Conductive 3d printer

Conductive 3D printing: Additive manufacturing for electronic

Posted By Lucie Gaget on Sep 4, 2018 |

Additive manufacturing can be really useful for electronics: you could totally use this 3D printing technology to manufacture the enclosure of electronic device, or to develop prototypes. Now, it is possible to go further and print the electrical elements. Indeed, a lot of devices are now 3D printable, but is it really possible to create conductive 3D printed objects?

In this blog post, we are going to see how additive manufacturing can help to create electrical systems and how conductive 3D printing is now becoming a reality.

How can 3D printing be useful for electronic?

The additive manufacturing technology is quite useful for electronic applications.

Some of our customers with electronic projects are for example using our 3D printing service to manufacture enclosures. Or, for example, Simusolar, one of our clients, is using 3D printing to manufacture parts of circuit boards. Read more about this amazing project here.

For your electronics project, 3D printing can be useful to develop prototypes, but also to produce. Indeed, if you need a prototyping solution, this method will allow you to make many iterations at a lower price and will be perfect to help you to develop your final product. Thanks to all the materials available on an online 3D printing service like Sculpteo, you will be able to produce qualitative parts.

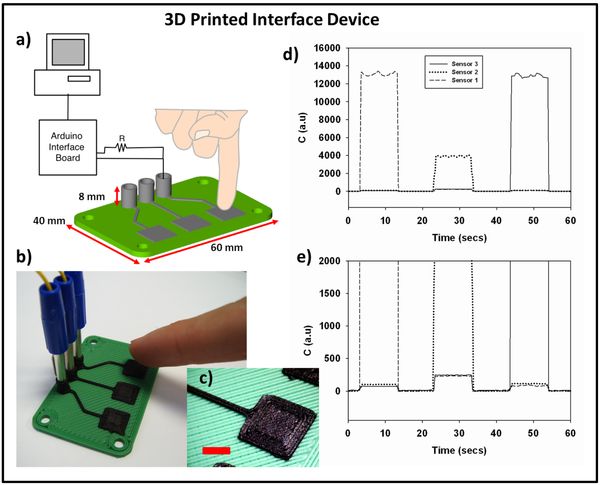

Conductive 3D printing could allow going even further. The creation of electronic devices with conductive features using 3D printing can particularly be useful to develop IoT (Internet of Things) projects. It could be a way to develop even better and efficient products.

Conductive 3D printing: Offering new possibilities

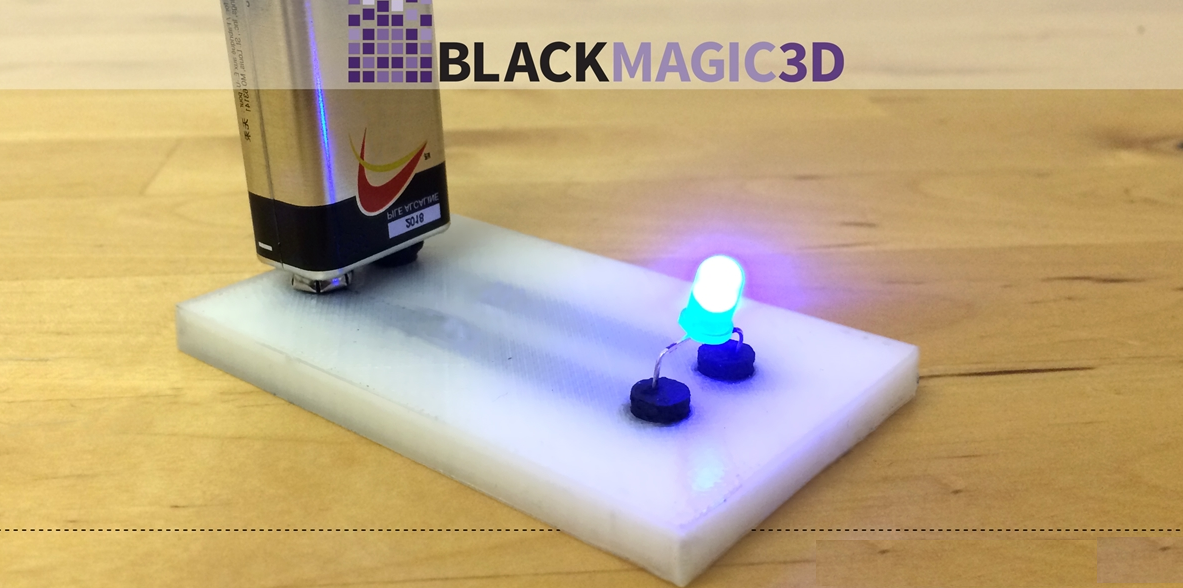

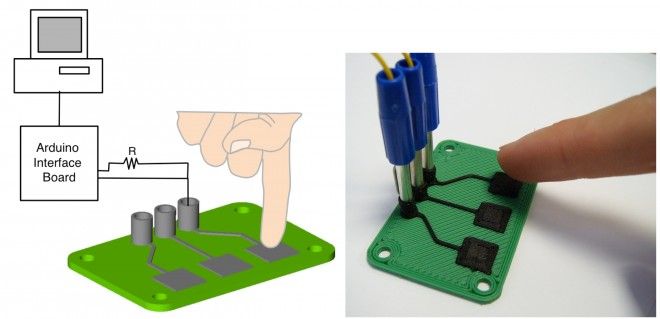

Several experiments have been made to create conductive 3D printed parts. This innovation could allow you to create 3D printed devices like LED, or touch sensor. But it could be involved in bigger projects, in soft robotics, 3D electronics, and also for communication devices such as 3D printed Near Field Communication (NFC) antennas.

Let’s see what the viable possibilities to 3D print conductive devices are, using new 3D printing material or new printing techniques.

Conductive 3D printing materials

Graphene

There are some conductive materials that could totally revolutionize new electronic constructions. We already told you about graphene, the wonder material in 3D printing. This material has great intrinsic properties. Indeed, it is not only one of the most resistant materials, but it is also electrically conductive!

