Loughborough university 3d printing concrete

3D Concrete Printing | Loughborough University

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

Groundbreaking advances in 3D concrete printing

Revolutionising the manufacture of construction and architectural components

What's new

- Visit the project website for more information and the latest media coverage

- "Tomorrow's Buildings: Construction industry goes robotic" (BBC coverage of 3DCP, 4 May 2016)

- Commercial prototyping and development work with the Skanska consortium re-locates to The Manufacturing Technology Centre - the UK’s pre-eminent centre for manufacturing innovation (February 2016)

- "Technical advances are making 3D printed concrete a reality" (RIBA Journal, 23 December 2015)

- "Will 3D printing revolutionise manufacturing?" (BBC report, 28 July 2011)

Partners

The 3DCP technology is currently being developed in association with ABB, Buro Happold, Foster + Partners,The Manufacturing Technology Centre (MTC), Skanska and Tarmac.

[PDF] Loughborough University Institutional Repository 3 D printing using concrete extrusion : a roadmap for research

- Corpus ID: 67839710

@inproceedings{Silvab2018LoughboroughUI, title={Loughborough University Institutional Repository 3 D printing using concrete extrusion : a roadmap for research}, author={W. R. Leal de Silvab and S. Z. Jonesc and J. Dirrenbergerd}, year={2018} }- W. R. L. D. Silvab, S. Jonesc, J. Dirrenbergerd

- Published 2018

- Materials Science

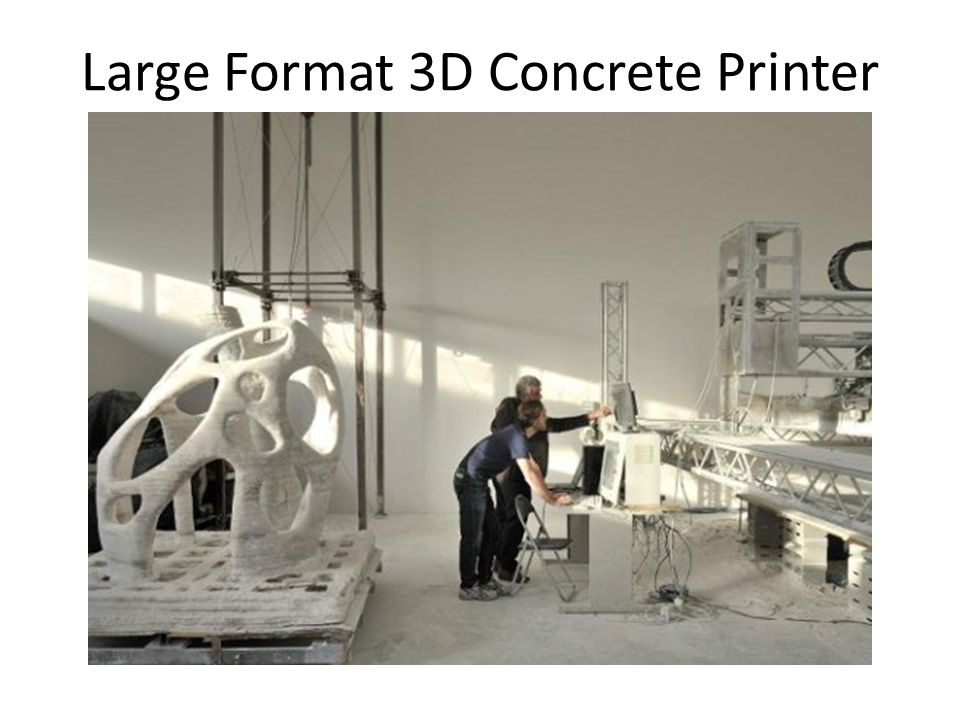

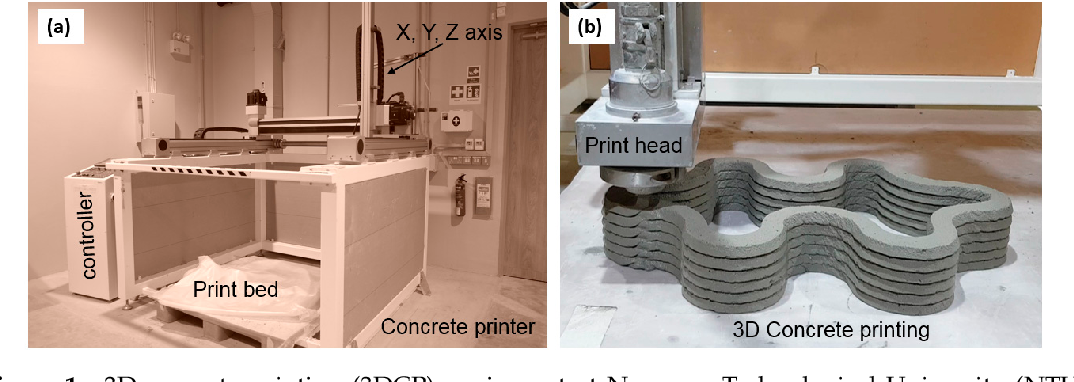

Large-scale additive manufacturing processes for construction utilise computer-controlled placement of extruded cement-based mortar to create physical objects layer-by-layer. Demonstrated applications include component manufacture and placement of in-situ walls for buildings. These applications vary the constraints on design parameters and present different technical issues for the production process. In this paper, published and new work are utilised to explore the relationship between fresh…

In this paper, published and new work are utilised to explore the relationship between fresh…

dspace.lboro.ac.uk

Injection 3D Concrete Printing (I3DCP): Basic Principles and Case Studies

- N. Hack, Inka Dressler, L. Brohmann, Stefan Gantner, D. Lowke, H. Kloft

Materials Science, Engineering

Materials

- 2020

The initial results confirmed both the technological and economic feasibility of the I3DCP process, and demonstrate the potential to further expand the scope of this novel technology.

SHOWING 1-10 OF 58 REFERENCES

SORT BYRelevanceMost Influenced PapersRecency

Mix design and fresh properties for high-performance printing concrete

- T. Le, S. Austin, S. Lim, R. Buswell, A. Gibb, T. Thorpe

Materials Science, Engineering

- 2012

This paper presents the experimental results concerning the mix design and fresh properties of a high-performance fibre-reinforced fine-aggregate concrete for printing concrete. This concrete has…

This concrete has…

Particle-bed 3D printing in concrete construction – Possibilities and challenges

- D. Lowke, E. Dini, A. Perrot, D. Weger, C. Gehlen, Benjamin Dillenburger

Engineering, Materials Science

Cement and Concrete Research

- 2018

Modelling curved-layered printing paths for fabricating large-scale construction components

- Sungwoo Lim, R. Buswell, Philip J. Valentine, Daniel Piker, S. Austin, X. D. Kestelier

Materials Science

- 2016

Optimising 3D printed concrete structures using topology optimisation

- P. Martens, M. Mathot, F. Bos, J. Coenders

Materials Science

- 2017

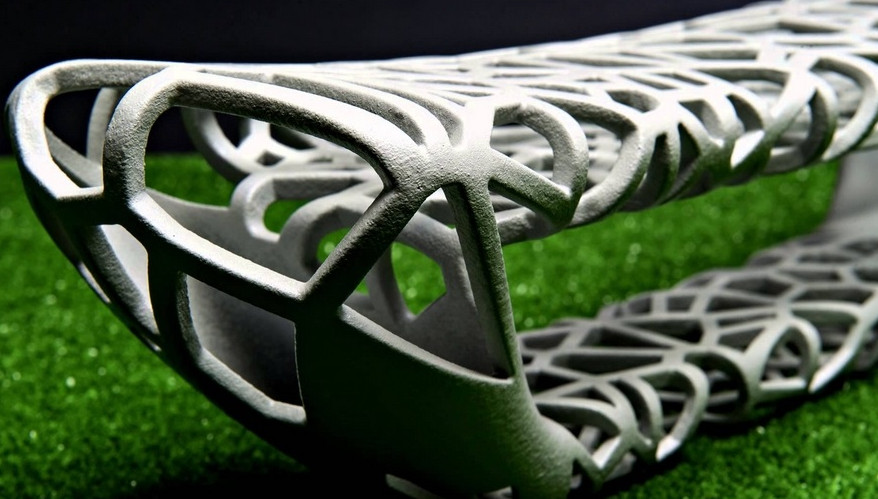

The potential of using this technology is that it will be possible to create complex and/or customised concrete designs with the expectation that the costs will be low and the construction speeds will be high, and this new technology will provide opportunities to create more efficient structures.

