Is buying a 3d printer worth it

Is 3D Printing Worth it? 4 Key Things to Consider

Brendan Powell3D Printing, Maker CultureLeave a Comment on Is 3D Printing Worth it? 4 Key Things to Consider

3D printing is awesome but it’s just not worth it for everyone.

Many people spend a lot of money on 3D printers when all they need to do is outsource a few parts.

Even worse, some people buy a 3D printer, only to find out that they don’t like using it.

My goal is to provide you with a realistic approach to whether or not you should purchase your own 3D printer before you spend the big bucks.

What 3D Printers Cannot Do

Surprisingly, there are a lot of myths and false information on 3D printers that people tend to believe. While the maker community knows better, many beginners do not. Let’s make sure that you aren’t misled into getting a 3D printer for the wrong reasons!

Misunderstanding #1: You can make anything.Technically this is true, but if you don’t have a team working with you or a lot of experience in 3D modelling, it might as well be impossible.

In the beginning, if you don’t know how to make your own items, you will most likely be downloading other people’s designs.

Misunderstanding #2: 3D printing will save you money.While this is possible in the long run, it won’t add up to very much. Besides, you are probably better off buying most things you need around the house for a little more money, rather than spending hours trying to make them.

For example, many people selling 3D printers may indicate that you can save hundreds of dollars if you 3D print your common household items.

However, like any hobby, you will be spending a lot more than you save because of the initial cost, maintenance and time spent on 3D printing.

Equally as important, using a 3D printer for the sole reason of saving money can make 3D printing a chore rather than a fun hobby.

The truth is that most 3D printers only print plastic, and usually, that’s enough. If you want to print metals, you should be prepared to fork out a bit more cash.

3D printers are only capable of depositing materials that have a melting point, so don’t expect to be able to make flowers and leather clothing.

Misunderstanding #4: You can just download things from Thingiverse.While this is true, I included it because merely downloading and printing things can get boring very quickly.

The point of a 3D printer is to aid your own projects and yes, sometimes download things online.

But what usually happens is people (with no intention of creating their own things) go to Thingiverse and see the infinite list of STL’s (free 3D printing files) made by the Thingiverse community.

Although this initially sparks excitement, it will most likely end in boredom. After you’ve printed 10 useless items that you really don’t need, you will eventually get tired of 3D Printing. Not to mention, you will have a bunch of useless stuff lying around.

After you’ve printed 10 useless items that you really don’t need, you will eventually get tired of 3D Printing. Not to mention, you will have a bunch of useless stuff lying around.

How Do I Know if I Should Buy a 3D Printer?

So how do you know if 3D printing is worth it for you?

There are 4 Key Things you need to consider to make an informed decision:

- Your other hobbies and interests.

- The technical difficulties of 3D printing.

- Costs associated with 3D printing.

- Your career and it’s relation to making.

Do Your Other Hobbies and Interests Relate to 3D Printing?

Why do you want to 3D print? Spend some time thinking about this. Is it something you feel like you should do for no particular reason? Or do you have specific projects in mind?

Do you love action figures, board games or models? Are you into puzzles, model making or interesting mechanisms and contraptions?

If you can come up with some good reasons to purchase your own 3D printer similar to the ones mentioned above, that probably means you’re a maker.

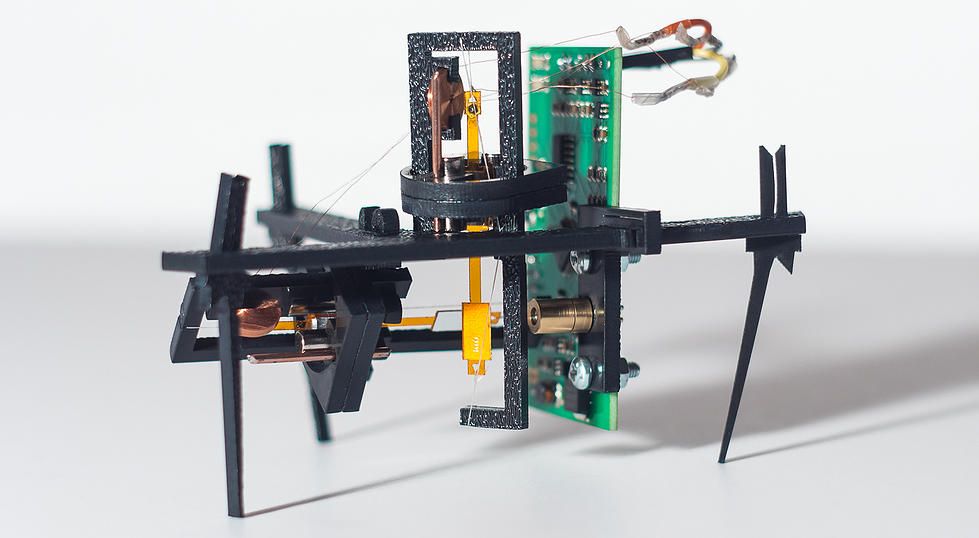

Quite often, people who enjoy 3D printing the most are those with complementary skills, such as circuitry, laser cutting, programming, or other engineering or trade type skills. We call these maker skills.

Makers usually have more reason to use a 3D printer. Essentially, the 3D printer becomes another tool that a maker uses, rather than it being what they revolve their projects around.

The 3D printer benefits the maker by allowing them to quickly test and fix parts.

Will you use a 3D printer in large projects?

For those who want to print one-time use objects from a website, ordering them from a 3D printing service may be a more viable option.

Here Are Some Things That a 3D Printer Could Be Useful For:- Board Games: Print pieces for existing board games or make your own games. As a kid, I used to love making my own games but I always ended up cutting out paper to make game pieces.

Instead, I could have easily used 3D printing.

Instead, I could have easily used 3D printing. - Models: Cars, planes, buildings, etc…you can make models of anything with a 3D printer, and it can be very fun and beneficial to explore your creativity!

- Action figures: Perfect for gamers and fantasy fiction fans.

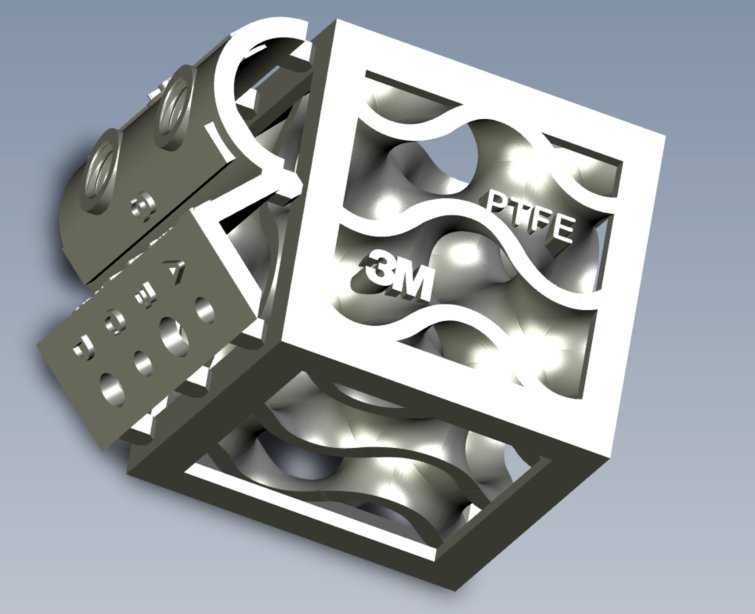

- Teachers: Use 3D printed items to help teach and inspire children. One of my middle school teachers was a maker and used to make these cool octahedrons with different shapes and letters on each side to match with other octahedrons to encourage students to interact with each other.

