Prague 3d printer

Original Prusa 3D printers directly from Josef Prusa

Our 3D Printers

Price quote request

Are you considering Original Prusa 3D printers for your classroom, school, library, university or maker space?

Our specialists are here to assist you throughout the whole buying and information-gathering process. To get in touch with us, please fill out the form below and we will take it from there.

Contact us

Bestsellers

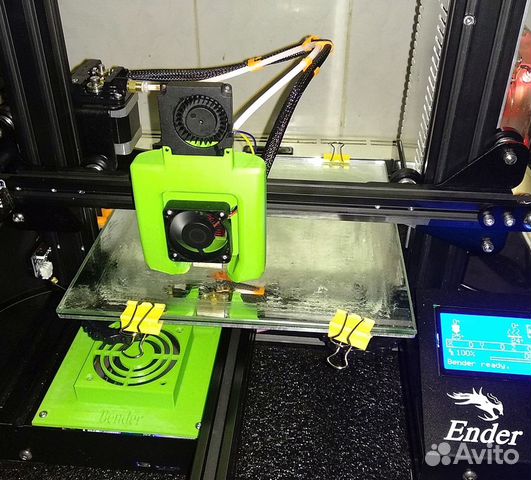

Original Prusa i3 MK3S+ kit

Leadtime 3–4 weeks

€849 with VAT

Choose variant

Original Prusa i3 MK3S+ 3D printer

Leadtime 1–2 weeks

€1,159 with VAT

Choose variant

Prusament PETG Prusa Galaxy Black 1kg

In stock

€29.99 with VAT

Double-sided Textured PEI Powder-coated Spring Steel Sheet

In stock

€39.

99 with VAT

Original Prusa MINI+ Semi-assembled 3D Printer

Leadtime 1–2 weeks

€489 with VAT

Choose variant

Prusament PETG Prusa Orange 1kg

In stock

€29.99 with VAT

Prusament PETG Jet Black 1kg

In stock

€29.99 with VAT

SuperPINDA

In stock

€25.99 with VAT

Spring Steel Sheet With Smooth Double-sided PEI

In stock

€34.99 with VAT

Prusament ASA Sapphire Blue 850g

In stock

€29.99 with VAT

Prusament ASA Lipstick Red 850g

In stock

€29.99 with VAT

Prusament PLA Blend Pearl White 970g

In stock

€29.99 with VAT

Hello, we are Prusa Research!

And we make more than just amazing 3D printers!

Read our story

Prusa Services

Printables.

com

comDiscover thousands of great printable 3D models

Downloads

Get the latest firmware and apps

Forum

Discuss 3D printing topics with the community

Prusament

Affordable filament for everyday printing in premium quality

Help

Assembly and troubleshooting guides, technical documentation

Blog

3D printing highlights, tips and interviews all in one place

E-Book: Basics of 3D Printing

This book will help you understand what kinds of 3D printing technologies are currently available and how they work. We will take you through the whole process of 3D printing.

I don’t agree with subscribing to newsletterand I want to buy the e-book for 5 USD / 5 EUR.

News from the blog

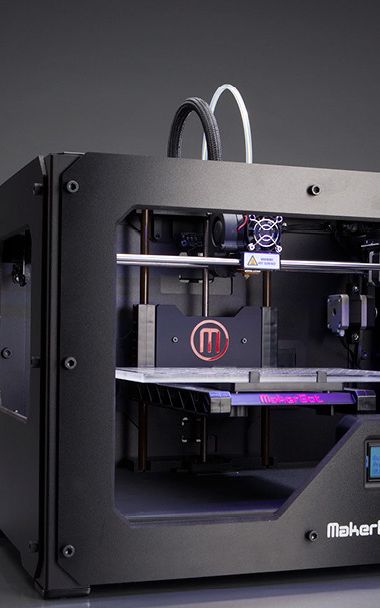

Our printers continue to collect great reviews and awards all around the world. Original Prusa i3 MK3/S is the best 3D Printer in the Ultimate Guide to Digital Fabrication by MAKE: Magazine and our printers also received several editor's choices and awards from respected media outlets like All3DP, PC Mag, Tom's Hardware, TechRadar, Forbes, WireCutter, Windows Central and many more!

When we weigh up the price, performance, reliability and overall product, it is highly recommended for most people to purchase because it does things so well.

– 3D Printerly ReviewThe preassembled version of the Original Prusa i3 MK3S is a cinch to get up and running, is easy to operate, and has a good slicing program. It produced consistently beautiful prints in our testing, with no misprints.

