Polycaprolactone 3d printing

The Application of Polycaprolactone in Three-Dimensional Printing Scaffolds for Bone Tissue Engineering

1. Bhattacharjee P., Kundu B., Naskar D., Kim H.-W., Maiti T.K., Bhattacharya D., Kundu S.C. Silk scaffolds in bone tissue engineering: An overview. Acta Biomater. 2017;63:1–17. doi: 10.1016/j.actbio.2017.09.027. [PubMed] [CrossRef] [Google Scholar]

2. Samorezov J.E., Alsberg E. Spatial regulation of controlled bioactive factor delivery for bone tissue engineering. Adv. Drug Deliv. Rev. 2014;84:45–67. doi: 10.1016/j.addr.2014.11.018. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

3. Bishop E.S., Mostafa S., Pakvasa M., Luu H.H., Lee M.J., Wolf J.M., Ameer G.A., He T.-C., Reid R.R. 3-D bioprinting technologies in tissue engineering and regenerative medicine: Current and future trends. Genes Dis. 2017;4:185–195. doi: 10.1016/j.gendis.2017.10.002. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

4. Derakhshanfar S., Mbeleck R., Xu K., Zhang X. , Zhong W., Xing M. 3D bioprinting for biomedical devices and tissue engineering: A review of recent trends and advances. Bioact. Mater. 2018;3:144–156. doi: 10.1016/j.bioactmat.2017.11.008. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

5. Yan Q., Dong H., Su J., Han J., Song B., Wei Q., Shi Y. A Review of 3D Printing Technology for Medical Applications. Engineering. 2018;4:729–742. doi: 10.1016/j.eng.2018.07.021. [CrossRef] [Google Scholar]

6. Huang K.-H., Wang C.-Y., Chen C.-Y., Hsu T.-T., Lin C.-P. Incorporation of Calcium Sulfate Dihydrate into a Mesoporous Calcium Silicate/Poly-ε-Caprolactone Scaffold to Regulate the Release of Bone Morphogenetic Protein-2 and Accelerate Bone Regeneration. Biomedicines. 2021;9:128. doi: 10.3390/biomedicines9020128. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

7. Cao Y., Cheng P., Sang S., Xiang C., An Y., Wei X., Shen Z., Zhang Y., Li P. Mesenchymal stem cells loaded on 3D-printed gradient poly(ε-caprolactone)/methacrylated alginate composite scaffolds for cartilage tissue engineering. Regen. Biomater. 2021;8:rbab019. doi: 10.1093/rb/rbab019. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

Regen. Biomater. 2021;8:rbab019. doi: 10.1093/rb/rbab019. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

8. Dias D., Vale A.C., Cunha E.P.F., Paiva M.C., Reis R.L., Vaquette C., Alves N.M. 3D -printed cryomilled poly(ε-caprolactone)/graphene composite scaffolds for bone tissue regeneration. J. Biomed. Mater. Res. Part B Appl. Biomater. 2021;109:961–972. doi: 10.1002/jbm.b.34761. [PubMed] [CrossRef] [Google Scholar]

9. Radhakrishnan S., Nagarajan S., Belaid H., Farha C., Iatsunskyi I., Coy E., Soussan L., Huon V., Bares J., Belkacemi K., et al. Fabrication of 3D printed antimicrobial polycaprolactone scaffolds for tissue engineering applications. Mater. Sci. Eng. C. 2021;118:111525. doi: 10.1016/j.msec.2020.111525. [PubMed] [CrossRef] [Google Scholar]

10. Guo W., Chen M., Wang Z., Tian Y., Zheng J., Gao S., Li Y., Zheng Y., Li X., Huang J., et al. 3D-printed cell-free PCL–MECM scaffold with biomimetic micro-structure and micro-environment to enhance in situ meniscus regeneration. Bioact. Mater. 2021;6:3620–3633. doi: 10.1016/j.bioactmat.2021.02.019. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

Bioact. Mater. 2021;6:3620–3633. doi: 10.1016/j.bioactmat.2021.02.019. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

11. Lee H., Yeo M., Ahn S., Kang D.-O., Jang C.H., Lee H., Park G.-M., Kim G.H. Designed hybrid scaffolds consisting of polycaprolactone microstrands and electrospun collagen-nanofibers for bone tissue regeneration. J. Biomed. Mater. Res. Part B Appl. Biomater. 2011;97:263–270. doi: 10.1002/jbm.b.31809. [PubMed] [CrossRef] [Google Scholar]

12. Zimmerling A., Yazdanpanah Z., Cooper D.M.L., Johnston J.D., Chen X. 3D printing PCL/nHA bone scaffolds: Exploring the influence of material synthesis techniques. Biomater Res. 2021;25:3. doi: 10.1186/s40824-021-00204-y. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

13. Seyedsalehi A., Daneshmandi L., Barajaa M., Riordan J., Laurencin C.T. Fabrication and characterization of mechanically competent 3D printed polycaprolactone-reduced graphene oxide scaffolds. Sci. Rep. 2020;10:22210. doi: 10.1038/s41598-020-78977-w. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

[PMC free article] [PubMed] [CrossRef] [Google Scholar]

14. Cakmak A.M., Unal S., Sahin A., Oktar F.N., Sengor M., Ekren N., Gunduz O., Kalaskar D.M. 3D Printed Polycaprolactone/Gelatin/BacterialCellulose/Hydroxyapatite Composite Scaffold for Bone Tissue Engineering. Polymers. 2020;12:1962. doi: 10.3390/polym12091962. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

15. Park S.A., Lee H.J., Kim S.Y., Kim K.S., Jo D.W., Park S.Y. Three-dimensionally printed polycaprolactone/beta-tricalcium phosphate scaffold was more effective as an rhBMP-2 carrier for new bone formation than polycaprolactone alone. J. Biomed. Mater. Res. Part A. 2021;109:840–848. doi: 10.1002/jbm.a.37075. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

16. Turnbull G., Clarke J., Picard F., Riches P., Jia L., Han F., Li B., Shu W. 3D bioactive composite scaffolds for bone tissue engineering. Bioact. Mater. 2018;3:278–314. doi: 10.1016/j.bioactmat.2017.10.001. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

17. Moreno Madrid A.P., Mariel Vrech S., Alejandra Sanchez M., Paola Rodriguez A. Advances in additive manufacturing for bone tissue engineering scaffolds. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019;100:631–644. doi: 10.1016/j.msec.2019.03.037. [PubMed] [CrossRef] [Google Scholar]

Moreno Madrid A.P., Mariel Vrech S., Alejandra Sanchez M., Paola Rodriguez A. Advances in additive manufacturing for bone tissue engineering scaffolds. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019;100:631–644. doi: 10.1016/j.msec.2019.03.037. [PubMed] [CrossRef] [Google Scholar]

18. Arealis G., Nikolaou V.S. Bone printing: New frontiers in the treatment of bone defects. Injury. 2015;46:S20–S22. doi: 10.1016/S0020-1383(15)30050-4. [PubMed] [CrossRef] [Google Scholar]

19. Wu G.H., Hsu S.H. Review: Polymeric-Based 3D Printing for Tissue Engineering. J. Med. Biol. Eng. 2015;35:285–292. doi: 10.1007/s40846-015-0038-3. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

20. Xie C., Gao Q., Wang P., Shao L., Yuan H., Fu J., Chen W., He Y. Structure-induced cell growth by 3D printing of heterogeneous scaffolds with ultrafine fibers. Mater. Des. 2019;181:108092. doi: 10.1016/j.matdes.2019.108092. [CrossRef] [Google Scholar]

21. Eichholz K.F., Hoey D.A. Mediating human stem cell behaviour via defined fibrous architectures by melt electrospinning writing. Acta Biomater. 2018;75:140–151. doi: 10.1016/j.actbio.2018.05.048. [PubMed] [CrossRef] [Google Scholar]

Acta Biomater. 2018;75:140–151. doi: 10.1016/j.actbio.2018.05.048. [PubMed] [CrossRef] [Google Scholar]

22. He J., Xu F., Cao Y., Liu Y., Li D. Towards microscale electrohydrodynamic three-dimensional printing. J. Phys. D Appl. Phys. 2016;49:055504. doi: 10.1088/0022-3727/49/5/055504. [CrossRef] [Google Scholar]

23. Kade J.C., Dalton P.D. Polymers for Melt Electrowriting. Adv. Healthc. Mater. 2021;10:e2001232. doi: 10.1002/adhm.202001232. [PubMed] [CrossRef] [Google Scholar]

24. Hochleitner G., Jungst T., Brown T.D., Hahn K., Moseke C., Jakob F., Dalton P.D., Groll J. Additive manufacturing of scaffolds with sub-micron filaments via melt electrospinning writing. Biofabrication. 2015;7:035002. doi: 10.1088/1758-5090/7/3/035002. [PubMed] [CrossRef] [Google Scholar]

25. Kim M., Yun H-s Kim G.H. Electric-field assisted 3D-fibrous bioceramic-based scaffolds for bone tissue regeneration: Fabrication, characterization, and in vitro cellular activities. Sci. Rep. 2017;7:3166. doi: 10.1038/s41598-017-03461-x. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

doi: 10.1038/s41598-017-03461-x. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

26. Youssef A., Hollister S.J., Dalton P.D. Additive manufacturing of polymer melts for implantable medical devices and scaffolds. Biofabrication. 2017;9:1. doi: 10.1088/1758-5090/aa5766. [PubMed] [CrossRef] [Google Scholar]

27. Swetha S., Lavanya K., Sruthi R., Selvamurugan N. An insight into cell-laden 3D-printed constructs for bone tissue engineering. J. Mater Chem. B. 2020;8:9836–9862. doi: 10.1039/D0TB02019B. [PubMed] [CrossRef] [Google Scholar]

28. Kuss M.A., Wu S., Wang Y., Untrauer J.B., Li W., Lim J.Y., Duan B. Prevascularization of 3D printed bone scaffolds by bioactive hydrogels and cell co-culture. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018;106:1788–1798. doi: 10.1002/jbm.b.33994. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

29. Chen Y.-W., Shen Y.-F., Ho C.-C., Yu J., Wu Y.-H.A., Wang K., Shih C.-T., Shie M.-Y. Osteogenic and angiogenic potentials of the cell-laden hydrogel/mussel-inspired calcium silicate complex hierarchical porous scaffold fabricated by 3D bioprinting. Mater. Sci. Eng. C. 2018;91:679–687. doi: 10.1016/j.msec.2018.06.005. [PubMed] [CrossRef] [Google Scholar]

Mater. Sci. Eng. C. 2018;91:679–687. doi: 10.1016/j.msec.2018.06.005. [PubMed] [CrossRef] [Google Scholar]

30. Xie H., Wang Z., Zhang L., Lei Q., Zhao A., Wang H., Li Q., Chen Z., Zhang W. Development of an angiogenesis-promoting microvesicle-alginate-polycaprolactone composite graft for bone tissue engineering applications. PeerJ. 2016;4:e2040. doi: 10.7717/peerj.2040. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

31. Jian Z., Zhuang T., Qinyu T., Liqing P., Kun L., Xujiang L., Diaodiao W., Zhen Y., Shuangpeng J., Xiang S., et al. 3D bioprinting of a biomimetic meniscal scaffold for application in tissue engineering. Bioact. Mater. 2021;6:1711–1726. doi: 10.1016/j.bioactmat.2020.11.027. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

32. Do A.V., Khorsand B., Geary S.M., Salem A.K. 3D Printing of Scaffolds for Tissue Regeneration Applications. Adv. Healthc. Mater. 2015;4:1742–1762. doi: 10.1002/adhm.201500168. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

33. Fedorovich N.E., Alblas J., Hennink W.E., Oner F.C., Dhert W.J. Organ printing: The future of bone regeneration? Trends Biotechnol. 2011;29:601–606. doi: 10.1016/j.tibtech.2011.07.001. [PubMed] [CrossRef] [Google Scholar]

Fedorovich N.E., Alblas J., Hennink W.E., Oner F.C., Dhert W.J. Organ printing: The future of bone regeneration? Trends Biotechnol. 2011;29:601–606. doi: 10.1016/j.tibtech.2011.07.001. [PubMed] [CrossRef] [Google Scholar]

34. Liao G., Jiang S., Xu X., Ke Y. Electrospun aligned PLLA/PCL/HA composite fibrous membranes and their in vitro degradation behaviors. Mater. Lett. 2012;82:159–162. doi: 10.1016/j.matlet.2012.05.085. [CrossRef] [Google Scholar]

35. Guarino V., Causa F., Taddei P., Di Foggia M., Ciapetti G., Martini D., Fagnano C., Baldini N., Ambrosio L. Polylactic acid fibre-reinforced polycaprolactone scaffolds for bone tissue engineering. Biomaterials. 2008;29:3662–3670. doi: 10.1016/j.biomaterials.2008.05.024. [PubMed] [CrossRef] [Google Scholar]

36. Doyle S., Henry L., McGennisken E., Onofrillo C., Bella C., Duchi S., O’Connell C., Pirogova E. Characterization of Polycaprolactone Nanohydroxyapatite Composites with Tunable Degradability Suitable for Indirect Printing. Polymers. 2021;13:295. doi: 10.3390/polym13020295. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

Polymers. 2021;13:295. doi: 10.3390/polym13020295. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

37. Liu H., Du Y., Yang G., Hu X., Wang L., Liu B., Wang J., Zhang S. Delivering Proangiogenic Factors from 3D-Printed Polycaprolactone Scaffolds for Vascularized Bone Regeneration. Adv. Health Mater. 2020;9:e2000727. doi: 10.1002/adhm.202000727. [PubMed] [CrossRef] [Google Scholar]

38. Wu Y.-H.A., Chiu Y.-C., Lin Y.-H., Ho C.-C., Shie M.-Y., Chen Y.-W. 3D-Printed Bioactive Calcium Silicate/Poly-epsilon-Caprolactone Bioscaffolds Modified with Biomimetic Extracellular Matrices for Bone Regeneration. Int. J. Mol. Sci. 2019;20:942. doi: 10.3390/ijms20040942. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

39. Wang W., Junior J.R.P., Nalesso P.R., Musson D., Cornish J., Mendonça F., Caetano G.F., Bartolo P. Engineered 3D printed poly(ε-caprolactone)/graphene scaffolds for bone tissue engineering. Mater. Sci. Eng. C. 2019;100:759–770. doi: 10.1016/j.msec.2019. 03.047. [PubMed] [CrossRef] [Google Scholar]

