Starting a 3d printing business reddit

gettingstarted - 3dprinting

- Getting Started

- Why 3D Printing?

- Getting started with 3D Printing

- Where to get a model printed

- What printer to get

- Where to find models

- Material Choices

- Slicers

- Printing and Troubleshooting

- Post Processing

- How to make models

- Further Info

| If you're new around here, welcome! We thought we'd put a few links together to springboard your foray into the fabulous (and sometimes frustrating!) world of 3D printing. :) |

|---|

| If you are contributing to this wiki please keep this page incredibly concise and extremely high level, keep further detail for the Detailed Info pages. |

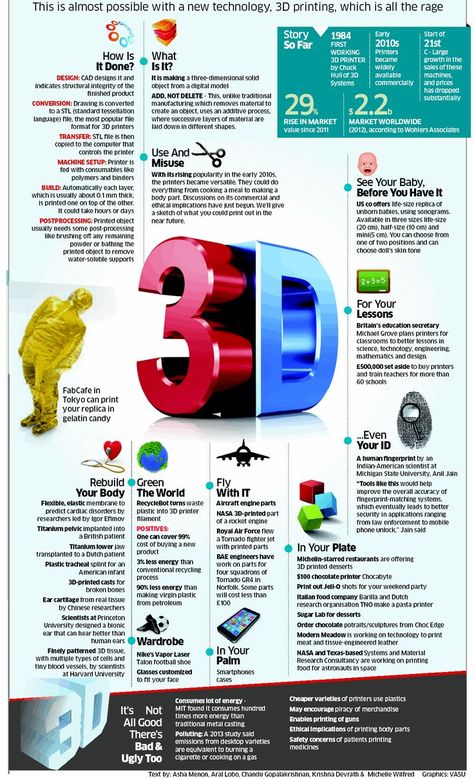

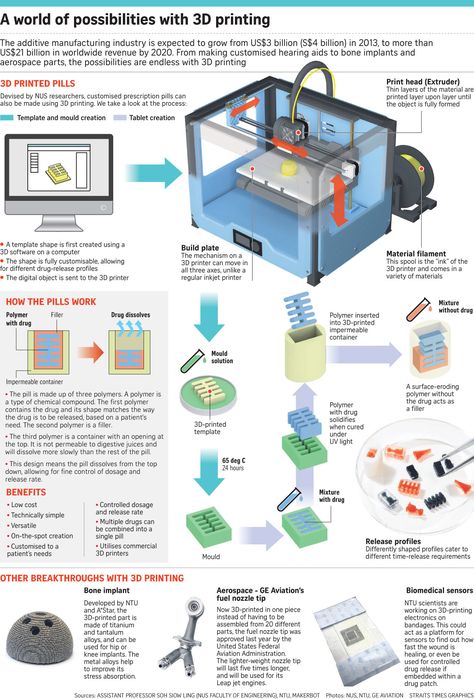

Why 3D Printing?

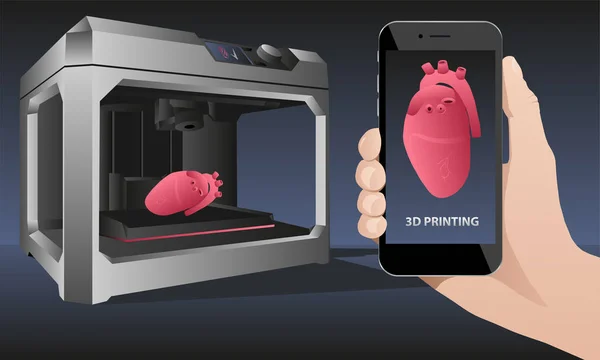

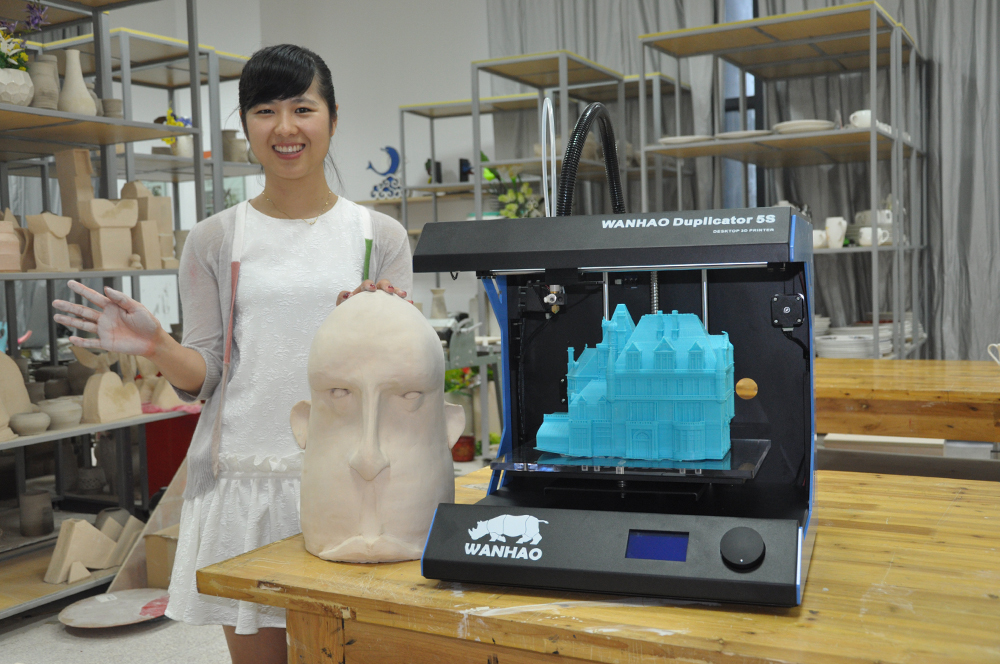

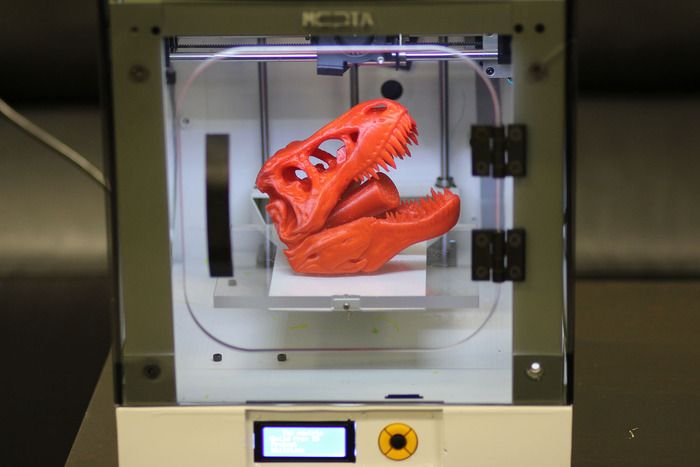

3D printing (a.k.a Additive Manufacturing) is now pretty well established in industry as a prototyping tool, and is becoming more common as a process for creating finished custom or low-run parts.

