3D printer geldermalsen

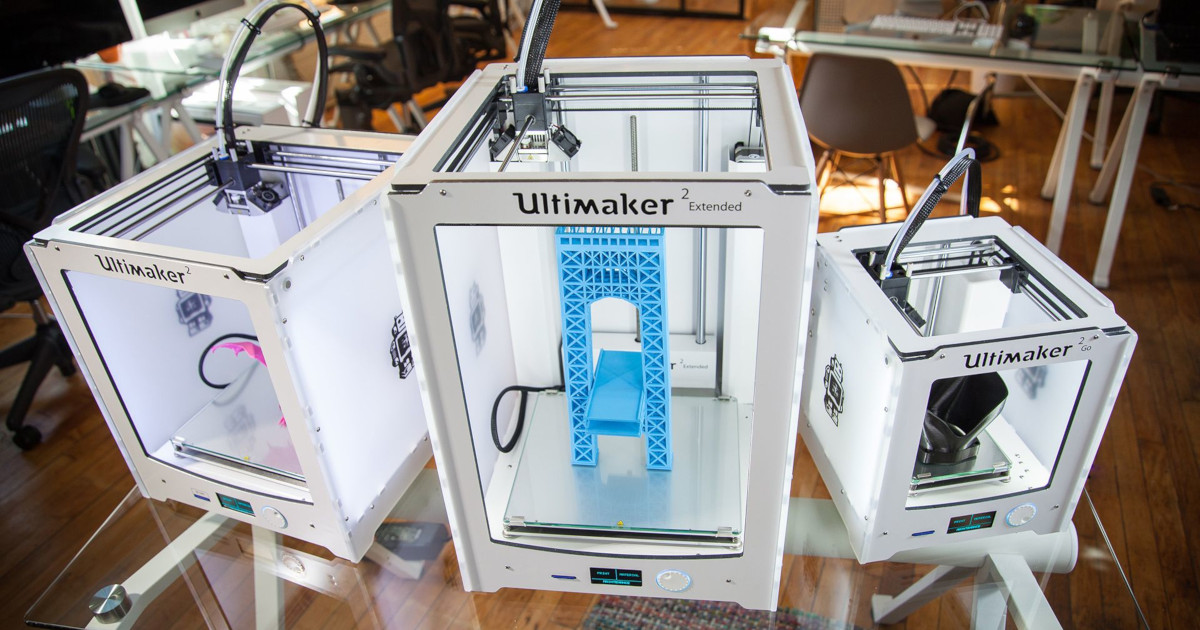

Start 3D printing the Ultimaker way

Take your first step into our world of easy and seamless 3D printing – with a new touchscreen and remote printing capabilities.

Get pricing

Single extrusion with swappable nozzles

Cloud-enabled remote 3D printing

Filter up to 95% of UFPs (optional)

Print with 9 materials (including PP & PC)

The physical space inside the Ultimaker 2+ Connect that can be used for single extrusion 3D printing.

223 x 220 x 205 mm (8.7 x 8.6 x 8 inches)

The XYZ 3D printer dimensions, including the spool holder and Bowden tubes.

342 x 460 x 580 mm (13.5 x 18.1 x 22.8 in)

This is the process of depositing layers of filament, one on top of the other, to build up shapes and models. It is a form of additive manufacturing technology and the process used by all Ultimaker 3D printers.

Fused filament fabrication (FFF)

The filament diameter that achieves optimal results on Ultimaker 3D printers.

2.85 mm

The net weight of the 3D printer.

10.3 kg (22.7 lbs)

Required power input.

100 - 240 VAC, 50 - 60 Hz

The peak power output that the printer can reach – usually when the heated bed and hot ends are heating up.

A micron is the measurement used to define the thickness of a 3D printed layer. 20 micron is 0.02 mm thick. Thinner layers are used for high-detail prints, thicker layers are great for fast prototypes.

0.25 mm nozzle: 150 - 60 micron

0.4 mm nozzle: 200 - 20 micron

0.6 mm nozzle: 400 - 20 micron

0.8 mm nozzle: 600 - 20 micron

The more accurate the stepper motors within the printer, the greater degree of accuracy and finer resolution can be achieved with each print.

12.5, 12.5, 5 micron

A geared feeder exerts more force on the filament, and also reduces heat exposure from the motor.

