Samsung 3d printing

Samsung best 3D printer models・Cults

Galaxy Watch5 /5 Pro Charging Watch Stand

€3.46

TrayStation TV Tray Organization System

€10.17

Samsung ssd t5 black magic pocket cinema camera smallRig

€1.25

Samsung S21 Ultra (in Otterbox Commuter case) Wall Charger Stand with headphone out

€2.55

Samsung Galaxy S4 case / Smartfriendz Logo

Free

Phone and charger holder

Free

Table suport (Samsung Galaxy Tab 3 10.1)

Free

Samsung remote control wall mount

Free

Samsung Watch Active Support

€2.50

Notebook stand (very stable structure)

€0.50

Wireless Samsung Charger Stand

Free

U Got This Phone Holder with Sound Amplifier

€5. 09

Samsung TV accidental button push prevention

Free

Samsung galaxy s3 phone holder belt clip

Free

Theranos Samsung S21 phone case

€0.75

Volume Key Replacement for Samsung Galaxy XCover 4s

Free

Funda para Samsung galaxy core2 duos.

€1.30 -47% €0.69

Samsung watch series 4, 5 charger support

€2

iPhone 14 pro case 6,1" with hanging rings

€1

Lens Cap holder (Samsung NX3000) 43mm

Free

Wonder Woman Phone Holder 📱

€3

Samsung Frame 2022 remote control holder

Free

Samsung S7-Halterung für Fahrrad (mit Hülle)

Free

Wanhao duplicator i3 phone holder

Free

Galaxy s9 plus case

Free

Palmeiras FC Standphone or Tablet Holder

€1. 93

93

IPHONE 8 Plus PALS Armor Plate Carrier Phone Molle Mount

€8.08

Samsung Galaxy A03 Batman

€4.60

Charging station for Samsung watch and phone

€0.50

SAMSUNG TV remote control holder

Free

Phone holder

€1.44

Samsung a22 5g cell phone case

€2.06

Samsung CRG5 (or similar) monitor bracket

€2.06

Samsung A50 stand

Free

Table stand for Samsung S10

Free

Table stand for Samsung S10 with Spigen Neo Hybrid case

Free

Samsung Galaxy Watch 4 Charging Stand

Free

Samsung NX2000 Quadcopter mount

Free

Xiaomi Poco F4 case

€1. 45

45

Don't Panic SG S7 case

Free

Plane Holder S21 (Otterbox)