In the home, printers can be a marvelous tool for solving practical household problems for example by repairing items, or creating new items that are fully customised for their position or use case. They also can be used for fun, and are popular for making tabletop gaming minis, and toys.

For inspiration browse the top posts of this subreddit.

Getting started with 3D Printing

The various types of 3D printing technologies all create real-world three-dimensional objects from digital models via the addition of material. These processes are able to produce novel structures that other manufacturing techniques cannot. Usually the 3D printing process looks like this:

Get a digital 3D model (by downloading or making one)

Slice it (use a program to generate instructions for the printer)

Print it (and troubleshoot it)

Post-process it (remove support material, clean up areas, paint etc)

Where to get a model printed

If you don't want to buy a printer (and you just want to have something printed), you can engage the help of a 3D printing service. Some popular choices include:

Some popular choices include:

For a full list of service-providers (including design and model hosting services), please see the Services page.

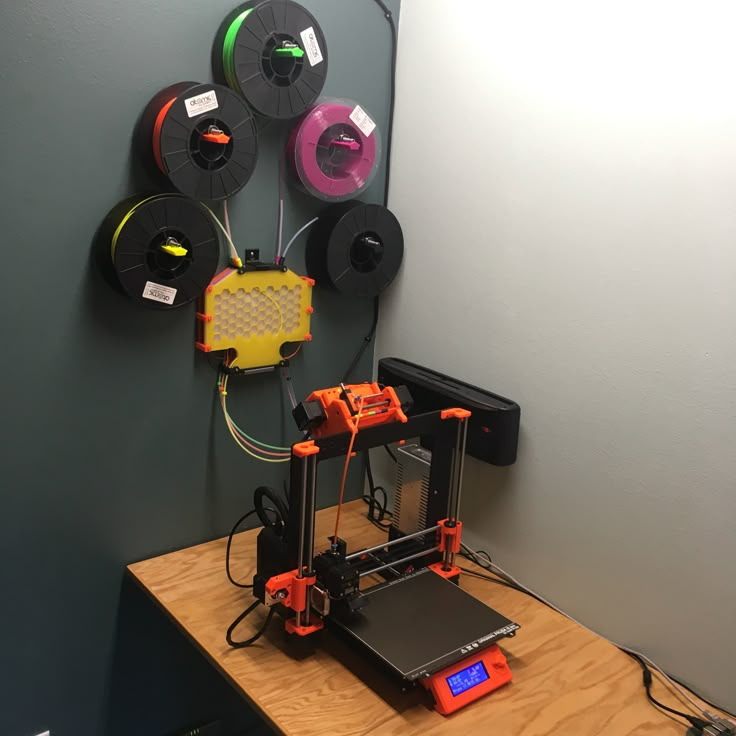

What printer to get

If you're totally new to printing, the best place to ask for help when deciding what printer is right for you is our stickied monthly Purchase Advice Megathread.

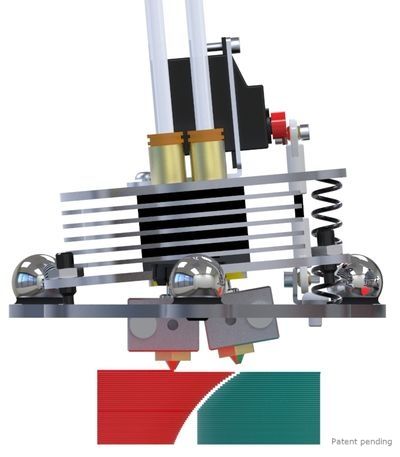

Generally personal printers come in two main categories;

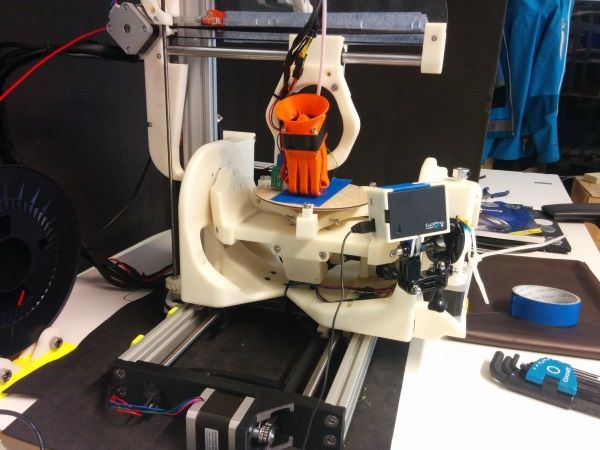

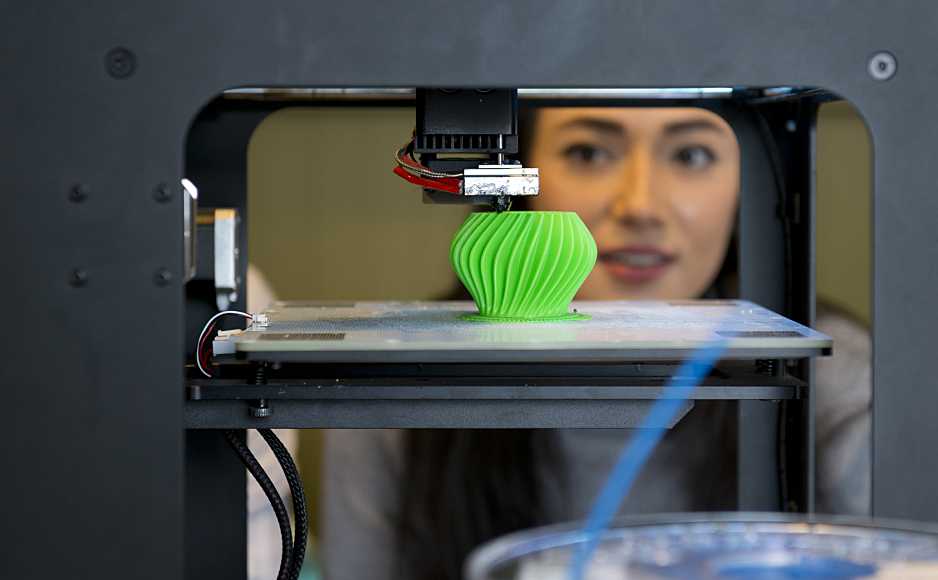

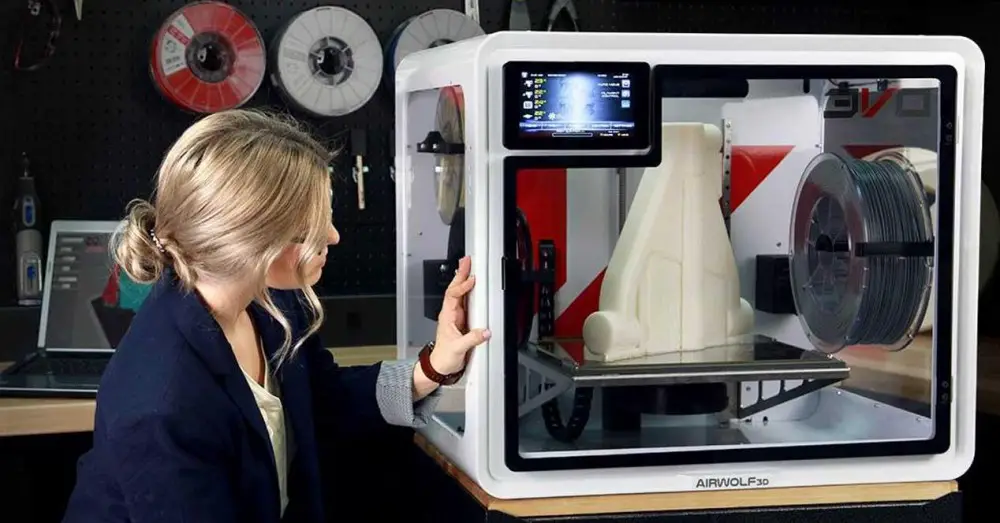

FDM (FFM) printers are best suited to larger objects and functional parts and work a bit like a like a hot glue gun that moves around, extruding plastic filament and building up an object layer by layer.

