Ghost gunner 3d printer

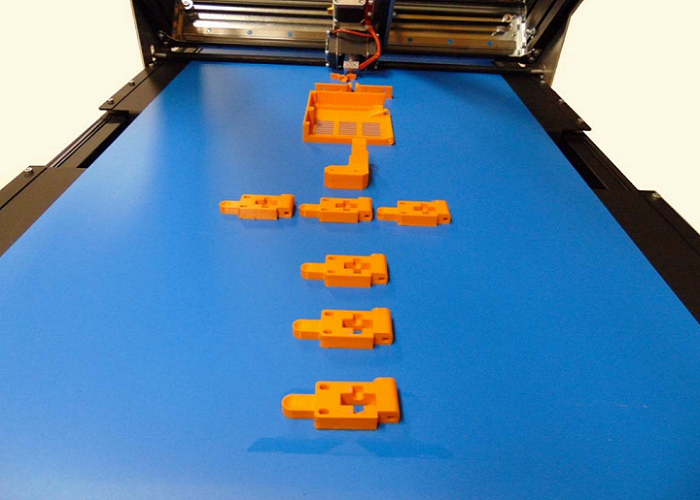

FAQ - Ghost Gunner

How much does Ghost Gunner cost?

The total cost of the machine is $2,500 before shipping is applied. We now offer a layaway option. Please contact us at [email protected] for more details.

What end mills does Ghost Gunner use?

Ghost Gunner uses industry standard ER-11 collets. Changing end mills is a simple process and full instructions are included.

How is the work piece held on the table?

Injection-molded jigs are used to hold the part in place as each milling step is performed. For example, milling an 80% AR-15 lower receiver requires 2 jig pieces to secure the lower in place while the trigger pocket is milled, and then two more jig pieces are installed to drill the trigger pin holes. As most 80% firearms require deep pocket milling, Ghost Gunner’s mounting table is parallel to the end mill shaft. This orientation maximizes fixture strength, minimizes complexity, and mechanically aligns the part to the machine upon insertion into the MakerSlide-patterned, open source T-slot stainless rails.

Which 80% receivers does Ghost Gunner use?

GG3 can machine any mil-spec AR-15 or DPMS 308 lower receiver with a pre-milled rear take down well. It also accepts 1911 single stack government and Polymer80 specter frames. We recommend the lower receivers we sell here. Note: you can also program the machine to finish your own custom jobs. We cannot currently recommend anodized lowers or frames, but for additional information on anodized lowers please email us at [email protected]

Can Ghost Gunner do engraving?

Yes, GG can be programmed to engrave with popular softwares. For GG-compatible engraving services we recommend GhostWriter by Komar Enterprises.

What is included with my Ghost Gunner?

Ghost Gunner CNC, 6’ USB A-B cable, 6’ NEMA 5-15/IEC C13 three prong power cable, DD USB drive, 17mm wrench, 12mm wrench, 3mm ball-end allen wrench, 5/32″ allen wrench, and ER11 collet nut.

What else do I need to buy for the machine to work?

Just plug Ghost Gunner into your computer, install our software and use any compatible .dd design file (See minimum system requirements here). For finishing guns, you’ll need to provide the 80% lower receiver or frame and all other firearm parts. Additionally the Ghost Gunner does not ship with any jig sets, so you will need to add one jig set for each type of 80% lower or frame you wish to mill. The machine is also fully programmable if you want to complete your own projects outside of 80 percents. These parts are not regulated for sale in the United States and you can have them delivered to your door without an FFL.

What Open Source parts did Ghost Gunner design?

The entire machine is open source. For other open source designs, Ghost Gunner developed a custom spindle that exceeds the quality, accuracy, and cutting capabilities of any sub-$400 spindle. GG also developed a custom signal conditioning PCB called GrbIO that reduces RF noise generated by the several stepper motors used on the machine. GrbIO includes screw-posts for easy wiring, including separate analog, digital, power supply and chassis grounds, which internally isolate noisy components from sensitive ground planes. The plug-and-play PCB connects between existing Arduino boards, requires zero software changes, and should resolve many headaches on other derivative designs.

GG also developed a custom signal conditioning PCB called GrbIO that reduces RF noise generated by the several stepper motors used on the machine. GrbIO includes screw-posts for easy wiring, including separate analog, digital, power supply and chassis grounds, which internally isolate noisy components from sensitive ground planes. The plug-and-play PCB connects between existing Arduino boards, requires zero software changes, and should resolve many headaches on other derivative designs.

How fast can the machine run?

When cutting aluminum, there’s little reason to cut as fast as possible. For example, many machines that claim to cut aluminum do so by cutting as fast as possible at depths of just 0.001″, which results in poor part tolerance, as only the tip of the end mill actually cuts the metal. The result is the end mill tip dulls quickly and then part quality suffers. Ghost Gunner is designed to cut deep grooves and thus doesn’t require a nonsense feed rate to overcome inadequate design. To directly answer the question, Ghost Gunner can run fast (80ipm), but doesn’t need to, as it’s rigid enough to cut like a real CNC.

To directly answer the question, Ghost Gunner can run fast (80ipm), but doesn’t need to, as it’s rigid enough to cut like a real CNC.

Do I need a special power supply?

No. Ghost Gunner uses a standard IEC power cord and is compatible with any 110/220V circuit. No external power brick is used; the machine is entirely self contained.

How do I connect to Ghost Gunner?

Ghost Gunner has two ports: Power (IEC standard) and USB (Type ‘B’).

What sort of maintenance is required for Ghost Gunner?