- Tools and machines: As someone interested in mechanical engineering, this is my reason. I love making things fit together and move to serve a purpose. Someone even made a 3D printed lathe.

If your interests align with a need for a 3D printer, great! But there are three more things to consider.

Technical Difficulties of 3D Printing

Can You Design?3D printing isn’t necessarily easy to get into, but neither are most hobbies. It is going to take some time, dedication and maybe some frustrations before it can be rewarding.

It is going to take some time, dedication and maybe some frustrations before it can be rewarding.

Are you good at using computer software? Is it something that comes naturally to you? 3D modelling or computer hardware programs are important aspects of 3D printing.

Are you willing to learn proper 3D modelling? Lots of people hate trying to use new technology, and in 3D printing, there is a lot of technology to learn before you print your first piece.

To make the most of this hobby you will eventually want to start 3D modelling things yourself. Everything that is 3D printed needs its 3D model, to begin with.

Using programs like Solidworks, Inventor, Blender and other 3D modelling software take time and effort to learn.

General Computer Skills RequiredAfter you make the model, you must know how to convert it into the right file format or what slicer to use to send the code to the printer.

Although this may sound complicated, don’t be scared to learn because it can be super rewarding. Many people get frustrated easily and quit.

Many people get frustrated easily and quit.

The bottom line is: if you don’t know how to design and you aren’t willing to learn, then 3D printing is likely not for you.

Can You Troubleshoot?Many things can go wrong while 3D printing. Whether your devices are set up incorrectly, or the filament is jamming in the nozzle, you are going to have to troubleshoot somewhere along the way.

Nevertheless, some makers treat this as a hobby and focus on upgrading their machine first, to avoid errors and improve the quality of their 3D printer.