Geared feeder

Display

2.4-inch (6 cm) TFT color touchscreen

Thanks to the swappable nozzle, you can easily switch between different nozzle diameters. This results in higher uptime and easier maintenance of your 3D printer.

This results in higher uptime and easier maintenance of your 3D printer.

Single extrusion with swappable nozzle and dual cooling fans

Smaller nozzle diameters enable more detailed prints, large diameters reduce overall print time. 0.4 mm nozzle included, others sold separately.

0.25, 0.4, 0.6, 0.8 mm

The build speed relates to how fast the filament can be extruded through the hot end of the 3D printer. The higher the value the greater the achievable print speed.

< 24 mm³/s

A wide nozzle temperature range means greater flexibility in the 3D printing material choice.

180 - 260 °C

The nozzle heat-up time relates to how fast you can start printing, as well as how fast it can melt the polymer filament.

< 2 minutes

Thanks to their quiet operation, Ultimaker 3D printers are suitable for use in the office, studio, or classroom environment.

< 50 dBA

Assisted leveling is easy with the Ultimaker 2+ Connect. The setup wizard guides you through the process, using the included calibration card and build plate knobs to ensure the build plate is perfectly level.

Assisted leveling

With a build plate temperature range of 20 - 110 °C, you can be confident of reliable first-layer adhesion with a range of materials

20 - 110 °C heated glass build plate

This Ultimaker 3D printer operates best in locations between these temperatures.

15 - 32 °C (59 - 90 °F)

This Ultimaker 3D printer can be safely stored or left inactive at these temperatures.

0 - 32 °C (32 - 90 °F)

The printer will notify you when the filter needs replacing (every 1,500 print hours – about once per year). Ultimaker 2+ Connect Air Manager sold separately.

Replaceable EPA filter

The Air Manager filter catches, traps, or diffuses up to 95% of ultrafine particles (UFPs). Ultimaker 2+ Connect Air Manager sold separately.

Up to 95% of UFPs

Ultimaker Cura is our industry-leading slicing software that turns your 3D model into a file your printer can use. Use Ultimaker Digital Factory to manage printers and print jobs via your local network or the cloud

Ultimaker Cura

Ultimaker Digital Factory

Software security

Data encryption in transit and at rest. Two-factor authentication

Two-factor authentication

Supported OS

MacOS, Windows, and Linux

More plugins are available from Ultimaker Marketplace to make your 3D printing experience even easier.

SolidWorks, Siemens NX, Autodesk Inventor

An STL file is the most used file type for 3D printing. Nearly any 3D modeling software program is able to create these files.

Ultimaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

Printable formats: UFP

Print with one click via Wi-Fi or Ethernet connection. Or export your print job to a USB stick.

Wi-Fi, Ethernet, USB

Certification

CE, Declaration of safe unattended use

More information

Training

Training is available online or via our dedicated network of local service partners.

Register your Ultimaker 2+ Connect for a free, online setup and onboarding tutorial in the Ultimaker 3D Printing Academy.

Warranty period

12 months

Expert support

Market-leading technical support via email, phone, or from our global community is available to you in your language and timezone.

Extended support

Online resources, extensive manuals, material technical and safety data sheets (in multiple languages), a detailed knowledge base, and much more.

Explore the tech behind the Ultimaker 2+ Connect with one of the R&D Engineers who created it. You will learn:

• Every hardware feature and its performance benefits

• How the printer's connectivity enables a more seamless workflow

• The thinking behind key design decisions

• And lots more!

"Last year, we produced around 1,000 different 3D printed parts. The benefits of these are improved ergonomics, productivity, and operator satisfaction. In the end, we get very good feedback from the operators working on the line."

Luis Pascoa, Pilot Plant Manager at Volkswagen Autoeuropa

Read the full story

"So far in the pilots that have ran, we've significantly seen a cost reduction in the functional applications that we've found from 70 - 90%.

On delivery time we've seen the same decrease."

On delivery time we've seen the same decrease."Isabelle Haenen, Global Supply Chain Procurement at Heineken

"We chose Ultimaker because the machines are reliable and the results are repeatable. That's important for us, for a stable production process."