Ghost Gunner’s moving parts are entirely sealed from chip debris. All bearings are sealed and contain wipers to prevent foreign contaminate entry. The rails are stainless steel and are factory lubricated, but do require periodic wiping to prolong life. End Mills dull over time and are considered a consumable. With proper use, end mills should manufacture approximately 8 to 10 AR pattern lowers before needing to be replaced. Emptying the chip tray by use of a shop vac or similar after each build will prevent chip overflow (shaved aluminum chips occupy approximately 15 times their solid volume). We also offer technical support at [email protected]

Emptying the chip tray by use of a shop vac or similar after each build will prevent chip overflow (shaved aluminum chips occupy approximately 15 times their solid volume). We also offer technical support at [email protected]

Is manufacturing a firearm legal?

In general, yes. Semi-automatic firearms, including the AR-15 lower receivers, are generally legal to manufacture for private individuals under federal law. However, some states/municipalities restrict either the manufacture of certain firearms, or, more recently, the personal manufacture of a firearm with a 3D printer and/or CNC machine. GG makes no claim regarding your local manufacturing legalities. In some localities, lower receiver files provided by Ghost Gunner may require special licensing to manufacture and/or possess.

Under federal law, manufacturing firearms for purpose of sale and distribution without an FFL is prohibited. Without an FFL, you should manufacture firearms for personal use only. Recent ATF determinations have signaled that allowing others use of your CNC equipment may itself constitute manufacturing, therefore Ghost Gunner advises GG owners to neither print firearms for other individuals, nor allow other individuals to use their Ghost Gunner to manufacture firearms without the advice of counsel.

Recent ATF determinations have signaled that allowing others use of your CNC equipment may itself constitute manufacturing, therefore Ghost Gunner advises GG owners to neither print firearms for other individuals, nor allow other individuals to use their Ghost Gunner to manufacture firearms without the advice of counsel.

When does my order ship?

All machines are made to order. When placing your order, the GG3 Deposit page will indicate your ship date. To find out more about shipping timelines and order status, please contact our customer support team at [email protected]

Is Ghost Gunner legal in California?

Ghost Gunner CNC machines are general purpose machines classified by the US Department of Commerce. While we believe the machines are legal to purchase and own in the state of California, you agree to purchase Ghost Gunner at your own risk.

What is Ghost Gunner?

GG is a manufacturing concern managed by Defense Distributed.

Terms of Service?

Please see our latest terms of service here.

Ghost Guns

$500.00

Assembled in USA

Ghost Gunner 3 allows you to manufacture firearms with confidence and ease, in the privacy of your own home.

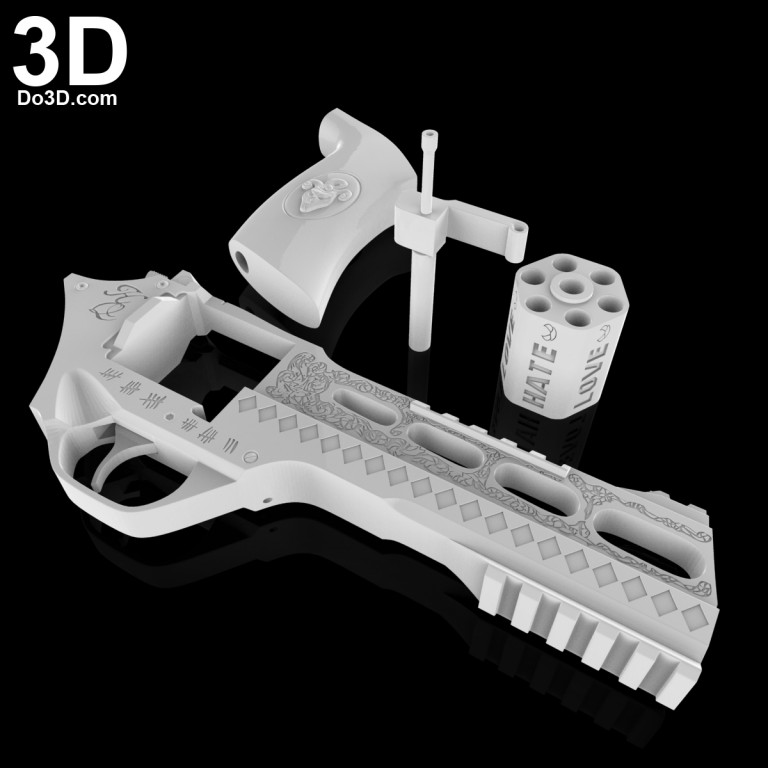

It is sold with the cut codes for the AR-15, AR-.308, 1911, Polymer80 and AK-47 receivers and frames. GG3 is also compatible with aftermarket jigs and cut codes (including the AR-9 and skeletonization) and engraving software. Learn more here.

Please note this is a nonrefundable deposit.

In stock

GG3-S CNC Deposit quantity

SKU: GGCNC3.0-DEPOSIT Categories: Best Sellers, GG Deposit Product, gg hardware software, Ghost Gunner, Tools and Jigs

Note: your jurisdiction may require you to be a licensed FFL or licensed gunsmith to purchase this product.

add to cart

This is a deposit product. By placing this deposit, you reserve your unit in the next production run of machines which begins in Q1 of 2023. The full price of the unit is $2,500.00 (before shipping), and your deposit goes toward that total price.

By placing this deposit, you reserve your unit in the next production run of machines which begins in Q1 of 2023. The full price of the unit is $2,500.00 (before shipping), and your deposit goes toward that total price.

When you are emailed to complete the order closer to your ship date, we do have a layaway option available in lieu of paying in full. Placing a deposit couldn't be easier. To learn more about that please click here.

GG3-S Purchasing Information

GG3-S - Deposit

GG3-S allows you to perform common firearms machining operations with confidence and ease, in the privacy of your own home. GG3-S removes material 5 times faster than GG2 and the new unibody construction provides greater rigidity, drastically improving finished part quality.

