How to make a heated bed for 3d printer

DIY 3D Printer from scratch — Heated bed | by Daniel Faegnell | 3DPrinterChat

Welcome to 3DPrinterChat.com, this article is part of the DIY 3D Printer from scratch, and you will learn a bit more about how the Heated bed works.

What is a heated bed and how it works?

The heated bed is a device that should provide a warm surface to the plastic stick, heated-beds have a huge advantage against warping and other adhesion issues when compared to cold beds. The heated bed have the heating element and the surface material, that can be glass, aluminium or the heating element itself.

The heating element works by converting electrical energy into heat, this happens when electric current flows through an resistance or non-ideal electronic, the amount of energy converted into heat is measured in watts. for example, an ordinary heated bed produces about 80W of heat.

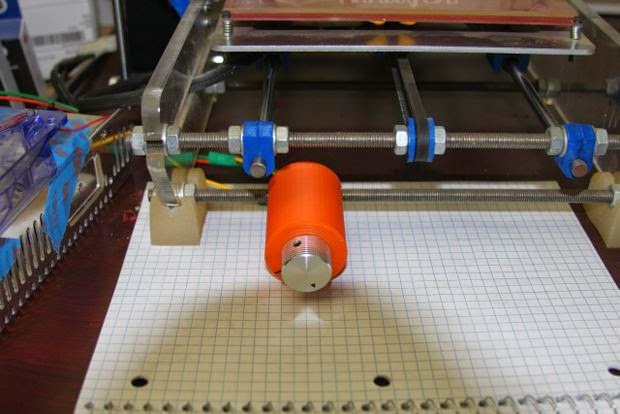

There are two main kinds of heated beds, the printed circuit board and the resistor bank, since the resistor bank is not used due its disadvantages, we wont cover it, but here is a image of how it looks.

How a PCB Heated bed works

The heated bed is made using the printed circuit board concept, which is basically a board (which is usually made of glass or fenolite) with a thin layer of copper on one side (or even multiple layers), then this board is printed or treated in a way that will protect some lines of copper, and leave the rest exposed, then this copper will receive a treatment with acid to remove the parts not protected, this process will leave us with only the useful circuits and connections,

Those tiny lines of copper will behave like an resistor (remember that everything in the universe poses some resistance to electrical flow, and this resistance is dissipated as heat), When we connect those “wires” to a power supply will we will generate heat, exactly what we were expecting.

The PCB has the great advantage of using a small amount of space when compared to other kinds of heating elements, it also can contain multiple layers, which will increase the power/cm² dissipated dramatically.

If properly designed, the printed circuit board is capable of distributing the heat more efficiently than any other kind of heated bed, since the power distribution can be drawn and simulated.

Heat distribution and why it matters

See these two examples below:

[caption id=”attachment_15225" align=”aligncenter” width=”501"]

First example: Heated bed without heat distribution correction[/caption]

[caption id=”attachment_15246" align=”aligncenter” width=”502"]

Second example: Heated bed without heat distribution correction and weird behavior[/caption]

[caption id=”attachment_15224" align=”aligncenter” width=”501"]

Third example: Heated bed with heat distribution correction[/caption]

As you can probably guess, a deficient heat distribution is bad, but why is it bad? For materials with high “warping rate”, or technically speaking: with high contraction propensity. These temperature differences will create opposite forces (contraction and expansion), that will force the material to bend, see the image below:

[caption id=”attachment_15295" align=”aligncenter” width=”554"]

Source: https://goo. gl/lIvCgV[/caption]

gl/lIvCgV[/caption]

On the first example, we have a cold bed, you can see the red area which the nozzle has just passed by, and the heat it leaves behind, this is likely to cause warping. On the second example, with the heated bed, we can see that the printed part is also hot, this will reduce the contraction and expansion forces because the temperature difference is lower (ΔT), this part is not likely to have issues with warping.