Free

Samsung Gear 2 Pip Boy

Free

Samsung Galaxy M53 case

€1.45

Inter Standphone or Tablet Holder

€1.25

Srp-275iii 5-1-2 Ribbon Feed Assembly Replacement

€10.18

Thrustmaster F1 Wheel - S7 Edge Phone Mod

€2.24

Galaxy s9 case - Gengar artwork

Free

Galaxy Watch 4 support

€1.50

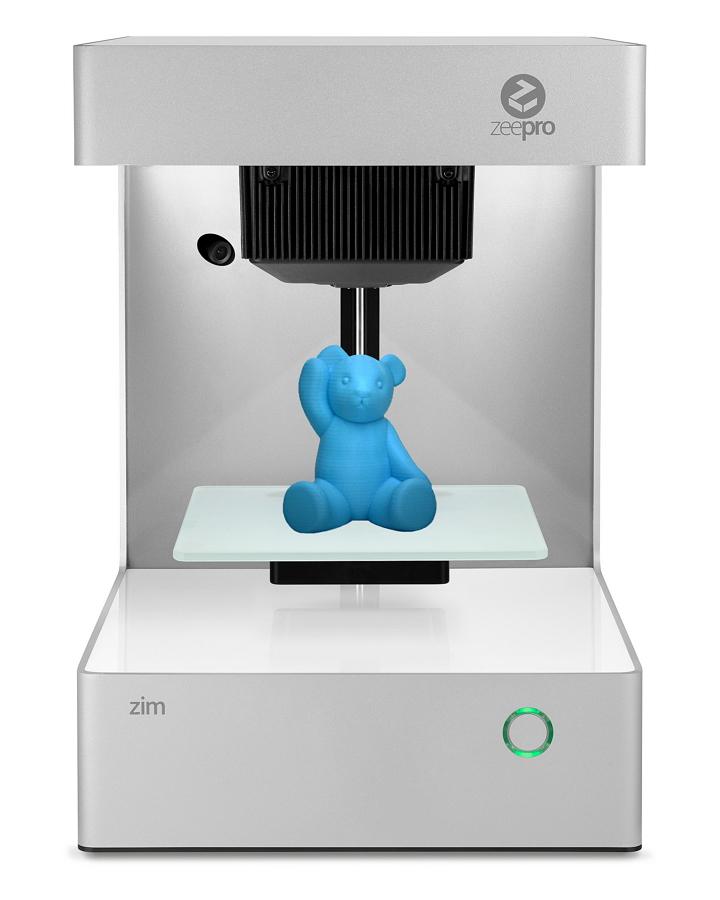

Samsung Joins Forces with Makerbot to Inspire the Next Generation of Innovations – Samsung Global Newsroom

Samsung Electronics Europe today announces that it is joining forces with MakerBot, a global leader in the desktop 3D printing industry, to inspire the next generation of innovators by bringing 3D printers to classrooms across Europe.

Samsung and MakerBot are equipping schools, colleges and museums with 3D printers as part of Samsung’s digital skills programme so that students at any grade level can both code and create. The planned first phase launches in Germany, Italy, Spain, UK and Sweden this year and builds on Samsung’s network of 1,300 Smart Classrooms and 65 Digital Academies.

The vision behind the partnership is to combine design and coding classes with 3D printing so students can experience the full design cycle as a way to develop ideas and innovate. With MakerBot, educators and students have access to a full set of solutions and services that enables them to tackle real-world problems.

“In response to the alarming skills gap and high levels of youth unemployment in 2013, we backed the European Commission’s Grand Coalition for Digital Jobs with a pledge to engage 400,000 young people across Europe by 2019. We will achieve our goal 3 years early so we can now invest further in educating thousands of young people in the latest digital skills. ” says Evelyn Nicola, Sustainability & Citizenship Manager, Samsung Europe.

” says Evelyn Nicola, Sustainability & Citizenship Manager, Samsung Europe.

“Our partnership with MakerBot will support a network of ‘Lighthouse Schools’ – centres of excellence for digital learning across Europe – to teach technology skills and encourage design and manufacture. Just imagine a 9 year old girl with her idea for a new design, being able to turn her idea at school into reality and take home. Experiencing the entire creation journey, from idea to digital concept to physical object represents the future of learning and R&D.”

“Samsung and MakerBot share the same vision of developing new technologies that help prepare students for the jobs of the future,” said Andreas Langfeld, General Manager of MakerBot EMEA. “3D printing can help teach many of the 21st century skills that employers are looking for and applying knowledge to the real world. We’re excited to partner with Samsung to help even more educators and students discover the power of 3D printing. ”

”

Europe has particularly high youth unemployment. Many young people leave education without the digital and soft skills that their future jobs demand. At the same time education systems are struggling to respond to the changing needs of employers. Some teachers also lack the support and confidence to adapt how they teach to match the increasingly digital world. To address these challenges, Samsung focused its European citizenship programmes on digital education and employability. It helps young people to experience how digital skills can open new doors to their future through two core programmes:

- Firstly, Smart Classrooms create new learning opportunities for 6 – 16 year olds. Since 2013, over 1,300 Smart Classrooms have opened across 20 countries in Europe. Samsung not only provide technology, but also offer educational content and teach digital skills, such as coding to students and teachers.

- The second programme, Digital Academies is Samsung’s targeted contribution to tackling the digital skills gap.

There are over 65 across Europe. In these learning centres, 16 – 24 year olds can access smart technology, ICT training and employability programmes to help their transition from education to employment.

There are over 65 across Europe. In these learning centres, 16 – 24 year olds can access smart technology, ICT training and employability programmes to help their transition from education to employment.

