Print box 3d

CREATEK 3D Printable Storage Boxes

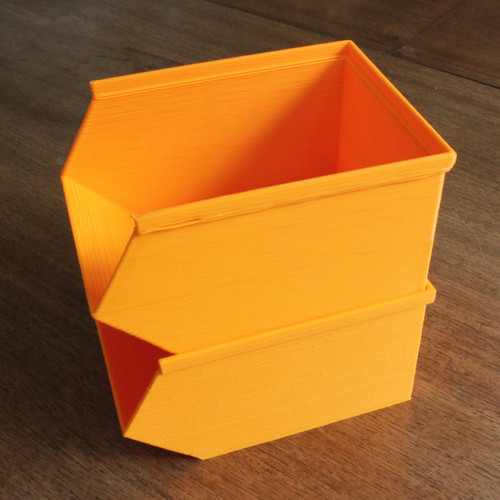

We set out to make a 3D printable product line. Something consumers can download and print at home. We’re starting with a small series of universal storage boxes. Simple, stackable, and designed for FFF 3D printing.

Today, we invite you to test our MLP (minimum lovable product). Consider this version one. We understand this version is not the most innovative, but we believe in starting small and iterating fast.

We’ll improve the product and expand the offerings as we collect feedback. You can help us out by downloading and 3D printing our files below, followed by sharing your thoughts via our feedback survey.

Happy Printing!

-Kevin from PDO & Noah from NMD

Table of Conents

- Storage Box Features

- Naming Convention

- Free STL Downloads

- Change Log: What’s New

- Printing Recommendations

- Get Notified – Product Updates

- Feedback Survey

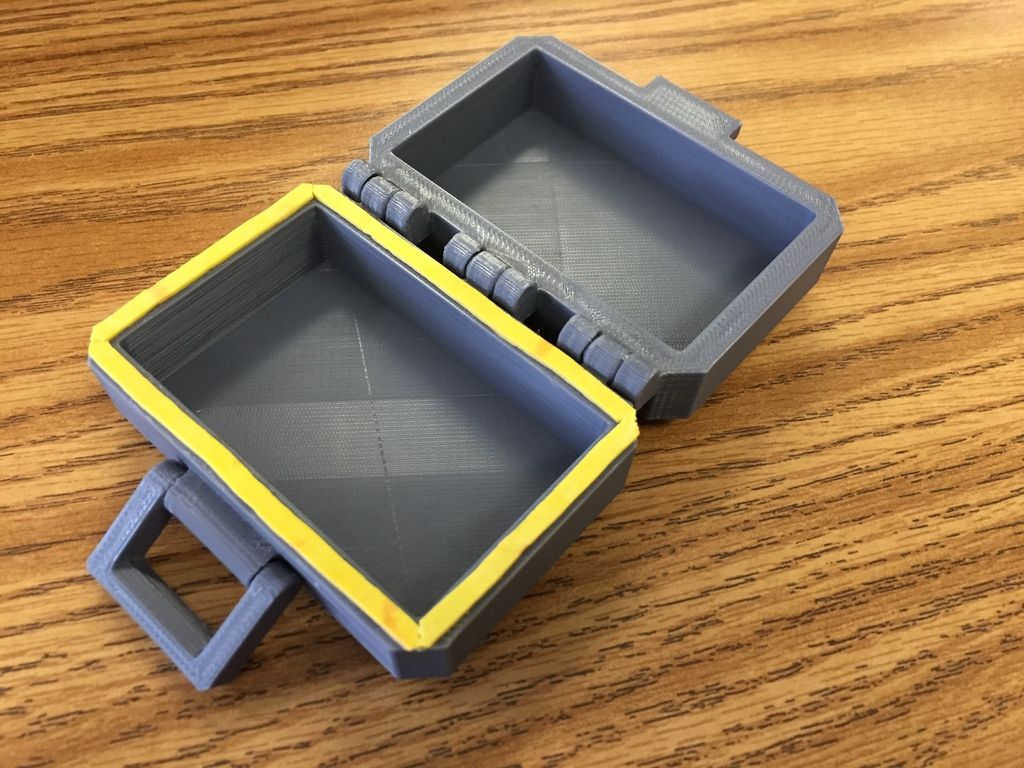

CREATEK Storage Box Features

All of our storage boxes stack, including a combination of smaller sizes that nest on a larger one.

Our unique design includes reinforced corners, providing extra-durable 3D prints – less warping.