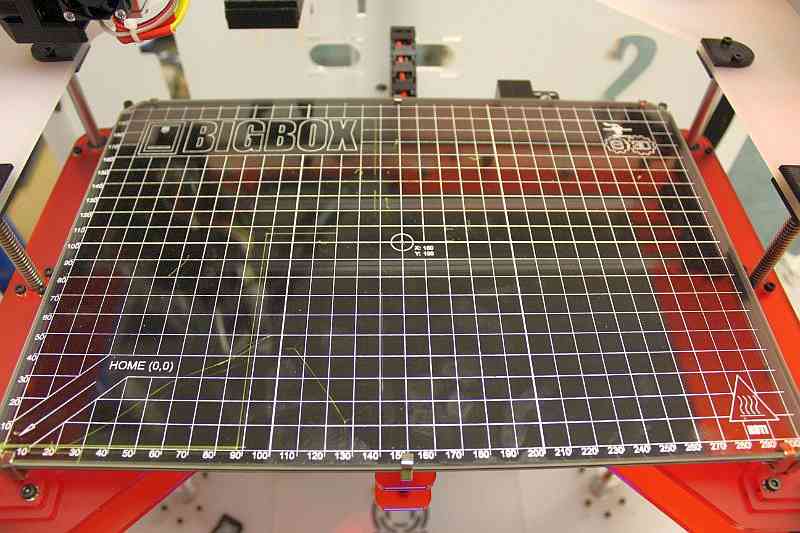

Now that you understood why a proper bed heat distribution matters, i’ll take as example the famous MK2 Heated bed

RepRap MK2 | $14–18

The MK2 Heated bed is by far the most used heated bed on the DIY community, it is an printed circuit board heated bed, which has the advantage of being capable of handling 12 or 24v just by changing the wires position.

Bed dimensions: 200x200 mm (heated area)

[caption id=”attachment_15302" align=”aligncenter” width=”430"]

Mk2 heating from 60ºC to 110ºC[/caption]

[caption id=”attachment_15303" align=”aligncenter” width=”430"]

Mk2 Holding 60ºC[/caption]

Final judgement:

The Mk2 is a good and cheap bed, for lower temperatures the heat distribution is fair, but is good to mention, if you will print something with the maximum allowed size (200x200) on a material that can be printed with 60ºC (like PLA) the warping propensity is smaller than a material that needs 110º (like ABS).

Improving my current bed

If you don’t want to replace your current heated-bed, there are some workarounds, like adding a glass on the top of the heating element, 3–5mm gives the best result. (keep in mind that this will slow down the heating process, but it also will makes the temperature distribution better)

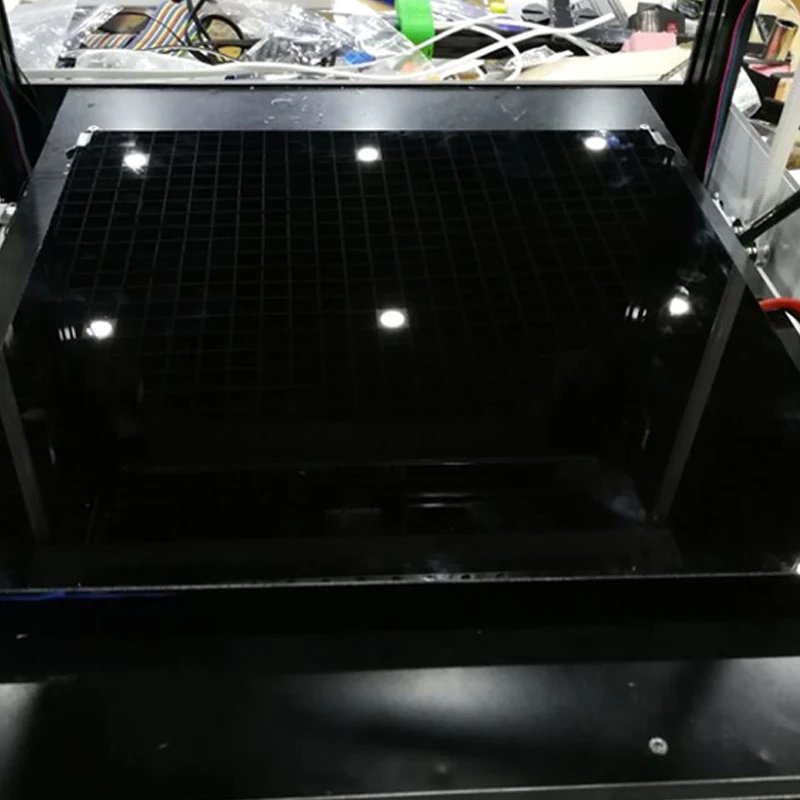

Example image of a MK2 with 4mm glass. source

Credits and Sources:

All this work would not be possible without the awesome posts below, consider visiting them!