3D Printing Concrete with Reinforcement

- F. Bos, Zy Zeeshan Ahmed, Rjm Rob Wolfs, Tam Theo Salet

Materials Science

- 2017

It is shown that high-performance steel cables can provide suitable reinforcement characteristics, although improved bond would allow better use of the cable capabilities, and several options for online reinforcement medium are compared for printability and structural performance.

Developments in construction-scale additive manufacturing processes

- Sungwoo Lim, R. Buswell, T. Le, S. Austin, A. Gibb, T. Thorpe

Materials Science

- 2012

Additive manufacturing of geopolymer for sustainable built environment

- B. Panda, S. C. Paul, L. Hui, Y. Tay, M. Tan

Materials Science

- 2017

3D concrete printing – a structural engineering perspective

- Tam Theo Salet, F. Bos, Rjm Rob Wolfs, Zy Zeeshan Ahmed

Materials Science

- 2018

3D Concrete Printing (3DCP) is being developed in an increasing number of places around the globe. The focus is mainly on a trial-and-error based exploration of the possibilities. However, to obtain…

The focus is mainly on a trial-and-error based exploration of the possibilities. However, to obtain…

Development of a viable concrete printing process

- Sungwoo Lim, R. Buswell, T. Thorpe

Materials Science

- 2011

A novel Concrete Printing process has been developed, inspired and informed by advances in 3D printing, which has the potential to produce highly customised building components. Whilst still in their…

Large-scale 3D printing of ultra-high performance concrete – a new processing route for architects and builders

- C. Gosselin, R. Duballet, Philippe Roux, N. Gaudillière, J. Dirrenberger, P. Morel

Materials Science

- 2016

Once again about the use of 3D technologies

3D Printer in the Construction Industry

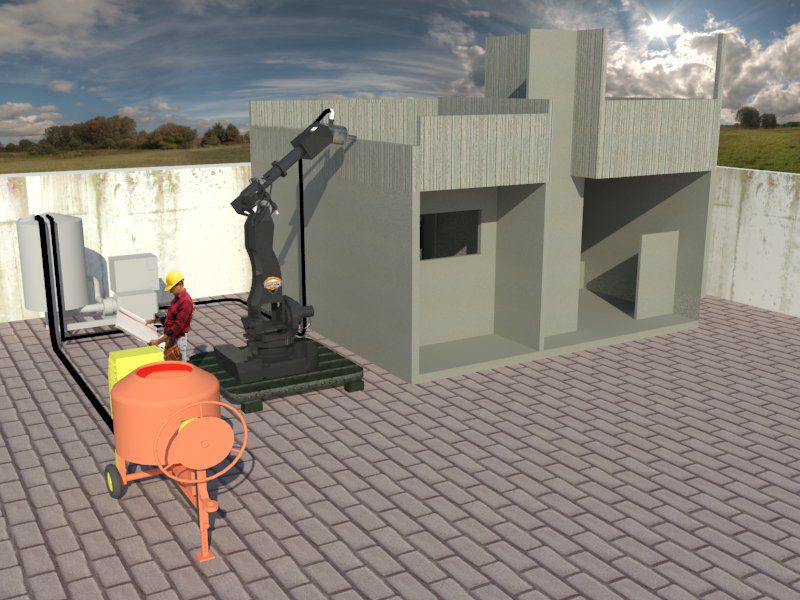

A group of engineers from the British University of Loughborough, working under the direction of Dr. Sungwu Lim, managed to create a unique cement composition that allows printing products of any shape: convex, cornerstone, curved, cubic.

Researchers abandoned the use of laser sintering technology and digital light processing. Instead, they returned to the origins of 3D printing with a slightly modified fusing technology.

Advanced cement formula is extruded, which greatly simplifies construction work, as it eliminates the need for formwork. Ready-made concrete figures are easy to adjust and finish.

The experiments of British engineers did not go unnoticed. Their idea aroused the keen interest of scientists from the University of Southern California. They suggested using huge 3D printing machines directly on construction sites.

At the moment, a project called Contour Crafting has been sent to the US Patent Office, on the basis of which it is planned to assemble a huge printer that can print complete houses: not only load-bearing walls, but also wiring along with plumbing.

Jewelry Sphere

The main advantages of jewelry 3D printers are ultra-high printing precision and excellent surface quality. We emphasize once again that thanks to the technologies used, the printed three-dimensional models are exceptionally smooth and do not require additional processing or adjustment.

We emphasize once again that thanks to the technologies used, the printed three-dimensional models are exceptionally smooth and do not require additional processing or adjustment.

Now about a dozen specialized (CAD) programs have come to your aid, allowing you to virtually work out all the smallest details of a future gold or silver jewelry on a computer screen. And if we add the capabilities of modern 3D scanners, which are also available in our company, to the capabilities of CAD programs, then the work of a jeweler will be even more simplified.

Photo - a few examples of 3D printing models of future jewelry, pay attention to the complexity and detail of the elaboration of the smallest elements.

Automotive

Local Motors uses 3D printing to produce their Strati cars.

Local Motors hopes to start selling their car, called the Strati, next year. The car, which will be produced in small series, still has to pass crash tests and overcome a number of other obstacles before this happens. They report that the finished car, which receives the powertrain, suspension and other parts from Renault, will cost in the region of $18,000 - $30,000, including the production of printed parts, which cost more than $5,000.

They report that the finished car, which receives the powertrain, suspension and other parts from Renault, will cost in the region of $18,000 - $30,000, including the production of printed parts, which cost more than $5,000.

But the use of 3D printers is not limited to designs or extravagant cars. Supercar Koenigsegg One:1 with 1,341 hp uses some 3-D printed parts, including a turbo assembly and a titanium exhaust tip, which take only three days to produce, but this reduces their weight by half a kilo. Race car designers Nissan Motor Corp. Delta-Wing uses 3-D printing to create brake radiators, air intakes and transmission side covers.

Among more mainstream production vehicles, the next generation of the Mercedes-Benz S-Class due in 2018 will feature 3-D printed interiors, including air vents and speaker grilles, British website AutoExpress told in August. chief designer of Mercedes.

Medicine

Prostheses - recently in medicine, prostheses made on 3d printers have become widespread, which take into account the individual characteristics of a person as much as possible and can be quite complex in design and withstand heavy loads;

Skull copy – using special scanners, it became possible to reproduce an exact copy of a human skull and use part of this copy as an implant;

Intervertebral discs - thanks to a 3D printer that works with materials containing stem cells, it is possible to restore damaged areas of the spine or even create new, artificial discs;

3D models and crowns - using 3D printing technologies, special 3D models are produced that help in surgery, and dental crowns are also made;

An operation has now been performed to implant a piece of the skull into the patient. This implant was made using a 3d printer, but before that, a model of the patient's skull was created thanks to a 3d scanner, which is also widely used. The advantage of this model is that it takes into account all the uniqueness of the structure and shape of the patient's skull, which means it fits him better. Such a model was made for two weeks after scanning, it was made up of 23 bones, which are part of the human skull. All even the smallest details are taken into account. Such implants are currently helping a large number of people who have suffered from traumatic brain injuries.

