Hp 3d printer demo

HP Industrial 3D Printers - Leading The Commercial 3D Printing Revolution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Data courtesy1

Integrity.

Production ready

and reliable

Together, we can take revolutionary designs seamlessly from prototype to production grade.

Ability meets

agility

Let’s implement production processes that allow you to rapidly develop unique solutions while remaining flexible.

Reimagining

realities

Now we have the power to customize like never before and produce wherever, whenever your product is needed.

The possibilities are endless

Partnership makes anything

possible

Breakthrough digital technology alone isn’t enough. Today, you need a trusted partner who knows how to apply it effectively to help solve your specific supply-chain challenges.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Data courtesy of Bastian Solutions & Fast Radius, Heygears, Avular, Breezm, Volkswagen and Cupra Racing

- Data courtesy of GoProto and Ropes Edge

- Data courtesy of Gimatic

- Data courtesy of SmileDirectClub

- Data courtesy of Volkswagen

- Data courtesy of Invent Medical

- Data courtesy of Cobra Golf

- Data courtesy Addit.ion

- Data courtesy of Hopkins, J., Lobete, A., Remacha, C.

- Data courtesy of Lumenium

- Data courtesy of Breezm

Industrial 3D Printer – HP Jet Fusion 5200 Series 3D Printing Solution

Contact an HP 3D Print expert

Choose the phone number for your country to speak to a local HP 3D Printing sales expert today.

België/Belgique

+32 78 48 44 69

Czech Republic

+420 239 050 531

Deutschland

+49 7031 986 90 13

+49 7031 986 90 17

España

+34 93 003 45 95

France

+33 6 28 78 35 59

Italia

+39 02 8295 2406

Nederland

+31 20 241 5685

Norway

+47 23 96 00 13

Österreich

+43 720 117035

+43 1424 0091

Romania

+40 376 300 174

Sweden

+46 8 446 891 49

Suisse/Switzerland

+41 44 511 2308

+41 44 511 2333

United Kingdom

+44 20 7365 8158

United States

+1 877 468 8369

Expand and scale into volume production with HP industrial 3D printers

Enhanced manufacturing predictability

Breakthrough productivity and automation

Expand into new applications and markets

See how the HP industrial 3D printer works

Explore the complete HP Jet Fusion 5200 Series Industrial 3D Printing Solution

HP 3D High Reusability PP

1enabled by BASF

Chemical resistant,2 weldable, low moisture absorption, functional parts

Data courtesy3

HP 3D High Reusability PA 11

4Ductile,5 quality parts

Data courtesy6

HP 3D High Reusability PA 12

7Strong, low cost,8 quality parts

Data courtesy9

HP 3D High Reusability PA 12 GB

10Stiff, dimensionally stable, quality parts

Data courtesy11

BASF Ultrasint® TPU01

Flexible, functional parts.

HP Jet Fusion 5200 Series 3D Automatic

Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

HP 3D API

12Streamlined data access and automation across industrial management systems.

HP 3D Center

13Dashboard view into production data and remote monitoring for greater efficiency and agility.

Learn

Watch

HP 3D Process Control

14Dimensional accuracy and repeatability—faster—for manufacturing predictability.

HP SmartStream 3D Build Manager

Quickly and easily prepare your jobs for printing with all the elements you need.

Download

Autodesk® Netfabb® with HP Workspace

Provides advanced software for the additive manufacturing of production quality parts.

HP Build Processor

The industry standard software for professional 3D Printing, to unlock the full potential to manage every step in your production process.

Siemens NX AM

Combine design, optimization, simulation, preparation of print jobs, and inspection processes all in a single managed environment and with minimal steps.

HP Jet Fusion 5200 3D Natural Cooling Unit

Designed to remove and cool each build naturally, thereby enabling continuous production.

Hovmand Forklift 5200

HP recommended accessory to remove and place the HP Jet Fusion 5200 3D Natural Cooling Unit from the processing station.

HP 3D Solution Services

Explore new opportunities to scale production and accelerate growth with support and consultancy from HP.