DLP (Layer Masking) printers are best suited to extremely detailed prints, and use light to cure resin in layers, masking it with an LCD screen.

There are, however, many other types of 3D printing technologies, which are explained here.

Where to find models

If you don't want to make your own models to print, there are many sites that host models for download. The more popular ones are:

The more popular ones are:

Printables: upcoming and community-focused, feature-rich

Thingiverse: biggest model host, often buggy

Thangs: free models, which can be searched by geometry

My Mini Factory: free and paid models, guaranteed to print

GrabCad: functional/ technical models

YouMagine: Open source models

pinshape: free and paid models

yeggi: 3D model aggregator/search

CGTrader: free and paid models, not all of them made to be printed

A community-curated list of model host services can also be found on the services page.

The RepRap foundation also keeps a list of printable model-host services here.

When selecting a model you need to ensure they are manifold, here's an explanation of what that means and guide on fixing them. You can also try these free, automated services; Netfab, and Microsoft's tool

Material Choices

When you are just starting out with FDM 3D printing PLA is the recommended choice. It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

It's very easy to work, relatively strong, with and comes without many of the safety concerns of other materials. A deeper discussion of materials can be found here.

If you are starting on a resin printer, check out our Resin Info page.

Slicers

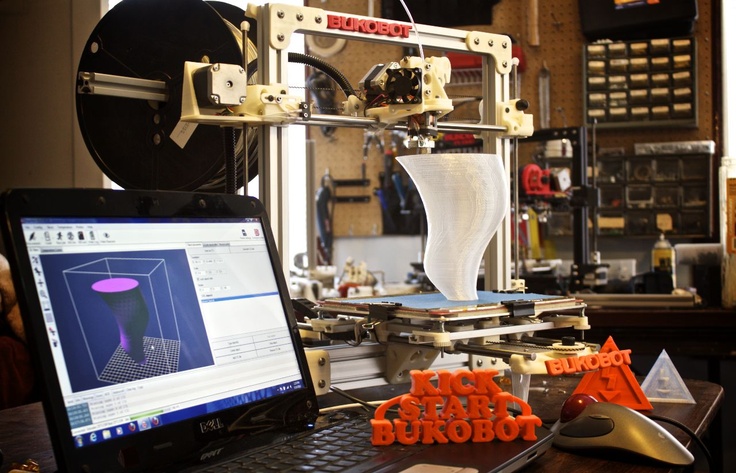

Slicing software takes a 3d model and turns it into instructions for the 3D printer. The instructions are generally exported in GCode which essentially is a list of locations to move to, amount of filament to extrude, etc.

The popular choices for slicing software are:

Ultimaker Cura: free, open source, highly customisable. Getting Started, Full Manual

Prusa Slicer (Based on Slic3r), Beginning with Prusa Edition (old version)

There are, however, many other options, most of which are discussed here

Be sure to check the layer preview to see if it makes sense in your slicer before printing (no unsupported overhangs, no parts missing, etc). More info on the Slicers Page

Printing and Troubleshooting

Follow your manufacturer's instructions in setting up your printer and starting your first print. It's a good idea to print a test print first (usually printers come with one).

It's a good idea to print a test print first (usually printers come with one).

If it succeeds congrats on your first print! You can now start slicing and printing your own models or some calibration prints

If your print fails you can begin troubleshooting.

This video helps you get to know the parts of your machine, so you know what we're talking about! :)

By far the most common reason for prints failing is an issue with levelling/tramming:

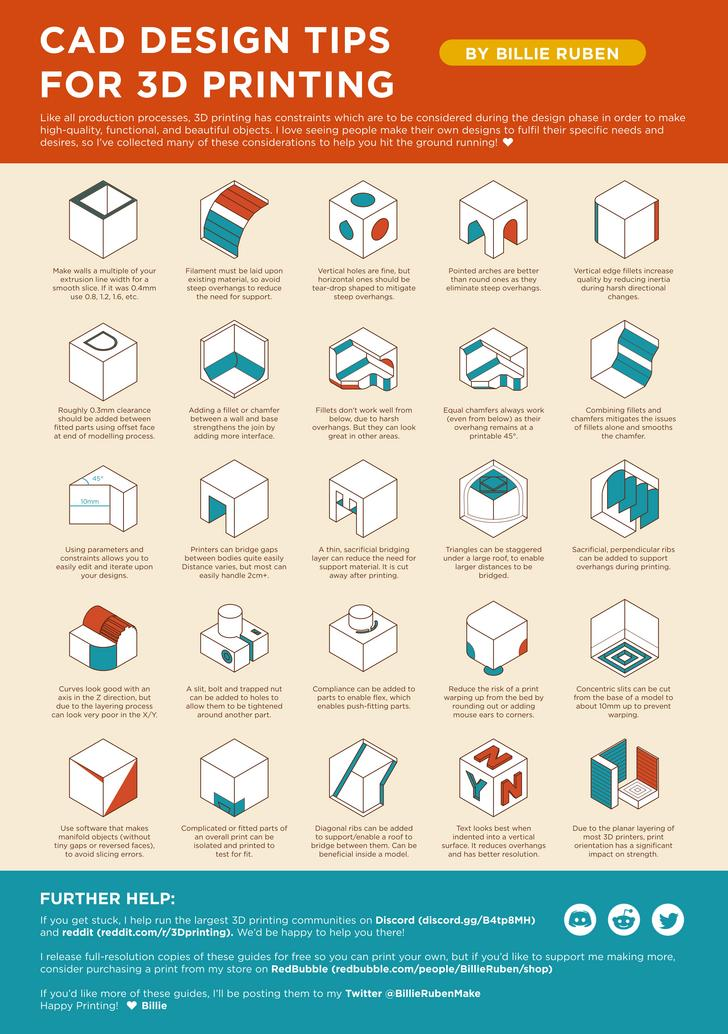

Full-resolution printable copy can be found here.

This visual reference, and this video may also help.

