Best glue for 3d printing

What is the Best Glue for 3D Printing Bonds? PLA, ABS, PETG – 3D Printerly

3D prints can get detached and broken sometimes, so you want to find a way to stick it back together. This leads many people to wonder whether superglue works on PLA and other 3D printing materials, so I decided to look into it.

There are so many options that you can use for gluing 3D prints together and they differ across material types. This article should simplify the process and make it easier for you to choose a solid option that you can stick with.

Keep on reading through this article for some more information about getting the best glue for your 3D prints once and for all.

What is the Best Glue for 3D Printing Bonds?

The best glue for 3D printing is superglue because it provides a strong bond between plastic and is very easy to use. A good brand of superglue cures quickly, so for materials like PLA, ABS, and PETG, it should work great. It doesn’t work so well for flexible filament like TPU or Nylon.

There are other options out there that several 3D printer users have success with, but superglue is the most recommended.

Make sure you are in a ventilated place and are wearing a protective mask and goggles when using some of these adhesives. They can be fairly irritating to your breathing and skin if you come into contact with it.

If you want to get some good quality superglue for your 3D prints, I’d recommend getting yourself some Gorilla Super Glue (20 Grams) from Amazon.

This one does take some extra time to cure, so you can use a separate activator like baking soda to speed up the curing process. Other people have said even water works well to achieve this, although it’s going to run as you would expect.

You can also go with the Bob Smith Industries BSI Maxi Cure Clear Adhesive from Amazon. It comes as a combination pack of the superglue and an accelerator to cure in just 10-25 seconds.

It states that it can bond metal, plastic, wood, ceramics, rubber, leather and more.

A further read into this article will give you an insight into things you can use in gluing your 3D print.

What is the Best Glue for PLA?

The best glue for PLA 3D prints is superglue. Other popular options are 2-part epoxy resins that are mixed together to activate then cures together to bond two objects. A specialized glue that works very well for PLA is PLA Gloop. It bonds PLA 3D prints together strongly, but can also be used as a bed adhesive.

Superglue has a short time for curing and it forms just a thin layer of bonding that is mostly not visible to the eyes when done carefully. One user said you can remove excess superglue with baby oil as it penetrates the bond between the plastic and the superglue itself.

Other adhesives that join PLA are:

- Epoxy Resin

- 3D Gloop

- Contact Cement

- Hot Glue Gun

- Acetone

- Soldering Iron

- 3D Printing Pen

Epoxy Resin

Epoxy resin is a popular solution to gluing and combining up 3D prints, especially for rigid materials like PLA. It does take longer to cure than superglue though, taking around 5 minutes to set, and another 10-15 minutes to fully cure.

It does take longer to cure than superglue though, taking around 5 minutes to set, and another 10-15 minutes to fully cure.

The difference is the level of strength that you get with the right kind of epoxy resin.

It’s a great solution to joining up those larger 3D prints like cosplay items and other similar items. You’ll get the best results with an epoxy resin by clamping it down during the curing process.

I’d recommend going with the Loctite Epoxy Instant Mix from Amazon for your 3D printing needs if you go with this option.

3D Gloop

3D Gloop is a great alternative to superglue and may even be a better product for bonding/gluing PLA 3D prints together. It is known to be a solvent which actually slightly melts the PLA plastic and weld it together.

In the video below by MatterHackers, you can see just how well this product works to stick PLA together. It also can be used as a bed adhesive to help 3D prints stick to the bed while printing.

Contact Cement

Contact cement is also great at bonding PLA, though some people have complained about the visibility of the adhesive after using it. With practice, you should be able to apply is carefully and smoothly to not show up very much.

You can also sand any areas which show the contact cement on your PLA prints with 120 grit sandpaper.

A popular one that I found on Amazon is the Permatex Contact Cement 1.5 oz. It’s known to be great for instant bonding applications, is heat and water resistant, and can even bond rubber to glass and metal.

They mention that no clamping is required for this product to work well.

Hot Glue Gun

You can’t go wrong with a hot glue gun when it comes to gluing plastics, being a very popular solution for many applications. It has pretty good strength and isn’t too difficult to apply, with a 45-second application time.

It has pretty good strength and isn’t too difficult to apply, with a 45-second application time.

When you do use this though, the glue tends to be fairly thick, so it would be better for larger 3D prints and big projects like cosplay armor. For something like miniatures or smaller 3D prints, I wouldn’t recommend using a hot glue gun.

I’d recommend going with the Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks from Amazon.

- It has a precision nozzle that makes operation a lot easier

- An easy-squeeze trigger

- Weather-resistant hot glue sticks so you can use it in or outdoors

- 45-second working time and withstands strong impacts

- Has an insulated nozzle that prevents burns

- It also has an integrated stand to keep the nozzle off other surfaces

Acetone

This has been known to weld and smooth PLA but only with certain types, most likely based on the manufacturing methods and chemical properties. Thomas Sanladerer shows us this in the video below.

Thomas Sanladerer shows us this in the video below.

You can get yourself a bottle of Pure Acetone from Amazon for a pretty good price.

Soldering Iron

Another method of “gluing” PLA together consists of using a soldering iron to apply enough heat to melt the PLA part, then hold it together so it hardens and joins. It’s obviously not a glue, but it works very well to bond PLA parts together.

You can also use a line of the same filament you used to print the object, then solder that into both the 3D printed plastic parts to weld it together as shown in the video below.

The basic instructions of this video are to:

- Get your 3D printed pieces and make sure the surface is good enough to together

- Get your soldering iron and set it to a temperature around 200°C

- Use a length of the PLA filament you used for printing

- Line up the length of filament with the 3D print and melt the filament to use as a solder to combine the pieces together.

You want to filament to actually get into the gaps and holes

You want to filament to actually get into the gaps and holes - Let the PLA cool down and it should be joined together strongly.

A great one that should work well for the purpose of joining PLA together is the Anbes 60W Soldering Iron Kit from Amazon.

Here is another video which shows you how to weld together two parts. It was from a 3D print that failed halfway, which he split up and managed to print the other half and then combine it with soldering.

3D Printing Pen

A lesser known solution for gluing or joining PLA 3D printed parts together is to use a 3D printing pen. It’s not as popular since it isn’t as effective as the other solutions, but it definitely has its uses for 3D printing.

It’s similar to the soldering iron in a way, but uses the heat from a 3D printing pen to join PLA plastic parts together.

The MYNT3D Professional Printing 3D Pen from Amazon is a great choice.

One user did mention how they used this specific 3D printing pen to weld pieces of prototype parts together since they were too big to print in one part.

You can get better results with “gluing” pieces together by applying heat from a hair dryer or heat gun. It’s a pretty quick solution since you don’t have to hold things for long periods of time to set.

You should try to use fairly high temperatures to achieve this as compared to what you would usually set, though heat controls for this 3D printing pen is really simple.

