to the CAD environment. The application can be used both for metrological control and reverse engineering of parts and assemblies. The proprietary algorithms of mesh alignment and restoration, a wide range of options for fitting elements, the capability of creating cross sections, and high performance when working with large amounts of data can significantly reduce the work time of specialists.

This software is designed to work with scans made by the Shining 3D EinScan Pro 2X (a joint product of 3D Systems and Shining 3D), which automatically processes and transfers the received data to the CAD environment. The application can be used both for metrological control and reverse engineering of parts and assemblies. The proprietary algorithms of mesh alignment and restoration, a wide range of options for fitting elements, the capability of creating cross sections, and high performance when working with large amounts of data can significantly reduce the work time of specialists.

Employing Geomagic Essentials to reverse engineer fan blades by user Gregory George

Geomagic Design X

Source: 3dsystems.com

Geomagic Design X is versatile professional reverse engineering software that combines traditional CAD functionality with 3D scan data processing. Design X allows creating functional, editable solid models compatible with CAD software. The proprietary algorithms for accurate surface fit to 3D scans, mesh editing, and point cloud processing enable the design of components that perfectly integrate with existing parts. The easy-to-use mesh repair tools provide fast hole filling, smoothing, optimization, and comparison with the original model.

Design X allows creating functional, editable solid models compatible with CAD software. The proprietary algorithms for accurate surface fit to 3D scans, mesh editing, and point cloud processing enable the design of components that perfectly integrate with existing parts. The easy-to-use mesh repair tools provide fast hole filling, smoothing, optimization, and comparison with the original model.

Reverse engineering of a compressor at Artec 3D using 3D scanning and the Geomagic Design X software

Autodesk Meshmixer

Source: all3dp.com

Autodesk Meshmixer is completely free software popular with 3D printing professionals. Meshmixer is designed for working with polygonal meshes rather than for parametric modeling and has a large set of tools for this. The functions of automatic analysis and correction are very convenient for processing 3D scans. The program is also capable of preparing a model for 3D printing, including supports. Meshmixer is simple and easy to use, with many tutorials available online.

The program is also capable of preparing a model for 3D printing, including supports. Meshmixer is simple and easy to use, with many tutorials available online.

The first video by AutoDesk to demonstrate the capabilities of Meshmixer

Software for working with solid models

SolidWorks

Source: blog.trimech.com

SolidWorks is a 3D design and reverse engineering program. Apart from traditional CAD/CAM functions, the software includes specialized tools for designing sheet metal parts, welds, and dies. A huge library of components and parts, improved realistic rendering, the capability of design check and structure analysis make SolidWorks one of the most powerful 3D engineering software products available.

The first video from the series of SolidWorks software tutorials: reverse engineering and 3D scan processing

Solid Edge

Source: youtu. be

be

Solid Edge is an easy-to-learn toolset that covers all phases of product development: CAD design and rendering, modeling, reverse engineering, data management, and more. Siemens also provides training resources, access to the Solid Edge community, and ongoing software updates. If certain conditions are met, Solid Edge Premium can be used free of charge for one year.

Demonstration of the capabilities of Solid Edge 2021 from Siemens Software

Autodesk Fusion 360

Source: all3dp.com

The Autodesk Fusion 360 software and all of its modules are free for students, educators, hobbyists, and small businesses. The program is designed primarily for working with solid objects and is equipped with functional plug-ins.

Reverse engineering of a plastic housing at Dream3D using the HDI 3D scanner and the Autodesk Fusion 360 software

Legal issues of reverse engineering

Source: scantech. com

com

The dark side of reverse engineering is intellectual property forgery and theft. The growing availability of the technology can give an advantage to unscrupulous manufacturers when legislation lags behind modern requirements. This means that prototypes that took developers a lot of time and money can be counterfeited with impunity using 3D scanning and printing technologies.

The ease of copying product designs forces large companies to experiment with ways to protect their intellectual rights — for example, by creating product defects that appear only in unauthorized production, or by embedding authentication barcodes directly into manufactured products.

Full 3D scanning and reverse engineering of a car body using the Creaform Go!SCAN SPARK 3D scanner.