The structure of this material makes it electrically conductive. Graphene is the structural element of many forms of carbon. Carbon atoms are arranged in a honeycomb structure and there is a single free electron in each atom.

This way, the material can transmit currents through these free electrons. Conductive graphene filaments could be a great solution to create functional electrical elements. Keep in mind that this material is still less conductive than metals such as iron or copper.

ABS and PLA filaments

Some electrically conductive filaments have been developed using some ABS or PLA material, like graphene PLA filament. Regarding the strength of this material, it is more flexible than traditional PLA but has less layer adhesion.

For the moment, it seems that the only conductive 3D printing materials available are filaments, which can be used on desktop 3D printers. Soon, bigger professional 3D printers could be able to print with these electrically conductive materials but to begin with, these first options are offering great possibilities.

Indeed, these filaments could be useful in the development of wearable electronics, making it possible to create small electrical circuits.

Hydroprinting conductive patterns

Here is another 3D printing method to develop conductive parts: hydroprinting.

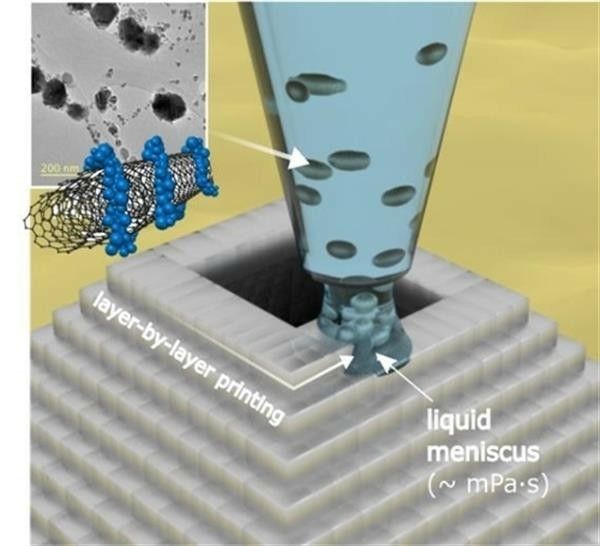

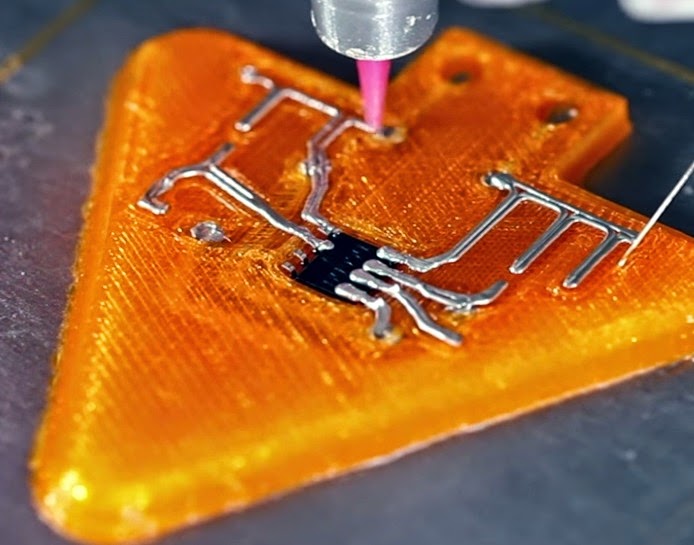

A paper in Advanced Materials Technologies published by Professor Shlomo Magdassi with some other researchers from The Hebrew University of Jerusalem and The Nanyang Technological University in Singapore, these researchers actually found a solution to 3D print conductive patterns. Using hydroprinting on a 3D printed part is allowing to manufacture a functional 3D printed conductive part. This process enables to print several layers circuits. It only requires repeating the same printing process for as many layers as needed.

Using hydroprinting on a 3D printed part is allowing to manufacture a functional 3D printed conductive part. This process enables to print several layers circuits. It only requires repeating the same printing process for as many layers as needed.

If you need more information about this impressive innovation and more details about the printing process of these conductive parts, please check our previous blog post, we tell you all you need to know about hydroprinting and conductive patterns!

The stretchable and conductive 3D printing material

Combining elasticity and conductivity in one material isn’t easy, but 3D printing enabled researchers to develop totally new materials. Why are they important? Stretchable and conductive materials are particularly interesting for biological systems and artificial intelligence.

There have been a few ways developed to achieve soft, but conductive materials. One of them is to add plasticizers and flexible channels to polymers. This allows for creating soft areas. Electronic fillers or ionic electrolytes, which are incorporated in paths, are responsible for conductivity.

This allows for creating soft areas. Electronic fillers or ionic electrolytes, which are incorporated in paths, are responsible for conductivity.

Zhouyue Lei and Peiyi Wu, researchers from Shanghai, recently published a study ‘’A highly transparent and ultra stretchable conductor with stable conductivity during large deformation’’. Their challenge was to test the conductivity of flexible materials, in some cases, in extreme environments. Were any developments made?

Electrical properties in dynamic environments. a Schematic illustration of the conductive paths in this material adapting to deformation. Blue lines represent ion nanochannels and the purple parts represent the dynamic networks. b Photographs of the 3D-printing conductor during a stretch-release cycle (scale bar: 2 cm). c The stability of the ionic conductivity during the deformation process. d The relative changes in ionic conductivity in the temperature range of −10 to 100 °C (error bars: standard deviations). e The stability of the ionic conductivity at extremely low or high temperatures for a long period. These measurements are humidity control (60 RH%)

e The stability of the ionic conductivity at extremely low or high temperatures for a long period. These measurements are humidity control (60 RH%)

https://www.nature.com/articles/s41467-019-11364-w

Lei and Wu studied transparent materials and their electromechanical characteristics, defects, and deformations. Their mission was to produce soft nanochannels, connected with crosslinked networks. The result was a 3D printing material, filled with conductors and paths which ‘’dynamically adapted’’ to stretching and deformation.