About MakerBot

MakerBot, a subsidiary of Stratasys Ltd. (Nasdaq: SSYS), believes there’s an innovator in everyone, and sets the standard in reliability and ease of use. As a global leader in the desktop 3D printing industry, MakerBot offers a set of solutions that illuminate and guide every stage of the 3D printing process, making it easy to go from idea to end result. Founded in 2009, MakerBot has one of the largest installed bases in the industry with more than 100,000 MakerBot Desktop 3D Printers sold to date. MakerBot also runs Thingiverse, the largest 3D printing community in the world. The company’s industry-leading customers include designers, educators, engineers, and consumers. To learn more about MakerBot, visit makerbot.com.

materials, equipment and technologies for advertising production

- Product catalog

Product catalog

Go to expanded catalog

PDF catalogs

CONSUMABLES

- Silk-screen materials

- Advertising and decorative lighting

- Chemistry (adhesives, paints, varnishes, special chemicals, cleaners)

- Mounting and packaging materials

- Aluminum and plastic profiles

- Materials and equipment DTF

- Digital printing ink

- POS materials and equipment, Joker, Uno and Tritix systems

- Mobile stands, Flagpoles, Pavement signs, Fencing posts

- Rigid sheet materials

- Colored self-adhesive films

- Materials for printing and lamination

- Reflective materials

- Thermal transfer materials

- Souvenir and premium products

- Clothes and accessories for labeling

- CRAFT materials and equipment

EQUIPMENT AND TOOLS

- Printers for advertising production

- 3D printers

- Equipment for nesting and cutting

- Milling and engraving equipment and laser engravers

- Fabric printing equipment

- T-shirt printers

- Laminators

- power tool

- Printers for printing and transfer printing

- Aluminum ladders and ladders

- Thermopresses

- Equipment for the production of liquid acrylic letters

- Trimmers, abrasives, film tools

- Eyelets and tools for their installation

- Knives, blades, scissors, mats

- Silk-screen equipment

- Spare parts, add.

hardware and software

hardware and software

Sale

- Zenon Academy

- Video

- Articles

- Webinar Schedule

- About Us

- About company

- Our staff

- News

- News

- Stock

- New

- Developments

- Seminars

- Exhibitions

- Congratulations

- Webinars

- Service

- Signboard calculation

- Service

- Working conditions

- Delivery

- Payment

- Contacts

You are using an outdated browser

In order to use all the features of the site,

download and install one of the following browsers:

Google Chrome

download the latest version

Opera

download the latest version

Mozilla

download the latest version

Yandex Browser

0 download the latest version 9005

article

Subscribing to the newsletter

A confirmation email has been sent to the email you specified.

Please follow the instructions in the letter.

Sorry, an error has occurred, please try the service later.

To subscribe to the newsletter, please fill in ALL fields of the form

Subscription regions

- Moscow - Golyanovo

- Moscow - Losiny Ostrov

- Moscow region - Odintsovo

- Moscow region - Podolsk

- Arkhangelsk

- Barnaul

- Belgorod

- Vladivostok

- Vladimir

- Volgograd

- Voronezh

- Yekaterinburg

- Izhevsk

- Irkutsk

- Kazan

- Kaliningrad

- Krasnodar

- Krasnoyarsk

- Kursk

- Lipetsk

- Nizhny Novgorod

- Novosibirsk

- Omsk

- Orenburg

- Penza

- Permian

- Pyatigorsk

- Rostov-on-Don

- Ryazan

- Samara

- St.

Petersburg

Petersburg - Saransk

- Saratov

- Simferopol

- Smolensk

- Sochi

- Stavropol

- Tambov

- Tolyatti

- Tomsk

- Tula

- Tyumen

- Ulyanovsk

- Ufa

- Khabarovsk

- Cheboksary

- Chelyabinsk

- Yakutsk

- Yaroslavl

I agree for the processing of personal data

Product request:

You can submit this product request form, or contact us by phone or by email , informing the manager of the article

I agree for the processing of personal data

Comments and suggestions

If you are faced with a situation in which you could not get an answer or the help you need from our employees, were dissatisfied with the service or did not find a solution to your question, you can directly contact the company's management with your problem.

I agree to the processing of personal data.

