3D denture printer

3D Printed Dentures | Lucitone Digital Print

image-comparisongrip-linesarrow-top-rightziparrow-rightvideominusarrow-backtextshoptwitterfilehomequick-orderarrow-leftyoutubesearcharrow-downcheckallfiltersite_referencesimageSlice 1zoom🎬 icons / _ icon size / _ download-queue Created with Sketch. chevron-downarrow-rightpicturepdfpodcastexeplushotlineclosexxx-1burgerclipboardlinked-inpptArtboard🎬 icons / _ icon size / _ download-queue_add Created with Sketch. Layer 1 Created by potrace 1.15, written by Peter Selinger 2001-2017 My Accountpress_releases Created with Sketch. PRESS ds-instrumentsds-preventiveds-implantsds-endodonticsCartpresentation Created with Sketch. DS-Preventive-Icon-Greyvideo Created with Sketch. other Created with Sketch. advertisement Created with Sketch. AD text_piece Created with Sketch. promotion Created with Sketch. Spare Partsds-imaging-systemscase_study Created with Sketch. ds-treatment-centersbroschure Created with Sketch. upload Created with Sketch. version Created with Sketch. globeEndoEquipmentGreypngImaging Grey 2svgEndoGlideShapingGreypngirrigation blueImaging 1svgImaging 2svgDS-Preventive-Icon-GreyFinal_Implants_Category_Implant-SystemsAccess Blueobturation bluerestorationrestoration greyAccess GreytreatmentEndoEquipmentBluepngirrigation greyDiagnosisprimeprint-greyHub BluesvgFinal_Implants_Procedure_Single-toothDiagnsis blueDS Points Logo(cubes)Imaging blueEndoRetretmentBluepngrestoration blueFinal_Implants_Procedure_Edentulous-therapyFinal_Implants_Procedure_Hard-and-soft-tissue-managementobtruation greyendo greytreatment blueImaging blue 1svgImaging greyEndoGlideShapingBluepngEndoRetretmentGreypngpolishingHubsvgFinal_Implants_Category_Implant-Dentistrypolishing blueDiagnosis GreyCerec BluesvgImaging Blue 2svgtreatment greyHub GreysvgScalingCerec Greysvgendo bluepolishing greysearchImaging Grey 1svgscaling blueCerecsvgDS Points LogoImagingscaling grey

upload Created with Sketch. version Created with Sketch. globeEndoEquipmentGreypngImaging Grey 2svgEndoGlideShapingGreypngirrigation blueImaging 1svgImaging 2svgDS-Preventive-Icon-GreyFinal_Implants_Category_Implant-SystemsAccess Blueobturation bluerestorationrestoration greyAccess GreytreatmentEndoEquipmentBluepngirrigation greyDiagnosisprimeprint-greyHub BluesvgFinal_Implants_Procedure_Single-toothDiagnsis blueDS Points Logo(cubes)Imaging blueEndoRetretmentBluepngrestoration blueFinal_Implants_Procedure_Edentulous-therapyFinal_Implants_Procedure_Hard-and-soft-tissue-managementobtruation greyendo greytreatment blueImaging blue 1svgImaging greyEndoGlideShapingBluepngEndoRetretmentGreypngpolishingHubsvgFinal_Implants_Category_Implant-Dentistrypolishing blueDiagnosis GreyCerec BluesvgImaging Blue 2svgtreatment greyHub GreysvgScalingCerec Greysvgendo bluepolishing greysearchImaging Grey 1svgscaling blueCerecsvgDS Points LogoImagingscaling grey

Want to know more?

Connect with one of our Lab product specialists to learn how our innovative solutions can help you.

Contact us

A revolution in digital dentistry

Dentsply Sirona and Carbon combine best-in-class materials and technology to produce a streamlined workflow that labs of any size can seamlessly integrate into existing digital practices.

The system is indicated for existing dentition (single arch) or full-over-full dentures (double arch).

The trusted Lucitone family of products brings high-impact performance and long-lasting esthetics to a reliable, long-term denture solution.

The five-step digital workflow is a reliable, validated process to incorporate the unmatched material solutions of Dentsply Sirona with the high-level performance of Carbon 3D printing. Laboratories of any size can easily integrate the program into existing digital practices to lift levels of capacity, accuracy, and esthetics.

Benefits

The complete Lucitone Digital Print Dentures workflow with the Carbon 3D printing platform streamlines the connection between the dentist and lab. With advantages from the best-in-class materials and cutting-edge technology, the program elevates the production of digital dentistry to a reliable, long-term solution that improves the entire edentulous process.