This implant was made using a 3d printer, but before that, a model of the patient's skull was created thanks to a 3d scanner, which is also widely used. The advantage of this model is that it takes into account all the uniqueness of the structure and shape of the patient's skull, which means it fits him better. Such a model was made for two weeks after scanning, it was made up of 23 bones, which are part of the human skull. All even the smallest details are taken into account. Such implants are currently helping a large number of people who have suffered from traumatic brain injuries.

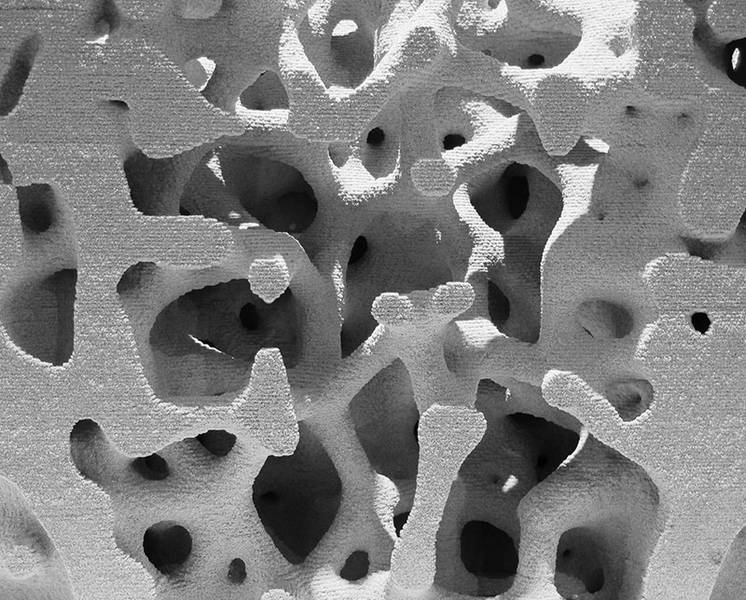

In addition to implants, 3D printing is also used to make prostheses for various parts of the human body. These prostheses take into account the individuality of the structure and the uniqueness of human needs, and therefore are very comfortable. In these prosthetic systems, microcavities are specially left, thanks to which the patient's own healthy tissue cells are able to move in them. Thus, faster adaptation to the prosthesis is carried out.

Thus, faster adaptation to the prosthesis is carried out.

Aircraft industry

In 1995, the Northwest Polytechnic Institute of China (NPU) launched the Laser Additive Manufacturing (LAM) research program to develop metal 3D printing devices using titanium alloys, superalloys, and stainless steel.

At present, LAM developments are widely used in the design and manufacture of Chinese military aircraft, in particular, the J-15 carrier-based fighter, the J-16 fighter-bomber, the J-20 stealth fighter and the latest fifth-generation fighter J-31.

In addition to the military, 3D printers are also being used in China's civil aviation.

In 2013, in the laboratory of the already mentioned NPU institute, a 5-meter central wing spar was printed for the promising Comac C-919 passenger aircraft, which was supposed to enter commercial operation in 2016.

Thanks to the use of 3D technologies, it was possible to significantly reduce the weight of the spar - it weighs only 136 kg (a similar part obtained by forging - 1607 kg). At the same time, material savings amounted to 91.5%, and tests have shown that 3D printed parts behave at least as well as those obtained by traditional methods.

At the same time, material savings amounted to 91.5%, and tests have shown that 3D printed parts behave at least as well as those obtained by traditional methods.

FOOD

According to most films, our future is scary and wonderful at the same time. What will we see? What do we do? What will we eat? Since microwaves are radiation to many of us, we are constantly inventing new ways of cooking. Now that the world has learned about 3D printing, it is only natural that this technology will be used for cooking and make this process easier, or at least more fancy. If you believe the Star Trek movie, then 3D printing will be the only way to cook food in 2,000 years. So let's go over the list of eleven different food printing machines to get an idea of the near future of food:

1. 3D Systems ChefJet Printer

The ChefJet 3D premiered at CES in January of this year. The 3D printer produces some of the most amazing 3D prints I've ever seen, and they taste just as good as they look. The ChefJet was originally developed by a small firm, Lab Sugar, founded by a married couple of architects, Kyle and Liz von Hasseln.

The ChefJet was originally developed by a small firm, Lab Sugar, founded by a married couple of architects, Kyle and Liz von Hasseln.

To satisfy their sweet tooth, 3D Systems acquired a start-up and rebranded the company, emphasizing that this 3D printer is the ideal tool for restaurateurs, professional chefs. It is also a must for consumers who want to 3D print goodies in beautiful and decorative shapes that are even a pity to eat. ChefJet comes in two versions - standard and professional, which allows you to print in color. What's more, ChefJet prints just about any flavor that a modern food lab can create.

According to 3D Systems, the ChefJet is scheduled to be released in "the second half of 2014" for less than $5,000, the only problem is that the second half of 2014 is almost over and the printer still hasn't hit store shelves. Unfortunately, 3D Systems revealed during its Q3 financial report that many of the printers scheduled for release this year never saw the light of day, so we won't see the ChefJet outside of shows and blogs until next year.

2. Natural Machines Foodini Printer

Although this list is not meant to be rated, Foodini ranks first alongside ChefJet in terms of how they attract public attention. With a marvelous marketing campaign and the ability to prepare savory meals, Natural Machines Foodini 3D Printer is the answer to the age-old question of healthy eating. Foodini users can cook with fresh ingredients, create a variety of pastas, and place them in reusable capsules, which are then printed in any 3D shape. By using freshly made pastas, there is an opportunity to opt for healthy, natural foods, as opposed to processed foods that are crammed with additives.

Natural Machines launched a Kickstarter campaign back in March of this year, but the goal was not met. And it's pretty amazing, as Potato Saladearned got 554928% of its Kickstarter goal. Being confident in their idea, Natural Machines does not give up. Instead, they are completing their funding phase and planning to mass-produce their printers in the second half of 2015 for a retail price of around $1,000. I would like to point out that Foodini does not cook the food it prints, so you need to either print the food that is already edible or cook it. after printing.

I would like to point out that Foodini does not cook the food it prints, so you need to either print the food that is already edible or cook it. after printing.

3. f3d 3d printer designed by smart students from England

is able to use up to five different extruders, and prepares his food prints using a 1400W halogen oven. The students were able to print out three different ingredients—dough, tomato sauce, and cheese—and make one dish: a tiny pizza. The total cost of the components is about $1900.

4. SMRC Food Printer for NASA

What associations do most people have when they hear the word NASA? Food. NASA has been making strides in food science ever since they sent the Tang drink into orbit in 1962 with the Friendship 7 spacecraft. Texas, where Senior Mechanical Engineer Anyan Contractor is working on a food printer for astronauts bound for Mars. Using raw ingredients packaged in capsules, SMRC's food printer can combine different individual ingredients to 3D print a wider variety of food. The firm has already printed proof of its concept, a pizza that was ready in just 70 seconds after printing. The next step for the SMRC is to add nutrients to their meals so that one day, the Mars colonists will be provided with the vitamins and minerals they need to fight the space monsters.

Texas, where Senior Mechanical Engineer Anyan Contractor is working on a food printer for astronauts bound for Mars. Using raw ingredients packaged in capsules, SMRC's food printer can combine different individual ingredients to 3D print a wider variety of food. The firm has already printed proof of its concept, a pizza that was ready in just 70 seconds after printing. The next step for the SMRC is to add nutrients to their meals so that one day, the Mars colonists will be provided with the vitamins and minerals they need to fight the space monsters.

5. Choc Creator Printer by Choc Edge

There are a number of companies on the market that 3D print chocolate. They can either print sweets for you or sell you their own 3D chocolate printers. Choc Creator by Choc Edge is one of the first chocolate 3D printers on the market. Designed by Dr. Liang Hao in 2012, Choc Creator can draw most of the 2D shapes you can think of individually or on cakes and cookies. And with some skill, you can create entire 3D layers. Choc Creator II is currently available for a discounted price of £3200.