All of our designs consider FFF 3D printing, including orientation, durability, and printing speed.

All of our designs are optimized to print without supports or rafts. Yes, we despise them too!

Each design includes a part number, making it easier to keep track of your prints and print more.

Our sizes scale with a 50mm grid, making it easy to utilize a combination that suits your needs.

Change Log: What’s New

| What’s New | Date Published | Link |

|---|---|---|

| G (grid) models released: G-100, G-200, G-300, G-400 | March 24, 2022 | Grid Series |

| S-400 models released | March 13, 2022 | 400 Series |

| Createk Product Launch: S-100, S-200, S-300 models released | February 22, 2022 | 100 Series |

CREATEK Naming Convention

Each model includes a letter and a series of three numbers. The letter represents the model type outlined below (more to be added in the future). The numbers represent the X, Y, and Z dimensions (in order) in increments of 50mm. For example, S-331 is our Standard box with a 150mm length (3x50mm), 150mm width (3x50mm), and 50mm height (1x50mm).

The letter represents the model type outlined below (more to be added in the future). The numbers represent the X, Y, and Z dimensions (in order) in increments of 50mm. For example, S-331 is our Standard box with a 150mm length (3x50mm), 150mm width (3x50mm), and 50mm height (1x50mm).

S = Standard

G = Grid

Free STL Downloads

Select your desired model number below.

Standard Files

- S-111 (v1.0)

- S-211 (v1.0)

- S-221 (v1.0)

- S-311 (v1.0)

- S-321 (v1.0)

- S-331 (v1.0)

- S-411 (v1.0)

- S-421 (v1.0)

- S-431 (v1.0)

- S-441 (v1.0)

Grid Files

- G-111 (v1.0)

- G-211 (v1.0)

- G-221 (v1.0)

- G-311 (v1.0)

- G-321 (v1.0)

- G-331 (v1.0)

- G-411 (v1.0)

- G-421 (v1.0)

- G-431 (v1.

0)

0) - G-441 (v1.0)

S-111 (v1.0) – Download STL (Thangs)

Our standard 50mm reinforced storage cube stacks with all other models. Perfect for those small parts or miscellaneous goods.

200 SeriesS-211 (v1.0) – Download STL (Thangs)

Our standard elongated 100mm x 50mm reinforced storage cube stacks with all other models. Perfect for tall skinny parts and miscellaneous goods.

S-221 (v1.0) – Download STL (Thangs)

Our standard large 100mm x 100mm reinforced storage cube stacks with all other models. Perfect for pencils, pens, and longer goods.

300 SeriesS-311 (v1.0) – Download STL (Thangs)

Our standard large 150mm x 50mm reinforced storage cube stacks with all other models. Perfect for computer parts, larger objects, and miscellaneous goods.

S-321 (v1.0) – Download STL (Thangs)

Our standard large 150mm x 100mm reinforced storage cube stacks with all other models. Perfect for cell phones, glasses, or other large parts.

Perfect for cell phones, glasses, or other large parts.

S-331 (v1.0) – Download STL (Thangs)

Our standard large 150mm x 150mm reinforced storage cube stacks with all other models. Perfect for larger objects or for stacking on top of a number of smaller CREATEK containers.

400 SeriesS-411 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 50mm reinforced storage cube. Perfect for elongated objects, such as pencils.

S-421 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 100mm reinforced storage cube. Perfect for larger objects or for stacking on top of a number of smaller CREATEK containers.

S-431 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 150mm reinforced storage cube. Perfect for larger objects or for stacking on top of a number of smaller CREATEK containers.

S-441 (v1.0) – Download STL (Thangs)

Our standard large 200mm x 200mm reinforced storage cube is our largest model.

GRID –

100 SeriesG-111 (v1.0) – Download STL (Thangs)

GRID –

200 SeriesG-211 (v1.0) – Download STL (Thangs)

G-221 (v1.0) – Download STL (Thangs)

GRID –

300 SeriesG-311 (v1.0) – Download STL (Thangs)

G-321 (v1.0) – Download STL (Thangs)

G-331 (v1.0) – Download STL (Thangs)

GRID –

400 SeriesG-411 (v1.0) – Download STL (Thangs)

G-421 (v1.0) – Download STL (Thangs)

G-431 (v1.0) – Download STL (Thangs)

G-441 (v1.0) – Download STL (Thangs)