Conclusion

Source: ductim-x.com

The future of reverse engineering lies in even greater process automation. Manufacturers are increasingly employing the power of artificial intelligence and cloud technologies in scanning and post-processing to enable inexperienced clients to carry out their work autonomously. This can be useful for specialists in a variety of fields, from doctors scanning body parts to workers on construction sites. 3D scanners keep on penetrating the consumer market and may eventually become as commonplace as cameras on smartphones (some of them are already equipped with a ToF sensor).

Manufacturers are increasingly employing the power of artificial intelligence and cloud technologies in scanning and post-processing to enable inexperienced clients to carry out their work autonomously. This can be useful for specialists in a variety of fields, from doctors scanning body parts to workers on construction sites. 3D scanners keep on penetrating the consumer market and may eventually become as commonplace as cameras on smartphones (some of them are already equipped with a ToF sensor).

3D scanners for reverse engineering — best Artec 3D scanning solutions

Applications

HD meshes for CAD workflows

Confidently and easily capture data from existing parts with the assurance of ultra-high precision and accuracy.

Rapid prototyping

With tools that seamlessly integrate into your existing workflow, you can quickly and easily prototype, test, and get insightful feedback on design solutions.

Retrofitting

Redesigning parts that are no longer in production has never been easier, with none of the errors, inconsistencies, and time demands that come with taking measurements manually.

Aftermarket parts production

With reliable 3D scan datasets, paired with Artec Studio’s versatility, you have the ability to develop high-quality aftermarket parts.

Additive manufacturing

You can take advantage of the flexibility that 3D printing brings to quickly actualize and test reverse-engineered designs.

A leading developer of high-performance chassis saves days of work by using Artec Eva, Artec Studio, and Geomagic Design X to engineer custom solutions for racing.

7x

reduction in time spent capturing and processing scans.

“Eva has been such a game-changer. Now I’ll take a bunch of parts and scan them in before lunch. By the end of the day, we’ve done all our analysis, everything is on schedule to create the final design. ”

”

Jason Heard, Co-founder, Tekk Consulting Inc.

Read full story

In the media

Royal Netherlands Navy 3D scans their ships using handheld Artec 3D scannersTHE VERGE

Classic Land Rover goes electric with the help of Artec LeoTop Speed

3D scanning ensures cameras will mount to helicoptersMake Parts Fast

User-friendly portable 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Learn more

Our bestselling 3D scanner. Fast, versatile, and accurate.

Learn more

A metrological structured-light 3D scanner, set apart with its ability to render complex geometry, sharp edges, and thin ribs in high precision.

Learn more

Powerful long-range laser 3D scanner with an inbuilt battery, for precise capture of large objects.

Learn more

Metrology-grade desktop 3D scanner for quality control, inspection, jewelry, medical/dental components, etc.

Learn more

Using Artec 3D scanning technology to keep Dutch Royal Navy ships seaworthy

“We are now able to work a lot faster and more accurately. Because we now have a complete 3D model, we have all the correct dimensions of every object. It results in a far more efficient way of working and it is faster, so we save a lot of money in these projects.”

Ben Jansen, CNC coordinator at the Netherlands Defense Ministry

Read full story

Reverse engineering huge machine parts in difficult locations with Artec Eva and Geomagic Design X

“Artec Eva was the suitable scanner for this job as the parts were very big and the accuracy required was in the range of Artec Eva’s accuracy. The scanning was pretty fast and easy considering that those were huge parts, around 3 meters…No other scanner can measure such big parts this accurately and fast.”

Ali Can Boysan, Teknodizayn Sales & Technical Support Manager

Read full story

Putting Claws on the Black Panther Lexus with Artec Eva at West Coast Customs

“It's a huge help that Eva is lightweight and comfortable to hold, which makes scanning actually fun to do … you don’t need to use it for long before you look over at the laptop and realize that you’ve scanned the whole car … it either would’ve been just impossible without Eva or much more difficult and definitely not as precise. ”

”

Lorenzo Strong, West Coast Customs Sales VP

Read full story

Slashing weeks off reverse engineering farm equipment with Artec Eva

“Eva has literally saved us days if not weeks of work, and that’s no exaggeration. Previously we were spending all that time creating prototypes to test, then that many more hours on alterations to reach the level of perfect, compared to now achieving perfection the first time, and every time, with Eva.”

