Context z450 3d printer

Zcorp 3D Printer Review 2022

3.9

See Price

Although manufacturer ZCorporation no longer exists, the company’s range of printers stays a reference in the annals of 3D printing history for bringing full-color printing to the forefront of 3D possibilities.

Among the shining lights of this revolutionary series of printers is the ZCorp Z450 and today we’ll focus on this very model to determine how well it stacks up to trials and tribulations of time. Let’s jump in and find out what this 3D printer has to offer.

| Printing Area | 203 mm x 254 mm x 203 |

| Layer Resolution | 90 – 100 microns |

| Supported Filament | ZP130 Powder and ZB59 Binder |

| Printing Technology | 3DP/ZPrinting/ColorJet Printing |

| Resolution | 300 x 450 dpi |

Table of ContentsShow

Design & Features

Visually, the ZCorp Z450 isn’t the most appealing and is very much a product of tech production of the early 2010s with a rather uninspiring grey scheme covering the entire unit only interrupted by a questionably stylish orange near the control panel.

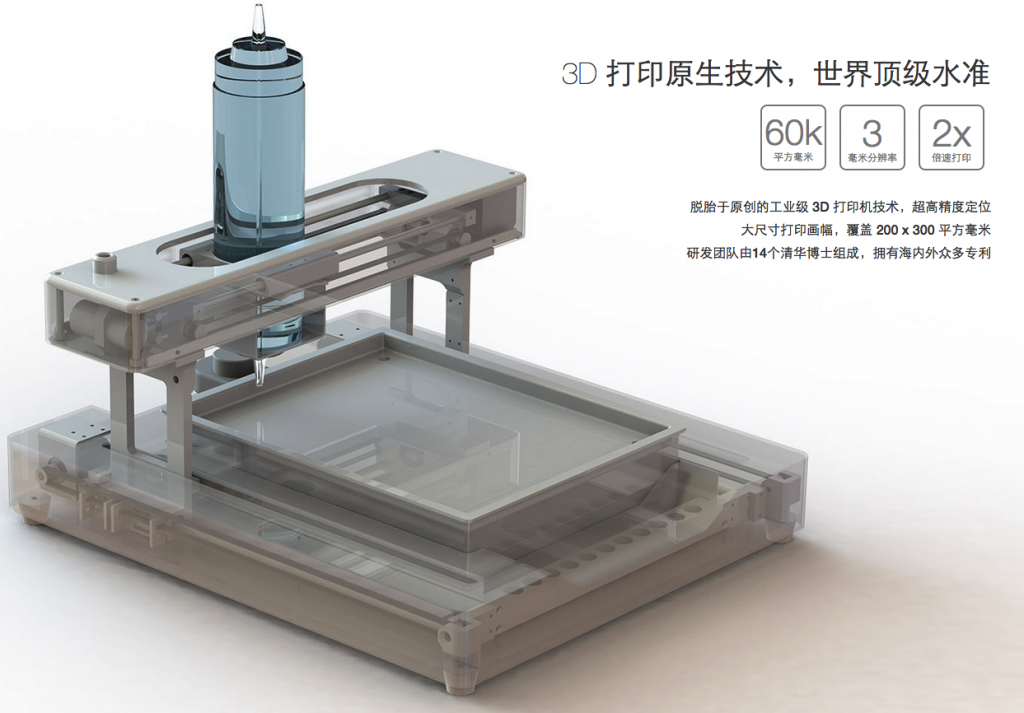

Rather than relying on Fused Deposition Modelling, the Zcorp Z450 is based on a patented additive manufacturing technology known as 3DP, ZPrinting, or ColorJet Printing depending on who you ask.

The basic tenet of the process involves a print head – very similar to that found in traditional inkjet printers – selectively laying down a liquid binding material on a thin layer of powder causing it to solidify into a specific shape and design. The main upside of the technology is a near limitless use of color because the inkjet selectively colors the binder from a range of 180,000 individual shades before applying it to the powder.

