Dsm 3d printing

DSM 3D Printing Filament | MatterHackers

- Home

- Store

- 3D Printer Filament

- DSM 3D Printing Filament

Committed to the science-driven development of an ever-increasing catalog of advanced 3D printing materials, DSM continues to raise the bar in materials applications with innovations that improve heat stability, hydrolysis resistance, wear and friction, thermal conductivity, soft touch, and high barrier properties. These innovations translate into materials that make people’s lives safer, healthier, and more convenient. With their in-depth know-how and giant portfolio of high-quality materials, they work with manufacturers worldwide to consistently update and innovate new solutions. DSM has translated its most popular injection-molding materials into ready to print, 3D printing materials. Novamid®, a nylon-based polyamide6/66 material; Arnitel® is a 100% recyclable engineering plastic previously used in dashboard production and other large-scale automotive injection molds; and Arnite® is a pure PET material, which is perfect for high-temperature applications that require increased dimensional stability.

DSM 3D Printing Filament Collections

All DSM 3D Printing Filament 3D Printer Filament

DSM 3D Printing Filament

DSM Novamid 3D Printing Filament

Advanced material for automotive and electrical 3D printing applications.

DSM Arnite 3D Printing Filament

Versatile, sustainable, high-performance 3D printing thermoplastics.

DSM Arnitel 3D Printing Filament

A superior flexible filament for automotive and industrial applications.

Guides & Articles

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

Learn how to print this material like a Pro in this in-depth guide.

How to Succeed when 3D Printing with PETG Filament

This in-depth guide provides everything you need to succeed when printing with PETG filament. Embrace the fantastic properties of durable and easy to print, PETG filament!

How to Succeed with 3D Printing Metal on a Desktop 3D Printer

The time is here to explore easy and affordable metal 3D printing. 3D printing with real metal on a desktop 3D printer is now possible using Ultrafuse Metal 3D printing filament from BASF Forward AM.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When Printing With Flexible Filament

Let’s take a look at what makes flexible filaments easier to print and how you can add flexible filament to your 3D printing material toolbox.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

How to Succeed When 3D Printing with MH Build Resin

Make SLA resin 3D printing easier with this helpful detailed article on how to successfully fine-tune photopolymer resin to your 3D printer.

How To Succeed: 3D Printing with Nylon and Nylon Composites

Nylon and nylon composites perform exceptionally well in a variety of uses, it just takes a gentler touch to print it successfully.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

DSM is a world leader in manufacturing and a trusted brand with over 100 years of experience creating and improving high-performance, engineering-grade thermoplastics that are used worldwide in industrial applications that produce and manufacture automotive, electrical and electronics, building and construction, medical, and consumer goods, to name but a few. Focused on creating more sustainable thermoplastics, DSM’s company strategy is in line with the United Nation’s Sustainable Development Goals (SDGs) to help reduce waste and carbon emissions. DSM’s materials help create stronger, more durable products while raising the bar on creating more environmentally-friendly manufacturing methods.

Focused on creating more sustainable thermoplastics, DSM’s company strategy is in line with the United Nation’s Sustainable Development Goals (SDGs) to help reduce waste and carbon emissions. DSM’s materials help create stronger, more durable products while raising the bar on creating more environmentally-friendly manufacturing methods.

Covestro acquires DSM Additive Manufacturing, outlines plans to “bring benefits of SLA to DLP”

0Shares

German polymer manufacturer Covestro has completed its acquisition of DSM’s Resins & Functional Materials unit, including its 3D printing offering, and the ex-DSM team is working to “bring the benefits of SLA to DLP” with a new line of Somos resins.

According to what was DSM, and is now Covestro, the adoption of DLP/LCD 3D printing is growing rapidly thanks to the technology’s high throughput capabilities, but existing materials are proving to be a barrier to scalability. To prevent the distortion that’s often seen in prints from larger 8K machines, the firm is now working on a new range of ‘hybrid resins’ with an SLA-like chemistry, that could yield parts with significantly reduced shrinkage.

“What we’re seeing in the DLP world is that these printers were very small, but they’re getting much larger now,” explained Andrew Graves, Equipment Partnership Manager at former-DSM-now-Covestro. “DLP is getting to 4K and 8K, and the LCD printers are kind of unlimited about how big they can get.”

“As printers get larger, you’re going to get distortion and a lot of curling using current materials,” he added. “So we are looking at bringing our expertise in SLA hybrid materials into the DLP and LCD world for end-use, and specifically, for larger parts that need to be accurate and conform to an engineering drawing.”