03.047. [PubMed] [CrossRef] [Google Scholar]

40. Unagolla J.M., Jayasuriya A.C. Enhanced cell functions on graphene oxide incorporated 3D printed polycaprolactone scaffolds. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019;102:1–11. doi: 10.1016/j.msec.2019.04.026. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

41. Park J., Park S., Kim J.E., Jang K.J., Seonwoo H., Chung J.H. Enhanced Osteogenic Differentiation of Periodontal Ligament Stem Cells Using a Graphene Oxide-Coated Poly(epsilon-caprolactone) Scaffold. Polymers. 2021;13:797. doi: 10.3390/polym13050797. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

42. Huang B., Vyas C., Roberts I., Poutrel Q.-A., Chiang W.-H., Blaker J.J., Huang Z., Bártolo P. Fabrication and characterisation of 3D printed MWCNT composite porous scaffolds for bone regeneration. Mater. Sci. Eng. C. 2019;98:266–278. doi: 10.1016/j.msec.2018.12.100. [PubMed] [CrossRef] [Google Scholar]

43. Rogowska-Tylman J., Locs J., Salma I. , Woźniak B., Pilmane M., Zalite V., Wojnarowicz J., Kędzierska-Sar A., Chudoba T., Szlazak K., et al. In vivo and in vitro study of a novel nanohydroxyapatite sonocoated scaffolds for enhanced bone regeneration. Mater. Sci. Eng. C. 2019;99:669–684. doi: 10.1016/j.msec.2019.01.084. [PubMed] [CrossRef] [Google Scholar]

, Woźniak B., Pilmane M., Zalite V., Wojnarowicz J., Kędzierska-Sar A., Chudoba T., Szlazak K., et al. In vivo and in vitro study of a novel nanohydroxyapatite sonocoated scaffolds for enhanced bone regeneration. Mater. Sci. Eng. C. 2019;99:669–684. doi: 10.1016/j.msec.2019.01.084. [PubMed] [CrossRef] [Google Scholar]

44. Bas O., Hanßke F., Lim J., Ravichandran A., Kemnitz E., Teoh S.-H., Hutmacher D.W., Börner H.G. Tuning mechanical reinforcement and bioactivity of 3D printed ternary nanocomposites by interfacial peptide-polymer conjugates. Biofabrication. 2019;11:035028. doi: 10.1088/1758-5090/aafec8. [PubMed] [CrossRef] [Google Scholar]

45. Petretta M., Gambardella A., Boi M., Berni M., Cavallo C., Marchiori G., Maltarello M., Bellucci D., Fini M., Baldini N., et al. Composite Scaffolds for Bone Tissue Regeneration Based on PCL and Mg-Containing Bioactive Glasses. Biology. 2021;10:398. doi: 10.3390/biology10050398. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

46. Rumiński S., Ostrowska B., Jaroszewicz J., Skirecki T., Włodarski K., Swieszkowski W., Lewandowska-Szumieł M. Three-dimensional printed polycaprolactone-based scaffolds provide an advantageous environment for osteogenic differentiation of human adipose-derived stem cells. J. Tissue Eng. Regen. Med. 2018;12:e473–e485. doi: 10.1002/term.2310. [PubMed] [CrossRef] [Google Scholar]

Rumiński S., Ostrowska B., Jaroszewicz J., Skirecki T., Włodarski K., Swieszkowski W., Lewandowska-Szumieł M. Three-dimensional printed polycaprolactone-based scaffolds provide an advantageous environment for osteogenic differentiation of human adipose-derived stem cells. J. Tissue Eng. Regen. Med. 2018;12:e473–e485. doi: 10.1002/term.2310. [PubMed] [CrossRef] [Google Scholar]

47. Luo W., Zhang S., Lan Y., Huang C., Wang C., Lai X., Chen H., Ao N. 3D printed porous polycaprolactone/oyster shell powder (PCL/OSP) scaffolds for bone tissue engineering. Mater. Res. Express. 2018;5:045403. doi: 10.1088/2053-1591/aab916. [CrossRef] [Google Scholar]

48. Moncal K.K., Heo D.N., Godzik K.P., Sosnoski D.M., Mrowczynski O.D., Rizk E., Ozbolat V., Tucker S.M., Gerhard E.M., Dey M., et al. 3D printing of poly(ε-caprolactone)/poly(d,l-lactide-co-glycolide)/hydroxyapatite composite constructs for bone tissue engineering. J. Mater. Res. 2018;33:1972–1986. doi: 10.1557/jmr.2018.111. [CrossRef] [Google Scholar]

[CrossRef] [Google Scholar]

49. Rindone A.N., Nyberg E., Grayson W.L. 3D-Printing Composite Polycaprolactone-Decellularized Bone Matrix Scaffolds for Bone Tissue Engineering Applications. Methods Mol. Biol. 2018;1577:209–226. [PubMed] [Google Scholar]

50. Hung B.P., Naved B.A., Nyberg E.L., Dias M., Holmes C., Elisseeff J.H., Dorafshar A., Grayson W.L. Three-Dimensional Printing of Bone Extracellular Matrix for Craniofacial Regeneration. ACS Biomater. Sci. Eng. 2016;2:1806–1816. doi: 10.1021/acsbiomaterials.6b00101. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

51. Park S.A., Lee S.J., Seok J.M., Lee J.H., Kim W.D., Kwon I.K. Fabrication of 3D Printed PCL/PEG Polyblend Scaffold Using Rapid Prototyping System for Bone Tissue Engineering Application. J. Bionic. Eng. 2018;15:435–442. doi: 10.1007/s42235-018-0034-8. [CrossRef] [Google Scholar]

52. Kim J.-Y., Ahn G., Kim C., Lee J.-S., Lee I.-G., An S.-H., Yun W.-S., Kim S.-Y., Shim J.-H. Synergistic Effects of Beta Tri-Calcium Phosphate and Porcine-Derived Decellularized Bone Extracellular Matrix in 3D-Printed Polycaprolactone Scaffold on Bone Regeneration. Macromol. Biosci. 2018;18:e1800025. doi: 10.1002/mabi.201800025. [PubMed] [CrossRef] [Google Scholar]

Macromol. Biosci. 2018;18:e1800025. doi: 10.1002/mabi.201800025. [PubMed] [CrossRef] [Google Scholar]

53. Vella J.B., Trombetta R.P., Hoffman M.D., Inzana J., Awad H., Benoit D.S.W. Three-dimensional printed calcium phosphate and poly(caprolactone) composites with improved mechanical properties and preserved microstructure. J. Biomed. Mater. Res. Part A. 2018;106:663–672. doi: 10.1002/jbm.a.36270. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

54. Tamjid E. Three-dimensional polycaprolactone-bioactive glass composite scaffolds: Effect of particle size and volume fraction on mechanical properties and in vitro cellular behavior. Int. J. Polym. Mater. Polym. Biomater. 2018;67:1005–1015. doi: 10.1080/00914037.2017.1417285. [CrossRef] [Google Scholar]

55. Neufurth M., Wang X., Wang S., Steffen R., Ackermann M., Haep N.D., Schröder H.C., Müller W.E. 3D printing of hybrid biomaterials for bone tissue engineering: Calcium-polyphosphate microparticles encapsulated by polycaprolactone. Acta Biomater. 2017;64:377–388. doi: 10.1016/j.actbio.2017.09.031. [PubMed] [CrossRef] [Google Scholar]

Acta Biomater. 2017;64:377–388. doi: 10.1016/j.actbio.2017.09.031. [PubMed] [CrossRef] [Google Scholar]

56. Hwang K.-S., Choi J.-W., Kim J.-H., Chung H.Y., Jin S., Shim J.-H., Yun W.-S., Jeong C.-M., Huh J.-B. Comparative Efficacies of Collagen-Based 3D Printed PCL/PLGA/β-TCP Composite Block Bone Grafts and Biphasic Calcium Phosphate Bone Substitute for Bone Regeneration. Materials. 2017;10:421. doi: 10.3390/ma10040421. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

57. Park J., Lee S.J., Jo H.H., Lee J.H., Kim W.D., Lee J.Y., Park S.A. Fabrication and characterization of 3D-printed bone-like β-tricalcium phosphate/polycaprolactone scaffolds for dental tissue engineering. J. Ind. Eng. Chem. 2017;46:175–181. doi: 10.1016/j.jiec.2016.10.028. [CrossRef] [Google Scholar]

58. Shim K.-S., Kim S.E., Yun Y.-P., Jeon D.I., Kim H.J., Park K., Song H.-R. Surface immobilization of biphasic calcium phosphate nanoparticles on 3D printed poly(caprolactone) scaffolds enhances osteogenesis and bone tissue regeneration. J. Ind. Eng. Chem. 2017;55:101–109. doi: 10.1016/j.jiec.2017.06.033. [CrossRef] [Google Scholar]

J. Ind. Eng. Chem. 2017;55:101–109. doi: 10.1016/j.jiec.2017.06.033. [CrossRef] [Google Scholar]

59. Chiu Y.-C., Fang H.-Y., Hsu T.-T., Lin C.-Y., Shie M.-Y. The Characteristics of Mineral Trioxide Aggregate/Polycaprolactone 3-dimensional Scaffold with Osteogenesis Properties for Tissue Regeneration. J. Endod. 2017;43:923–929. doi: 10.1016/j.joen.2017.01.009. [PubMed] [CrossRef] [Google Scholar]

60. Daly A.C., Cunniffe G.M., Sathy B.N., Jeon O., Alsberg E., Kelly D.J. 3D Bioprinting of Developmentally Inspired Templates for Whole Bone Organ Engineering. Adv. Healthc. Mater. 2016;5:2353–2362. doi: 10.1002/adhm.201600182. [PubMed] [CrossRef] [Google Scholar]

61. Miao S., Zhu W., Castro N.J., Leng J., Zhang L.G. Four-Dimensional Printing Hierarchy Scaffolds with Highly Biocompatible Smart Polymers for Tissue Engineering Applications. Tissue Eng. Part C-Methods. 2016;22:952–963. doi: 10.1089/ten.tec.2015.0542. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

62. Gonçalves E.M., Oliveira F., Silva R., Neto M.A., Fernandes M.H., Amaral M., Vallet-Regí M., Vila M. Three-dimensional printed PCL-hydroxyapatite scaffolds filled with CNTs for bone cell growth stimulation. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016;104:1210–1219. doi: 10.1002/jbm.b.33432. [PubMed] [CrossRef] [Google Scholar]

Gonçalves E.M., Oliveira F., Silva R., Neto M.A., Fernandes M.H., Amaral M., Vallet-Regí M., Vila M. Three-dimensional printed PCL-hydroxyapatite scaffolds filled with CNTs for bone cell growth stimulation. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016;104:1210–1219. doi: 10.1002/jbm.b.33432. [PubMed] [CrossRef] [Google Scholar]

63. Karimipour-Fard P., Jeffrey M.P., JonesTaggart H., Pop-Iliev R., Rizvi G. Development, processing and characterization of Polycaprolactone/Nano-Hydroxyapatite/Chitin-Nano-Whisker nanocomposite filaments for additive manufacturing of bone tissue scaffolds. J. Mech. Behav. Biomed. Mater. 2021;120:104583. doi: 10.1016/j.jmbbm.2021.104583. [PubMed] [CrossRef] [Google Scholar]

64. Wang C., Xu H., Liu C., Peng Z., Min R., Zhang Z., Li J., Jin Y., Wang Y., Li Z., et al. CaO2/gelatin oxygen slow-releasing microspheres facilitate tissue engineering efficiency for the osteonecrosis of femoral head by enhancing the angiogenesis and survival of grafted bone marrow mesenchymal stem cells. Biomater. Sci. 2021;9:3005–3018. doi: 10.1039/D0BM02071K. [PubMed] [CrossRef] [Google Scholar]

Biomater. Sci. 2021;9:3005–3018. doi: 10.1039/D0BM02071K. [PubMed] [CrossRef] [Google Scholar]

65. Nyberg E., Rindone A., Dorafshar A., Grayson W.L. Comparison of 3D-Printed Poly-epsilon-Caprolactone Scaffolds Functionalized with Tricalcium Phosphate, Hydroxyapatite, Bio-Oss, or Decellularized Bone Matrix. Tissue Eng. Part A. 2017;23:503. doi: 10.1089/ten.tea.2016.0418. [PubMed] [CrossRef] [Google Scholar]

66. Domingos M., Gloria A., Coelho J., Bartolo P., Ciurana J. Three-dimensional printed bone scaffolds: The role of nano/micro-hydroxyapatite particles on the adhesion and differentiation of human mesenchymal stem cells. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2017;231:555–564. doi: 10.1177/0954411916680236. [PubMed] [CrossRef] [Google Scholar]

67. Chen F., Hochleitner G., Woodfield T., Groll J., Dalton P.D., Amsden B.G. Additive Manufacturing of a Photo-Cross-Linkable Polymer via Direct Melt Electrospinning Writing for Producing High Strength Structures. Biomacromolecules. 2016;17:208–214. doi: 10.1021/acs.biomac.5b01316. [PubMed] [CrossRef] [Google Scholar]

2016;17:208–214. doi: 10.1021/acs.biomac.5b01316. [PubMed] [CrossRef] [Google Scholar]

68. Butscher A., Bohner M., Hofmann S., Gauckler L., Muller R. Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater. 2011;7:907–920. doi: 10.1016/j.actbio.2010.09.039. [PubMed] [CrossRef] [Google Scholar]

69. Loh Q.L., Choong C. Three-dimensional scaffolds for tissue engineering applications: Role of porosity and pore size. Tissue Eng. Part B Rev. 2013;19:485–502. doi: 10.1089/ten.teb.2012.0437. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

70. Fonseca D.R., Sobreiro-Almeida R., Sol P.C., Neves N.M. Development of non-orthogonal 3D-printed scaffolds to enhance their osteogenic performance. Biomater. Sci. 2018;6:1569–1579. doi: 10.1039/C8BM00073E. [PubMed] [CrossRef] [Google Scholar]

71. Shim J.-H., Jeong J.-H., Won J.-Y., Bae J.-H., Ahn G., Jeon H., Yun W.-S., Bae E.-B., Choi J.-W., Lee S.-H., et al. Porosity effect of 3D-printed polycaprolactone membranes on calvarial defect model for guided bone regeneration. Biomed. Mater. 2017;13:015014. doi: 10.1088/1748-605X/aa9bbc. [PubMed] [CrossRef] [Google Scholar]