The authors comment: ‘’Herein, we introduce a type of intrinsically stretchable conductors. Small-molecular liquid-like electrolytes, such as ILs, provide charge carriers; polymers with similar ionic structures, e.g., polyzwitterions, realize ionic synergy with the liquid electrolytes and thus assemble conductive nanochannels to avoid aggregates or leaking risk of the electrolytes; dynamic networks are constructed by polymers that also have molecular synergy with the conductive nanochannels, to guarantee the structural integrity, deformation adaptability, and environmental stability. ”

”

A great achievement was also prooving that the material kept its stability, performing a 3% chance of conductivity in 24 hours, and in extreme temperatures performed no melting point or glass transition.

This revolutionary development is very encouraging for the soft robotics industry. Without Additive Manufacturing technologies, the researchers wouldn’t be able to work in nanoscale, creating highly complex structures.

3D printing conductive elements in the future

All of the experiments made to create conductive systems using 3D printing technology are really promising. Nanotechnology and metal 3D printing could soon allow printing really small conductive components, circuit boards, and electrical circuits. Hydroprinting and new conductive materials are all offering to brand new possibilities and could make it possible to create fully 3D printed electronic devices.

As you can see additive manufacturing has a lot to offer for electronics. It could become quite common to 3D print electrical elements. If you have an electronic project, but you don’t know what software you could use to start it: here is our selection of the best CAD software for electronics. Then, don’t hesitate to try out our online 3D printing service. You will just have to upload your 3D file, we will take care of it and send you your 3D printed objects in a few days.

It could become quite common to 3D print electrical elements. If you have an electronic project, but you don’t know what software you could use to start it: here is our selection of the best CAD software for electronics. Then, don’t hesitate to try out our online 3D printing service. You will just have to upload your 3D file, we will take care of it and send you your 3D printed objects in a few days.

Don’t forget to subscribe to our weekly newsletter to learn about all the different 3D printing applications.

Electrically Conductive Polymer Composites for 3D Printing

Last week we took a look at ESD safe materials for 3D printing. These are materials that are safe against electrostatic discharge, and have uses largely in electronics manufacturing.

This article, we will look at polymer composites with lower surface resistivity, in other words, electrically conductive 3D printing feedstocks.

Conductive materials have a surface resistivity of less than 1 x 10 5 Ω/ sq./91f3dfd02cdc286.s.siteapi.org/img/353ea9928d2283b0b7f1f3b4b8f8864c90a6b903.jpg) This is compared to dissivative (ESD) materials which lie in the range of 1 x 10 5 Ω/ sq to 1 x10 11 Ω/ sq.

This is compared to dissivative (ESD) materials which lie in the range of 1 x 10 5 Ω/ sq to 1 x10 11 Ω/ sq.

Conductors allow electricity to flow, and so have a bunch of potential uses, ranging from 3D printed circuits, wearable tech and maybe even one day, conductive substrates for electroplating.

Here are a few options for you, depending on what type of additive manufacturing process you are using.

Extruded Materials

For a while, filaments have been available in conductive form. Similar to ESD materials, conductivity generally tends to be manipulated by addition of some form of carbon to the feedstock during filament manufacture.

There are a lot of smaller companies offering these conductive filaments, yet strangely we don’t see much from the larger companies.

Fans of tougher thermoplastics such as ABS, TPU and PC will be pleased to know there are plenty of options for conductive variants of this polymer. A google search of the term “conductive X filament” (with “X” being your thermoplastic of choice) will yield a fairly huge selection to choose from.

Sintered Materials

Anyone with access to a SLS machine will be pleased to hear that there are options available (and in development) to those who enjoy sintering things.

There is currently research underway into addition of metallic fillers such as copper and aluminium also.

There are a variety of methods involved in manufacturing electrically conductive SLS materials. Many involve the mixing of carbon into the feedstock, while others focus on actually coating the actual particles with a conductive filler, as you can see in the image below.

The graphic above shows the addition of carbon nanotubes to the surface of the powder particles. Image credit: Materials & Design JournalA lot of research is focused on the shape and size of the additive particles (for example spherical vs. flakes), to determine the optimum parameters for successful bonding and increased electrical conductivity.

Photopolymers

Similar to the ESD materials of last week, the selection of conductive resins is smaller than the extrusion & sintering feedstocks. Last week we pointed out that mixing carbon particles into a resin can result in the contents settling, which can require constant mixing immediately before printing.

Last week we pointed out that mixing carbon particles into a resin can result in the contents settling, which can require constant mixing immediately before printing.

This is one possible explanation for the small selection of these resins available.

While there aren’t many options for SLA/DLP printing conductive materials available commercially, conductive resins are being researched by various universities around the world, so there is potential for the market to grow, once manufacturers iron out the creases, whatever they may be.

This team from Yeungnam University, South Korea, for example, has manufactured a Polyacrylate Resin Solution with Polyaniline Nanofiber and Graphene additives, for improved conductivity.

Another team, from Georgia Institute of Technology and Xi’an Jiotong University, has mixed multi-walled carbon nanotubes (MWCT) with resins and demonstrated that they show conductivity. In fact, these research resins have been shown to be very useful indeed, having been shown to be useful for electrically activated shape memory composites. 10 times LESS conductive than copper.

10 times LESS conductive than copper.

So bear that in mind when buying a conductive polymer material, and if in doubt…always read the datasheet.

liquid plastic, and conductive filament of graphite and graphene

Archive

Why 3D printed products look far from perfect. And the lack of conductive filaments on the market does not allow you to start printing anything more than plastic knick-knacks. We all know what finished 3D printed items look like. Lines are clearly visible on their surface, where one layer of filament was welded onto another. More often than not, such a surface is often not what the designer wanted to achieve, and is one of the factors why the finished model does not look exactly the same as the model on the monitor screen.