It can also be used to fix small imperfections and gaps in your other 3D prints which is very practical.

What is the Best Glue for ABS?

A popular product to glue ABS 3D prints is acetone because it is a solvent which can actually dissolve ABS then harden up again. When you apply acetone to both ABS parts then hold it together, the softened part will start to form a strong bond until it cures fully. This process is called solvent bonding.

When you apply acetone to both ABS parts then hold it together, the softened part will start to form a strong bond until it cures fully. This process is called solvent bonding.

Other great glues or adhesives you can use for ABS are:

- Superglue

- ABS Juice, Glue, Slurry

- Epoxy

- Polyurethane

- Hot Glue Gun

Superglue

As previously mentioned, superglue is great for rigid objects and plastics. You can apply some superglue to your ABS 3D print and have it glue together fairly quickly.

You want to ensure that your objects are aligned nicely before you apply the superglue though because once it cures, you won’t be able to realign it nicely.

ABS Juice, Glue, Slurry

Another great set of products is ABS juice, glue and slurry, which are very similar in characteristics but mainly differ in thickness. You mainly want to use ABS slurry which is the thickest of the three to repair ABS prints and help with gluing pieces together.

It’s also used as a way to repair layer separation.

Epoxy

Epoxies are a great method for bonding and gluing ABS plastic 3D prints.

One advantage of epoxies is that they are water and chemical resistant, making them a suitable choice for high-strength bonding. It requires no heat to cure, although if you want an accelerated result, you can apply heat.

Again, I’d go with the Loctite Epoxy Instant Mix from Amazon.

Hot Glue Gun

This is another fast way of gluing your ABS together. Simply load some filaments into the gun and use the heated extrusion to join the parts. It can also fill gaps. Ensure not to move the nozzle too close to the ABS to avoid melting.

Surface Preparation: It is important to prepare the surfaces of the ABS parts you want to glue by cleaning, degreasing, and sanding.

Caution: The precautionary measure against the dangers that can arise from using acetone is keeping it away from flame because it is highly inflammable. Also, use it in a ventilated space to avoid excessive inhalation.

What is the Best Glue for PETG?

The best glue for PETG is superglue since it holds the parts together strongly and still maintains the quality and integrity of the 3D print.

You won’t need to bother about clamping the parts together as it pretty quickly bonds together and cures fast. Loctite glue and gorilla glue is some of the best.

Other adhesives that can glue PETG are:

- Two-Part Epoxy

- Hot Glue Gun

- Solder Iron

Two-Part Epoxy

A two-part epoxy is pretty popular with 3D printer users to glue PETG parts together. They usually come with another container in the pack called the hardener or accelerator.

The two products are meant to be mixed together before applying it to the surface of the PETG.

Although, the curing time varies; some take 5 minutes, while some take more time. The combination of a hardener and the glue itself will make a long-lasting and strong bond between the parts.

Hot Glue Gun

Most of the tests that were carried out on PETG using a hot glue gun prove its ability to bond two PETG permanently.

Check out this video on YouTube where a series of tests were carried out on different adhesives and the hot glue gun was confirmed to be one of the most reliable.

Again, I’d recommend going with the Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks from Amazon.

Soldering Iron

A soldering iron with a temperature control option can glue PETG parts when used in melting the surfaces of the print. This process requires patience and it will yield good results in the end.

This process requires patience and it will yield good results in the end.

Ensure to wear a protective mask and goggle when using any of these adhesives. Use it in a ventilated area.

It works in the same way that it would with PLA, so you can watch the video in that section to see how you would do this with PETG.

What is the Best Glue for TPU?

The best glue for TPU is flexible superglue like Loctite 406 Superglue. It is designed in a way that allows it to bond rubber and flexible materials together with ease. The bonding and curing times of this glue is very quick and provides a strong bond which can’t easily be broken.

Other glues that work well with TPU are:

- Flexible Superglue

- DMF (N-Dimethylformamide)

- THF (Tetrahydrofuran)

- Soldering Iron

Flexible Superglue

A tried and tested product that works great to glue TPU 3D prints is the Genuine Loctite 406 Superglue Instant Adhesive from Amazon.

It has the following features:

- Rapid bonding with plastic and flexible materials

- Great adhesion of materials that are hard to bond

- Multi-purpose and works in many applications

- Very easy to use

It does have a pretty small margin of error, so you want to be very quick and accurate when using this stuff. It has an early bond strength said by users to be in just seconds, showing just how strong it is.

One user even bonded a broken rubber roller belt with this product. It’s best used to join TPU with another type of material like PLA. For TPU to TPU, it can still work well, but the solvents below are more efficient.

DMF (N-Dimethylformamide)

DMF is a solvent that can melt your two pieces of TPU or flexible filament together. When it comes to joining up TPU with another TPU 3D printed part, using a solvent is usually the best solution.

When it comes to joining up TPU with another TPU 3D printed part, using a solvent is usually the best solution.

THF (Tetrahydrofuran)

THF is another pretty strong solvent which dissolves TPU and allows you to bond two separate TPU prints by applying it on the surface and holding it together.

Soldering Iron

Similar to using a soldering iron for PLA and other materials, it can also be used for TPU and flexible 3D prints.

In the video below, he uses a soldering iron with a flat mouth to create a specific space for the TPU to be bonded together. He then filled it up with TPU filament and heated it up to let the parts soften and bond together.

After the TPU parts harden, it should create a very strong bond that can’t easily be pulled apart, unless the soldering wasn’t done accurately.

What is the Best Glue for Nylon?

The best glue for Nylon is a hot glue gun. Superglue doesn’t work as well with Nylon unless you have a flexible superglue. Many people have gotten great results when gluing Nylon with a hot glue gun. You can choose a method of heat like a soldering iron to bond Nylon 3D prints together.

Superglue doesn’t work as well with Nylon unless you have a flexible superglue. Many people have gotten great results when gluing Nylon with a hot glue gun. You can choose a method of heat like a soldering iron to bond Nylon 3D prints together.

Other methods you can adhere nylons are:

- Hot Glue Gun

- Soldering Iron

- 3D Printing Pen

You may think epoxy and superglue can work well on Nylon but it doesn’t have the same effect, mainly because of the flexibility and composition. You could do well with some of the flexible superglues mentioned in the TPU section above.

I’d recommend going with the hot glue gun or the soldering iron option. Another great method for “gluing” Nylon together would be a friction welding method which works with a rotary tool to heat up the surface and bond it together with friction.

It actually works pretty well for all sorts of materials, though you’ll want to keep safety in mind due to the dust and fumes it can cause. Some people even recommend combining the hot glue gun and friction welding method for even better results.

Some people even recommend combining the hot glue gun and friction welding method for even better results.

Another technique which isn’t talked about a lot of friction welding. You don’t need any kind of adhesive, but you do need a special tool to get this method working properly.