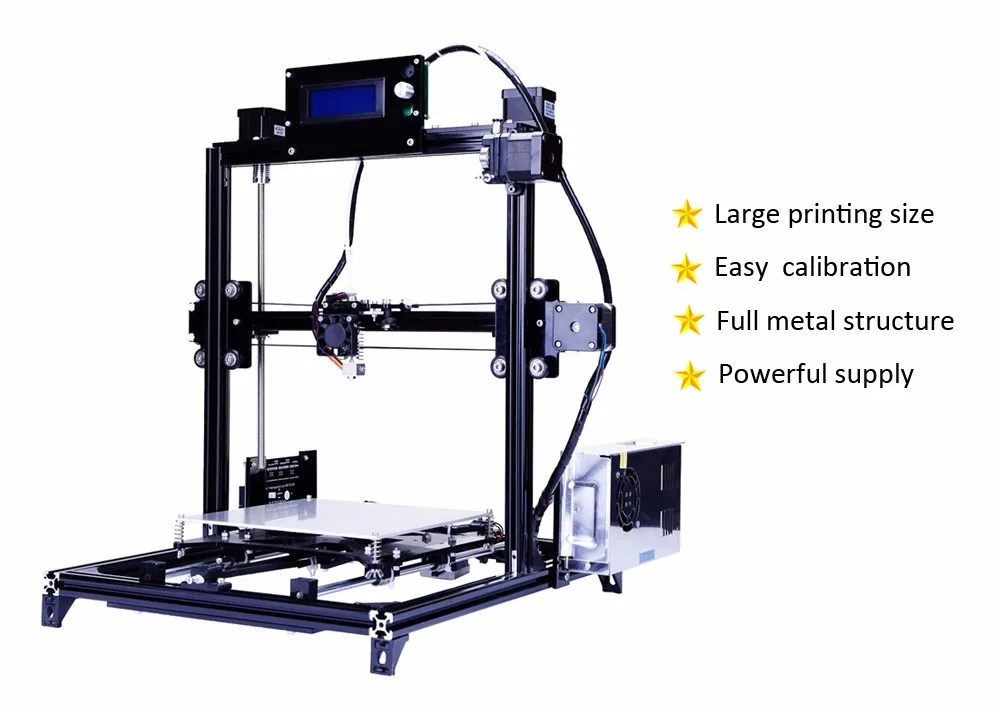

Printing Recommendations

| Layer Height: | 0.2mm |

| Nozzle Size: | 0.4mm |

| Support: | No |

| Raft / Brim: | No |

The CREATEK line will print well in most PLA and ABS filaments. We do not currently test other filament types at this time. For best printing results, follow our recommended print settings outlined above.

For best printing results, follow our recommended print settings outlined above.

For all test prints and pictures, we’ve used the following eSun PLA Pro* filament:

- Purple – eSUN PLA PRO (PLA+) 3D Printer Filament

- Green – eSUN PLA PRO (PLA+) 3D Printer Filament

*Disclosure: This post contains affiliate link(s). An affiliate link means I may earn advertising or referral fees if you make a purchase through my link, without any extra cost to you. It keeps my site free, fast, and available to everyone. Thanks for your support!

All CREATEK 3D Printable Storage Boxes are tested with eSUN PRO (PLA+) 3D Printer Filament.Get Notified – Product Updates

CREATEK Feedback Survey (3 minutes)

Here are some future improvements we have planned:

- special version that has magnets in all four corners (in the works)

- universal lids

- version that has spot for labeles

- storage grid to help organize the boxes in drawers

If you’re having printing issues, please share images and details in the PDO Community.

We value your feedback and appreciate everything you share. Your feedback will help us continue to improve the CREATEK 3D printable storage boxes. Please be descriptive, constructive, and include as much detail as possible.

3d Printed Box - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

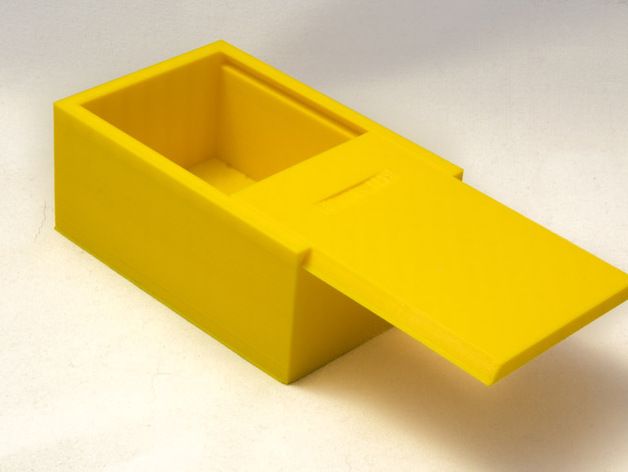

3D printed molds for box molding.

