3D nylon printers

The 8 Best Nylon 3D Printers for Easy Nylon Printing (2022) – Clever Creations

Nylon filament is one of the most versatile 3D printing materials that you can print on a desktop 3D printer. It has excellent tensile strength, is flexible, and has a high melting point, making it ideal for functional prototypes and interlocking prints that undergo high wear and tear.

Despite these benefits, 3D printing Nylon filament has its own set of challenges, and not all 3D printers are equipped or designed to print with Nylon. For someone looking for printing with Nylon, this might become a challenge and confuse them further as to what printer will deliver the best results with Nylon.

To help make it easier for you and to make you aware of your choices in the market, we’ve curated a list of some of the best Nylon 3D printers that you can buy right now. We have also included the things you should look for when getting a Nylon printer.

Read on to learn how to choose the best Nylon 3D printer for you!

| Best Nylon 3D Printer | Summary | Build Volume | Price (~) | Best Offer |

|---|---|---|---|---|

| Matterhackers Pulse XE | Best overall | 250 x 220 x 215 mm | $899 | MatterHackers |

| Ultimaker S5 | Best high-end | 330 x 240 x 300 mm | $6355 | MatterHackers |

| Flashforge Adventurer 3 | Best on a budget | 150 x 150 x 150 mm | $369 | Flashforge |

| Creality Ender 3 S1 | Most silent | 220 x 220 x 270 mm | $429 | Creality |

| QIDI Tech X-Plus | Highest print temperature | 270 x 200 x 200 mm | $699 | Geekbuying |

| FlashForge Adventurer 4 | Best air filtration | 220 x 200 x 250 mm | $799 | Flashforge |

| Dremel DigiLab 3D45 | Most user-friendly | 254 x 152 x 170 mm | $1880 | MatterHackers |

| Raise3D Pro 2 | Largest Nylon 3D Printer | 305 x 305 x 300 mm | $3999 | MatterHackers |

The Best Nylon 3D Printers in 2022

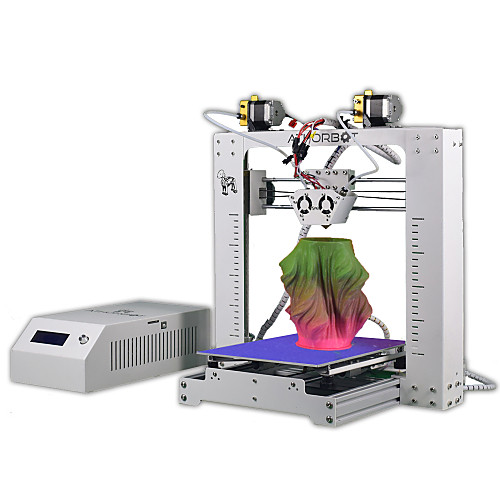

Matterhackers Pulse XE

Best overall

Check price at

MatterHackers

The Matterhackers Pulse XE is a 3D printer specifically designed to print with NylonX material. It comes with a hardened steel nozzle, a specially engineered bed surface, and a maximum extruder temperature of 300 °C, letting you print Nylon filament with ease.

You get a Prusa i3 style open-frame design, and a BLTouch leveling sensor for ease of use. The print surface is textured with Garolite, which guarantees better print adhesion with Nylon and is durable enough to last for many print cycles. The Pulse XE uses the best components currently available right now, such as a Bondtech extruder and a E3D V6 hot end, to deliver high-quality 3D prints.

For under $1000, the Pulse XE is a feature-packed printer, which serves excellent value to the end-user, making it the best overall Nylon 3D printer on the list. It will print anything you throw at it with ease, and if you’re in the market for a professional-grade Nylon 3D printer, the Pulse XE is the best choice for you.

Standout Features

- BLTouch leveling probe

- Garolite print surface

- Robust i3 design

Technical Details | |

|---|---|

| Build Volume | 250 x 220 x 215 mm |

| Materials | PLA, ABS, PETG, Nylon, Carbon Fiber, PC |

| Bed leveling | Automatic |

| Max hot end temperature | 295°C |

| Max bed temperature | 100°C |

| Connectivity | SD card, USB |

| Supported slicers | Mattercontrol |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to upgrade

- Hardened steel nozzle

- Easy to use interface

Could Be Better

- Lacks enclosure

- Outdated LCD

Find Matterhackers Pulse XE at

MatterHackers

Ultimaker S5

Best high-end

Check price at

AmazonMatterHackers

Ultimaker 3D printers are known for their premium build quality and excellent print results. The Ultimaker S5 is the flagship 3D printer in the Ultimaker printer lineup and comes with the best features that make it great for printing industrial prototypes and end-use components.

The Ultimaker S5 is a dual extruder 3D printer with a large print volume of 330 x 240 x 300 mm that lets you fully take advantage of its dual print heads. It offers convenient swappable print cores and a removable glass bed to print with advanced materials such as NylonX, Polycarbonate, and Polypropylene.

The airflow manager add-on maintains a stable printing temperature, which is useful when printing with Nylon. And with the material station, you can easily store Nylon filament without having to resort to a filament dry box.

And with the material station, you can easily store Nylon filament without having to resort to a filament dry box.

Given its features and the high-end components, printing with Nylon should be as easy as printing with PETG or PLA filament on the Ultimaker S5. Overall, it’s an excellent 3D printer that will deliver consistent printing results and cover nearly all FDM 3D printing needs.