Once you have your prints sticking and printing, these guides can help you identify and solve any other issues you're experiencing:

Our Troubleshooting and Calibration wiki page

A Printa Pro PrintaGuide

rigid.ink poster and visual guide

Matterhackers Troubleshooting Guide

Simplify 3D Visual Troubleshooting Guide

Ultimaker Visual Troubleshooting Guide

RepRap Wiki Pictorial Troubleshooting Guide and Descriptive Troubleshooting Guide, these are a bit more technical/ advanced

It's also worthwhile seeking information from the manufacturer of your machine.

You can try searching for similar issues that other folk have experienced in the following communities: /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord

If the above suggestions don't solve your issue then it's time to seek help from the community:

This video is a great overview on how to seek help with prints.

The best places to ask for help are here on /r/3Dprinting, /r/FixMyPrint, the 3D Printers Discord. When asking for help be sure to provide the following:

- A highly descriptive title (even if you don't know exactly what everything is officially called, please do your best to describe the issue in plain English. This not only helps you get the help you want, but also helps the rest of the community by keeping the sub searchable, so others can benefit from the help you receive.)

- Photos of the issue, screengrabs of the layer view in your slicer, screengrabs of the model itself.

- A description of what the machine was doing as it produced this issue.

- Your basic settings such as: nozzle and bed temperature, speed, nozzle/line width and later height, the printer you're using and the material you're printing in. Or better yet, a screengrab or an export of your settings (you can upload files free without an account here)

- Any other information you think could be relevant such as modifications or hypotheses.

Post Processing

Most prints need some work after they come off the printer to turn them into a finished part. Supports need to be removed, and surfaced may need to be smoothed. Here are some tutorials:

- How to finish 3D Prints guide

More info on the Post Processing page

How to make models

Can't find what you want online? Why not design and make it? Model-making software is split into 4 main categories, depending on your goal:

Full-resolution, printable copy here

These are just the top picks, model making is discussed in more depth on the Making Models page

More communities:

/u/Devtholt keeps a Multireddit of all 3d printing subreddits including some specifically for help, or tailored to certain printers or printer manufacturers.

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC

Also has some subs that are related to 3D printing peripherally, such as /r/lasercutting and /r/CNC3D Printers Discord great platform for troubleshooting and socialising.

RepRap Forums

How to make money with a 3d printer?

How profitable is 3D printing?

But first, let's answer this question. Can you really make money with a 3D printer?

The answer is yes and no. It depends on the niche that you serve. If you're 3D printing for the general consumer, then your profit margin might not be high because it's for personal use. Consumers love cheap stuff. You'll barely cover your cost because of the amount of labor required to finish just one job. But if you're serving clients where 3D printing solves a costly problem that they have, then they are more willing to pay you a lot more to solve it for them.

Here's what we mean by that.

Scenario A: Joe is looking to 3D print a door handle because his door handle broke.

Scenario B: Amanda is looking to 3D print a prototype of a product she plans to sell on Kickstarter.

Believe it or not, we get a lot of Joe's looking to get a quote for their missing appliance part. And most of them are surprised by how expensive 3D printing is and why can't it be as a cheap as Amazon!

We turn them away. Cheap clients are not worth your time.

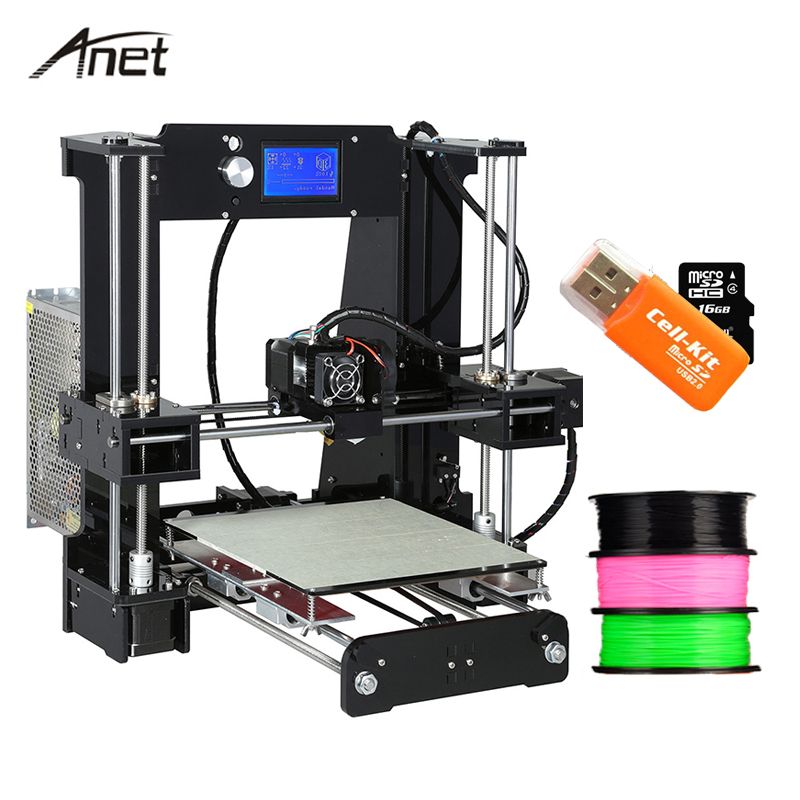

Best entry level 3D Printer

Don't have a 3D printer already?

Phrozen Sonic Mini 4k 3D Printer

Check out this Phrozen Sonic Mini which is very popular among 3D printed miniatures enthusiasts.

$349.99 from Phrozen3D

Commisions earned

Different ways to make money with 3D printing

We've listed a couple of ways you can make money with a 3D printer. Some of these ideas are really good, some of them are bad. But we're listing them any way and it's up to you to make that decision if it's even worth considering.

Let's dive right in!

1.

Sell pre-made 3D prints on Etsy

Sell pre-made 3D prints on EtsyEtsy is one of the biggest marketplace for 3D printing. A lot of 3D printing hobbyists and even professional gravitate towards Etsy because of its large audience who are into handcrafted stuff. Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

When we were starting out back in 2016, we were the first ones to start selling 3D printed planters. Made boatloads of money but ultimately had to stop because of copyright issues. But also partly, because it wasn't where we imagined company .

Remember how we said cheap clients aren't worth your time. On Etsy, you will encounter a lot of cheap clients.

Pros

- Quick way to validate your 3D printing idea

- Benefit from Etsy's huge audience

- Running ads are cheaper compared to Google

List of 3D printed products that you can sell on Etsy:

D&D miniatures

Planters

Vase

Freezing Bernie

How do you choose which products to sell?

On Etsy, you will see a lot of people selling different variations of the same thing - planters, iphone holder, headphone holder, etc.

Why?

Because these things sell!

Like it or not, Etsy will be full of copycats and originality doesn't matter. If your product sells, people will copy it. (And vice versa)

How can you stand out on Etsy?

There's a lot you can do to stand out, but here are some of the common ones that we hear over and over again.

Offer something unique that differentiates your product. Whether that's offering higher quality 3D print (resin), custom finishing, etc.

Avoid competing for price. It becomes

Ask your happy clients to leave a review

Take high quality product photos

2. Offer a specialized 3D printing

This comes down to finding a niche that you're comfortable to work with or if there's enough margin for you to be profitable.