Mark Taylor, Taylor Attachments

Read full story

User-friendly portable 3D scanner with an inbuilt touchscreen and intuitive UI for easy 3D scanning.

Learn more

Our bestselling 3D scanner. Fast, versatile, and accurate.

Learn more

A metrological structured-light 3D scanner, set apart with its ability to render complex geometry, sharp edges, and thin ribs in high precision.

Learn more

Powerful long-range laser 3D scanner with an inbuilt battery, for precise capture of large objects.

Learn more

Metrology-grade desktop 3D scanner for quality control, inspection, jewelry, medical/dental components, etc.

Learn more

Complex motorcycle engine captured by Artec Leo in just 8 minutes

Artec Leo

Pipe bend captured with Artec Micro in only two scans over four minutes

Artec Micro

Motorcycle crankcase captured by Artec Space Spider in 15 minutes

Artec Space Spider

Compound bow captured by Artec Eva in just five minutes

Artec Eva

Artec Ray was used to scan an airplane suspended three meters high.

Artec Ray

Choosing a 3D scanner for reverse engineering | 3Dcast

Modern production technologies involve the use of certain equipment. In recent years, manufacturing companies have begun using 3D scanners for reverse engineering.

Definition of Reverse Engineering

Over the years, products have been created without the right set of documentation. Masters were guided by their experience and knowledge. After some time, programs for creating drawings and three-dimensional models appeared. Reverse engineering is the process of creating technical documentation by scanning a part with special equipment. The digital model can be opened in CAD or other software. This is done to optimize parameters and add new features. In the virtual space, it is possible to conduct tests that would be very expensive in practice and would not lead to a result.

Reverse engineering has also become popular due to the growing popularity of 3D printing. This technology greatly simplifies the process and reduces the cost of the product. Today, production using 3D printing is available to everyone, it is enough to purchase the appropriate printer and install the appropriate software on the computer.

This technology greatly simplifies the process and reduces the cost of the product. Today, production using 3D printing is available to everyone, it is enough to purchase the appropriate printer and install the appropriate software on the computer.

Selection criteria

There are many different models of 3D scanners on the market. Their selection is carried out according to several criteria:

- Detail precision.

- How it works.

- Compatible with certain software.

- Cost.

The choice of the scanner is also carried out according to the assigned tasks. Scanning can be performed on parts of different sizes and geometries. Universal devices are expensive and require more professionalism.

ToF Scanners are designed to work with large cabinet products that are larger than 10,000 mm on either side. Handheld models with structured illumination are used to scan small objects. If the object has dimensions up to 3000 mm, portable models are used. They are laser and optical type. Laser scanners are the easiest to use, as optical ones require proper preparation.

They are laser and optical type. Laser scanners are the easiest to use, as optical ones require proper preparation.

Small items are best scanned with optical portable devices. Universal options are equipped with a multi-axis rotary platform. It copes well with scanning the relief surface represented by various materials.

There are many dental scanners on the market. The devices are characterized by high accuracy, allow you to get detailed images for the formation of the model.

Applicable software

The field of 3D design and simulation has evolved over the years. The software was created by many companies. At the same time, some became in demand, others are no longer supported. Recently, developers have been trying to support various file formats. To do this, we made the import and export functions

There are several programs that are most popular. They are:

- Geomagic Essentials. A partner product of a company that produces equipment for automatic design upon receipt of the necessary data.

The software allows you to work with images obtained using Shining 3D EinScan Pro 2x. The software allows you to work with data that is obtained when scanning premises or products. The functionality includes obtaining a cross section, restoring the mesh and fitting elements to simulate the assembly process.

The software allows you to work with images obtained using Shining 3D EinScan Pro 2x. The software allows you to work with data that is obtained when scanning premises or products. The functionality includes obtaining a cross section, restoring the mesh and fitting elements to simulate the assembly process. - Geomagic Desing X. Professional software used to work with scans for further design. The functionality allows you to work with solid objects, emit the connection of individual elements.

- Autodesk Meshmixer. Popular software with a large set of tools. It is able to independently process the received images to form a grid. The advantages include a clear interface and a large number of patches.