HP 3D Professional Services

Expert guidance to help you and your customers identify viable strategic opportunities, optimize design for breakthrough applications, and streamline manufacturing processes.

Data courtesy15

HP 3D as a Service

Pay based on usage: Gain new levels of cost predictability and the flexibility to scale your business as you grow.

HP Integrated Financial Solutions

Accelerate your time to value. Enjoy the flexibility to meet both your technology and financial plans while allocating your cash to other priorities.

Data courtesy16

Expand your offering with quality white applications

Achieve consistent white - part after part, with the HP Jet Fusion 5420W 3D Printing Solution that delivers enhanced manufacturing predictability and outstanding part quality at the right cost.

Disclaimers

The content of this site is for information purposes only and it is showing the product configuration for the US market only.

Availability, pricing, product configuration and specifications may differ according to geographical location, local laws and practices.

Please contact us or talk to your local HP 3D Printing representative for further information or for product configurations specific to your local country.

- Based on internal HP testing, May 2020.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use.

HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PP enabled by BASF provide up to 100% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and reclaimed powder is tracked by generations (worst case for reusability). Parts are then made from each subsequent generation and tested for mechanical properties and accuracy showing no degradation of properties up to three generations of use. - Based on internal HP testing, May 2020, with tests for mechanical property retention, dimensional stability, and weight change after 7- and 30-day immersion with acids, bases, organic solvents, and aqueous solutions. Due to the material characteristics, extra tuning is required in part design and printing, compared to other rigid HP 3D Printing materials.

- HP 3D High Reusability PA 11 image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 11 provide up to 70% powder reusability ratio, producing functional parts batch after batch.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy. - Testing according to ASTM D638, ASTM D256, and ASTM D648 using HDT at different loads with a 3D scanner for dimensional accuracy. Testing monitored using statistical process controls.

- HP 3D High Reusability PA 12 image is data courtesy of Addit.ion

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 provide up to 80% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- Supplies price, and maintenance costs recommended by manufacturer. Cost criteria: printing 1.4 full build chambers of parts per day/5 days per week over 1 year of 30 cm3 parts at 10% packing density on Fast print mode using HP 3D High Reusability PA 12 material, and the powder reusability ratio recommended by manufacturer, and printing under certain build conditions and part geometries.

- HP 3D High Reusability PA 12 GB image is data courtesy of NACAR

- HP Jet Fusion 3D Printing Solutions using HP 3D High Reusability PA 12 Glass Beads provide up to 70% powder reusability ratio, producing functional parts batch after batch. For testing, material is aged in real printing conditions and powder is tracked by generations (worst case for reusability). Parts are then made from each generation and tested for mechanical properties and accuracy.

- BASF Ultrasint® TPU01 image is data courtesy of Kupol.

- Supported industrial management systems for HP Jet Fusion 5200 / 4200 Series 3D Printing Solutions : 3D Control Systems, AMFG, LINK3D, Siemens NX AM, Siemens Opcenter. Access to additional data modules available only for the HP Jet Fusion 5200 Series 3D Printing Solution. Additional purchases required. Supported industrial management systems for HP Jet Fusion 5420W 3D Printing Solution : 3D Control Systems, AMFG, LINK3D. Access to additional data modules available only for the HP Jet Fusion 5420W 3D Printing Solution.

Additional purchases required.

Additional purchases required. - Available only for the HP Jet Fusion 5420W 3D Printing Solution and HP Jet Fusion 5200/4200 Series 3D Printing Solutions. Compatible software. Additional purchase required.

- Available only for the HP Jet Fusion 5200 Series 3D Printing Solution. This software is sold as an HP 3D Solution Service. For more information visit https://h30195.www2.hp.com/v2/GetDocument.aspx?docname=4AA7-7931EEW

- Data courtesy of Meidai

- Data courtesy of Invent Medical

HP's entry into 3D printing will revolutionize manufacturing | Computer World

The news that HP was entering the 3D printing market with an industrial machine that was ten times faster and cost half the price of existing 3D printers went viral online.

