Stratasys 3d printing materials

3D Printing Materials & Filaments

3D Printing Materials & Filaments - Stratasys Stratasys Invests in Axial3D to Make Patient-Specific 3D Solutions Available to All - Learn MoreUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

3D printer materials and filament.

To ensure ultimate performance and quality, we provide a robust range of advanced 3D printing materials and filaments in the below three distinctive tiers:

- Stratasys Preferred: Preferred by Stratasys for its customers for the highest performance applications. These materials are engineered to provide the best combination of material and printer performance and are developed either by Stratasys or third-party material partners.

- Stratasys Validated: Materials validated by Stratasys with basic reliability testing to accelerate the expansion of material options available in the marketplace. These materials may or may not be exclusive to Stratasys.

- Open: Unvalidated materials accessed via an Open Material License (OML). These materials may offer unique attributes and the potential to address new applications but they have not received validation testing or optimization relative to performance and functionality on a Stratasys printer.

Specifically created for tooling, functional prototyping, jigs & fixtures and end-use production parts, the Stratasys materials & filaments meet the most demanding industry standards.

Make sure it's always the best.

The Stratasys Aircraft Interiors Solution gives aerospace companies a faster, more streamlined process.

Learn more

Make it as vibrant as your ideas.

With its exquisite detail and unsurpassed realism, Stratasys’s range of clear, flexible and rigid PolyJet materials can help you 3D print prototypes that look and feel like the final product.

Learn more

"Time is our greatest enemy. With the Stratasys F370, we can spare more resources for other complex designs, saving logistic and prototyping costs and time. Developing a drone used to take up to a year, now we have it down to around eight months.

"

"Guy Nickless, R&D director, Toy State International

Learn more

Explore all our materials

Explore all

Want to consult a materials expert?

Contact Us

Stratasys announces two new composite 3D printers, 16 new materials, and software updates

0Shares

3D printer manufacturer Stratasys has announced a slew of new developments for its additive manufacturing business.

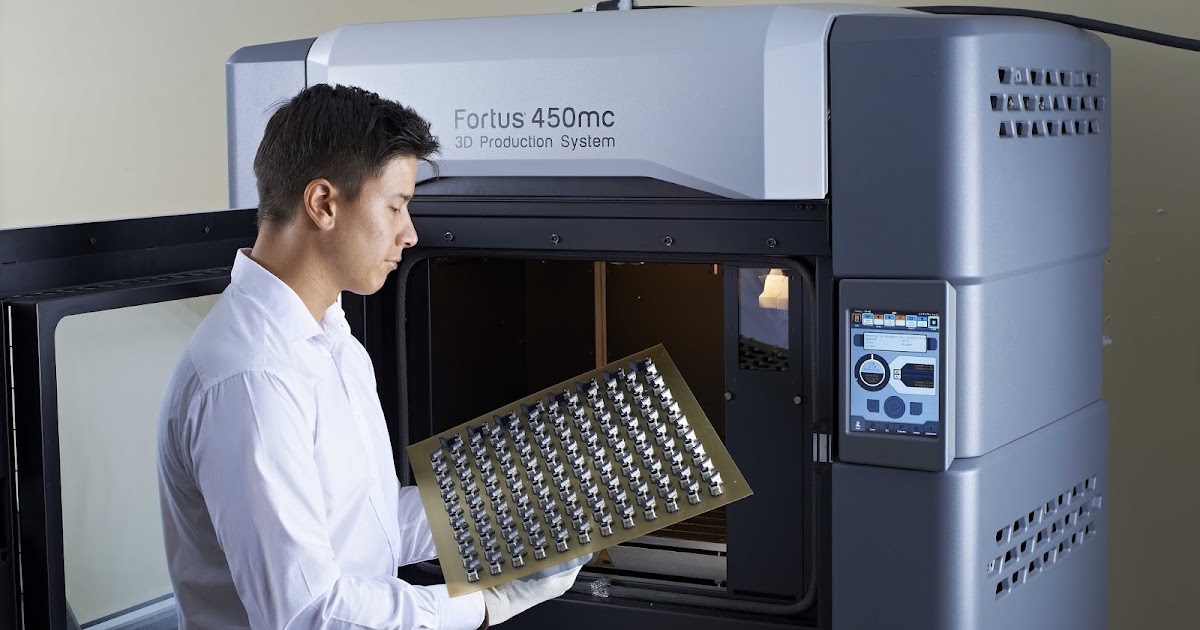

The mass launch includes two new industrial FDM 3D printers, the F190CR and F370CR, which are designed for high-strength composite parts. Stratasys is also launching a total of 16 new 3D printing materials across its FDM, P3, and SAF technologies. As a bonus, the firm has also introduced GrabCAD Print software for the Stratasys Origin One and Origin One Dental 3D printers.