The custom spindle is powered by a specially designed closed-loop digital VFD, which sets a new standard in desktop CNC machining. GG3-S ships with code to complete the following:

- AR-00 Zero Percent Receivers

- Optic Cut for Pistol Slides

- 80% AR-15, AR-308, M1911, Polymer 80 and AK-47 lowers and frames.

- Lower and frame engraving operations

Many other third party cutcodes exist as well, such as those sold at ggd-store.com. GG3-S is an open source machine, meaning that it can be programmed for further operations by the end user.

Product Details

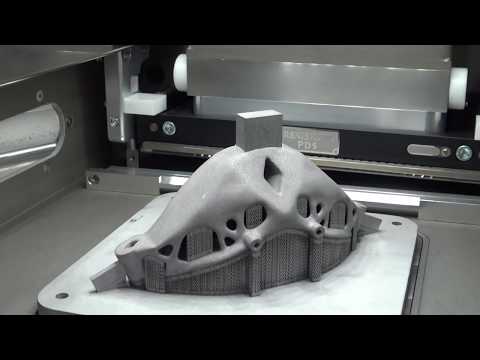

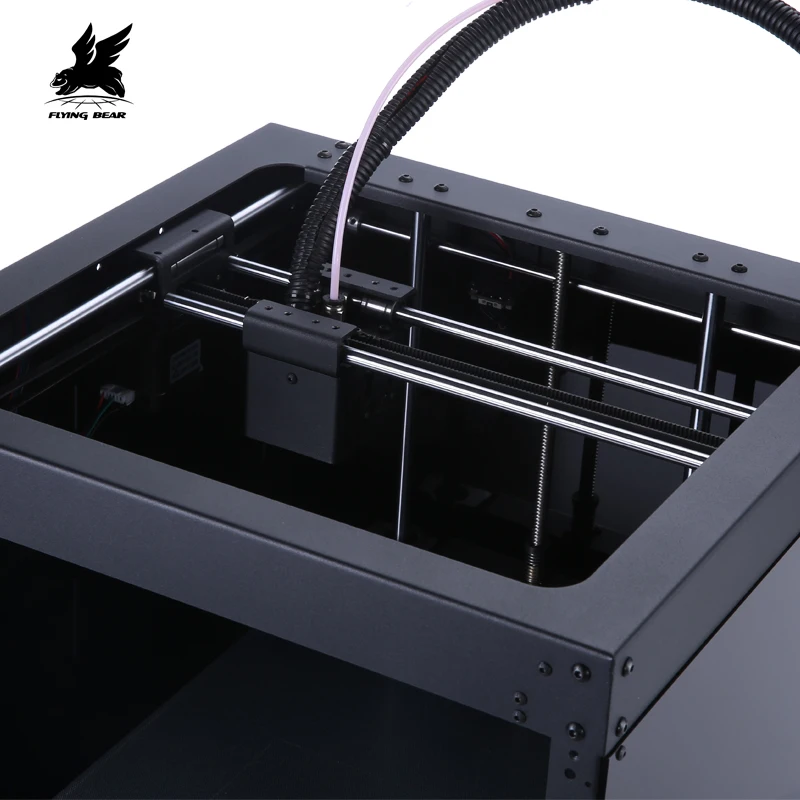

Ghost Gunner 3 is a complete redesign based on the successes of the GG2. It uses a milled, precision unibody frame for sharply improved squareness and rigidity. Optical limit switches and pre-loaded, self-aligning ballscrews allow it to deliver advanced positional accuracy.

GG3 incorporates a custom motion-control board with a closed loop, digital VFD controller. The machine accepts g-code from most CAM post-processors, and supports tool diameters up to 8 mm (~5/16”).

Included with the GG3: A DD USB with all our latest software. ER-11 collet nut, 5/16″ allen wrench, 3mm ball-end allen wrench, 12mm wrench, 17mm wrench, 6′ USB A-B cable, 6′ three-prong power cable. Laptop not included. Shipping is a flat rate of $150 in the United States. The machine dimensions are: 270mm / 425mm / 380mm.

Laptop not included. Shipping is a flat rate of $150 in the United States. The machine dimensions are: 270mm / 425mm / 380mm.

New Optic Cut Function!

GG3's electronic probing system allows us to perform the precision cuts required for an optic mount. The machine's power and rigidity allow it to cut hardened slide steel in a way that no other machine at its size and price point can do.

Most importantly, our user-friendly software allows you to do this with the touch of a button. No milling knowledge, coding or measurement required. Now you can perform optic cuts in your shop, storefront or garage.

Upon launch, GG3-S supports the most popular optic / slide combination: the RMR footprint on Glock 17, 19 and 26 slides. Very soon we will add support for additional popular footprints and slides.

The ultimate end of this project is a full library of slides and footprints with custom positioning and even custom cowitness cuts - all powered by our user-friendly DDCut software.

We are also in full development of optic cut capabilities on other platforms! We plan to launch updates for GG3-S optic cut function in Q1 of 2023 and beyond.

[embed]https://youtu.be/N2a1Gj4NBv8[/embed]

Other Products

After you place your deposit, GhostGuns.com has many other products to support your love for gun modification or building. Click here to see all the products we offer on our website!

Notice: California residents ordering a Ghost Gunner CNC machine consent to receiving a Coast Runner CNC machine in lieu of a Ghost Gunner.