Johannes Grimm, Manager Operation Excellence at Carl Zeiss Optical Components

Read the full story

"If you compare our 3D printed tools to conventionally manufactured tools, we can easily save approximately €1,000 per tool, which is of course a lot when you consider all the tools which are needed to produce a vehicle."

Raphael Koch, Research Engineer R&A at Ford Europe

Read the full story

The Ultimaker 2+ Connect gives you access to the entire Ultimaker ecosystem, including:

• Ultimaker Essentials (unending enterprise software subscription)

• Ultimaker Cura (full settings and monitoring compatibility)

• Ultimaker Digital Factory (remote printing and management)

• Ultimaker 3D Printing Academy (e-learning modules)

• A global network of service partners (setup and training)

Ultimaker 3D Printing - Ultimaker B.

V., Manufacturer in Geldermalsen, Gelderland, NetherlandsUltimaker 3D Printing - Ultimaker B.V., Manufacturer in Geldermalsen, Gelderland, Netherlands - Aloeus

V., Manufacturer in Geldermalsen, Gelderland, NetherlandsUltimaker 3D Printing - Ultimaker B.V., Manufacturer in Geldermalsen, Gelderland, Netherlands - Aloeus Manufacturer

Aloeus Map

Neighbouring location +/-

Rate this location

Please drag the slider to indicate your rating between 1 and 100. A short comment is sufficient to complete your rating.

Please log in to use this feature.

No ratings are available at the moment for this location. Be the first one to rate this location!

new tab

Sign in

Already have an account? Log in below:

Forgot your password?Sign up

Don't have an account? Try Aloeus® today!

By joining Aloeus®, you agree to the Agreement, Privacy Policy and Cookie Policy.

Legal Disclaimer Privacy Policy Additional Information

Please enter the email address you registered with on Aloeus below in order to receive an email with instructions on how to recover your password:

Bookmark parent folder:

Bookmark folder

Notes

Agenda

parent folder:

Name:

Notes:

car bicycle transit walk

DEPARTURE TIME

UNITS

km miles

AVOID

ferries highways tolls

TRAFFIC ESTIMATE

best optimistic pessimistic

PREFER

bus subway tram train rail

ROUTE PREFERENCE

fewer transfers less walking

Please select the request. Complete the request with a brief description. We can contact you if you submit your email. Thank you!

Complete the request with a brief description. We can contact you if you submit your email. Thank you!

Aloeus uses Cookies

We use cookies to personalize content, to authenticate users and to analyze our traffic. We do not share information about your use of our site with any third party. You consent to our cookies if you continue to use our website. Cookies are small text...

Necessary Aloeus Matomo (Piwik) Google Analytics

The Aloeus portal uses cookies to ensure the best possible service. If you continue surfing the site, you consent to the use of cookies.: Privacy Policy

Children built a 3d printer

»Ugly Swans by A. and B. Strugatsky

This news has already been mentioned in the previous article 3d printers. Overview of achievements in 2012

Overview of achievements in 2012

I decided to cover this event in more detail.

What kind of childhood would you like to have?

What education will you provide for your children?