– PC Mag ReviewOf the 11 printers we have tested over the past five years, the Prusa i3 MK3S printer has produced the largest and best-looking prints.

– THE NEW YORK TIMES REVIEW

We tested it using its default settings and found it extremely capable. Its print quality is truly exceptional and it’s an easy-to-use, straightforward machine.

– All3DP MK3S ReviewThe team at Prusa Research have made something special with the MK3. If you only ever own one printer, make it this one. Of course, once you buy it you will want more of them, and that's ok too.

– Windows Central ReviewIt is the most well-made resin printer that I have and it objectively produces the best prints.

– The Prusa SL1S redefines SPEED!

3D printers | Original Prusa 3D printers directly from Josef Prusa

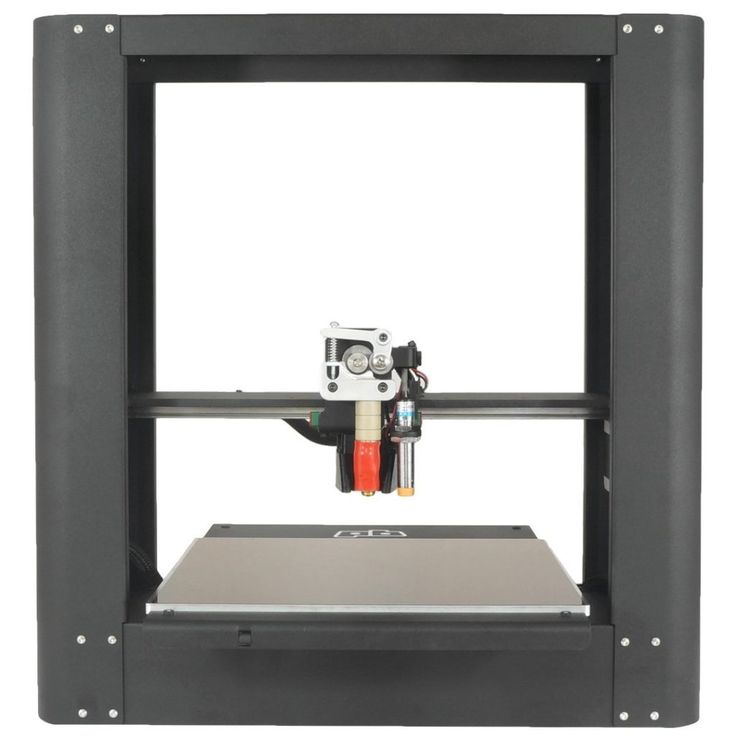

Original Prusa i3 MK3S+

Buy now

from 799 USD /

849 EUR (VAT incl.)

Original Prusa SL1S SPEED

Buy now

from 1,999 USD /

1,979 EUR (VAT incl. )

)

Original Prusa

MINI+

Buy now

from 429 USD /

459 EUR (VAT incl.)

How to Choose a 3D Printer?

Are you just entering the world of 3D printing, feeling overwhelmed by the volume of new information? Check our article on How to choose a 3D printer, which will guide you through all the basic terms and help you make the right choice according to your priorities.

Read our in-depth guide

Looking for a inspiration?

Wondering what you can print of 3D printer? Check out the Printables.com database. You will find a vast selection of toys, games, decorative items, practical things for your workshop or household, and even simple medical tools. All these models are available for a free download!

Browse Printables.com

3D Printing Case Studies

In the Prusa Stories, we showcase various examples of professional use of our printers. There are both small businesses and huge companies, museums, hospitals, filming studios…something for everyone, really, and we keep adding more!

There are both small businesses and huge companies, museums, hospitals, filming studios…something for everyone, really, and we keep adding more!