A Dremel Lite 7760 Cordless Rotary Tool from Amazon is a great product to use for friction welding.

Can You Use Superglue on PLA? What To Do If It Doesn’t Work

You can use superglue on PLA as a way to join parts together. It’s one of the best options for bonding PLA 3D prints, especially for smaller parts.

In some cases where superglue doesn’t work on PLA, it could be because:

- There are too many cavities or gaps where the parts are supposed to join together

- There was the presence of moisture or water on the surface which inhibits bonding

- The quality of your superglue isn’t at its best

- The PLA is exposed to heat which might break the bonding

If it doesn’t work, I’d recommend sanding the surface of both PLA parts to ensure a better fit. You want to use fairly low grit sandpaper like 120 grit to really prepare the surface to be glued together.

You want to use fairly low grit sandpaper like 120 grit to really prepare the surface to be glued together.

You also want to get another brand of superglue that cures faster and has better bonding properties, especially if your superglue is not very effective.

Does Contact Cement Work on PLA?

Yes, contact cement does work on PLA to glue 3D printed pieces together. It usually has a strong bond and also leaves you room for correction unlike with superglue.

Contact cement dissolves the surface of the PLA when applied and this process aids the bonding. A 3D enthusiast agreed with the fact that contact cement works on PLA, but you do need to use a good, reliable product that is known to work with your material.

When you follow the instructions of the specific contact cement you have, you should be able to have success in joining your parts together.

Best Glue for 3D Printed Miniatures (Minis)

The best glue for 3D printed miniatures is standard superglue (Cyanoacrylate). It provides a strong bond for your 3D prints and cures pretty quickly. You’ll usually have to hold the piece on the model for it to set, but you can use an activator to speed up the curing process.

It provides a strong bond for your 3D prints and cures pretty quickly. You’ll usually have to hold the piece on the model for it to set, but you can use an activator to speed up the curing process.

Accessibility is easy as compared to some solvents, it is very effective and easy to use, as well as being really cheap and long-lasting.

Other adhesives like epoxy work too, but they tend to have a longer curing time. There are definitely some quick-curing epoxies that you can make use of for minis, which many people have had success with.

Contact cement glue is another good option for plastic minis. They bond quickly too (although not as quick as glue) through melting and subsequent fusion. This bond is lasting and more durable than CA.

I wouldn’t use contact cement for very small minis because of the noticeable damage the corrosion will do to the parts.

How Do You Connect & Join PLA Filament Together?

It’s possible to connect and join two pieces of filament or even rolls of filament using a piece of a PTFE tube and a lighter. This is great for when you have small strands of filament left over from spools, which you can join end-to-end.

This is great for when you have small strands of filament left over from spools, which you can join end-to-end.

The method consists of pushing through the filament through the tube, lighting one end with a lighter so it’s softened, pulled it back through the PTFE tube and pushing the second piece of filament in the tube so it can then join together and harden.

The video below shows how it’s done very clearly.

On a final note, if you have followed the instructions above in terms of avoiding certain adhesives for certain materials (like superglue for nylons), you should be good to go by sticking to the recommended ones.