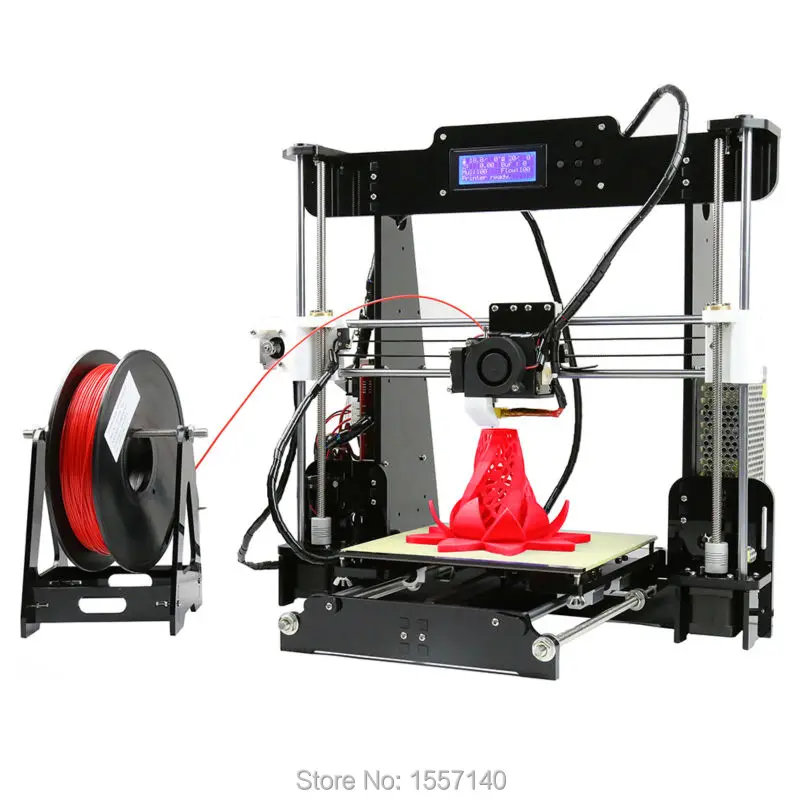

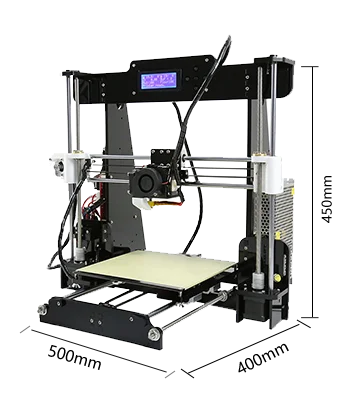

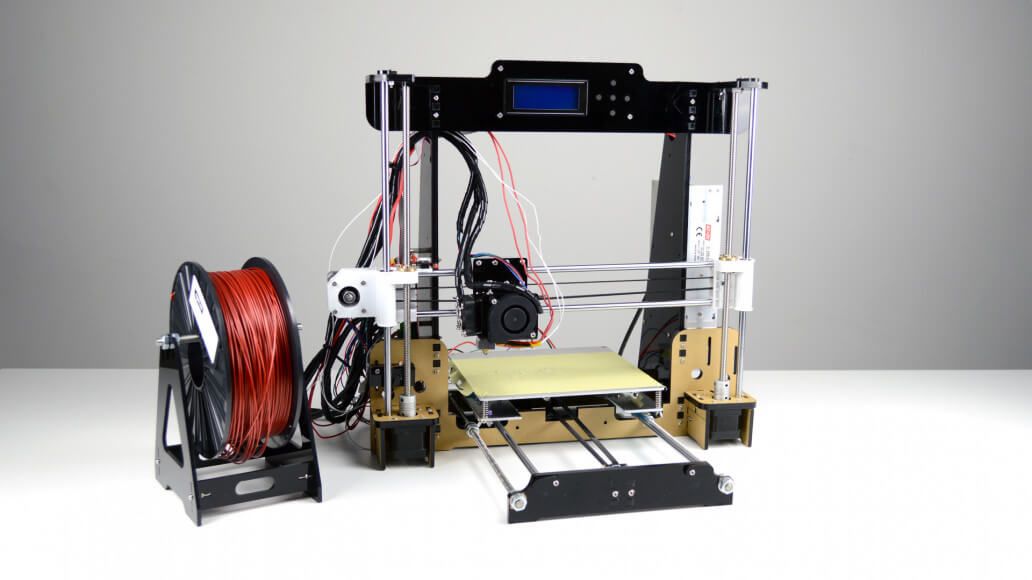

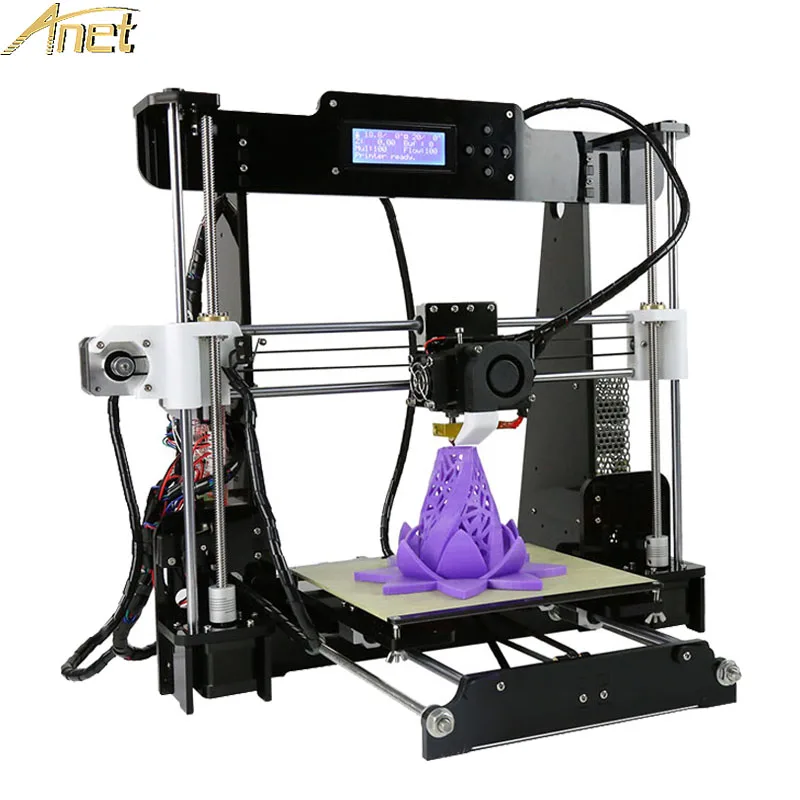

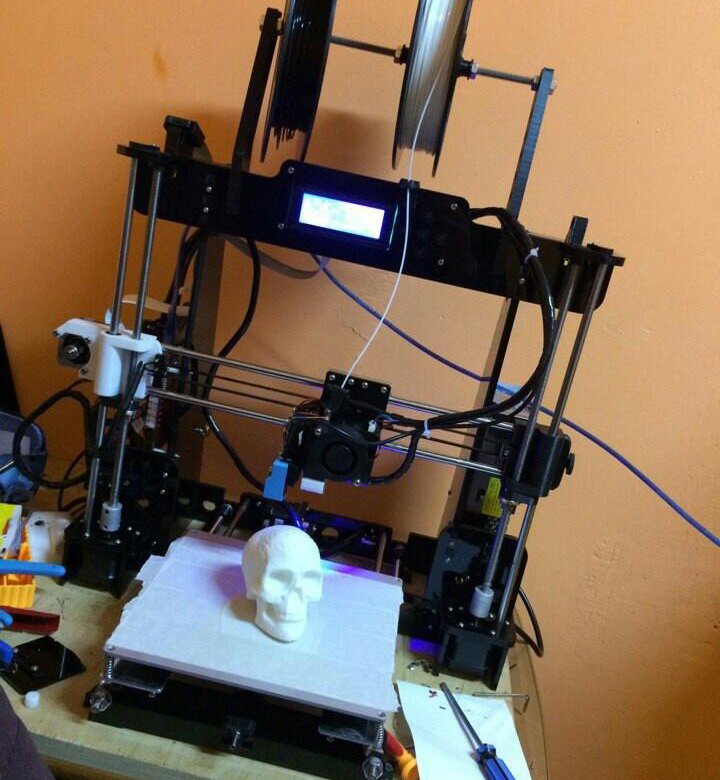

Although the Anet A8 is a pretty poor and unreliable 3D printer, it’s also really popular because it’s cheap and those who buy it typically enjoy upgrading it to make it a better machine.

Can You Do Simple Maths For 3D Printing?Nothing complex is needed but often you’ll have to do some calculations including volume and costs when designing to make sure you are making the optimal product.

If you are not big on problem-solving (school did make math boring sometimes), then you may not be prepared to handle the inevitable issues that will arise.

But if you are interested and capable of handling technical difficulties, let’s see if you’re willing to pay the price of making things with 3D printers.

The Costs of 3D Printing

How Much Do 3D Printing Materials Cost?Something people forget about 3D printing is the recurring cost because you have to buy the materials that you print with on a regular basis.

There is a lot of different materials you can use and for different purposes. For now, let’s just look at a couple of the most common materials.

Most common materials:

- ABS (Acrylonitrile Butadiene Styrene)

- PLA (polylactic acid)

These filaments can cost anywhere between $10 to $50 and even more if you’re buying quality or specialty filament.

Keep in mind as well that you’re not going to be buying the $10 filament every time, as those can’t even give a satisfactory result.

You’re more likely going to spend around $20 for every roll of filament. This cost can add up quickly or slowly depending on how much you’re going to be 3D printing.

Digitalharbor.org did some research on how long a 1kg spool of 3D printing filament lasts. It is important to note that you may want to have a couple of different types of filaments as well.

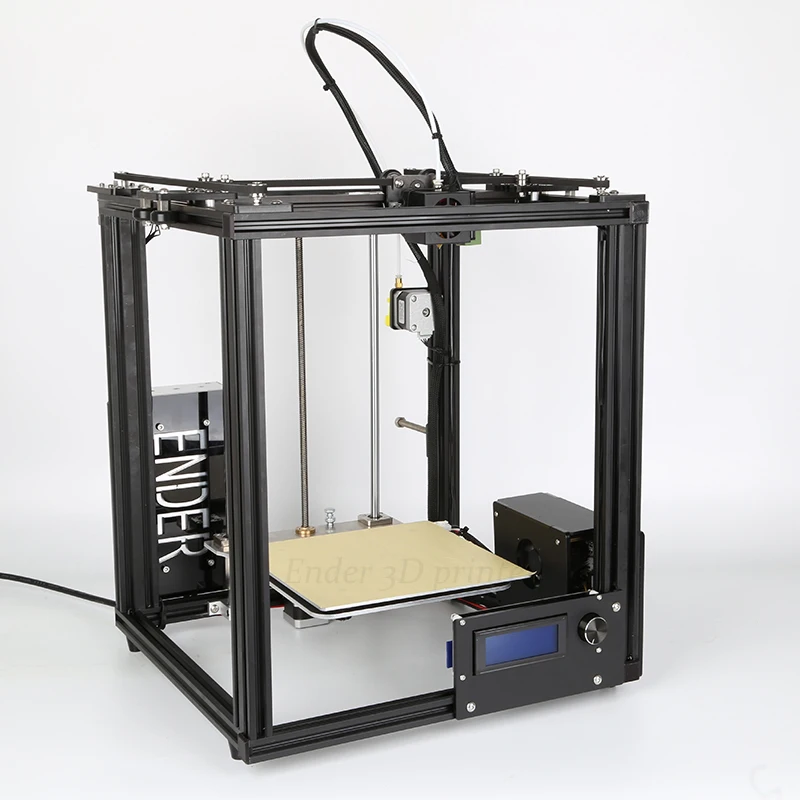

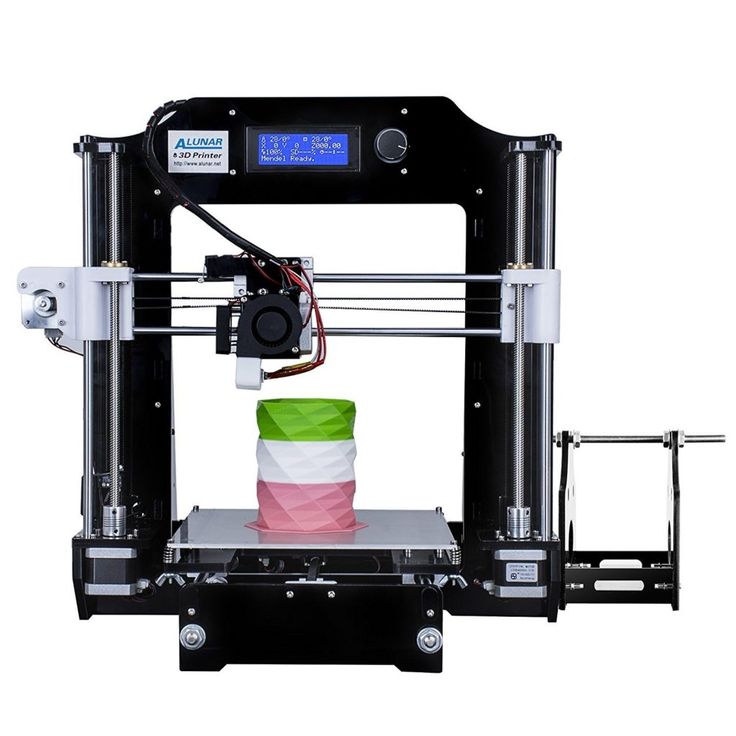

How Much Does a 3D Printer Cost?This is usually the part where most people put their wallets down.