In my opinion, a good example of setting goals for children. nine0010

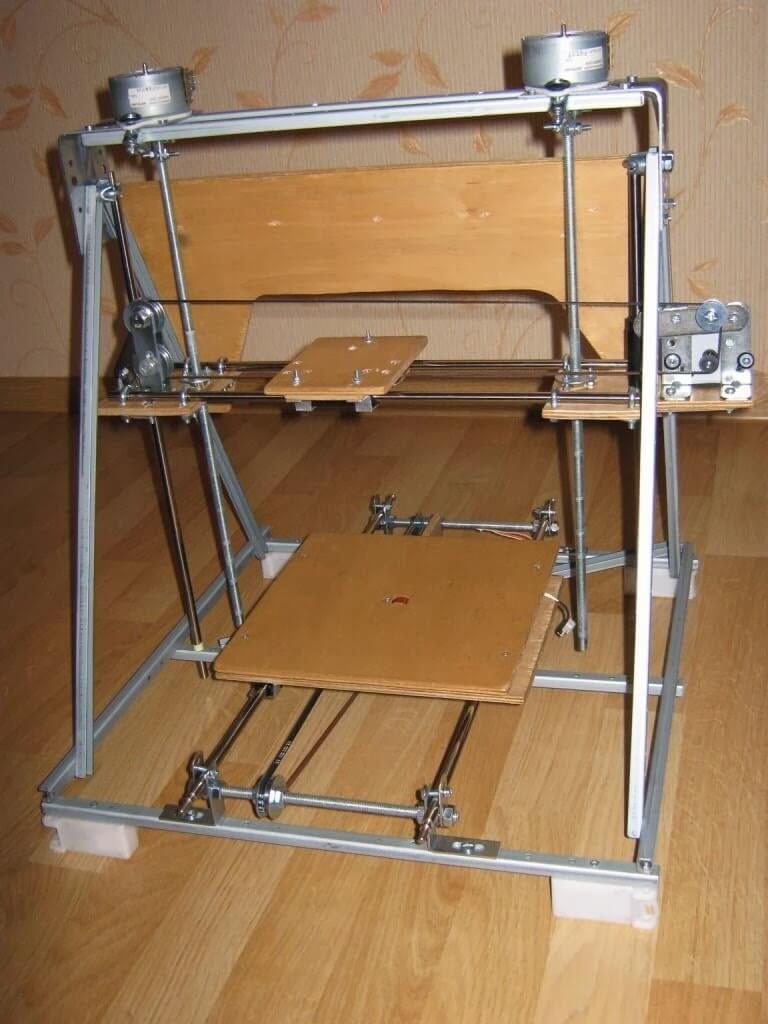

16 children aged 8 to 12 and one teacher Manuela van den Bos started building an Open Source 3D printer in the Alant classroom at De Morgenster school in Geldermalsen, the Netherlands.

First there was a motivational presentation from Ultimaker representatives.

"The speed with which information spreads is much more important than the possession of information." - said the Ultimaker evangelist at a speech in front of the children. "Now everyone can contribute to the development of a device for experiments and for the design of objects." nine0005

First of all, the children drew a MindMap:

What is needed for the project:

F)

— An equally enthusiastic teacher who is focused on the process and can ask leading questions

— Blackboard and crayons (or adequate replacement)

- Collection kit from Ultimaker

- Drop dead screwdriver set

— Pouches for small parts

- "Let's make mistakes": making mistakes is a necessary part of the learning process (the only way you really understand the subject!)

- One machine per group to read the build instructions:

wiki. ultimaker.com/Mechanics_build_guide

ultimaker.com/Mechanics_build_guide

Completely optional:

– Know the full theory on 3d printers

- Be afraid to make a mistake, because you will make them at every step

The children were divided into groups and each had to assemble a certain part of the 3d printer and at the end of the week they would all work together on a common assembly.

Instead of learning from books and waiting for instructions from the teacher, the students were given the task of using their hands and head to assemble the entire printer. Now they had to find a solution. In the world of adults there is a word "difficult", but it seems that in the world of children it does not exist. They got down to business and continued no matter what until they were done. nine0005

What did the children learn from this program?

“They learned how to work in a coordinated way in a team, how to search and find solutions even from an online resource or by asking a specialist a question. It was new to them." says Manuela

It was new to them." says Manuela

This is an effective way to spark kids with ideas, instill curiosity and create a desire to learn new technologies. When they successfully completed the project, they gained self-confidence and self-esteem. nine0005

“When the kids came home and told their parents what they knew about the 3d printer and how they built it when their parents had never even seen it. It gave the kids a boost of positive emotions.” Manuela adds.

While most parents still think that they know more than their children, the current generation is likely to have enough (and sometimes even more!) skills when it comes to modern technology.

“Some people think kids can never do it, they're too young. And when they see that we did it, they have to think about it.” "Actually, it's not even that difficult." said Suus and Joel, students of the De Alant program.

Manuela was excited to work on a 3d printer assembly project with the kids. “I recommend that all schools start a similar project.”

“I recommend that all schools start a similar project.”

Film about the project (with English subtitles)

www.youtube.com/watch?v=elp1FeZpqFQ

Gifts printed for Christmas

Gift to the astronaut printed on the printer collected by the guys:

at the Dutch Design Week

exhibition 3d Print Show 2012 London 9000

Opening the most mobile 3D PAVINE the KamerMaker'

A couple of months later, the school repeated the project and in two weeks (two days off) they assembled another printer.