The Best Glue for PLA, PETG & ABS – Clever Creations

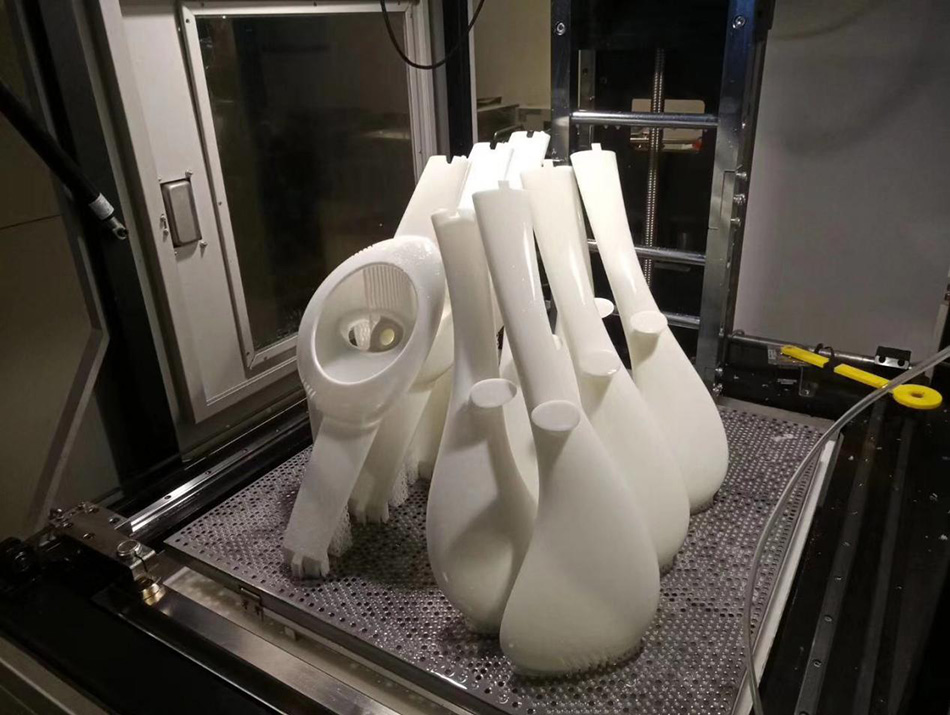

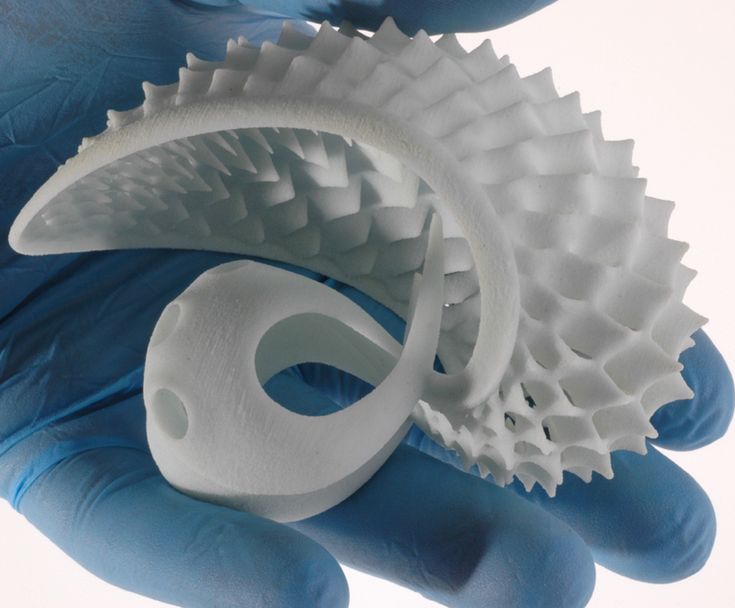

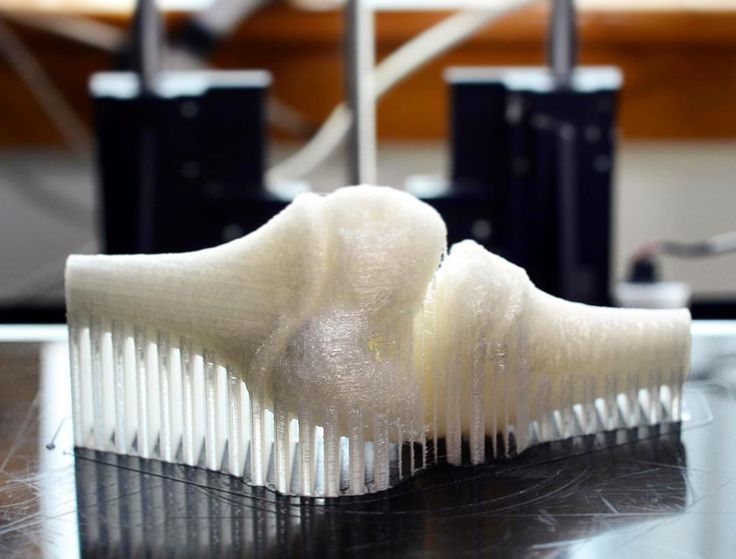

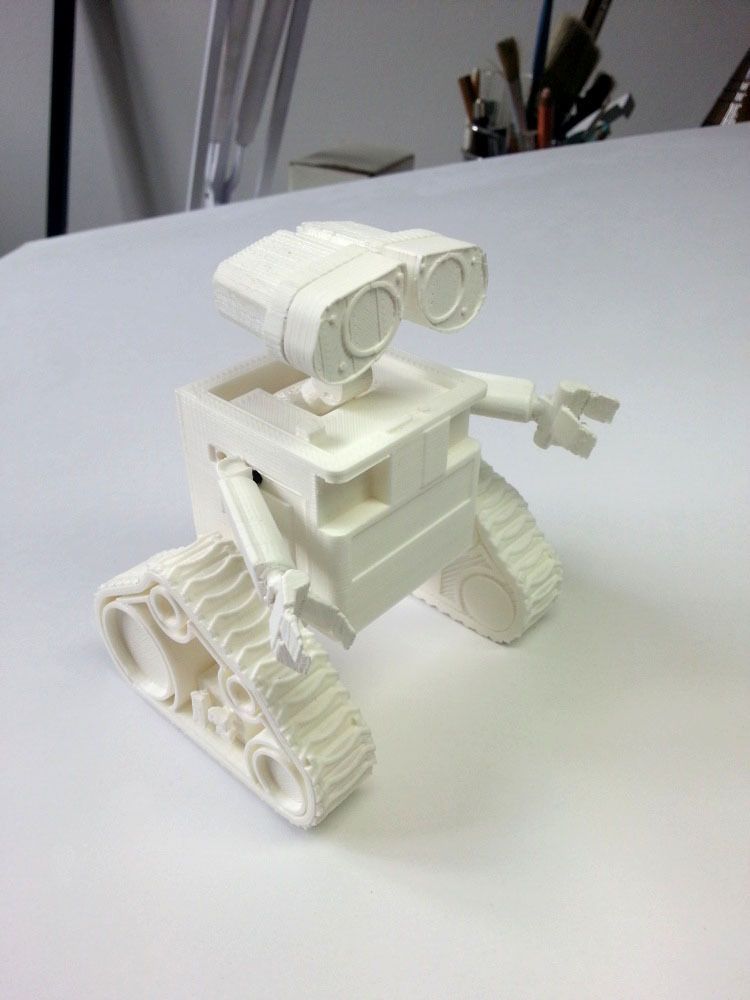

Gluing 3D printed parts together is something you will most likely have to do when you are starting to get into 3D printing. Maybe your printer’s build plate wasn’t large enough to print a model in one piece, or your print failed partway through and you are trying to fix it.

Maybe your printer’s build plate wasn’t large enough to print a model in one piece, or your print failed partway through and you are trying to fix it.

Whatever the reason for needing to glue 3D printed parts, there are a lot of things to consider before you get started. For example, choosing the right glue for your filament and project type. Gluing PLA, ABS, and PETG filament all prefer different adhesives.

If you aren’t sure which glues work on which materials, when to use one type of glue over another, and what brands are the best choice for each type of glue, keep reading! We’ve covered all of that and more in the sections below.

What Makes a Good Adhesive for Gluing 3D Prints?

While there are dozens of adhesives on the market, very few are suitable for gluing 3D prints together. 3D printing is a versatile technology that uses different types of materials to create prints that are used for a variety of applications. Most adhesives aren’t formulated to work with some of these materials and lack the properties needed for the finished print’s intended purpose.

First and foremost, any adhesive used for gluing 3D printed parts together should be formulated to work with the type of plastic the 3D print is made from. Commonly used 3D printing filaments are PLA, ABS, PETG, and TPU. Some adhesives contain chemicals that react poorly or do not bond well with certain types of plastic.

A good adhesive for 3D prints will form a strong bond between the parts, leave as small of a seam between the two parts as possible, dry quickly, and not produce a lot of heat while curing.

What is the Best Glue for PLA?

Super Glue (Cyanoacrylate)

The best glue for PLA filament is standard super glue or cyanoacrylate glue. It’s widely available, forms a strong bond between printed parts within seconds, and dries clear.

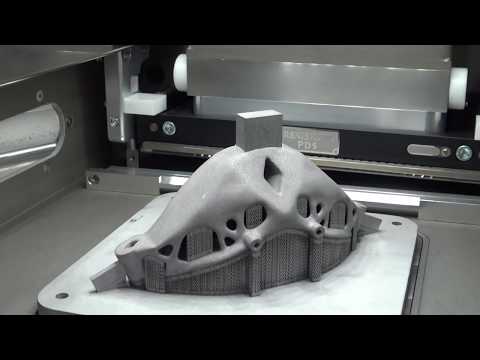

Image: Proto3000 via Youtube

Cyanoacrylate superglue is one of the best glues for PLACapable of bonding surfaces with very thin layers of adhesive, super glue lets you create flush seams that are easy to hide. It also doesn’t produce any heat while bonding, so there is no worry about it warping low-temperature filaments like PLA.

It also doesn’t produce any heat while bonding, so there is no worry about it warping low-temperature filaments like PLA.

One of the most common cyanoacrylate glue brands is Gorilla Glue, which is known for being one of the best glue products in its category. However, most super glue brands should suit your purposes just fine in this case.

Gorilla Super Glue Gel, 20 Gram, Clear, (Pack of 1)

55,323 Reviews

Check Price3D Gloop

An adhesive specifically made for 3D printing, 3D Gloop is a versatile glue that can be used in several ways. 3D Gloop comes with a built-in brush in its cap to easily apply it to 3D printed parts. It creates an ultra-strong bond between parts that mostly cures within an hour (and fully cures in six hours).