Covestro has now completed the acquisition of DSM’s Resins & Functional Materials business. Image via Covestro.“We are bringing our expertise in the engineering polymers field to DLP and LCD printers.”

An expanded polymeric portfolio

Based in the Dutch city of Geleen, DSM’s former 3D printing materials division was acquired by Covestro in a deal announced last year, and formally absorbed into its wider business on April 1st 2021. Prior to its acquisition, the subsidiary had built up a broad material portfolio, purchasing part of Clariant’s filament and pellet range in June last year, that will now serve to supplement Covestro’s burgeoning product line-up.

Prior to its acquisition, the subsidiary had built up a broad material portfolio, purchasing part of Clariant’s filament and pellet range in June last year, that will now serve to supplement Covestro’s burgeoning product line-up.

The ex-DSM division’s range already caters for a broad church of printing technologies, and includes everything from FDM-suitable filaments to SLS-ready powders. Over the last two years, the team has developed glass-filled 3D printing pellets as well as new sustainable materials, debuting its bio-based EcoPaXX AM4001 GF polymer in November 2020.

Elsewhere, leveraging its growing expertise in large-format printing, the former DSM team has contributed to a number of eco-friendly infrastructure projects, including a Dutch 3D printed footbridge built entirely from recycled materials. Moving forwards, the team continues to encourage more sustainable production, and is currently developing a Life Cycle Assessment (LCA) tool for assessing the green merits of its upcoming products.

Levelling-up DLP printing

Another core component of the team’s future material strategy, lies in its analysis of trends within the DLP and LCD 3D printing segments. According to the company, light-powered machines have grown larger to the point that there’s now a demand for resins that offer reduced distortion, yet there aren’t any materials that offer SLA-like stability on the market.

“All SLA materials that are available today from either Covestro (formerly DSM) or other companies, consist of a hybrid chemistry which is an epoxy acrylate combination with two materials and two photo-initiators,” explained Graves. “It gives you tough materials with very low shrinkage, which is important when you’re building large parts.”

By launching DLP resins that feature a unique acrylate/epoxy-based chemistry, the ex-DSM team is therefore aiming to corner a market niche for DLP/LCD-optimized hybrid materials. Under DSM, the company previously dipped its toe into the market with the launch of the non-hybrid Somos QuickGen 500, a dedicated DLP polymer with enhanced flexibility, and it intends to supplement this portfolio moving forwards.

Under DSM, the company previously dipped its toe into the market with the launch of the non-hybrid Somos QuickGen 500, a dedicated DLP polymer with enhanced flexibility, and it intends to supplement this portfolio moving forwards.

In terms of speed, the resin is reportedly capable of printing twice as quickly as other similar polymers, making it better-suited to functional prototyping applications. Later this year, Covestro (formerly DSM) also plans to launch the Somos PerFORM HW, a new hybrid material that could take DLP to the next level by bringing true SLA functionality to market.

Previewing the PerFORM

The former DSM team has worked closely with various 3D printer manufacturers to optimize the performance of SomosPerFORM HW. During initial testing, the material reportedly demonstrated an SLA-like tensile strength after post-curing of 80 MPa, in addition to an extremely high heat resistance to temperatures up to 260°C.

Having successfully tweaked the formulation of its new material based on the feedback gained via test prints on their partners’ machines, the team is lining up a Q2 2021 release for its first truly-hybrid DLP polymer.

“As far as we know, there’s nothing like it,” concluded Graves. “If you look at the PerFORM HW, there are competitive versions of PerFORM for the SLA, and there are similar materials in the DLP world, but there’s nothing that is based on this hybrid chemistry, which offers the same low shrinkage and high accuracy in the DLP world.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows two jigsaw pieces representing DSM and Covestro being put together. Image via Covestro.

Tags Andrew Graves Clariant Covestro DSM EcoPaXX AM4001 GF Somos PerFORM HW Somos QuickGen 500

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

Free STL file Keychain 3D printing DSM file with custom text・3D printing idea for download・Cults