Information taken from websites

www.3ders.org/articles/20120605-the-first-3d-printer-assembled-by-children.html

www.3dabc.nl

選擇語言Bahasa Indonesia (Bahasa Indonesia)Bahasa Malaysia (Malay) Čeština (Czech)Dansk (Danish)Deutsch (German)English (English)Español (Spanish)繁體中文 (Chinese (Traditional))Français (French)한국어 (Korean)Italiano (Italian)简体中文 (Chinese (Simplified))Nederlands ( Dutch)日本語 (Japanese)Norsk (Norwegian)Polski (Polish)Português (Portuguese)Română (Romanian)Russian (Russian)Svenska (Swedish)Tagalog (Tagalog)ภาษาไทย (Thai)Türkçe (Turkish)العربي)0010

Wedج المحاولة مورة خرى للصص اليا# أو الال لـship imesز المς للمزيد ← المومات

0

Omlouváme se, nemůžeme najít stránku, kterou hledate.

Zkuste se vrátit zpátky na předchozí stránku, nebo se podívejte do našeho Centra nápovědy pro více informací Přejít do informačního kanálu

Zkuste se vrátit zpátky na předchozí stránku, nebo se podívejte do našeho Centra nápovědy pro více informací Přejít do informačního kanálu

Vi kan desværre ikke finde den side, du leder efter. Gå tilbage til den forrige side, eller besøg Hjælp for at få flere oplysninger

Gå til dit feed

Die gewünschte Seite konnte leider nicht gefunden werden. Versuchen Sie, zur vorherigen Seite zurückzukehren, or besuchen Sie unseren Hilfebereich, um mehr zu erfahren.

Zu Ihrem Feed

Uh oh, we can't seem to find the page you're looking for. Try going back to the previous page or see our Help Center for more information

Go to your feed

Vaya, parece que no podemos encontrar la pagina que buscas. Intenta volver a la página anterior o visita nuestro Centro de ayuda para más información.

Ir a tu feed

Nous ne trouvons pas la page que vous recherchez.

Essayez de retourner à la page précédente ou consultez notre assistance clientèle pour plus d’informations Ouvrez votre fil

Essayez de retourner à la page précédente ou consultez notre assistance clientèle pour plus d’informations Ouvrez votre fil nine0109 Maaf, sepertinya kami tidak dapat menemukan halaman yang Anda cari. Coba kembali ke halaman sebelumnya atau lihat Pusat Bantuan kami untuk informasi lebih lanjut Buka feed Anda

Non abbiamo trovato la pagina che stai cercando. Prova a tornare alla pagina precedente o visita il nostro Centro assistenza per saperne di più.

Vai al tuo feed

申し訳 あり ませ。 お 探し の ページ 見つかり ませ ん。 前 の に 戻る か 、 ヘルプセンター で 詳細 ご 確認 ください

원하시는 이전 페이지로 돌아가거나 고객센터에서 자세히 알아보세요.

홈으로 가기

Harap maaf, kami tidak dapat menemui laman yang ingin anda cari. Cuba kembali ke laman sebelumnya atau lihat Pusat Bantuan kami untuk maklumat lanjut

Pergi ke suapan

De pagina waar u naar op zoek bent, kan niet worden gevonden.

Probeer terug te gaan naar de vorige pagina of bezoek het Help Center voor meer informatie Ga naar uw feed

Probeer terug te gaan naar de vorige pagina of bezoek het Help Center voor meer informatie Ga naar uw feed

Vi finner ikke siden du leter etter. Gå tilbake til forrige side eller besøk vår brukerstøtte for mer informasjon

Gåtil din feed

Nie możemy znaleźć strony, ktorej szukasz. Spróbuj wrócić do poprzedniej strony lub nasze Centrum pomocy, aby uzyskać więcej informacji

Przejdź do swojego kanalu

A página que você está procurando não foi encontrada. Volte para a página anterior ou visite nossa Central de Ajuda para mais informações

Voltar para seu feed

Ne pare rău, nu găsim pagina pe care o căutatţi. Reveniţi la pagina anterioară sau consultaţi Centrul nostru de asistenţă pentru mai multe informaţii

Accesati fluxul dvs.

The page you are looking for cannot be found.