While this brand offers separate formulas for PLA and ABS, you can use either on both materials. This allows you to bond different materials together with little to no visible difference in the bond. However, when bonding the same materials together, you should try to use the glue formula for that type of material for the best results.

You can also brush 3D Gloop onto glass and mirrored print beds to help with print adhesion and eliminate warping. They don’t recommend using it on coated or PEI beds since it can permanently bond to the surface.

One consideration that should be made with 3D Gloop is that it needs to be used carefully. It produces fumes when uncured (and on the print bed) that should not be breathed in, so use in a well-ventilated area and/or with a respirator is ideal.

3D Gloop can also be an irritant, so you should wear gloves and safety goggles when working with it and try to avoid getting it on your skin. Using it requires similar precautions as when working with 3D printing resin and dealing with 3D printer fumes, so you might already have some of the equipment you need available.

Urethane Glues

With similar bond strength to superglue but with added flexibility, urethane glue is a great option for gluing PLA 3D printed parts together. They take several days (sometimes up to a week) to fully cure, however, so they are not a great option for projects that need to be finished quickly.

Urethane glues are popular in the construction industry and are made for both indoor and outdoor use. This makes them more resilient than other glues to things like moisture, freezing, UV light, and so on. If your 3D prints will spend time out in the elements, urethane glue is a good choice for bonding any seams.

They also produce some heat during their curing process. While it doesn’t reach the temperature needed to warp PLA, it may still affect small or thin pieces. Despite the curing process, urethane glues form a very strong bond between glued PLA plastic and are a favorite of many 3D printing enthusiasts.

Gorilla Original Gorilla Glue, Waterproof Polyurethane Glue, 8...

Check PriceHot Glue Gun

If you’re in a pinch and need to glue PLA parts together, using a hot glue gun will technically do the trick. Hot glue doesn’t have the same bond strength as other adhesives mentioned so far in this article, so it shouldn’t be used on anything that is going to have a lot of mechanical stress on it.

Hot glue is also quite thick and stringy, so it is hard to apply an even, thin layer. It is equally difficult to get a close seam with it, and you can expect your joins to be messy. On the other hand, it dries incredibly fast, so you don’t need to wait around for long cure times.

Recommended:

The Essential Guide to Hot Glue

The interesting thing about using a hot glue gun is that you can also melt PLA filament in it and use it as a rudimentary 3D pen. If you 3D print PLA cylinders in the diameter your hot glue gun uses, you can feed them through your gun like a regular glue stick for good results when gluing PLA parts together!

Image: Brodie via MyMiniFactory

3D printing a PLA glue stick let’s you glue with PLA!This will produce better results than traditional hot glue sticks, but the process can clog up your glue gun (especially cheaper ones) so don’t use it this way if you are concerned about switching back to plain glue after.

Gorilla Dual Temp Mini Hot Glue Gun Kit with 30 Hot Glue Sticks

Check PriceEpoxy Resin

Epoxy resin is another great PLA glue that can be used to join PLA plastic pieces. Usually sold as a two-part kit (the resin and a hardener), the components need to be mixed to start the curing process. How long they take to cure depends on the brand and can vary from minutes to days.

Usually sold as a two-part kit (the resin and a hardener), the components need to be mixed to start the curing process. How long they take to cure depends on the brand and can vary from minutes to days.

The Bob Smith Industries Quik-Cure Epoxy is a good choice for gluing PLA plastic since it starts to cure in five minutes, is mostly cured in 15 minutes, and reaches full cure within an hour. It is designed to be slightly flexible when cured, so like the urethane glues we looked at earlier, it is a good option for parts that need vibration dampening or impact resistance.

The bond strength on the epoxy resin is excellent, and it allows you to make very thin invisible seams. Most emit some heat during the curing process, so it is important to ensure it won’t reach the temperatures needed to melt your prints.

Bob Smith Industries BSI-201 Quik-Cure Epoxy (4.5 oz. Combined),Clear

Check Price3D Pen

A more sophisticated version of the process we outlined in the hot glue gun section, a 3D pen is a handheld device that melts and extrudes filaments. 3D pens can be used to pipe on melted PLA material and weld two parts together.

3D pens can be used to pipe on melted PLA material and weld two parts together.

One big advantage to this method is that you can use the same filament as the prints, making the seam less noticeable. In terms of adhesion strength, however, a 3D pen is not the best glue for PLA.

The bonds created with this method will most likely hold under most light applications, but the strength won’t be as good as other methods outlined on the list. This technique should not be used for joining parts that will undergo mechanical stress or impacts.

While you can find several different 3D pens currently on the market, the 3Doodler Create+ is our favorite. It works with both PLA and ABS, so you have a lot of versatility in what you can use your pen for. It also has a dual extruder motor to push the filament through on both sides for more even feeding.

3Doodler Create+ 3D Printing Pen for Teens, Adults & Creators! -...

3,493 Reviews

Check PriceSoldering Iron

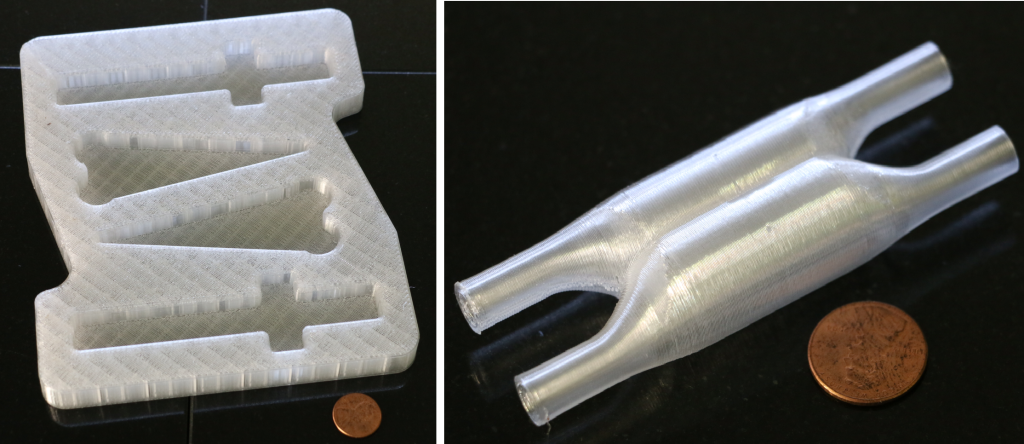

Image: ubcengphysprojectlab via Youtube

PLA welding with a soldering iron does not provide a lot of strengthAs a last resort, you can use a piece of PLA filament and a soldering iron to weld two PLA prints together. Using the tip of the soldering iron on the piece of PLA, you slowly melt the material along the line where the two parts meet. This process works better on something with a groove or curve to hold more PLA material, so this process is especially bad for adding two flat pieces together.