Standout Features

- Dual extrusion

- Swappable print cores

- Large build volume

Technical Details | |

|---|---|

| Build Volume | 330 x 240 x 300 mm |

| Materials | PLA, ABS, PETG and CPE, ASA, Nylon, NylonX and NylonG, PV, Polycarbonate, Polypropylene |

| Bed leveling | Automatic |

| Max hot end temperature | 280°C |

| Max bed temperature | 140°C |

| Connectivity | Wi-Fi, Ethernet, USB |

| Supported slicers | Ultimaker Cura |

| Filament diameter | 2. 85 mm 85 mm |

What We Like

- Multi-material printing

- Premium components

- Remote monitoring

Could Be Better

- Serious investment

- Separate enclosure kit

Find Ultimaker S5 at

AmazonMatterHackers

Flashforge Adventurer 3

Best on a budget

Check price at

AmazonFlashforgeBanggood

The Flashforge Adventurer 3 is a fully-enclosed 3D printer designed to be easy to use and beginner-friendly. With its intuitive interface and an excellent feature set, it gives you excellent value for your money.

The Adventurer 3 comes with an interchangeable nozzle design that lets you upgrade the default nozzle set up to a high-temperature nozzle that goes up to 265 °C, letting you print with ABS, PETG, PC, and Nylon. Its heated print bed and the enclosure help maintain a passively heated, stable printing temperature, further improving print quality.

Its automatic filament loading, inbuilt camera, and remote monitoring greatly benefit the user experience and are nice features for beginners to use the 3D printer efficiently and safely.

Overall, the Flashforge Adventurer 3 is a great package that comes at an affordable price of under $400. It is excellent for beginners and hobbyists that need a reliable 3D printer that can print with Nylon filament on a budget.

Standout Features

- Detachable nozzle design

- Automatic filament loading

- Wireless 3D printing

Technical Details | |

|---|---|

| Build Volume | 150 x 150 x 150 mm |

| Materials | PLA, ABS, PETG, Nylon |

| Bed leveling | Automatic |

| Max hot end temperature | 240°C / 265°C |

| Max bed temperature | 100°C |

| Connectivity | USB stick, Wi-Fi, Ethernet FlashCloud, PolarCloud |

| Supported slicers | Flashprint |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Beginner-friendly

- Fully enclosed

- Removable print bed

Could Be Better

- Small build area

- Only compatible with FlashPrint

Find Flashforge Adventurer 3 at

AmazonFlashforgeBanggood

Creality Ender 3 S1

Most silent

Check price at

AmazonCrealityCreality3DOfficialMatterHackers

The Creality Ender 3 S1 is the latest printer from Creality and comes with all the best features you would expect from a desktop 3D printer in 2022. The PC-coated flexible spring steel bed is a new inclusion in the Creality lineup and is perfect for adhesion with printing materials such as Nylon.

It also offers a newly designed “sprite” extruder that weighs less than traditional direct drive setups and is excellent for printing flexible filaments like TPU. It comes with a 32-bit motherboard with silent stepper motors, letting it print at < 50 dBs. This makes it one of the quietest 3D printers available right now, especially when coupled with its official enclosure.

This makes it one of the quietest 3D printers available right now, especially when coupled with its official enclosure.

The hot end is designed to reach up to 260 °C, letting you print Nylon filament with ease. However, the aforementioned enclosure is something you will need as well if your goal is to 3D print Nylon filament. It helps prevent the warping of your Nylon prints, significantly increasing your success rate with this tricky filament.

The Creality Ender 3 S1 is a superb hobbyist-level printer resulting from years of community feedback. Its silent stepper drivers make it an ideal 3D printer for a home or an office setup. It is a great fit if you want a Nylon 3D printer with all essential features, that is easy to set up and delivers excellent print quality.

Recommended:

Creality Ender 3 S1 Review: A New Standard

Standout Features

- Improved "sprite" extruder

- Dual Z-axis design

- PC spring steel print bed

Technical Details | |

|---|---|

| Build Volume | 220 x 220 x 270 mm |

| Materials | PLA, TPU, PETG, ABS, Nylon |

| Bed leveling | Automatic |

| Max hot end temperature | 260°C |

| Max bed temperature | 100°C |

| Connectivity | Type-C USB, SD Card |

| Supported slicers | Ultimaker Cura |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to assemble

- Automatic bed leveling

- Direct extrusion for TPU, TPE

Could Be Better

- Open-frame design

- Enclosure comes separately

Find Creality Ender 3 S1 at

AmazonCrealityCreality3DOfficialMatterHackers

QIDI Tech X-Plus

Highest print temperature

Check price at

AmazonGeekbuyingAliExpressBanggood

The QIDI Tech X-Plus 3D printer is one of the rare 2-in-1 3D printers that is fine-tuned for printing with basic and advanced materials alike. It has two separate direct-drive extruders and bed surfaces, each configured for different printing materials.

You get one extruder that reaches up to 250 °C, combined with a textured print surface meant for printing with PLA, ABS, and PETG. The second hotend-extruder set up can go as high as 300 °C and can be combined with the smooth bed surface on the opposite side of the printing bed. This second setup enables you to 3D print with Nylon, PC, and Carbon Fiber.

This second setup enables you to 3D print with Nylon, PC, and Carbon Fiber.

The dual Z-axis setup delivers stable and precise printing and the enclosed spool holder design, too, is beneficial when printing with Nylon filament.

One of its biggest shortcomings, however, is its relatively small build height (200mm) given the machine’s price. If your needs include printing tall Nylon 3D prints, the Tech X-Plus is not the best option.

Considering the features and ease of switching hot ends when printing with different materials, the QIDI Tech X-Plus offers a great printing experience. It is a great choice for hobbyists and even professionals who need a versatile 3D printer that is well-built and delivers reliable results.