The Stratasys F190CR 3D printer. Photo via Stratasys.The F190CR and F370CR

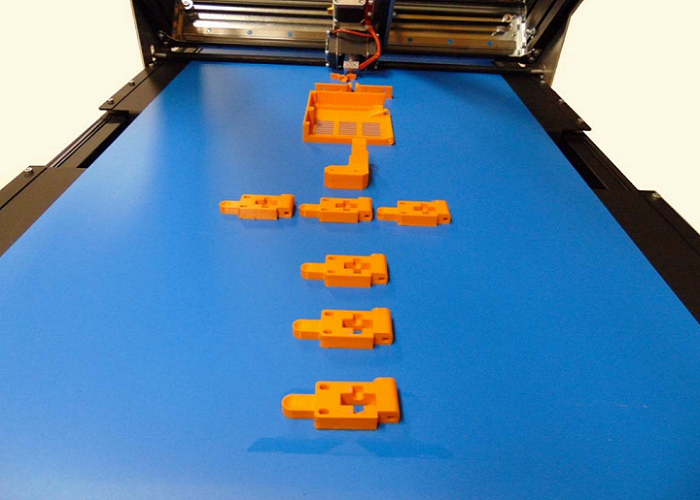

The latest additions to Stratasys’ F123 product line are the F190CR and F370CR. Both composite FDM systems are designed to print with high-stiffness, high-strength engineering materials, enabling applications such as jigs, fixtures, workholding tools, and other high-performance end-use parts.

The F190CR is the smaller of the two, sporting a build volume of 305 x 254 x 305mm. It features two filament spool bays (one model, one support) and is capable of processing Stratasys’ ABS-M30, ASA, FDM TPU 92A, ABS-CF10, and FDM Nylon-CF10 materials.

On the other hand, the larger F370CR boasts a build volume of 355 x 254 x 355. The system comes equipped with four filament spool bays (two models, two supports) with auto material changeover functionality, allowing for multi-material prints with PC-ABS, Diran 410MF07, ABS-ESD7, and more.

Both 3D printers feature reusable build trays, built-in cameras for remote monitoring, and 7” full-color touchscreens. They also include integrated GrabCAD Print software and enterprise application connectivity via the MTConnect standard.

Dave Thompson, VP of Worldwide Engineering and Customer Care – Contractor Equipment Division for Graco, said, “Over the years we have grown our fleet of Stratasys printers and expanded our applications beyond prototyping to tooling, fixtures and grippers for our robots. The new Stratasys F370CR printer will allow us to bring our AM applications to a new level, extend the life of our tools and even provide for a better surface finish.”

Carbon fiber composite part 3D printed on the F190CR. Photo via Stratasys.

Photo via Stratasys.16 new 3D printing materials

Stratasys has also announced the launch of 16 new materials across three of its additive manufacturing technologies: FDM (6), P3 (8), and SAF (2).

The FDM list includes Arkema/Kimya PEKK-SC, a PEKK based on Arkema’s KEPSTAN; VICTREX AM 200, a semi-crystalline LMPAEK; Covestro PA6/66 GF20 FR, a flame-resistant glass fiber composite; Kimya PC FR, a flame-resistant polycarbonate; HIPS high-impact polystyrene; and Stratasys’ own FDM Nylon-CF10, a new carbon fiber composite for use with the F190CR and F370CR.

Customers using the P3-based Origin One 3D printer also have access to open materials through the annual Open Material License (OML) introduced by Stratasys last year. The OML program has just been bolstered with eight new resins suitable for molding, casting, high-temperature, ceramic, ESD, and elastic applications. They can be purchased directly from the materials developers: Covestro, Evonik, Arkema, Forward AM, Mechnano, Tethon 3D, Liqcreate, and polySpectra.