Using the tip of the soldering iron on the piece of PLA, you slowly melt the material along the line where the two parts meet. This process works better on something with a groove or curve to hold more PLA material, so this process is especially bad for adding two flat pieces together.

The most common use for PLA welding is trying to fix failed prints. Cracks, holes, and other issues can be somewhat resolved with PLA welding, so if you need to adhere split layers, this process is worth knowing.

However, for joining two separate 3D printed pieces, you are better off using one of the other solutions on this list. For this, a soldering iron is not optimal.

Weller WLC100 40-Watt Soldering Station

Check PriceHow to Glue PLA 3D Printed Parts

- Sand down any rough or uneven edges with sandpaper until the edges of the two pieces are flat.

- Make sure both surfaces are clean and free of debris. If you need to wipe them with a wet cloth or wash them with soap and water, make sure to dry them thoroughly before gluing.

- Apply glue near the center of the printed parts. Don’t apply it too close to the edges to avoid it getting on the outside of the print.

- Spread the glue with a toothpick, the nozzle of the glue bottle, or some other small applicator until the part is evenly coated.

- Carefully press the parts together, making sure they are properly lined up. Hold them together with your hands or a clamp until a strong bond forms.

What is the Best Glue for ABS?

Acetone

The best way to glue ABS prints together is with acetone. ABS is acetone-soluble, meaning it breaks down when it comes into contact with it. Spreading a small amount of acetone on both surfaces being glued will break down the outer layers of ABS. When these layers are pressed together, the edges will reform as a single piece. This is called solvent welding.

Not only is the bond between the two printed parts very strong with this method, but it also eliminates the seam where the two parts meet. If done properly, they will look and act like they were printed as a single part. This is ideal if you want to 3D print cosplay armor or make a 3D printed helmet.

If done properly, they will look and act like they were printed as a single part. This is ideal if you want to 3D print cosplay armor or make a 3D printed helmet.

However, using too much acetone on the edges can damage them and leave an ugly or unstable join. It is therefore important to have some practice before potentially wasting your best ABS filament.

Acetone also poses some risks while using. It has strong fumes, so you should keep your workspace well ventilated. It is also highly flammable, so take care around open flames and high temperatures.

While acetone works well with ABS, it can’t be used with most other plastics the same way. PLA isn’t acetone soluble like ABS, so you can’t use it to glue PLA prints together.

Recommended:

PLA vs ABS: Which Filament is Better?

ABS Plumber’s Cement

ABS Plumber’s Cement is a thick paste-like adhesive that works extremely well with ABS. Since it is solvent-based glue, it works like acetone to form a solvent weld in the ABS. This creates a very strong bond between the parts, but it won’t be as clean as acetone welding since the putty is colored.

This creates a very strong bond between the parts, but it won’t be as clean as acetone welding since the putty is colored.

While it is best used with ABS, a plumber’s cement can also work to glue PLA parts together. Since you can find it in most hardware and general stores, it’s an easy solution if you are in a pinch. However, it doesn’t work well with PETG plastic.

Oatey 30889 Medium Bodied Solvent Cement, 8 Oz, Can, Liquid, Black

Check PriceABS Juice / Glue / Slurry

Easy to make yourself from ABS scraps (supports, failed 3D prints, etc.), ABS juice, glue, and slurry are the byproducts of ABS dissolving in acetone. All three of these products are great for forming bonds between two printed parts.

ABS juice is a thin milky substance that is brushed onto build plates for better print adhesions. ABS glue is a bit thicker and is ideal for joining parts together. The ABS slurry is the thickest in consistency and is used to fill in gaps, cracks, and holes in 3D prints.

You can make ABS juice, glue, or slurry by adding scrap ABS to a container of acetone and letting it dissolve (eventually the acetone used for ABS smoothing turns into a slurry as well). The more scrap you add, the thicker the resulting adhesive becomes.

Since these glues are made from acetone and ABS plastic, they are solvent-based. They will work well on ABS and similar plastics using solvent welding, but they aren’t the best glue for PLA and PETG.

Other Glues

The other adhesives listed above for PLA will also work with ABS. Superglue, urethane glue, and epoxy resin all work just as well with ABS as they do PLA. The 3D Gloop brand even has a formula specifically for ABS.

While all of these products technically can be used for ABS, solvent welding with acetone will almost always produce the best results.

What is the Best Glue for PETG?

PETG is one of the harder plastics to post-process. Paints, glues, and other materials don’t bond well with even the best PETG filament, but some work better than others. Superglue, Gorilla glue, silicone glue, and epoxy resin all work relatively well with PETG. 3D Gloop’s PETG formula is also worth trying, as it is one of the few products specifically formulated for the material.

Superglue, Gorilla glue, silicone glue, and epoxy resin all work relatively well with PETG. 3D Gloop’s PETG formula is also worth trying, as it is one of the few products specifically formulated for the material.

Frequently Asked Questions

Can you superglue PLA?

Superglue is the best option for gluing PLA together. It bonds quickly and forms a strong, lasting bond. However, it won’t work as well with other 3D printing filament types like ABS. For those plastics, solvent welding tends to be a better option.

Does Gorilla Glue Gel work on PLA?

Yes. Gorilla Glue Gel is a water-based contact adhesive that is specifically designed to work on both porous and non-porous materials. It forms an instant, permanent bond on contact and can be used on a wide range of materials, including wood, metal, plastic, rubber, glass, and more.

PLA (polylactic acid) is a biodegradable thermoplastic made from renewable resources like corn starch or sugarcane. It is often used for 3D printing because it has a low melting point and does not release any harmful fumes when melted. Gorilla Glue Gel can be used to adhere PLA prints together or to attach them to a surface.

Gorilla Glue Gel can be used to adhere PLA prints together or to attach them to a surface.

Gorilla Super Glue Gel, 20 Gram, Clear, (Pack of 1)

55,323 Reviews

Check PriceAre there special glues for 3D printing?

Yes, there are some adhesives specifically designed for gluing 3D prints. The 3D Gloop products we mentioned above are some of the most popular options, but your glue doesn’t necessarily need to be formulated for 3D printing. Many standard glues and adhesives work just as well (if not better) on printed plastics.

What glues work with all filaments?

Basic adhesives like superglue, Gorilla glue, epoxy resin, urethane glue, silicone glue, etc. all work with most of the common filament types. While some will work better with certain filaments than others, you can use any of them for finishing your 3D printing projects if they are all you have available.

The most effective way to use them is to focus on the best in each category rather than to try to find a one-size-fits-all product. The best glue for PLA and PETG is super glue, while solvent welding is the best glue for ABS.

The best glue for PLA and PETG is super glue, while solvent welding is the best glue for ABS.

How do you bond 3D printed parts together?