Check out Prusa Stories

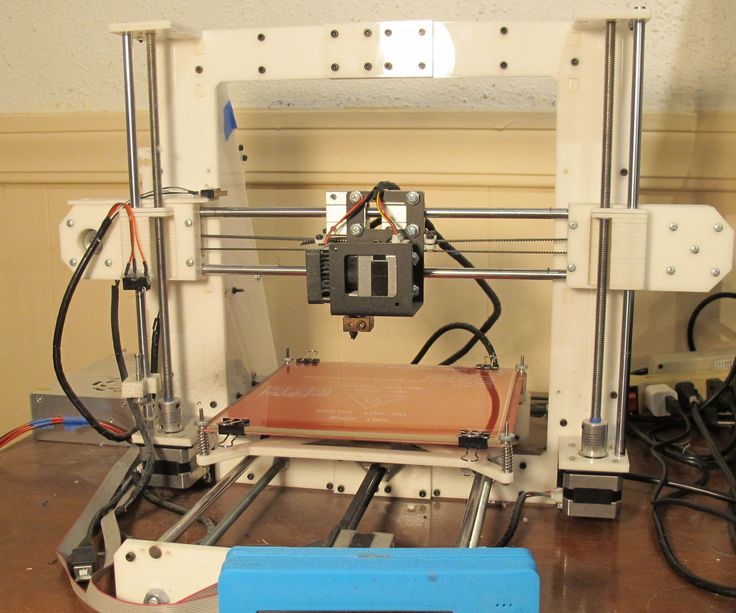

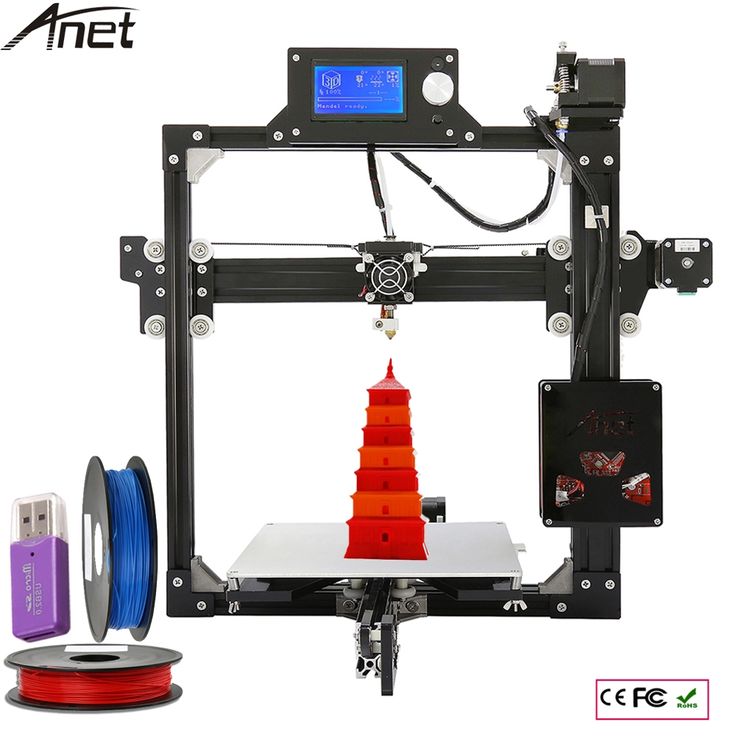

FFF vs SLA Basic Comparison

Original Prusa i3 MK3S+ (FFF printer)

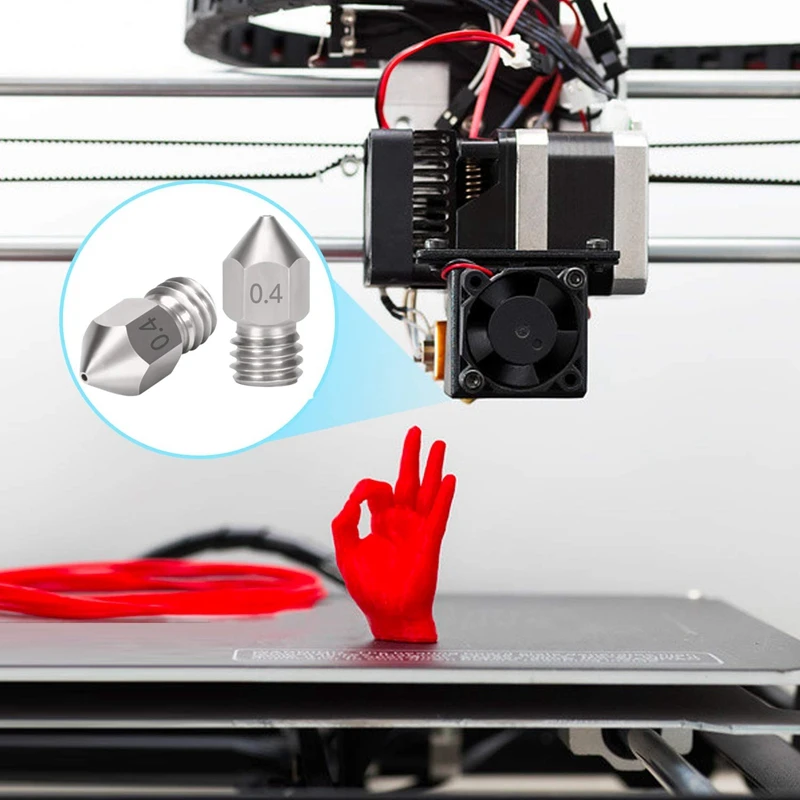

Prints 3D objects by extruding melted plastic, compatible with materials such as PLA, PETG, ABS, flexible filaments and many more