3D Printers on average are pretty expensive, and ‘pretty’ might be an understatement.

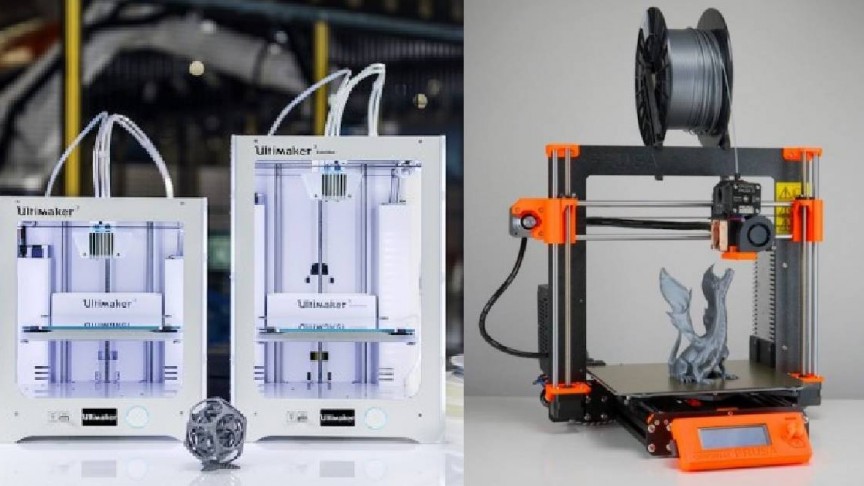

The price of a 3D printer ranges between as low as $200 to over $3000 for a high-end home 3D printer.

Industrial printers are over $10,000 and the most expensive ones cost millions!

However, if you’re a beginner, your price range is probably between $200 to $1000, (unless you have a lot of piggy bank money ready to invest).

I would suggest that you keep away from anything under $200 as they usually don’t work very well. When it comes to 3D printers, you get what you pay for.

When it comes to 3D printers, you get what you pay for.

Surveys show that when a company owns a 3D printer, they print more prototypes than they would have if they used a 3D printing service.

If you’re involved with product development, it is my recommendation that you should have your own 3D printer.

However, if you are confident that you will only use it a few times, then you are better off sending it to a 3D printing service.

If you live in a populated enough area, chances are you have a few options to choose from.

How to Find a 3D Printing Service- Check P2P shopping websites/apps. These are good options because they are just regular people like you and me; however, they may not be as professional or knowledgeable about the various printing options.

- Local businesses. There are usually a couple of places in cities that stock up on 3D printers and materials.

While expensive, you will have a lot of options and great customer service.

While expensive, you will have a lot of options and great customer service. - Maker Spaces. Maker spaces are usually clubs with a paid membership where you can participate in maker culture. Given they usually require memberships, you should make sure you will use the place quite frequently to make it worth your money. Maker spaces are great options as you can do things on your own with support if needed and you can use any of the other tools found in the maker space.

When you use a 3D printing service, the costs will always vary depending on the service.

For instance, you may be charged with a monthly fee for maker spaces and if you send your part somewhere else, they may request approximately $15 (depending on part specifications).

If you need less than 10 parts, it’s probably worth just sending them to a service. If you need more than 10 or need to experiment, then it’s more economically viable to buy your own 3D printer.

Your Vocation’s Relation to 3D Printing

3D Printing Could Be Good For Your CareerDoes your company have a 3D printer? Companies that have 3D printers use them frequently and find them to be of great use.

Someone who knows how to use 3D printers is also of great use.

Do you have a career in prototyping, design or entrepreneurship?

There are lots of great opportunities here in terms of money-making!

For example, there are many jobs in product design, prototyping, etc. where 3D printing is used on a regular basis. You could make your own products and sell them on e-commerce websites or you could sell the 3D models. There are plenty of people doing this right now.

You can teach people your new skills for a fixed fee, or lease your own 3D printer to others. There might even be requests for specific items on online marketplaces for freelancers, like Fiverr.

If your current job is in engineering or product design, then purchasing a 3D printer will be a worthwhile investment. It could help you when working from home (especially during this pandemic) or if you want to be creative and prepare items for a presentation.

It could help you when working from home (especially during this pandemic) or if you want to be creative and prepare items for a presentation.

If your hobbies or vocation relate to 3D printing, and you can handle the costs and technical difficulties associated with it, then buying a 3D printer is absolutely worth it.

If you are eager to try it out first, then you could always try to find a maker space near you. And when you think you’re ready, check out some 3D printers.

Are you going to buy a 3D printer? Let me know why or why not in the comments below!

Are 3d printers worth it? Their Pros and Cons explained – 3D Solved

Some years ago, the idea of having a machine in your own house that can transform a digital model into a real tangible object looked like something out of a sci-fi movie. If you wanted to have in your own hands a figure of let’s say, Batman, there was no other option than going to a local shop and buying it. None of us thought about having our own toy-making machine, with thousands of options to print and collect.

None of us thought about having our own toy-making machine, with thousands of options to print and collect.

Even more, a device that allows you to replace a broken part of a home appliance that you can’t get at a spare parts store.

Do you need to hang your headset under your desk but you don’t have the right hook for it? Just explore the web, search for the one you like the most and print it. Just like that.

Well, nowadays we know 3d printers are real and anyone can have one at home. There are hundreds of different models for every budget available. With some learning, you can start creating (almost) anything.

3d printing technology offers a new way of making things, and its applications are vast: rapid prototyping, research, bio-printing, automotive/aerospace applications, education, art, you name it.

But, if you’re interested on becoming a member of this community, there are some considerations to do before you spend your hard earned cash on a printer.

So, In Short: Once you get over the learning curve and are capable of producing quality prints that can be used for prototyping, repairing household items, and even for making money (in some cases), 3D printing is definitely worth it. However, 3D printers are expensive, as is the filament, you will need to learn to design the models and even troubleshoot the printer, which may lead you to stop using it.

However, 3D printers are expensive, as is the filament, you will need to learn to design the models and even troubleshoot the printer, which may lead you to stop using it.

Let’s explore a little of the 3d printing world so you can decide for youself.

Table Of Contents

- Advantages of owning a 3d printer

- Disadvantages of owning a 3D printer

- Myths about 3d printing

- Technical difficulties of 3d printing

- Are your other hobbies and interest somehow related?

- Is a 3d printer worth it for yourself?

Advantages of owning a 3d printer

There are some clear advantages to owning a 3D printer as well as disadvantages, so let’s go over some of them.

Just keep in mind that some of these points may not apply to you specifically, but I think that they are worth mentioning.

It improves your creativity

A 3d printer won’t transform you into a creative person, although it may help the creative juices start flowing over time, but it will let you transform those ideas into something real.