When the shape has been etched into the powder, the print bed lowers down ushering in a fresh layer of powder spread thanks to a roller for the process to repeat itself. Add up all these layers, dust off any extra powder, and you get a full-color 3D model. The results can include graded color fades, intricate patterns, and near lifelike color renditions.

The innards of the printer are divided into two chambers one for building and one for fine-powder removal. Nearing the end of the build process the first chamber runs a cursory powder removal cycle that removes the bulk of the excess powder. When the model is dry, it is moved to the second chamber where a stronger, deeper removal process cleans off any remaining powder.

The build area of the Z450 totals in at 203 mm x 254 mm x 203 for an entirely respectable surface area that is in line with similarly sized printers, but doesn’t set any records. A happy middle ground if you will. It can print up to 23 mm per hour with a layer resolution range of 90 to 100 microns and a print resolution of 300 x 450 dpi.

In what is undoubtedly the most significant negative of the Z450, the printer is only compatible with ZP130 Powder and ZB59 Binder materials. In itself, this isn’t an issue as there are many printers on the market with proprietary material limitations. The problem here is that buying the powder and binder is a bit like finding a needle in a haystack. Vendors are out there, but they charge a pretty penny for the materials.

Vendors are out there, but they charge a pretty penny for the materials.

An LCD controlled by a wheel knob sits on the front of the printer providing an array of functions ranging from de-powdering, status details, and platform raising controls. Connectivity is assured via Ethernet.

The printer runs alongside the ZPrint software that acts as both a slicer and interface to communicate with the printer. It can read STL, VRML, PLY, 3DS, ZPR file types and is compatible up to Windows 7 or older. The software isn’t innately shoddy but does show its age with an absence of functions and tinkering options we’ve come to expect from modern slicing software.

Assembly & Unpacking

Due to its 193 kg total weight and 122 cm x 79 cm x 140 cm dimensions, the Z450 falls into the crate shipped printer category, and this is precisely how the model was delivered when it was still being manufactured and how we took custody of it second hand.

The printer comes fully assembled other than fitting a new printhead and replacing the binder/powder cartridges. Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Printing

The Z450 produces high-quality prints with an eye-watering range of colors that put standard FDM 3D printers to shame. The printing process is also extremely streamlined due to the arrangement of the chambers and their various dry, vacuum, and print functions. The printer is also very waste conscious and automatically reuses excess powder. The added vacuum nozzle also works admirably for manual powder clearing.

Where this printer truly shines is in the speed of the printing process. In what is near enough twice the rate of traditional 3D printers, the Z450 is the fast prototypers dream with the ability to produce conceptual parts very quickly.

The models look and feel amazing, but there is a certain frangibility to them that is absent in PLA or ABS models for example. There’s a distinct sense that beyond being a visual representation of an idea or model, the prints from the Z450 won’t fare well being handled for practical uses or mechanical purposes, even as a functional proof of concept.

Support

In light of 3D Systems taking over Z Corporation and manufacturing of the Z450 long since abandoned, official support is unavailable. Any warranties for new units have long since expired with the chances of obtaining one is confined to merchants and auction sites flogging the printer second hand. These vendors may offer other warranties so check before committing to a purchase.

It is, however, possible to successfully hew through successive Google search pages to find advice and tips for using the Z450. Among these are niche communities of users who vow by the Z450 for all their printing needs. The difficulty lies in tracking them down.

The user manual is also a great source of information for troubleshooting problems and maintenance guidelines.