Standout Features

- Two different extruder setups

- Dual print surface

- Double Z-axis

Technical Details | |

|---|---|

| Build Volume | 270 x 200 x 200 mm |

| Materials | PLA, ABS, PETG, Flexibles, Nylon, PC |

| Bed leveling | Automatic |

| Max hot end temperature | 260°C / 300°C |

| Max bed temperature | 100°C |

| Connectivity | USB, WiFi, LAN |

| Supported slicers | QIDIPrint, Cura, Simplify3D |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to set up and configure

- Stores filament inside

- Wi-Fi connectivity

Could Be Better

- Easy to damage print surface

- No filament guiding system

Find QIDI Tech X-Plus at

AmazonGeekbuyingAliExpressBanggood

FlashForge Adventurer 4

Best air filtration

Check price at

AmazonFlashforgeGeekbuyingAliExpress

The Flashforge Adventurer 4 is the next iteration of the Adventurer 3 / 3 Pro 3D printers and keeps many of the existing features while improving in areas related to the design and user experience of the printer.

It offers a fully-enclosed print chamber to maintain a stable printing environment and a HEPA 13 air filtration system to keep away any harmful 3D printer fumes. This is something that is of use when working with Nylon filament.

Additionally, the Adventurer 4 offers an interchangeable nozzle design to let you quickly swap between high-temperature nozzles and a flexible metal printing plate that facilitates easy print removal.

The Adventurer 4 is designed for beginners, hobbyists, prosumers, and educational use. The air filtration system is excellent for using the printer indoors and near kids or pets. With this Nylon 3D printer, you get a machine that is full of features and that is safe to use.

Standout Features

- HEPA 13 air filtration

- Quick release nozzle

- Built-in spool holder

Technical Details | |

|---|---|

| Build Volume | 220 x 200 x 250 mm |

| Materials | ABS/PLA/PC/PETG/PLA-CF/PETG-CF/Nylon |

| Bed leveling | Automatic |

| Max hot end temperature | 265°C/240°C |

| Max bed temperature | 110°C |

| Connectivity | USB. Wi-Fi, Ethernet, Cloud |

| Supported slicers | FlashPrint |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to use

- Remote monitoring

- Fully enclosed design

Could Be Better

- Small build volume

- Assisted bed leveling

Find FlashForge Adventurer 4 at

AmazonFlashforgeGeekbuyingAliExpress

Dremel DigiLab 3D45

Most user-friendly

Check price at

AmazonMatterHackers

Coming from a renowned tool manufacturer, the Dremel DigiLab 3D45 is easy and intuitive to use, even when 3D printing with advanced materials such as Nylon, PC, and Carbon Fiber.

The DigiLab 3D45 comes with 9-point automatic bed leveling, removing the need for manual leveling and improving first-layer adhesion. You get a hot end capable of reaching up to 280°C and a maximum print bed temperature of 110°C for easy and high-quality prints with high-temperature filaments such as ABS and Nylon.

It also includes 30 lesson plans, which is a valuable addition to a 3D printer designed to improve the educational experience in classrooms. The 3D45 is just that, with an intuitive user-friendly touchscreen that makes it easy for students to access all of the printer’s features, and a design that is focused on safety.

The 3D45 is just that, with an intuitive user-friendly touchscreen that makes it easy for students to access all of the printer’s features, and a design that is focused on safety.

While the Dremel DigiLab 3D45 is specifically designed for use in classrooms, based on its features and capabilities to print with advanced materials, you can equally use it for your hobby and prosumer prototyping needs. Do keep in mind that it comes at a significant 3D printer cost. As far as Nylon 3D printers are concerned, it is one of the most expensive.

Standout Features

- RFID Filament recognition

- Remote 3D print monitoring

- Industrial design

Technical Details | |

|---|---|

| Build Volume | 254 x 152 x 170 mm |

| Materials | PLA, Eco-ABS, Nylon, PETG |

| Bed leveling | Manual |

| Max hot end temperature | 280°C |

| Max bed temperature | 110°C |

| Connectivity | Wifi, USB, Ethernet |

| Supported slicers | Dremel DigiLab 3D Slicer (Cura), Dremel Print Cloud (3DPrinterOS) |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Plug-n-play design

- Over 30 lesson plans

- Intuitive touchscreen

Could Be Better

- Manual bed leveling

- Small build volume

Find Dremel DigiLab 3D45 at

AmazonMatterHackers

Raise3D Pro 2

Largest Nylon 3D Printer

Check price at

AmazonMatterHackers

The Raise3D Pro 2 is a large-sized, fully enclosed dual extruder 3D printer built for professionals. It includes a 305 x 305 x 300 mm large print volume that offers enough space for larger Nylon 3D prints.

In terms of features, it has a hot end capable of going up to 300 °C and a heated bed that reaches up to 110 °C, letting you print with Nylon, Metal PLA, Carbon Fiber, and PC. The dual extruders allow you to do multi-material printing, for example, letting you print with soluble supports.

The addition of a large 7-inch touchscreen, a HEPA filtration system, a filament sensor, and a 32-bit mainboard are all designed to enhance the user experience. However, with a price tag of $3999, the Raise3D Pro 2 is aimed squarely at professional users.

However, with a price tag of $3999, the Raise3D Pro 2 is aimed squarely at professional users.

It is one of the best Nylon 3D printers on the list and combines the best of all the others mentioned. The Raise3D Pro 2 is an ideal fit for your professional 3D printing workflow or use in print farms and industries.

Standout Features

- Dual extrusion

- Large build volume

- High-temp hot end

Technical Details | |

|---|---|

| Build Volume | 305 x 305 x 300 mm |

| Materials | PLA, ABS, HIPS, TPU, PC, NYLON, TPE, FLEX, PETG, Metallic PLA, Wood PLA, Carbon Fiber Reinforced Materials |

| Bed leveling | Automatic |

| Max hot end temperature | 300°C |

| Max bed temperature | 110°C |

| Connectivity | WiFi, LAN, USB Port |

| Supported slicers | Ideamaker |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Multi-material printing

- Large touchscreen

- Inbuilt spool holders

Could Be Better

- Reliability issues

Find Raise3D Pro 2 at

AmazonMatterHackers

What to look for in a Nylon 3D printer

Enclosure

Nylon is a high-temperature material, meaning it extrudes at high temperatures beyond 230 °C. This makes it prone to warping quickly with even the slightest temperature differences in the print chamber. Enclosed 3D printers help to dial down these issues.