One of HP's 3D printed designs, a miniature model of an oil rig, included many intricate pencil lead-thin components in various colors. Source: HP Source: HP |

“I wonder if she can print a black prototype from yellow polymer?” asked Reddit user ILikeLenexa.

“3D printing from a company that bills sky-high for refilling ink cartridges? Complete blocking by the supplier of any user initiatives? I don’t think it will be of any use,” another user hiding behind the nickname TotalWaffle sarcastically remarked.

However, jokes aside. With $112 billion in business and consumer products, HP is well positioned to bring the fruits of its 30 years of research from 2D printing to the 3D printer space.

This step will be unprecedented.

"There are many parallels between document printing and 3D printing, which is why we've been watching HP for a long time," said Terry Wohlers, president of research firm Wohlers Associates. “HP is a great candidate to enter this market.” Wohlers recently reported attending a demonstration of the new HP Multi Jet Fusion printer and was "very impressed" with its speed, quality, print detail, and gorgeous colors. nine0003

nine0003

“It turned out much better than I expected,” he admitted. “The new printer is many times faster than alternative devices on the market. We see something completely different compared to what has been developed before.”

Rumors about HP's entry into the 3D printing market have been circulating for the past year. Users of 3D printers languished in anticipation of change, and a small but rapidly growing community of 3D printer manufacturers expressed their concerns. nine0003

Today's largest 3D printer manufacturer, Stratasys, is seeing a 60 percent year-on-year growth in turnover, and HP's arrival isn't scary. "The activity of HP will contribute to further development and understanding of what is happening, expanding the space covered," the company's press service said in a statement. We see huge opportunities for the entire industry.”

“While 3D printing is still in its infancy, HP's entry into the world will accelerate growth at an unprecedented rate,” Wohlers said. “If the new 3D printer hasn’t blown everyone away yet, then they just don’t understand what it takes to make individual components in a traditional manufacturing process. This device will not only change the nature of the game, but will completely rewrite all the rules that industry players adhere to today.” nine0003

“If the new 3D printer hasn’t blown everyone away yet, then they just don’t understand what it takes to make individual components in a traditional manufacturing process. This device will not only change the nature of the game, but will completely rewrite all the rules that industry players adhere to today.” nine0003

3D printing, which dates back to the 1980s, has been used primarily to speed up the production of prototypes, a process called additive manufacturing rapid prototyping. Rapid prototyping using additive technologies speeds up development and reduces its cost, because mock-ups of tested components do not need to be sent to a design firm and prototypes are cut on giant lathes from blanks of metal or some other materials. With this technique, the slightest mistake forces you to return to the drawing board. nine0003

According to HP, the technology of three-dimensional printing Multi Jet Fusion will allow not only organizing rapid prototyping, but also mass production of components. Of course, it is unlikely that the number of components released in this way will be measured in millions and billions, but it is quite possible to talk about tens, hundreds and thousands.

Of course, it is unlikely that the number of components released in this way will be measured in millions and billions, but it is quite possible to talk about tens, hundreds and thousands.

Imagine 100 Multi Jet Fusion printers for the aviation or automotive industries. In this case, you can forget about the costs of warehousing and overproduction. Whether you need to make a new car model or modify a failed component, all you have to do is set up your CAD software and hit the Print button. nine0003

If you have doubts about the prospects of such projects, look at the experience of Ford and Airbus, two multi-billion dollar multinational corporations that have been successfully using 3D printing in the production of components for several years.

"I see that we are dealing with revolutionary technology - said Gartner Vice President Pete Basilier. “This is a unique experience, not only because the components for these printers have never existed before, but also because new, faster processes have never been built on the basis of their combination. ” nine0003

” nine0003

The printer uses a print bar, which resembles the scanning ruler of a conventional two-dimensional apparatus. A 3D printer's print bar has 30,000 nozzles that emit 350 million drops of thermoplastic or some other powdered material every second as they move back and forth over the print platform.