Biomed. Mater. 2017;13:015014. doi: 10.1088/1748-605X/aa9bbc. [PubMed] [CrossRef] [Google Scholar]

72. Yang T., Hu Y., Wang C., Binks B.P. Fabrication of Hierarchical Macroporous Biocompatible Scaffolds by Combining Pickering High Internal Phase Emulsion Templates with Three-Dimensional Printing. ACS Appl. Mater. Interfaces. 2017;9:22950–22958. doi: 10.1021/acsami.7b05012. [PubMed] [CrossRef] [Google Scholar]

73. Olubamiji A.D., Izadifar Z., Si J.L., Cooper D.M.L., Eames B.F., Chen D.X.B. Modulating mechanical behaviour of 3D-printed cartilage-mimetic PCL scaffolds: Influence of molecular weight and pore geometry. Biofabrication. 2016;8:025020. doi: 10.1088/1758-5090/8/2/025020. [PubMed] [CrossRef] [Google Scholar]

74. Lee S.-H., Cho Y.S., Hong M.W., Lee B.-K., Park Y., Park S.-H., Kim Y.Y., Cho Y.-S. Mechanical properties and cell-culture characteristics of a polycaprolactone kagome-structure scaffold fabricated by a precision extruding deposition system. Biomed. Mater. 2017;12:055003. doi: 10.1088/1748-605X/aa8357. [PubMed] [CrossRef] [Google Scholar]

2017;12:055003. doi: 10.1088/1748-605X/aa8357. [PubMed] [CrossRef] [Google Scholar]

75. Feasibility of Fabricating Personalized 3D-Printed Bone Grafts Guided by High-Resolution Imaging. [(accessed on 27 June 2021)]; Available online: https://www.spiedigitallibrary.org/conference-proceedings-of-spie/10138/101380O/Feasibility-of-fabricating-personalized-3D-printed-bone-grafts-guided-by/10.1117/12.2254475.short?SSO=1

76. Barbara O., Andrea D.L., Lorenzo M., Wojciech S. Influence of internal pore architecture on biological and mechanical properties of three-dimensional fiber deposited scaffolds for bone regeneration. Biomed. Mater Res. A. 2016;104:991–1001. [PubMed] [Google Scholar]

77. Roh H.-S., Lee C.-M., Hwang Y.-H., Kook M.-S., Yang S.-W., Lee D., Kim B.-H. Addition of MgO nanoparticles and plasma surface treatment of three-dimensional printed polycaprolactone/hydroxyapatite scaffolds for improving bone regeneration. Mater. Sci. Eng. C. 2017;74:525–535. doi: 10.1016/j. msec.2016.12.054. [PubMed] [CrossRef] [Google Scholar]

msec.2016.12.054. [PubMed] [CrossRef] [Google Scholar]

78. Stichler S., Böck T., Paxton N., Bertlein S., Levato R., Schill V., Smolan W., Malda J., Tessmar J., Blunk T., et al. Double printing of hyaluronic acid/poly(glycidol) hybrid hydrogels with poly(ε-caprolactone) for MSC chondrogenesis. Biofabrication. 2017;9:044108. doi: 10.1088/1758-5090/aa8cb7. [PubMed] [CrossRef] [Google Scholar]

79. Zheng P., Yao Q., Mao F., Liu N., Xu Y., Wei B., Wang L. Adhesion, proliferation and osteogenic differentiation of mesenchymal stem cells in 3D printed poly-ε-caprolactone/hydroxyapatite scaffolds combined with bone marrow clots. Mol. Med. Rep. 2017;16:5078–5084. doi: 10.3892/mmr.2017.7266. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

80. Szlazak K., Jaroszewicz J., Ostrowska B., Nabiałek M., Szota M., Swieszkowski W. Characterization of Three-Dimensional Printed Composite Scaffolds Prepared with Different Fabrication Methods. Arch. Met. Mater. 2016;61:645–650. doi: 10. 1515/amm-2016-0110. [CrossRef] [Google Scholar]

1515/amm-2016-0110. [CrossRef] [Google Scholar]

81. Theodoridis K., Aggelidou E., Vavilis T., Manthou M.E., Tsimponis A., Demiri E.C., Boukla A., Salpistis C., Bakopoulou A., Mihailidis A., et al. Hyaline cartilage next generation implants from adipose-tissue-derived mesenchymal stem cells: Comparative study on 3D-printed polycaprolactone scaffold patterns. J. Tissue Eng. Regen. Med. 2019;13:342–355. doi: 10.1002/term.2798. [PubMed] [CrossRef] [Google Scholar]

82. Yang G.H., Kim M., Kim G. Additive-manufactured polycaprolactone scaffold consisting of innovatively designed microsized spiral struts for hard tissue regeneration. Biofabrication. 2016;9:15005. doi: 10.1088/1758-5090/9/1/015005. [PubMed] [CrossRef] [Google Scholar]

83. Yang G.-H., Lee H., Kim G. Preparation and characterization of spiral-like micro-struts with nano-roughened surface for enhancing the proliferation and differentiation of preosteoblasts. J. Ind. Eng. Chem. 2018;61:244–254. doi: 10.1016/j.jiec. 2017.12.022. [CrossRef] [Google Scholar]

2017.12.022. [CrossRef] [Google Scholar]

84. Cho Y.S., Hong M.W., Quan M., Kim S.-Y., Lee S.-H., Lee S.-J., Kim Y.Y., Cho Y.-S. Assessments for bone regeneration using the polycaprolactone SLUP (salt-leaching using powder) scaffold. J. Biomed. Mater. Res. Part A. 2017;105:3432–3444. doi: 10.1002/jbm.a.36196. [PubMed] [CrossRef] [Google Scholar]

85. Gupta D., Singh A.K., Kar N., Dravid A., Bellare J. Modelling and optimization of NaOH-etched 3-D printed PCL for enhanced cellular attachment and growth with minimal loss of mechanical strength. Mater. Sci. Eng. C-Mater. Biol. Appl. 2019;98:602–611. doi: 10.1016/j.msec.2018.12.084. [PubMed] [CrossRef] [Google Scholar]

86. Shan Y., Wang Y., Fan Y., Yang J., Ren W., Yu X., Li J., Shi H. Biomechanical properties and cellular biocompatibility of 3D printed tracheal graft. Bioprocess Biosyst. Eng. 2017;40:1813–1823. doi: 10.1007/s00449-017-1835-6. [PubMed] [CrossRef] [Google Scholar]

87. Lee S.-H., Lee K.-G., Hwang J.-H., Cho Y. S., Jeong H.-J., Park S.-H., Park Y., Cho Y.-S., Lee B.-K. Evaluation of mechanical strength and bone regeneration ability of 3D printed kagome-structure scaffold using rabbit calvarial defect model. Mater. Sci. Eng. C. 2019;98:949–959. doi: 10.1016/j.msec.2019.01.050. [PubMed] [CrossRef] [Google Scholar]

S., Jeong H.-J., Park S.-H., Park Y., Cho Y.-S., Lee B.-K. Evaluation of mechanical strength and bone regeneration ability of 3D printed kagome-structure scaffold using rabbit calvarial defect model. Mater. Sci. Eng. C. 2019;98:949–959. doi: 10.1016/j.msec.2019.01.050. [PubMed] [CrossRef] [Google Scholar]

88. Lee J.W., Chu S.G., Kim H.T., Choi K.Y., Oh E.J., Shim J.-H., Yun W.-S., Huh J.B., Moon S.H., Kang S.S., et al. Osteogenesis of Adipose-Derived and Bone Marrow Stem Cells with Polycaprolactone/Tricalcium Phosphate and Three-Dimensional Printing Technology in a Dog Model of Maxillary Bone Defects. Polymers. 2017;9:450. doi: 10.3390/polym9090450. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

89. Bae J.C., Lee J.-J., Shim J.-H., Park K.-H., Lee J.-S., Bae E.-B., Choi J.-W., Huh J.-B. Development and Assessment of a 3D-Printed Scaffold with rhBMP-2 for an Implant Surgical Guide Stent and Bone Graft Material: A Pilot Animal Study. Materials. 2017;10:1434. doi: 10. 3390/ma10121434. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

3390/ma10121434. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

90. Rider P., Kacarevic Z.P., Alkildani S., Retnasingh S., Schnettler R., Barbeck M. Additive Manufacturing for Guided Bone Regeneration: A Perspective for Alveolar Ridge Augmentation. Int. J. Mol. Sci. 2018;19:3308. doi: 10.3390/ijms19113308. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

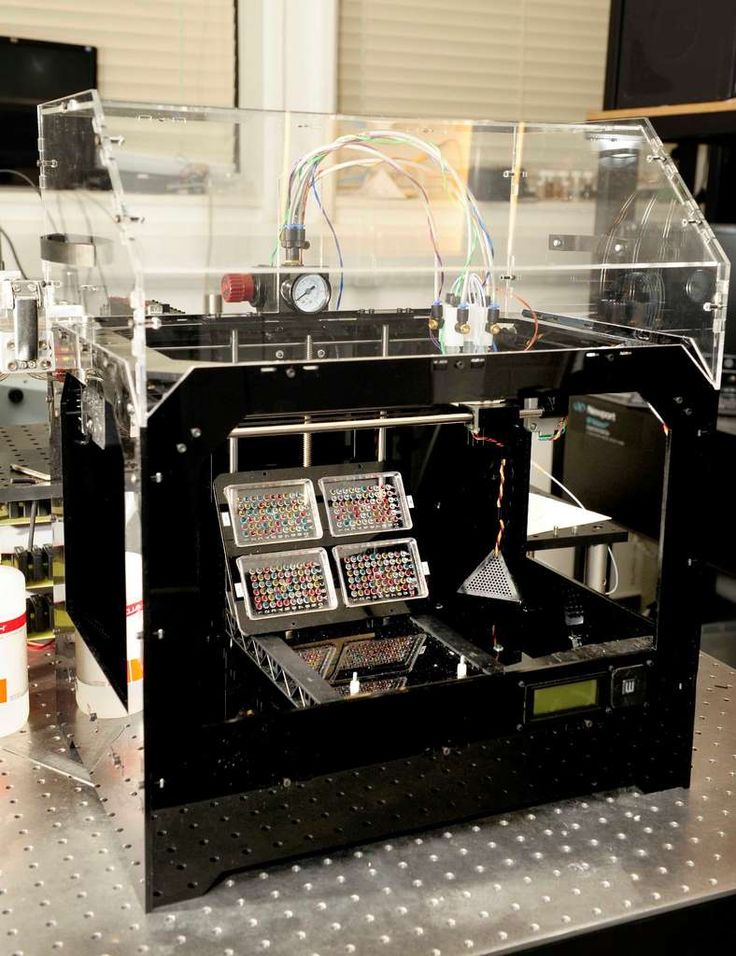

91. Bartolo P., Domingos M., Gloria A., Ciurana J. BioCell Printing: Integrated automated assembly system for tissue engineering constructs. CIRP Ann. 2011;60:271–274. doi: 10.1016/j.cirp.2011.03.116. [CrossRef] [Google Scholar]

92. Daly A.C., Critchley S.E., Rencsok E.M., Kelly D.J. A comparison of different bioinks for 3D bioprinting of fibrocartilage and hyaline cartilage. Biofabrication. 2016;8:045002. doi: 10.1088/1758-5090/8/4/045002. [PubMed] [CrossRef] [Google Scholar]

93. Critchley S., Sheehy E., Cunniffe G., Diaz-Payno P., Carroll S.F., Jeon O., Alsberg E., Brama P.A., Kelly D.J. 3D printing of fibre-reinforced cartilaginous templates for the regeneration of osteochondral defects. Acta Biomater. 2020;113:130–143. doi: 10.1016/j.actbio.2020.05.040. [PubMed] [CrossRef] [Google Scholar]

Acta Biomater. 2020;113:130–143. doi: 10.1016/j.actbio.2020.05.040. [PubMed] [CrossRef] [Google Scholar]

94. Sun Y., Wu Q., Zhang Y., Dai K., Wei Y. 3D-bioprinted gradient-structured scaffold generates anisotropic cartilage with vascularization by pore-size-dependent activation of HIF1α/FAK signaling axis. Nanomedicine. 2021:102426. doi: 10.1016/j.nano.2021.102426. [PubMed] [CrossRef] [Google Scholar]

95. Murphy C., Kolan K., Li W., Semon J., Day D., Leu M. 3D bioprinting of stem cells and polymer/bioactive glass composite scaffolds for bone tissue engineering. Int. J. Bioprinting. 2017;3:54–64. doi: 10.18063/IJB.2017.01.005. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

96. Kim Y.B., Lee H., Yang G.-H., Choi C.H., Lee D., Hwang H., Jung W.-K., Yoon H., Kim G.H. Mechanically reinforced cell-laden scaffolds formed using alginate-based bioink printed onto the surface of a PCL/alginate mesh structure for regeneration of hard tissue. J. Colloid Interface Sci. 2016;461:359–368. doi: 10.1016/j.jcis.2015.09.044. [PubMed] [CrossRef] [Google Scholar]

doi: 10.1016/j.jcis.2015.09.044. [PubMed] [CrossRef] [Google Scholar]

97. Garcia J.R., Garcia A.J. Biomaterial-mediated strategies targeting vascularization for bone repair. Drug Deliv. Trans. L Res. 2016;6:77–95. doi: 10.1007/s13346-015-0236-0. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

98. Amini A.R., Laurencin C.T., Nukavarapu S.P. Differential analysis of peripheral blood- and bone marrow-derived endothelial progenitor cells for enhanced vascularization in bone tissue engineering. J. Orthop. Res. 2012;30:1507–1515. doi: 10.1002/jor.22097. [PubMed] [CrossRef] [Google Scholar]

99. Zhang Q., Nettleship I., Schmelzer E., Gerlach J.C., Zhang M.X., Wang J., Liu C. Tissue Engineering and Regenerative Medicine Therapies for Cell Senescence in Bone and Cartilage. Tissue Eng. Part B Rev. 2020;26:64–78. doi: 10.1089/ten.teb.2019.0215. [PubMed] [CrossRef] [Google Scholar]

100. Dang H.P., Shabab T., Shafiee A., Peiffer Q.C., Fox K., Tran N., Dargaville T., Hutmacher D. W., A Tran P. 3D printed dual macro-, microscale porous network as a tissue engineering scaffold with drug delivering function. Biofabrication. 2019;11:035014. doi: 10.1088/1758-5090/ab14ff. [PubMed] [CrossRef] [Google Scholar]