When choosing a scanner, the possibility of using one of the above programs is taken into account. This is due to the fact that sometimes after scanning a document is obtained in a rare resolution. 9Ol000 Blog

Contacts

Today, 3D scanners are widely used for reverse engineering of complex shapes. The process is characterized by the creation of a mathematical model or drawings from an existing physical model.

The process is characterized by the creation of a mathematical model or drawings from an existing physical model.

- How it works

- Advantages

- Examples of use

- Video

- How it works

- Examples of use

How it works

Principal circuit of the reverse design. can be depicted as follows: 3D scanning of a physical sample, transferring the resulting point cloud to a polygonal 3D model, processing the model in special software for converting to a CAD format.

How it works

A reverse engineering concept using a 3D scanner can be depicted as follows: 3D scanning of a physical sample, converting the resulting point cloud into a polygonal 3D model, processing the model in special software for converting to CAD format.

On the basis of the obtained CAD model, tools are created for mass production of the finished product. If necessary, changes and improvements are made to the resulting model. Let's consider this process using the example of reverse engineering of an industrial fan casing.

Let's consider this process using the example of reverse engineering of an industrial fan casing.

Based on the received CAD model, tools are created for mass production of the finished product. If necessary, changes and improvements are made to the resulting model. Let's consider this process using the example of reverse engineering of an industrial fan case.

1. We disassemble the test product into the maximum number of components.

2. We scan each element using an optical or laser 3D scanner. We get a cloud of points with data on surfaces and geometry of objects.

1. We disassemble the test product into the maximum number of components.

2. We scan each element using an optical or laser 3D scanner. We get a cloud of points with data on surfaces and geometry of objects.

3. Using the software, we convert the point cloud into a polygonal 3D model.

4. We convert the data into a convenient CAD format (the process depends on the technical requirements and features of the software used).

3. Using the software, we convert the point cloud into a polygonal 3D model.

4. We convert the data into a convenient CAD format (the process depends on the technical requirements and features of the software used).

Benefits

There is a fine line between digital modeling and reverse engineering. Sometimes both methods can be correct in solving problems with 3D models. However, reverse engineering has a number of advantages. Here are some of them:

- the model can be loaded into parametric modeling programs;

- the parametric model will have key construction points, with the ability to edit;

- Unlike artificially modeled surfaces, reverse engineering models contain more geometric features, making them more suitable for design and measurement;

- reverse engineering models are great for CFD and FEA engineering analysis programs (Such as ANSYS).

Benefits

There is a fine line between digital modeling and reverse engineering. Sometimes both methods can be correct in solving problems with 3D models. However, reverse engineering has a number of advantages. Here are some of them:

Sometimes both methods can be correct in solving problems with 3D models. However, reverse engineering has a number of advantages. Here are some of them:

- the model can be loaded into parametric modeling programs;

- the parametric model will have key construction points, with the ability to edit;

- Unlike artificially modeled surfaces, reverse engineering models contain more geometric features, making them more suitable for design and measurement;

- reverse engineering models are great for CFD and FEA engineering analysis programs (Such as ANSYS).

Examples of using 3D scanners in reverse engineering This item has been out of production for a long time. Based on the surviving part, its exact 3D copy was recreated, which was subsequently printed on a 3D printer in the required quantity just in time. With conventional production tools, it would have been impossible to fulfill an order within a narrow time frame.

The design bureau of the US Space Agency needed to develop a new product, relying on the basis of existing solutions. Such tasks often arise in connection with the need to save budget funds. In this case, the 3D scanner also turned out to be indispensable - scanning technology significantly saved money and time, becoming an alternative to expensive modeling.

Examples of using 3D scanners in reverse engineering This item has been out of production for a long time. Based on the surviving part, its exact 3D copy was recreated, which was subsequently printed on a 3D printer in the required quantity just in time. With conventional production tools, it would have been impossible to fulfill an order within a narrow time frame.

The design bureau of the US Space Agency needed to develop a new product, relying on the basis of existing solutions. Such tasks often arise in connection with the need to save budget funds. In this case, the 3D scanner also turned out to be indispensable - scanning technology significantly saved money and time, becoming an alternative to expensive modeling.