With an enclosure, you get a stable printing temperature, and the heat emitted from the bed stays contained in the print chamber, keeping an evenly heated area near the print. Moreover, a fully enclosed 3D printer that offers internal spool storage is able to keep Nylon filaments from absorbing any external moisture.

If the Nylon 3D printer you have an eye on is not enclosed, you can always opt for a DIY 3D printer enclosure or an aftermarket one.

Maximum nozzle temperature

As mentioned earlier, Nylon filament has a high melting temperature. Its typical extrusion temperature lies somewhere between 230°C – 270°C depending on the filament brand. When getting a 3D printer to print Nylon, you need to ensure that it has an all-metal hot end capable of reaching and sustaining these temperatures.

All of the 3D printers mentioned in this list are capable of printing at such high temperatures, with the maximum nozzle temperature of some printers going as high as 300°C. It gives a bit of freeway to print Nylon at higher temps and better quality. Higher nozzle temperatures let you set a faster printing speed, too, as they can melt and push Nylon filaments at a high rate.

Heated bed

The high-temperature hot end and a heated bed go hand in hand while printing with Nylon filament. A heated bed helps with better print surface adhesion of Nylon, while also passively heating the print area. It leads to relatively stable printing temperatures, thus reducing warping with Nylon prints.

For printing with Nylon filament, you need bed temperatures between 70°C – 90°C. The exact temperature varies from brand to brand, which you will need to figure out with a bit of experimentation or by reading the recommended temperatures in the documentation.

In addition to the heated bed, you need to look at the print surfaces too. A Garolite print surface and a glass bed with a PVA glue stick result in the best bed adhesion and can easily sustain the heating temperatures of 70 °C and beyond that is required to print with Nylon filament.

Build volume

The build volume of a 3D printer is one of its defining characteristics, and it becomes an important criterion to consider when deciding to get a printer to print with Nylon filaments.

Nylon filament has excellent mechanical properties with high resistance to abrasion and a low coefficient of friction.

Having a large print volume for such applications will give you more freedom to print bigger models in a single piece. It will lead to better uniformity throughout the print, resulting in excellent mechanical properties. Similarly, you can print larger-sized display pieces in a single part, thus saving you post-processing times and giving you a seamless model.

It will lead to better uniformity throughout the print, resulting in excellent mechanical properties. Similarly, you can print larger-sized display pieces in a single part, thus saving you post-processing times and giving you a seamless model.

Remote monitoring

Nylon as a filament is expensive compared to other materials like the PLA, ABS, and PETG. It is difficult to 3D print too, and there are chances of print failures due to poor bed adhesion or something else going wrong during the printing process. It leads to material losses, wasted filament, and an overall loss in productivity.

With a remote monitoring setup, you get a camera and Wi-Fi connectivity to view the current printing progress remotely. If something were to go wrong, you can immediately stop the print and remedy any issue. Asides from this, you get the flexibility to be away from the 3D printer and continue with any other work without worrying about the print’s status.

Common problems with 3D printing nylon

Moisture Absorption

Nylon is a hygroscopic material, which means that it readily absorbs moisture from its surroundings. It will cause under-extrusion issues, air bubbles, or blobs on the print’s surface, eventually leading to print failures.

It will cause under-extrusion issues, air bubbles, or blobs on the print’s surface, eventually leading to print failures.

It is recommended to store Nylon in airtight containers with desiccants that absorb any moisture. Before printing, drying it in an oven or a filament dryer will help remove any residual moisture from the material. And an enclosure that will isolate the material from the external environment will help keep the filament dry during the printing process.

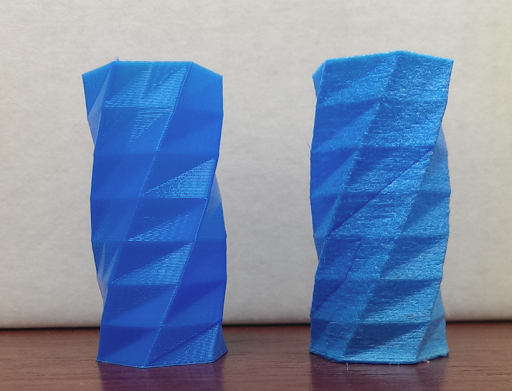

Warping

We’ve established that Nylon is a high-temperature material that melts between 230°C – 270°C. If we cannot control this cooling rate once Nylon is extruded out of the nozzle and let its temperature come down drastically, it will contract rapidly and result in warping and layer separation issues.

To counter this, you need a heated bed to maintain a heat zone near the print’s surface and an enclosure to prevent any sudden air drafts and keep the hot air inside the print chamber. A printing surface with Garolite or PVA glue stick also helps with better bed adhesion and reduces any warping of Nylon.

Advantages of Nylon filament

High impact strength

Nylon has the highest impact strength than PLA, ABS, and PETG. It makes it highly durable and perfect for applications where parts are constantly subject to impact loads such as hammering, banging, or crashing with each other.

Low coefficient of friction

Nylon has a low coefficient of friction, meaning it can easily slide on other parts without substantial damage to the surface. It is beneficial for applications such as interlocking gears and constant motion mechanisms.

Flexibility

Nylon’s flexibility can be varied by varying its thickness. If you have thinner models or print thin walls, you can create a very flexible part that flexes without breaking apart.

Post-processing

Nylon’s hygroscopic nature makes it easier for you to use fabric paints or dyes with it as the print will quickly absorb the color leading to quick and easy post-processing.