W., A Tran P. 3D printed dual macro-, microscale porous network as a tissue engineering scaffold with drug delivering function. Biofabrication. 2019;11:035014. doi: 10.1088/1758-5090/ab14ff. [PubMed] [CrossRef] [Google Scholar]

101. Govender M., Indermun S., Kumar P., Choonara Y.E., Pillay V. 3D Printed, PVA–PAA Hydrogel Loaded-Polycaprolactone Scaffold for the Delivery of Hydrophilic In-Situ Formed Sodium Indomethacin. Materials. 2018;11:1006. doi: 10.3390/ma11061006. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

102. Shao J., Ma J., Lin L., Wang B., Jansen J.A., Walboomers X.F., Zuo Y., Yang F. Three-Dimensional Printing of Drug-Loaded Scaffolds for Antibacterial and Analgesic Applications. Tissue Eng. Part C Methods. 2019;25:222–231. doi: 10.1089/ten.tec.2018.0293. [PubMed] [CrossRef] [Google Scholar]

103. Kim S.E., Yun Y.-P., Shim K.-S., Kim H.J., Park K., Song H.-R. 3D printed alendronate-releasing poly(caprolactone) porous scaffolds enhance osteogenic differentiation and bone formation in rat tibial defects. Biomed. Mater. 2016;11:055005. doi: 10.1088/1748-6041/11/5/055005. [PubMed] [CrossRef] [Google Scholar]

Biomed. Mater. 2016;11:055005. doi: 10.1088/1748-6041/11/5/055005. [PubMed] [CrossRef] [Google Scholar]

104. Puppi D., Piras A.M., Pirosa A., Sandreschi S., Chiellini F. Levofloxacin-loaded star poly(ε-caprolactone) scaffolds by additive manufacturing. J. Mater. Sci. Mater. Med. 2016;27:44. doi: 10.1007/s10856-015-5658-1. [PubMed] [CrossRef] [Google Scholar]

105. Bessa P.C., Balmayor E.R., Azevedo H., Nürnberger S., Casal M., van Griensven M., Reis R.L., Redl H. Silk fibroin microparticles as carriers for delivery of human recombinant BMPs. Physical characterization and drug release. J. Tissue Eng. Regen. Med. 2010;4:349–355. doi: 10.1002/term.245. [PubMed] [CrossRef] [Google Scholar]

106. Jang C.H., Lee J., Kim G. Synergistic effect of alginate/BMP-2/Umbilical cord serum-coated on 3D-printed PCL biocomposite for mastoid obliteration model. J. Ind. Eng. Chem. 2019;72:432–441. doi: 10.1016/j.jiec.2018.12.046. [CrossRef] [Google Scholar]

107. Melke J., Midha S., Ghosh S. , Ito K., Hofmann S. Silk fibroin as biomaterial for bone tissue engineering. Acta Biomater. 2016;31:1–16. doi: 10.1016/j.actbio.2015.09.005. [PubMed] [CrossRef] [Google Scholar]

, Ito K., Hofmann S. Silk fibroin as biomaterial for bone tissue engineering. Acta Biomater. 2016;31:1–16. doi: 10.1016/j.actbio.2015.09.005. [PubMed] [CrossRef] [Google Scholar]

108. Wagner E., Parry J., Dadsetan M., Bravo D., Riester S.M., Van Wijnen A.J., Yaszemski M.J., Kakar S. VEGF-mediated angiogenesis and vascularization of a fumarate-crosslinked polycaprolactone (PCLF) scaffold. Connect. Tissue Res. 2018;59:542–549. doi: 10.1080/03008207.2018.1424145. [PubMed] [CrossRef] [Google Scholar]

109. He Y., Liu W., Guan L., Chen J., Duan L., Jia Z., Huang Z., Li W., Liu J., Xiong Z., et al. A 3D-Printed PLCL Scaffold Coated with Collagen Type I and Its Biocompatibility. Biomed Res. Int. 2018;2018:5147156. doi: 10.1155/2018/5147156. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

110. Kim W., Jang C.H., Kim G. Optimally designed collagen/polycaprolactone biocomposites supplemented with controlled. release of HA/TCP/rhBMP-2 and HA/TCP/PRP for hard tissue regeneration. Mater. Sci. Eng. C-Mater. Biol. Appl. 2017;78:763–772. doi: 10.1016/j.msec.2017.04.144. [PubMed] [CrossRef] [Google Scholar]

Mater. Sci. Eng. C-Mater. Biol. Appl. 2017;78:763–772. doi: 10.1016/j.msec.2017.04.144. [PubMed] [CrossRef] [Google Scholar]

111. Lee S.J., Lee H.-J., Kim S.-Y., Seok J.M., Lee J.H., Kim W.D., Kwon I.K., Park S.-Y., A Park S. In situgold nanoparticle growth on polydopamine-coated 3D-printed scaffolds improves osteogenic differentiation for bone tissue engineering applications:in vitroandin vivostudies. Nanoscale. 2018;10:15447–15453. doi: 10.1039/C8NR04037K. [PubMed] [CrossRef] [Google Scholar]

112. Bartnikowski M., Moon H.-J., Ivanovski S. Release of lithium from 3D printed polycaprolactone scaffolds regulates macrophage and osteoclast response. Biomed. Mater. 2018;13:065003. doi: 10.1088/1748-605X/aad916. [PubMed] [CrossRef] [Google Scholar]

113. Hamlet S.M., Vaquette C., Shah A., Hutmacher D.W., Ivanovski S. 3-Dimensional functionalized polycaprolactone-hyaluronic acid hydrogel constructs for bone tissue engineering. J. Clin. Periodontol. 2017;44:428–437. doi: 10.1111/jcpe. 12686. [PubMed] [CrossRef] [Google Scholar]

12686. [PubMed] [CrossRef] [Google Scholar]

114. Lee S.J., Lee D., Yoon T.R., Kim H.K., Jo H.H., Park J.S., Lee J.H., Kim W.D., Kwon I.K., A Park S. Surface modification of 3D-printed porous scaffolds via mussel-inspired polydopamine and effective immobilization of rhBMP-2 to promote osteogenic differentiation for bone tissue engineering. Acta Biomater. 2016;40:182–191. doi: 10.1016/j.actbio.2016.02.006. [PubMed] [CrossRef] [Google Scholar]

115. Bari E., Scocozza F., Perteghella S., Sorlini M., Auricchio F., Torre M., Conti M. 3D Bioprinted Scaffolds Containing Mesenchymal Stem/Stromal Lyosecretome: Next Generation Controlled Release Device for Bone Regenerative Medicine. Pharmacrutics. 2021;13:515. doi: 10.3390/pharmaceutics13040515. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

116. Gong L., Li J., Zhang J., Pan Z., Liu Y., Zhou F., Hong Y., Hu Y., Gu Y., Ouyang H., et al. An interleukin-4-loaded bi-layer 3D printed scaffold promotes osteochondral regeneration. Acta Biomater. 2020;117:246–260. doi: 10.1016/j.actbio.2020.09.039. [PubMed] [CrossRef] [Google Scholar]

Acta Biomater. 2020;117:246–260. doi: 10.1016/j.actbio.2020.09.039. [PubMed] [CrossRef] [Google Scholar]

117. Li J., Chen M., Wei X., Hao Y., Wang J. Evaluation of 3D-Printed Polycaprolactone Scaffolds Coated with Freeze-Dried Platelet-Rich Plasma for Bone Regeneration. Materials. 2017;10:831. doi: 10.3390/ma10070831. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

118. Cunniffe G.M., Gonzalez-Fernandez T., Daly A., Sathy B.N., Jeon O., Alsberg E., Kelly D. Three-Dimensional Bioprinting of Polycaprolactone Reinforced Gene Activated Bioinks for Bone Tissue Engineering. Tissue Eng. Part A. 2017;23:891–900. doi: 10.1089/ten.tea.2016.0498. [PubMed] [CrossRef] [Google Scholar]

119. Wei P., Xu Y., Gu Y., Yao Q., Li J., Wang L. IGF-1-releasing PLGA nanoparticles modified 3D printed PCL scaffolds for cartilage tissue engineering. Drug Deliv. 2020;27:1106–1114. doi: 10.1080/10717544.2020.1797239. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

120. Mostafavi A. , Abudula T., Russell C.S., Mostafavi E., Williams T.J., Salah N., Alshahrie A., Harris S., Basri S.M.M., Mishra Y.K., et al. In situ printing of scaffolds for reconstruction of bone defects. Acta Biomater. 2021;127:313–326. doi: 10.1016/j.actbio.2021.03.009. [PubMed] [CrossRef] [Google Scholar]

, Abudula T., Russell C.S., Mostafavi E., Williams T.J., Salah N., Alshahrie A., Harris S., Basri S.M.M., Mishra Y.K., et al. In situ printing of scaffolds for reconstruction of bone defects. Acta Biomater. 2021;127:313–326. doi: 10.1016/j.actbio.2021.03.009. [PubMed] [CrossRef] [Google Scholar]

121. Zhao S., Xie K., Guo Y., Tan J., Wu J., Yang Y., Fu P., Wang L., Jiang W., Hao Y. Fabrication and Biological Activity of 3D-Printed Polycaprolactone/Magnesium Porous Scaffolds for Critical Size Bone Defect Repair. ACS Biomater. Sci. Eng. 2020;6:5120–5131. doi: 10.1021/acsbiomaterials.9b01911. [PubMed] [CrossRef] [Google Scholar]

122. Hansske F., Bas O., Vaquette C., Hochleitner G., Groll J., Kemnitz E., Hutmacher D.W., Börner H.G. Via precise interface engineering towards bioinspired composites with improved 3D printing processability and mechanical properties. J. Mater. Chem. B. 2017;5:5037–5047. doi: 10.1039/C7TB00165G. [PubMed] [CrossRef] [Google Scholar]

123. Yang L., Ullah I. , Yu K., Zhang W., Zhou J., Sun T., Shi L., Yao S., Chen K., Zhang X., et al. Bioactive Sr(2+)/Fe(3+)co-substituted hydroxyapatite in cryogenically 3D printed porous scaffolds for bone tissue engineering. Biofabrication. 2021;13:035007. doi: 10.1088/1758-5090/abcf8d. [PubMed] [CrossRef] [Google Scholar]

, Yu K., Zhang W., Zhou J., Sun T., Shi L., Yao S., Chen K., Zhang X., et al. Bioactive Sr(2+)/Fe(3+)co-substituted hydroxyapatite in cryogenically 3D printed porous scaffolds for bone tissue engineering. Biofabrication. 2021;13:035007. doi: 10.1088/1758-5090/abcf8d. [PubMed] [CrossRef] [Google Scholar]

124. Poh P.S.P., Hutmacher D.W., Holzapfel B.M., Solanki A.K., Stevens M.M., Woodruff M.A. In vitro and in vivo bone formation potential of surface calcium phosphate-coated polycaprolactone and polycaprolactone/bioactive glass composite scaffolds. Acta Biomater. 2016;30:319–333. doi: 10.1016/j.actbio.2015.11.012. [PubMed] [CrossRef] [Google Scholar]

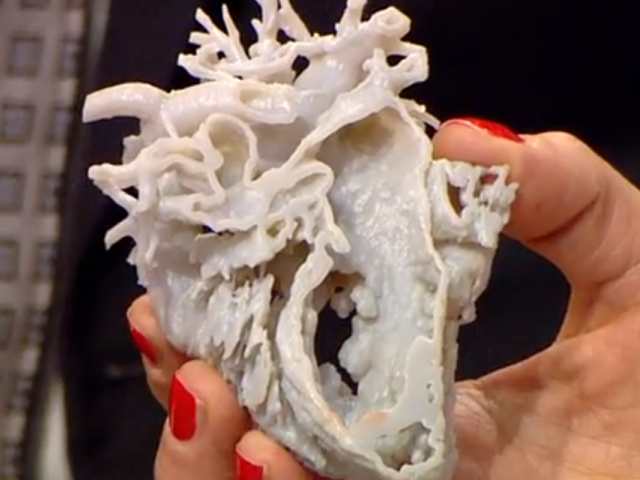

125. Nyberg E.L., Farris A.L., Hung B.P., Dias M., Garcia J.R., Dorafshar A., Grayson W.L. 3D-Printing Technologies for Craniofacial Rehabilitation, Reconstruction, and Regeneration. Ann. Biomed. Eng. 2017;45:45–57. doi: 10.1007/s10439-016-1668-5. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

126. VijayaVenkataRaman S. , Lu W.F., Fuh J.Y.H. 3D bioprinting of skin: A state-of-the-art review on modelling, materials, and processes. Biofabrication. 2016;8:032001. doi: 10.1088/1758-5090/8/3/032001. [PubMed] [CrossRef] [Google Scholar]

, Lu W.F., Fuh J.Y.H. 3D bioprinting of skin: A state-of-the-art review on modelling, materials, and processes. Biofabrication. 2016;8:032001. doi: 10.1088/1758-5090/8/3/032001. [PubMed] [CrossRef] [Google Scholar]

127. Yeo M., Lee H., Kim G.H. Combining a micro/nano-hierarchical scaffold with cell-printing of myoblasts induces cell alignment and differentiation favorable to skeletal muscle tissue regeneration. Biofabrication. 2016;8:035021. doi: 10.1088/1758-5090/8/3/035021. [PubMed] [CrossRef] [Google Scholar]

128. Bahcecioglu G., Hasirci N., Bilgen B., Hasirci V. A 3D printed PCL/hydrogel construct with zone-specific biochemical composition mimicking that of the meniscus. Biofabrication. 2018;11:025002. doi: 10.1088/1758-5090/aaf707. [PubMed] [CrossRef] [Google Scholar]

129. Zhang Z.-Z., Wang S.-J., Zhang J.-Y., Jiang W.-B., Huang A.-B., Qi Y.-S., Ding J.-X., Chen X.-S., Jiang D., Yu J.-K. 3D-Printed Poly(ε-caprolactone) Scaffold Augmented With Mesenchymal Stem Cells for Total Meniscal Substitution: A 12- and 24-Week Animal Study in a Rabbit Model. Am. J. Sports Med. 2017;45:1497–1511. doi: 10.1177/0363546517691513. [PubMed] [CrossRef] [Google Scholar]

Am. J. Sports Med. 2017;45:1497–1511. doi: 10.1177/0363546517691513. [PubMed] [CrossRef] [Google Scholar]