Watch Strap Adapter for Casio General Standard 18mm to NATO Zulu 22mm

2,62 €

Watch Strap Adapter for Casio DW291H / DW-291H to Nato 24mm

2.91 €

STRAP ADAPTER FOR CASIO F91W WATCH TO NATO ZULU 18 MM

2,80 €

Strap Adapter for G-Shock GA1000 to 22mm Nato Zulu

2 €

Mini Portable Desk Stand for Rode Videomicro

0.88 €

Nato strap adapter for Casio DBC32 to Nato 24 mm

1 €

Watch Strap Adapter for Suunto Core to Nato 24mm

3,05 €

Casio F91W and F94W bezel for 22 mm strap

4,50 €

The best files for 3D printers in the Tools category

Star Trek TNG Phaser

Free

Macrotube micro 4/3 - macro ring - extension for lens m4 / 3

2,50 €

Wall mounted reel rack saves space

Free

4mm Platform Clip

Free

Jet Engine, Geared Turbofan (GTF)

Free

Proton - Open Source 3D Printer

Free

100% Printable Lock

Free

Engineers Hammer Holder 100g 027 I for screws or peg board

Free

Bestsellers in the Tools category

Chill Buddy 9 lighter case0004

1. 01 €

01 €

UNIVERSAL BED LEVELING INDICATOR FOR PRACTICALLY ALL PRINTERS

3,19 €

well designed: Hemera fan duct

2.50 €

Tool holder for 3D printer V3.0

1.12 €

SUPERBOX

1,50 €

BED LEVELING INDICATOR FOR ENDER 3 PRO

3.19 €

Filament shielding

2.95 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.68 €

NEW GENERATION CAR PHONE HOLDER

2,50 €

NASA BOX

2.05 €

PRECISION CALIPER 3D PRINT DIY

3,03 €

Paint stand with scissors

5. 62 €

62 €

Business card embossing system

3 €

GEAR AND DRIVE

3.56 €

Grinder | Grinder

€1.50

Quick Print Stackable Parts Containers / Storage Boxes

2.88 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

3D printing using the new MOVINGlight technology

Alla Aspidova, Ivan Papusha – [email protected]

Published in issue: Control Engineering Russia August 2017

PDF version

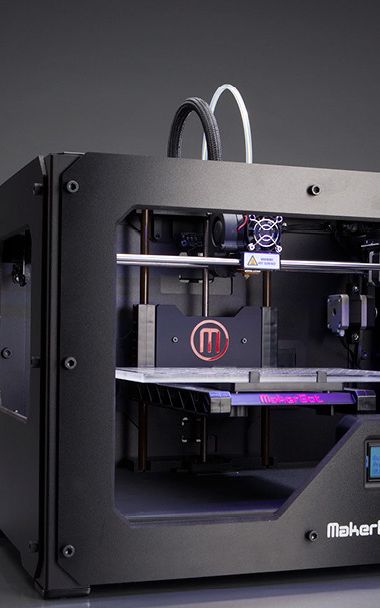

Today, additive technologies are confidently gaining a place in the manufacturing process. A 3D printer has long ceased to be a toy in the hands of experimental enthusiasts and has become a means of production, or at least a technological link - for example, GE successfully uses metal 3D printing in the production of gas turbine engines. And thanks to the creation of new materials, even well-known technologies such as stereolithography (SLA) or plastic filament deposition (FDM) can gain a second wind and open up more applications.

If 10 years ago in Russia 3D printers were used only in some closed enterprises, then over the next decade we may well see a change in the usual cycles and principles of production due to the introduction of additive technologies on an industrial scale. In addition, we are already actively working on the standardization and regulation of the use of 3D printers in production at the state level.

In addition, we are already actively working on the standardization and regulation of the use of 3D printers in production at the state level.

Ostek-SMT LLC not only offers equipment for industrial 3D printing, but also conducts its own research, which makes it possible to profitably apply existing technologies to solve complex problems. This article will take a fresh look at stereolithography, or 3D printing with a light-cured photopolymer.