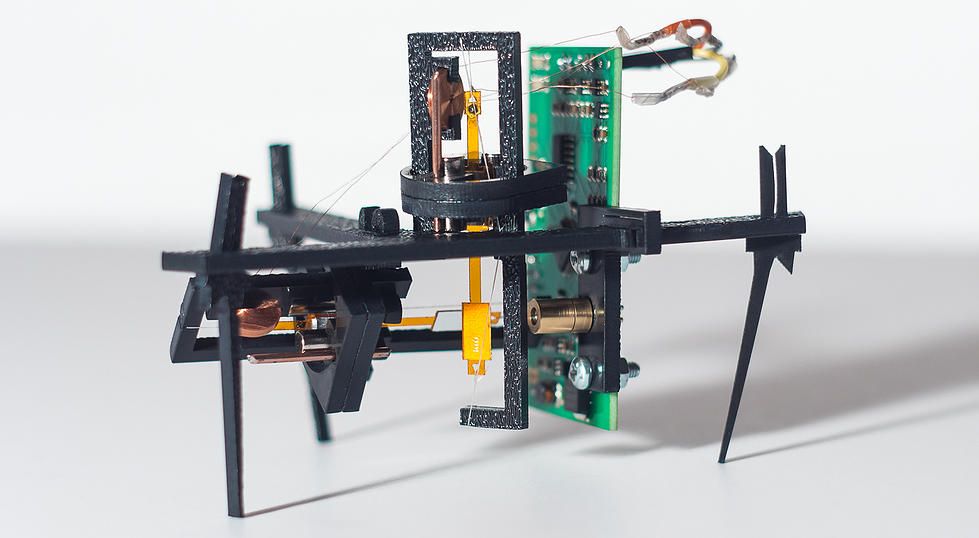

What is 3D printing and how it works. Fundamentals of 3D printing. Types of printing. 3D Skill

From the name it is already clear that 3D printing is the creation of full-fledged volumetric parts.

But how is it done?

There are many 3D printing technologies, but one of them is the most widespread.

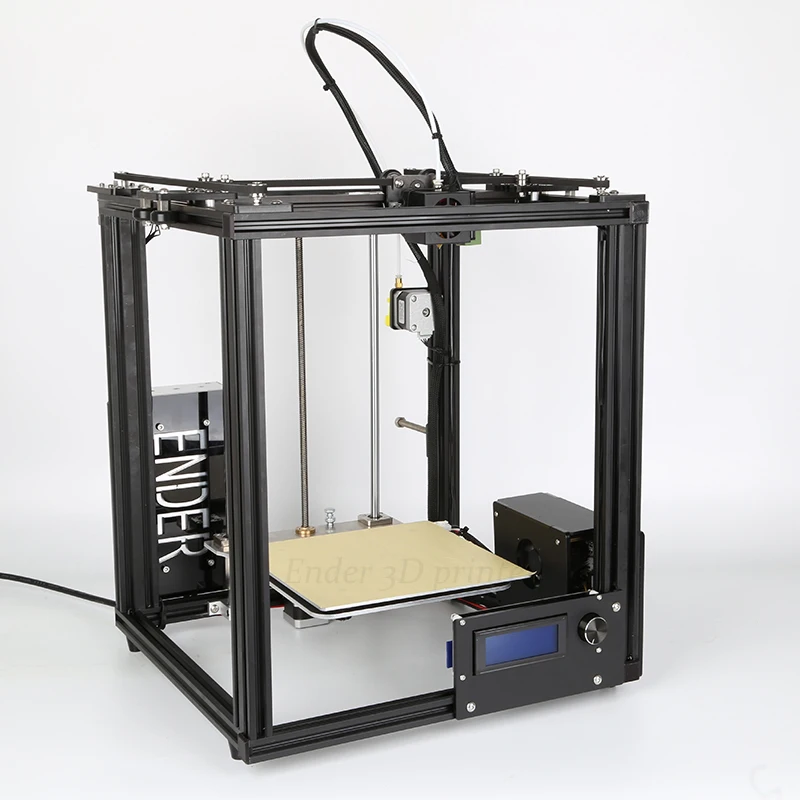

FDM .

