Polypropylene 3d printing filament

Ultimate Materials Guide - 3D Printing with Polypropylene

Overview

Polypropylene is a semi-rigid and lightweight material that is commonly used in storage and packaging applications. The semi-crystalline structure of the material causes the 3D printed parts to heavily warp upon cooling, making it challenging to 3D print. Polypropylene is tough and has a good fatigue resistance making it ideal for low strength applications like living hinges, straps, leashes, etc. A few manufacturers have even created polypropylene blends that have improved toughness making it suitable for practical use. The tips in this article will cover all the different types of polypropylene filaments available for 3D printing.

- Good impact and fatigue resistance

- Good heat resistance

- Smooth surface finish

- Heavy warping

- Low strength

- Difficult to adhere to bed and other adhesives

- Expensive

Hardware Requirements

Before 3D printing with Polypropylene make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 85-100 °C

Heated Bed Required

Enclosure Recommended

Build Surface

Packing Tape

Polypropylene Sheet

Extruder

Temperature: 220-250 °C

No special hotend required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with Polypropylene such as warping and poor bed adhesion.

Choosing the Right Build Surface

Finding a good build surface can be very challenging when you need to print with Polypropylene. The low surface energy of polypropylene makes it extremely difficult to get good bed adhesion even with heated beds. We have found that polypropylene adheres well only to itself. Thankfully, packaging tape is a readily available surface that is also Polypropylene based, so it can be a great option. A thick strip of packing tape along with a heated bed can greatly improve the success of your first layer with this material. Some packing tapes melt around 90 ºC so it is important to keep the heated bed at a temperature slightly less than the melting point of the tape.

Some packing tapes melt around 90 ºC so it is important to keep the heated bed at a temperature slightly less than the melting point of the tape.

Use Rafts to Protect the Base Layer

Polypropylene prints can sometimes bond too well to the packaging tape on the surface of your bed, which makes it hard to separate the tape from the finished part once the print is complete. This happens because the high temperature of the heated bed allows the tape and the part to slightly fuse together. To avoid this, consider using a raft for your prints. The raft will act as an interface between the hot build surface and the bottom of your part. Once the print is complete, the raft can be discarded, so even if it partially fuses to the tape, this will not affect the final part. Version 4.0 of Simplify3D added several new features that use less time, less material, and create rafts that are far easier to remove, so consider giving this option a try if you are having trouble with the parts bonding to the tape.

Using a Heated Chamber or Enclosure

Having a good build surface may not be enough to prevent printing issues. Since we know that Polypropylene can warp quite heavily, it helps to have an enclosure of some sort to trap the heat around the print. Using a printer that has a heated chamber will help eliminate warping. Temperatures of 45-60 °C for a heated chamber will usually work well. Having a standard enclosure can also significantly control warping when used with the heated bed, since the bed will help heat the air around the part, which is contained by the enclosure. However, be careful to control the heated bed temperature to avoid damaging the packaging tape as mentioned above.

Pro-Tips

- Although Polypropylene can print well at low temperatures, printing at slightly higher temperatures in the range of 240 ºC can help with adhesion between layers to create a stronger part.

- Consider using a lower temperature for the first few layers of your print to prevent the part from fusing to the build surface.

Get Started with Polypropylene

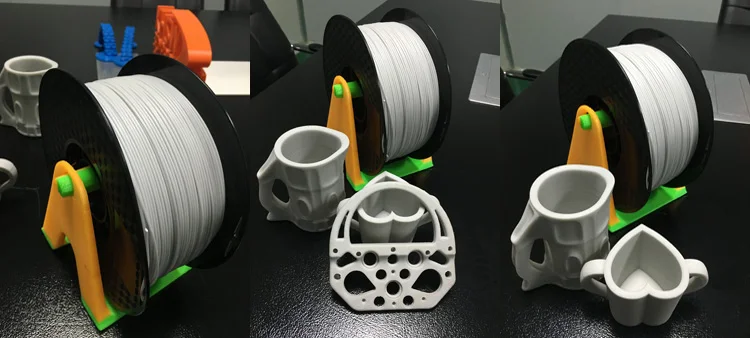

Now that you understand some of the unique characteristics of this material, you are ready to try your first print. We’ve included a few ideas below to help you get started.