Packing for burgers, WOK

Packing for burgers, WOK Time pressure, safety, convenience and image dictate new requirements. All self-respecting companies have acquired their own branded elements. If for simple shops these are ordinary packages, then for catering everything is much more complicated.

Disposable utensils are used to comply with security measures, food safety, ease of transportation, as well as for advertising purposes. At the same time, plastic is not environmentally friendly and therefore more and more preference is given to boxes, mainly from kraft paper, sometimes with lamination.

Probably each of us has come across such individual packaging:

- burger packaging,

- WOK noodle box,

- lunch box tray,

- pizza box,

- box for french fries, etc.

At present, not only fast food, but also many producers of fruits, berries, vegetables, pastries are trying to pack their products in neat boxes that present the product in a favorable light.

However, no one wondered how these comfortable and neat boxes are made? But even in this industry it was not without 3D technologies.

Production of fast food boxes and packaging: how does it work?

Everything starts with 3D modeling. Each box is modeled and worked out in detail for specific products and needs. Comfort and functionality will play a key role in this, but design is also important. As a rule, this is done by printing houses and similar companies.

When all the details are thought out, the boxes are sent for printing and cutting - on the production line, according to the template, a box is cut from a standard cardboard blank, a special compound is applied to the right places, if necessary. This composition will later serve as an adhesive.

The blanks of future boxes are flat and in this form they are sent to their customer. So they are convenient to store, transport, but before use, you need to give them a shape. For this, a special machine is used.

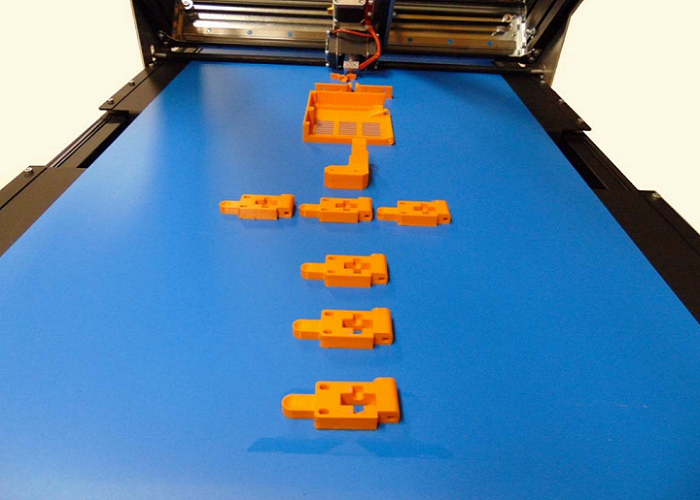

The machine is quite standard and various boxes can be formed on it. The workpiece is fed into the apparatus, where the finished product is molded (extruded) with the help of a mold pusher. Moreover, if hot air is supplied, which melts the glue (if any), and the box is securely fixed. The only caveat is that the mold is created for each type of container separately.

This is where 3D modeling and 3D printing come in again.

This means that a pusher is modeled for each finished box, repeating the interior of the finished product. And the simplest and most effective method of its manufacture is 3D printing.