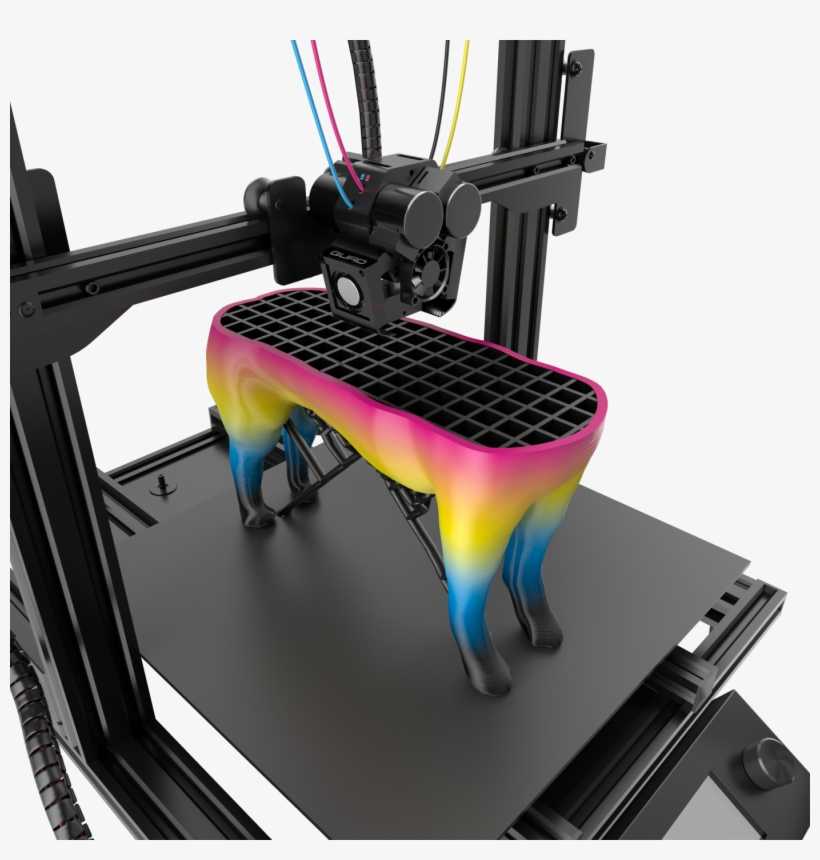

The essence of this technology is that the plastic is heated and extruded layer by layer. Just like when you are going to brush your teeth, you squeeze toothpaste out of a tube.

Why is this method most widely used?

Because of cheapness and simplicity.

There are many other ways to 3D print, the main ones are:

- SLA .

The photopolymer solidifies layer by layer under the action of a laser in a bath of liquid photopolymer. If you have ever put light fillings on your teeth, then remember how they shined on the filling to harden it. Yes, yes, dentists also used a photopolymer for fillings and then polymerized (hardened) it with a light lamp.

The photopolymer solidifies layer by layer under the action of a laser in a bath of liquid photopolymer. If you have ever put light fillings on your teeth, then remember how they shined on the filling to harden it. Yes, yes, dentists also used a photopolymer for fillings and then polymerized (hardened) it with a light lamp. - SLS . Laser sintering. Plastic in the form of a powder is melted by a laser and thus soldered together.

- Plaster print . Gypsum in the form of a powder is glued together with glue, and at the same time a pattern can be applied to the resulting surface.

Have you noticed something in common in all these 3D printing methods?

All of the above is created automatically by a computer without human intervention and manual labor.

But there is one more subtlety. The model is created, grown, and not cut by cutting off the excess, as in the CNC machine .

It turns out there is still an area close to 3D printing - CNC .

CNC machine (computer numerical control) is essentially a 3D printer, but instead of creating a part, the machine cuts off everything unnecessary from the workpiece with a cutter.

But all the basics and principle in 3D printing came from CNC as an earlier technology.

For example G-code .

What is model ?

This is a file with the coordinates of the model's vertices, connecting which create the surface of the model, its volume. But the 3D printer does not understand such a representation structure.

Therefore, the model is translated into a code that the printer understands, in the so-called G-code . G-code is just a sequence of commands to the printer. The program that translates the model into G-code is called slicer .

That is, you do not need to be a 3D printing specialist and know the G-code, the slicer will automatically translate the model into the G-code.

Usually a slicer is supplied with the printer, or you can use a free and universal slicer, such as Cura .

Why, then, has 3D printing not become mainstream, if it's so easy, and why don't such eminent manufacturers as Samsung make 3D printers?

It's just that the field of 3D printing is at the very beginning of development and there are many "pitfalls".

That's why there are some very funny hacks in 3D printing. For example, tea with sugar, beer or an adhesive stick are used to fix the part on the table. And castor oil is used to lubricate the nozzle.

In general, if you want to do 3D printing, you need to start with FDM printing. Why?

FDM printers cost from 15 thousand rubles , and plastic - from 1 thousand rubles per kilogram .