Common Applications

- Living hinges

- Storage containers

- Watch Straps

Sample Projects

- Pebble Watch Strap

- Travel Bottle

- Parts box

Popular Brands

- Ultimaker Polypropylene

- GizmoDorks Polypropylene

- Verbatim Polypropylene

PP+GF30 3D Printing Filament | Professional Glass Fiber

$48.00 – $190.00

4 interest-free payments with Learn More

FibreX™ PP+GF30 is made using a specialty formulated 30% glass fiber reinforced polypropylene copolymer that we created specifically for 3D printing. Our PP+GF30 is ideal when you need improved strength, stiffness, impact, dimensional stability, chemical resistance and high thermal properties.

[yith_wcwl_add_to_wishlist]

SKU: Select options above Brand: FibreX™ Categories: PP (Polypropylene) Family, Glass Fiber Filaments

- Description

- Reviews

- Questions & Support

FibreX™ PP+GF30 [Polypropylene] 3D Printing Filament

FibreX™ PP+GF30 is made using a specialty formulated 30% glass fiber reinforced polypropylene copolymer which we created specifically for 3D printing. Our formulation offers improved thermal properties and lower shrinkage & warp compared to competitive PP-based compounds.

Reinforcing this trusted engineering polymer with glass fiber really made it a game changer for industrial applications. 3D printed PP+GF30 parts can be found in a wide array of real-world functional end uses or prototypes with automotive, tooling fixtures and jigs, appliances, and sporting goods.

Extruder Temp

240-270°C

Bed Temp

80-110°C

Heated Chamber

Not required

Nozzle Specs

0. 4mm diameter minimum

4mm diameter minimum

Hardened Steel Nozzle

Bed Adhesion

Magigoo Bed Prep

Layer Height

0.25mm or higher

Drying Specs

4 Hours at 65°C

Supports

Water Soluble Support

Benefits of PP+GF Include:

- Excellent resistance against a huge variety of chemicals

- Low density and weight

- Low shrinkage and warping

- Typically does not absorb moisture, no drying required!

- High strength, stiffness, and impact resistance

Chemical Resistance of PP+GF

Since properties can change depending on print environment and 3D model geometry and/or surface area, it is always required to do your own testing, but Polypropylene is famous for its chemical resistances to a huge range of environments including:

- Acids: Acetic, Boric, Hydrochloric, Phosphoric, Stearic, Sulfuric, Uric

- Bases: Hydrocides of Ammonium, Barium, Calcium, Magnesium, Potassium, Sodium

- Solvents: Acetone, Ethanol, MEK, Phenol (10%), Water

Safety Data Sheet

This material doesn’t yet have a formal SDS.

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 240-270°C

- Bed Temp: 80-110°C

- Nozzle: We highly recommend a hardened steel nozzle with a minimum diameter of 0.4mm for abrasive materials such as this

- Other: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers smaller than 0.2mm with abrasive filaments

- Bed Prep: Magigoo Bed Prep gives us the best results

- Heated Chamber: Not required

- Supports: AquaTek™ Water Soluble X1 USM Universal Support Material is one of the few materials capable of properly forming a strong, temporary bond for support. Polypropylene is infamous for being difficult to support, and X1 USM is ideal for the job

- Drying Instructions: 4+ Hours at 65°C

What Is It?

Fibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament.

This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

- High strength

- High stiffness

- High chemical resistance

- Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament which exhibits the best properties of both fiberglass and the plastic of choice.

What Is It Good For?

Ideal for any applications which require strength and rigidity.

For these reasons, glass fiber reinforced filament is very popular in automotive, mechanical, civil engineering, and research industries.

What Is It?

Fibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament.