The 3D printer combines the properties of inkjet printing, in which a liquid binding agent is selectively added to a powdered material, and laser technologies, which sinter the toner under the influence of an electron laser beam. The printing process consists in the layer-by-layer fusing of powder material under the influence of high temperature. nine0003

HP demonstrated 3D printing samples that looked surprisingly complex and durable. During the demonstration, representatives of the company printed out a metal chain in half an hour, which weighed just over 100 grams and withstood a pressure of 4.5 tons. Another example, a miniature model of an oil rig, included many intricate components of various colors as thick as pencil lead.

Although the Multi Jet Fusion printer won't hit the market until 2016 (beta testing by manufacturers will be organized in 2015), its launch is sure to spur R&D in the 3D printing industry and beyond. After all, the company that can invent and successfully market the best manufacturing technology will be the winner. nine0003

A survey of 100 leading manufacturers by PricewaterhouseCoopers found that two-thirds of them use 3D printing for both rapid prototyping and custom components. As 3D printing technologies continue to develop, their scope will begin to go beyond rapid prototyping.

“As has happened so many times in history, the invention of a new manufacturing process will bring new, higher quality products to the market,” said Carl Bass, CEO of Autodesk, a maker of professional 3D design software. nine0003

Welcome! Hewlett Packard HP Multi Jet Fusion 3D Printer

News

Hewlett Packard has already made a lot of noise with its announcement of its intention to enter the 3D printing market.

Existing manufacturers get into the pose of an angry cat every time, and it's understandable: even such "giants" of the 3D printing industry as 3D Systems and Stratasys simply do not have a similar capitalization or production capacity. Moreover, HP also declares its intention to create its own "ecosystem" (a combination of 3D printing devices, scanners, Internet resources, etc.). So imagine the reaction of potential victims when an elephant, who has rich experience in the development and production of computers and office equipment, with a fat wallet and factories around the world, intends to enter a china shop. nine0003

Existing manufacturers get into the pose of an angry cat every time, and it's understandable: even such "giants" of the 3D printing industry as 3D Systems and Stratasys simply do not have a similar capitalization or production capacity. Moreover, HP also declares its intention to create its own "ecosystem" (a combination of 3D printing devices, scanners, Internet resources, etc.). So imagine the reaction of potential victims when an elephant, who has rich experience in the development and production of computers and office equipment, with a fat wallet and factories around the world, intends to enter a china shop. nine0003 Actually, 3D Systems has already made an official announcement. It sounds like this:

“As the founders and pioneers of 3D printing technology, we find it very inspiring for a company like Hewlett Packard to enter the 3D printing market. We view HP's announcements as a guarantee of industry-wide success. At the same time, we must point out that our 30 years of experience means that it is impossible to create universal 3D printing devices suitable for any user or any task.With a rich selection of printers, supplies and digital assets already available, we intend to continue to grow and remain at the forefront.” nine0013

In general, 3D Systems is not going to give up. Moreover, he teaches the "elephant" how to properly dance the mazurka. There are two ways to consider such a reaction, especially against the backdrop of complete silence from Stratasys, the main competitor of 3D Systems. On the one hand, this is a challenge, but on the other... HP is no longer just unfoundedly declaring its intention to chop off its piece of the market, but also demonstrating working prototypes of future components of its "ecosystem".