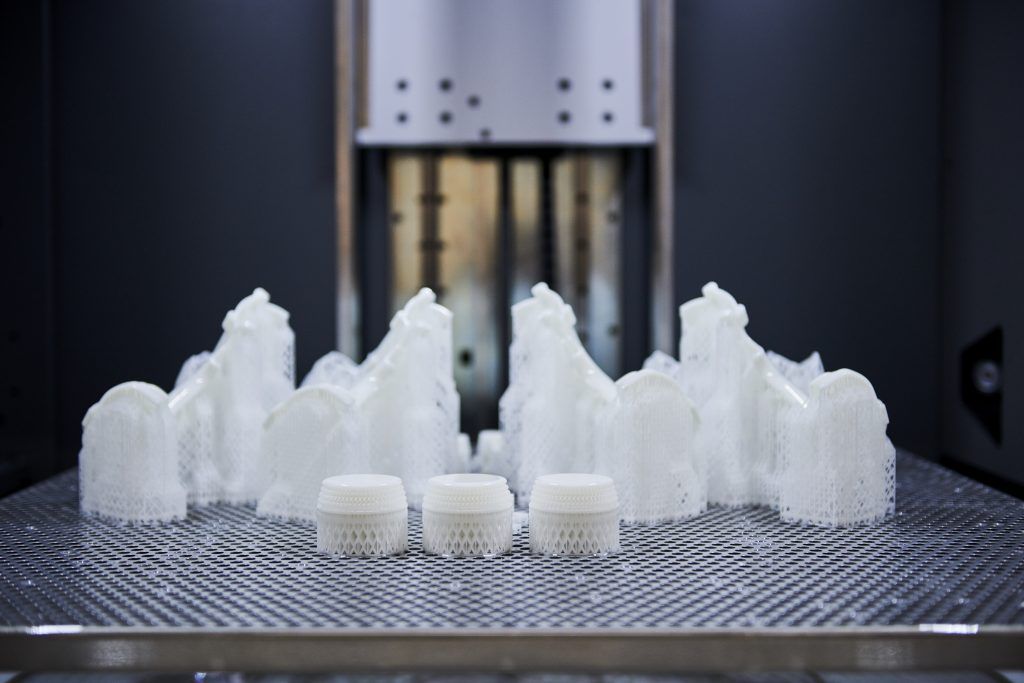

Benefits of MOVINGlight technology

Stereolithography started the development of 3D printing technology. She appeared in the 1980s. in the United States, then used in the USSR. Its essence is quite simple: the model is built in a tank with a liquid photopolymer, the product is virtually divided into layers by means of software, and an ultraviolet laser installed above the tank illuminates the photopolymer according to the shape of each layer. In the 2010s the technology has been upgraded: instead of a slow laser, MOVINGlight uses a fast ultraviolet projector, which, by moving, allows you to increase the speed of production up to ten times. In addition, a wider range of applied materials has become available: from high-temperature plastics to bio- and oxide (technical) ceramics (Fig. 1). The result of printing using MOVINGlight technology is precise plastic and ceramic products (up to 0.1% of linear dimensions) with high surface quality: Ra is 0.5–5 microns. The hardware resolution of such a 3D printer makes it possible to print 605 × 605 × 1016 dpi (resolution of the order of 40 microns).

In addition, a wider range of applied materials has become available: from high-temperature plastics to bio- and oxide (technical) ceramics (Fig. 1). The result of printing using MOVINGlight technology is precise plastic and ceramic products (up to 0.1% of linear dimensions) with high surface quality: Ra is 0.5–5 microns. The hardware resolution of such a 3D printer makes it possible to print 605 × 605 × 1016 dpi (resolution of the order of 40 microns).

Fig. 1. Working area of Prodways 3D printer powered by MOVINGlight technology

Due to the size of the printing area, MOVINGlight technology can be used to print both small and large items - up to 800×330×400 mm. The variety of available materials allows the use of a multifunctional printer, and also allows the implementation of effective solutions for layer-by-layer additive growth in many areas, including biomedicine and industry (table).

| PLASTCure Model 100* | PLASTCure Model 300* | PLASTCure Clear 100* | PLASTCure Clear 200* | |

| Appearance | Beige Opaque | Reddish beige opaque | Transparent material | Transparent material |

| Liquid density (g/cm 3 ) | 1. 113 113 | 1.105 | 1.113 | 1.103 |

| Viscosity at +28°C (cP) | 600–700 | 300–400 | 600–700 | 500–600 |

| Hardness (Shore D ) | 85–90 | 85–90 | 80–85 | 85–90 |

| Tensile strength A5TM D638 (MPa) | n/a | n/a | n/a | n/a |

| Elongation at break ASTM D638 (%) | n/a | n/a | n/a | n/a |

| Tensile modulus ASTM D638 (MPa) | n/a | n/a | n/a | n/a |

| Residual ash | Not applicable | Not applicable | Not applicable | Not applicable |

| Flexural strength ASTM D790-10 (MPa) | 75–85 | 110-120 | 80–90 | 110–120 |

| Flexural modulus ASTM D790-10 (MPa) | 1900-2100 | 2300–2500 | 2000–2200 | 2400–2600 |

| Impact strength Izod ASTM D256A (J/m) | n/a | n/a | n/a | n/a |

| Heat resistance bending at 0.  46 MPa ASTM D648 (°C) 46 MPa ASTM D648 (°C) | n/a | n/a | n/a | n/a |