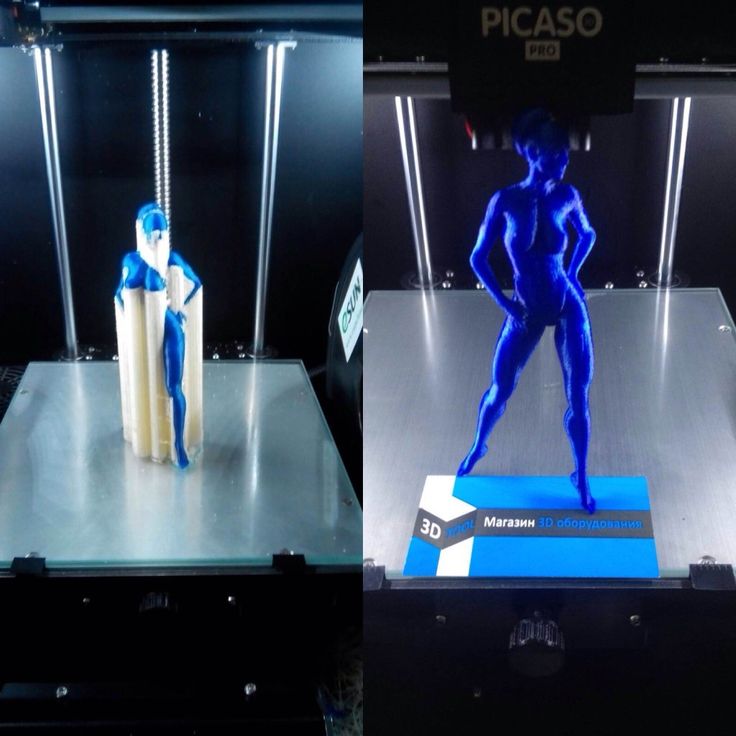

As you get more experienced with this tool, new ideas will come to you. Eventually, you’ll learn that a 3d printer can make complex pieces which can’t be made by traditional modeling, and this way you can create prototypes, fun and intricate 3D models, or just replace broken things in your home by printing a replacement part, such as a gear.

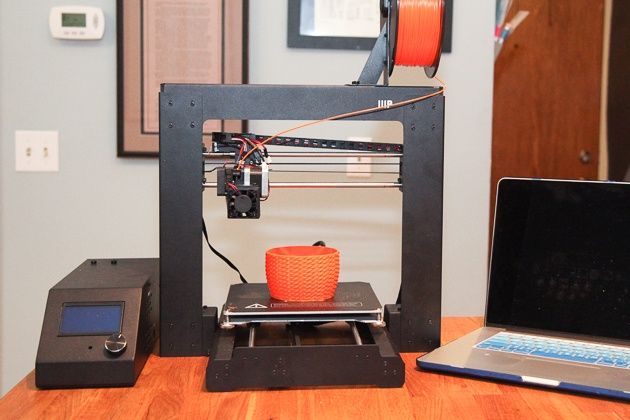

It’s fun

Just watching a 3d printer running is something hypnotic. The way the extruder moves across the bed, the “futuristic machine” sounds, the electronic parts with sparkling lights… Every person’s first encounter with a 3d printer is unforgettable.

If you haven’t seen one working yet, just do it… You’ll know what I mean.

In addition to being actually useful, this is one of the reasons I decided to get one, since I love watching it print, plus you get to learn quite a lot (more on this later one since you actually will need to learn more than you probably thought).

You can save time and money

Specific spare parts can be very expensive. Sometimes, they are sold as a pack, so you have to buy parts you don’t need just to replace one. With a 3d printer, you only print what you want, at a very low cost and really fast.

Sometimes, they are sold as a pack, so you have to buy parts you don’t need just to replace one. With a 3d printer, you only print what you want, at a very low cost and really fast.

If you don’t care much about the aesthetics of the print, a small piece can be printed in less than an hour.

Now, when I say that it can save you money, I don’t mean “go out and buy a printer just to stop buying a couple replacement parts at the hardware store”, since this wouldn’t make much financial sense, but over time, since you can fix so many things that might break at home or in your car, it may end up paying for itself.

It could help you develop a profitable venture

You can start your own business by selling your prints. Decorative objects, toys, lamps, keychains, dog tags… just find out what’s needed in your neighborhood and offer it, or you could start an online store, Etsy shop… the possibilities are endless.

Many people have succeeded by finding original ideas to sell. As you don’t necessarily need to have items in stock, you can avoid sticking with objects that no one wants to buy and just print whatever someone orders.

As you don’t necessarily need to have items in stock, you can avoid sticking with objects that no one wants to buy and just print whatever someone orders.

Disadvantages of owning a 3D printer

Source: 3DNatives.comNow that some of the pros are out of the way, let’s get into the cons, since not everything about 3D printing is all sunshine and rainbows.

3d printers take up a lot of space

Each printer needs at least 60 cm2 of free space on a stable desk or piece of furniture exclusively dedicated to it. If you live in a small apartment, it will be very difficult to find a proper space to place your brand new 3d printer.

Besides that, if you wish to use some particular plastics, like ABS or Nylon, you can’t have your printer running in the same room with you or other people since they emit fumes and toxic gases when heated.

They are noisy

When sitting next to a working 3d printer, you’ll be hearing about 60 dB of sound. That’s comparable to a vacuum cleaner.

Sometimes, you’ll have to print big objects that require approximately 10 or more hours, so you’ll probably end up with the printer running at night. I hope your partner shares your passion… or both you and your new 3d printer will soon have to find a new home.

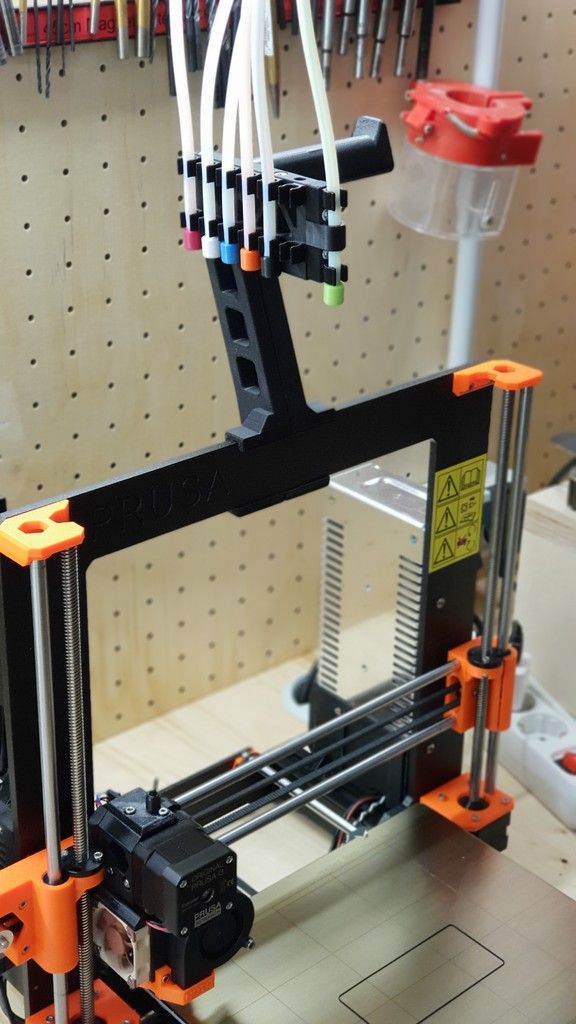

Important Note: Some printers, like the Prusa Mini which I own, are nowhere near as loud as some of the other printers. The newly released Elegoo Neptune barely makes a sound and you’ll find yourself checking it quite often because you’ll think that it stopped printing.

You can’t print creativity

3d printers are the perfect tool for creative people. Most people buy a printer, they place it on a rigid stable base and… they don’t know what to print.

Even if you had a lot of ideas, sooner or later you’ll have to create something new unless you want your 3d printer to become an expensive paperweight.

If you have any experience in design and using CAD software, then a 3D printer will be extremely useful and fun for you.