Windows 7+, Mac OSX 10.13+

| Parameter | Value | Unit | Note | |

|---|---|---|---|---|

| Weight | 19 | Kg | ~42 pounds | |

| X/Y/Z travel | 89/242/79 | mm | Double the GG2 build volume | |

| X/Y/Z interior clearance | 116/299/162 | mm | Measurements with cover on | |

| Peak Spindle Power | 375 | W | Overload protection prevents exceeding | |

| Continuous Spindle Power | 190 | W | Long-term average, temperature limited. 2 2 |

8 times more than GG2 |

| Spindle runout | 0.0009 | in | Measured on tapered collet, 1mm from tip | |

| T-Slot Spacing | 40 | mm | Center-to-center | |

| Table T-slots | 2 | QTY | Compatible with 20 mm T-nuts | |

| Collet system | ER11 | – | Accepts tools up to 8 mm |

frequently bought together:

out of stock

AR-15 Raw Ghost Gunner 80% Lower Receiver

$103.50

out of stock

DPMS 308 Raw Ghost Gunner 80% Percent Lower Receiver

$107.

10

10Best files for 3D printing Opera・Cults

Mask of the Phantom of the Opera

12.50 €

The Phantom of the Opera (1925)

2.99 €

Baut's mask - set of masks for opera

2 €

Bust of Andrea Bocelli for 3D printing

25.54 €

Ghost Shooter

Free

Phantom of the Opera Pendant

Free

Ballerina stl

1,50 €

ACTION FIGURE HALLOWEEN THE PHANTOM OF THE OPERA KENNER STYLE 3.75 POSABLE ARTICULATED .STL .OBJ

3,50 €

Lady mask

11.14 €

Mego Curse of the Red Death Phantom Head

Free

Wolf shoulder pad

5 €

Chinese Peking Opera Facebook cdr dxf file format

Free

Bottle and sign of Zirdata

4. 80 €

80 €

BLOT = Blocky Little Orville Tribute

4.80 €

launcher primaris

1.25 €

District gate

6.95 €

Cantina courtyard

2.95 €

Power relay station

9.95 €

Load stacks

3.95 €

Meeting places

3.95 €

Wall combs

2.95 €

Courtyard/dock bay

11.95 €

Starport Terraces

6.95 €

Modular houses Starport

6.95 €

Starport walls

6. 95 €

95 €

Truck tractor

9.95 €

Siba Workshop

9.95 €

Landing pad

9.58 €

Antiquities of Bo'Gtan

11.92 €

Opera mask

11.14 €

THE SIMPSONS HOMER OPERA .STL .OBJ 3D

2,50 €

Horror Board Game - Phantom of the Opera - New Monster

Free

Flash Gordon Spaceship

Free

Pasion de Gavilanes sign or poster

€4.99

Sydney Cityscape

Free

Z-95 Starfighter 1:200 scale

Free

phantom of the opera : mask

1,25 €

Halloween

1. 50 €

50 €

Ballet Cookie Cutter Set (Both with the Debossers!!!)

4.03 €

Lithophane, Sydney Opera

1.50 €

Devil Mask Hannya

10.34 €

Devil Mask Hannya

9.53 €

SUPER MONSTERS THE KILLER OF THE OPERA COMANSI VINTAGE 90S

1 €

Space Pirate's Treasure Chest

Free

The Phantom of the Opera

4.80 €

Mog - Dissidia Final Fantasy Opera Omnia

2,99 €

Death Star scaled one in two million

Free

Starkiller Base scaled one in ten million

Free

I made an AR-15 ghost rifle in the back room - and it was easy

InoSMI materials contain only foreign media assessments and do not reflect the position of the InoSMI editors

This is my rifle. There are many such rifles. But this one is mine. It's called the Ghost Rifle. The term was made popular by gun control advocates, but is increasingly used by shooting enthusiasts as well, because this semi-automatic rifle has no marks. She has no serial number and is unknown and beyond the control of law enforcement.

There are many such rifles. But this one is mine. It's called the Ghost Rifle. The term was made popular by gun control advocates, but is increasingly used by shooting enthusiasts as well, because this semi-automatic rifle has no marks. She has no serial number and is unknown and beyond the control of law enforcement.

This is my rifle. If you listen to the representatives of the tribe of shooters, there are many such rifles. But this one is mine. It's called the Ghost Rifle. The term was made popular by gun control advocates, but is increasingly used by shooting enthusiasts as well, because this semi-automatic rifle has no marks. She has no serial number and is unknown and beyond the control of law enforcement. And if I feel any deep personal attachment to this lethal, free will weapon, it's because I made the rifle myself in the back room of WIRED in downtown San Francisco.

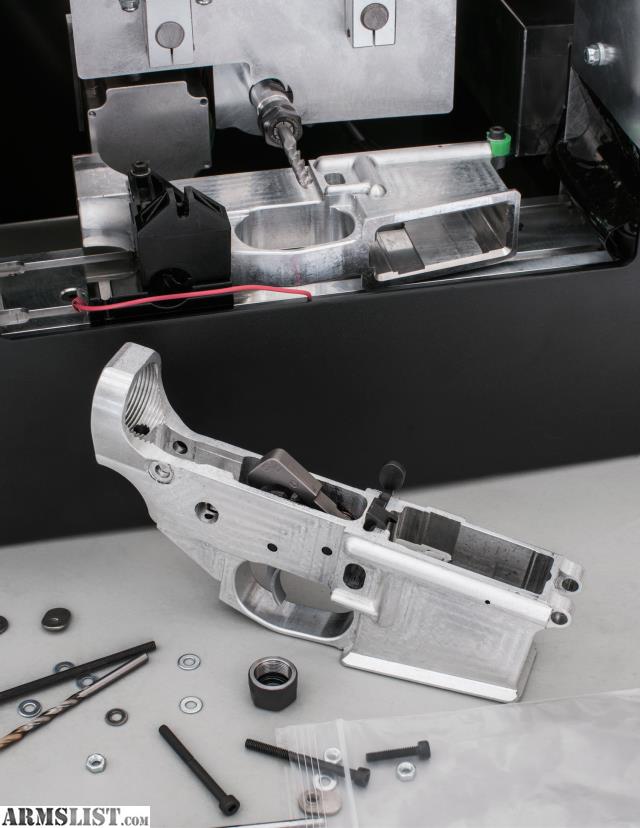

I did it mostly by myself. I have practically no technical knowledge about firearms, and as for working on machines, I am a real Cro-Magnon in this regard. However, I still made an all-metal, fully functional and accurate AR-15 rifle. To be more precise, I made the lower part of the receiver, which is the body of the rifle and the only part that falls under US law under the definition of "firearms". All I needed to complete this perfectly legitimate DIY project was six hours of time, a good grasp of computer programs, an $80 piece of aluminum, and an unremarkable cubic foot desktop mill called the Ghost. Gunner - "Ghost Shooter".