This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

- High strength

- High stiffness

- High chemical resistance

- Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament which exhibits the best properties of both fiberglass and the plastic of choice.

What Is It Good For?

Ideal for any applications which require strength and rigidity.

For these reasons, glass fiber reinforced filament is very popular in automotive, mechanical, civil engineering, and research industries.

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently and the printer will experience extrusion issues.

Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

Questions?

Send us a message and we'll reach out as soon as we can!

Please enable JavaScript in your browser to complete this form.Name *

Business / Organization

Email *

Phone

What can we help you with? *

Newsletter Signup

- Sign me up for the 3DXTECH newsletter

print parameters, characteristics and properties

REC PP+ is a modified polypropylene filament that allows you to print strong and durable products with high chemical and impact resistance.

Continue reading →

The main advantages and disadvantages of REC PP+

Polypropylene is one of the most common polymers due to a number of positive characteristics. This polymer is non-toxic and has a low specific gravity (with the same volume, polypropylene is about a third lighter than the popular PLA plastic), excellent resistance to abrasion, impact loads and mechanical fatigue, has a fairly high softening point (in the case of REC PP + about 95°C) and elasticity, perfectly recyclable. In addition, polypropylene is waterproof and highly resistant to chemicals including acid and alkali solutions, mineral and vegetable oils, salt solutions, various organic solvents, including alcohols, acetone, and gasoline, although swelling may occur with prolonged exposure to some organic solvents.

This polymer is non-toxic and has a low specific gravity (with the same volume, polypropylene is about a third lighter than the popular PLA plastic), excellent resistance to abrasion, impact loads and mechanical fatigue, has a fairly high softening point (in the case of REC PP + about 95°C) and elasticity, perfectly recyclable. In addition, polypropylene is waterproof and highly resistant to chemicals including acid and alkali solutions, mineral and vegetable oils, salt solutions, various organic solvents, including alcohols, acetone, and gasoline, although swelling may occur with prolonged exposure to some organic solvents.

The combination of these characteristics makes polypropylene an attractive choice for the production of packaging containers, including food (if plastic bottles are made mainly from PET, then caps for them are made of polypropylene), pipes, electrical insulation, syringes and inhalers, flexible fasteners, automotive components , all kinds of parts of household appliances, toys and consumer goods. In many cases, polypropylene serves as a more effective replacement for its relative polyethylene, especially in terms of thermal and chemical resistance, as well as a more durable and safer alternative to PVC, ABS and polycarbonate.

In many cases, polypropylene serves as a more effective replacement for its relative polyethylene, especially in terms of thermal and chemical resistance, as well as a more durable and safer alternative to PVC, ABS and polycarbonate.

Polypropylene also has disadvantages, including vulnerability to direct sunlight and oxygen, loss of elasticity at sub-zero temperatures (operation is possible at -60 ° C, but impact resistance begins to decrease at -15 ° C), as well as high heat shrink. The last point is very important, because thanks to it, polypropylene has gained a reputation as a “difficult” plastic for 3D printing. To combat this problem, we have developed REC PP+, a chemically modified polypropylene filament with significantly reduced shrinkage. 93

3D Printing Preparation Guidelines

REC PP+ A major problem with polypropylene 3D printing is shrinkage, exacerbated by unwillingness to set with adhesive coatings. Although our polypropylene filament option is much friendlier in this regard, certain precautions still need to be taken for optimal results.

Although our polypropylene filament option is much friendlier in this regard, certain precautions still need to be taken for optimal results.

The only material that polypropylene adheres well to is polypropylene itself. On the one hand, this is good, because it indicates high interlayer adhesion and, accordingly, the strength of 3D printed products. On the other hand, conventional adhesives in the form of adhesives, varnishes or masking tape are ineffective. Fortunately, there is one widely available and very effective option: polypropylene is often used to make adhesive tapes, in particular double-sided and packaging tape. The latter is just perfect as an adhesive coating.

There are a few things to remember here:

First of all, make sure you are dealing with polypropylene tape. Other options, such as polyethylene, will not work.