You will have to learn more about 3d printing than you initially thought

Even the most expensive 3d printers require you to invest some time to learn the basics. There is no “plug and play” in 3d printing: you must get over the “learning curve” before getting started.

Of course, getting an extremely affordable printer will only make things harder, which is why sometimes getting a printer that comes with a couple extra features, such as automatic bed leveling, can make your life that much easier.

That’s the reason why I got the Ender 3 v2, since the assembly is straightforward and all the settings that come in the slicer software are specifically tailored for that printer, meaning that you put it together and you’re ready to print without much fuss. It is not due to chance that this printer is one of the most popular entry-level machines.

If you are not a handy person, then I’d recommend spending a little more and getting one that will get you printing fast, since lots of people end up selling their printers after one or two months of failed attempts.

Fortunately, the 3d printing community is huge, and it’s full of gentle people that will help you get through this initial learning stage.

They increase the risk of fire at home

3d printers and pets, small children or even a curtain, are bad combinations. The use of high temperatures and moving parts may lead to a fire if you don’t supervise your printer.

An incorrect assembly or the lack of fire protection on a 3d printer are the main causes of accidents related to these machines.

You should keep your children and pets as far from the printer as possible, not only because of the fire hazard, but because they could get hurt, break the printer, ruin the filament, etc.

Myths about 3d printing

3D printers are oftentimes viewed as the end all be all solution for all your needs, but they aren’t genies that grant you wishes.

So, here are I will debunk a couple myths about 3D printing so that you don’t get disappointed if you decide to purchase one.

You can print anything

In some sense, this might be true. But, you depend on having the digital model you want to print.

So, besides learning how to print objects with your new printer, you’ll have to learn about digital design. And that’s even more difficult than learning the basics of 3d printing.

If you still haven’t developed your design skills and how to properly operate a CAD software, you will end up using some of the designs found on websites like Thingiverse, which will get old pretty quickly, plus the feeling of creating your own designs if much more fulfilling.!

3D printing will save you money

Unless you start your own business, 3d printers (still) can’t print money. So, if you bought one thinking about making money, you better have a really good idea that will make a products that people will love and buy. After all, it’s just like any other business.

However, like I mentioned before, if you own a 3D printer you can replace broken gears, repair many things in your home or car, and more, which will make you save money in the long run… I just wouldn’t get a 3D printer for this sole purpose. But it’s a nice bonus.

But it’s a nice bonus.

You can print with every material out there

When you search for 3d printing on the internet, there are lots of articles about biomedical implants, aircraft innovations or machines that can print an entire house or a car in one day… yes, a house!

Your FDM 3d printer, however, is limited to some plastics, and some materials need temperatures so high to be printed that a regular printer can’t even handle them. Other thermoplastics require an enclosure (not very common among cheap 3d printers), otherwise, they will start warping or cracking.

Before buying one, think well about what do you want to print and check if your machine meets the necessary requirements.

Some very cheap printers may only be able to print with PLA, for example.

If you want to know what temperatures each filament type requires to be printed properly if a heated bed is needed if the printer should have an enclosure, etc. then check the table I included in this article.

Technical difficulties of 3d printing

As I said before, there’s no “plug and play” here: you’ll have to learn new skills if you want to succeed. At first, you won’t be satisfied with the quality of your prints… if you get to print something, that is. A 3d printer will give you the results you desire after you learn some of of the basics, otherwise you’ll get frustrated soon and leave your printer there, gathering dust.

Again, this will vary depending on what printer you get: The cheaper ones usually will take more time to learn, you’ll have to do a lot more troubleshooting, etc.

Design skills

Unless you know how to design your own pieces or how to modify existing models, 3D printing will be an uphill battle. A complete designer must manage both organic (Blender, Zbrush…) and parametric (Solidworks, Solid Edge…) modeling software in order to deal with any situation required.

And that means hours and hours of practice in front of the screen.

Repair skills

3d printers are complex machines from the “computational” point of view, but they are simple from a “mechanical” standpoint. So, some issues can be solved just by adjusting screws or changing simple two-wired components.

So, some issues can be solved just by adjusting screws or changing simple two-wired components.

In fact, most models are open-source: they were created under the idea of building your own printer with little knowledge. You can search for tutorials on YouTube explaining every single aspect of a 3d printer. There’s no excuse for not being able to learn how to calibrate and fix your machine.

Otherwise, you’ll end up spending even more money on a technician.

Computational skills

You don’t need to know about programming to start printing, but when the mechanical problem is solved and still your prints are ugly, or you want to get some upgrades for your printer, it’s time to modify other settings, like PID control, acceleration and jerk or the steps of each motor.

Some basic Arduino programming may be enough to handle this.

Sometimes, you’ll also need to modify G-codes. Again, getting all this knowledge demands lots of time, so consider it well.

Are your other hobbies and interest somehow related?

Getting into 3d printing can make developing your current activity a lot easier. As you know more about this technology and its capabilities, you’ll eventually find out how to make it work with your projects.

As you know more about this technology and its capabilities, you’ll eventually find out how to make it work with your projects.

Many cosplayers print parts of their costumes with great accuracy, obtaining pieces that fit exactly to their bodies. Excellent helmets and other armor parts, as well as weapons, are printed in a very economical way.

As an engineering student, a 3d printer can be used for rapid prototyping of mechanisms for testing and size/movement verification.

A 3d printed object can be used as a foundry model for metal casting. It replaces traditional wood models, being stronger and faster to make.

If you love playing board games or role-play games (RPG), you can print trees, bridges, animals, vehicles and other miniatures for your scenarios to create the perfect atmosphere.

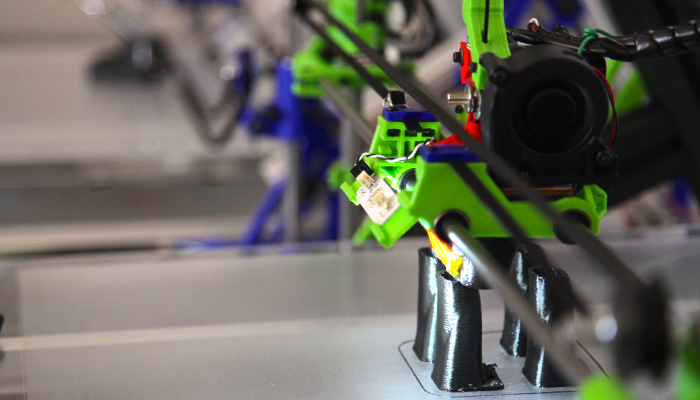

Nowadays, industries are turning to automation and robotics. If you already work in this, you’ll find 3d printing helps you complementing all the electronic parts.

New types of artists are using 3d modeling to create complex shapes that can’t be made with traditional tools.

Maybe it can be better to get started by buying a used 3d printer, so you don’t have to spend too much money on something that could not be what you were looking for. But, this can lead you to other issues, like dealing with worn parts or battered components.