SD3D — Not all heated beds are created equal

RepRap — Heated_Bed

3D Printing Systems — Warping

Heated bed - DIY 3D Printer from scratch

Welcome to 3DPrinterChat.com. This article is part of the DIY 3D Printer from scratch. You will learn a bit more about how the Heated bed works.

What is a heated bed and how it works?

The heated bed is a device that should provide a warm surface to the plastic stick. Heated-beds have a huge advantage against warping and other adhesion issues when compared to cold beds. Because of the smaller temperature difference. The heated bed have the heating element and the surface material, that can be glass, aluminium or the heating element itself.

Because of the smaller temperature difference. The heated bed have the heating element and the surface material, that can be glass, aluminium or the heating element itself.

The heating element works by converting electrical energy into heat. This phenomenon happens as result of electric current flows through an resistance. The amount of energy converted into heat is measured in WATTS. for example, an ordinary heated bed produces about 80W of heat.

There are two main kinds of heated beds:

- Printed circuit board Heated Bed;

- Resistor bank Heated Bed;

- Peltier Effect Heated Bed.

since the resistor bank and the Peltier effect are not used due its disadvantages, we wont cover it. Here is a image of how the resistor bank looks.

How a PCB Heated bed works

The heated bed is made using the printed circuit board concept, which is basically a board (which is usually made of glass or fenolite) with a thin layer of copper on one side (or even multiple layers).

Then this board is printed or treated in a way that will protect some lines of copper, and leave the rest exposed, then this copper will receive a treatment with acid to remove the parts not protected, this process will leave us with only the useful circuits and connections,

Those tiny lines of copper will behave like an resistor (remember that everything in the universe poses some resistance to electrical flow, and this resistance is dissipated as heat), When we connect those “wires” to a power supply will we will generate heat, exactly what we were expecting.

The PCB has the great advantage of using a small amount of space when compared to other kinds of heating elements, it also can contain multiple layers, which will increase the power/cm² dissipated dramatically.

If properly designed, the printed circuit board is capable of distributing the heat more efficiently than any other kind of heated bed, since the power distribution can be drawn and simulated.

Heat distribution and why it matters

See these two examples below:

First example: Heated bed without heat distribution correctionSecond example: Heated bed without heat distribution correction and weird behaviorThird example: Heated bed with heat distribution correction

As you can probably guess, a deficient heat distribution is bad, but why is it bad? For materials with high “warping rate”, or technically speaking: with high contraction propensity. These temperature differences will create opposite forces (contraction and expansion), that will force the material to bend, see the image below:

Source: https://goo.gl/lIvCgV

On the first example, we have a cold bed, you can see the red area which the nozzle has just passed by, and the heat it leaves behind, this is likely to cause warping.

On the second example, with the heated bed, we can see that the printed part is also hot, this will reduce the contraction and expansion forces because the temperature difference is lower (ΔT), this part is not likely to have issues with warping.

Now that you understood why a proper bed heat distribution matters, i’ll take as example the famous MK2 Heated bed

RepRap MK2 | $14 – 18

The MK2 Heated bed is the most used heated bed by the DIY community. It is an printed circuit board heated bed which has the advantage of being capable of handling 12 or 24v, you just need to change the wires position.

Bed dimensions: 200×200 mm (heated area)

Mk2 heating from 60ºC to 110ºCMk2 Holding 60ºCFinal judgement:

The Mk2 is a the best and cheapest bed and you should consider it. The heat distribution is indeed fair. for a naked bed. But keep in mind. If you are considering to print something with the maximum allowed size (200×200), The warping propensity is bigger, since there will be a great temperature difference.