Layer height 0.05 mm - 0.15 mm

Maximum print area size 25 x 21 x 21 cm (9.84 x 8.3 x 8.3 in)

Great for: prototyping, printing toys, RC models or mechanical parts

Post-processing: possible, depends on the type of used materials. Possible sanding, gluing, painting

Original Prusa SL1S (SLA printer)

Uses UV light pattern to cure layers of resin. Photo polymers are cured layer by layer to create the final object

Min layer height: 0.01 mm, recommended layer height: 0.025 - 0.1 mm

Maximum print area size: 127 × 80 × 150 mm (5 × 3. 14 × 5.9 in)

14 × 5.9 in)

Great for: prototyping, jewelry, art models, medical use (e.g. dental molds for casting)

Post-processing: easy, models can be glued, sanded and painted

1

GREAT USER SUPPORT

We are providing full 24/7 customer support with live chat and e-mail in several languages. There are also unofficial user groups on Facebook, where makers help each other. You will never be alone in the big world of 3D printing!

2

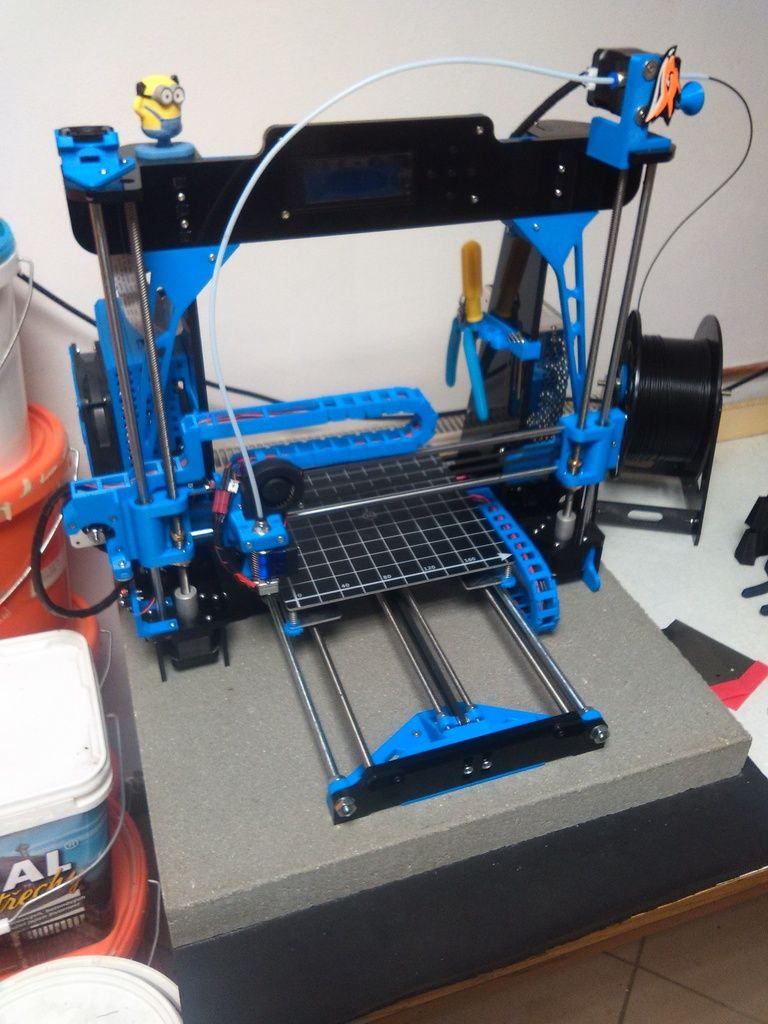

UPGRADABILITY

One of the most popular features of Original Prusa i3 concept is upgradability. If you buy our 3D printer, you can upgrade it later to the new version, so you don't need to buy the whole new model every two years as you get used to with your phone or laptop. ;-)

3

READY TO PRINT SETTINGS

We provide high-quality print settings with the printer and we are developing our own slicing software. In PrusaSlicer you can set everything you want. It's very easy to use and we are adding new features regularly.