Disadvantages of Nylon filament

Absorbs moisture

Nylon filament will readily absorb the moisture from the air, even during the printing process, and it results in poor print quality and might even cause print failures.

Warping

Nylon has a high melting point. If it is allowed to cool down gradually or the print area is not at a stable temperature, the Nylon print will warp, resulting in a deformed part.

Prior drying

Even if you’ve stored Nylon in an airtight container, there are chances of still some moisture being present in the filament. It would be best to dry Nylon before printing to remove any leftover moisture. This can be a cumbersome process and adds to the overall time spent on 3D printing Nylon.

Frequently Asked Questions

Can 3D printers print Nylon?

Yes, 3D printers can print Nylon. However, the printer needs to be calibrated properly to ensure proper printing quality. In addition, you also need to take into account the high printing temperature and warping issues that come with using Nylon filament.

What is a good brand of Nylon filament?

There are many brands of Nylon filament available in the market. Some of the more popular brands include OVERTURE, Taulman3D, and Polymaker. Either of these brands likely has the right Nylon filaments to cover your needs.

Either of these brands likely has the right Nylon filaments to cover your needs.

Polymaker Nylon Filament 1.75 Black, Easy to Print Nylon Filament...

167 Reviews

Check PriceWhat are some applications where Nylon filament can be used?

Nylon filament can be used in a variety of applications including industrial parts, mechanical parts, and consumer products. It has high impact strength and low friction making it ideal for use in wearable products, automotive parts, and other moving parts.

What type of Nylon is used for 3D printing?

There are two types of Nylon that are used for 3D printing: Nylon 6 and Nylon 12. Nylon 6 is the most popular type as it has a low melting point and is easier to print with. Nylon 12 has a higher melting point and is less brittle, but it is more difficult to print with.

Is Nylon stronger than PLA?

Nylon is stronger than PLA filament, but it also has a higher printing temperature. It is more flexible than PLA and can withstand more impact loads. However, it is also more prone to warping. Both are likely to absorb moisture from the air and need proper filament storage.

However, it is also more prone to warping. Both are likely to absorb moisture from the air and need proper filament storage.

What 3D printer will print in Nylon?

Not all 3D printers can print in Nylon. The printer needs to be able to handle temperatures up to 260 degrees Celsius in order to print with Nylon filament. In addition, the printer also needs to be calibrated properly to ensure good printing quality. An enclosure is beneficial as well.

Is Nylon hard to 3D print?

Nylon is not hard to 3D print. However, the high printing temperature and tendency to warp can cause some issues if the printer is not calibrated properly. It is important to make sure that the area where the print is taking place is at a stable temperature.

Can Nylon be used without a heated bed?

Nylon can be used without a heated bed, but it is not recommended. The print will likely not stick to the bed and the quality of the print may be affected. A heated bed helps to keep the Nylon filament at a stable temperature, which reduces warping and helps get high-quality prints.

Conclusion

Nylon is an excellent 3D printing material with outstanding mechanical strength and practical applications. You can use Nylon in functional components, interlocking gears, constant motion mechanisms, and even display models owing to its various properties.

In our comparison, the Matterhackers Pulse XE stands out as the best Nylon 3D printer that covers all of your Nylon printing needs. Since it is designed to print with Nylon material, it has all the features you need to achieve excellent print results. You get a high-temperature hot end, a heated bed with Garolite, and a decent print volume, all at a relatively budget price.

The only thing the Pulse XE lacks is an enclosure. And this is where the QIDI Tech X-Plus and the Flashforge Adventurer 4 have the edge. These 3D printers come with a fully-enclosed design, are easy to use, can print at high temps with ease, and have loads of other valuable features to make the Nylon 3D printing experience a little easier.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

Everything you need to know about Nylon 3D printing

Before you get started with Nylon 3D Printing, we’ve compiled some of the basic information you’ll need to know. Read on to learn the advantages, disadvantages, history and applications of Nylon 3D printing

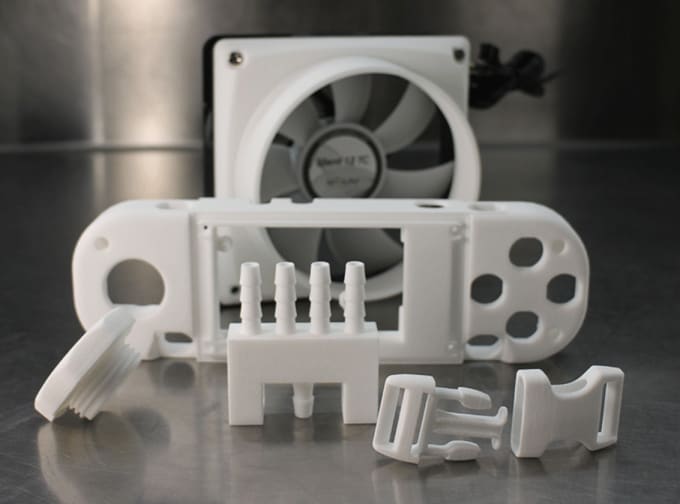

Nylon Filament and 3D Printed Gear

When it comes to 3D printing materials, Nylon has to be mentioned as one of the most popular materials for professional users. This can be attributed in large part to its popularity outside of 3D printing. Nylon has a wide range of applications thanks to its unique properties and the benefits of 3D printing mean that parts can be made on the fly easily and inexpensively.

That said, desktop Fused Deposition Modeling (FDM) 3D printing technology, which is one of the most widely-used types of 3D printing, can sometimes involve a lot of trial and error. Some materials are easy to print with while others have a comparatively bigger learning curve.

Some materials are easy to print with while others have a comparatively bigger learning curve.