The most common way to bond 3D printed parts together is with adhesives. Many different types of adhesives can be used, but the most effective ones usually contain cyanoacrylate (CA) molecules. These adhesives are fast-acting and can be used to bond parts together in a matter of seconds.

Another popular way to bond 3D printed parts together is through the use of screws and bolts. This approach is often used when assembling large or complex structures. By using screws and bolts, it’s possible to create assemblies that are much stronger than those that can be created with adhesive bonding alone.

Will plastic glue work on PLA?

It depends on the type of plastic glue you’re using. Some glues will work better than others on PLA, so it’s worth doing some research to find the right one for your needs. If you’re looking for a strong bond, we recommend using an epoxy or cyanoacrylate adhesive.

Final Thoughts

When you need to bond 3D printed parts together, there are several options to choose from. While your standard super glue and epoxies work well for most types of 3D printing filament, things like homemade ABS glues, PLA welding, and friction welding are just a few of the other ways you can join 3D prints.

Whether you need to piece together a large model, fix a failed print, or join two different materials together, understanding how each glue works with the different plastics will make sure your bonded 3D prints are as strong as possible. The best glue for PLA is Cyanoacrylate super glue.

Do you still have questions about how to glue PLA or other filaments? Let us know in the comments!

Testing liquid adhesives for adhesion

Technician

Subscribe to the author

Subscribe

Don't want

10

So we managed to assemble the whole team of liquid products to increase the adhesion of the table in 3D printing. And this means that Mnogo3D, obsessed with adhesion, is back with you. Picaso 3D glue, 3DM 3D glue and I made 4D glue gathered in our hands at the same time. The first two are already familiar to the readers of the portal according to the test "Adhesion means: professional versus amateur". The last one just arrived. And so we will do a test of who is capable of what. In order not to be bored, the glue stick "Kalyaka-Malyaka" and Eeeee ... Povidone on isopropyl alcohol will take part in the test. Kalyaka is the standard of adhesion and it is needed as a guideline. And povidone to debunk or confirm the myth that a professional remedy can be created at home.

And this means that Mnogo3D, obsessed with adhesion, is back with you. Picaso 3D glue, 3DM 3D glue and I made 4D glue gathered in our hands at the same time. The first two are already familiar to the readers of the portal according to the test "Adhesion means: professional versus amateur". The last one just arrived. And so we will do a test of who is capable of what. In order not to be bored, the glue stick "Kalyaka-Malyaka" and Eeeee ... Povidone on isopropyl alcohol will take part in the test. Kalyaka is the standard of adhesion and it is needed as a guideline. And povidone to debunk or confirm the myth that a professional remedy can be created at home.

Since the last test, we have diluted our "Nurofen", bringing the concentration to approximately 1 sachet of medicine per 0.5 liter of alcohol. And very thoroughly mixed, getting rid of the flakes. Thanks for the recommendations on finalizing the solution to Ilya Pinchuk and advice on the test in general.

This time we decided not to test on nylon, ABS is enough. For the purity of the experiment, we will carry out the test on the material from two manufacturers. Black is Chinese, sold under the Good3D brand, and gray is from REC.

For the purity of the experiment, we will carry out the test on the material from two manufacturers. Black is Chinese, sold under the Good3D brand, and gray is from REC.

Disclaimer: I express my gratitude to the portal 3DToday because 3DM glue, as well as REC gray plastic are winnings in competitions held by him. Let's not forget Top3DShop either. Glue Picaso provided by them for the last test free of charge.

4D glues "I made" and "Kalyaka-malyaka" were bought from office. dealers without informing about the intention to conduct testing.

Introducing the participants. Glue from Picaso and 3DM are longtime players in the 3D printing market. Their composition is declared the same: Water, Isopropyl alcohol, P-complex and flavor. But manufacturers are different. 3DM smells stronger of alcohol. Either they saved on the fragrance, or the spirit was vigorous. 4D glue "I made" is different. In its composition, PVP is immediately indicated. It has a yellowish tint and is thicker. The smell of alcohol is less noticeable. On the contrary, there is a pronounced woody smell. Apparently the wombat is on the label for a reason. All three are supplied in 250 ml squeeze bottles. "I did" is also available in 100 ml bottles.

The smell of alcohol is less noticeable. On the contrary, there is a pronounced woody smell. Apparently the wombat is on the label for a reason. All three are supplied in 250 ml squeeze bottles. "I did" is also available in 100 ml bottles.

Homemade remedy is simpler and cheaper. In a pharmacy, we buy a sachet of medicine Enterodez 5 grams with the active ingredient POvidone and dissolve it in 0.5-1.0 liters of isopropyl or ethyl alcohol. Doesn't dissolve well. Therefore, you need to periodically shake the bottle until the flakes disappear. Why Povidone and where does the pharmacy?! It's simple, PVP is polyvinylpyrrolidone. And its other name is just povidone or polyvidone. This substance has a very wide range of applications in medicine and chemistry. But it is one thing to know the composition, and another to know the recipe. In the last test, homemade did not show itself in any way. Let's see what happens this time.

Magic glue stick "Kalyaka-Malyaka" is also not simple and has its own legends. We took several briquettes of this glue. we prefer this particular method of adhesion and can debunk a few more myths about it. Actually everything is in the photo.

We took several briquettes of this glue. we prefer this particular method of adhesion and can debunk a few more myths about it. Actually everything is in the photo.

Even in one briquette there are tubes of different shades of yolk with contents of different shades of pink. Also different ends of the glue. Some are pointed, while others are flat. And all this in one sealed pack from the dealer.

And so... to the test!

Test piece:

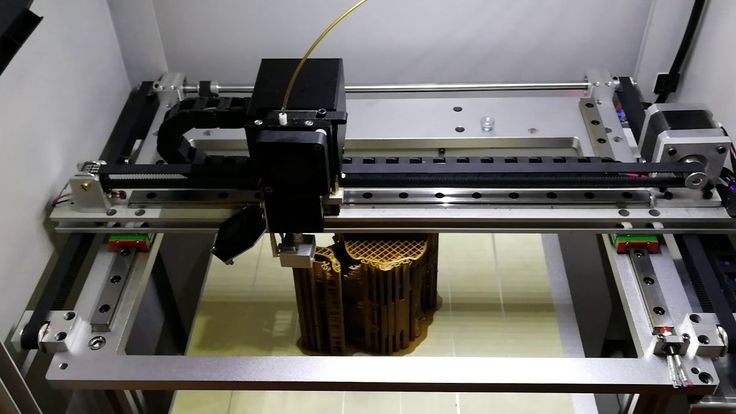

Frame with 0.8mm wall, 15x150mm, 50mm high. We print with a nozzle of 0.8 mm and a layer of 0.3. The first layer is 50% of the base layer height. Speed up to 50 mm/sec. Brim at 5 perimeters. Printer open Corexy with ball screw. The temperature in the room is 22-25 degrees, without drafts. The surface is a mirror. The conditions are deliberately set to be unrealistic, so that it would be easier to evaluate the result by the amount of printed material.