However, I still made an all-metal, fully functional and accurate AR-15 rifle. To be more precise, I made the lower part of the receiver, which is the body of the rifle and the only part that falls under US law under the definition of "firearms". All I needed to complete this perfectly legitimate DIY project was six hours of time, a good grasp of computer programs, an $80 piece of aluminum, and an unremarkable cubic foot desktop mill called the Ghost. Gunner - "Ghost Shooter".

"Ghost Shooter" is a $1,500 computer numerical control (CNC) machine sold by Defense Distributed, a free gun ownership organization. The organization gained notoriety in 2012 and 2013 when it began 3D printing weapon parts and the world's first 3D printed Liberator pistol. The political scandals surrounding the notion that anyone can now download and print deadly plastic weapons have gradually subsided, and attention has waned. Now Defense Distributed has moved from plastic to metal in handcrafted weapons. Like other CNC machines, the Ghost Arrow uses a digital file to turn aluminum parts. The first batches of this sold-out machine went on sale in the spring, and now Defense Distributed intends to make it much easier for ordinary people to make weapons parts from materials that have almost the same strength as those used to manufacture weapons in industrial conditions.

Like other CNC machines, the Ghost Arrow uses a digital file to turn aluminum parts. The first batches of this sold-out machine went on sale in the spring, and now Defense Distributed intends to make it much easier for ordinary people to make weapons parts from materials that have almost the same strength as those used to manufacture weapons in industrial conditions.

In early May, I received the Ghost Gunner, which was the first of these rare CNC milling machines that our publication had borrowed, and I decided to try it out. I'll jump ahead and tell the end of the story. Except for a small mechanical problem, the machine worked just fine. In fact, Phantom Shooter worked so well that it could signal the start of a new era in the gun control debate. In this era, it will be possible for unheard-of little money and with minimal skills, it will be quite legal to create durable, deadly, semi-automatic weapons that are not registered or tracked anywhere.

However, the Phantom Shooter is a gradual evolution in amateur gunsmithing, not a revolution. Homegrown gunsmiths have been working in an artisanal fashion for years, turning lower receivers to build rifles that go beyond what is allowed under US firearms law. In fact, when we announced the existence of the Ghost Gunner last year, the comments section of my article was filled with critics pointing out that the same weapon-making job anyone could do in their garage using an old drill press.

Homegrown gunsmiths have been working in an artisanal fashion for years, turning lower receivers to build rifles that go beyond what is allowed under US firearms law. In fact, when we announced the existence of the Ghost Gunner last year, the comments section of my article was filled with critics pointing out that the same weapon-making job anyone could do in their garage using an old drill press.

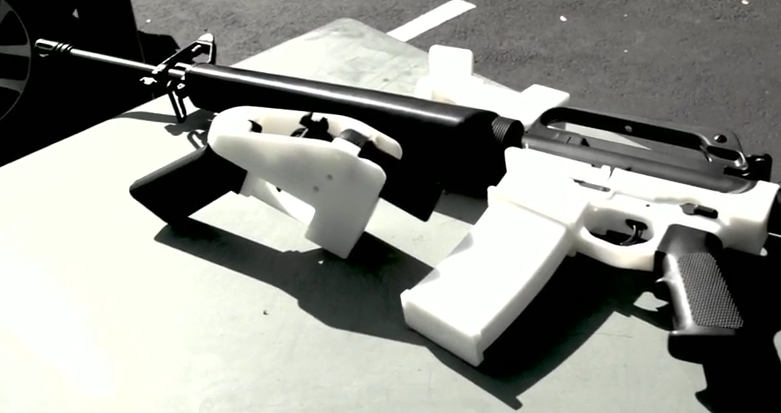

I couldn't rate the new CNC curiosity when it arrived at the WIRED office without first trying the method. And also the previous WIRED trick with printing weapon parts on a 3D printer. Before I fully realized what I was getting myself into, I set out to try out all three methods of making ghost weapons as part of my research. I decided that I would create a traceless AR-15 rifle in all three ways that I heard about: using an old vertical drilling machine, a freely available 3D printer, and finally using a new Defense Distributed machine.

Ghost Rifle Ingredients

Almost no one builds a ghost rifle from scratch, and I did exactly the same. The shortest way to build an AR-15 with no traces is to do it yourself with just one fairly simple component that causes fierce debate between supporters and opponents of the weapon, namely, the lower part of the receiver.

The shortest way to build an AR-15 with no traces is to do it yourself with just one fairly simple component that causes fierce debate between supporters and opponents of the weapon, namely, the lower part of the receiver.

The emphasis on the bottom of the receiver in the US gun code is because it is an extremely important part that forms the basis of the weapon. The lower part of the receiver holds together the butt, the handle, the magazine with cartridges and the upper part of the receiver, which includes the barrel with the chamber, where detonation occurs. As National Rifle Association Senior Museum Curator Doug Wicklund explained to me, there is always a serial number stamped on the bottom of the receiver because if other parts wear out and are replaced, this one stays. It's like a bicycle frame or a computer motherboard - the core around which everything else is built.