Through this article, we will share everything you should know about Nylon 3D printing. Nylon can be 3D printed using three different technologies, namely FDM, Selective Laser Sintering (SLS), and MultiJet Fusion (MJF). However, the scope of this article is focused around FDM 3D printing.

UNDERSTANDING NYLON AS A MATERIAL

Chemical Composition

Nylon was first synthesized by DuPont, the American chemical company, in 1935. It developed the material for commercial usage and since then Nylon has become a common feature in numerous industries.

Nylon refers to a group of plastics known as polyamides. They are mostly semi-crystalline and generally very tough materials. It is found in many variants but the most common ones are Nylon 6, Nylon 6-6, and Nylon 12. It is a thermoplastic material, i.e., it becomes soft on heating or liquid when heated beyond its melting point and hardens on cooling. This process of heating and cooling can be carried out multiple times without significantly affecting its inherent chemical or mechanical properties.

This process of heating and cooling can be carried out multiple times without significantly affecting its inherent chemical or mechanical properties.

Nylons can be easily blended with numerous other plastics to form composites, enhancing their performance parameters. This is widely done in automotive industries and some common composites in 3D printing are glass-filled nylon and carbon-fiber-filled nylon. Nylon is a versatile material and is suitable for almost all types of manufacturing operations like injection molding, extrusion, and additive manufacturing (in FDM, SLS & MJF).

Some of the most popular applications of nylon material are:

➜ In the textiles industry, nylon is used in the manufacturing of fishing lines, and food packaging.

➜ In the fashion industry, nylon is used as a fabric to manufacture products like hosiery, lingerie, raincoats, windbreakers, and athletic wear used in sports.

➜ In the electronics industry, nylon is used as insulators and switch housings.

➜ In the automotive industry, nylon is used in the production of parts such as intake manifolds, door handles, and radiator grills.

In consumer products, nylon is used in sporting goods such as ski bindings and skateboard wheels.

➜ In manufacturing machinery for moving parts such as gears and rollers.

NYLON in 3D PRINTING

In the same way that nylon has become a go-to material in traditional manufacturing, nylon has become a popular material to use with 3D printers. 3D printing provides the added benefits of unlimited geometries, iteration and customization, and low-volume affordability.

Nylon’s flexibility and durability help in 3D printing parts with thin walls. Its low coefficient of friction with a high melting point makes it especially resistant to abrasion and enables it to be used in printing for parts such as functional interlocking gears.

Nylon exhibits mechanical properties comparable to ABS (another widely used material in traditional & additive manufacturing). ABS is defined by its strength but Nylon’s resistance to wear and fatigue makes it superior for applications requiring such properties.

ABS is defined by its strength but Nylon’s resistance to wear and fatigue makes it superior for applications requiring such properties.

Apart from the advantages, nylon has one major drawback that can often hamper its printing performance – hygroscopicity, i.e., its moisture absorption property. This property is detrimental in delivering predictable performance. But this same property helps nylon in easy post-processing with fabric dyes and spray paints thereby making it suitable for use in the printing of aesthetic (display) models.

There have been successful cases of a patient receiving a titanium pelvis implant, another getting a new titanium lower jaw. A motorcyclist patient whose face had been seriously injured in a road accident had it rebuilt with 3D printed parts.

Bioprinting allows for the 3D printing of artificial organs, helping solve organ failure issues in patients faster, important to both the patient and his/her family and to healthcare systems.

3D printed tissues have been developed for pharmaceutical testing as a cost-effective and ethical means of helping identify the side effects of drugs and validating safe dosages.

Pills can be produced, using the 3D printing process of Binder Jetting. The process allows the pills produced to be very porous, therefore enabling high dosages in a single pill that can be dissolved quickly and easily digested, useful for treating conditions such as epilepsy.

FUSED DEPOSITION MODELING (FDM) NYLON 3D PRINTING

As mentioned earlier, nylon 3D printing in FDM is a bit difficult but with the right tools it can be used to produce consistent results. We will start with some of the common challenges with nylon 3D Printing.

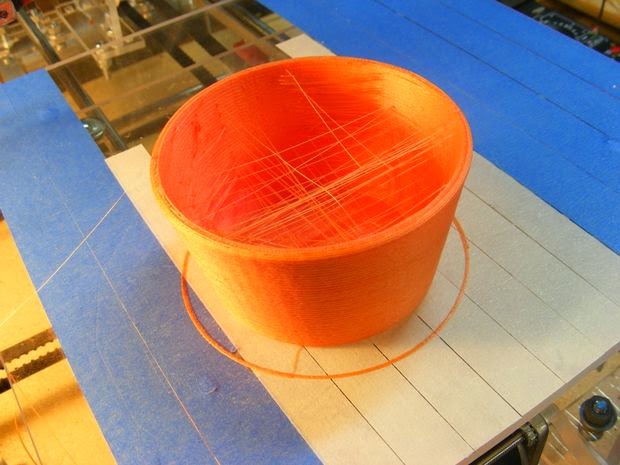

Common Challenges with Nylon 3D Printing

One challenge in nylon 3D printing is that nylon is highly hygroscopic. Even short-term exposure to high humidity can result in “wet” filament which, when printed, can lead to inconsistency in dimensional accuracy and part strength. Due to this property, it is critical to store the nylon filament in a dry place. Professional FDM 3D printers are enclosed so moisture can be safely avoided but for new users working with DIY or cheaper desktop printers, the material is exposed to air while printing. This makes it prone to moisture. The moisture absorbed by nylon gets heated up when it passes through the heater and the moisture forms bubbles only to burst during the heating process. This bursting leaves visible gaps in the 3D printed parts, leading to poor output.

This makes it prone to moisture. The moisture absorbed by nylon gets heated up when it passes through the heater and the moisture forms bubbles only to burst during the heating process. This bursting leaves visible gaps in the 3D printed parts, leading to poor output.