Here's a list of niches you can offer your 3D printing services to:

Tabletop Miniatures

Toy Designers

Jewelry Designers

Architecture firms

Engineering firms for prototyping services

Pros

- You can standardize your process

- Repeatable business

- Easier to master one industry than be a jack of all trades

- You can become a known expert in that industry

3.

Start a 3D printing business in your local area

Start a 3D printing business in your local areaWe'll start off by saying that starting a 3D printing business is the most difficult thing to do out of all the other ideas on this list.

Pros

- Potential for high profits

- Local advantage over online only 3D printing companies

We were fortunate that we were located in NYC, where there is huge demand for 3D printing, and that we started in the early days when 3D printing was still new.

We're not saying this because we don't want you to compete with us, but we're saying this because we want you to know the risks involved in the 3D printing business. Many 3D printing companies have gone out of business because they could not make a sustainable profit to keep the lights on.

The amount of work that you have to put in on fulfilling custom orders is a lot. If you don't opt for an automated system, you end up doing a lot of back and forth with clients. And if you do opt in for these instant quoting systems, you can get a lot of low end jobs and lose out on clients with a very custom need.

The real money in offering a 3D printing service, especially if your a small business, is if you can differentiate yourself from merely becoming a commodity.

For us, we had to become more than just a 3D printing service. It sounds corny, but that was the reality. We had to offer other services that would add value to 3D printing. For example, a marketing agency came to us for 3D printed trophy in 24k gold. But we know that we can't 3D print gold. We can either tell them to take it to a metal plating shop or we can do it ourselves and charge on top of it.

We can charge a lot more because:

We're taking all the risk. If that metal plating fails, we have to 3D print again.

We're making their lives so much easier by being an expert at this field.

And if they're on a really tight deadline, we can charge even more because we're guaranteeing results.

Clients who care more about their time and results are willing to pay you a lot if you can deliver.

So we've partnered with a local metal plating company and later on started offering metal plating services for 3D printing.

Having capabilities more than 3D printing will allow you to charge more than just the 3D print by itself.

Whether that's painting, or creating molds. Whatever it is, you need to find the right clients.

Bonus: Offer 3D scanning services

3D scanning and printing services are perfect way to increase money you can make from owning 3D printer. Although this would require buying a 3D scanner, it's a good option to think about when increasing your chances of landing a 3D printing client.

4. Sell your 3D printing designs

Making money with 3D printing isn't only limited to running your 3D printer 24 hours a day. You can also make money from selling 3D models!

This might be hard if you don't have any design skills. You can either learn or hire a designer on Fiverr or Upwork.

Pros

- You can make money while you sleep

- More scaleable than running a 3D printing business

Patreon Business Model

Here's how it works. People pay you an X amount every month for you to publish 3D models for them.

People pay you an X amount every month for you to publish 3D models for them.

This business model is very popular among the tabletop miniature community.

The above picture is from LordOfThePrint's Patreon. They're one of the popular designers focused on building 3D designs for tabletop gaming. They currently have 1,933 subscribers as of this writing. Assuming only 5% of that is merchants, (about 100) that's $3,866 of monthly recurring revenue!

Take this WallStreetBets 3D model by ChaosCoreTech for example. We spent $50 to have the rights to sell their design for a month. Imagine having 10 Etsy sellers wanting to sell your 3D model. That's have $500 of passive income every month for a few hours of design work!

Merchants/Etsy sellers are great target to sell your 3D models to because:

They'll use it to make more money

They know that your 3D model would print properly because you also know how to 3D print. You might also include supports to make it easier for them

You can show them how it would like 3D printed, thus, making it even easier to sell.

Marketplace Business Model

Some prefer to sell their designs as one-off product that people can just buy online without having to subscribe monthly.

Places where you can sell your 3D models

MyMiniFactory

CGTrader

TurboSquid

5. Start a YouTube Channel

We know that this is easier said than done. Creating content requires time, effort and consistency. With the amount of 3D printing related youtube channels out there, it might be hard to stand out.

But we're not here to stop you from starting your own channel. We're just here to tell you that you can make money with it.

Pros

- Potential for high earnings

- You can use your audience to make more money aside from YouTube Ads

6. Sell an online 3D printing course

If your confident enough with your 3D printing skills and you have knack for teaching others, then selling an online course about 3D printing can

What should you teach?

Again, you need to find a problem where people are willing to pay money for. If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

It doesn't have to be "how to operate a 3D printer", it can be a course on "how to operate a profitable 3D printing business". With this strategy, you'll attract clients who are willing to pay money to make more money.

Pros

- Passive income

The following ideas are not so good

So you can probably skip to the end if you wish to.

7. Rent your 3D printer for events

With the pandemic and all, this is probably not a good idea. But it's still an idea right?

The business is very similar to a photo booth. A bar mitzvah will hire you for 3 hours to 3D print keychains for them.

But 3D printing takes a long time. They are going to complain that you didn't 3D print for everyone.

Yup, bad idea.

8. Sell your 3D printer

You can quickly make money if you sell the 3D printer you just bought. Guaranteed.

Guaranteed.

All jokes, aside

9. 3D print the word "money"

You will literally make "money" with a 3D printer with this strategy.

In summary

Yes, you can make money with a 3D printer. And there are a lot of ways that you can do it, whether that's selling 3D printed items, digital goods, or even offering a 3D printing service in your local area. Is it easy to make money 3D printing? It's not. You still need to work hard(and smart) to become successful in the 3D printing business.

How to make money with 3D printing?・Cults

3D printing has completely changed the world of design. The discovery of 3D printers offers innovative entrepreneurs new ways to make money with their creativity. You can print a lot of commercial objects that have a high market value. Owning 3D printers is a real help for those who want to make money online. Learn how to make money with 3D printing in this guide.

This is one of the fastest ways to start your business. Designing models for 3D printing is a rather complicated technology even for owners of 3D printers. They are willing to pay for professionally designed 3D printing files to create their model. 3D model designers have the opportunity to earn money by selling their creations online. Aside from being a hobby, 3D printed models can become a livelihood.

Designing models for 3D printing is a rather complicated technology even for owners of 3D printers. They are willing to pay for professionally designed 3D printing files to create their model. 3D model designers have the opportunity to earn money by selling their creations online. Aside from being a hobby, 3D printed models can become a livelihood.

There are many sites where you can sell 3D printable models to hobbyists and printer owners. The Cults site, for example, is home to strong community of 3D printer owners . This makes it easier for 3D print modellers to find buyers for their creations. This very active community is constantly looking for great OBJ or STL 3D models. Therefore, you can earn money from your 3D models by creating an account on our website. You then upload 3D print files to attract potential buyers.

On Cults, the designer earns about 80% of the selling price of his projects. Our site takes a commission of 20% of the sale price of the print to cover technical management costs. You set the selling price of your creations yourself, so you can easily make money with your 3D printer. When selling files for 3D printing, choosing the path through Cults3D , you will earn money, and this is from the first sale.