Second , make sure that the tape is firmly and evenly attached to the table, without wrinkles or bubbles, so that there are no problems with applying the first layer.

Thirdly , be careful when heating the table so that the glue or tape itself does not melt.

Fourth, , try to use rafts or skirts (aka "brims"). On the one hand, this will help increase the area of contact with the work surface and reduce the likelihood of the model twisting or tearing off the table. On the other hand, the model and the adhesive tape can grab so well that they will not be torn off. In this case, the best option is to print the model on a wide raft, and then separate the auxiliary structure along with adhesive tape.

Another important point is the temperature regime. Since polypropylene falls into the category of semi-crystalline polymers, it has a pronounced solid-to-melt transition boundary with fairly strong shrinkage during crystallization. For this reason, the temperature of the hot end must be set carefully to ensure the necessary fluidity during extrusion, but at the same time, a quick cure after laying. Wide and sharp temperature drops are undesirable, as this can negatively affect the recrystallization and mechanical characteristics of the product, and therefore it is worth avoiding heating the material above the recommended temperatures and using blowing, if possible.

Wide and sharp temperature drops are undesirable, as this can negatively affect the recrystallization and mechanical characteristics of the product, and therefore it is worth avoiding heating the material above the recommended temperatures and using blowing, if possible.

Stabilization of the background temperature, on the other hand, is highly desirable, so if possible, try to use 3D printers with thermal cameras - at least passive ones, and preferably with active background temperature control in the range of 30-35 ° C, similar to table heating.

Recommended settings for 3D printing with material REC PP+ :

- Nozzle temperature: 210-230°C

- Table temperature: 20-40°C

- Airflow not recommended

- Recommended adhesives: Polypropylene packing tape

- Minimum nozzle diameter: 0.1 mm

Storage REC PP+

In contact with oxygen, polypropylene gradually ages, that is, loses its mechanical properties. The process is catalyzed by ultraviolet light and heat, so the filament must be stored in a dark place or opaque packaging.

The process is catalyzed by ultraviolet light and heat, so the filament must be stored in a dark place or opaque packaging.

One of the positive properties of this polymer is its high hydrophobicity, that is, the material practically does not absorb moisture. However, in humid climates, condensation can form on the surface of the filament, and this can lead to various undesirable effects during 3D printing - uneven melt flow, defective product surfaces, and the like. For this reason, it is recommended to store the filament in a tightly sealed plastic bag or a container with a bag of dry silica gel.

At the same time, this will help to avoid the accumulation of dust that can form carbon deposits in the hot ends and plugs in the nozzles. If dust does get on the filament, a simple foam filter can be used to clean the filament along the way from the coil to the hot end (for example, this or that).

If necessary, the filament can be dried using a fruit dryer, electric oven or other suitable device, ideally at a temperature not exceeding 55°C for at least six hours.

More about the storage and drying of filaments from different materials is described in the articles below:

Storage of Philiament

Drying Plastic

Post -cutting REC PP+

Polypendering is well lendered to mechanical processing (drilling, milling treatment grinding), but heating the material to softening point must be avoided.

Chemical processing and bonding of this polymer is difficult due to its high chemical inertness, second only to Teflon. Polypropylene dissolves in aromatic hydrocarbons (for example, benzene or toluene), but only at fairly high temperatures - above 80 ° C.

The most reliable method of joining polypropylene parts is hot welding.

Painting of polypropylene products is also difficult, but possible when using a suitable acrylic primer with preliminary grinding and degreasing of the surfaces. Keep in mind that this option is only suitable for products that are not subject to mechanical stress, since cracking and destruction of the paintwork will begin at the slightest deformation. In general, painting polypropylene products is not recommended due to low practicality.

In general, painting polypropylene products is not recommended due to low practicality.

Safety REC PP+

Polypropylene is non-toxic and therefore widely used in the food and medical industries, but for safety reasons we always recommend working in a well-ventilated area, if possible equipped with an exhaust hood near the 3D printer.