Verdict

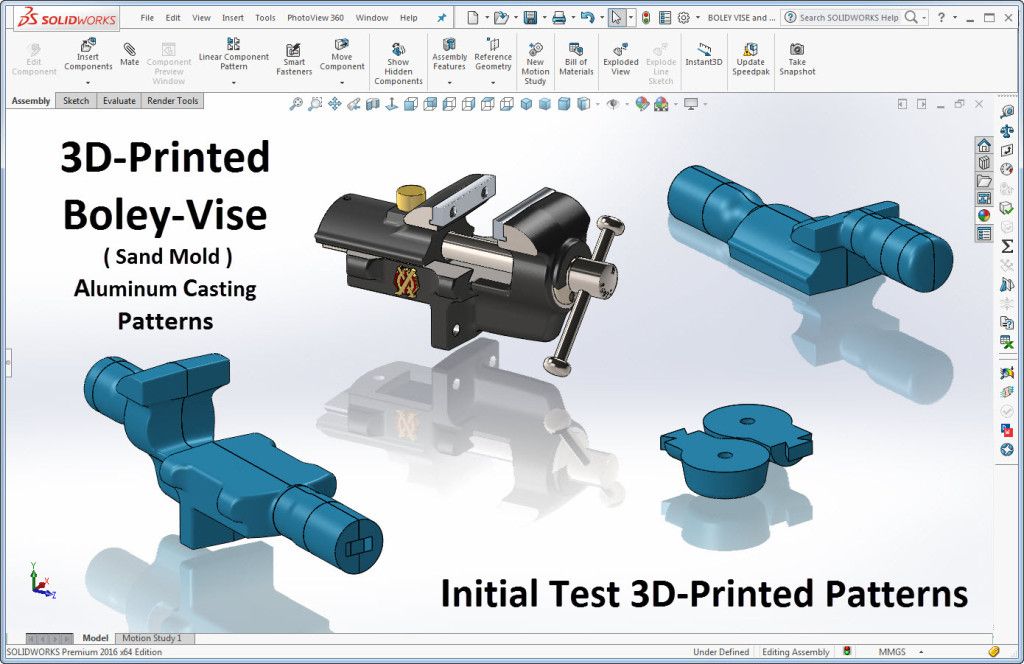

In our eyes, the Zcorp Z450 is geared towards fast prototyping for design concepts, architectural models, form-and-fit prototypes, and demonstration pieces. Within these spheres, the Z450 performs admirably, but the questionable reliability of the end product with a propensity for being unduly brittles means practical uses are out of the picture.

Equally, a hobbyist who wants reliable models for either ornamental purposes will find use in the Z450 but venture even slightly into application based printing, and this model falls short.

The real allure of the Zcorp 3D printer is that it is possible to pick one up for a fraction of the retail price (approximately around $40,000 at its peak price). We are talking less than a $1000, if not less.

A hobbyist who wants a printer with powder/binder-based technology to add to their workshop should strongly consider the Z450 for its reliability and low cost.

CONTEXT: 3D printing sector “buoyant” despite 2021 supply chain woes

0Shares

Review the 3D printing trends to keep an eye on this year. Our latest article has the perspective of more than 40 additive manufacturing insiders.

According to market intelligence specialist CONTEXT’s latest industry report, the recent return of in-person trade events has led to a renewed interest in 3D printing which has carried through into the order books of 3D printer manufacturers.

The report states that shipments of industrial 3D printers priced over $100,000 were up 39 percent throughout the first three quarters of 2021, although remained 6 percent down on pre-Covid levels. However, the firm says that while shipments of new high-end printers grew over Q3 2021, in many cases demand outstripped supply due to the rise of the omicron variant and various supply chain woes, leaving 3D printer shipments in h3 2021 limited.

Despite this, CONTEXT says the market is now “poised for strong growth” as it heads into 2022, with demand for consumer-targeted printers remaining higher than pre-pandemic levels over the first three quarters of 2021.

CONTEXT’s report has identified industrial 3D printer sales rebounded strongly across the globe during Q1-Q3. Photo via Stratasys.Accelerating industrial 3D printer orders

CONTEXT’s latest figures echo the trend of its previous quarterly reports throughout 2021, finding industrial 3D printer shipments have continued to bounce back after a Covid-hit 2020. During 2021, CONTEXT observed shipments of industrial and “design” printers – those defined here as selling for over $20,000 – rebounded strongly across the globe, while the recovery of Western 3D printing markets continued to gather pace towards the end of the year.

During 2021, CONTEXT observed shipments of industrial and “design” printers – those defined here as selling for over $20,000 – rebounded strongly across the globe, while the recovery of Western 3D printing markets continued to gather pace towards the end of the year.