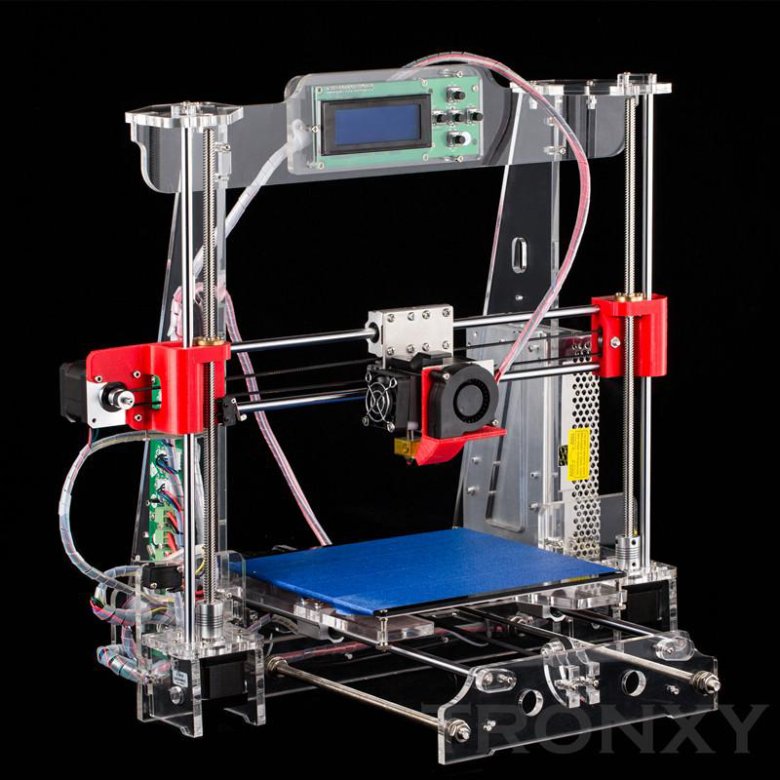

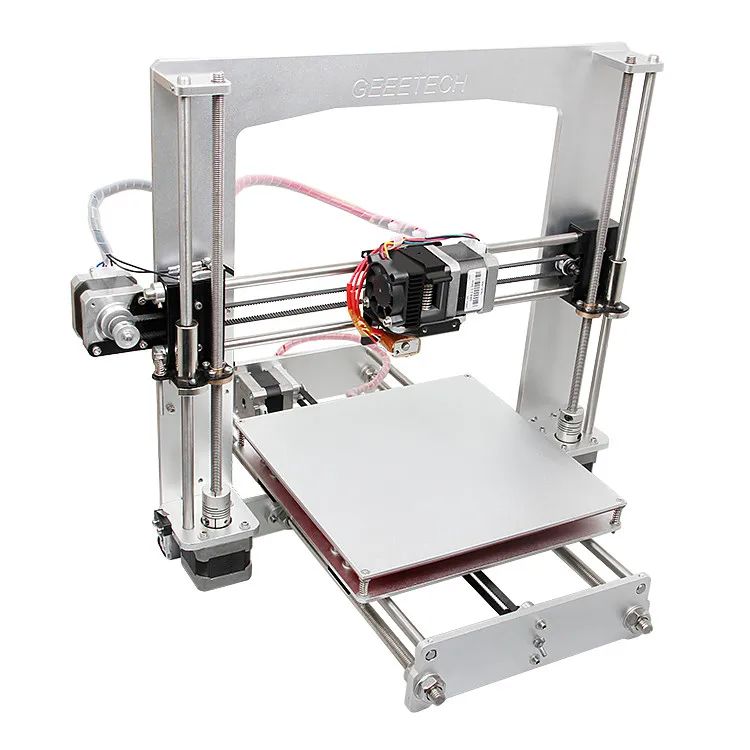

Building your own printer is a great option too: DIY kits are the cheapest option if you want a brand new machine.

You’ll learn every part’s function as you assemble it, so you’ll save time and money while getting through the learning curve. I highly recommend you this, especially because repairing it later on will be second nature to you.

With all this in mind, the main question still floats in the air: Is it worth it?

Is a 3d printer worth it for yourself?

At this point, you should decide if the cost and time spent will be worth it.

There are some additional costs associated with 3D printing such as buying filament spools, some tape or hairspray to improve adhesion to the bed, even a decent glue to stick pieces together.

And that’s just the beginning, later you will have to buy additional cooling fans, PTFE tubes, new nozzles, and some spare parts to repair your printer when something does eventually go wrong.

In my opinion, yes. Getting a 3D printer is worth it for many people since it’s so versatile: Not only can you fix stuff at your house or create prototypes for your work, but you can even use it to have some fun, like making an RC boar or plane, printing shoes… yes, shoes!

The possibilities are endless!

Now, I know that it’s easy to buy into the hype, but really question whether or not you’re going to give the printer the required use to make the investment worth it, otherwise, like I mentioned earlier, you’ll just be buying a very expensive paperweight.

I hope this information was useful!

Have a wonderful day!

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

When should I buy 3D printers for home use?

We all need a Star Trek Replicator: a machine that can create any object we desire. 3D printers, which create objects out of plastic and other materials, are the closest thing we have. And every year they get cheaper.

Just a few years ago, there was a lot of hype around 3D printers. Now the hype has died down, but 3D printer manufacturers still want to install a 3D printer in every home, including yours.

How expensive are 3D printers?

Cost is a big factor here. 3D printers used to cost thousands of dollars, and now they have come down a lot. you can get Amazon's Best Selling 3D Printer for $500, and that's before the next wave of large consumer printers showcased at CES in 2015. We haven't tried this printer in particular, so we can't recommend it, but it's a good example of where the prices are.

you can get Amazon's Best Selling 3D Printer for $500, and that's before the next wave of large consumer printers showcased at CES in 2015. We haven't tried this printer in particular, so we can't recommend it, but it's a good example of where the prices are.

If you want a larger brand 3D printer, you will probably end up paying more. Cheapest and Smallest MakerBot 3D Printer - " Replicator Mini - currently worth $1,375. It's a lot cheaper than the few thousand a MakerBot printer cost a few years ago, but it's quite expensive for the limited use that most households could get.

3D printers are great for prototyping

3D printers are not just toys. Companies that need rapid prototyping or design can design an object and immediately 3D print it, which helps speed up the design process and create prototypes faster. If you see the obvious business case for a 3D printer, buy it.

But this is not about companies that already know they need their own 3D printers. We are talking about typical home users who are now advertised by 3D printer companies. 3D printer manufacturers want a 3D printer in every home, but is it worth it to buy one more?

We are talking about typical home users who are now advertised by 3D printer companies. 3D printer manufacturers want a 3D printer in every home, but is it worth it to buy one more?

ZD Printing 101

A 3D printer is a device that, given an appropriate 3D model that you download or create on your computer, creates a physical copy of that 3D model. A 3D printer is usually a box with a head that stacks layers of special plastic on top of each other. The heated plastic hardens and creates a physical 3D copy of the model.

3D printers can print all sorts of small toys, busts, play pieces and figurines. From a practical standpoint, a 3D printer could be used to produce many of the different objects we already use today. Basics like plastic utensils are obvious, but there are already 3D printed shoes. However, we are not sure how comfortable it will actually be to wear such shoes!

In order to use a 3D printer, you need to buy the printer as well as the appropriate raw materials - usually plastic filaments - for the printer. It's a bit like buying paper printer ink . (3D printers can also use other materials such as metals, but consumer 3D printers typically use plastic.)

It's a bit like buying paper printer ink . (3D printers can also use other materials such as metals, but consumer 3D printers typically use plastic.)

Interested in 3D printing? You don't need a 3D printer!

If you've never had the desire to 3D print something before, a 3D printer may not be for you. In fact, you don't need a 3D printer at all to get started in the world of 3D printing. Here's what you can play with before you buy:

- ZD-Printing-On-Demand Services : shapeways and similar websites allow you to select an existing model or upload your own and this service will use its own 3D printer to print your model and then mail it to you for a fee. If you just want to 3D print a random object, it's probably more cost-effective and easier than buying your own 3D printer. You can get into 3D printing without having your own.

- Pay-Per-Use zd Printers : If you just need Fax print or copy documents from time to time, you do not need to have your own fax and photocopier.