You set the selling price of your creations yourself, so you can easily make money with your 3D printer. When selling files for 3D printing, choosing the path through Cults3D , you will earn money, and this is from the first sale.

Today there are many buyers on the Internet who want to purchase 3D printed objects. You have the opportunity to make money quickly by creating 3D parts that are sold to various clients. Earn money by showing off your creations. You can also create a website to showcase your details.

Small businesses that want to generate leads often choose Shopify. To make money with a 3D printer , you also have the option to receive direct orders from customers. They will tell you what objects they need and you will take care of the 3D printing. Use your creativity and offer your services to the market in your area.

For example, you can start selling a series of 3D printed vases with different designs and colors. If you take care to respect the license to distribute your works, you will be able to open your online business and earn rewards for your creations. However, you must ensure that you are registered as a self-employed person with the local tax authorities. nine0003

If you take care to respect the license to distribute your works, you will be able to open your online business and earn rewards for your creations. However, you must ensure that you are registered as a self-employed person with the local tax authorities. nine0003

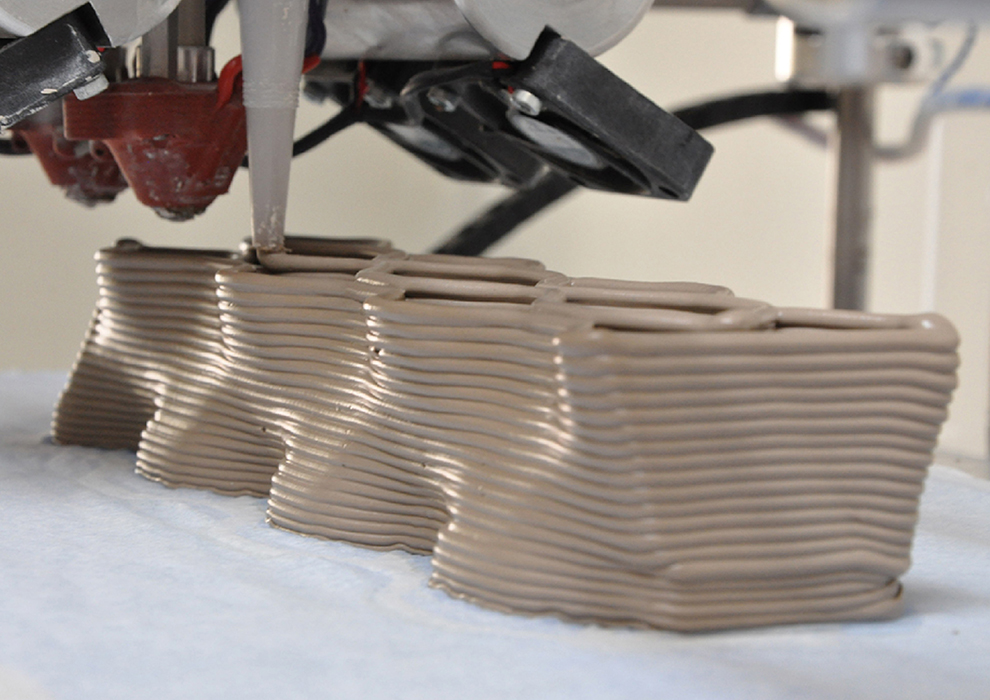

This is a great way to make money doing 3D printing. Today it is a very popular service. Professionals in the field of construction, architecture and engineering sometimes urgently need the services of prototyping . You can create prototypes for various clients with a 3D printer. The contractor will then use the prototype for series production.

Rapid prototyping services are very popular among professionals due to their many benefits. Prototypes created using 3D printing reduce the possibility of errors in the design process. Plus, printing costs less and offers more options. This means that you can easily make money with your 3D printer. nine0003

The 3D printer is also used by automotive designers to prototype car parts. Prototypes, made on the 3D printer, will be used to test various features on new models.

Prototypes, made on the 3D printer, will be used to test various features on new models.

Mastering a 3D printer can be a great way to make money. You can use your tech and 3D printing skills to teach classes to people who want to learn. However, you may not have many members at first. Your role will be to arouse the curiosity of as many people as possible by showing that it is quite possible to make money with a 3D printer. nine0003

Indeed, very few people know about the benefits of 3D printing . This justifies the fact that printing courses are not well known in local markets. If you speak well about your services yourself, you will be able to gather enough audience to create a large community. In various social networks, you will get more attention. Newspapers are also a great way to advertise your 3D printing courses. Also consider hosting workshops that showcase the many possibilities of 3D printing. nine0003

This will help many people understand the value of 3D printing course . They learn how to make money with their 3D printer. Both sides will benefit. You teach your students how to make money with 3D printing and in return you get paid for your services.

They learn how to make money with their 3D printer. Both sides will benefit. You teach your students how to make money with 3D printing and in return you get paid for your services.

12 common 3D printing mistakes from easy to hard. How to avoid them?

1. Underestimation of the importance of the first layer. 2. Don't ask the 3D printing communities for help. 3. Random entanglement of the filament. 4. Fast assembly of your 3D printer. 5. Incorrect table and nozzle height calibration. 6. Using the wrong slicer settings. 7. Using a high % infill to reinforce details instead of walls/shells. 8. Don't use support when needed. nine. Never replace worn parts. 10. Lack of 3D printing monitoring. 11. Neglect of safety rules in 3D printing. 12. Buying a bad 3D printer out of over-enthusiasm. Output.

There's nothing worse than 3D printing for days, weeks, months and years only to find out you're making common mistakes.

We're sure many of you are familiar with that feeling, which is why we've written this post to get you back on the road to success by outlining some common mistakes to avoid on your 3D printing journey. nine0003

nine0003

Here you will find both small errors that you did not pay attention to before, and serious errors that can lead to a complete cessation of 3D printing.

Join our research to identify the most common 3D printing mistakes, as well as simple solutions to fix them quickly.

1. Underestimation of the importance of the first layer.

Too often 3D printing fails in the middle of the process due to poor adhesion of the first layer.

Definitely keep this important factor in mind if you want a successful print. nine0061 This is a mistake that is made too often, and it causes people to chase ghosts, trying to figure out what the problem is.

All this time, the reason was the bad first layers, which did not have a strong enough connection with the working platform.

Although your first layer is held at the start of printing, adhesion decreases as the print head moves. It is likely that your print may shift or fall off after a few hours if the first layer was not well extruded. nine0003

nine0003

Solution .

- Make a few test prints ahead of time to see how well the material adheres.

- Use an adhesive such as 3D Printer Varnish or at least a glue stick.

- Increase the flow rate (extrusion multiplier) for the first layer so the material has a better chance of sticking to the printer bed.

2. Do not seek help from the 3D printing communities.

Every user of a 3D printer has encountered some kind of problem that required some effort to fix. Some people took on entire projects just to solve a 3D printer problem, when the solution was easy to find. nine0003

3D printing communities are known for helping people solve their problems, so be sure to check out these free resources. From 3D printing forums to Facebook groups and YouTube surveys of other 3D printer users, the options are endless.