And with some skill, you can create entire 3D layers. Choc Creator II is currently available for a discounted price of £3200.

6. Extruder for cakes and chocolate from ZMorph

As you already understood, buying a food 3D printer is not so easy. With the exception of the Choc Creator, commercial food 3D printers really aren't on the shelves yet. Thus, you have to either wait or make them yourself. You can also buy a "regular" desktop 3D printer and make it print with something edible. Some printer makers have already picked up on the idea, like ZMorph, who make a versatile 3D printer with interchangeable tools, including a pasta extruder that can 3D print chocolate and dough.

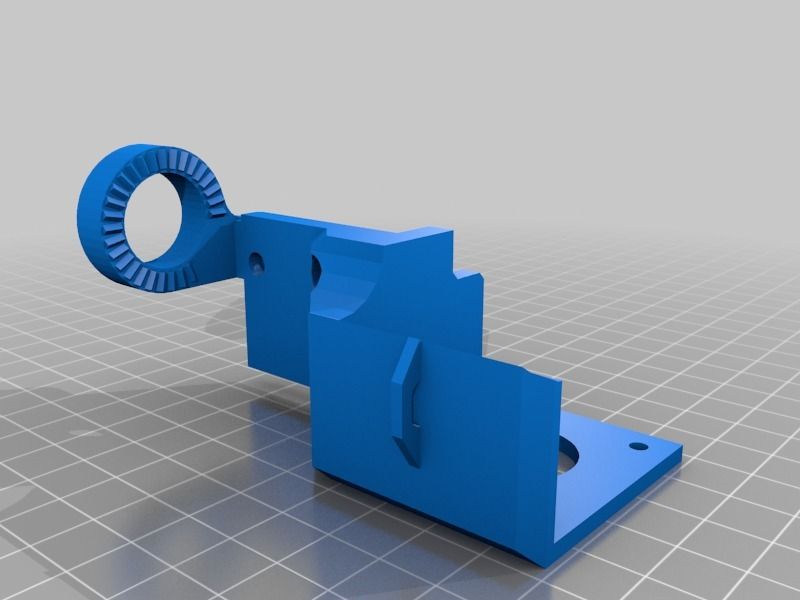

7. Structur3D's Discov3ry Extruder

If you already have a 3D printer but want to use it for food purposes, you should consider Structur3d's Discov3ry Extruder, which isn't really available online yet. store. Discov3ry is a versatile paste extruder. The campaign to fund it has already been successfully launched on Kickstarter. In no time, you will be able to meet all your printing needs with paste, namely chocolate, icing, or other viscous but less edible materials such as silicone and clay. If you don't feel like waiting, you can build your own versatile grazing extruder, following the example of designer Richard "RichRap" Horne.

store. Discov3ry is a versatile paste extruder. The campaign to fund it has already been successfully launched on Kickstarter. In no time, you will be able to meet all your printing needs with paste, namely chocolate, icing, or other viscous but less edible materials such as silicone and clay. If you don't feel like waiting, you can build your own versatile grazing extruder, following the example of designer Richard "RichRap" Horne.

8. Dovetailed Fruit 3D Printer

If you're picky enough that you don't want to eat pasta, then wait until Fruit 3D Printer comes out. Its creators have come up with a way to fill a sodium gel with flavors that mimic strawberries, after which the entire mixture is placed in a solution of calcium chloride to obtain a product that looks like raspberries. After an initial flurry of media coverage and prints that look more like jelly than real fruit, the firm is never heard from again. However, this is an innovative approach to the art of food printing.

9. TNO's 3D Everything Printer

TNO (or "Nederlandse Organisatie voor Toegepast Natuurwetenschappelijk Onderzoek", I hope you haven't broken your tongue) has come a long way in the field of food printers. This Dutch research group has been working on 3D food printing since 2012 and treats the topic as a major technological breakthrough, not a kitchen fantasy.

TNO believes that these printers can help humanity print food according to the individual needs of each individual. Using historical and physiological data, the printer can prepare food that contains the right amount of nutrients, and at the same time uses flavors according to the user's mood, using alternative sources of nutrients: algae, beet leaves and even insects.

TNO is already partnering with Barilla 3D printing 15-20 pasta every two minutes. They have also teamed up with Chloé Rutzerveld and 3D printed biscuits made from dried fruits, vegetables, nuts and seaweed filled with yeast, bacteria and germinated seeds. Delicious!

10. Goop Printer by Biozoon

If you're under 60, chances are you won't see this printer any time soon. The German company Biozoon is developing mold printing from a nutrient mash specifically for elderly residents of a nursing home. With financial support from the EU, Biozoon plans to complete the 3D food printer by 2015. Using 48 nozzles, liquefied food and a thickening agent, this printer will recreate the shape and taste of something hard to swallow, like a chicken wing, but such a product will simply melt in the mouths of old people. Moreover, such food will be full of nutrients, so necessary to maintain their health.

11. The original food printer from Fab@Home

It is possible that the entire food printer industry began with Fab@Home. The fact is that the creators of this device, Hod Lipson and Evan Malone from Cornell University, just decided to experiment with the introduction of rapid prototyping to the masses at a low price, and the instructions were posted in the public domain. With this, their task was completed. Since 2010, their lab, along with local partners such as the French Culinary Institute, have been among the first to experiment with food extrusion: 3D baked livers with letters baked inside, spaceship-shaped scallops, chocolate, icing, cheese and more. . If it weren't for their creation, we might never have even seen 3D like this - non-printed cakes, chicken wing-shaped porridges, or small pizzas.

With this, their task was completed. Since 2010, their lab, along with local partners such as the French Culinary Institute, have been among the first to experiment with food extrusion: 3D baked livers with letters baked inside, spaceship-shaped scallops, chocolate, icing, cheese and more. . If it weren't for their creation, we might never have even seen 3D like this - non-printed cakes, chicken wing-shaped porridges, or small pizzas.

What associations do most people have when they hear the word NASA? Food. NASA has been making strides in food science ever since they sent the Tang drink into orbit in 1962 with the Friendship 7 spacecraft. Texas, where Senior Mechanical Engineer Anyan Contractor is working on a food printer for astronauts bound for Mars. Using raw ingredients packaged in capsules, SMRC's food printer can combine different individual ingredients to 3D print a wider variety of food. The firm has already printed proof of its concept, a pizza that was ready in just 70 seconds after printing. The next step for the SMRC is to add nutrients to their meals so that one day, the Mars colonists will be provided with the vitamins and minerals they need to fight the space monsters.

The next step for the SMRC is to add nutrients to their meals so that one day, the Mars colonists will be provided with the vitamins and minerals they need to fight the space monsters.

Weapons

For the first time the idea to print military weapons on a 3D printer appeared in the United States of America.

In May 2013, a video appeared on the Internet in which a man shoots from a printed mock-up of a Liberator pistol. It was 25-year-old Cody Wilson, head of Defense Distributed, which promotes the idea of universal availability of 3D weapons.

Using a 3D printer, they printed firearms and uploaded the files of their work to the World Wide Web. Defense Distributed employees have already made magazines that hold more cartridges for the AR-15s rifle and the legendary Kalashnikov assault rifle (AK-47 modification). Also on their account is the manufacture of the lower part of the receiver, in which the bolt of a self-loading rifle AR - 15 is placed. You can attach the barrel and magazine to it, having received a finished weapon without any problems. No authorization is required to purchase parts in the USA. Now work is underway on a 3D printout of the entire rifle. In doing so, Cody and his team dealt a major blow to the American gun control debate. The discussion began in December, after twenty children and six adults were killed by assassins at a junior high school in Connecticut. The vast majority of Americans rallied to support government reform. This is a thorough check that will make it difficult for criminals to obtain weapons. However, this did not prevent Mr. Wilson from obtaining a federal license to manufacture and sell firearms.