It's very easy to use and we are adding new features regularly.

4

THE BEST ASSEMBLY INSTRUCTIONS

We didn't want to leave anything to chance, so our assembly instructions are pictured to the smallest detail. All fasteners and mechanical parts have 1:1 drawing so you can easily find them, and there is no chance of you picking a wrong one.

5

FUN TO ASSEMBLE

Assembling the kit is an excellent first step to the world of 3D printing. You will understand the principles of printer construction and get a huge advantage when you need to solve possible problems and replacements later.

6

QUALITY GUARANTEED BY JOSEF PRUSA

Prusa Research is a 3D printing company based in Prague, Czech Republic. It was founded in 2012 by Josef Prusa, one of the core RepRap developers, as a one-man startup and grows to a 600+ team now.

This book will help you understand what kinds of 3D printing technologies are currently available and how they work. We will take you through the whole process of 3D printing, starting with obtaining a printable 3D model, through the pre-printing preparations, to the final post-processing of a printed object. You will learn what an extruder is, as well as slicing, perimeters or infill. We’re going to explain the differences between commonly used materials, and how to utilize 3D printing for practical application. This book will give you a very good understanding of 3D printing and also provide you with all the basic knowledge required to start. The only thing remaining will be to buy a 3D printer and start printing!

We will take you through the whole process of 3D printing, starting with obtaining a printable 3D model, through the pre-printing preparations, to the final post-processing of a printed object. You will learn what an extruder is, as well as slicing, perimeters or infill. We’re going to explain the differences between commonly used materials, and how to utilize 3D printing for practical application. This book will give you a very good understanding of 3D printing and also provide you with all the basic knowledge required to start. The only thing remaining will be to buy a 3D printer and start printing!

- 60+ pages about 3D printing

- Material guides

- 3D printing process from A to Z

- Which 3D printer is the best for you?

- …and more!

You can either purchase my e-book or get it for free by entering your email and agreeing to subscribe to my newsletter below. If you choose the first option, you will get the book for 5 USD / EUR in print form and we will not process your personal data. If you choose the second option, you will receive the e-book for free. After that, we will occasionally send you news from Prusa Research and other tips & tricks from the world of 3D printing that I think might be useful for you. Of course, you can unsubscribe whenever you want and we never send you unsolicited advertising.

If you choose the second option, you will receive the e-book for free. After that, we will occasionally send you news from Prusa Research and other tips & tricks from the world of 3D printing that I think might be useful for you. Of course, you can unsubscribe whenever you want and we never send you unsolicited advertising.

– Jo Prusa

I don’t agree with subscribing of the newsletter and I want to buy the book for 5 USD / 5 EUR (VAT incl).

3D printed houses grow in the Czech Republic

Photo: Patrik Salát, Český rozhlas

Sounds like science fiction? In Tršest, in the Jihlava region, one prototype of the house design has already been printed. A local engineering and construction company has been developing a unique 3D printer for four years together with specialists from the Czech Technical University in Prague. Although it is of considerable size, according to the creators, it can be moved almost anywhere and printed a concrete house on site in a matter of hours.

“The test print of this design, on which we studied, lasted about 35 hours. This printer is different from other 3D printers. In fact, it looks like a gantry crane. The difference is that we have a moving platform on this portal, on which our printhead moves,” says Marek Stadler from the Faculty of Mechanical Engineering of the Czech Technical University.

Photo: Patrik Salát, Český rozhlas

Next to the portal of the 3D printer in Tršest is the first prototype of the printed house.

The print head models an angle pattern, but makes it, not like similar machines, round, but square, because the printer does not use a classic robotic “hand”, but just its own print head. The dimensions of the printer are significant, and it can turn around 122 square meters of area. In height, the structure can reach a height of five meters. So, all that is needed to start construction is a pre-prepared project on a computer. Thanks to this, with the help of 3D printing, houses can be built in a matter of days and replace a number of craftsmen of various professions.

Photo: Patrik Salát, Český rozhlas

“It operates in the same way as conventional CNC machining centres. This means that it is controlled by G-code. If we already have the code ready, then two people are enough to work, one of whom takes care of the preparation of the mixture, and the other manages and controls the printing process.