If you don’t want to replace your current heated-bed, there are a lot of workarounds, but the two best are:

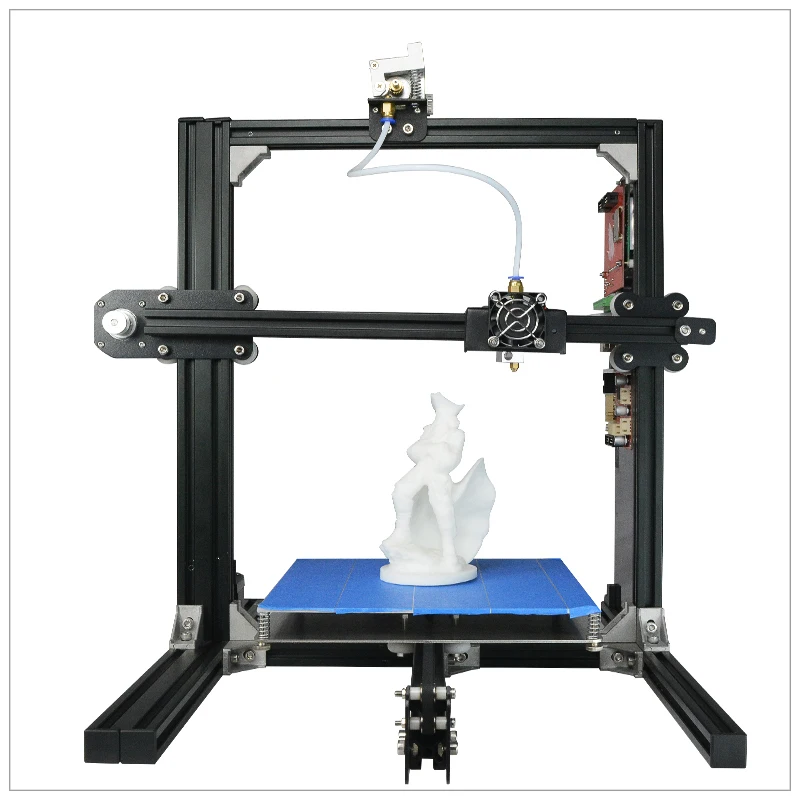

Improving with glass

adding a glass sheet on the top of the heating element, 3-5mm gives the best result.

Example image of a MK2 with 4mm glass. source

Improving with Aluminion

Adding a aluminium sheet on the top of the heating element, 3-4mm gives the best result. the output will be the same as the previous image. This setup is preferred for use with inductive probing on autoleveling.

Credits and Sources:

All this work would not be possible without the awesome posts below, consider visiting them!