3D printing of molds

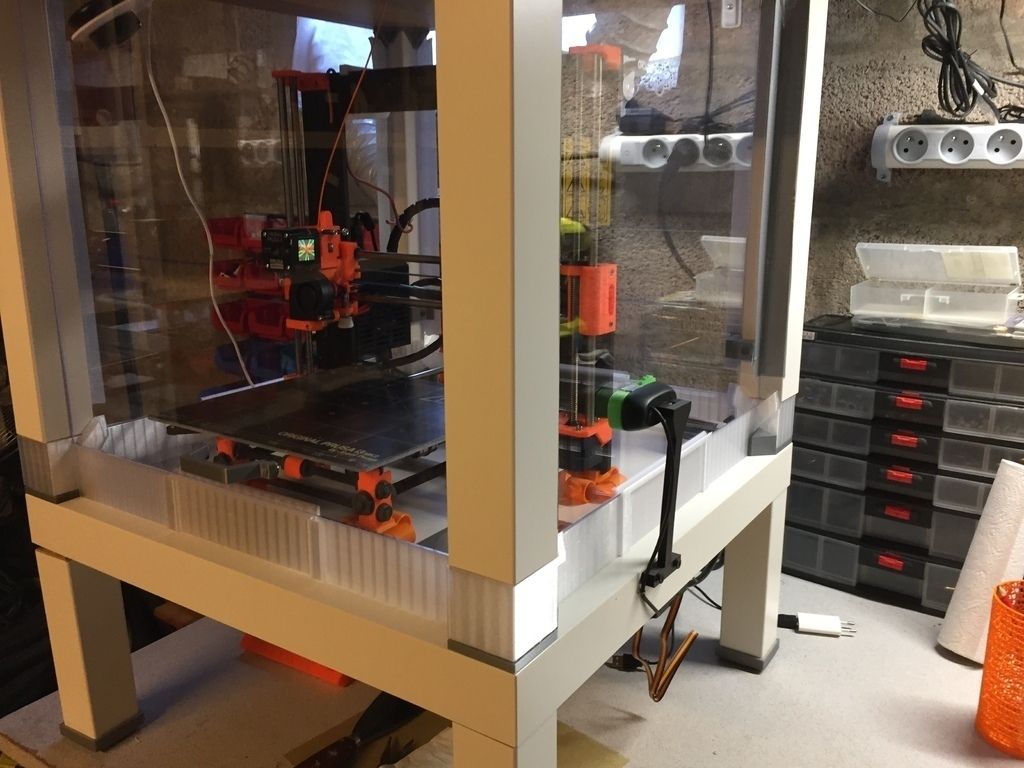

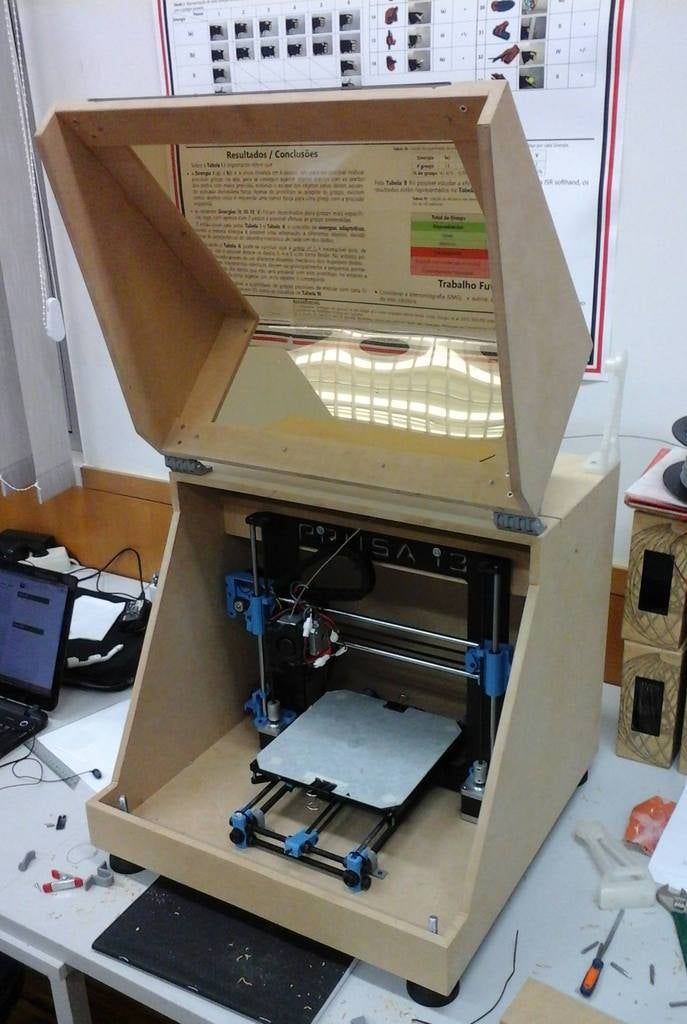

At 3DServis you can order modeling and 3D printing of a mold pusher for molding boxes, boxes, packaging, etc. We guarantee the high quality of the product, its accuracy and compliance with all necessary parameters. We understand that such a mold must withstand a large number of cycles, that is, the product must be not only functional, but also durable. That is why we use proven materials and printing technologies, professional equipment.

That is why we use proven materials and printing technologies, professional equipment.

Trust our professionalism, experience and technical equipment.

Still have questions? Contact our staff!