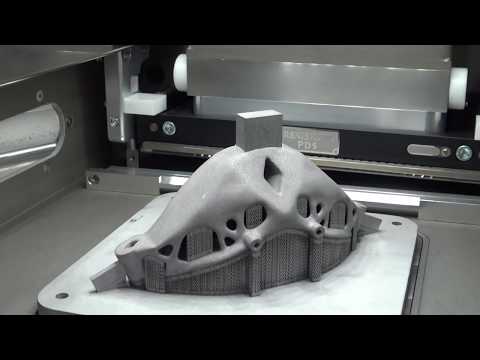

Stratasys has also announced two new materials for use with the h450 3D printer, which operates on the firm’s SAF technology. PP is defined by its ductility and chemical resistance, while PA12 is the most widely-used polymer powder in industrial 3D printing.

Some of Stratasys’ new Origin materials. Photo via Stratasys.GrabCAD Print for the Origin One

Finally, Stratasys has introduced GrabCAD Print for the Origin One and Origin One Dental 3D printers. As a piece of the GrabCAD Additive Manufacturing Platform, GrabCAD Print is a comprehensive slicing software designed to make print preparation as easy as possible.

Now compatible with the Origin systems, resin customers will be able to leverage the software’s automatic support generation tools, labeling functionality, native CAD file support, printer status monitoring, and build scheduling functionality.

Ronen Lebi, Vice President, Head of Production (P3) for Stratasys, said, “After being acquired by Stratasys, customers told us that the ability to use GrabCAD Print should be a top development priority. Today we are happy to announce that we’re able to bring the productivity and simplified workflow of GrabCAD Print to that rapidly growing community of Origin One users.”

Today we are happy to announce that we’re able to bring the productivity and simplified workflow of GrabCAD Print to that rapidly growing community of Origin One users.”

To complement the GrabCAD integration, Stratasys will also begin offering Origin One Local, a new on-premise printer configuration, and the Origin One ProAero air extractor system for use in enclosed spaces. GrabCAD Print for Origin One, Origin One Local, and Origin One ProAero are all expected to launch in h3 2022.

The Stratasys Origin One 3D printer. Photo via Stratasys.Technical specifications and pricing

Below are the technical specifications for the F190CR and F370CR 3D printers. Visit the Stratasys store page to request a quote.

| F190CR | F370CR | |

| Build volume | 305 x 254 x 305mm | 355 x 254 x 355mm |

| Filament bays | Two | Four |

| Machine size | 1626 x 864 x 711mm | 1626 x 864 x 711mm |

| Weight | 227kg | 227kg |

| Heated chamber | Yes | Yes |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Stratasys F190CR 3D printer. Photo via Stratasys.

Tags Arkema Covestro Dave Thompson Evonik F190CR F370CR Forward AM GrabCAD print Liqcreate Mechnano Origin One Origin One Dental polySpectra Ronen Lebi Stratasys Tethon 3D

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

3D printing services on Stratasys Connex3 Objet260

Intrasoft JSC offers 3D printing services on Stratasys F270 and Stratasys Connex3 Objet260

3D printer Stratasys Connex3 Objet260 prototype. For parts that require a wide range of mechanical, optical or thermal properties (for example, multi-layer casting, the production of transparent covers, flexible joints or heat-resistant surfaces).

For parts that require a wide range of mechanical, optical or thermal properties (for example, multi-layer casting, the production of transparent covers, flexible joints or heat-resistant surfaces).

The Objet260 Connex3 professional resin 3D printer can use a wide range of materials in a single job to create realistic prototypes without the need for unnecessary assembly and post-processing.

Applications Objet260 Connex3

- Instrumentation - for making molds using inserts with complex internal cooling channels;

- Architecture and design - to quickly create accurate and visual models, layouts and compositions;

- Industry (aerospace, defense, automotive industry) - modeling and high-precision prototyping of various samples, parts, improvement of drawings, innovative developments;

- Advertising, marketing - creation of mockups, three-dimensional models, samples of commercial products;

- Education - the creation of test, educational and training products that most accurately repeat the physical and geometric properties of real objects.