SD3D

RepRap – Heated_Bed

3D Printing Systems – Warping

Techno Print 3D Company

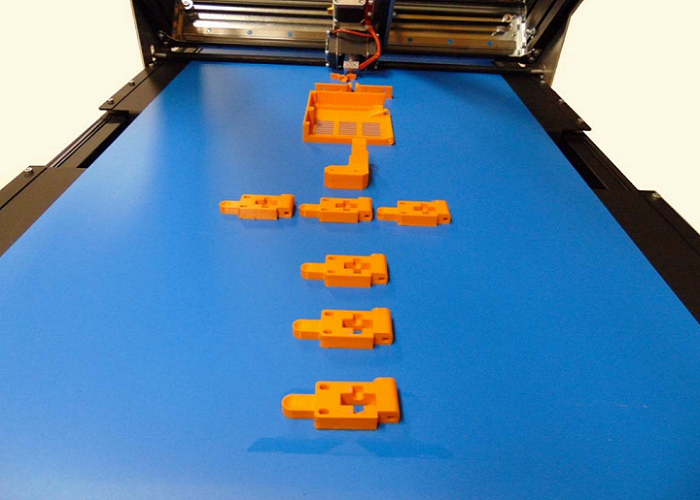

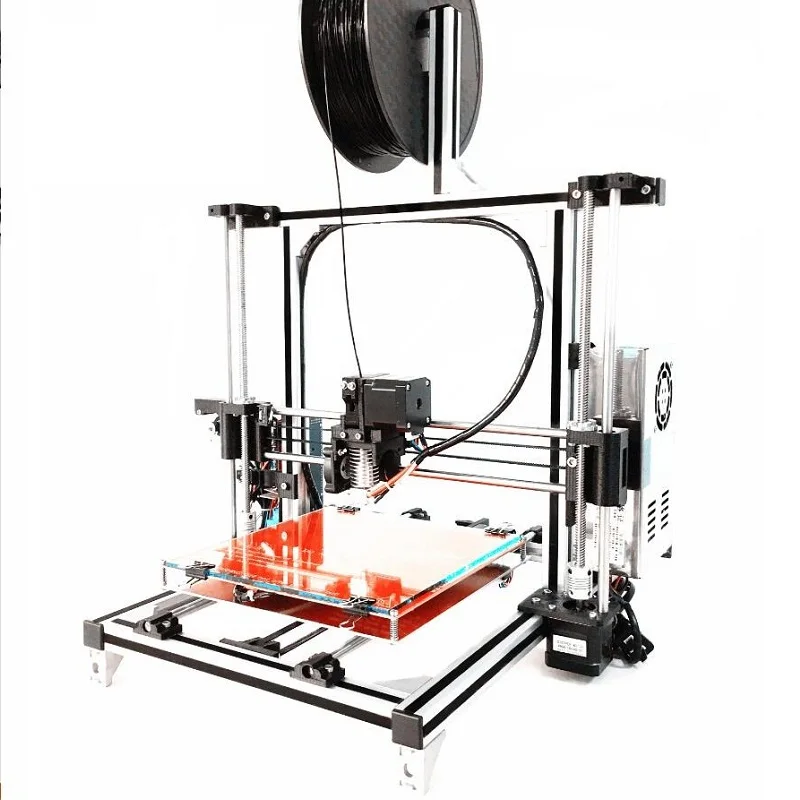

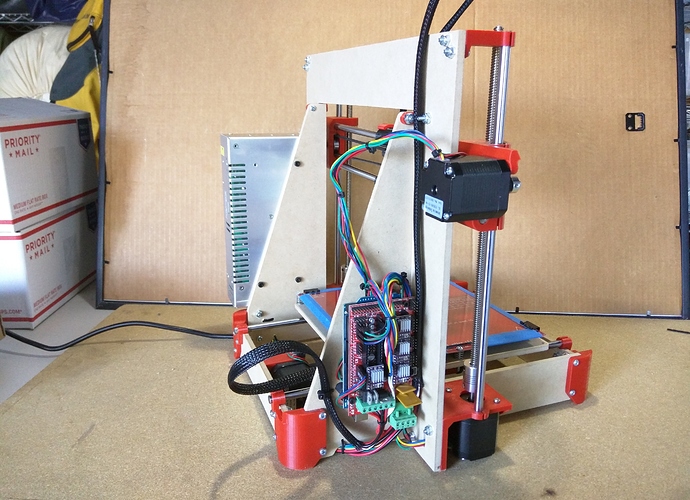

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

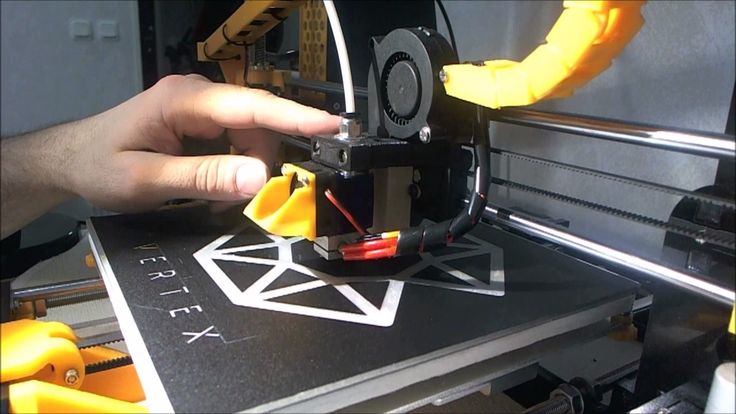

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

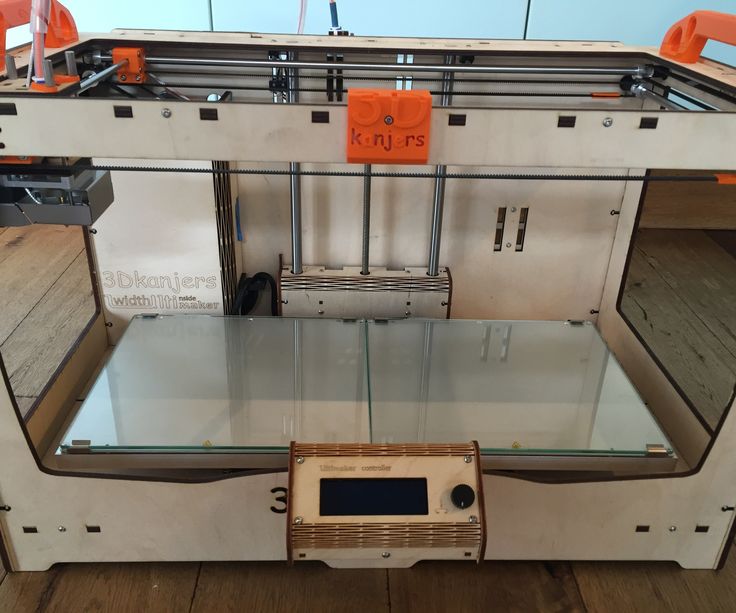

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

Many will say that it is wrong to compare them or Read more→

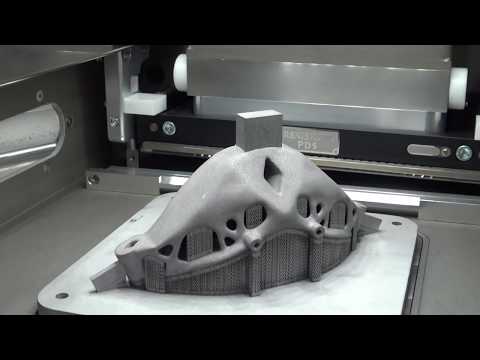

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

Free STL file Heated bed (Raspberry IR camera)・Template for download and 3D printing・Cults

Lampadario Lotus 3D

1,50 €

Ciaki

0,80 €

CiakiShow 3D logo

2 €

Stripper Dima

2 € -fifty% 1 €

INGRANAGGIO JOLLY Z=39 CAL1036 (BA01096)

Free

BolMask

Free

Magic Flute

Free

Raspberry (IR camera)

Free

The best files for 3D printers in the Tools category

FILAMENT SPOOL HOLDER

Free

Pumpkin Carving Knife

Free

Filament Spool Holder

Free

Side Load Bottle Cage - Slanted

0. 71 €

71 €