You can attach the barrel and magazine to it, having received a finished weapon without any problems. No authorization is required to purchase parts in the USA. Now work is underway on a 3D printout of the entire rifle. In doing so, Cody and his team dealt a major blow to the American gun control debate. The discussion began in December, after twenty children and six adults were killed by assassins at a junior high school in Connecticut. The vast majority of Americans rallied to support government reform. This is a thorough check that will make it difficult for criminals to obtain weapons. However, this did not prevent Mr. Wilson from obtaining a federal license to manufacture and sell firearms.

More serious developments in the field of printing firearms on a 3D printer are being carried out in Austin, Texas. The project is led by Eric Macler, coordinator at Solid Concepts, a 3D printing company.

Erik Machler

Ten industrial 3D printers are installed at the Austin plant. Solid Concepts received a federal license to manufacture weapons, and now, using direct metal laser sintering technology, produces the Browning 19 pistol.eleven". Making a pistol takes up to 35 hours. Depending on which printer and materials are used. More than 1,000 shots have already been fired from the first printed pistol, Solid Concepts, while the company has created a second version of the Browning 1911 model.

Solid Concepts received a federal license to manufacture weapons, and now, using direct metal laser sintering technology, produces the Browning 19 pistol.eleven". Making a pistol takes up to 35 hours. Depending on which printer and materials are used. More than 1,000 shots have already been fired from the first printed pistol, Solid Concepts, while the company has created a second version of the Browning 1911 model.

FASHION

Another famous designer has started experimenting with 3D printing technology. And the results are simply amazing. Katherine Wales started her career in the fashion industry over 15 years ago. She has trained and collaborated with some of the most eminent professionals in the profession, including Jasper Conran, Jean Charles de Castelbajac, Oswald Boateng, Emmanuel Ungaro and Saint Laurent. However, she worked independently on her latest collection. The collection was born thanks to the innovative achievements in the field of additive technologies of the London College of Fashion. She combined all the models into a collection called "DNA Project", thanks to which, among other things, the designer touched the world of 3D printing and transferred her ideas to the creation of accessories.

The collection was born thanks to the innovative achievements in the field of additive technologies of the London College of Fashion. She combined all the models into a collection called "DNA Project", thanks to which, among other things, the designer touched the world of 3D printing and transferred her ideas to the creation of accessories.

The DNA Project is not entirely unique. The collection is the result of a synergy of haute couture, technology and science. As a result of this interaction, incredible models were born that embody the features and structure of human chromosomes. The DNA Project is almost entirely made up of separate and identical balls and structural components (through the use of 3D printing technology) that can create a wide variety of shapes.

FURNITURE

A graduate of the Royal Academy of Art in The Hague, Lillian van Daal was one of the first to develop a unique structure ideal for creating 3D printed furniture.

The designer took the cell structure of living organisms as a basis. A mixture of modern technology, creative genius, and the ability to visualize the finished result helped her create a Biomimicry soft chair printed with plastic filament. The finished product consists of a binding of soft and hard elements, thanks to which it provides a comfortable fit and stands out for its high strength and wear resistance compared to other furniture designs.

It is noteworthy that Lillian van Daal continues to work in this direction. The designer plans to replace polyamide with an environmentally friendly material to create truly safe furniture. It is possible that in the near future stands of the new Biomimicry brand will appear in furniture stores.

EDUCATION

The introduction of 3D printers into the school system is a progressive phenomenon. It contributes to the creation of new opportunities in the study and consolidation of many school subjects. For example, a teacher in a biology class can create a visual aid: some part of an animal skeleton, a human eye, and so on. Or prepare a model of a system of blocks for students for a physics lesson, details of various mechanisms.

For example, a teacher in a biology class can create a visual aid: some part of an animal skeleton, a human eye, and so on. Or prepare a model of a system of blocks for students for a physics lesson, details of various mechanisms.

ARCHITECTURE

Throughout twenty years of work in the field of computer-aided design, R. "Parta" Parthasarati meets a new client with the same question: "What problem can we solve for you?"

The usual answer is: "Accelerate time to market for our product."

With regard to architecture, Parthasarathy found that the two main causes of delays came down to a lack of theoretical study of the project and poor communication. Two years ago, he discovered 3D printing, a completely new technology that significantly reduces design time. It allows you to make an accurate three-dimensional physical model of the building and make it an important element in the work of every designer. Partha saw this as a great opportunity to improve understanding among all those involved in the project, increase efficiency and eliminate costly mistakes. Thus was born iKix, India's first architectural 3D printing service bureau.

Thus was born iKix, India's first architectural 3D printing service bureau.

Previously, all construction models were made by hand. Since this process is time consuming and expensive, architects only make the layout at the final stage of the project, just before the public presentation.

“iKix prints a 3D layout in an average of six to ten days, which is much faster than the month it takes to produce a similar layout by hand,” says Parta. “Let's say a 1,000-acre plot layout—including houses, schools, churches, golf courses, and more—we can build in six weeks versus five months of manual work. The time and cost savings become even more noticeable when plans change and the layout has to be adjusted on the fly.”

iKix uses the color Spectrum Z510 from Z Corp. The capabilities of this printer allow the architect and project manager to quickly obtain multiple copies of the layout - one each for the architect, client, general contractor, subcontractor and civil authorities. “A 3D printer is more than just a prototyping machine,” Parta says. – It really became one of the developer's tools. 3D printing is a breakthrough that I believe will determine the future of technical information exchange for the next two hundred years. Each project must be presented in 3D, and soon it will be so. I sincerely believe that all architects will work in 3D. iKix clients come here to implement more and more new projects in three-dimensional layouts. The benefits are undeniable."

– It really became one of the developer's tools. 3D printing is a breakthrough that I believe will determine the future of technical information exchange for the next two hundred years. Each project must be presented in 3D, and soon it will be so. I sincerely believe that all architects will work in 3D. iKix clients come here to implement more and more new projects in three-dimensional layouts. The benefits are undeniable."

Parta believes that infrastructure objects also need physical layouts. For example, when the authorities decided to build a highway interchange, it is necessary to plan traffic in all modes of its operation. The presence of a physical 3D model simplifies the solution of this problem.

MEDICATIONS

The US Food and Drug Administration has approved the use of 3D printed medicines for the first time. Aprecia Pharmaceuticals has received permission to manufacture tablets using 3D printing. The drug is used to prevent seizures in adults and children with epilepsy.

The tablet, called Spritam, contains a large dose of an anti-epileptic drug that dissolves in a small amount of water, which the manufacturer says should help patients with swallowing problems.

However, the big news is that this is the first time a 3D printed drug has been approved by the FDA (Food and Drug Administration), writes Business Insider.

Researchers are impressed with the potential of 3D drug printing. The technology makes it possible to create individual medicines with an accurate dosage for each patient.

3D printing can also be seen as an inexpensive way to produce drugs for developing countries. The main thing here is to prevent the production of illicit drugs, the recipe and chemical components of which can be obtained using the Internet.

It is worth noting that the FDA has long appreciated the benefits of 3D printing in medicine. The organization previously approved 3D printing of medical devices.

The organization previously approved 3D printing of medical devices.

MUSICAL INSTRUMENTS

Olaf Diegel, a talented designer who is crazy about 3D printing, presents to your attention his new creation - incredibly beautiful musical instruments. As you may have guessed, many components of the drum kit and synthesizer were recreated using a 3D printer.

“I thought that the consumable that was used in the printing process would greatly affect the sound. Fortunately, this did not happen. Of course, there are some differences, but there is no particular distortion,” says Digel.