Despite this, the report says that the number of new high-end printers sold during 2021 still lagged behind pre-Covid levels, with industrial printers down six percent compared to Q1-Q3 2019. According to CONTEXT’s report, the strongest demand within the industrial 3D printer sector during 2021 was seen from printers focused on production or mass customization. In fact, polymer vat polymerization printers were found to be 22 percent up on 2019 levels, while demand for metal binder jetting models soared 104 percent.

In particular, CONTEXT identified resin vat polymerization 3D printers remained heavily in-demand from the dental industry across the globe, with the “ever-accelerating” production of clear dental aligners being one way high-end 3D printers are being leveraged for mass customization applications. A key example of this is Prodways’ recently announced contract to 3D print up to a million dental aligners per year as part of a ‘major industrial project.’

A key example of this is Prodways’ recently announced contract to 3D print up to a million dental aligners per year as part of a ‘major industrial project.’

While demand continued to grow for industrial 3D printers throughout the latter stage of 2021, the rise of omicron and subsequent supply chain challenges regarding 3D printer parts meant that for many vendors, demand outpaced supply, the report says. Saying this, the report states that global supply chain concerns also caused a new and renewed interest in 3D printing which coincided with the return of in-person events such as RAPID+TCT in the US in September and Germany’s Formnext 2021 in November.

According to CONTEXT, this piqued interest has translated into the order books of industrial 3D printer vendors, leaving the industry “buoyant” and poised for growth in 2022.

Global 3D Printer Shipments by Price Class. Image via CONTEXT.Personal and professional growth

CONTEXT’s latest figures suggest that the ‘professional’ 3D printer price class – those selling for between $2,500-$20,000, was least impacted by the pandemic, with its relatively high 2020 baseline making its 14 percent year-on-year growth in the first three quarters of 2021 look less impressive than the recovery growth seen in other price categories. The sector’s growth appears consistently strong, though, as the report says shipments were up not only on 2020’s figures but also came in 13 percent higher than the same period pre-Covid.

The sector’s growth appears consistently strong, though, as the report says shipments were up not only on 2020’s figures but also came in 13 percent higher than the same period pre-Covid.

The report attributes the sector’s recent growth to new product lines and the expedited introduction of benchtop SLS polymer machines, like the Fuse 1 3D printer from Formlabs.

Looking at the ‘personal’ and ‘hobby’ price class of printers, those selling for less than $2,500 according to CONTEXT’s classification, and the report identified a continuation of the trend of fully assembled personal 3D printers giving way to lower-priced kits, despite demand for both skyrocketing at the height of the Covid-19 lockdowns in 2020. The report states that while demand at the lower end of the market waned and settle into a “new normal” during 2021, shipments remained above 2019 levels.

According to CONTEXT, its Q4 figures will be the most telling for this sector, with current projections suggesting that annual shipments of personal printers could be down by as much as 10 percent on 2020. Despite this, the latest figures state that shipments of personal machines are still up by more than a third on 2019 levels, while kit and hobby printer shipments are on track for at least 36 percent year-on-year growth. Given that sales in 2020 were almost double those of 2019, though, these figures fall short of many vendors’ expectations, the report indicates.

Despite this, the latest figures state that shipments of personal machines are still up by more than a third on 2019 levels, while kit and hobby printer shipments are on track for at least 36 percent year-on-year growth. Given that sales in 2020 were almost double those of 2019, though, these figures fall short of many vendors’ expectations, the report indicates.

In its report, CONTEXT continues to identify resin-based LCD printers as the “hottest” items in the hobbyist market currently, many of which sell for less than $250.

Q1–Q3 2021 Global 3D printer shipments: Market leaders by class, material and process. Image via CONTEXT.Looking ahead to 2022 and beyond

According to Chris Connery, VP of Global Analysis at CONTEXT, the key 2022 3D printing trends he expects to see this year include the proliferation of high-temperature, material extrusion thermoplastic printers, composites, binder jetting for metal, and company growth by way of consolidation. CONTEXT also predicts supply chain mitigation and the role of digital manufacturing alongside 3D printing to be central themes going forwards.