Safety certificates are published in a special section of our website.

What is the strongest material for 3D printing?

It's no exaggeration to say that most of you reading this article have often wondered, "What is the strongest 3D printing material?" This is certainly an intriguing question. The one everyone wants to know the answer to. Whether you're a hobbyist or an expert, most of your projects require strong and durable materials. In this article, we aim to compare the most durable 3D printing materials and give you the answer.

But this also raises the question of what does the strength of 3D printing materials mean?

What does "strong" mean when it comes to 3D printing?

Well, the strength of materials for 3D printing can be determined in several ways. Some of them include hardness, impact resistance, compressive strength and so on. However, the two most commonly understood types of strength that most people care about are tensile strength and flexural strength. This is how much the material can be stretched and bent accordingly. In the following overview, we will list the pressure in megapascals (MPa) that each material can withstand. The higher these numbers, the "stronger" the material is when subjected to those particular loads. The numbers we use are based on. Materials from other brands may vary.

Some of them include hardness, impact resistance, compressive strength and so on. However, the two most commonly understood types of strength that most people care about are tensile strength and flexural strength. This is how much the material can be stretched and bent accordingly. In the following overview, we will list the pressure in megapascals (MPa) that each material can withstand. The higher these numbers, the "stronger" the material is when subjected to those particular loads. The numbers we use are based on. Materials from other brands may vary.

Best FFF/FDM materials for durable parts printing

To compare the strongest 3D printing materials, we'll look at seven different materials. Namely, polylactic acid (PLA), Tough PLA, acrylonitrile butadiene styrene (ABS), polycarbonate (PC), glycol modified polyethylene terephthalate (PET-G), nylon and polypropylene (PP). Which one is best for you depends on your needs, budget, and a number of other factors. Later in this article, we will discuss specific applications and what material might be best for them.

thread PLA

PLA, or polylactic acid, is a very versatile and popular FDM 3D printing material. Its popularity stems from the fact that it is easy to print, readily available at a low cost, and available in a variety of colors. For this reason, it is probably the first material that most people will print with.

PLA is generally not chosen due to its strength properties due to the brittleness of the material. If you're printing on a budget, PLA may be fine in some cases, but if your part needs to bend before it breaks, you're usually better off using a different material.

PLA filament properties

Tensile strength: 53-59 MPa

Flexural strength: 97-101 MPa

Durable PLA filament

Tough PLA is a tougher version of regular PLA or polylactic acid. It combines the ease of printing you would expect from PLA and eliminates PLA's main disadvantage: its brittleness. For this reason, it is ideal for functional prototypes that require flexibility.

Tough PLA is not as brittle as ordinary PLA, exhibits higher tear strength than ABS, is easier to print than ABS, and is compatible with PVA water-soluble auxiliary material.

Strength properties of PLA filament

Tensile strength: 45-48 MPa

Flexural strength: 83-96 MPa

ABS thread

ABS, also known as acrylonitrile butadiene styrene, is a popular thermoplastic polymer. It is well known for its impact, chemical, water and heat resistance. It also has outstanding high and low temperature performance, making it ideal for automotive components. ABS plastic also has good electrical insulating properties, making it a good choice for enclosures and housings for electrical parts.

In addition, ABS is comparatively cheaper than most materials and relatively easy to process. As a result, it is an excellent material for mass production and is used in a wide range of conventional products. The fact that ABS is easy to post-process also means that it can be glued and painted.

ABS thread properties

Tensile strength: 34-36 MPa

Flexural strength: 60-61 MPa

Polycarbonate (PC) thread

Polycarbonate filament (PC) is a tough thermoplastic polymer that is resistant to heat and chemicals. It is a high strength material designed for use in harsh environments and technical applications. It has good heat dissipation due to its high glass transition temperature and is usually available in an improved impact resistance version.

Polycarbonate filament has many uses in daily life. Polycarbonate, unlike plexiglass, does not break. It bends and deforms like hard rubber until it finally breaks. It also has excellent optical clarity.