The idea was to put 4 parts side by side and see what happens.

But the idea turned out to be so-so. A part that went out of the way caused the test to stop. Here, either apply the Olympic system, or test it for a long time and dreary piece by piece.

We settled on the last method and started printing the same code with different adhesives. Accordingly, they waited for the platform to cool down, washed it, dried it, degreased it with pure alcohol, dried it, and applied the composition.

Contrary to advertising, one coat of compound does not work! Not even two work. Applying a large amount is also not an option. You need at least three layers. And for 3DM, even three layers do not work. In this regard, for the outsiders of the first round, the adhesives 3DM and "I did" were given a second chance to prove themselves. In the second attempt, only 3DM was given a second chance. The concentration of the substance, apparently, is less in it. Therefore, after a failed attempt on 3 layers, the printing was repeated on 4. The difference, as they say, is "on the face. " Assigned seats are our subjective decision on typing comfort. And it wasn't easy. You run the test. You control that the brim began to stick to the table. If the composition is small, then a new layer of the composition was applied and the test was started again. If the print has gone, then you sit and wait for the coveted click and crackle of the extruder on skipping steps. You fix the % of the task completion and the separation. Stop printing. Table cooling, washing, drying and new. Over 100 photographs were taken. Let's show some.

" Assigned seats are our subjective decision on typing comfort. And it wasn't easy. You run the test. You control that the brim began to stick to the table. If the composition is small, then a new layer of the composition was applied and the test was started again. If the print has gone, then you sit and wait for the coveted click and crackle of the extruder on skipping steps. You fix the % of the task completion and the separation. Stop printing. Table cooling, washing, drying and new. Over 100 photographs were taken. Let's show some.

Picasso 1st attempt.

Most printing stopped within 30-50%. The best results were shown only by "Kalyaka-Malyaka".

3DM glue and its 3rd attempt.

It should be noted that REC plastic, unlike Good3D, is more rigid and more prone to delamination. On it, the subjects showed poorer results. In particular, in the second attempt, when printing on a painter, the plastic tore the brim, and not completely tore it off, as in all other cases.

And almost broke another corner

Well, actually the results.

And in tabular form:

Thanks for reading.

Sincerely, Mnogo3D (3D printing in Ryazan and beyond)

PS Eta4Ever was the first in our VK mini-survey to guess which of the trinity of liquids is the best. Cool!

adhesion glue

Follow author

Follow

Don't want

10

ATECO BASIC - adhesive for 3D FDM printing

ATECO basic

best adhesion for base materials

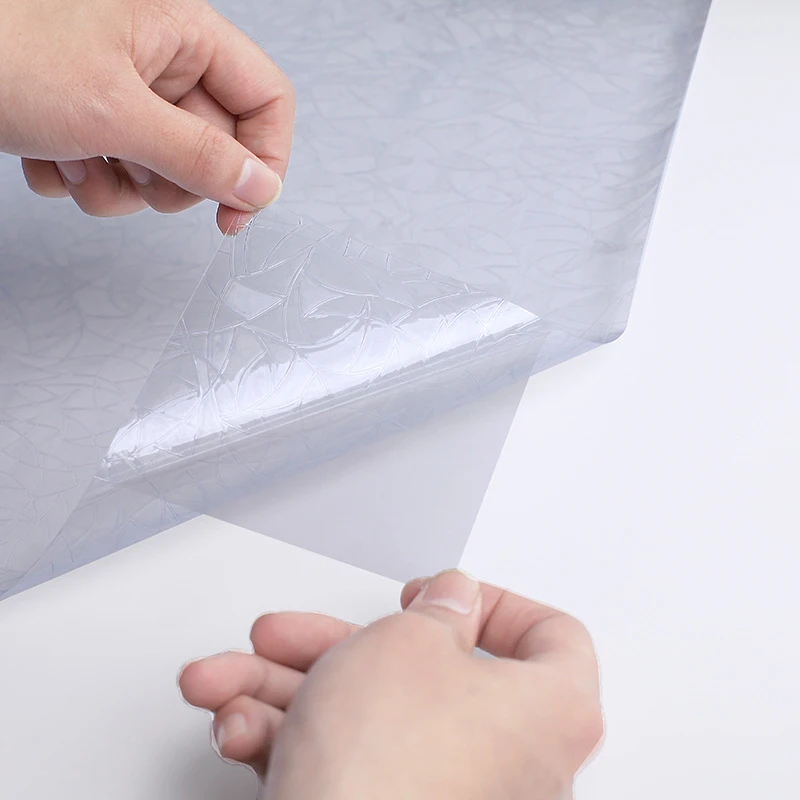

Adhesive varnish is designed to create adhesion between the first layer of the model and the 3D printer desktop. It works only on a hot table, when the surface on which the adhesive is applied cools, the adhesion weakens and allows you to remove the finished product from the printing table. It is a clear, alcohol-based liquid that can be easily washed off with water.

Harmless

Contains no harmful substances and is completely safe when used as directed.

fast application 2-5 sec

The adhesive is applied to a cold working table before heating. After application with a lint-free cloth, the desktop is ready for printing in just a few seconds.

thin adhesive layer

After applying the adhesive, a very thin polymer film is formed that is difficult to see with the naked eye. With proper uniform application, you can achieve a perfect glossy surface of the lower layer of the model.

wide range of materials

Ateco BASIC 3D printing adhesive has been tested on a wide range of base materials such as PLA, PETG, ABS, HIPS, TPU, ULTRAN, CARBEX, CREADUR.

approved by 3D printing experts

Our adhesive has been tested and recommended by leading 3D printing studios and 3D printer manufacturers.

hot bed

When used on hot bed of 3D printer

* bed temperature may vary depending on the materials the user is printing on

60℃

to 135℃

A variety of volumes for everyone

We made different volumes because different people have different needs, and whatever you don't overpay, you can take just such glue by volume that is most convenient for you.

Volume 100 ml - very compact and does not take up much space, suitable if printing is not frequent or you want to take it with you on a trip.

The 250 ml capacity will last you for a long time, according to the survey and the reviews collected, this is the best adhesive in terms of price and quality.

400 ml - a volume for luminaries of 3D printing, it lasts for a long time and is designed as an aerosol can, due to which the consumption is reduced without excessive spraying.

* one application is enough for 3 to 10 prints depending on the thickness of the application and differences in the geometry of the models

100 ml

250 ml

400 ml

ATECO BASIC

Adhesive adhesive for FDM printing with base materials, allows you to securely fix the first layer on the printing platform and is suitable for printing on hot flat surfaces:

- Glass

- Metal (aluminium, steel)

- Basalt

- PEI

The number of surfaces may be more, the list is constantly updated as tests are carried out.