When we first started exploring 3D printing, we noticed that many people mention how helpful other 3D printer users are, so we immediately registered on all kinds of Russian and English resources, Facebook and Reddit communities and joined this space . nine0003

nine0003

In most cases, people will offer the right solution and will be happy to help you try various troubleshooting options.

Not only can they help you with troubleshooting, but they can point you to some fun projects to try, as well as some of the latest innovations in the world of 3D printing.

Solution .

- Join active Facebook groups on 3D printing and your specific 3D printer. nine0075

- Subscribe to news feeds of authoritative 3D printing resources.

- Be sure to check out YouTube 3D printing bloggers who post new and interesting content on a regular basis.

- Find groups in Viber and Telegram. This is the fastest way to get an answer to your question.

3. Random entanglement of the filament.

We have read many reviews about 3D printer materials including PLA, ABS, PETG, etc. and some of the negative reviews mention tangled filament. nine0003

Unfortunately, in most cases, the thread becomes tangled due to the fault of users.

As a general rule, when the thread is wound onto the spool, there is very little chance of tangling, much more often after you take the spool out of the package.

If you loosen the windings in the winding and then wind the deflated windings back on the spool, you could accidentally wind them unevenly and create an overlap that will ruin your prints.

Solution .

When storing the filament, make sure that the end is securely fastened and cannot be easily loosened.

If there are already tangles on the spool, unwind enough thread and wind it tightly again so that it does not cross over.

If you are still unlucky, and you have purchased plastic of inadequate quality, during the production of which all technological cards were violated, then here is our advice: buy plastic for a 3D printer from trusted brands. The $100 price difference is infinitesimal compared to all sorts of other 3D printing costs. nine0003

However, this 100 UAH will save you not only from problems with overlaps, but also provide a stable diameter and color along the entire length, the absence of ovalities and smooth feeding.

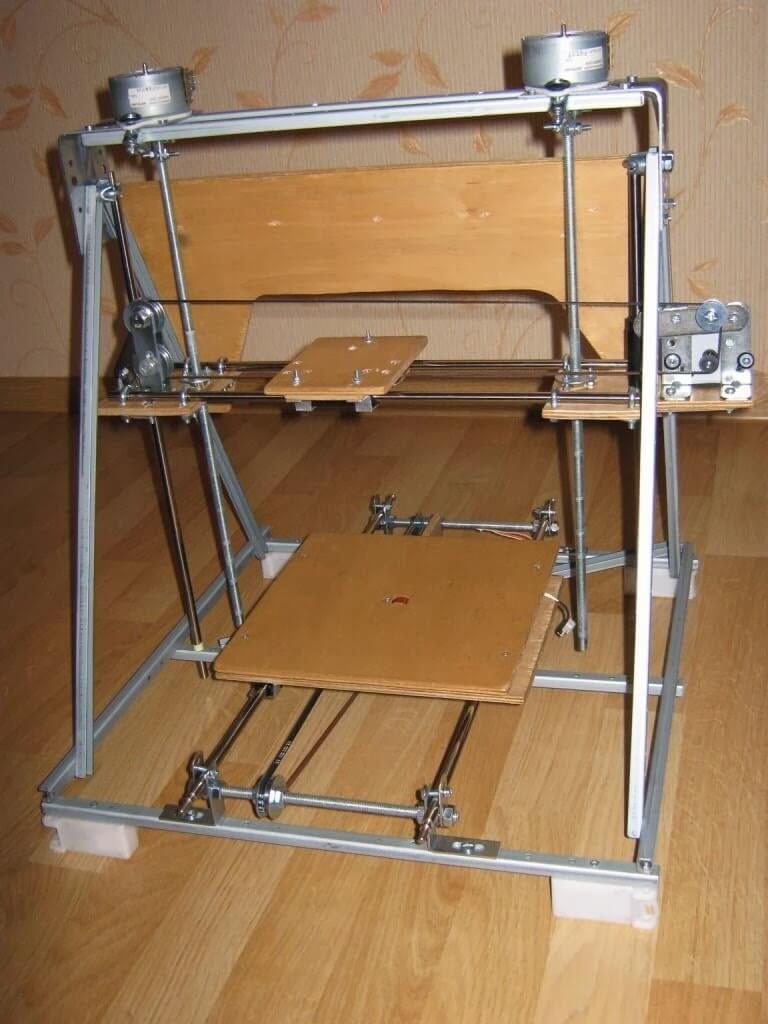

4. Quickly assemble your 3D printer.

We were all very excited when we got our first 3D printer and it came to assembling it, but being overly excited can cause your 3D printer to build too quickly, resulting in poor print results.

This may not be immediately noticeable and you will get good quality prints within a few months. nine0003

What can happen gradually is wear due to incorrect assembly.

Ask yourself these questions before starting your first print.

Was your belt tight? Did you properly and securely fasten each wire? Is the Bowden tube installed correctly?

When it comes to a 3D printer, every little detail counts, so don't fall prey to 3D printing problems because of a quick and careless build.

Solution .

Find an authoritative YouTube video tutorial from an experienced 3D printer operator and follow assembly. nine0061 There are always a few little tricks they advise you to do for durability and high quality prints.

Even if you've already built your 3D printer, you can fix some things you may have missed.

The correct and high-quality assembly of a 3D printer actually leads to higher quality prints.

See also: How to set up your new 3D printer.

5. Incorrect table and nozzle height calibration.

Of all the layers in your 3D print, the first layer is the most important and it depends a lot on how well you leveled your platform and set your nozzle height. nine0003

It's not as easy as uploading a 3D model, sending it to an SD card and starting printing.

The software side of things is important, but the hardware side is just as important.

Many 3D printers come with manual platform calibration, so you have to raise or lower each corner yourself.

Your 3D printer doesn't have a perfect feedback system, which means it can't always check where the print head is.

The best he can do is use the X, Y and Z limit switches to make sure the printhead is 0. 00mm in each axis. nine0003

00mm in each axis. nine0003

What your 3D printer is very good at is extremely precise movements in the X, Y and Z axes, but if the nozzle height is not set properly at the beginning, everything falls apart.

The Z axis is height, so the nozzle must be properly adjusted so that it smoothly extrudes the filament along the surface of the build, neither too high nor too low.

Solution .

- Learn how to manually calibrate the table.

- Once your table is properly calibrated and the nozzle height adjusted, you can expect good prints. nine0075

- It might be a good idea for you to invest in an auto leveling system like BLTouch. We at our 3D printing studio in Odessa prefer manual calibration.

6. Using incorrect slicer settings.

The slicer settings you use to print are some of the most important things when it comes to successful 3D printing.

Of the hundreds of setting changes you can make, one wrong setting is enough to ruin your print. nine0003

nine0003

Fortunately, there are printer profiles and default settings that give people a basic starting point for printing.

After a few prints, you will start experimenting with different settings such as temperature, line width, flow rate, and so on.

Some of the misapplied misconfigurations are related to changing materials.

Whether PLA or ABS or PLA of different brands and/or colors, temperature recommendations will vary. nine0003

Make sure you set them correctly.

Slicer settings can either help you or break your 3D printing, so use them wisely, preferably with some kind of guide.