A mechanical engineer 3D printed a working gearbox for a Toyota engine (+ video)

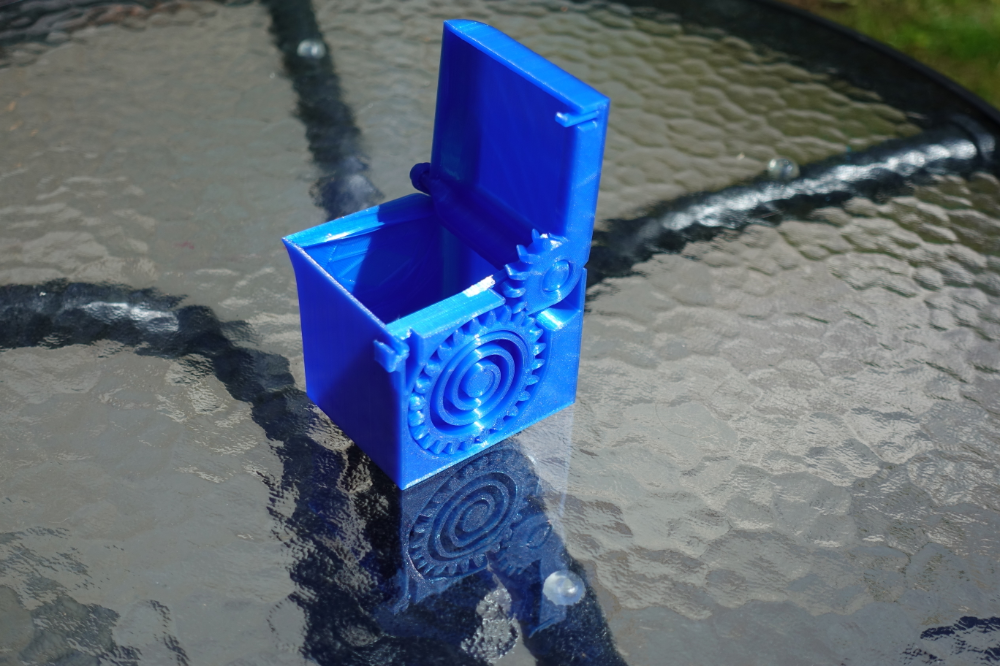

One of the unusual novelties is a 3D printed five-speed gearbox for a Toyota 22RE engine. The author of the work is mechanical engineer Eric Harrell from the city of Santa Cruz in California. His brainchild not only looks convincing, but is also a fully functional model.

In January, Harrell had already reverse-engineered a Toyota engine from scratch using a 3D printer (in other words, analyzed and reproduced its design). Thingiverse users and the American media have positively evaluated Harrel's project, and he decided to take his creation to the next level by supplementing the engine with a gearbox, also printed on a 3D printer. Harrell's two designs can work together to create a unique piece of 3D printed mechanical construction.

“The success of my first project, a Toyota four-cylinder engine, inspired me to get into the gearbox business,” says Harrell. “It's amazing how many people are interested in my work. I never thought that my design could generate such interest and, moreover, that people would actually print and assemble it, simply because it is a complex and time-consuming process. To date, eight people have already assembled the engine, and many are now working on it.”

In total, it would take approximately 48 hours of 3D printing to complete all parts of the gearbox. After printing all the components, you need to assemble the structure according to the drawings provided by Harrell. The engineer recognizes that assembling a gearbox is not an easy task, so he is available to answer questions from those who have encountered any difficulties in the process.

“Anyone who assembles one of my designs—a gearbox or an engine—will get a pretty good idea of how they actually work, because my models are exactly replicas of real mechanisms,” Harrell explains. “And it’s amazing because most people who are interested in 3D printing are unlikely to ever get the opportunity to actually recreate an engine or gearbox.”

“And it’s amazing because most people who are interested in 3D printing are unlikely to ever get the opportunity to actually recreate an engine or gearbox.”

Although most parts of the gearbox are 3D printed, some small parts cannot be printed on a personal 3D printer. We are talking about such details as a rod with a diameter of 3 mm, 628ZZ bearings, washers with a diameter of 3 mm and several other small elements that serve mainly for fasteners. At the same time, Harrell does not guarantee that all parts can be 3D printed in the correct scale - some of them may have to be adjusted to fit the rest of the structure. On the other hand, the author of the project notes that instead of resizing the parts in the project, you can simply file them as necessary after printing.

“The transmission works exactly like most manual transmissions in cars or trucks,” Harrell says. “Nevertheless, I can hardly explain how it works. This is very difficult to understand until you assemble the gearbox yourself, or at least watch a cutaway video of the mechanism in operation.