Coffee Hand

Free

Reversible pocket screwdriver with bit handle

Free

Fire hydrant storage container

1.92 €

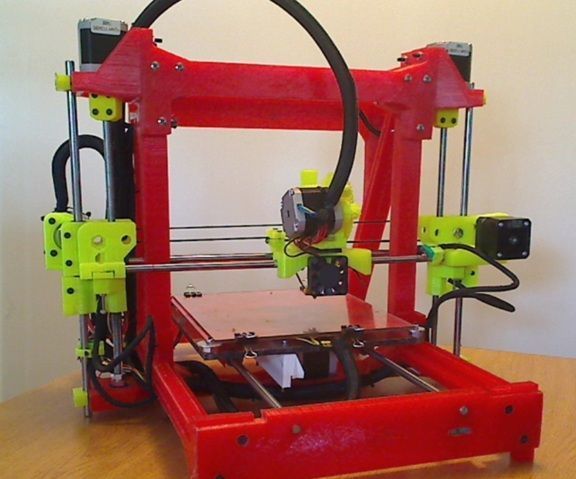

3D Printer The Lutin 3D PNX

Free

Bestsellers in the Tools category

Cooling system Minimus Hotend

€2.38 -fifty% 1.19 €

Bit holder Spartan 4 mm Hex

1,80 €

ENDER 3 S1/PRO SPRITE, 4020 FAN CR TOUCH NO Y OFFSET

1.96 € -fifteen% 1. 66 €

66 €

Armadillo - flexible wire conduit

€1.72 -fifty% 0.86 €

Phone holder

2.49 €

Business card embossing system

3 €

3D printed wave transmission (harmonic drive)

4.99 €

ENDER 3 S1/PRO SPRITE, V3 AIR DUCT 5015 OR 4020

€2.49 -fifteen% 2.11 €

well designed: Hemera 9 fan duct0022

€2.50

telephone ring holder

0,90 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

€1.80

Grinder | Grinder

€1.50

ARTEMIS -> Shop for Alligator 2 || 6.5" Arrows || Repeating Crossbow

6.25 €

Quick print stackable parts containers / storage boxes

2.91 €

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.62 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

2.87 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.