It's worth noting that buying an AR-15 in the US is pretty easy. But people who are obsessed with privacy, and those who are prohibited from buying weapons due to criminal records and mental disorders, can make the lower part of the receiver themselves and buy everything else, since other parts are subject to almost no regulation. All parts for my AR-15, with the exception of the bottom of the receiver, I ordered from Ares Armor, a Southern California gun-selling site that does not require any personal information other than a shipping address. If I wanted to hide my purchase from the company that issued my credit card, I could pay with bitcoins, because Ares Armor accepts them too.

All parts for my AR-15, with the exception of the bottom of the receiver, I ordered from Ares Armor, a Southern California gun-selling site that does not require any personal information other than a shipping address. If I wanted to hide my purchase from the company that issued my credit card, I could pay with bitcoins, because Ares Armor accepts them too.

There is even one way to anonymously purchase a finished lower receiver, which is subject to strict regulations. Well, almost finished lower part. Like many other gun dealers, Ares Armor sells what is known as the "80 percent part". This is a piece of aluminum that is 80% workable on the bottom of the receiver. Since there are no multiple holes and one very precise cavity called the trigger receiver, technically this part is not subject to control rules.

I thought: if I cut the other 20% with a CNC mill or a drill, I'll have a rifle with no serial number, no trace of registration, and I'll get it without delay. I don't even have to show my ID to anyone. Law enforcement will be completely in the dark about my rifle. This kind of secrecy appeals to Americans, who see their relationship with firearms as a deeply personal matter that the authorities should have nothing to do with.

Law enforcement will be completely in the dark about my rifle. This kind of secrecy appeals to Americans, who see their relationship with firearms as a deeply personal matter that the authorities should have nothing to do with.

The ghost rifle controversy erupted in the summer of 2013, when John Zawahri, a mentally disturbed 23-year-old, killed five people in Santa Monica. However, these rifles were not outlawed. Buying and selling them is against the law, but American gun law does not prohibit making them yourself. California State Senator Kevin Deleon proposed a bill last year to ban ghost rifles following the Santa Monica massacre. But Gov. Jerry Brown vetoed it a few months later.

But while the screams about ghost rifles are getting louder, few screamers have actually attempted to make such weapons. Even fewer were those who tried to check how the emergence of new digital machines and tools is changing the issue of gun control.

So I decided to do the following in the WIRED office for one strange week. At the same time, I will tell you how it all turned out.

At the same time, I will tell you how it all turned out.

Drilling machine

Remember how I said I don't know anything about working on machines? Naturally, this part of my weapons making experiment did not go well.

Step one. Purchase a drilling machine on a massive plate for drilling holes and various shapes in the semi-finished lower part of the receiver. With a $250 rental fee, two of my co-workers helped me haul this almost 180 cm high machine into the loading bay of our building. It is a dark and cold room with concrete walls and floor, where there are a couple of large garbage containers. I paid Ares $97 for the carbide drills and end cutters. These are tools that work like drills, but can also cut sideways like a milling machine. All this was recommended to me for my work by representatives of the seller company. I paid another $110 for a set of steel templates and for metal stencils to guide the machine as I try to make holes and indentations into precise shapes.

As it turned out, all these expenses and all these preparatory activities could not compensate for my complete lack of work skills, even at the level of a school workshop. Even before I started work, I realized that I had chosen the wrong jig, and we had to spend an hour of time and $ 80 to go and buy another one. And then it turned out that drilling is not as easy as it seems, looking at the footage on the Internet.

I took one last YouTube look at how to drill out the bottom of the receiver, put on my latex gloves, inserted a piece of aluminum into the clamps, screwed them in, and pressed the fat green button.

When the drill started to bite into the aluminum, I felt a wave of excitement and fine aluminum dust on my teeth. The drill threw away metal chips, leaving a shiny and polished depression. But my wild joy faded when I realized how badly I drilled the trigger receiver. No matter how I tightened the nuts of the clamping device, it constantly shook, and with it the aluminum billet moved. The holes I drilled went awry until they were almost diagonal.

The holes I drilled went awry until they were almost diagonal.

When I put in the end cutter to clean up the space between the drilled holes, it became clear to me that almost all of them were of different depths. For some reason, the drill went up and down, but I didn’t even notice it. The bottom of the cavity that I made began to resemble the lunar surface. Meanwhile, the massive machine was loudly protesting and shaking like a train about to derail. Throughout this ordeal, WIRED video producer Patrick Farrell, who has repaired motorcycles in the past and could certainly offer useful advice, looked at my torment through the camera lens and smirked discreetly. The unwritten rule is you're the only one in this business.

So I suffered for five and a half hours. Then the head of the drilling machine that holds the drill flew off. Later I learned that it is also called a chuck. I had no idea if some kind of safety device went off in this case, or if I ruined an expensive part rented with Farrell's money. I turned the chuck back in, but after a few minutes of brutal metal-on-metal violence, it fell off again. (I still don't know if I messed up the machine, but one gunsmith later told me that it was most likely not designed for horizontal loads and could not work as a milling machine.)

I turned the chuck back in, but after a few minutes of brutal metal-on-metal violence, it fell off again. (I still don't know if I messed up the machine, but one gunsmith later told me that it was most likely not designed for horizontal loads and could not work as a milling machine.)

That's when I capitulated. The result of my labor attempts turned out to be a pathetic piece of metal with a labyrinth of crooked recesses. And a bunch of tiny aluminum splinters on my arm where my latex glove had torn.

3D printing

I left the grease-coated machine in the WIRED loading bay, went upstairs, and pulled the $2,800 Makerbot Replicator out of the box. It was like a time machine that reduces the age-old distance of technological progress.