The firm projects that the current record backlog looks set to push aggregate system revenues for 2022 up by 23 percent on 2021 numbers. Over the next five years, CONTEXT expects those technologies with mass production capabilities, such as binder jetting, polymer vat polymerization and polymer PBF, to see a CAGR of 30 percent or more in unit volumes.

EOS presented Sintavia with a 3D printed ‘1,000th 3D printer’ award to mark its printer delivery and installation milestone. Photo via EOS.Cross-analyzing CONTEXT’s figures

Market analyses aren’t always able to capture the full complexities of their target sectors, however in this case CONTEXT’s report seems to echo the recent sentiments of industrial 3D printer manufacturers in particular.

For instance, the report’s suggestion that industrial printer sales are continuing to rebound is backed up by Chinese PBF 3D printer manufacturer Farsoon Technologies achieving its highest ever monthly turnover during November 2021 after rising demand saw it install 500 3D printers worldwide, while fellow market leader EOS announced the delivery and installation of its 1,000th 3D printer in North American in December.

The turbulence of Q3 was also acknowledged by the likes of Desktop Metal, which lowered its full-year financial guidance after it failed to meet its revenue expectations for the period.

Elsewhere, a “dramatic increase in demand” from customers in the space and energy sectors was experienced by VELO3D, with the firm attributing its 278 percent revenue boost between Q3 2020 and Q3 2021 primarily to a rise in its machine sales.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows CONTEXT’s report has identified industrial 3D printer sales rebounded strongly across the globe during Q1-Q3. Photo via Stratasys.

Photo via Stratasys.

Tags Chris Connery CONTEXT Desktop Metal EOS Farsoon Technologies Formlabs Formlabs Fuse 1 Formnext 2021 Prodways RAPID + TCT 2021 Velo3D

Hayley Everett

Hayley is a Technology Journalist for 3DPI and has a background in B2B publications spanning manufacturing, tools and cycling. Writing news and features, she holds a keen interest in emerging technologies which are impacting the world we live in.

Home - 3D Ceram

Our news expense

3D printers

Ceramic oxide compounds

Ceramic irrigation compositions

Read more from our cars.

We offer 3D printing training that allows you to control the process on Ceramaker machines to successfully complete your projects. nine0003

3DCeram offers tools for integrating 3D printing solutions into ceramic parts projects.

-

The aerospace and defense industries are constantly striving to optimize the performance of their equipment (satellites, measuring instruments, optical instruments, etc.

) by exploiting the properties of ceramics and setting new challenges, accompanied by a strong trade-off between performance and cost. In this context, products should be more technologically advanced and reduce development time. DETAILS

) by exploiting the properties of ceramics and setting new challenges, accompanied by a strong trade-off between performance and cost. In this context, products should be more technologically advanced and reduce development time. DETAILS Read more

3DCeram offers production lines tailored to the operating conditions of industrial markets (electronics, chemistry, telecommunications, etc.) that seek to integrate this new technology.

More details

3DCeram has been using SLA 3D printing technology for more than 10 years to produce custom or small batch bone implants (intervertebral cages and osteotomy-tibia wedges), as well as cranial and maxillary implants… READ MORE

More

-

3DCeram is the preferred partner of large research groups and universities. Indeed, the resistance and various properties present in ceramic make it the material of choice.