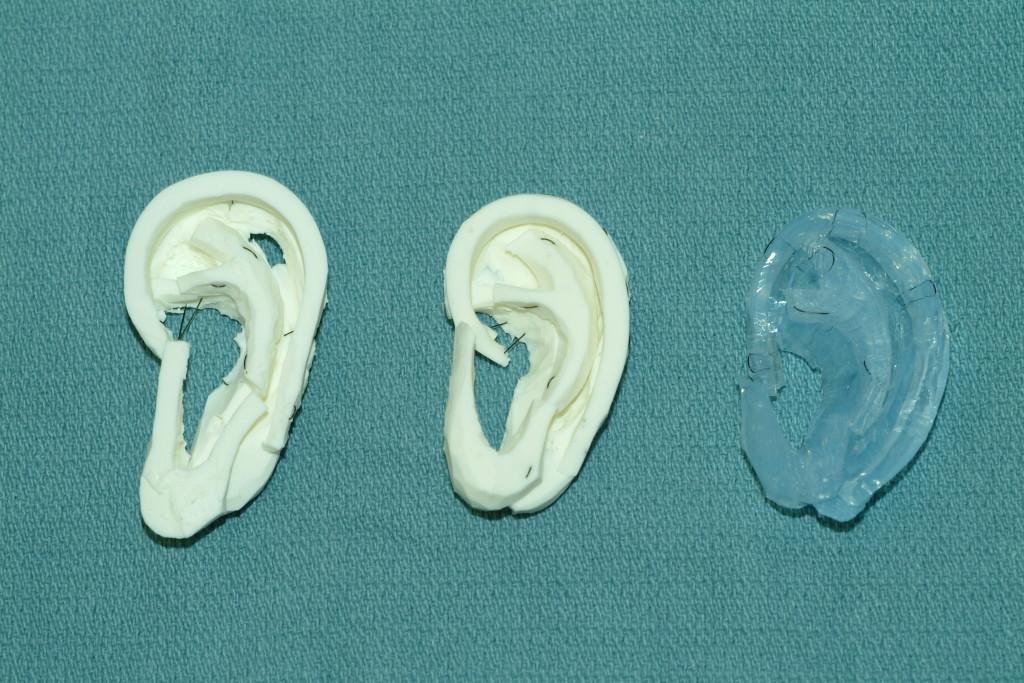

130. Jung B.K., Kim J.Y., Kim Y.S., Roh T.S., Seo A., Park K.-H., Shim J.-H., Yun I.S. Ideal scaffold design for total ear reconstruction using a three-dimensional printing technique. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019;107:1295–1303. doi: 10.1002/jbm.b.34222. [PubMed] [CrossRef] [Google Scholar]

131. Park H.S., Lee J.S., Jung H., Kim D.Y., Kim S.W., Sultan T., Park C.H. An omentum-cultured 3D-printed artificial trachea: In Vivo bioreactor. Artif. Cells Nanomed. Biotechnol. 2018;46:S1131–S1140. doi: 10.1080/21691401.2018.1533844. [PubMed] [CrossRef] [Google Scholar]

132. Gao M., Zhang H., Dong W., Bai J., Gao B., Xia D., Feng B., Chen M., He X., Yin M., et al. Tissue-engineered trachea from a 3D-printed scaffold enhances whole-segment tracheal repair. Sci. Rep. 2017;7:5246. doi: 10.1038/s41598-017-05518-3. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

133. Soares C.S., Barros L.C., Saraiva V., Gomez-Florit M., Babo P.S., Dias I., Reis R.L., Carvalho P.P., E Gomes M. Bioengineered surgical repair of a chronic oronasal fistula in a cat using autologous platelet-rich fibrin and bone marrow with a tailored 3D printed implant. J. Feline Med. Surg. 2018;20:835–843. doi: 10.1177/1098612X18789549. [PubMed] [CrossRef] [Google Scholar]

Soares C.S., Barros L.C., Saraiva V., Gomez-Florit M., Babo P.S., Dias I., Reis R.L., Carvalho P.P., E Gomes M. Bioengineered surgical repair of a chronic oronasal fistula in a cat using autologous platelet-rich fibrin and bone marrow with a tailored 3D printed implant. J. Feline Med. Surg. 2018;20:835–843. doi: 10.1177/1098612X18789549. [PubMed] [CrossRef] [Google Scholar]

134. Chung R., Kalyon D.M., Yu X., Valdevit A. Segmental bone replacement via patient-specific, three-dimensional printed bioresorbable graft substitutes and their use as templates for the culture of mesenchymal stem cells under mechanical stimulation at various frequencies. Biotechnol. Bioeng. 2018;115:2365–2376. doi: 10.1002/bit.26780. [PubMed] [CrossRef] [Google Scholar]

135. Temple J.P., Hutton D.L., Hung B.P., Huri P.Y., Cook C.A., Kondragunta R., Jia X., Grayson W.L. Engineering anatomically shaped vascularized bone grafts with hASCs and 3D-printed PCL scaffolds. J. Biomed. Mater. Res. Part A. 2014;102:4317–4325. doi: 10.1002/jbm.a.35107. [PubMed] [CrossRef] [Google Scholar]

doi: 10.1002/jbm.a.35107. [PubMed] [CrossRef] [Google Scholar]

136. Vaquette C., Mitchell J., Fernandez-Medina T., Kumar S., Ivanovski S. Resorbable additively manufactured scaffold imparts dimensional stability to extraskeletally regenerated bone. Biomaterials. 2021;269:120671. doi: 10.1016/j.biomaterials.2021.120671. [PubMed] [CrossRef] [Google Scholar]

3D-Printed Poly-Caprolactone Scaffolds Modified With Biomimetic Extracellular Matrices for Tarsal Plate Tissue Engineering

Introduction

The tarsal plate is one of the most important components of the eyelid. It is composed of dense connective tissue, rich elastic fibers, and a large number of meibomian glands. The tarsal plate provides both structural support and physical form, making it an essential component of the eyelid's function and appearance (Sun et al., 2015). The meibomian gland is a type of sebaceous gland with a tubuloacinar structure and holocrine function. It is located in the superior and inferior tarsal plates (Nichols et al. , 2011). Meibomian glands secrete meibum, a compound made up of polar (phospholipids) and non-polar (cholesterol, wax esters, and cholesterol esters) lipids (Foulks and Bron, 2003). These lipids then diffuse onto the tear film, forming the lipid layer of the tear film, which acts to stabilize the tear film and prevent tear evaporation (Hwang et al., 2017).

, 2011). Meibomian glands secrete meibum, a compound made up of polar (phospholipids) and non-polar (cholesterol, wax esters, and cholesterol esters) lipids (Foulks and Bron, 2003). These lipids then diffuse onto the tear film, forming the lipid layer of the tear film, which acts to stabilize the tear film and prevent tear evaporation (Hwang et al., 2017).

The common causes of eyelid defects are mainly the tumor invasion of the tarsal plate or orbital trauma, leading to partial- or full-thickness defects of the eyelids (Zhou et al., 2010). Tarsal plate tissue engineering is vital for eyelid reconstruction, but presently it remains limited by the complexity of the tarsal plate tissue and the lack of suitable substitutes. An ideal tarsal plate substitute should have characteristics similar to the thickness, surface characteristics, strength, and flexibility of natural tarsal tissue. Moreover, it should be tissue compatible and easy to obtain and handle (Chen et al., 2005). The commonly used substitutes to repair defects of the tarsal plate mainly include hard plate mucosa (Mannor et al. , 1994; Goldberg et al., 1999), nasal cartilage, and heterogenic sclera (Tenzel et al., 1975). However, these tissues have their limitations, such as large shrinkage of postoperative grafts, a limited range of tissues, and immune rejection. The biggest defect is the inability to replace the secretory function of the meibomian glands in the tarsal plate. Therefore, fabricating a tarsal plate substitute that has a certain secretion function of lipids is important.

, 1994; Goldberg et al., 1999), nasal cartilage, and heterogenic sclera (Tenzel et al., 1975). However, these tissues have their limitations, such as large shrinkage of postoperative grafts, a limited range of tissues, and immune rejection. The biggest defect is the inability to replace the secretory function of the meibomian glands in the tarsal plate. Therefore, fabricating a tarsal plate substitute that has a certain secretion function of lipids is important.

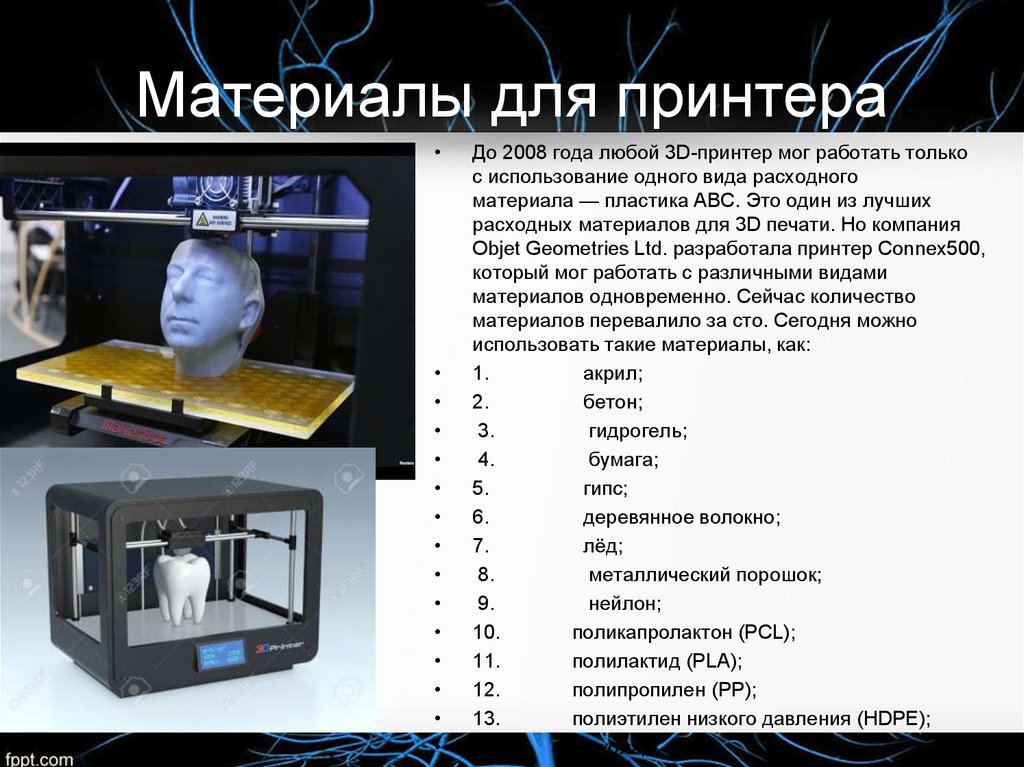

Three-dimensional (3D) printing is a technique for creating 3D objects of an individual nature using computer-aided design (Song et al., 2018). It has played a revolutionary role in the production of tissue engineering scaffolds because it overcomes the existing limitations and creates the most suitable scaffolds through simple and effective porosity dimensions that cannot be achieved using traditional scaffolding techniques (Kao et al., 2015; Yu et al., 2016). The useful features of the additive manufacturing technology can also be further implemented in the bioprinting and bio-scaffolding of biological objects with intricate architecture (Bae et al. , 2018; Hiller et al., 2018). Because of these advantages, the 3D printing technology can be very well used to print delicate and complex tissues such as printing cornea (Isaacson et al., 2018; Sorkio et al., 2018).

, 2018; Hiller et al., 2018). Because of these advantages, the 3D printing technology can be very well used to print delicate and complex tissues such as printing cornea (Isaacson et al., 2018; Sorkio et al., 2018).