Source

Tags:

Printing cement, laser sintering, layer -by -layer, jewelry 3D printing, 3D prosthesis printing, 3D printing titanium, implant, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models, 3D models. prosthesis printing, house printing, additive manufacturing, food printer,

Construction 3D printing - HiSoUR – HiSoUR – Hi So You Are

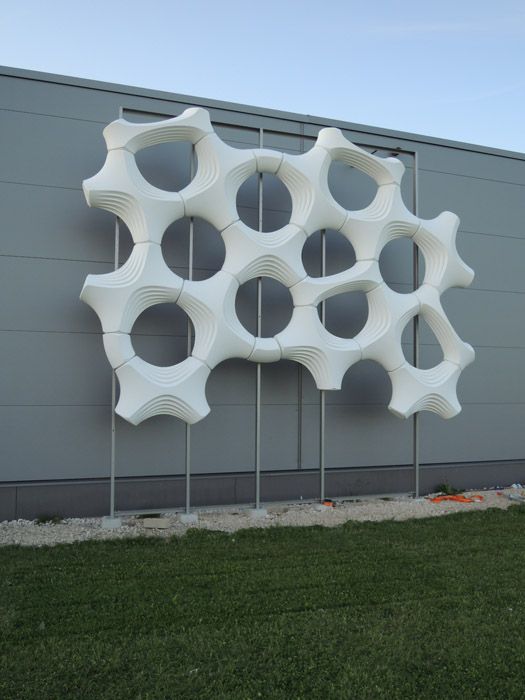

Construction 3D printing (c3Dp) or 3D Construction Printing (3DCP) refers to various technologies that use 3D printing as the main method for the manufacture of buildings or building components. Alternative terms such as large scale additive manufacturing (LSAM) or Freeform construction (FC) are also used, as well as subgroup references such as "3D concrete" used to refer to concrete extrusion technologies.

Alternative terms such as large scale additive manufacturing (LSAM) or Freeform construction (FC) are also used, as well as subgroup references such as "3D concrete" used to refer to concrete extrusion technologies.

There are many 3D printing methods used in building scale, including the following main methods: extrusion (concrete/cement, wax, foam, polymers), powder bonding (polymer bonding, reactive bonding, sintering) and fillet welding. Building scale 3D printing will have a wide range of applications in the private, commercial, industrial and public sectors. Potential benefits of these technologies include faster construction, reduced labor costs, increased complexity and/or accuracy, greater feature integration, and less waste.

A number of different approaches have been demonstrated to date, which include on-site and off-site fabrication of buildings and building components using industrial robots, gantry systems and tethered autonomous vehicles. 3D technology demonstrations to date include fabrication of housing, building components (cladding and structural panels and columns), bridges and civic infrastructure, artificial reefs, follies, and sculptures.

In recent years, this technology has seen a significant increase in the popularity of many new companies, including some backed by well-known names from the construction industry and academia (Purdue University). This has led to several milestones such as the first 3D printed building (Winsun), the first 3D printed bridge (D-Shape), the first 3D printed part in a public building (XtreeE), the first living 3D printed building in Europe and CIS (Specavia) , the first fully approved 3D printed building in Europe (3DPrinthuset), among many others.

history

Seeding technology 1950 - 1995

Robotic masonry was conceptualized and explored in the 1950s, and related technology development around automated building began in the 1960s, with the pumping of concrete and isocyanate foams. Japan pioneered the automated assembly of entire buildings using slip forming techniques and robotic assembly of components, akin to 3D printing, to eliminate the hazards of Shimizu and Hitachi high-rise building construction in 1980s and 1990s. Many of these early on-site automation approaches collapsed due to bubble building, their inability to respond to new architectures and the challenges of supplying and preparing materials for site in built-up areas.

Many of these early on-site automation approaches collapsed due to bubble building, their inability to respond to new architectures and the challenges of supplying and preparing materials for site in built-up areas.

Early development 1995 - 2000

Since 1995, the development and research of the early development of 3D graphics has begun. Two methods were invented, one from Joseph Pegna which focused on sand/cement forming technology that used steam to bind material selectively in layers or solids, although this method was never demonstrated.

The second method, "Contouring" by Behrok Khoshnevis, originally started as a new ceramic extrusion and molding method as an alternative to new printing and metal 3D printing technologies and was patented in 1995. Khoshnevis realized that this method could exceed these methods, "Existing methods are limited to the manufacture of part dimensions, which are usually less than one meter, are each dimension." Around 2000, Khoshnevis' team at USC Vertibi began focusing on 3D printing of cement and ceramic pastes, as well as automated integration of modular fittings, built-in plumbing and electrical services within one continuous assembly process. This technology has only been tested in a lab to date and is controversial and is said to have provided the basis for recent efforts in China.

This technology has only been tested in a lab to date and is controversial and is said to have provided the basis for recent efforts in China.

First generation 2000 - 2010

In 2003, Rupert Soar secured funding and formed a freeform group at Loughborough University, UK, to explore scaling up existing 3D printing technologies for construction applications. Early work identified the challenge of achieving some realistic flawlessness for the technology at construction scale and highlighted that there could be ways to apply it by massively increasing the value proposition of integrated design (many features, one component). In 2005, the group secured funding to build a large-scale 3D printed construction machine using off-shelf components (concrete pump, sprayer, gantry system) to explore how complex such components can be and realistically meet construction requirements.

In 2005, Enrico Dini, Italy, patented the D-Shape technology, using large-scale technology for inkjet/powder bonding over an area of approximately 6m x 6m x 3m. This method, although originally developed with an epoxy bonding system, was later adapted to use inorganic binders. This technology is used commercially for a range of projects in the construction and other sectors, including for.

This method, although originally developed with an epoxy bonding system, was later adapted to use inorganic binders. This technology is used commercially for a range of projects in the construction and other sectors, including for.

One of the latest developments is the printing of the bridge, the first of its kind in the world, in collaboration with IaaC and Acciona.

In 2008, 3D concrete printing began at Loughborough University, UK, led by Richard Buswell and colleagues to extend the groups' preliminary research and look at commercial applications moving from gantry-based technology to the industrial robot they managed to license the Skanska technology in 2014.

Second generation 2010 - present

On January 18, 2015, the company received further press coverage with the opening of two more buildings, a mansion villa and a 5-story tower using 3D printed components. A detailed photographic inspection reveals that the buildings were fabricated using both prefabricated and 3D printed components. The buildings are the first complete structures made using 3D printing technology. In May 2016, a new "office building" opened in Dubai. The 250 square meters (2,700 square feet) area is what the Dubai Museum of the Future project is called the world's first 3D printed building. In 2017, an ambitious 3D skyscraper project was announced in the United Arab Emirates. Building Kazza will help build the structure. There are currently no specific details such as the height of the buildings or the exact location.

The buildings are the first complete structures made using 3D printing technology. In May 2016, a new "office building" opened in Dubai. The 250 square meters (2,700 square feet) area is what the Dubai Museum of the Future project is called the world's first 3D printed building. In 2017, an ambitious 3D skyscraper project was announced in the United Arab Emirates. Building Kazza will help build the structure. There are currently no specific details such as the height of the buildings or the exact location.

FreeFAB Wax™ invented by James B. Gardiner and Steven Janssen at Laing O'Rourke (construction company). The patented technology has been in development since March 2013. This technique uses scale 3D printing to print large volumes of engineered wax (up to 400 l/hr) to make a "quick and dirty" 3D printable mold for precast concrete, glass fiber reinforced concrete (GRC) and other spatter/castable materials. Then, the casting surface of the mold is processed by 5 times grinding, removing approximately 5 mm of wax to create a high-quality mold (surface roughness of about 20 μm). Once the component is cured, the mold is then either ground or melted and the wax is filtered and reused, greatly reducing waste compared to traditional mold technologies. The advantages of this technology are fast mold making speeds, increased production efficiency, reduced labor force, and virtual elimination of waste by reusing custom mold materials compared to traditional mold technologies.