Additionally, nylon is prone to warping issues. Warping occurs when there is uneven cooling of the print and the print curls from the build plate, distorting the printed part. This can be avoided by efficient gluing of the print bed and using a heated bed to keep the bottom layer of the print mildly heated so that it sticks to the bed for the duration of the print. As an extra precaution, the cooling fans can be switched off (all slicers have options to switch off fans during printing) while printing with nylon.

It is also recommended that printing nylon is conducted in a well-ventilated area due to its chemical composition.

Solutions to Nylon 3D Printing

Luckily, there are professional 3D printers such as the MakerBot METHOD that are both affordable for businesses, and have features that enable easy and consistent 3D printing with nylon. One example of these advanced professional features is an enclosed heated build chamber, which minimizes warping and inconsistent cooling during the print, and can also be used before printing to dry the filament on the spool. Another such feature is sealed material bays, which prevents the material from contact with the surrounding environment. These two additions almost entirely solves the problems associated with nylon 3D printing and might be worth considering during purchase if nylon is a preferred 3D printing material.

One example of these advanced professional features is an enclosed heated build chamber, which minimizes warping and inconsistent cooling during the print, and can also be used before printing to dry the filament on the spool. Another such feature is sealed material bays, which prevents the material from contact with the surrounding environment. These two additions almost entirely solves the problems associated with nylon 3D printing and might be worth considering during purchase if nylon is a preferred 3D printing material.

FDM NYLON MATERIAL PROPERTIES

| PARAMETER | Imperial | Metric |

|---|---|---|

| Heat Deflection (ASTM 648, 66 psi) | 196°F | 91°C |

| Flexural Modulus (ASTM D790, 15 mm/min) | 250,000 psi | 1,700 MPa |

| Flexural Strength (ASTM D790, 15 mm/min) | 14,000 psi | 97 MPa |

| Tensile Strength at yield (ASTM D638, 50 mm/min) | 9500 psi | 66 MPa |

| Tensile Modulus (ASTM D638, 50 mm/min) | >320,000 psi | >2,200 MPa |

| Strain at Yield - Elongation (%) | >10% | >10% |

| Notched Impact Strength (ASTM D256) | >3. 5 ft-lb/in 5 ft-lb/in | >187 J/m |

(Specifications for MakerBot Nylon)

ADVANTAGES

➜ Mechanical Properties

➀ High impact resistance - Durable in situations where parts are constantly banging together or being dropped.

➁ Abrasion resistant - Nylon’s low coefficient of friction allows nylon to be used in applications with moving parts that would otherwise wear on each other

➂ Flexible - In thinner geometries nylon can be flexed repeatedly without fracturing

➜ Post-Processing: Nylon is hygroscopic and this property helps it to be easily post-processed by absorbing fabric dyes and spray paints.

DISADVANTAGES

➜ Hygroscopic: Nylon is hygroscopic, i.e., it absorbs moisture from the air which can affect its print quality and ultimately the part performance.

➜ Pre-Drying: Nylon should be pre-dried to remove any moisture it has absorbed. This requires extra effort, extra equipment, and extra time. And if the drying is insufficient, then the print shows

This requires extra effort, extra equipment, and extra time. And if the drying is insufficient, then the print shows

➜ Warping: Nylon is prone to warping and thus can distort the part.

WHERE TO BUY?

Nylon material can either be bought from filament manufacturers or 3D printer manufacturers.For the MakerBot 3D METHOD, we recommend use of MakerBot Nylon as it is optimized to deliver great results.

Looking for a professional 3D printing platform that works with a variety of manufacturing-grade materials? Learn more at makerbot.com/method.

Related Posts

3D Printable Nylon

- 1 Description

- 2 Specifications

- 3 Advantages and disadvantages of nylon

- 3.1 Features

- 3.2 Disadvantages

- 4 3D printing use

- 5 Use of available materials

Description

Nylon is attractive as a material for 3D printing due to its high wear resistance, affordability and excellent slip coefficient, which allows the use of nylon in bearings and other similar mechanisms, often without the use of lubricants.

An example of a model created using Stratasys Nylon 12

Despite the widespread use of nylon in the industry, the use of this material in 3D printing is quite limited due to certain technological difficulties. However, in recent years, specialized nylon consumables have appeared, focused on use with SLS and FDM printers.

Taulman and Stratasys nylon threads are the most popular examples.

Specifications

| Taulman 618 | Taulman 645 | Stratasys Nylon 12 | |

| Density | 1.134 g/cm³ | – | – |

| Hygroscopicity | 3.09% | 3.09% | – |

| Tensile strength | 65. 99 MPa 99 MPa | 85.68 MPa | 48.26-53 MPa |

| Elongation at Break | Over 300% | Over 300% | 9.5-30% |

| Melting point | 218°C | 214°C | 178°C |

| Glass transition temperature | 49.4°C | 68.2°C | – |

| Extrusion temperature | 235-260°C | 235-260°C | – |

| Pyrolysis temperature | 350-360°C | 350-360°C | – |

Stratasys Nylon 12 is designed for use with Fortus brand 360mc, 400mc and 9 professional rigs00mc, while Taulman's nylon filaments are designed to work with any home and office 3D printer optimized for the popular ABS plastic. In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

In addition, Taulman is testing a range of laser sintered nylon materials, including a powder version of Taulman 618.