Trusted Lucitone brand of materials:

- High-Impact Performance: Exceeds ISO Improved Impact Resistance

- Durability: Smart polymer technology with BAM! to resist breakage

- Proven Esthetics: Matches the acrylic-resin colors that professionals have long favored

Streamlined processing for labs:

- Increased Capacity: Print up to 8 denture bases in 2 hours

- Streamlined: Less labor per denture with no grinding required

- Efficiency: Simple, reliable assembly for technician

Improved function for patients:

- Long-Lasting: Exceptional Wear Resistance

- Natural: Beautifully esthetic denture that looks and feels natural

- Accuracy & Stability: Functional and long-lasting fit

Learn more about Digital Dentures

with Lucitone Digital Print - 3D Denture Resin and IPN 3D - Digital Denture Teeth.

Lucitone Digital Print Denture - Try-In Clinical Checklist 35 kB

Checklist for printed Try-Ins.

Lucitone Digital Print Denture - Reference Denture guide 2 MB

Clinical Workflow

Lucitone Digital Print Denture Certified Labs 603 kB

Listing of Lucitone Certified Labs

Lucitone Digital Print Denture Materials - for Carbon M-series printers 1 MB

Instructions for use

inLab Speedcure IFU 3 MB

Instructions for use

Lucitone Digital Print: 3D Trial Replacement Resin 145 kB

Safety Data Sheet

Lucitone Digital Print: 3D Denture Resin 144 kB

Safety Data Sheet

Lucitone Digital Fuse Step 1 146 kB

Safety Data Sheet - 3D Tooth Conditioning Agent

Lucitone Digital Fuse Step 2 148 kB

Safety Data Sheet - 3D Denture Bonding Resin

Lucitone Digital Fuse Step 3 179 kB

Safety Data Sheet - 3D Sealer

Lucitone Digital Print Dentures

I'm interested now what?

Thank you for your interest in our Dentsply Sirona Lucitone Digital Print Denture!

To get more information on how to setup a product overview and training with one of our Dentsply Sirona representatives, please fill out and complete the information requested below.

Once we receive your information, a Dentsply Sirona representative will contact you about next steps.

We look forward to connecting with you soon.

I am a*

Please select Dental Assistant Dental Hygienist Dental Laboratory Technician Dentist Distributor Sales Rep Office Staff/Front Desk Patient Other

Specialty

Please select Dental Public Health Dentist Anesthesiologist Endodontics Cosmetic Dentistry General Practice Implantology Oral and Maxillofacial Surgery Orthodontics and Dentofacial Orthopedics Pediatric Dentistry Periodontics Prosthodontics

Comment

Email*

Academic Title

Please select

Dr. Prof.

Prof. Dr.

Prof.

Prof. Dr.

Company*

Street

Postal Code & City*

Province*

Please choose Alberta Manitoba British Columbia New Brunswick Newfoundland and Labrador Nova Scotia Northwest Territories Nunavut Ontario Prince Edward Island Quebec Saskatchewan Yukon Territory

Country*

Canada

We would like to keep you informed with updates and offers from the Dentsply Sirona Group via email. Please tick the box if you are happy for us to do so. You can change your mind at any time. Simply adjust your email settings or unsubscribe from email marketing communications in your preference centre.

Please tick the box if you are happy for us to do so. You can change your mind at any time. Simply adjust your email settings or unsubscribe from email marketing communications in your preference centre.

load-icon

We are currently unable to process this time. Please try again later.

3D Dentures | Affordable Dentures & Implants

Our Services

- Dentures

- Compare Our Dentures

- Full Dentures

- New Denture Wearer Package

- Partial Dentures

- RealFit 3D Dentures

- Implants

- All-In-One Solution

- Denture Implants (Snap-In)

- Single & Multiple Tooth Implants

- Tooth Extractions

- Denture Services

- Denture Adjustments

- Denture Relines

- Denture Repairs

- Gold Dentures

- Dental Services

- Crown Solutions

- Sedation Dentistry

- Free Consult X-Rays

- General Dentistry

Custom 3D Printed Dentures

Affordable Dentures & Implants is re-imagining dentures with our game-changing, FDA-approved RealFit 3D Denture.