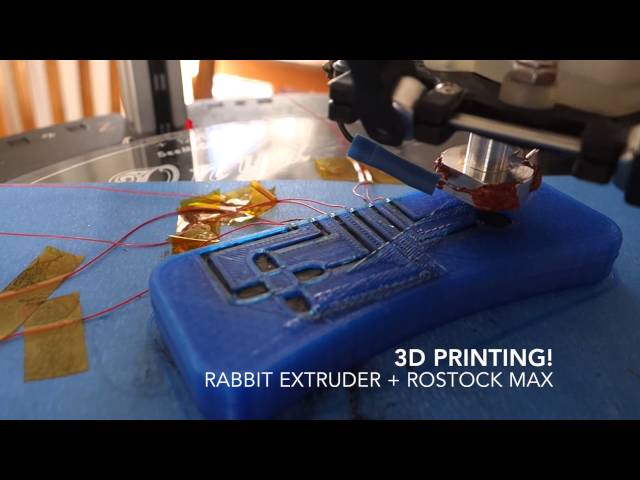

Today, however, a man named Stephen Mills from the UK has started an Indiegogo campaign to raise funds for the production of 3D printing filaments, which he believes can solve two of the major shortcomings of 3D printing technology today.

The most unique and arguably revolutionary of these materials is what Mills calls "liquid plastic." And this name quite accurately reflects what this material is: plastic in liquid form. To better understand the benefits of such plastic in the 3D printing industry, we first need to touch on how a typical FDM 3D printer works.

Those of you who have your own 3D printers know firsthand that in order to print objects, you need to thread a spool of filament (most often hard plastic) into the printer, which is fed into the extruder, where it heats up passing through the hot nozzle. When heated, the plastic melts and then, and after a time sufficient to cool, it hardens again. This is very similar to how a glue gun works. As the plastic fuses onto the build platform, or previous layers, it cools and hardens.

This technology has its limitations, such as the diameter of the nozzle opening must be wide enough for the molten plastic to escape through. This is the main reason why printed objects have visible layer lines on the surface.

Visible layer lines in conventional fusing

Will's revolutionary new "liquid plastic" can help eliminate these shortcomings. Liquid plastic solidifies when it is exposed to air, and so it is stored in an airtight container. But at the same time, you can change the consistency of liquid plastic by adding a solvent to it. This means that it can be diluted so that it can flow from a hypodermic needle-sized nozzle, thereby solving the problem associated with large diameter nozzles. This makes it possible to significantly reduce the thickness and height of the layer, which, in turn, allows printing objects with very high resolution.

Mills also revealed that he is working on making liquid plastics infused with graphene and/or graphite that have conductive properties.

“Our low cost 3D printer filament is highly conductive and can therefore be used for circuit and sensor printing and many other applications where conductive properties are needed,” Mills said.“The possibilities of these materials are almost limitless. They are only limited by our imagination."

By giving designers and engineers the ability to print objects that have conductive properties, we may soon see 3D printing of not only plastic objects, but objects with electrical components, light bulbs, and perhaps more, as the technology advances.

“The use of our conductive filaments and new forms of liquid plastics opens up a huge field of exciting new possible applications for 3D printing, from electronics to micron-resolution applications,” said Mills. “We think this is a very important stage of development.”

3D Printing Liquid Conductive Plastic

Mills is aiming to raise £11,700 through this crowdfunding campaign. This campaign uses Indigogo's "flexible funding option", which means that whether the funding goal is met or not, all funds raised will go to Mills. As a reward to those who support his project, Mills offers a variety of conductive and liquid plastic filaments. In addition, among its options is an extruder, which will allow you to create your own filaments.

In addition, among its options is an extruder, which will allow you to create your own filaments.

It will be interesting to see how this campaign plays out. In addition, these new materials will require 3D printers capable of printing with these new filaments. They will need an extruder that can be used with a nozzle the size of a hypodermic needle.

What do you think of this project? Will Mills achieve his funding goal? Will this 3D printing method be effective? Share your thoughts on this subject in the comments to this article. The two videos below provide the details of 3D printing with liquid plastic:

Article prepared for 3DToday.ru

used in modern industrial and home 3D printing.

When it comes to 3D printing, there is (almost) nothing impossible when it comes to materials, and researchers are constantly creating new ones.

There are certain "master" materials. The most common of these are plastics, ranging from industrial grade plastics like PEEK to very easy-to-handle plastics like PLA. Another common material is polymers, which are used in SLA printers. Composites are another category, and, as the name suggests, they are created (as if composed by a composer) by combining several materials, and the best is taken from each. The next large group of materials are metals. They are printed only by industrial machines.

The most common of these are plastics, ranging from industrial grade plastics like PEEK to very easy-to-handle plastics like PLA. Another common material is polymers, which are used in SLA printers. Composites are another category, and, as the name suggests, they are created (as if composed by a composer) by combining several materials, and the best is taken from each. The next large group of materials are metals. They are printed only by industrial machines.

In this guide, we will only consider commercially available 3D printing materials. This means that we have excluded those that cannot be bought in the store, such as biological ones.

So, it's time to start talking about what materials you can work with in 3D printing, about their applications, properties and technologies.

Which material should I choose?

Sorry, but it depends on a lot of circumstances. For example, if you need to print a food container, you will need a 3D printing material that is also food compatible, like PETG. If you want to see in advance and on a smaller scale what will then be made as a result of injection molding, then it is not necessary to immediately use expensive materials when thermoplastics such as nylon are available.

If you want to see in advance and on a smaller scale what will then be made as a result of injection molding, then it is not necessary to immediately use expensive materials when thermoplastics such as nylon are available.

There are also additive technologies such as Binder Jetting (jet printing with a binder) or stereolithography, which greatly expanded the range of materials used in 3D printing. Many jobs that have been the domain of manual craftsmen for centuries are now automated and can be done by anyone with even the slightest understanding of 3D printing 3D modeling. Here you can point to the wide possibilities of producing full-color concepts, architectural models and visualization of art projects from paper (SDL), sandstone (Binder Jetting) and polymers (PolyJet). Thus, it can be said that 3D printing materials have led to a kind of democratization of rapid prototyping of design ideas.

Materials for 3D printing with metals have revealed forms and applications that were previously unimaginable. Nowadays, it is no longer surprising that the aerospace industry is creating complex one-piece structures that use less material than before, and are therefore lighter, resulting in lower fuel consumption for aircraft compared to traditional approaches.