Once the component is cured, the mold is then either ground or melted and the wax is filtered and reused, greatly reducing waste compared to traditional mold technologies. The advantages of this technology are fast mold making speeds, increased production efficiency, reduced labor force, and virtual elimination of waste by reusing custom mold materials compared to traditional mold technologies.

The system was originally demonstrated in 2014 using an industrial robot. The system was later adapted to be integrated with a 5-axis high-speed gantry to achieve the high speeds and surface milling tolerances required by the system. The first commercial system is installed at the Laing O'Rourke plant in the UK and is due to enter commercial production for the well-known London project in late 2016.

MX3D Metal, founded by Loris Jaarman and team, has developed two 6-axis robotic 3D printing systems, the first one uses thermoplastic that is extruded, especially this system can produce free-form non-planar balls. Secondly, a system that relies on additive welding (basically spot welding on previous spot welds), additive welding technology has been developed by various groups in the past, however the MX3D metal system is the most advanced to date. MX3D is currently working on fabricating and installing a metal bridge in Amsterdam.

Secondly, a system that relies on additive welding (basically spot welding on previous spot welds), additive welding technology has been developed by various groups in the past, however the MX3D metal system is the most advanced to date. MX3D is currently working on fabricating and installing a metal bridge in Amsterdam.

BetAbram is a simple gantry based extrusion 3D printer developed in Slovenia. This system has been commercially available, offering 3 models (P3, P2 and P1) to consumers since 2013. The largest P1 can print objects up to 16m x 9m x 2.5m. The general custom concrete 3D printer designed by Rudenko is a concrete precipitation technology mounted in a gantry system configuration, the system has similar output for Winsun and other technologies concrete 3D printing, however it uses a lightweight portable truss type. This technology was used to make a version of the backyard castle and hotel room in the Philippines

The first serial production of serial printers in the world was launched by SPECAVIA, located in Yaroslavl (Russia). In May 2015, the company introduced the first model of a 3D printer for construction and announced the start of sales. As of the beginning of 2018, the AMT-SPECAVIA group of companies produces 7 models of portal building printers: from small format (for printing small architectural forms) to large-scale (for printing buildings up to 3 floors) printers. Today, Russian-made 3D printers under the AMT trademark are operating in several countries, including the first construction printer delivered in Europe in August 2017 - for 3DPrinthuset (Denmark). This printer was used in Copenhagen to build the first 3D printed building in the EU (50 m2 office hotel).

In May 2015, the company introduced the first model of a 3D printer for construction and announced the start of sales. As of the beginning of 2018, the AMT-SPECAVIA group of companies produces 7 models of portal building printers: from small format (for printing small architectural forms) to large-scale (for printing buildings up to 3 floors) printers. Today, Russian-made 3D printers under the AMT trademark are operating in several countries, including the first construction printer delivered in Europe in August 2017 - for 3DPrinthuset (Denmark). This printer was used in Copenhagen to build the first 3D printed building in the EU (50 m2 office hotel).

XtreeE has developed a multi-component printing system mounted on a 6-axis robotic arm. The project began in July 2015 and boasts collaborations and investments from strong names in the construction industry such as Saint Gobain, Vinci and LafargeHolcim.

3DPrinthuset, the successful start of Danish 3DPrinting, also entered the construction industry with its own portal-based printer in October 2017. In collaboration with strong names in the Nordic region such as NCC and Force Technology, the company's spin-off has grown rapidly with the construction of the first 3DPrinted home in Europe. The Building on Demand (BOD) project, referred to as the structure, is a small office hotel in Copenhagen, Nordhavn district, with the walls and part of the foundation completely imprinted, while the rest of the construction is done in traditional construction. As of November 2017, the building is in the final phase of luminaires and roofing, with all 3DPrinted details fully completed.

In collaboration with strong names in the Nordic region such as NCC and Force Technology, the company's spin-off has grown rapidly with the construction of the first 3DPrinted home in Europe. The Building on Demand (BOD) project, referred to as the structure, is a small office hotel in Copenhagen, Nordhavn district, with the walls and part of the foundation completely imprinted, while the rest of the construction is done in traditional construction. As of November 2017, the building is in the final phase of luminaires and roofing, with all 3DPrinted details fully completed.

design

Architect James Bruce Gardiner pioneered a 3D printed architectural design for a two-project building. First Freefab Tower 2004 and second Villa Roccia 2009-2010. The FreeFAB Tower was based on an original concept to combine a hybrid form of 3D printing construction with a modular design. It was the first architectural design for a building focused on the use of 3D printing. Influences can be seen in various projects used by Winsun, including articles in Winsun's original press release and the office of the future. The FreeFAB Tower project also depicts the first speculative use of multi-axis robotic arms in 3D printing for construction, the use of such machines over the past years in construction is being built steadily with MX3D and Branch Technology 9 projects0003

The FreeFAB Tower project also depicts the first speculative use of multi-axis robotic arms in 3D printing for construction, the use of such machines over the past years in construction is being built steadily with MX3D and Branch Technology 9 projects0003

Villa Roccia 2009-2010 takes this pioneering work one step further with the design of a villa in Porto Rotondo, Sardinia, Italy in collaboration with D-Shape. The design of the villa focused on developing a site-specific architectural language, influenced by the rock formations on the site and along the coast of Sardinia, and using a panelized, prefabricated 3D printing process. The project went through prototyping and did not proceed to full construction.

Francios Roche (R&Sie) developed an exhibition project and a monograph "I Heard About" in 2005 that explored the use of a highly speculative homing kite such as an offline 3D printing machine and generator design system to create high-rise residential towers. The project, which cannot be put into practice using modern or modern technologies, demonstrated a deep study of the future of design and construction. The exhibition showcased large-scale CNC milling of foam and its renovation to create free-form molds envisaged by the shell.

The exhibition showcased large-scale CNC milling of foam and its renovation to create free-form molds envisaged by the shell.

The planned three-dimensional building by the Dutch architect Janjaap Ruijsenaars was planned to be built by a partnership of Dutch companies. The house was planned to be built at the end of 2014, but this deadline was not met. The companies said they remain committed to the project.

Building On Demand or BOD, a small office hotel 3D printed by 3D Printhuset’s and designed by architect Ana Goida, incorporated curved walls and rippled effects on their surface to showcase the design freedom that horizontal 3D printing allows.

structures

3D printed buildings

The 3D Print Canal House was the first full scale building project of its kind to come off the ground. In a short span of time, Kamermaker has been further developed to increase production speed by 300%. However, progress has not been fast enough to claim the title of "World's First 3D Printed House".

The first residential building in Europe and the CIS, built using 3D printing technology, was a house in Yaroslavl (Russia) with an area of 298.5 sq. The walls of the building were printed by SPECAVIA in December 2015. 600 wall elements were printed in the shop and assembled at the construction site. After completing the roof structure and interior decoration, the company unveiled the fully completed 3D building in October 2017. The peculiarity of this project is that for the first time in the world, the entire technological cycle of construction has gone through: design, obtaining a building permit, registration of the building, connection of all engineering systems. An important feature of the 3D house in Yaroslavl, which also distinguishes this project from others implemented, is not a presentation structure, but a full-fledged residential building. Today it is home to a real ordinary family.

Dutch and Chinese demonstration projects are slowly building 3D printed buildings in China, Dubai and the Netherlands. Using efforts to inform the public about the possibilities of new plant-based construction technology and stimulate new innovations in 3D printing of residential buildings. The small concrete house was 3D printed in 2017.

Using efforts to inform the public about the possibilities of new plant-based construction technology and stimulate new innovations in 3D printing of residential buildings. The small concrete house was 3D printed in 2017.

Building on Demand (BOD), Europe's first 3D printed house, is a 3DPrinthuset-led project for a small 3D office building in Copenhagen's Nordhavn district. As of November 2017, the building is in the final phase of luminaires and roofing, with all 3DPrinted details fully completed. The building is also the first 3D printed permanent building with all permits and is fully approved by the authorities.