Polycarbonate can be difficult to work with due to its high heat resistance, meaning warping can be a problem. Choosing the right adhesive and avoiding sharp corners on parts will help you successfully print with this material.

Properties of polycarbonate thread

Tensile strength: 43-65 MPa

Flexural strength: 89-114 MPa

PETG thread

PETG, or polyethylene terephthalate glycol, is a thermoplastic polyester chemically modified with glycol to limit crystallization and improve toughness. The inclusion of glycol improves PET, durability and moldability for production. It has high impact and abrasion resistance and can withstand higher temperatures compared to PLA.

The inclusion of glycol improves PET, durability and moldability for production. It has high impact and abrasion resistance and can withstand higher temperatures compared to PLA.

Due to its excellent properties and relatively low price, PETG is widely used in 3D printing. It is a good engineering material that can be used instead of ABS. It also has less tendency to warp, which means it's easier to print precise details on it.

PETG thread properties

Tensile strength: 38-44 MPa

Flexural strength: 75-79 MPa

Nylon thread

3D printing nylon is commonly found in several forms: PA6 and PA6/66, which are stiffer versions of nylon, and PA 12, which is a flexible type of nylon. Nylon has useful qualities that make it an attractive material for 3D printing. Nylon is strong and durable, as well as flexible. This characteristic is useful when printing parts with thin walls. In addition, nylon has a high melting point with a very low coefficient of friction, making it suitable for printing functional interconnected items such as gears.

One of the main disadvantages of nylon as a material for 3D printing is its high hygroscopicity, that is, the ability to absorb moisture. This can make it difficult to achieve the expected printing performance.

Nylon thread properties

Tensile strength: 63-65 MPa

Flexural strength: 63-83 MPa

Polypropylene (PP) thread

Polypropylene (PP) is a widely used plastic that can be found in almost every home. It is the material of choice for storage and packaging, and for many traditional forms of production such as injection molding. The popularity of polypropylene is due to its high chemical resistance, heat resistance, impact resistance and flexibility.

Its qualities make it ideal for applications such as food packaging, outdoor display, chemical storage tanks, and even medical applications such as prostheses, among others.

Polypropylene yarn properties

Tensile strength: 10-12 MPa

Flexural strength: 13-15 MPa

Best settings for printing durable parts

Wouldn't it be great to be able to print stronger parts without even changing the material used? Fortunately, this is possible. The main thing is to optimize the settings. To get the most out of your printer and media, you must adjust the settings you use, not just for each media, but for each part.

The main thing is to optimize the settings. To get the most out of your printer and media, you must adjust the settings you use, not just for each media, but for each part.

Below are some of the best settings you can change to enhance your part:

Fill type and density . The type and density of the infill are important factors influencing the strength of the printed part. The greater the filling density, the higher the strength. However, high infill density is generally not recommended as it uses a lot of media and takes longer to print. To increase the strength of a part without increasing density, you can also change the infill pattern depending on the functionality of the part. For example, in compressive strength tests, triangular/lattice infill shows higher compressive strength compared to cubic and gyro infill patterns.

For most visual prints, you can use about 20 percent infill, but for stronger details, try increasing it to 50 percent. An alternative is to use modifier meshes to selectively create a higher infill density in areas where stresses will be highest.

An alternative is to use modifier meshes to selectively create a higher infill density in areas where stresses will be highest.

Part orientation. Orientation of the part may not be on your checklist for crisper prints, but it is critical. Tensile strength is lower along the Z axis in 3D printing (typically 40-70% strength compared to the XY axis), especially in tall and thin printed parts. As a result, you must carefully orient the part to match the required axis of strength. In doing so, you will also have to consider the support structure and a balance will need to be found based on what matters most in that particular part.

Shell thickness: The thickness of the outer surface of the part is called the shell thickness. Generally speaking, the thicker the shell, the stronger the part. Based on this, you can decide what shell thickness you need for your part. A sheath thickness of twice the layer thickness is usually a good starting point.