Objet260 Connex3 3D Printer Features

Print technology:

PolyJet Matrix Layer-by-layer deposition of photopolymer materials, with the possibility of simultaneous use of two modeling materials with different properties.

Supported materials

3D base materials:

Vero family color opaque materials:

- VeroGray (RGD850) 90)

- VeroBlue (RGD840) (blue)

- VeroBlackPlus (RGD875) (black)

- VeroCyan (blue)

- VeroMagenta (Purple)

- VeroYellow (yellow)

- VeroBlack (black)

- VeroWhitePlus (white)

- Vero PureWhite, a brilliant white 20% brighter than VeroWhitePlus and half as transparent

Digital Materials:

- Hundreds of composite materials can be made on the fly, including:

- Bright mixed colors of rigid and opaque material

- Translucent color shades

- Elastic materials in various Shore hardnesses

- Digital ABS materials for durability, including blends with rubber

- High temperature resistant polypropylene materials

Construction area size (maximum model size): 255 × 252 × 200 mm

T layer thickness: 16. 30 µm

30 µm

Axis resolution: X-axis: 600 dpi (42 µm) ; Y-axis: 600 dpi (42 µm) ; Z-axis: 1600 dpi (16 µm).

Accuracy: 20-85 µm for parts up to 50 mm; up to 200 µm for full-size models (only for solid materials, depending on geometric parameters, axes parameters and model orientation).

Print modes:

High Speed - speed up to 20 mm/h, layer thickness 30 µm, work with one material,

High Quality (high quality) - layer thickness 16 µm, speed up to 12 mm/h, work with one material,

Digital Material (DM) (composite material) - production of models from a mixture of 2 materials, layer thickness 30 microns.

Software

Supported file formats: STL, SLC and objDF File

Learn more and calculate the cost: +7 812 363-14-09, [email protected]

Also see 3D printing services and samples of finished products on the Stratasys F270 printer

Stratasys

Add to favorites

Add to compare

Go to the Stratasys website for more information

Specifications

- Printing materials

- for plastics

- Technology

- PolyJet

- Applications

- Automotive, Electronics, Prototyping, Medical

- Other Features

- High Performance, High Speed, Colour, Auto-Stop, Heated Cab

- Stroke

-

255 mm (10 in)

- Stroke Y

-

252 mm (10 in)

- Stroke Z

-

200 mm (8 in)

- Layer thickness

-

14 µm

- Weight

-

234 kg (516 lb)

Description

matches with versatility. In the time it takes to make a single prototype using traditional methods, you can get 5 times more design iterations with the J826 3D printer. The printer's compact design holds seven materials, allowing you to load your most commonly used resins and avoid downtime due to material changes. Plus, you can quickly print every design with Super High-Speed, a fast-paced workflow that lets you design, test, and refine a prototype in days, not weeks. For design With over 500,000 unique colors, realistic texture simulation, flexible and transparent materials, and a click-to-print workflow, the J826 and J850 Prime 3D printers are the most versatile full color printers on the market. For engineering From effective concept models to functional testing and single color multi-material prototypes, the J850 Pro is the perfect engineering solution to help you speed up form and fit verification. Design Applications Consumer goods With thousands of unique shades, including over 600,000 PANTONE® verified colors and a full range of opacity, the only limit is your imagination.

In the time it takes to make a single prototype using traditional methods, you can get 5 times more design iterations with the J826 3D printer. The printer's compact design holds seven materials, allowing you to load your most commonly used resins and avoid downtime due to material changes. Plus, you can quickly print every design with Super High-Speed, a fast-paced workflow that lets you design, test, and refine a prototype in days, not weeks. For design With over 500,000 unique colors, realistic texture simulation, flexible and transparent materials, and a click-to-print workflow, the J826 and J850 Prime 3D printers are the most versatile full color printers on the market. For engineering From effective concept models to functional testing and single color multi-material prototypes, the J850 Pro is the perfect engineering solution to help you speed up form and fit verification. Design Applications Consumer goods With thousands of unique shades, including over 600,000 PANTONE® verified colors and a full range of opacity, the only limit is your imagination.