Advantages and disadvantages of nylon

Advantages of

- High wear resistance

- High elasticity

- Resistant to most organic solvents

- High temperature resistance

- Easy to machine

Disadvantages

- High hygroscopicity

- Release of toxic fumes during pyrolysis

- Taulman brand nylon threads available in 1.75mm and 3mm diameters

3D printing use

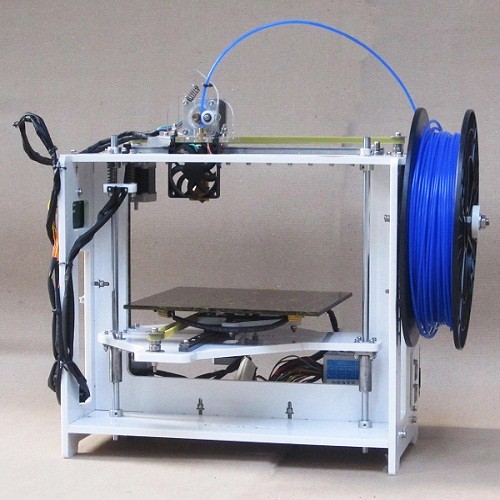

Taulman brand nylon filaments are available in 1.75mm and 3mm diameters

Nylon printing technology is similar to ABS printing, but with some differences. Like ABS, nylon is prone to twisting and warping when cooled unevenly, requiring the use of a heated bed.

The nylon layers have excellent adhesion, which minimizes the chance of delamination of models. Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding.

Users of Taulman plastics note the durability of models at the level of analogues made by traditional injection molding.

Nylon is almost impossible to bond, which makes it difficult to manufacture large-sized parts from components. Alternatively, it is possible to connect nylon parts by melting the surfaces to be joined.

Nylon can be dyed with acid-based dyes.

Nylon does not adhere to glass or other smooth surfaces, so it is recommended to apply painter's tape to the desktop or use a wood backing when printing.

Due to the high hygroscopicity of nylon (the ability to absorb moisture), it is recommended to dry the nylon filament immediately before printing. Otherwise, water vapor may be released from the nozzle, which is not catastrophic for the extruder, but may affect print quality.

Use of scrap materials

Some hobbyists prefer to use inexpensive nylon line for printing, which is fraught with some unpleasant consequences. As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle.

As a general rule, trimmer line is preferred, available in 3mm diameter, which is the same diameter as commercially available ABS filaments for FDM printing. However, these "nylon threads" are not pure nylon, which is evident due to their excessive stiffness, which is not characteristic of nylon. The reason for this is additives - usually in the form of fiberglass. Additives are designed to both increase stiffness and reduce the cost of the material. It should be borne in mind that the melting point of fiberglass is much higher than the melting point of nylon and, in fact, exceeds the pyrolysis temperature of nylon. Thus, it is impossible to achieve complete melting of such composite materials. As a result, tough glass fiber particles will contribute to increased wear and clogging of the extruder nozzle.

Go to the main page of the Encyclopedia of 3D Printing

Features 3D printing Nylon plastic (nylon)

3DPrintStory 3D printing process Features of 3D printing Nylon plastic (nylon)

Nylon is a polyamide that is often (though not always) found in PA 11 and PA 12 variants. Nylon is a very strong and durable material, providing some flexibility in thin walls. Since Nylon has a high melting point and a very low coefficient of friction, it is mainly used for 3D printing of functional assemblies that have good strength.

Nylon is a very strong and durable material, providing some flexibility in thin walls. Since Nylon has a high melting point and a very low coefficient of friction, it is mainly used for 3D printing of functional assemblies that have good strength.

Another important property of Nylon plastics is hygroscopicity, in other words, it absorbs moisture. This property can be useful as 3D printed models are easily processed with fabric and spray paints. But it also makes Nylon prone to picking up moisture from the air, which affects its performance and causes problems during direct 3D printing.

Nylon 3D printing can be realized with Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS) and MultiJet Fusion (MJF).

Standard 3D printer settings for printing Nylon plastic

- Nozzle temperature: 220° C to 270° C

- Table temperature: 75° C to 90° C

- Print speed: approx. may differ)

- Soluble: No

- Hygroscopic: yes

- Fatigue resistance: Yes

- Temperature resistant: Yes

- Impact resistant: Yes

- Flexibility: Yes (thin-walled)

- Deformation: moderate

3D printing technologies used for Nylon plastics you use FDM 3D printing, but if you use SLS and MJF 3D printing options, then these problems will not be relevant for you, so below we will look especially at 3D printing with nylon using various technologies.

FDM 3D printing

Nylon is highly hygroscopic, meaning it absorbs moisture from the air. Therefore, nylon should be stored in a dry place with silica gel. In practice, it absorbs about 10% of its weight in the form of water. When the material is heated during 3D printing, moisture rushes out, affecting not only the substrate and layer adhesion, but also giving the surface an unwanted roughness.

Therefore, it is recommended to dry it before 3D printing. Oven drying is one of the best options for successful printing.

Nylon also has problems with first coat adhesion. When 3D printing with nylon, it is recommended to use a heated table. In addition to heating the table, you should also think about applying glue to its surface. Avoid using cooling fans.

Nylon oven drying instructions. Before inserting the plastic, the oven must be preheated to the desired temperature. Make sure the temperature is set correctly as overheating can cause the plastic to melt.

General drying settings. Typically preheating temperature: 70° C to 80° C. Required time: 4 to 6 hours. After completion of the drying process described above, the nylon should be placed in a sealed container with a desiccant.

IMPORTANT. Set the drying temperature so that it is below the glass transition temperature (Tg) otherwise you may ruin the plastic.

Selective Laser Sintering (SLS)

SLS is the most suitable technology for nylon 3D printing. 3D printing nylon mainly exists as PA 11 and PA 12 or as composite materials such as carbon fiber nylon and glass fiber. Nylon PA 11 is more flexible than PA 12, while the latter has excellent mechanical properties ideal for functional prototypes.

When printing with SLS, nylon is added as a powder. This technology produces excellent 3D models with excellent material properties, albeit with a slightly rough surface.

Standard Nylon SLS Print Settings:

- Tolerance: ± 0.3% (min: ± 0.