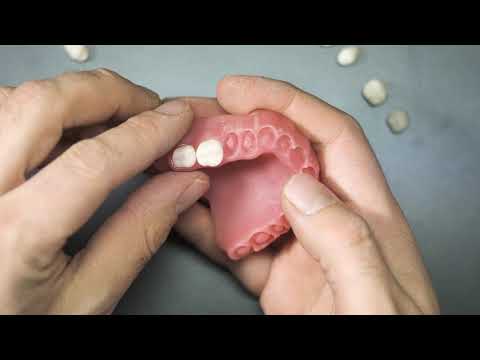

The RealFit3D Denture is the industry’s first premium digital denture that combines accuracy and durability with a computer-aided digital design. The innovative 3D printing and digital design process accurately creates a durable, natural looking denture that feels and fits better than dentures made through a traditional process.

Patients report their RealFit 3D Denture feels comfortable in their mouth and the fit is amazing!

iframe video

What are 3D Dentures?

3D dentures are born from a digital scan of your mouth that is then turned into a CAD file. This file is then uploaded to a 3D printer that will build your completely custom set of dentures in as little as hours.

This state-of-the-art technology ensures that your denture will be close to a perfect fit in your mouth when you receive them, and they can be completed in much less time than a traditional denture.

Benefits of 3D Dentures

3D Dentures Last Longer

The 3D dentures are made with a tough resin that won’t break down as fast over time, compared to acrylic or plastic dentures.

Repairs are Faster & More Convenient

Because the scans of your mouth can be saved on our computer, if you need a new pair of dentures we can just send your scans to the lab and have a new set fabricated. You will only need to come back to the office to pick them up!

Little to No Adjustments

You can expect your 3D dentures to fit perfectly and look amazing the first time, without the hassle of creating molds and getting multiple scans of your mouth like with traditional dentures.

Choose How Natural They Look

The 3D printing technology lets you choose the exact color of teeth that you want for your dentures and can even color match with an actual photo of your remaining teeth.

How long does it take to get 3D Dentures?

At Affordable Dentures & Implants, we can usually get you your brand new set of 3D dentures with same-day service. Not all practices offer this option, so contact your local office to see how fast we can get you your new smile.

Are 3D dentures more expensive than traditional dentures?

It is important to consider the value of your time when comparing denture options. While the price point for 3D dentures may seem higher, you must consider the time you will save when you don’t have to come back in for multiple adjustment appointments and relines. You will be able to have your perfectly fit, natural looking dentures in one day at most of our offices. 3D dentures will also last longer than traditional dentures, so it is important to consider these as a strong investment in your future smile as well.

How long do 3D printed dentures last?

10 - 15 years or more with good care habits.

Can I get 3D dentures with implants?

Yes! Your 3D dentures will be placed once your mouth heals completely from the surgery.

Buy With Confidence

Your satisfaction means everything to us! We want you to not only walk out of our practice with a confident, new smile… we also want you to feel confident in the decision you make to trust us with your tooth replacement care. We look forward to serving you.

We look forward to serving you.