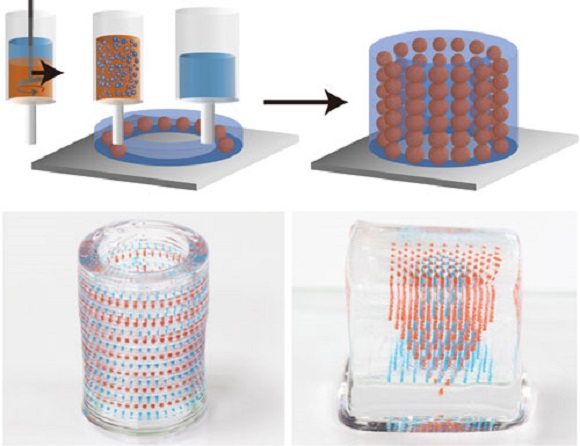

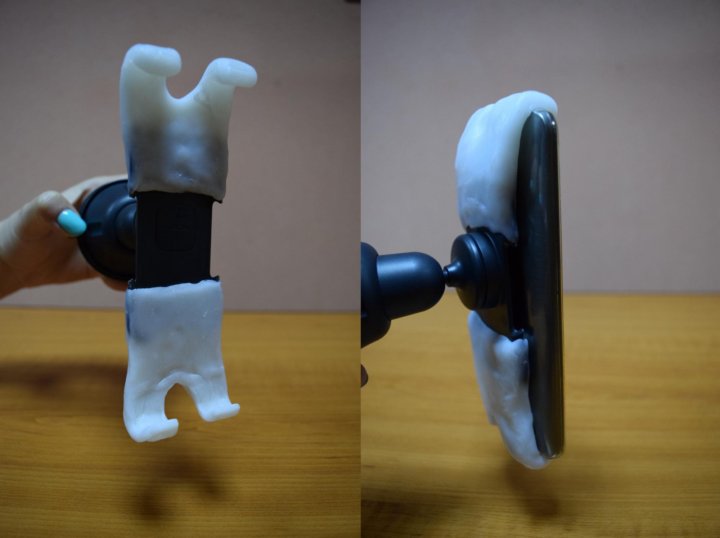

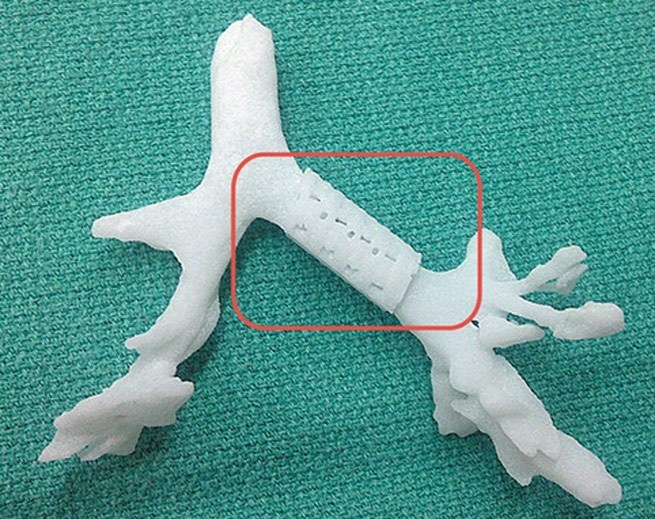

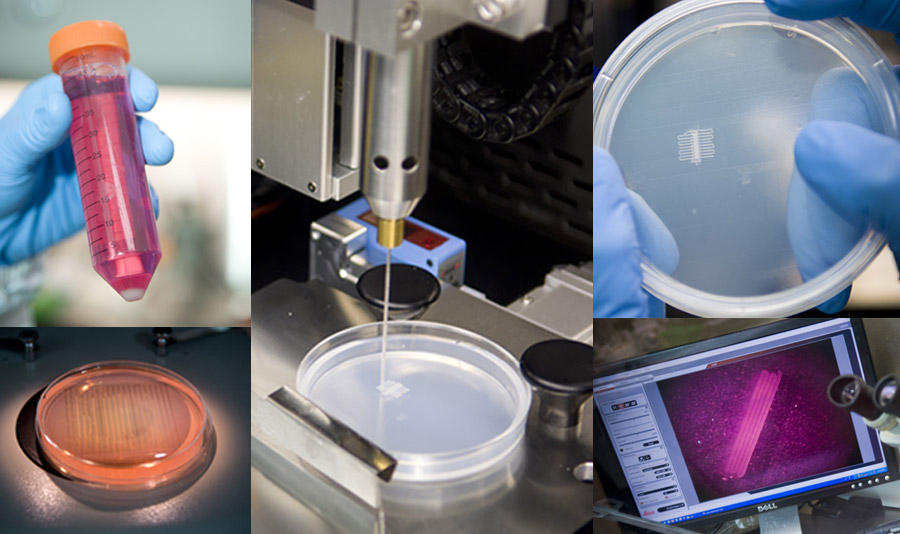

In this study, the 3D printing technology was applied, for the first time, to the fabrication of tarsal plate scaffolds through PCL. Human adipose tissue–derived stem cells (hADSCs) were seeded on PCL scaffolds and then decellularized to get a DMA–PCL scaffolds so as to enhance the biological behavior. SZ95 sebocytes were seeded on the scaffold to secrete lipids. This study aimed to assess the potential value of SZ95 sebocytes seeded on DMA–PCL scaffolds in future tarsal plate tissue engineering. The extent of cytocompatibility, cell adhesion, proliferation, and adipogenesis of the scaffolds was verified in vitro using human SZ95 sebocytes and in vivo using nude mice. A schematic showing the processes used in this study is presented in Figure 1.

Figure 1. Schematic diagram of this study. The schematic diagram of fabrication of 3D-printed DMA–PCL scaffolds and seeding of SZ95 sebocytes on the scaffolds for tarsal plate tissue engineering.

Schematic diagram of this study. The schematic diagram of fabrication of 3D-printed DMA–PCL scaffolds and seeding of SZ95 sebocytes on the scaffolds for tarsal plate tissue engineering.

Materials and Methods

Fabrication of PCL Scaffolds

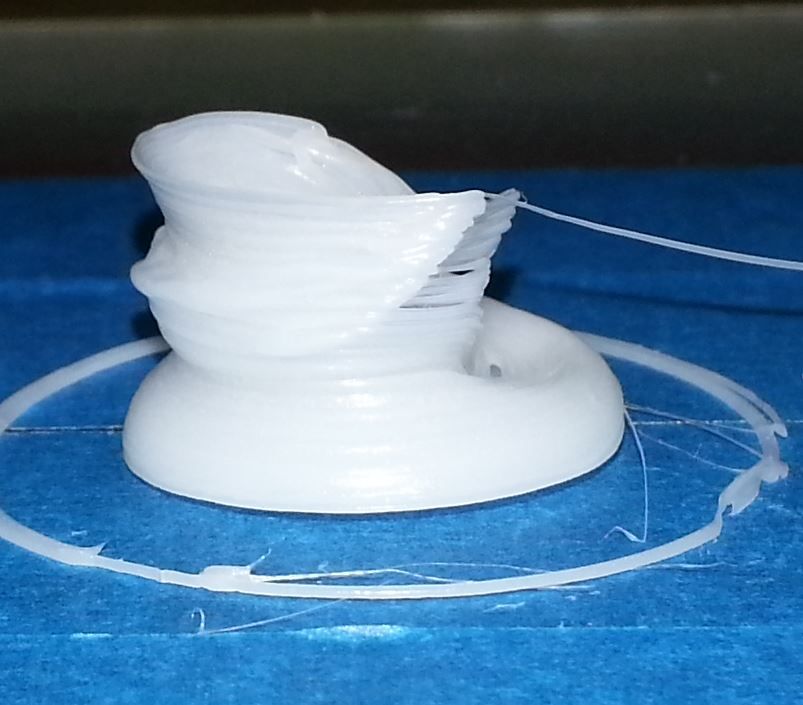

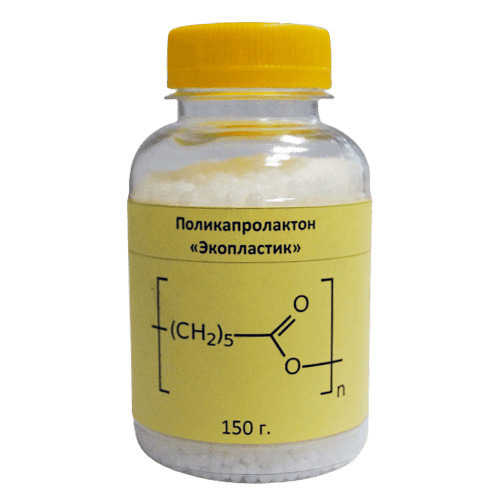

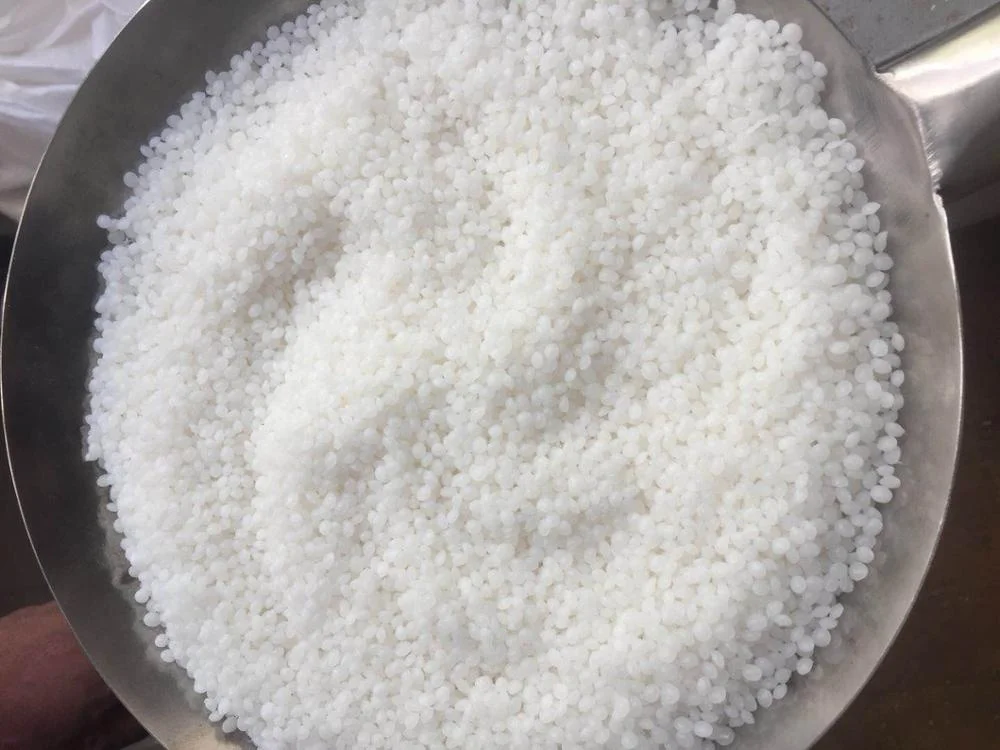

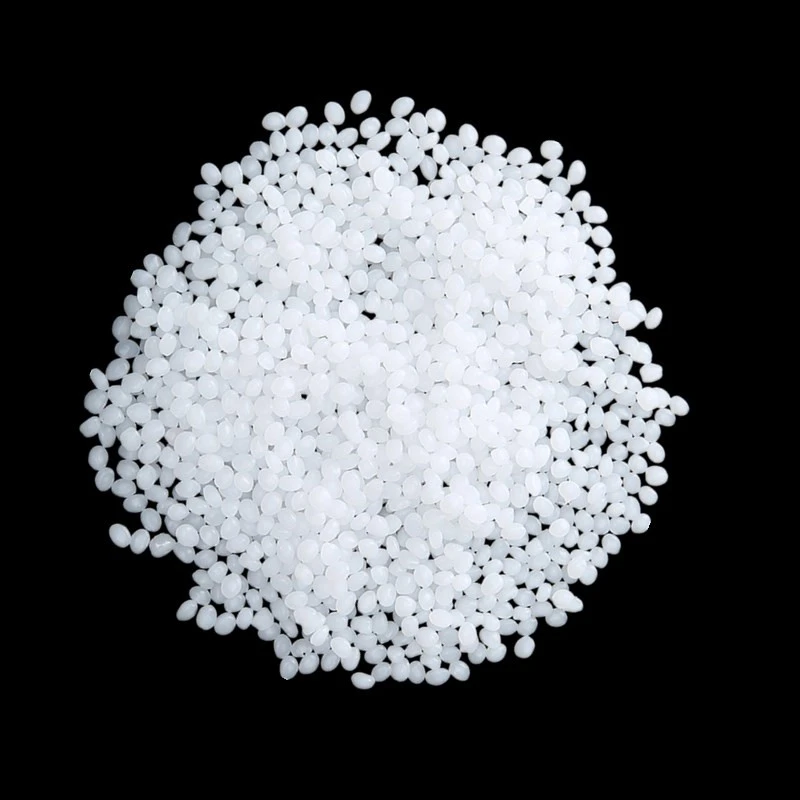

The 3D scaffolds were fabricated using a 3D printer (HTS−1200, Fochif Tech, China). The PCL beads (Mw: 40–45 kDa, supplied by Wuxi Shaxinnaxin Material, China) were put into the printing cartridge and pre-heated. Subsequently, the paste was heated to 70°C and layered with a nozzle (diameter, 0.31 μm) at a printing speed of 2 mm/s. Different pore sizes (200, 300, and 400 μm) of PCL were evaluated and an optimal pore size was chosen.

Characterization of PCL Scaffolds

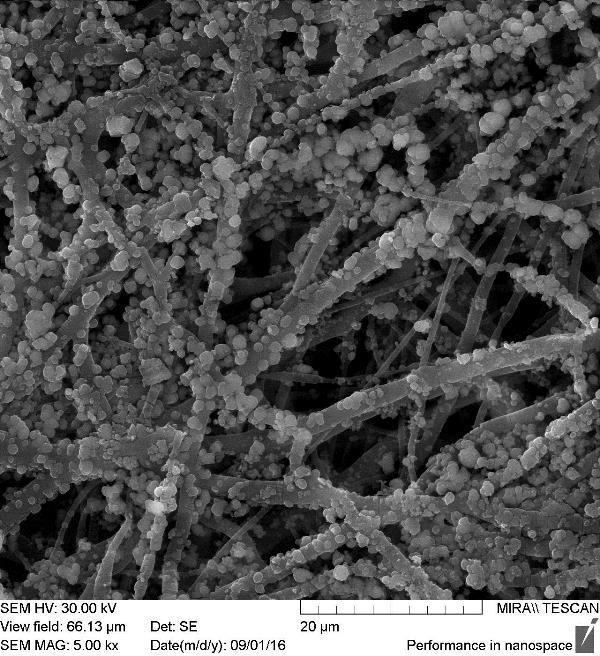

The morphology of PCL scaffolds was observed using scanning electron microscopy (SEM; JSM-6701; JEOL, Tokyo, Japan). Samples were sputtered with gold for 50 s to increase conductivity before imaging using SEM.

Mechanical properties of PCL scaffolds were determined using a uniaxial material testing machine (CMT4202, China). Rectangular-shaped specimens (20 × 10 mm) were compressed at a constant speed of 0.5 mm/min. For each sample, the maximum slope in the linear region of the compressive stress-strain curve corresponding to a strain of 0–20% was used to calculate the compressive modulus. At least three samples were tested.

Rectangular-shaped specimens (20 × 10 mm) were compressed at a constant speed of 0.5 mm/min. For each sample, the maximum slope in the linear region of the compressive stress-strain curve corresponding to a strain of 0–20% was used to calculate the compressive modulus. At least three samples were tested.

Isolation and Culture of hADSCs

hADSCs were isolated from the eyelid subcutaneous adipose tissue of young outpatients (mainly female, aged 20–25 years) admitted for blepharoplasty. This study was approved by the Institutional Review Board of Shanghai Ninth People's Hospital affiliated to the Shanghai Jiao Tong University School of Medicine. In brief, the collected adipose tissues were minced into small pieces and digested with 0.2% collagenase A for 10 h with shaking at 37°C. The cells were then centrifuged at 1200 rpm for 10 min, and the precipitated cells were cultured in Dulbecco's modified Eagle's medium (DMEM)/F12 (Invitrogen, USA) containing 10% fetal bovine serum (FBS) and 100 U/mL penicillin/streptomycin (Gibco, USA) at 37°C in the presence of 5% CO2. The medium was replaced every 2 days.

The medium was replaced every 2 days.

DMA–PCL Scaffolds

hADSCs were cultured in DMEM/F12, containing 10% FBS and 50 μmol/L vitamin C (Sigma–Aldrich, USA) as discussed in a previous study (Ji et al., 2018). Before cell seeding, PCL scaffolds were placed in a 24-well plate. 5 × 104 of hADSCs (passage 3-5) were suspended in a 50 μL culture medium, and the cell suspension was applied dropwise on top of the scaffolds. The cell-seeded scaffolds were subsequently incubated at 37°C for half an hour to allow the adhesion of the cells into the porous structure before the expansion medium was added (500 μL/scaffold). The medium was changed every 2 days for 2 weeks. After 2 weeks, the cell separation buffer was applied. The cell separation buffer was composed of 0.5% ammonium hydroxide Triton + 20 mmol/L NH4OH and dissolved in phosphate-buffered saline (PBS). The cell separation buffer was gradually dropped into the plate, allowed to stand for 5 min, and then washed three times with PBS. Subsequently, 100 U/mL DNase (Sigma–Aldrich, USA) was added. The scaffolds were retained at 37°C for 1 h, washed three times with PBS, dried, and stored (in the dark) at 4°C.