Read more

Aerospace, collaboration between Anywaves and 3DCeram

Anywaves has developed an innovative ceramic antenna concept for the aerospace industry. 3DCeram assists Anywaves with a 3D-AIM service to refine the entire manufacturing process https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/anywaves-designs-new-satellite-antenna-with-3dceram-ceramic -/ https://www.3d-grenzenlos.de/magazin/3d-objekte/prototyp-bandantenne-gnss-l1-e-mit-3d-drucker-hergestellt-27649103/ https://siusystem.ru/news/servis-3d-aim-ot-3dceram-pomog-anywaves-zapustit-vypusk-antenn-dlya-kosmosa

3DCeram assists Anywaves with a 3D-AIM service to refine the entire manufacturing process https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/anywaves-designs-new-satellite-antenna-with-3dceram-ceramic -/ https://www.3d-grenzenlos.de/magazin/3d-objekte/prototyp-bandantenne-gnss-l1-e-mit-3d-drucker-hergestellt-27649103/ https://siusystem.ru/news/servis-3d-aim-ot-3dceram-pomog-anywaves-zapustit-vypusk-antenn-dlya-kosmosa

DETAILS

Additive manufacturing, innovative in nature

3DCeram Sinto, a French company based in Limoges, has 15 years of experience in 3D printing complex ceramic parts, offers a wide range of services and a line of 3D printers. Interceram met with Nicolas Rousselet, Aerospace Segment Manager, and Karen Malsalle, Marketing Manager, to discuss a new service that meets the expectations of aerospace customers. Read Article

DETAILS

3D printed blade cores

3D printing opens the door to mass production of optimized blade cores. The rods are an important component in the manufacture of aircraft cooled turbine blades and land based gas turbines. The internal channels of the turbine blade reduce its temperature. This reduces fuel consumption and therefore reduces emissions. But, above all, it increases the efficiency of the turbine. Note that the demand for complex rod designs is growing to meet the demand for smaller, more efficient, and therefore more profitable engines. The engines of the new […]

The rods are an important component in the manufacture of aircraft cooled turbine blades and land based gas turbines. The internal channels of the turbine blade reduce its temperature. This reduces fuel consumption and therefore reduces emissions. But, above all, it increases the efficiency of the turbine. Note that the demand for complex rod designs is growing to meet the demand for smaller, more efficient, and therefore more profitable engines. The engines of the new […]

Read more

more

Phone: +33 (0) 5 55 04 10 90

Email: [email protected]

© 2009 - 2020 Copyright

SearschePrinting: Like using the help Ears, skin and noses are made by 3D printers

- Natalka Pisnya

- BBC Russian Service, USA

nine0003

Image copyright, Masela family archive

Photo caption, Luc Masela with his parents one month after the artificial bladder transplant. year 2001.

year 2001.

Luc Masela, now 27, is an athlete with a degree in economics, works for a large exhibition company, travels a lot and recently met, in his words, "the most beautiful girl in the world." Both she and most of his current friends were extremely surprised when they learned that 17 years ago he survived a dozen and a half operations. nine0064

Luke was born with spina bifida - and although he was able to walk, his bladder was severely damaged. By the age of 10, he almost did not leave hospitals: due to improper functioning of the bladder, fluid began to return to the boy's kidneys, doctors diagnosed an irreversible pathology of the organ.

You need JavaScript enabled or a different browser to view this content

Video caption,"3D printed" organs are here

Doctors offered the family two solutions: lifelong dialysis or the creation of a new bladder from a segment of the intestine. This would guarantee Luke several years of medically supervised life and a high risk of developing cancer.

This would guarantee Luke several years of medically supervised life and a high risk of developing cancer.

The urologist in charge of the boy suggested that Masela's family take part in an experimental program to grow a new bladder from his own cells. Then, in 2001, it sounded like science fiction: only nine people took part in the program before Luke. Despite this, his family agreed. nine0003

"The essence of the operation was reduced to two stages: first, a piece of bladder tissue was taken from me, and over the next two months, cells were grown in the laboratory in order to grow a new healthy bladder from them," says Luke.

Photo copyright, Masela family archive

Photo caption,Luc Masela, 17 years after his artificial bladder transplant

Next came the transplant, which he said took 16 hours. “I opened my eyes and saw a cut through my entire stomach, tubes of all possible sizes were sticking out of me, except for them - four IVs and a bottle-feeding machine,” he recalls. “I stayed in the hospital for another month, I was prescribed bed rest, after that I stayed at home for another month. nine0003

“I stayed in the hospital for another month, I was prescribed bed rest, after that I stayed at home for another month. nine0003

The operation was performed by Dr. Anthony Atala, Pediatric Regenerative Surgeon. In two months, out of a hundred patient cells, scientists created one and a half billion. Further, an engineering structure was created on a collagen frame: the bladder was “sculpted” like a two-layer pie, the core of which dissolved over time, and it started working like a normal organ, taking root thanks to Luke’s own cells.