Instead, you can go with it to the nearest store and use it. Various shops are trying to bring this "kinko" approach to 3D printing. For example, Staples is rolling out 3D printing centers in select stores. As 3D printers become more popular for home use, they will become even more common so you can use them without having your own.

Instead, you can go with it to the nearest store and use it. Various shops are trying to bring this "kinko" approach to 3D printing. For example, Staples is rolling out 3D printing centers in select stores. As 3D printers become more popular for home use, they will become even more common so you can use them without having your own.

If you're interested in 3D printing, you can already view models, modify them, or create your own and print them out on someone else's 3D printer. If you enjoy this experience, you might consider getting your own 3D printer. If this seems like a problem, or if you don't know what to do is practical or useful, you've saved yourself a lot of money that you could otherwise spend on a 3D printer!

What exactly will you be doing with a 3D printer?

3D printers are not a Star Trek replicator. In the near future you will not be cooking a slice of pizza with them and you will not print yourself a new laptop. You will be creating small items out of plastic. In most 3D printers, these plastic objects will be one color, not multiple colors. You could use white plastic and then paint the items yourself, but that's obviously more work. While we all yearn for a full fledged replicator, 3D printers aren't around yet.

You will be creating small items out of plastic. In most 3D printers, these plastic objects will be one color, not multiple colors. You could use white plastic and then paint the items yourself, but that's obviously more work. While we all yearn for a full fledged replicator, 3D printers aren't around yet.

So, if you're thinking about buying a 3D printer, ask yourself what you're actually going to do with it. Take a look at 3D printing sites such as Thingiverse to check other people's models and consider ordering the one you like.

The idea of having a small device at home that can create what we need - even the cheap plastic trash currently produced halfway around the world and sent to us - is attractive. But buying 3D printers isn't that cheap, they take a few minutes to print even small objects, and you need to pay for plastic filament to make those objects - they're not "free".

One thing that can make 3D printers more practical is "3D scanners" that can examine a physical object and convert it into a 3D model that can be 3D printed. $799 at MakerBot" MakerBot Digitizer » Works this way. This may help ordinary home users create and print models more easily, but it's still a long way from being affordable and practical.

$799 at MakerBot" MakerBot Digitizer » Works this way. This may help ordinary home users create and print models more easily, but it's still a long way from being affordable and practical.

Don't get us wrong: 3D printers are a great idea. We would love to live in a world where every home had a 3D printer and we could all download or custom-make anything we could buy. But 3D printers are still not that practical and need a lot of improvement until they become that dream device. Feel free to mess around with 3D printers, but - if you don't see the use of on-demand 3D printing services or 3D printers in local stores, you can pay to use - you really won't see yourself having your own 3D printer at home very much. come in handy.

But, of course, we are all geeks here. If you really want to play around with a 3D printer, take this one step further. Just understand that you are at the forefront of technology, and this is not very practical yet. Here's who really should buy a 3D printer: enthusiasts who realize it's not that much for them, but who really want to play with the technology. Everyone else should wait a little longer.

Here's who really should buy a 3D printer: enthusiasts who realize it's not that much for them, but who really want to play with the technology. Everyone else should wait a little longer.

Image credit: Creative tools on Flickr , Mirko Tobias Schaefer on Flickr , Cory Doctorow on Flickr , Kate Kissel on Flickr

Is it worth buying a 3D printer: pros and cons

Pros and cons > Technique > Should I buy a 3D printer: pros and cons

3D printing has become very popular in many industries. The development has brought so many changes in science that it is called one of the best inventions of our time . Many people buy printers for creative activities. Potential owners have a question whether they need such an acquisition, since the device and printing materials are not cheap.

Technology

The printer consists of several elements:

- Housing.

- Stepper motor.

- Print head (extruder).

- Guides for moving the extruder.

- The desktop where the item is created.

- Control electronics.

Media - plastic filament on spools - filaments . There are many types of material. The choice depends on the required properties. Fillers containing wood or stone create an imitation of wood or sandstone.

For work it is necessary to create computer three-dimensional model . For design, special programs are used. There is a wide variety of standard items available online if the user is unfamiliar with modeling. You can turn to professionals for help.

The model is cut into several layers, which are superimposed on each other, forming a single piece.

The slicer is installed in the printer - it sets the speed and direction of printing, the thickness of the layers, etc.

The filament enters the print head, where it is heated to a liquid state.![]() The extruder moves along the guides. The movement is carried out by a stepper motor. Plastic is applied to the platform.

The extruder moves along the guides. The movement is carried out by a stepper motor. Plastic is applied to the platform.

Why buying a 3D printer is a good idea

- Economy . 3D printing has been compared to other manufacturing technologies such as injection molding. It is well suited for the production of small series of products. Molds are required for casting and stamping, and more money will be spent on their creation. By mass production, the cost price is almost equal to the finished price of the parts. However, the industry is trying to fix this problem.

- Speed . Single products can be printed on a printer faster than by casting or stamping. During the time that the part will be milled, the 3D printer will produce several similar elements.

- Availability . The potential of the technology is not fully disclosed. The user can create unique items that cannot be bought in the store.

Many people use the printer to repair appliances. If you correctly create a model of the part, replacing the breakdown will be cheaper. 3D printing opens up great opportunities in all areas. It is enough to apply imagination and create a unique item.

Many people use the printer to repair appliances. If you correctly create a model of the part, replacing the breakdown will be cheaper. 3D printing opens up great opportunities in all areas. It is enough to apply imagination and create a unique item. - Environmental . The modern world is increasingly concerned about the problem of preserving the environment. Methods for processing secondary raw materials are being created. However, standard production methods still generate a lot of waste. Volumetric equipment produces a minimum of harmful and dangerous substances. The technology is aimed at preserving the environment.

- Customization . Items printed on the printer may have unique properties. Some parts are coated with a metallic coating, which affects their functionality. If required, the object is given resistance to sudden changes in temperature and to chemical attack.

- Complexity . There are problems to create complex parts with non-standard elements.

Standard methods will not allow you to do fine work or a special design with high quality. For volumetric technology, there are practically no restrictions on the complexity of execution. It does not require additional methods or resources, allowing you to create objects of different sizes and shapes.

Standard methods will not allow you to do fine work or a special design with high quality. For volumetric technology, there are practically no restrictions on the complexity of execution. It does not require additional methods or resources, allowing you to create objects of different sizes and shapes. - Material . Basically, plastic is used for printing, but there are other materials. The development of technology allows you to mix different substances, so that the result will have improved properties. Can imitate glass, plastic, metal, ceramic, etc.

- Precision . For many structures, it is important to maintain an exact likeness to the original. In standard technologies, the risk of defects is the highest. In the process of volumetric printing, the creation takes place in layers, at each stage it is possible to trace the accuracy of execution. In 3D printing, a defect in one part does not affect other copies. In mass production by other technologies, if a defective element is found, the entire batch goes to waste.

3D printing problems

- Energy consumption . The application of the technology on an industrial scale is not yet possible, since it requires large energy costs. Plastic casting requires 50-100 times less energy than when using bulk technology.

- Harm . Health problems may occur when using the printer at home. The device releases hazardous particles similar in composition to those found in cigarette smoke. The room should be well ventilated, otherwise, with frequent use, a person will become ill.

- Plastic . It was created to replace glass, as it was considered dangerous to the environment. In modern times, there is a struggle with the use of plastic - it is replaced with recyclable materials. If 3D printing enters industrial production, it will cause big environmental problems.

- Size . Printers are not designed to produce large items. Because of this, their use is limited.

Learn more