Nowadays, it is no longer surprising that the aerospace industry is creating complex one-piece structures that use less material than before, and are therefore lighter, resulting in lower fuel consumption for aircraft compared to traditional approaches.

PLASTIC

Most consumer goods today are made from thermoplastics, so this guide to 3D printing materials would be incomplete without them. And if we talk about widespread things, then here the plastics come out in all their glory. Designers and engineers prefer to create functional prototypes from 3D printing materials with the same or very similar properties as injection molding materials, the technology that creates the final product.

Most 3D printing thermoplastics can be handled at home in much the same way as professional solutions. The only thing is that some experts began to stare at laser sintering instead of filament fusing (FFF).

ABS

(Source: Wikipedia)

Do you remember the quality of Lego bricks? And this is ABS plastic, which is one of the most common materials for desktop 3D printing today.

It is completely inexpensive, strong and light. ABS filament comes in a variety of colors. There are some complaints about the smell that ABS emits when heated to its melting point, and if you're worried about that, there are alternatives like PLA. Because ABS is printed at temperatures between +220 and +250 °C, it is recommended to use a heated platform and in a closed working space so that the material cools in a controlled manner and does not warp. Also, 3D printing materials like ABS break down when exposed to atmospheric moisture, so you need to store them in airtight bags or containers.

Learn more about ABS: Everything you need to know about ABS filament for 3D printing

- Technologies: FDM, resin inkjet, SLA, PolyJetting

- Features: Rugged, lightweight, high resolution, quite flexible

- Applications: architectural models, concepts, assembly models, serial production

PLA

Another crowd favorite in our guide to 3D printing materials is PLA, which is made from cornstarch (although sugar cane and tapioca are also available). This is a simple material that exudes a pleasant sweetish aroma when heated, which is why many people prefer it over ABS. In addition, it can print disposable tableware and does not shrink as much when cooled compared to ABS. However, PLA is not as durable as ABS, and is afraid of heat. Therefore, ABS is better for any working structures.

This is a simple material that exudes a pleasant sweetish aroma when heated, which is why many people prefer it over ABS. In addition, it can print disposable tableware and does not shrink as much when cooled compared to ABS. However, PLA is not as durable as ABS, and is afraid of heat. Therefore, ABS is better for any working structures.

(Source: thingiverse)

Don't Miss: PLA Durability, Biodegradability Experiment

PLA is sold in a variety of colors and is found in many composites that give it the appearance of, for example, wood or metal. Like ABS, PLA filament breaks down when exposed to moisture in the air, so store it in airtight bags or containers.

- Technologies: FDM, SLA, SLS

- Characteristics: easy to print, no toxic smell when printed, food compatible

- Applications: concepts, assembly models, functional models, serial production

Nylon (polyamide)

Due to its flexibility and strength, nylon has become a leader in a wide range of applications, from engineering to artistic. In some places it is simply called "white plastic". Nylon printouts have a rough surface that can be easily polished. Among FDM filaments, nylon has the strongest layer bonding, making it ideal for 3D printing parts that require high tensile strength and mechanical strength. Like other thermoplastics, nylon decomposes when exposed to ambient moisture and is best stored in airtight containers or bags.

In some places it is simply called "white plastic". Nylon printouts have a rough surface that can be easily polished. Among FDM filaments, nylon has the strongest layer bonding, making it ideal for 3D printing parts that require high tensile strength and mechanical strength. Like other thermoplastics, nylon decomposes when exposed to ambient moisture and is best stored in airtight containers or bags.

- Technologies: FDM, SLS

- Characteristics: strong, smooth surface (after polishing), rather flexible, chemical resistant

- Applications: concepts, functional models, medical applications, instruments, visual arts

PEEK

PEEK is another 3D printing material designed for heavy duty parts. Plastics of this family perfectly tolerate mechanical stresses, temperature fluctuations and chemical influences. And that's not it. PEEK parts can be irradiated with X-rays and gamma rays. And with such reliability, this material is easily processed and produced. But here there is an ambush in the temperature, which in a 3D printer should reach +400 ° C, and it is better to entrust such work to professionals. In addition to high cost, security considerations can also be an argument for abandoning it. PEEK materials with their excellent properties are used in the most demanding applications - automotive, aerospace, chemical and medical industries. In particular, medical instruments and semiconductor components can be mentioned.

But here there is an ambush in the temperature, which in a 3D printer should reach +400 ° C, and it is better to entrust such work to professionals. In addition to high cost, security considerations can also be an argument for abandoning it. PEEK materials with their excellent properties are used in the most demanding applications - automotive, aerospace, chemical and medical industries. In particular, medical instruments and semiconductor components can be mentioned.

- Technologies: FDM, SLS

- Characteristics: biocompatible, very durable, heat resistant, wear resistant

- Applications: series production (automotive, aerospace, chemical and medical industries)

PET

Our next 3D printing material is PET, the material used to make plastic bottles, another alternative to ABS. Unlike ABS, PET does not stink when melted and is strong and flexible without the stench. More importantly, PET does not require heated print bed. The material gives a shiny surface, it is not hazardous to food, and this in some cases makes it a popular choice. Store PET materials for 3D printing in airtight bags or containers, the material is afraid of moisture.

Store PET materials for 3D printing in airtight bags or containers, the material is afraid of moisture.

- Technologies: FDM

- Characteristics: durable, food compatible, flexible, gives a smooth surface

- Applications: assembly models, serial production, functional models

PETG

PETG is a version of PET combined with glycol that has received a number of desirable properties in the 3D printing business, such as high transparency. What's more, PETG materials can be printed at lower temperatures and at higher flow rates (up to 100 mm/s), which speeds up production. PETG objects are not afraid of the weather, so they can often be found in gardens. Another commercial quality is food compatibility. Store PETG in airtight bags or containers, the material is afraid of moisture.