| Specifications | Easy construction of parts. High precision components. Quality appearance. | High accuracy and good resolution. Ability to produce products with sharp edges and a high level of detail. High green strength and good mechanical properties. | Ultra clear material. End products are biocompatible. Meets the criteria for irritation, sensitization and cytotoxicity for the biological evaluation of medical devices (DIN ISO 10993). Can be steam sterilized for extended periods (>15 min). | Ultra clear material. |

| Typical applications | Manufacture of the entire range of dentition models: from filling to orthodontic treatment. | Manufacture of the entire range of dentition models: from filling to orthodontic treatment. | Wide range of medical applications such as surgical templates or models. | Wide range of applications where transparent materials are required, such as surgical guides or models. |

| Manufacturer | Drave | Prodways | Drave | Prodways |

| PLASTCure Cast 100* | PLASTCure Cast 200* | PLASTCure Rigid 10 500* | PLASTCure ABS 3650* | PLASTCure ABS 2800* | |

| Appearance | Red translucent material | Orange translucent material | Ivory Opaque | Transparent material | White material |

| Liquid density (g/cm 3 ) | 1. 095 095 | 1.114 | 1.595 | 1.109 | 1.109 |

| Viscosity at +28°C (cP) | 100–200 | 250-300 | 650–750 | 100–200 | 140-150 |

| Hardness (Shore D ) | 80–85 | 85–90 | 90–95 | 85–90 | 85–90 |

| Tensile strength A5TM D638 (MPa) | 40–50 | n/a | 68 | 53 | 55–60 |

| Elongation at break ASTM D638 (%) | 3–4 | n/a | 1–2 | 9 | 3–5 |

| Tensile modulus ASTM D638 (MPa) | 2300–2500 | n/a | 10000-11000 | 2600-3650 | 2700–3000 |

| Residual ash | <0.1% | <0.1% | Not applicable | Not applicable | Not applicable |

| Flexural strength ASTM D790-10 (MPa) | 90–100 | 65–75 | 100–140 | 90–100 | 100-110 |

| Flexural modulus ASTM D790-10 (MPa) | 2300–2500 | 1600–2000 | 8000-10000 | 2000–2200 | 2600–3000 |

| Impact strength Izod ASTM D256A (J/m) | n/a | n/a | 17 | 20 | n/a |

| Heat resistance bending at 0.  46 MPa ASTM D648 (°C) 46 MPa ASTM D648 (°C) | n/a | n/a | 132 | 96 | n/a |

| Specifications | High reactivity and low viscosity. High green strength, good dimensional stability. Good burnout qualities and low residue content. Can be placed directly at +800°C. | Good reactivity and low viscosity. High precision. Ability to produce parts with sharp edges. Suitable characteristics for near zero ash burnout. | Good detailed resolution and sidewall quality. Easy handling. Improved thermomechanical properties. | Good chemical resistance. High transparency. Fast material adaptation to a wide range of building conditions. No manual processing required.  | Good chemical resistance. High transparency. Fast material adaptation to a wide range of building conditions. No manual processing required. |

| Typical applications | Meets the high demands of digital simulation. | Good for direct investment casting or application in dentistry. | Suitable for parts requiring thermal stability, high precision and fast cycle times. And also for wind tunnel tested products used in unique applications, high speed machining or high temperature testing, used as electrical conduit and housings in the automotive industry. | Well suited for medical, electronics, aerospace and automotive applications that require low temperature curing products, robust concepts, high accuracy, and moisture and temperature resistant products. | Well suited for medical, electronics, aerospace and automotive applications that require low temperature curing products, robust concepts, high accuracy, and moisture and temperature resistant products. |

| Manufacturer | Drave | Prodways | DSM Somos | DSM Somos | DSM Somos |

Applications

Due to the material characteristics listed in the table, MOVINGlight technology is suitable not only for printing high-precision prototypes (Fig. 2), but also for the creation of industrial tooling, and in some cases even final products.

Fig. Fig. 2. Functional prototype printed from ceramic-filled plastic

Let's look at examples of the use of this technology in such areas as plastic printing, injection molding and 3D-MID. Prototypes printed using MOVINGlight technology are already being used as master models for silicone injection molding, but the most interesting application in tooling is direct 3D printing of plastic molds for injection molding of plastics, as well as for vacuum forming. For these tasks, the temperature-resistant material PLASTCure Rigid 10500 with the addition of ceramic powder is used. The temperature that these molds can withstand depends on the geometry of the molded part and the cooling channels. The bending heat resistance at 0.46 MPa ASTM D648 of this ceramic-filled plastic is +132 °C, however after hardening it is possible to obtain a bending heat resistance at 0.46 MPa ASTM D648 of the order of +260 °C.