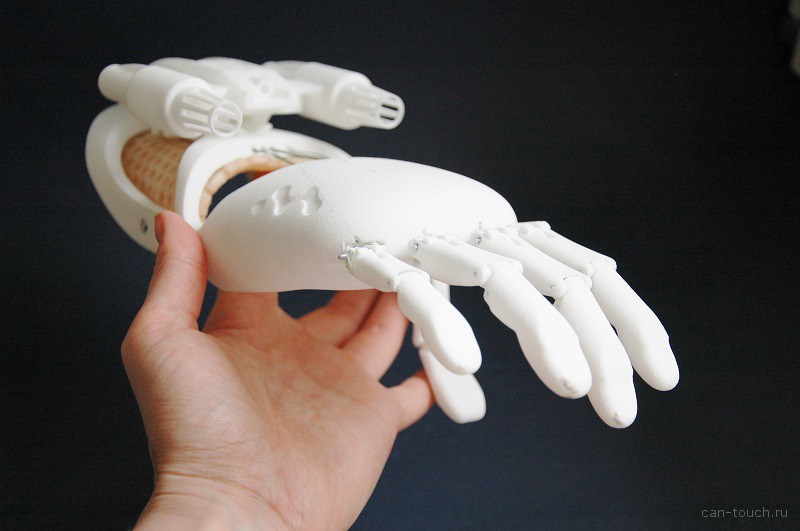

using 3D printing in dentistry to make dentures

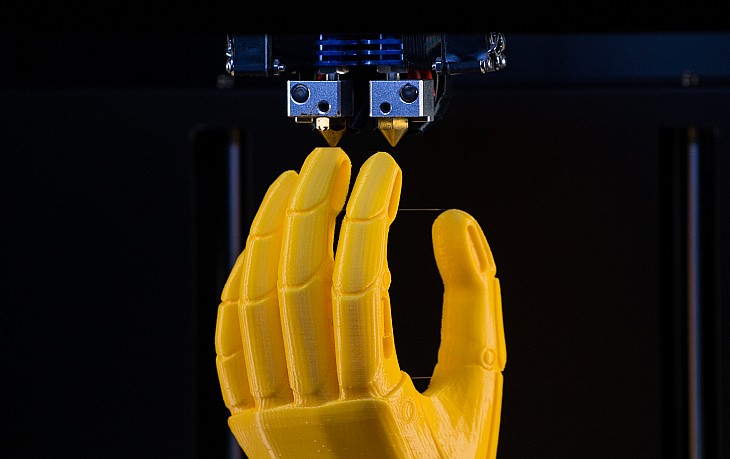

Modern additive printing technologies allow the production of a wide variety of products for an incredible range of applications. Medicine, in particular the field of dentistry, has long been no exception and is using the achievements of technological progress for the benefit of its patients with might and main, becoming digital.

Benefits of using a 3D printer

Clinics everywhere are moving to intraoral scanning, abandoning analog, uncomfortable for the patient methods of impression making. Some are not limited to diagnostic manipulations at all, transferring the stages of modeling and manufacturing of single works under their own roof and partially refusing laboratory services. In this case, a 3D printer for dentistry is indispensable in the manufacture of orthodontic and temporary orthopedic structures. Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Mouth guards, night guards, surgical templates for operations and even the printing of dentures, whether they be single crowns, bridges or even removable basic dentures - all this is under the power of dental 3D printing.

Comparison of the main 3D printing technologies used in dentistry

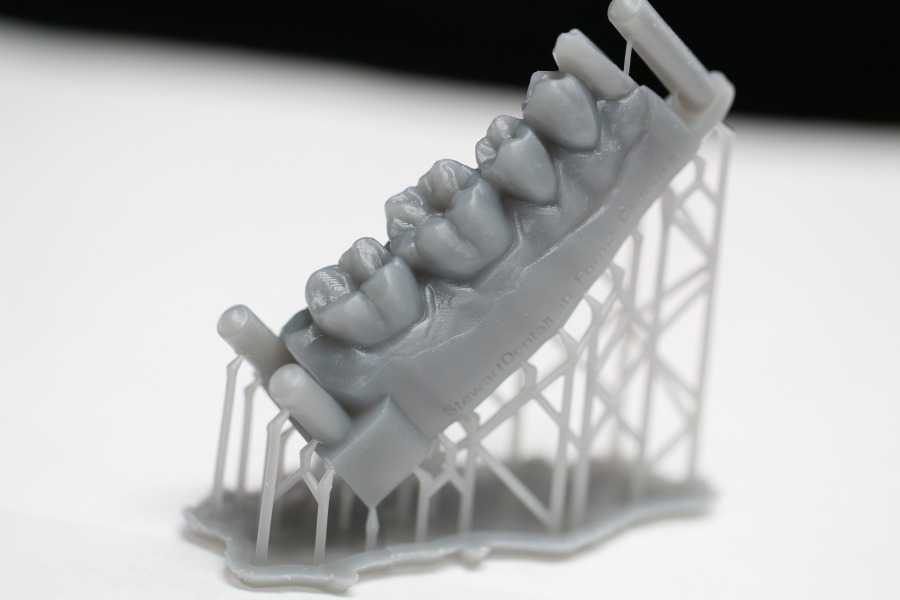

Laboratories are not left behind and are improving the manufacturing methods and range of dental products and services. The use of laboratory scanning eliminates the error that may occur during the manufacture of a plaster model. If desired, the model can be produced on a dental printer from a photopolymer, which is always less troublesome and faster. Gingival masks, individual trays, and any orthopedic constructions - the 3D printer opens up new horizons for dental laboratories.

If we talk about the main methods of manufacturing dental products on a 3D printer, these will be:

- SLA, or the so-called stereolithography, in which the laser beam polymerizes the material, quickly passing through each point of the object;

- DLP, or layer-by-layer illumination process, in which the projector illuminates the photopolymer layer by layer using ultraviolet radiation, transforming it into a future product.

Regardless of the printing method, the final properties of the work will depend on the material from which it is made, the very "resin".