Don't Miss: All You Need to Know About 3D Printing with PETG Filament

- Technologies: FDM

- Features: Rugged, food grade, all weather, flame retardant

- Applications: concepts, assembly models, functional models, serial production

ULTEM

ULTEM is an amazing 3D printing material often found in demanding applications. On the one hand, the plastics of this family perfectly tolerate mechanical stresses, temperature fluctuations and chemical influences, but at the same time they are easy to process and obtain. The only problem is heat resistance, because the extrusion temperature in a 3D printer must reach +400 ° C, and for safety reasons, it is better not to do this work at home, but to entrust it to specialized 3D printing services. Due to its ruggedness, ULTEM is used in the most demanding applications in the automotive, aerospace, chemical and medical industries. It can be found in electrical circuits, medical instruments, and microchip sockets.

On the one hand, the plastics of this family perfectly tolerate mechanical stresses, temperature fluctuations and chemical influences, but at the same time they are easy to process and obtain. The only problem is heat resistance, because the extrusion temperature in a 3D printer must reach +400 ° C, and for safety reasons, it is better not to do this work at home, but to entrust it to specialized 3D printing services. Due to its ruggedness, ULTEM is used in the most demanding applications in the automotive, aerospace, chemical and medical industries. It can be found in electrical circuits, medical instruments, and microchip sockets.

- Technologies: FDM, SLS

- Characteristics: biocompatible, very durable, heat resistant, wear resistant

- Applications: series production (automotive, aerospace, chemical and medical industries)

HIPS

HIPS has two main applications. First of all, it is often used in FDM or SLA printing as a backing material because it dissolves in a substance called limonene. With similar properties, HIPS works best in combination with ABS. But, if you decipher the name of this plastic, and HIPS is High-Impact Polystyrene, i.e. high-impact polystyrene, it becomes clear why it is also widely used for the manufacture of containers and in general where increased impact resistance is important. When printing, HIPS gives off fumes, so the room must be ventilated, especially at home. Like many other materials for 3D printing, this one is also capricious in relation to environmental conditions, so it must be stored tightly.

With similar properties, HIPS works best in combination with ABS. But, if you decipher the name of this plastic, and HIPS is High-Impact Polystyrene, i.e. high-impact polystyrene, it becomes clear why it is also widely used for the manufacture of containers and in general where increased impact resistance is important. When printing, HIPS gives off fumes, so the room must be ventilated, especially at home. Like many other materials for 3D printing, this one is also capricious in relation to environmental conditions, so it must be stored tightly.

- Technologies: FDM, SLA

- Characteristics: soluble, soft to the touch

- Applications: assembly models, print stands, shipping containers

PVA

PVA, like HIPS, was designed as a soluble support material, but unlike all other similar materials, it dissolves in plain water. And, like most filaments, it needs to be stored in an airtight container.

- Technologies: FDM

- Characteristics: instant

- Applications: assembly models, printing supports

COMPOSITES

Composites are filaments made up of several materials and using the best qualities of each. PLA, for example, can be paired with everything from wood to metal. Other composites are targeted at specific industries or applications and are used, for example, in engineering applications.

PLA, for example, can be paired with everything from wood to metal. Other composites are targeted at specific industries or applications and are used, for example, in engineering applications.

Conductive

A relatively new addition to the filament shelf are 3D printable conductive materials that open up many interesting possibilities. Such materials can be used, for example, in touch panels or in MIDI instruments. Other uses for conductive composites are wearable electronics, computer-to-computer interfaces, Arduino boards, and more for DIY projects. Conductive filaments for 3D printing are usually based on PLA or ABS, each with its pros and cons. Conductive ABS is more durable and heat-resistant than PLA-based, but has the same odor issues as regular ABS.

- Technologies: FDM

- Features: conductive

- Applications: DIY projects

Metal-plastic filament

All "metal" filaments on the market are actually thermoplastics mixed with a small amount of metal. Such 3D printing materials allow you to create objects with the visual properties of these metals. Metal-plastic filaments are heavier than conventional thermoplastics. Popular composites for 3D printing are bronze, copper, steel, and iron. Keep in mind that these printouts require post-processing to make them look like metal. Also make sure your printer's nozzle can handle this material.

Such 3D printing materials allow you to create objects with the visual properties of these metals. Metal-plastic filaments are heavier than conventional thermoplastics. Popular composites for 3D printing are bronze, copper, steel, and iron. Keep in mind that these printouts require post-processing to make them look like metal. Also make sure your printer's nozzle can handle this material.

- Technologies: FDM

- Features: metal look

- Applications: fine arts

Alumide

This is a nylon version with aluminum particles. In terms of durability and physical characteristics, it is very similar to nylon. The difference is that it is shiny, wear-resistant and has a porous surface. Objects printed with aluminium can be very precise in size, durable and long lasting. Alumide, like other similar materials for 3D printing, lends itself well to various kinds of post-processing, such as polishing and coating.

- Technologies: SLS

- Features: Rugged, heat resistant, high resolution

- Applications: DIY projects, functional prototypes, mass production

Wood

Human inquisitiveness knows no bounds, so it was only a matter of time before the engineers succeeded in adding wood fibers to plastic filament. Wood 3D prints can be processed like real ones, they can be sawn, sanded and painted. And while this kind of exotic 3D printing material is aesthetically pleasing, it doesn't have the same functional characteristics as the original. For example, you will not be able to make a chair out of it.

Wood 3D prints can be processed like real ones, they can be sawn, sanded and painted. And while this kind of exotic 3D printing material is aesthetically pleasing, it doesn't have the same functional characteristics as the original. For example, you will not be able to make a chair out of it.

Interestingly, by changing the extrusion temperature, it is possible to change the shades of brown in the wood filament. 3D printing at a lower temperature produces a very light shade, while at a higher temperature it produces a solid dark brown. Therefore, if you decide to imitate growth rings in a printout, play with temperature. Depending on the brand of wood filament, the printing process may be accompanied by the smell of wood. Some manufacturers offer a wide selection of such material - birch, olive, bamboo, willow ...

- Technologies: FDM

- Characteristics: fragile

- Applications: concept models, fine arts

METALS

Our guide to 3D printing materials would be incomplete without metals. Metal 3D printing has gained particular popularity in the aerospace, automotive and medical industries for its ability to create complex designs that do not require additional welding or machining. The disadvantage of these materials is that they require a lot of experience in development and combination.