Subsequently, 100 U/mL DNase (Sigma–Aldrich, USA) was added. The scaffolds were retained at 37°C for 1 h, washed three times with PBS, dried, and stored (in the dark) at 4°C.

Contact Angle of PCL and DMA-PCL Scaffolds

The water contact angles of PCL and DMA-PCL scaffolds were determined by the solid drop method. Measurements were handled using a goniometer, Data Physics (model OCA 15 Plus) System, equipped with an electronic syringe, a video camera and SCA 20 software. First, the scaffolds were placed on the plate of the goniometer and centered with the tip of the needle. Afterwards, using the software, a drop of 4 μL ultrapure water was released through the needle over the scaffold. The process was observed using a camera, which captured the exact moment the raindrops reached the surface of the scaffold. This procedure was repeated three times to obtain the average contact angle of the left and right parts of the droplet.

Immunofluorescence of Collagen I and Fibronectin on PCL and DMA-PCL Scaffolds

ADSCs both with and without decellularization on scaffolds were fixed with 4% paraformaldehyde, and the samples were incubated with the following antibodies overnight at 4°C: anti-fibronectin (1:500, BD Biosciences) and anti-collagen I (1:200, Santa Cruz). Following immunofluorescence, the scaffolds were incubated with a 1:400 dilution of fluorescence-labeled secondary antibodies diluted in PBS (Alexa Fluor 488-goat anti-rabbit/mouse and Alexa Fluor 546-goat anti-rabbit/mouse, BD Biosciences) and protected from light for 1 h at room temperature. A confocal laser scanning microscope (CLSM) (A1, Nikon, Japan) was used to capture images.

Following immunofluorescence, the scaffolds were incubated with a 1:400 dilution of fluorescence-labeled secondary antibodies diluted in PBS (Alexa Fluor 488-goat anti-rabbit/mouse and Alexa Fluor 546-goat anti-rabbit/mouse, BD Biosciences) and protected from light for 1 h at room temperature. A confocal laser scanning microscope (CLSM) (A1, Nikon, Japan) was used to capture images.

Culture of SZ95 Sebocytes and Cell Morphology on 3D Scaffolds

A total of 1 × 105 SZ95 sebocytes (Zouboulis et al., 1999) were seeded on PCL scaffolds or DMA-PCL scaffolds, in DMEM (Gibco, CA, USA), supplemented with 10% FBS (Gibco), 5 ng/mL recombinant human epidermal growth factor (Peprotech, USA), and 100 U/mL penicillin/streptomycin (Gibco, USA) in a humidified atmosphere containing 5% CO2 at 37°C. The detailed cell culture method was the same as mentioned earlier for hADSCs. The medium was replaced every other day. Seven days after cell seeding, the scaffolds were fixed with 0. 25% glutaraldehyde (Merck, Germany) at 4°C overnight. The samples were rinsed with PBS three times and then dehydrated with graded concentrations of ethanol (30, 50, 70, 80, 90, and 100% v/v) for 10 min each. Subsequently, the samples were critical-point dried, following which they were sputter-coated with gold and examined using an SEM.

25% glutaraldehyde (Merck, Germany) at 4°C overnight. The samples were rinsed with PBS three times and then dehydrated with graded concentrations of ethanol (30, 50, 70, 80, 90, and 100% v/v) for 10 min each. Subsequently, the samples were critical-point dried, following which they were sputter-coated with gold and examined using an SEM.

Live/Dead Viability Assay

Viability staining was performed using Live/Dead assay (Thermo Fisher Scientific, CA, USA) as described in a previous study (Chen et al., 2015). In brief, 5 × 104 SZ95 sebocytes were cultured for 7 days in the culture medium on scaffolds or in 24-well plates (control group). After the culture solution was sucked and rinsed with PBS, the cells were incubated in PBS containing ethidium homodimer 2 (EthD-2) and calcein-acetoxymethyl ester (CAM) at 37°C for 15 min and washed with PBS for three times. Live cells were stained with green-fluorescent CAM, and dead cells were stained with red-fluorescent EthD-2. A fluorescent microscope (Olympus BX51; Olympus, Tokyo, Japan) was used to capture images of cell staining.

A fluorescent microscope (Olympus BX51; Olympus, Tokyo, Japan) was used to capture images of cell staining.

Quantification of Cell Viability

To detect the effect of 3D-printed scaffolds with or without DMA on cell proliferation, a cell CCK-8 assay kit (Dojindo, Japan) was used. In brief, SZ95 sebocytes were seeded onto the scaffolds at a density of 2 × 104 cells/well in 24-well plates. After 0, 1, 3, 5, and 7 days of cell seeding, the cells were incubated with 10% CCK-8 in the medium. After incubation for 4 h, the absorbance of each well was measured at 450 nm using a microplate reader (ELx800, Bio-Tek, USA).

Immunofluorescence of F-actin and Assessment of Lipid Production on Scaffolds

SZ95 sebocytes were seeded onto the scaffolds at a density of 5 × 104 cells/well in 24-well plates. After 7 days of culture, the SZ95 sebocytes were fixed with 4% paraformaldehyde (Sigma–Aldrich), dissolved in PBS for 15 min, and washed with PBS at room temperature. The specimens were immersed in phalloidin conjugated to Alexa Fluor 505 (1:1,000 dilution in PBS, Invitrogen) to obtain an F-actin cytoskeleton for 1 h at room temperature. Then, the scaffolds were washed with PBS for three times. For neutral lipid droplet staining, the cells were incubated in HCS LipidTox solution (1:1,000 dilution in PBS, Invitrogen) for 30 min at room temperature. CLSM was used to capture images of cell staining.

The specimens were immersed in phalloidin conjugated to Alexa Fluor 505 (1:1,000 dilution in PBS, Invitrogen) to obtain an F-actin cytoskeleton for 1 h at room temperature. Then, the scaffolds were washed with PBS for three times. For neutral lipid droplet staining, the cells were incubated in HCS LipidTox solution (1:1,000 dilution in PBS, Invitrogen) for 30 min at room temperature. CLSM was used to capture images of cell staining.

RNA Isolation, Reverse Transcription, and Quantitative Polymerase Chain Reaction

The SZ95 sebocytes were seeded onto the scaffolds at a density of 5 × 104 cells/well in 24-well plates. After 7 days of culture, the cell-loaded scaffolds were taken out from the culture dish using microscope forceps and immersed in TRIzol reagent (Thermo Fisher Scientific, USA). Total RNA was extracted using TRIzol reagent following the manufacturer's protocols. The RNA concentration was measured using a spectrophotometer and NanoDrop 2000 software, and the OD260/280 ratio of RNA was considered to be of purity between 1. 9 and 2.1. Subsequently, 1,000 ng RNA was reverse-transcribed using a PrimeScript RT reagent kit (TaKaRa, Japan). A real-time polymerase chain reaction (PCR) was performed using a 7500 Real-Time PCR Detection System (Applied Biosystems). After 40 cycles of amplification, the relative mRNA was analyzed using the Pfaffl method (Pfaffl, 2001). The PCR efficiency of the reaction was measured with primers using serial dilutions of cDNA (1:1, 1:5, 1:25, 1:125, 1:625, and 1:3125). The primer sequences used for real-time PCR are listed in Table 1.

9 and 2.1. Subsequently, 1,000 ng RNA was reverse-transcribed using a PrimeScript RT reagent kit (TaKaRa, Japan). A real-time polymerase chain reaction (PCR) was performed using a 7500 Real-Time PCR Detection System (Applied Biosystems). After 40 cycles of amplification, the relative mRNA was analyzed using the Pfaffl method (Pfaffl, 2001). The PCR efficiency of the reaction was measured with primers using serial dilutions of cDNA (1:1, 1:5, 1:25, 1:125, 1:625, and 1:3125). The primer sequences used for real-time PCR are listed in Table 1.

Table 1. Primers used for quantitative polymerase chain reaction.

In vivo ImplantationSix nude mice were supplied by the Shanghai Animal Experimental Center. All procedures on animals were performed according to the Guidelines for Care and Use of Laboratory Animals of Shanghai Jiao Tong University School of Medicine and approved by the Animal Ethics Committee of Shanghai Ninth People's Hospital affiliated to Shanghai Jiao Tong University School of Medicine. 1 × 106 sebocytes were seeded on 3D scaffolds and cultured for 7 days in vitro. Then, the cell-seeded scaffolds were implanted into the nude mice subcutaneously. After implantation for 1 month, the nude mice were sacrificed and the samples were collected for further experiments. Each experiment was tested in triplicate. The implants were embedded in optimal cutting temperature compound (Sakura Seiki, Tokyo, Japan) and then cut into 8-mm-thick sections. Human SZ95 sebocytes were stained with human nuclear antigen antibody (Novus Biological, USA, 235-1) to evaluate the in vivo proliferation status. For Oil Red O staining, frozen DMA-PCL scaffold sections were fixed in 4% paraformaldehyde for 15 min, washed in PBS for 5 min, and stained for 10 min in freshly prepared Oil Red O solution. After washing with PBS for 15 min, the sections were counterstained with hematoxylin and mounted in 90% glycerol.

1 × 106 sebocytes were seeded on 3D scaffolds and cultured for 7 days in vitro. Then, the cell-seeded scaffolds were implanted into the nude mice subcutaneously. After implantation for 1 month, the nude mice were sacrificed and the samples were collected for further experiments. Each experiment was tested in triplicate. The implants were embedded in optimal cutting temperature compound (Sakura Seiki, Tokyo, Japan) and then cut into 8-mm-thick sections. Human SZ95 sebocytes were stained with human nuclear antigen antibody (Novus Biological, USA, 235-1) to evaluate the in vivo proliferation status. For Oil Red O staining, frozen DMA-PCL scaffold sections were fixed in 4% paraformaldehyde for 15 min, washed in PBS for 5 min, and stained for 10 min in freshly prepared Oil Red O solution. After washing with PBS for 15 min, the sections were counterstained with hematoxylin and mounted in 90% glycerol.

Statistical Analysis

A computer-based Sigma Gel System (SPSS Inc. , IL, USA) and the Image J program were used to analyze the integral optical density (IOD) of immunofluorescence images. A one-way analysis of variance followed by the Student t-test was used to determine the statistical significance (P-value) of the obtained data. All data presented in this study were reported as the mean ± SEM of three parallel studies. A P < 0.05 was considered statistically significant (*P < 0.05 and ***P < 0.001).

, IL, USA) and the Image J program were used to analyze the integral optical density (IOD) of immunofluorescence images. A one-way analysis of variance followed by the Student t-test was used to determine the statistical significance (P-value) of the obtained data. All data presented in this study were reported as the mean ± SEM of three parallel studies. A P < 0.05 was considered statistically significant (*P < 0.05 and ***P < 0.001).