The vision of a more robotic construction process that would solve the shortage of workers in the construction industry inspired Podzimek four years ago to start developing a 3D printer together with experts from the Czech Technical University.

Photo: Patrik Salát, Český rozhlas

“If I assume that there will be no workers at all, we will have no choice but to completely robotize the construction process,” says company director Martin Podzimek.

According to him, sooner or later robotization will still prevail in construction.

Therefore, his company wants to continue developing the 3D printer. If investors are interested, the firm plans to print more houses in the future.

Photo: Daniela Brychtová, Český rozhlas

However, one should not think that this case in the Czech Republic is unique and still really resembles lines from science fiction. In the Vysočina region, trial testing of house printing on a 3D printer is currently underway. If everything goes smoothly, in two years the firm plans to print... an entire school!

“We started with 3D printing of various benches, flower pots, urban furniture, but at the moment this is not enough for us, so we would like to move on to something more,” says ICE Managing Director Dominik Stupka.

It is in ICE's production facility, which is equipped with three giant 3D printers, that parts of houses are made.

Photo: Daniela Brychtová, Český rozhlas

“The working title of this facility is a bicycle garage. But in fact, this is a house about 3 x 8 meters in size, it consists of several segments, and we are making one of them here.”

But before the house could be printed, the company had to build the 3D printing machine itself. The goal is to improve the machine so that it can be operated by a non-specialist. In the future, the company wants to move from a small home to larger projects. According to Tomasz Vranek, director of the company, the first printed school building in the northern hemisphere will be built exactly in Zdar nad Sazavou.

The goal is to improve the machine so that it can be operated by a non-specialist. In the future, the company wants to move from a small home to larger projects. According to Tomasz Vranek, director of the company, the first printed school building in the northern hemisphere will be built exactly in Zdar nad Sazavou.

Photo: Daniela Brychtová, Český rozhlas

“We have set ourselves a huge task, but we want the school to be ready in the summer of 2023 so that children can start the 2023/2024 school year in the new building.

This is an alternative Montessori school in Ždiar nad Sázavou in the Radost district,” shares Tomasz Vranek. According to Tomasz Vranek, 3D printing technology should save time and money, as well as fill the shortage of masons in the market. Most of the development effort is planned to be focused on developing a material that will be comparable in price to existing conventional concrete, thus saving up to 70% of material and human labor, as 10 masons can be replaced by one robot In the near future in Ždiar nad Sazavou the first cafe printed on a 3D printer will also appear.

News

Subscribe to the author

Subscribe

I do not want

2

Shelter is designed using generative design, concrete elements are printed by a 3D printer based on a multi-axial robot robot-planter. The pavilion was installed near the Stromovka park not far from the center of the Czech capital.

The pavilion is designed taking into account the distribution of internal forces. Generative design using topological optimization allows you to create the most lightweight, but at the same time sufficiently strong elements with material savings of up to 60% and minimal manual labor costs. The pavilion was 3D printed and built by the construction company So Concrete, and the additive manufacturing phase took about thirty-six hours. The consumable material was ultra-high-strength concrete (UHPC). As a rule, this term refers to materials with a compressive strength above 120 MPa.

“Topological optimization ensures that volume and shape contain only the essentials. Let's imagine a 3D printer, but in contrast, our robot works on six axes, so we can afford more complex shapes. The service life of the material is extreme: it is used, for example, in the construction of dams - it is a hundred years or more, ”said Federico Diaz, CEO of So Concrete.

“I like to use the analogy with nature: the rocks are weathered and only loaded arcs remain. The same is created with this new technology, friendly to nature and the environment. We use this method, for example, for the construction of the Štvanice Bridge, the reconstruction of the Barrandovsky Bridge. We are trying to test it in various ways on the territory of Prague,” commented Adam Scheinherr, Deputy Mayor of Prague for transport infrastructure.

According to Novinky.cz, for now this stop will remain the only one of its kind: the Prague administration has no plans to build additional 3D-printed pavilions at the moment, although the technology itself is used in other projects to improve the urban environment.

For example, last year a playground with 3D printed parkour obstacles was opened in the Prague 11 municipal district ( in the illustration above ).

Another interesting project completed in 2020: the Czech company Scoolpt, led by artist-sculptor and architect Michal Trpak, built a 43-square-meter 3D printed house on a pontoon. The design was demonstrated near Streltsy Island.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

construction Prague So Concrete

Follow author

Follow

Don't want

2

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

Researchers from the Skolkovo Institute of Science and Technology and the National Research Nuclear.