Metal 3D printing has gained particular popularity in the aerospace, automotive and medical industries for its ability to create complex designs that do not require additional welding or machining. The disadvantage of these materials is that they require a lot of experience in development and combination.

In addition, they cannot be printed at home because they require high temperatures and large, specialized printers.

Learn more about metal 3D printing in our comprehensive article Everything you need to know about metal 3D printing

Aluminum

wide range of applications. Basically, we are talking about different alloys based on it. Aluminum elements can have thin walls and complex geometries, they tolerate physical stresses and high temperatures well, which is extremely important for low-cost prototypes, functional models, in particular for engines in the automotive and aerospace industries.

- Technologies: direct metal deposition, binder inkjet printing

- Characteristics: light, strong, heat-resistant, not afraid of corrosion

- Applications: functional models, mass production (automotive and aerospace)

Cobalt Chrome

The next material on the list is used for very serious applications. Chrome-cobalt is sometimes referred to as chromium-cobalt-molybdenum or cobalt-chromium, and sometimes simply as a superalloy. Its main use is in medical applications and in the aerospace industry, where it can be found in turbines and jet engines. It has outstanding strength, heat and corrosion resistance and is suitable for fine work.

Chrome-cobalt is sometimes referred to as chromium-cobalt-molybdenum or cobalt-chromium, and sometimes simply as a superalloy. Its main use is in medical applications and in the aerospace industry, where it can be found in turbines and jet engines. It has outstanding strength, heat and corrosion resistance and is suitable for fine work.

- Technologies: direct metal laser sintering, SLM

- Characteristics: biocompatible, durable, corrosion resistant, heat resistant, wear resistant, low electrical conductivity

- Applications: series production (medical and aerospace)

Copper and bronze

With rare exceptions, copper and bronze are used in investment casting processes and to a lesser extent in formed bed sintering. Due to their electrical conductivity, they are often used in electrical engineering. They are also very popular as art materials and with artisans.

- Technologies: investment casting, formed layer sintering, direct metal deposition

- Characteristics: electrical conductivity, wear resistance

- Applications: series production (electrical engineering), fine arts

Inconel

Inconel is a super alloy designed for the most extreme conditions. It consists mainly of nickel and chromium and is extremely heat resistant. Also resistant to extreme pressures, Inconel is indispensable in the production of aircraft black boxes and even rocket engine parts. Even more often, these features are used in solutions for the oil and chemical industries. The material is very strong and difficult to process, so direct laser sintering is preferred to obtain products of the desired shape.

It consists mainly of nickel and chromium and is extremely heat resistant. Also resistant to extreme pressures, Inconel is indispensable in the production of aircraft black boxes and even rocket engine parts. Even more often, these features are used in solutions for the oil and chemical industries. The material is very strong and difficult to process, so direct laser sintering is preferred to obtain products of the desired shape.

- Technologies: direct metal laser sintering

- Features: heat resistant, wear resistant

- Applications: petroleum, chemical and aerospace industries

Nickel

Nickel alloys are popular for 3D printing applications. Nickel alloy elements are stronger and more durable than traditional methods such as casting. This, in turn, allows engineers to create thinner parts, leading to more fuel-efficient aircraft, for example. There are many types of alloys that combine the characteristics of nickel and other materials such as monel or inconel.

- Technologies: formed bed sintering, direct metal deposition

- Features: strong, lightweight

- Applications: series production (automotive and aerospace)

Precious metals (gold, silver, platinum)

Most formed bed sintering companies can work with precious metals such as gold, silver and platinum. Here, in addition to the aesthetic qualities of materials, it is very important not to lose a single crumb of precious powder. Therefore, such parts are more often produced where a more easily controlled investment casting technology is used. Precious metals are used as materials for 3D printing in jewelry, medical solutions and electronics. Depending on the technology used, some of these materials may be used for casting.

- Technologies: Formed-bed sintering, investment casting, bonded inkjet printing

- Features: high resolution, smooth surface

- Applications: jewelry, dentistry, functional models

Stainless steel

If you're looking for cheaper metal in this guide to 3D printing materials, it's stainless steel. It is also very durable and can be used in many industrial and even artistic applications. Stainless steel alloys containing cobalt or nickel are extremely difficult to break, but have excellent elasticity and good magnetic properties. If you need a different color - please: steel can be coated, for example, with gold. The materials in question are mainly used for industrial purposes.

It is also very durable and can be used in many industrial and even artistic applications. Stainless steel alloys containing cobalt or nickel are extremely difficult to break, but have excellent elasticity and good magnetic properties. If you need a different color - please: steel can be coated, for example, with gold. The materials in question are mainly used for industrial purposes.

- Technologies: direct metal deposition, binder inkjet printing

- Characteristics: high resolution, corrosion resistance, some flexibility, strength

- Applications: tools, function models, mass production

Titanium

Pure titanium powder is often used in 3D printing. This is one of the most versatile materials - it is both durable and lightweight. They work with it using the technology of sintering in the formed layer or inkjet printing with a binder. It is most commonly found in demanding medical solutions, such as custom-made prostheses. Other uses for this material are parts and prototypes for aerospace, automotive and tool manufacturing. In addition to the price, it has another unpleasant feature - its powder explodes easily. Therefore, they print in a vacuum or in argon.

Other uses for this material are parts and prototypes for aerospace, automotive and tool manufacturing. In addition to the price, it has another unpleasant feature - its powder explodes easily. Therefore, they print in a vacuum or in argon.

- Technologies: formed bed sintering, binder inkjet printing, direct metal deposition

- Characteristics: biocompatibility, high resolution, heat resistance, high wear resistance

- Applications: tools, function models, mass production (automotive, aerospace and medical)

CERAMIC

(Source: SONY DSC)

Ceramic is such a popular material for 3D printing in specialized services that custom-made coffee mugs, for example, have become commonplace. And with specialized extruders such as the WASP Clay 2.0, ceramics are also relevant in home 3D printing.