- An animal capable of regrowing its head

- The birth of a chimera: why do scientists need a human-animal hybrid? nine0034

- Swedish company 3D prints body parts

Luke and Dr. Atala haven't seen each other for 10 years after being discharged from the hospital. Once a dying child became the champion of the school wrestling team and went to college.

The professor took charge of the Wake Forest Institute of Regenerative Medicine in North Carolina in those 10 years, but he never forgot about Luke: his bladder was one of the most challenging and most successful projects in his early practice.

By 2018, Atala won the Christopher Columbus Award for "work on a discovery that will have a significant impact on society"; The Times and Scientific American magazines at various times named him "Physician of the Year", he was also recognized as "one of the 50 scientists on the planet who in the next 10 years will change the way we live and work."

How to print a new face

Skip the Podcast and continue reading.

Podcast

What was that? nine0003

We quickly, simply and clearly explain what happened, why it's important and what's next.

episodes

The End of the Story Podcast

In the mid-2000s, Atala's team turned their attention to an ordinary household 3D printer and wrote special software for it, later specialized machines were created for the laboratory. Now the laboratory "grows" up to 30 different types of cells and organs, as well as cartilage and bones.

One of the team's latest achievements is ears and noses grown outside the human body. nine0003

The main customer and sponsor of Atala's developments is the US Department of Defense, and many of the patients are military victims of military operations.

It works like this: first, a CT scan of the ear or nose is done. One of Atala's assistants, Joshua Corpus, jokes that at this stage, people often ask to "improve" the shape of the nose if they thought theirs was too wide or hooked, and the ears if they were too wide.

After that, a special computer code is written, and the printing of the basis of the organs begins. nine0003

nine0003

For this, a bioresorbable polymer, polycaprolactam, is used. At the same time flexible and durable, in the human body it disintegrates within four years.

After printing, the layers of polycaprolactam resemble lace; after transplantation, their place will be taken by the person's own cartilage tissue in a few years.

Polycaprolactam is then saturated with a gel created from the patient's cells, cooled to -18 degrees Celsius - so the cells, according to scientists, are not damaged, they are "alive and happy." nine0003 Image caption,

Printing a test kidney sample on a bioprinter

In order for the polymer and gel structure to take shape and become something more durable, ultraviolet light is used in the laboratory - it does not damage cells.

The future implant is printed for 4-5 hours, then it is finally formed and inserted under the epidermis.

Skin can also be grown: children affected by the fires were the first to participate in the early trials of Atala - after the "printing" of the skin, scientists observed the patients for several more years. The new skin did not crack, did not burst, and grew with the children. nine0003

The new skin did not crack, did not burst, and grew with the children. nine0003

The most difficult job, according to the scientist, is facial wounds: it’s not enough just to stretch the skin, you need to accurately calculate the geometry, align the swelling, the structure of the bones, and understand how a person will look after that.

In addition to the skin and ears, Atala can "print" the bones of the jaws, grow blood vessels and cells of some organs - the liver, kidneys, lungs.

This technology is especially appreciated by oncologists: on the basis of patient cells, it is possible to recreate the body's response to various types of chemotherapy and observe the reaction to a particular type of treatment in the laboratory, and not on a living person. nine0003

But the liver, kidneys, lungs and heart are still being tested. Atala says he raised them in miniature, but creating organs from various tissues to real size requires a lot of additional research.

But, according to him, cells were grown in the laboratory and a vagina was created for a girl who was born several years ago with a congenital deformity of the genital organs - several years have passed since the transplant.