3D printed bridges

In Spain, the world's first 3D printed footbridge (3DBRIDGE) was inaugurated on December 14, 2016 in the City Park of Castilla La Mancha in Alcobendas, Madrid. The 3DBUILD technology used was developed by ACCIONA, which was responsible for the structural design, materials development and fabrication of the 3D printed elements. The bridge has an overall length of 12 meters and a width of 1. 75 meters and is printed in micro-reinforced concrete. The architectural design was carried out by the Institute of Advanced Architecture of Catalonia (IAAC).

75 meters and is printed in micro-reinforced concrete. The architectural design was carried out by the Institute of Advanced Architecture of Catalonia (IAAC).

The 3D printer used to assemble the pedestrian bridge was made by D-Shape. The 3D printed bridge reflects the complexity of nature's forms and has been developed through parametric design and computational design to optimize the distribution of materials and to maximize structural performance by allowing material to be placed only where needed, with total freedom of form. The Alcobendas 3D printed footbridge was a milestone for the construction sector internationally as the project pioneered large-scale 3D printing technology in civil engineering in a public space.

Extraterrestrial Printing Structures

Building printing has been proposed as a particularly useful technology for creating extraterrestrial habitats, such as those on the Moon or Mars. Since 2013, the European Space Agency has been working with London-based Foster + Partners to explore the possibilities of printing moon bases using conventional 3D printing technology. The architecture firm proposed 3D printer technology for building construction in January 2013 that would use lunar regolith raw materials to produce lunar building structures while using enclosed inflatable habitats to house humans living inside the printed lunar structures. In total, these habitats would require only ten percent of the mass of structure to be transported from Earth, while using local lunar materials for the remaining 90 percent mass structure.

The architecture firm proposed 3D printer technology for building construction in January 2013 that would use lunar regolith raw materials to produce lunar building structures while using enclosed inflatable habitats to house humans living inside the printed lunar structures. In total, these habitats would require only ten percent of the mass of structure to be transported from Earth, while using local lunar materials for the remaining 90 percent mass structure.

The domed structures would be a load-bearing chain, with structural support provided by a closed cell structure reminiscent of bird bones. In this concept, "printed" lunar soil would provide both "radiation and temperature insulation" for Lunar dwellers. The building technology mixes the lunar material with magnesium oxide, which will turn "the hammer into cellulose that can be pulverized to form a block" when a binder salt is applied, which "turns this material into a rock-like solid." A type of sulfur concrete is also provided.

A 3D printing test of an architectural structure with simulated lunar material was completed using a large vacuum chamber at a ground laboratory. This technique involves injecting a binding fluid under the surface of the regolith using a 3D printer nozzle, which, when tested, captures 2 millimeters (0.079 inches) of -cascal droplets below the surface through capillary forces. A D-Shape printer was used.

Various elements of the Moon's infrastructure have been designed for 3D structural printing, including landing pads, blast walls, roads, hangars, and fuel storage. In early 2014, NASA funded a small study at USC to further develop

Contour Crafting 3D printing technique. Potential applications of this technology include building lunar material structures that could be made up of 90 percent lunar material, a mere ten percent material that would need to be transported from Earth.

NASA is also considering another technique that would involve sintering lunar dust using low power (1500 W) microwave energy. The lunar material would be bonded by heating to 1200-1500°C (2190 to 2730°F), just below the melting point, to fuse the nanoparticle dust into a hard ceramic-like block and would not require transportation of the bonding material from Earth according to the requirements of Foster + Partners, Contour Crafting and D-shaped approaches to off-world construction printing. One particular proposed plan to build a lunar base using this technique would be called SinterHab and would use JPL's six-legged ATLLETE robot for autonomous or televolumetric assembly of lunar structures.

The lunar material would be bonded by heating to 1200-1500°C (2190 to 2730°F), just below the melting point, to fuse the nanoparticle dust into a hard ceramic-like block and would not require transportation of the bonding material from Earth according to the requirements of Foster + Partners, Contour Crafting and D-shaped approaches to off-world construction printing. One particular proposed plan to build a lunar base using this technique would be called SinterHab and would use JPL's six-legged ATLLETE robot for autonomous or televolumetric assembly of lunar structures.

Construction speed

Claims have been made by Behrokh Khoshnevis since 2006 for 3D printing a house a day, with further claims to finally complete the construction in about 20 hours after the "printer". By January 2013, working versions of the 3D printing technology were building 2 meters (6 ft 7 in) of building material per hour, with the next generation of printers proposed to have a capacity of 3.5 m (11 ft) per hour to complete construction in a week.

Chinese company WinSun built several houses using large 3D printers using a mixture of quick-drying cement and recycled materials. Ten demonstration houses were named Winsun, which were built in 24 hours, each at a cost of $5,000 (structure does not include, supports, services, doors/windows, and trim). However, 3D printing construction pioneer Dr. Behrokh Khoshnevis claims it is fake and that WinSun stole his intellectual property.

Research and public knowledge

There are several research projects dedicated to 3D construction printing, such as the 3D Concrete Printing (3DCP) project at Eindhoven University of Technology or various projects at the Institute of Advanced Architecture of Catalonia (Pylos, Mataerial and Minibuilders). The list of research projects has been expanding even more in the last couple of years due to the growing interest in this area.

State of the art research

Most of the projects focused on the study of the physical aspects of the technology, such as printing technology, material technology and various problems

related. 3DPrinthuset recently led research focused more on the state of the art technology around the world, visiting over 35 different 3D construction related projects. A research report was issued for each project and the collected data was used to unify all the different technologies in a first attempt at a common standardized categorization and terminology. Researchers at Purdue University have pioneered a 3D printing process known as Direct-ink-Writing to make cement-based architectural materials. They have demonstrated the use of 3D printing, bio-industrial designs of cement-based materials, and new performance characteristics such as rupture tolerances and compliance can be achieved.

3DPrinthuset recently led research focused more on the state of the art technology around the world, visiting over 35 different 3D construction related projects. A research report was issued for each project and the collected data was used to unify all the different technologies in a first attempt at a common standardized categorization and terminology. Researchers at Purdue University have pioneered a 3D printing process known as Direct-ink-Writing to make cement-based architectural materials. They have demonstrated the use of 3D printing, bio-industrial designs of cement-based materials, and new performance characteristics such as rupture tolerances and compliance can be achieved.

First 3D Printing Conference

Along with research, 3DPrinthuset organized two international conferences on 3D construction printing (February and November 2017 respectively), which aimed to bring together the strongest names in this emerging industry to discuss the potential opportunities and challenges that stand in front. These conferences were the first of their kind and brought together names such as D-Shape, Contour Crafting, Cybe Construction, Eindhoven's 3DCP study, Winsun and many more. In addition to the 3D designer, key players from the traditional construction industry were present in the first place, including names such as Sika AG, Vinci, Royal BAM Group, NCC. There was a general idea that the field of 3D construction needed a more unified platform where ideas, applications, problems, and issues could be discussed.

These conferences were the first of their kind and brought together names such as D-Shape, Contour Crafting, Cybe Construction, Eindhoven's 3DCP study, Winsun and many more. In addition to the 3D designer, key players from the traditional construction industry were present in the first place, including names such as Sika AG, Vinci, Royal BAM Group, NCC. There was a general idea that the field of 3D construction needed a more unified platform where ideas, applications, problems, and issues could be discussed.

Media interest

Although the first steps were taken almost three decades ago, 3D Construction Printing has struggled to cover the years. The first technologies to gain media attention were Contour Crafting and D-Shape, with a few sporadic articles in 2008-2012 and a TV report in 2012. D-Shape has also been featured in an independent documentary dedicated to its creator Enrico Dini called The Man Who Prints at Home.

One major breakthrough [when?] was seen with the announcement of the first 3D printed building using off-the-shelf 3D printed components made by Winsun who claimed to be able to print 10 houses in a day with their technology.