Clay consists of kaolinite and some other minerals, as well as a certain amount of water, which gives it plasticity. After the ceramic piece is printed, it is cured in an oven. The water evaporates and the minerals fuse together, maintaining the object's shape and strength. To make the printout shine, it is covered with glaze and placed in the oven again.

The water evaporates and the minerals fuse together, maintaining the object's shape and strength. To make the printout shine, it is covered with glaze and placed in the oven again.

Ceramics can be printed using both conventional FDM technology and complex methods such as SLA. Beginning "potters" are offered a choice: glass, porcelain or carborundum (silicon carbide). The resulting products are distinguished by heat resistance and wear resistance and today most often act as works of art, as well as dishes and dentures.

- Technologies: FDM, binder inkjet, SLA

- Characteristics: heat resistance, wear resistance, brittleness, porous surface

- Applications: fine arts, mass production (dishes, dentistry)

WAX

Wax 3D prints are not usually the final product, but they are an important milestone in a long journey. They are relevant for very high resolution molding (0.025 mm), as well as for investment casting. They are often used in the creation of custom-made jewelry, and at a relatively low price. Another industry that uses this kind of 3D printing materials is dentistry. When creating complex structures, wax, due to its low melting point, is an excellent material for props.

Another industry that uses this kind of 3D printing materials is dentistry. When creating complex structures, wax, due to its low melting point, is an excellent material for props.

- Technologies: SLA, PolyJet

- Features: high resolution, smooth surface

- Applications: series production (jewelry, dentistry)

PAPER

With Selective Deposition Lamination (SDL) technology, good old stationery around the corner finds its niche in 3D printing. SDL objects are tree-like, full-color, and this makes them popular in architectural and other conceptual models. On the other hand, parts made from SDL are not as strong as those made from other materials and do not have the level of detail that those made from PolyJet plastic or plaster.

- Technologies: Selective Deposition Lamination

- Features: cost effective, recyclable, full color

- Applications: concept models, fine arts

SANDSTONE

Sandstone as a printing medium is sometimes referred to as gypsum (in fact, gypsum is a component of natural sandstone) and is used to create impressive full-color objects in one process. To enhance the color and add strength, the printouts are covered with a protective layer of epoxy, without this the moisture will do its job and the sandstone will discolour. Objects turn out to be fragile, like porcelain, and this must be taken into account at the design stage. Bearing in mind the capriciousness of sandstone, it is mainly used in architectural models, concept prototypes and art projects.

To enhance the color and add strength, the printouts are covered with a protective layer of epoxy, without this the moisture will do its job and the sandstone will discolour. Objects turn out to be fragile, like porcelain, and this must be taken into account at the design stage. Bearing in mind the capriciousness of sandstone, it is mainly used in architectural models, concept prototypes and art projects.

- Technologies: FDM, binder inkjet, formed bed sintering

- Features: fragile, full color

- Applications: concept models, fine arts

- Technologies: SLA

- Characteristics: smooth surface, some flexibility

- Applications: concept models, functional models, fine arts, tools (prototypes)

(PHOTOS) POLYMERS

(Photo: Nervous System)

Photopolymers are a type of liquid resin that hardens when exposed to ultraviolet (UV) electromagnetic radiation or visible light. Today, they work mainly on two technologies - SLA (stereolithography) and PolyJet. SLA uses a UV laser to project a slice of an object onto the surface of a photopolymer poured into a bath, which solidifies into the shape of the object's layer. This is repeated for all layers.

This is repeated for all layers.

PolyJet technology takes a different approach. The printer directs a jet of resin onto a substrate, on which the resin is continuously cured by a UV lamp. SLA prints layers no thinner than 0.1 mm, and PolyJet produces up to 16 microns. And although the methods are similar and they use similar materials, the big difference lies in the methods of working with materials.

All photopolymers are sensitive to sunlight.

SLA Resins

Many SLA Resins are designed to mimic the different properties of the "traditional" materials discussed above. For example, there are materials that are compatible with wax, they are used to create impressions in investment casting. And if biocompatibility is important, then there are thermoplastics for SLA, which are very similar to PLA. Other SLA plastics can be as strong as ABS. There are even composite materials for SLA printing that have the properties of ceramics: the objects obtained on the printer can be put in an oven and then treated like ceramic.

Resins are an excellent choice for functional and conceptual models. They are especially good if you want to get a large object in a short time, while with a high level of detail. Some polymers even become hard enough for machining after quenching. In addition, high-temperature polymers are a cost-effective replacement for mold materials for low-volume moldings.

The popularity of the SLA process lies in its excellent speed and accuracy. The downside is that polymers are still significantly more expensive than everything that was mentioned here.

SLA printers are sold, you can work with them both at home and in a small office and use very interesting materials for semi-professional 3D printing.

PolyJet resins

(Source: Printshow)

Like SLA resins, PolyJet materials mimic the different properties of "traditional" 3D printing materials. Most PolyJet resins have fairly descriptive names. For example, rigur is designed for strength and sounds similar to the Latin root for hardness. It is also called "simulated propylene" for the similarity of the surface and functionality. A number of 3D printing materials are referred to as "digital ABS" because they are heat resistant and durable. Rubber-like materials are designed for non-slip surfaces and to absorb vibrations. Since there are so many PolyJet polymers, we decided to refrain from a detailed description of each of them.

Most PolyJet resins have fairly descriptive names. For example, rigur is designed for strength and sounds similar to the Latin root for hardness. It is also called "simulated propylene" for the similarity of the surface and functionality. A number of 3D printing materials are referred to as "digital ABS" because they are heat resistant and durable. Rubber-like materials are designed for non-slip surfaces and to absorb vibrations. Since there are so many PolyJet polymers, we decided to refrain from a detailed description of each of them.

It should be noted, however, that PolyJet polymers differ from SLA in that they allow obtaining the so-called. digital materials. These are mixtures of up to three 3D printing materials to obtain specific properties (strength, heat resistance, transparency, etc.) for a specific part and in a specific color range. This is a bright path to radiant prospects. While other materials described in this review allow you to create only a visual imitation of "traditional" objects, objects from PolyJet can also imitate tactile sensations, actually replacing reality.