Image caption,Bioprinted polycaprolactam ear implant base

Atala smiles and adds that his team is also working on a working penis. This research has been going on for several years, and the most troublesome for scientists is the complex structure of tissues and the specific sensitivity of the organ itself.

Among others, Igor Vasyutin, a Russian post-graduate student of the First Moscow State Medical University (MSMU) named after Sechenov, is working on this under laboratory conditions. He is a cell biologist, Atala's right hand. nine0003

Vasyutin has been in the USA for about a year - he came on an exchange. He is ready to talk about the behavior of stem cells for hours, but becomes less verbose when it comes to Russian science.

Vasyutin's alma mater has not reached mass regeneration of human organs and is still training on animals: local scientists "printed" a mouse thyroid gland on a 3D printer.

They are also involved in the study of human organs. According to the head of the Institute of Regenerative Medicine at MSMU Denis Butnar, several years ago the Institute recreated a special engineering design of the buccal mucosa. She functioned perfectly for the first six months, but subsequently had to undergo a second operation. nine0003 Image caption,

Ultraviolet test sample of an ear implant

In Russia, however, over the past few years, the Italian transplant surgeon Paolo Macchiarini has been practicing, the man who was the first in history to perform a synthetic organ transplant operation - a plastic tube that replaced the patient trachea.

- Paolo Macchiarini: the rise and fall of the famous surgeon

However, seven of his nine patients died, and the breathing tubes implanted in the remaining two subsequently had to be replaced with donor ones. nine0003

nine0003

Several criminal cases were brought against him, including on charges of pressure on patients and fraud, and the world's leading doctors called Macchiarini's operations "ethical Chernobyl."

Will printed organs replace donors?

At the zenith of his career, Macchiarini argued that a new perspective is opening up for humanity: you can "print" any human organ on a printer, create an engineering structure from it, enriched with the patient's stem cells, and get the perfect prosthesis. nine0003

Be that as it may, complex human organs - the liver, kidneys, heart, lungs - have not yet been able to grow any regenerative surgeon.

Bioprinting of the so-called simple organs, however, is already available in the US, Sweden, Spain and Israel - at the level of clinical trials and special programs.

The American government is actively investing in such programs - in addition to Wake Forest, cooperating with the Pentagon, the Massachusetts Institute of Technology also receives significant amounts to recreate the functioning of the liver, heart and lungs. nine0003 Image caption,

nine0003 Image caption,

Skin application test on a burnt wound

According to Professor Jorge Raquela, a gastroenterologist at the Mayo Clinic Research Center, "Bioprinting is one of the most exciting branches of modern medicine, it has huge potential, and the turning point of the most important discoveries is already close."

Meanwhile, Pete Basillier, head of R&D at analytics firm Gartner, insists technology is advancing much faster than understanding the implications of 3D printing. nine0003

Such developments, according to Basilière, even if created with the best of intentions, give rise to a set of questions: what will happen when "improved" organs are created, the basis of which will not only be human cells - will they have "superpowers"? Will a regulatory body be created to monitor their production? Who will check the quality of these organs?

According to a report from the US National Library of Medicine, more than 150,000 Americans are on the waiting list for organ transplants every year. Donor organs will receive only 18% of them; every day in the United States, without waiting for a transplant, 25 people die. Organ transplants and subsequent rehabilitation cost insurance companies and patients $300 billion in 2012 alone. nine0003

Donor organs will receive only 18% of them; every day in the United States, without waiting for a transplant, 25 people die. Organ transplants and subsequent rehabilitation cost insurance companies and patients $300 billion in 2012 alone. nine0003

- A 3D printer helped a cyclist who lost his jaw

- Genetically modified pigs - human organ donors?

- The world's first child who received both hands transplanted plays baseball

Most Americans are potential donors: upon obtaining a driver's license, they voluntarily answer the question of whether they agree to donate their organs in the event of a car accident or other dangerous incident . In case of consent, a small "heart" and the word "donor" appear in the corner of the document. nine0003

Professor Atala's driver's license is like that - despite all his achievements and faith in the "publishing organs", he is ready to share his with those around him.