In most cases, when you load a model from Thingiverse, for example, designers create a list of settings that generally work well, but don't blindly follow them and be careful.

For example, if you replaced a brass nozzle with a hardened steel nozzle, you would need to slightly increase the nozzle temperature because hardened steel does not conduct heat as well as brass. nine0003

nine0003

Another example is your work surface.

If you have added a glass substrate to your 3D printer, you should increase the table temperature to allow for the extra layer of heat transfer material.

Solution .

- Use calibration models such as speed and temperature towers for each new material.

- Spend a little more time looking at the slicer options to make sure you know what changing a setting will do. nine0075

- Repetition is the mother of learning. The more often you type, the faster you will become a pro.

Read also: The best models for 3D printing testing.

7. Using high % infill to reinforce details instead of walls/shells.

For years, most people have tried to reinforce their 3D printed parts with infill. This method definitely does the job, but there is a much more efficient method that has been proven to work much better. nine0003

Instead of wasting a lot of material and extra time printing the infill, you should use shells/walls to make the 3D printed part stronger.

In some cases, increasing the percentage of filling does not provide the necessary margin of safety, while increasing the wall thickness makes it possible to produce truly reliable and impact-resistant products.

Solution.

- Instead of adding more infill, add more shells/walls to your prints to make them stronger. nine0075

- For a functional 3D printed part requiring strength, about 4-6 walls are recommended.

8. Do not use supports when necessary.

Most people try to avoid the use of auxiliary supports to save time and material, but there are times when their use is necessary.

You can try tilting the prints in a certain way and moving them around the print bed, but sooner or later there will come a point when this approach doesn't work. nine0003

Many models are specially designed not to use support for successful printing, which is very convenient.

On the other hand, some designs are too complex to print without support.

3D printers cannot print in the air and large ridges definitely need support structures to extrude the material onto.

Most often you can do without supports on 45° or lower overhangs, but for anything higher it is recommended to use supports. nine0003

This is more of a visual skill that, with time and experience, allows you to understand when models need supports and when you can do without them.

Some slicers may not show support in preview, so you'll have to judge for yourself.

Solution.

- Make sure you don't avoid supports when they're needed, because then you'll just lose overall. nine0075

- Use proper part orientation to ensure your prints use as little backing material as possible.

9. Never replace worn parts.

Although the profile, power supply and stepper motors of your 3D printer are designed to last for several years, other parts are consumables.

These are parts such as belts, nozzles and bearings. Make sure you replace these parts as they wear out.

Make sure you replace these parts as they wear out.

You may notice a decline in print quality over time, and wear and tear on certain parts can definitely be the cause, so check these consumables and replace them as needed. nine0003

If you are printing with materials such as ABS, PA12, PC or glow-in-the-dark plastics, the brass nozzles wear out much faster than when printing with traditional materials.

Switching to a hardened steel nozzle is a good idea if you want to print with abrasive materials.

The disadvantage is that it does not have the same level of thermal conductivity as brass nozzles.

Here is a short list of 3D printer parts that wear out over time:

- Thermal barrier;

- PTFE tube;

- Fans;

- Wires/connectors;

- Thermistors;

- Belts;

- Glass platforms;

- Bearings;

- Heating block;

- Motherboard.

You can buy accessories for 3D printers in the corresponding section of our catalog.

Solution.

- Be aware that some parts will not last forever, so check these parts from time to time and replace them as needed. nine0075

- Make sure these components are installed in a way that reduces wear.

- Keep a set of replacement parts on hand in case they fail (nozzles, belts, wiring, PTFE tubing).

- Buy high quality parts designed for a long service life.

10. No 3D printing monitoring.

Whether you have a premium or budget 3D printer, any of them can fail. They can fail within the first few minutes when the first layer is not printing well, or a few hours after printing starts. nine0003

In our practice, there have been a few cases when checking our printers after a night shift, we found a mess on the work surface and the printer continued to extrude spaghetti plastic.

Monitoring is not a panacea for all problems, but with its help you can stop the process in time and avoid waste of plastic and electricity.

It is recommended to constantly monitor your 3D printers throughout the printing process to make sure everything is in order. nine0003

What we make sure to do is monitor the first coat and then come back 15 minutes later to make sure everything is going according to plan.

After that, checking the printers every hour or so is a good idea to control your prints.

Solution.

- Check the 3D print from time to time to make sure everything goes smoothly.

- Use the camera for remote fingerprint verification with remote power control. nine0075

- Be sure to teach others how to stop your 3D printer if necessary.

11. Neglect of safety rules in 3D printing.

Basic precautions are based on burn and fire hazards, mechanical hazards, and injury from tools or melted plastic.

The risk of fire is very rare these days because 3D printers are usually equipped with overheating protection.

Pay attention to burns from hot nozzle or print bed. nine0003

We've also heard stories of injuries from the sharp edges of the printer's scraper.

This can be easily avoided if you are careful in your actions.

Removing supports is not the most pleasant and interesting thing to do, but getting cuts or scratches when cleaning parts is even worse.

It is recommended to check the wiring, bolts, belts and all moving parts from time to time so that a potential malfunction can be detected in the future. nine0003

Connectors can sometimes fail, so be sure to check these aspects to ensure the 3D printing process runs smoothly and safely.

Solution.

- Be aware of your surroundings and be safe.

- Do not put your hand too close to the nozzle.

- Do not keep your hand on the platen when taking the print.

- Provide good ventilation.

12. Buying a bad 3D printer out of over-enthusiasm.

nine0057

nine0057 We are regularly contacted by clients who, on a wave of enthusiasm, bought a cheap 3D printer on Aliexpress or other market place, and this printer does not work.

Spontaneous cheap purchases do not give you time to analyze and compare 3D printer models. In other words, you are making your choice unconsciously.

People have experienced a number of problems, such as the SD card slot not working along with serious difficulties in transferring files over Wi-Fi.

Other options included poorly insulated wires, crooked frames and platforms. nine0003

Deformed threaded screws, cheap hot ends, broken parts, poor shipping packaging, poor assembly at the factory are also common when buying cheap "NoName" printers.

You may end up spending most of your time repairing, fixing poor print quality issues, and just getting frustrated with 3D printing.

If you've been one of those unlucky ones, you've probably learned to take your time buying a 3D printer. nine0003

nine0003

One of the most popular manufacturers of inexpensive 3D printers around the world is Creality, and their top product Ender-3 v2.

This 3D printer has been tested many times by users around the world, and its popularity proves to be the perfect combination of price and quality.

Every 3D company is a team that buys parts and builds a printer, but some do it much better than others and more consistently.

Some people who buy a bad printer either give up 3D printing, do a complete costly rebuild, or buy a better 3D printer much later. You might as well start by buying a good 3D printer! nine0003

Solution.

Choose a reliable 3D printer with a good reputation and avoid 90% of avoidable problems. We know a lot of stories about people going through the same thing, so save yourself the hassle.

We have never seen anyone call the Ender 3 Pro or the Voxelab Aquila X2 a bad first 3D printer because it really is a very good buy.