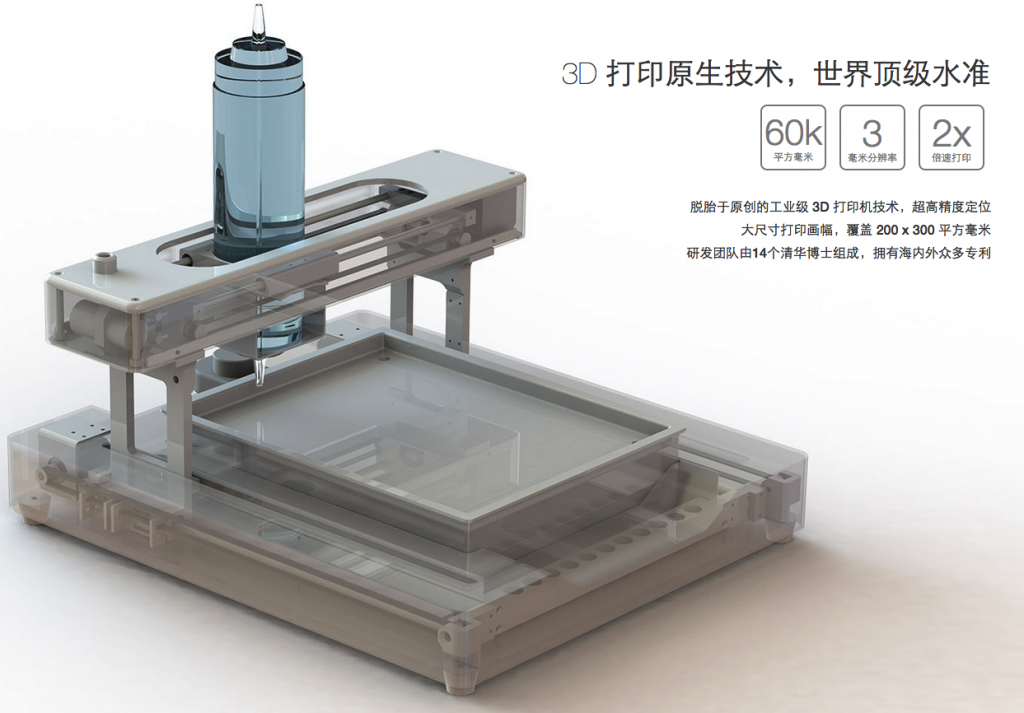

This time the company provided a prototype of its own 3D printer using a technology called "Multi Jet Fusion". It is known that this technology will build models from powder materials, applying a special binder to form layers. Similar methods have been used for a long time, often using photopolymer resins as a filler or adhesive. nine0003

nine0003

But in this case, HP mentioned a "chemical" process: the machine uses two types of binder filler. One of them is used to "bind" the particles, and the second weakens or enhances the process, allowing you to change the physical characteristics of the finished material. Moreover, the material does not sinter, which means that the possibility of processing models for consumables will be increased. According to the developers, the device uses a print head with 30 nozzles, capable of applying 350 million drops per second with an accuracy of 21 microns. Over time, the company intends to achieve a full color gamut of printed products. In fact, an application is being made for a 3D printer capable of printing 10 times faster than existing counterparts and with pluses in the form of economy, energy efficiency and high resolution. The new 3D printer will be offered for sale in 2016. nine0003

But that's just the beginning: HP showed off Sprout, a platform for designing and processing digital models. In fact, it is a full-fledged computer with a built-in scanner, high-resolution camera and projector. This miracle of technology works on Windows 8.1, alas. Throw in an Intel i7 processor and 1TB of storage. The system allows you to scan 3D objects and then manipulate the models on a 23-inch vertical touch screen or with a horizontal projector. In addition, it will be possible to work on models by design teams in real time. Moreover, if sales of the HP 3D printer are still delaying, then the start of sales of Sprout is scheduled for 9November!

In fact, it is a full-fledged computer with a built-in scanner, high-resolution camera and projector. This miracle of technology works on Windows 8.1, alas. Throw in an Intel i7 processor and 1TB of storage. The system allows you to scan 3D objects and then manipulate the models on a 23-inch vertical touch screen or with a horizontal projector. In addition, it will be possible to work on models by design teams in real time. Moreover, if sales of the HP 3D printer are still delaying, then the start of sales of Sprout is scheduled for 9November!

The ice has broken, ladies and gentlemen of the jury! Now it remains only to look at the price tags for new products. If HP is able to offer such equipment at reasonable prices, then we will guarantee serious changes in the stock price of 3D Systems and Stratasys. One last point of interest: HP has also expressed a desire to partner with enthusiasts and developers in the 3D printing industry. In fact, this is an open offer for start-up companies to join HP.