I plugged in the printer, read the instructions for idiots, and a few minutes later I was printing a tiny white coffee table to test. Soon I was ready to make weapon parts. And no obscure YouTube video tutorials, heads, cartridges and aluminum shavings.

I found a drawing for 3D printing of the lower part of the AR-15 receiver through The Pirate Bay website. It was one of dozens of weapon parts that can be downloaded from the BitTorrent database in the Physibles section, cleverly crafted in 2012 to house highly controversial blueprints not available or desirable on other sites. In fact, the file I downloaded was created in 2013 by Defense Distributed, but they removed it from their site when the State Department threatened to sue employees for violating gun export control regulations.

It took several minutes to download the file with the drawing of the lower part of the receiver. I opened it in the Makerbot print app, placed it in the center of the print table on the screen, and clicked the "Print" button. The printer motors spun, and a few minutes later the printhead was laying out layers of white plastic in a flat shape that vaguely resembled the receiver of a semi-automatic rifle. The work day was over, the WIRED office was empty, and I sat alone in a dimly lit room and, hypnotized, watched the slow process of materializing a rifle part.

Six of the nine hours required for printing have elapsed, at which point the print head has overheated. I had to give her time to cool down. To do this, it was necessary to press another button on the printer. I didn't touch her again. The next morning, I returned to the still dim room and found, inside the illuminated printer chamber, the finished translucent bottom of the receiver.

Although the manufacturing process was like something out of science fiction, there were still some defects. When I tried to remove the finished bottom of the receiver from the print chamber, one side of the receiver stuck to the backing, which keeps the hot plastic molds from flowing until they harden. Scraping and tearing off this matrix of plastic was difficult and unpleasant. And yes, it took a lot of time. I tried to use a knife, cut my finger and dripped blood on one side of the part. And the backing material also filled the tiny holes in the workpiece and hammered the thin threads designed to seat the metal screws.

Judging by the YouTube footage, it is very possible to 3D print the lower part of the AR-15 receiver, capable of firing hundreds of shots. But mine was useless. I found out about this only two days later, when I went to the gunsmith. In the end, I gave up all hope of assembling a rifle from a printed receiver, having done this long before this weapon could even somehow work.

"Ghost Shooter"

New generation tools and devices such as 3D printers and CNC machines are praised in every possible way, saying that with their help anyone can do anything. But from the very first moment after turning on the Ghost Gunner, I understood: this thing was simply created in order to make weapons.

The CNC Defense Distributed is a simple black box with two tiny stepper motors protruding from two of its six sides. As if to underline the power that lies in the bowels of this microwave-sized machine, it turned out to be so heavy that I could barely pull it out of the box. Putting it on the table, I was surprised at the lack of branding and the lack of toy lights and buttons, which are on the printer. The harsh simplicity of the machine shows that it is designed to create unmarked weapon parts.

Putting it on the table, I was surprised at the lack of branding and the lack of toy lights and buttons, which are on the printer. The harsh simplicity of the machine shows that it is designed to create unmarked weapon parts.

Ghost Gunner works with one of two programs. This is a general purpose, open source GRBL milling software and DDCut, a Windows-only weapon-machining program created by Defense Distributed and recommended for anyone who is not an advanced CNC machine user. The Phantom Shooter comes with an AR-15 Lower Receiver Processing Instructions file, which is located on a flash drive inside the box. (If this file was posted online, as is the case with 3D print files, the State Department could have threatened Defense Distributed with legal action—again, for violating gun export control regulations.)

I installed DDCut and found it absurdly easy to use the Phantom Shooter for its primary purpose of making and finishing the bottom of the receiver. This was mainly due to the fact that I did not have a single chance to make any decision. When the DDCut program kicked in and the AR-15 file started to bite into my 80% stock, the only thing I did was press the "Next" button, going through the entire 22-point step-by-step instruction, and then began to do with the aluminum part, what the program told me.

When the DDCut program kicked in and the AR-15 file started to bite into my 80% stock, the only thing I did was press the "Next" button, going through the entire 22-point step-by-step instruction, and then began to do with the aluminum part, what the program told me.

For an hour during the manufacturing process, I did nothing but marvel at the Phantom Shooter, watching its cylindrical blade carve out the trigger receiver with inhuman precision. At times Strelok seemed to be taking breaks between cuts to give me some task, such as repositioning a part, tightening or loosening bolts, switching from cutter to drill, or even vacuuming up the chips that had accumulated in and around the machine. In the end, I got the impression that it was the "Ghost Shooter" who programmed me as his weapon tool, and not vice versa.

All this time I have marveled at the beauty of the design and manufacture of the Ghost Gunner. He patiently removed the metal, while the aluminum billet moved in time with the cutter like a robot, and these movements were mesmerizing. The range of noise produced by the machine was quite wide: from a sharp screech to rough groans that echoed through the WIRED office, causing complaints from neighbors. But when there were periods of relative calm, the Ghost Gunner would also emit a series of rising and falling overtones produced by the vibration of the stepper motors. It all sounded like some alien tune. My editor, Joe Brown, who came into the room to look at the working machine, is still convinced that it was programmed to play composed music.

The range of noise produced by the machine was quite wide: from a sharp screech to rough groans that echoed through the WIRED office, causing complaints from neighbors. But when there were periods of relative calm, the Ghost Gunner would also emit a series of rising and falling overtones produced by the vibration of the stepper motors. It all sounded like some alien tune. My editor, Joe Brown, who came into the room to look at the working machine, is still convinced that it was programmed to play composed music.

But with only three steps left to finish the job, the Ghost Shooter ran into a serious obstacle. The sensor that is used in the machine to measure the location of the lower part of the receiver did not work correctly, and the "Ghost Shooter" was blocked. To get it up and running again, I had to break the purity of the experiment and seek advice from Defense Distributed founder Cody Wilson. At first he said that I would have to repeat the whole process again - and this is almost four hours of wasted time. “This is a design defect,” he admitted. “If the machine stops, everything must be repeated from the very beginning.”