Results

Characterizations of 3D-printed Scaffolds

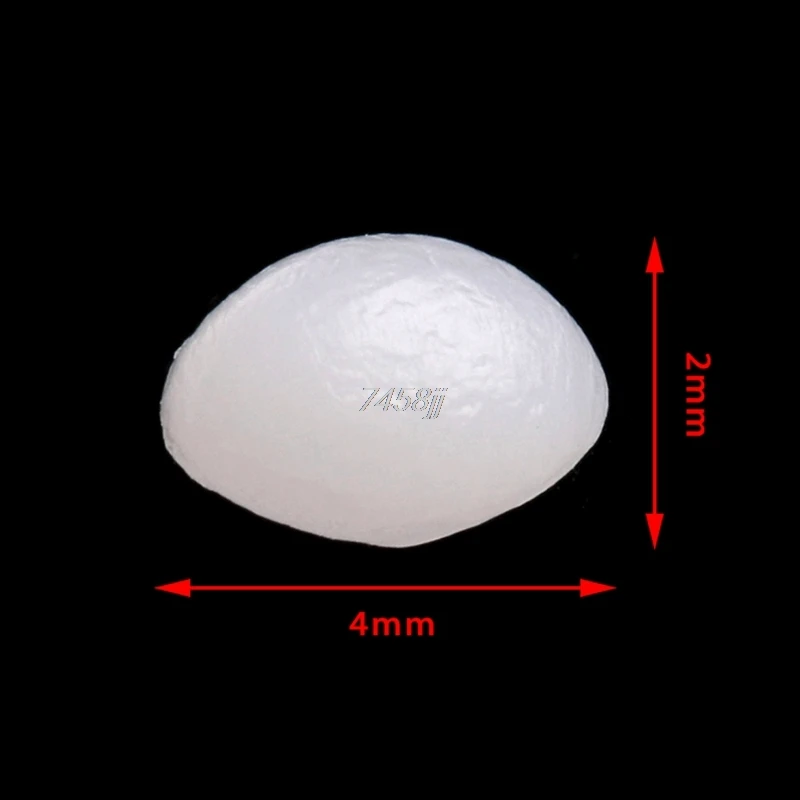

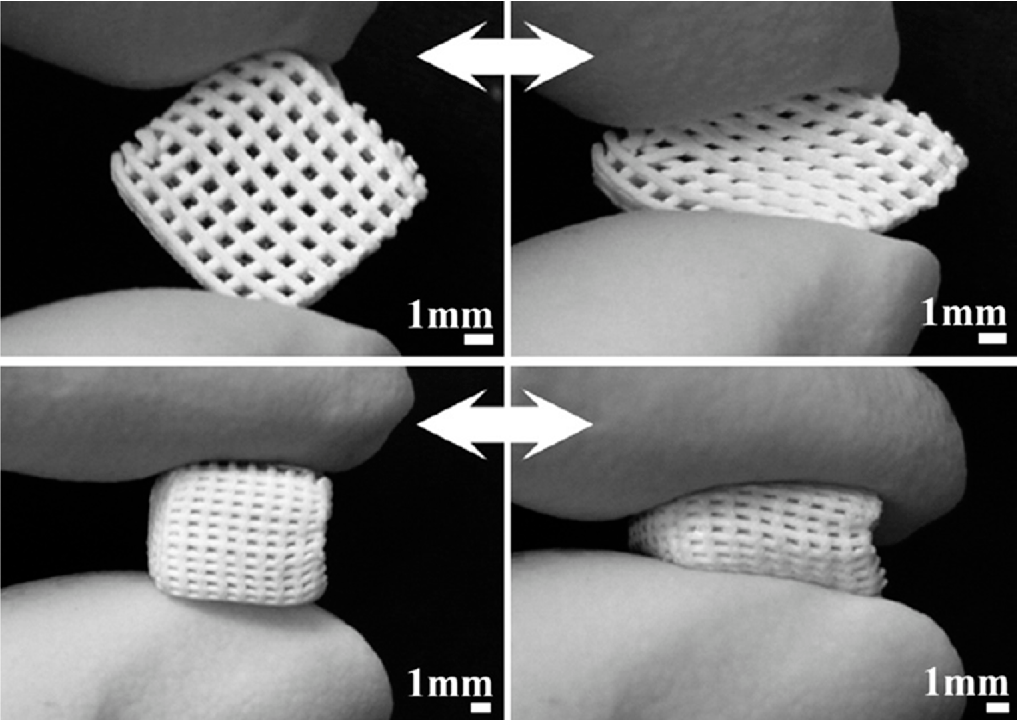

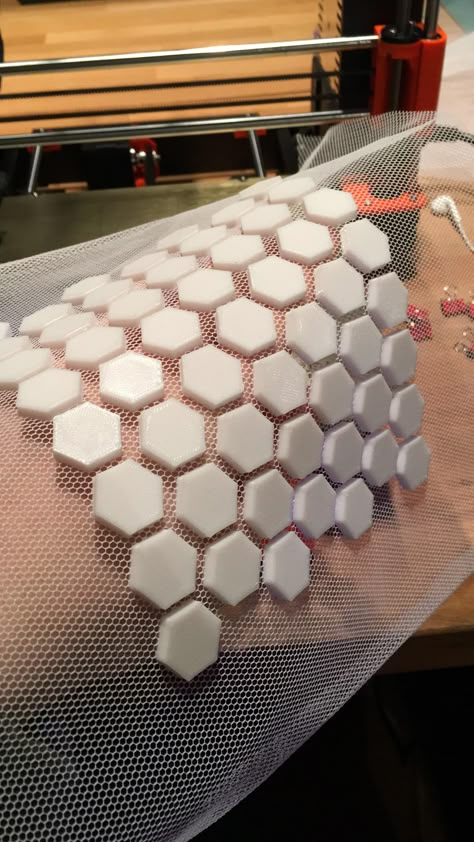

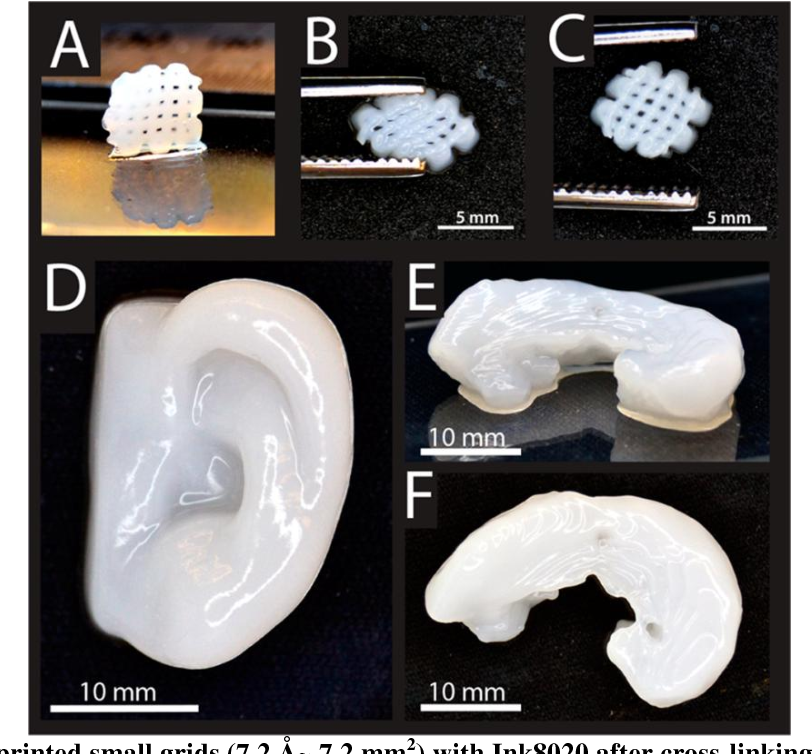

The parameters of this scaffold were based on the study by Dr. Michelle (Sun et al., 2015), who examined 10 healthy tarsal plate tissues. The 3D scaffolds measured 20 × 10 × 2 mm, with five central ducts (diameter, 1 mm) inside the scaffold (Figure 2A).

Figure 2. 3D-printed PCL scaffold and its detailed parameters. (A) Length, width and thickness (20 × 10 × 2 mm) of 3D-printed scaffolds were presented, with five central ducts (diameter, 1 mm) inside the scaffold. (B) Different printing pore sizes (200, 300, and 400 μm) were printed and shown. Central ducts were well-formed when the printing pore size was set to 200 or 300 μm. In contrast, when the pore size increased to 400 μm, the central ducts were not well formed due to the collapse of some areas. (C) Typical compressive stress-strain curves of different pore sizes of 3D-printed PCL scaffolds were demonstrated. Compressive modulus decreased when the pore size increased from 200 to 400 μm. (D) SEM images showed the top view and side view of 3D-printed scaffolds with a pore size of 200 μm. (E) Contact angle of water on PCL and DMA-PCL scaffolds. Photograph of the drop at the exact moment it reached the sample surface. The mean contact angle of water on PCL scaffolds was 93.3 ± 7.5°, while the water drop was immediately absorbed into the DMA-PCL scaffolds.

(B) Different printing pore sizes (200, 300, and 400 μm) were printed and shown. Central ducts were well-formed when the printing pore size was set to 200 or 300 μm. In contrast, when the pore size increased to 400 μm, the central ducts were not well formed due to the collapse of some areas. (C) Typical compressive stress-strain curves of different pore sizes of 3D-printed PCL scaffolds were demonstrated. Compressive modulus decreased when the pore size increased from 200 to 400 μm. (D) SEM images showed the top view and side view of 3D-printed scaffolds with a pore size of 200 μm. (E) Contact angle of water on PCL and DMA-PCL scaffolds. Photograph of the drop at the exact moment it reached the sample surface. The mean contact angle of water on PCL scaffolds was 93.3 ± 7.5°, while the water drop was immediately absorbed into the DMA-PCL scaffolds.

Printing pore size of 200, 300, and 400 μm were used (Figure 2B). When the pore size of the printing scaffold was set to 400 μm, the central ducts were not well-formed because the spacing of the central duct was too large. When the printing pore size was set to 200 or 300 μm, the shape of the central duct was well-formed. However, considering that the smaller the pore size, the larger the area of the cell for cell attachment, the more the cells proliferated in the duct. The compressive strength was measured to confirm the operability of the scaffolds in tissue engineering. Typical compressive stress-strain curves of different pore sizes of 3D-printed PCL scaffolds were shown (Figure 2C). The compressive modulus decreased slightly when the pore size increased from 200 to 400 μm. According to a previous study, the mean initial Young's modulus of the human tarsal plate was 0.14 MPa (Sun et al., 2015). The printing scaffolds (200 μm) presented a mean compressive modulus of 0.23 MPa, which was not particularly different from that of the human tarsal plate. Therefore, considering the structure and the strength of the scaffolds, 200 μm was chosen as the optimal printing parameter in this study.

When the printing pore size was set to 200 or 300 μm, the shape of the central duct was well-formed. However, considering that the smaller the pore size, the larger the area of the cell for cell attachment, the more the cells proliferated in the duct. The compressive strength was measured to confirm the operability of the scaffolds in tissue engineering. Typical compressive stress-strain curves of different pore sizes of 3D-printed PCL scaffolds were shown (Figure 2C). The compressive modulus decreased slightly when the pore size increased from 200 to 400 μm. According to a previous study, the mean initial Young's modulus of the human tarsal plate was 0.14 MPa (Sun et al., 2015). The printing scaffolds (200 μm) presented a mean compressive modulus of 0.23 MPa, which was not particularly different from that of the human tarsal plate. Therefore, considering the structure and the strength of the scaffolds, 200 μm was chosen as the optimal printing parameter in this study.

Figure 2D shows the SEM image of the scaffolds with a pore size of 200 μm. The diameter of the wire and the pore size were found to be the same, and the central duct was also well formed.

The diameter of the wire and the pore size were found to be the same, and the central duct was also well formed.

Material's wettability is an important parameter affecting the attachment, proliferation, migration, and viability of cells (Yao et al., 2017). The water contact angle was measured to determine the wettability of the scaffolds. The results revealed that the average water contact angle of the PCL scaffold was 93.3 ± 7.5°, resulting in hydrophobic surfaces (Figure 2E). The water drop in the DMA-PCL scaffolds was immediately absorbed into the scaffolds, indicating they were hydrophilic. However, because water droplets penetrated the surface too quickly for the camera to take a picture, the result was presented as a Supplementary Video 1.

Evaluation of DMA and Morphology of SZ95 Sebocytes on DMA–PCL Scaffolds

The partial composition of DMA was revealed using immunofluorescence staining of collagen I and fibronectin. As shown in Figure 3A, both matrix proteins of collagen I and fibronectin were immunostained with strong fluorescence intensity, indicating that the surface of the scaffold was covered with sufficient DMA. The ideal material scaffolds for tissue engineering ought to maintain a normal morphology and proliferation of the cells. The cells with a cobblestone-like morphology adhered to, and were spread on, the scaffolds 7 days after SZ95 sebocytes were seeded on DMA–PCL scaffolds (Figure 3B). Compared with the PCL scaffold, the cells on the DMA-PCL scaffold showed tighter cell connections and the cell morphology was more complete.

The ideal material scaffolds for tissue engineering ought to maintain a normal morphology and proliferation of the cells. The cells with a cobblestone-like morphology adhered to, and were spread on, the scaffolds 7 days after SZ95 sebocytes were seeded on DMA–PCL scaffolds (Figure 3B). Compared with the PCL scaffold, the cells on the DMA-PCL scaffold showed tighter cell connections and the cell morphology was more complete.

Figure 3. Evaluation of DMA and morphology of SZ95 sebocytes on PCL and DMA–PCL scaffolds. (A) Representative immunofluorescence staining images of collagen I and fibronectin. Both matrix proteins were immunostained with strong fluorescence intensity on DMA-PCL scaffolds (scale bar: 200 μm). Immunofluorescence was used to detect the expression of collagen I (green) and fibronectin (red) after hADSCs were seeded on the scaffold, before and after the decellularized matrix. After the decellularized matrix, the nucleus (4′,6-diamidino-2-phenylindole, DAPI, Blue) disappeared, and collagen I and fibronectin formed a uniform fiber network structure on the surface of the scaffold. (B) SEM images showed the morphology of SZ95 sebocytes 7 days after seeding on PCL and DMA-PCL scaffolds. Compared with the PCL scaffold, the cells on the DMA-PCL scaffold showed tighter cell connections, and the cell morphology was more complete.

(B) SEM images showed the morphology of SZ95 sebocytes 7 days after seeding on PCL and DMA-PCL scaffolds. Compared with the PCL scaffold, the cells on the DMA-PCL scaffold showed tighter cell connections, and the cell morphology was more complete.

Cell Viability and Proliferation

A Live/Dead assay kit was used to evaluate the biocompatibility of the scaffold. The biocompatibility of the scaffold was significantly increased by coating it with DMA, as shown in Figure 4A. Figure 4B shows statistics pertaining to Live/Dead results: the proportion of dead cells on PCL scaffolds was significantly higher than that on culture dish or DMA-coated culture dish, while the proportion of dead cells of DMA-PCL dropped significantly. The results of CCK-8 assay were shown in Figure 4C. It was observed that from day 3, the OD 450 value in the DMA group was significantly higher than that in the CTR group, which proved that DMA could promote the proliferation of sebocytes. Meanwhile, the OD 450 value in the PCL group was significantly lower than that in the other three groups on days 5 and 7, demonstrating that the simple PCL scaffolds were not conducive to cell proliferation. Compared with the PCL group, the OD 450 value in the DMA-PCL group significantly increased, confirming that DMA layer on the PCL scaffold promoted sebocyte proliferation as well.

Compared with the PCL group, the OD 450 value in the DMA-PCL group significantly increased, confirming that DMA layer on the PCL scaffold promoted sebocyte proliferation as well.

Figure 4. Cell viability and proliferation on DMA-PCL scaffolds. (A) Viable cells on the DMA–PCL scaffolds were evaluated using a Live/Dead staining assay. The live cells were stained green, and the dead cells were stained red (scale bar: 100 μm). (B) Statistical results of the Live/Dead staining assay showed that the proportion of dead cells on PCL scaffolds was significantly higher than that on the culture dish, while the proportion of dead cells of DMA-PCL dropped significantly. (C) Proliferation of SZ95 sebocytes on DMA-PCL scaffolds 0, 1, 3, 5, and 7 days after cell seeding were determined using a CCK-8 assay. DMA coated on the PCL scaffolds could significantly enhance the proliferation of sebocytes compared with the PCL group. Values are expressed as mean ± standard deviation. *P < 0.05 and ***P < 0.001. CTR, Culture dish; DMA, culture dish coated with DMA; PCL, poly-caprolactone scaffold; DMA-PCL, poly-caprolactone scaffold coated with DMA.

*P < 0.05 and ***P < 0.001. CTR, Culture dish; DMA, culture dish coated with DMA; PCL, poly-caprolactone scaffold; DMA-PCL, poly-caprolactone scaffold coated with DMA.

Lipid Synthesis on PCL and DMA–PCL Scaffolds

SZ95 sebocytes were cultured on PCL and DMA–PCL scaffolds for 7 days and then stained with F-actin and LipidTox. F-actin reflected the number of cells on scaffolds. Therefore, the relative IOD of Lipid/F-actin might partially reflect the cells' capacity to secrete lipids. Figure 5A showed the immunofluorescence of F-actin and lipid on PCL and DMA-PCL scaffold, and Figure 5B showed the statistical results of lipid synthesis. Figure 5C showed a 3D reconstruction of lipid on PCL scaffolds. SZ95 sebocytes seeded on DMA–PCL scaffolds secreted more lipids than those seeded on PCL scaffolds (P < 0.001), indicating that DMA could promote the differentiation of SZ95 sebocytes and contribute to the adipogenesis function.