The temperature that these molds can withstand depends on the geometry of the molded part and the cooling channels. The bending heat resistance at 0.46 MPa ASTM D648 of this ceramic-filled plastic is +132 °C, however after hardening it is possible to obtain a bending heat resistance at 0.46 MPa ASTM D648 of the order of +260 °C.

Prodways, a 3D printer manufacturer, conducted an experiment to test the capabilities of MOVINGlight technology in the production of molds for small-scale injection molding.

PLASTCure Rigid 10500 was printed into a two-part plastic injection mold for 3D printing. The objective was to produce at least 250 castings from polypropylene and polyformaldehyde and at least 30 castings from glass-filled polyamide. The dimensions of the parts are small and medium, in this case, injection machines for 50–100 tons were used. The specified number of castings was obtained, and the experiment was recognized as successful (Fig. 3).

Fig. Fig. 3. PLASTCure Rigid 10500 ceramic-filled mold (a) and castings produced in this mold (b)

3. PLASTCure Rigid 10500 ceramic-filled mold (a) and castings produced in this mold (b)

After that, casting tests were carried out on a wider range of plastics. As a result, several hundred castings were obtained from polypropylene (PP), polyethylene (PE), polystyrene (PS), ABS plastic (ABS), thermoplastic elastomers (TPE), polyformaldehyde (POM), polycarbonate-ABS alloy (PC+ABS). ) and polyamide (PA). Also, several dozen castings can be made from glass-filled polyamide (PA+GF), glass-filled polyformaldehyde (POM+GF) and glass-filled polycarbonate (PC+GF).

The advantage of MOVINGlight technology is that a pilot batch of plastic castings can be produced quickly and with minimal financial and time costs for the production of tooling. The mold is designed in CAD and then simply printed on a 3D printer. As a result, pilot production can be reduced from several months to one week with a quality of products similar to castings in aluminum molds.

Another available use of MOVINGlight in combination with PLASTCure Rigid 10500 ceramic resin is printing tooling for vacuum forming a limited series of products or a pilot batch. The advantages in this case are similar, an example of such an application is shown in Fig. 4. The ability to print mesh internal structures of the tooling for molding allows it to be vacuumed more evenly, which, in turn, allows for a closer fit of the heated sheet of material and a higher quality product. This tooling is made in about two days and can be used for a range of 10 to 100 moulds.

The advantages in this case are similar, an example of such an application is shown in Fig. 4. The ability to print mesh internal structures of the tooling for molding allows it to be vacuumed more evenly, which, in turn, allows for a closer fit of the heated sheet of material and a higher quality product. This tooling is made in about two days and can be used for a range of 10 to 100 moulds.

Fig. 4. Products produced by vacuum molding on a tooling made of ceramic-filled plastic PLASTCure Rigid 10500

Ostek-SMT conducted its own experimental work on the use of MOVINGlight technology in creating three-dimensional schemes on plastics (3D-MID), which consist of molded thermoplastic bases with integrated connection system. Products on plastics make it possible to simplify the design, reduce the number of assembly units and the weight of the product, as well as increase its reliability. In addition, they are more environmentally friendly than conventional PCBs, although they are not a replacement, but rather a complement. Key markets for 3D-MID technology are automotive electronics and telecommunications. Apart from these, 3D-MID is also suitable for computers, home appliances and medical technology.

Key markets for 3D-MID technology are automotive electronics and telecommunications. Apart from these, 3D-MID is also suitable for computers, home appliances and medical technology.

There are several prototyping steps between prototype and series production, but for single or small batch production, prototyping is usually either impossible or expensive. This problem can be solved with the help of MOVINGlight technology.

Fig. Fig. 5. Dielectric constant of PLASTCure Rigid 10500

PLASTCure Rigid 10500 was chosen for printing prototypes of products with three-dimensional schemes (Fig. 5), which, in addition to high temperature resistance, has acceptable dielectric constant. Plastic bases for products were printed from it, and a three-dimensional pattern was applied to the base using AJP (Aerosol Jet Printing) conductive material spray printing technology, in this case silver spray. On fig. Figure 6 shows an example of a housing prototype with a working Wi-Fi antenna applied to it, manufactured at the Ostek-SMT production center using MOVINGlight technology.