“This is a design defect,” he admitted. “If the machine stops, everything must be repeated from the very beginning.”

But Wilson soon came up with a better plan and sent me a new file that only repeated the last step of the AR-15 part. 20 minutes passed, and I took out of the machine the shiny, perfect lower receiver of a semi-automatic rifle, which was still warm as bread from the oven.

Assembly

The Ghost Gunner's bottom receiver looked decidedly better than the 3D printed one - and definitely better than the twisted piece of aluminum I made with my drill press. But before collecting weapons, I decided to get the opinion of a specialist. So I went to Novato, California, to the bright Bay Area Gunsmithing, which is run by two professional gunsmiths who have a very impressive collection of guns and a cute, aging dachshund named Ruth.

When I showed the bottom of the hand-drilled receiver, workshop owner Nathan Rynder immediately waved it off. The firing pin and trigger would not fit into the narrow and uneven recess I made for them. And I didn't even drill the holes for the firing switch and trigger pin. (But Rinder noticed that he had seen worse work, including a detail where there was a gaping hole that the client accidentally drilled from the side.)

The firing pin and trigger would not fit into the narrow and uneven recess I made for them. And I didn't even drill the holes for the firing switch and trigger pin. (But Rinder noticed that he had seen worse work, including a detail where there was a gaping hole that the client accidentally drilled from the side.)

I was more surprised by how Rinder insulted my lower part of the receiver, which was printed on a 3D printer. "No, that's no good," he said, fingering the detail skeptically. He noted that the blueprint showed a thing called a "releasing pin hole" in the wrong place, and also made a list of the next steps for me to complete before assembly. “You will need to reattach the pistol grip, clean the threads in the buffer tube, and clean out everything that the chisel went through,” Rinder advised. “It will take you several hours to do all this cleaning.”

He was annoyed by the idea of making the lower part of the receiver on a 3D printer. If the ring that connects the buffer tube and the stock (it's such a big clamp at the back of the receiver) breaks, Rinder noted, then pieces of the spring will fly into the shooter's face with great force. “It scares me a lot,” he said.

“It scares me a lot,” he said.

And here's the lower receiver for the AR-15, which was made on the Ghost Gunner, received a nod of approval. Rinder, who - let me emphasize this - makes his living by making weapons, did not shout “wow” when he saw my workable and almost flawless part. But he gave me the "go-ahead" to continue working on the creation of a rifle. "She's safe to assemble, safe to shoot," said the gunsmith. “Yes, you can collect it and it will work.”

Over the next hour, I assembled my AR-15 in Rinder's workshop. It turned out to be more difficult than in Forrest Gump. But I persevered by learning the process from YouTube videos from the Ares Armor site and doing everything step by step. (A couple of times Rinder couldn't help but point out to me that I had inserted the part the other way, and also gave me an unsolicited hint. I guess he violated the purity of my DIY experiment, but Rinder was friendly, kind, and turned out to be a very knowledgeable person . )

)

When I finally inserted the pins and secured the top of the receiver, which is much more gun-like than the bottom, but not regulated by any restrictive rules (which is quite strange), they made a nice click into place. My AR-15 was ready.

I looked at the fully assembled rifle and something changed in my mind. It became clear to me that those abstract details that I was fiddling with turned into an object that could kill people. My lower receiver went from a "weapon" in a legal sense to a "weapon" in a very practical sense.

I remember that you have to think where you are aiming.

Shooting

Three days later, arriving at a private shooting range in Richmond, California, half an hour from Rinder's workshop, I loaded the AR-15 with a 10-round magazine and fired the first shots. Aiming at a piece of cardboard 50 meters away, I hesitantly pulled the trigger. The deafening sound of the shot drowned out the birdsong and echoed through the wooden walls of the shooting range, and the butt hit me painfully in the shoulder. I saw a tiny hole in the cardboard. A cloud of dust rose from the parapet behind the target.

I saw a tiny hole in the cardboard. A cloud of dust rose from the parapet behind the target.

"Well, it's been good," said Rinder.

I fired again. Then three more times. Then he released the entire store. After that, he reloaded and shot another one.

Somewhere near the end, I pulled the trigger, but heard nothing but a soft click. Rangemaster Chris Cheng, who happened to be the winner of the Top Shot TV shooting contest, said that the top of the receiver was jammed and needed to be lubricated. This often happens with new rifles. He took it apart, dipped the bolt and buffer parts in grease, and then put the top of the receiver back in place.

After that, my rifle worked perfectly all morning. When our cameramen had fired all 40 rounds I had taken with me, Rinder went to a nearby shooting range where the local Special Police Squad was training and persuaded the friendly cops to give us another 60 rounds. We shot them too. There were no more misfires on the rifle.

Casting out the "ghost"

The day after the shooting, I had to fly home to New York. Taking three ghost rifles with me on the plane (and by law there were really three rifles, since I made three lower parts of the receiver) was unwise. At the WIRED office in San Francisco, I couldn't leave them either, because it could be considered a transfer of ownership of non-serial weapons, which is a crime. I decided to cut the parts with a hacksaw, but FDA regulations required the bottom of the receiver to be destroyed with a blowtorch so it couldn't be welded back together.

So I decided to turn these three parts over to the local police. I disassembled the AR-15 and left the parts box on my editor's chair - except for the bottom of the receiver. I then went to a nearby police station and told the front desk attendant that I wanted to turn in firearm parts. She looked at me puzzled and asked me to sit down.

Forty minutes later, a couple of policemen showed up and asked me what I was doing with them.