Speaking of photopolymers, one cannot but mention NextDent. The company is a subsidiary of the Dutch manufacturer of plastics for prosthetics Vertex. NextDent pioneered the field of biocompatible 3D printing resins and was soon bought out by global additive technology giant 3D Systems.

With 30 unique NextDent photopolymers, the widest range of any dental material supplier. A range of aesthetically accurate colors enable dental labs and clinics to achieve a close match of finished products to the patient's teeth and gums. 3D printing materials from NextDent are biocompatible and certified in accordance with the requirements of the European Union, which makes them widely used. Photopolymers meet the requirements of the European Medical Device Directive (93/42/EEC), approved by the Food and Drug Administration (USA) and certified in many other countries.

With such a promising line of dental resins in its portfolio, 3D Systems, as the inventor of 3D printing and a recognized industry leader, could not do without using its own revolutionary technologies in a new field for itself. This is how the first 3D printer for dentists NextDent 5100 appeared, specially designed for the manufacture of products from biocompatible photopolymers.

Its hallmarks are speed and ease of use. Incredibly fast in the production of dental work of any complexity, the NextDent 5100 will allow you to print more than 70 temporary crowns in 25 minutes. Or to make a whole prosthesis in front of the patient in just an hour.

NextDent Denture 3D+, a class IIa biocompatible material, was created for the fabrication of removable denture bases. This material has significantly less shrinkage than the already used, standard PMMA materials. Shrinkage can be avoided using software, resulting in a perfectly suitable base for a removable denture. Excellent mechanical properties make it possible to surpass the quality of traditional methods of manufacturing removable dentures. Available in the following shades: dark pink, light pink, opaque, reddish pink and transparent pink. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity.

Available in the following shades: dark pink, light pink, opaque, reddish pink and transparent pink. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity.

NextDent C&B Micro Filled Hybrid is a class IIa biocompatible material designed for the production of single crowns and bridges. The balance between inorganic fillers and resin gives the material its high strength and wear resistance. This material is easy to polish and can be tinted with any composite paint. Due to the excellent balance between opacity and translucency, printed crowns blend perfectly with the patient's natural teeth. Available in the following shades: BL, N1, N1.5, N2, N2.5, N3 and T1. Biocompatible, non-cytotoxic, non-mutagenic, does not cause redness and swelling, does not have sensitizing properties, does not cause systemic toxicity.

The combination of these two materials allows you to quickly and accurately produce a base, crown, bridge and even a removable denture. Perfectly polished and individualized, absolutely not capable of causing rejection in the patient, do not contain methyl methacrylates.

Perfectly polished and individualized, absolutely not capable of causing rejection in the patient, do not contain methyl methacrylates.

The future has already arrived. Join the future and you! Let's change dentistry together!

Overview of the Formlabs Form 3B dental 3D printer

At the end of 2019, the American company Formlabs created a division focused on the production of 3D printers and components specifically for the dental market. The result is the Form 3B for biocompatible printing. Form 3 printers released since 2020 no longer support printing with Dental LT clear, Biomed Amber, Biomed Clear, Surgical Guide, Temporary and Custom Tray photopolymers, giving way to the older model. Let's talk about the new product in more detail.

Key Features

Form 3 is powered by LFS (Low Force Stereolithography) technology. The light processing unit directs the beam to the polymer, giving it shape, and the flexible curette eliminates the possibility of deformation of the product.

Device weight – 17.5 kg, dimensions – 405×375×530 mm. The size of the construction area is 145×145×185 mm, so printing a large number of products will not be a problem. The resolution along the X and Y axes is 25 microns, the layer thickness is in the range of 25-300 microns.

Formlabs Form 3B has a USB 2.0 port, Ethernet cable, Wi-Fi. Management is carried out on an interactive touch screen with a resolution of 1280 × 720 pixels. Notifications are displayed here, on the display, you can configure sending via SMS or e-mail. There are also two LCD status indicators and a speaker for audio alerts.

The printer is compatible with computers running 64-bit Windows 7 or later, Mac OS X 10.10 or later. For stable operation, the printer needs to provide 4 GB of RAM. Before printing, you need to prepare an object in STL or OBJ format. Learn more about the benefits of the third generation of printers:

Dental polymers Formlabs

The manufacturer offers a line of several bi -compatible photopolymers:

Dental Model Resin 9000

, it is recommended to print:

- .

;

; - orthodontic and diagnostic models;

- implant models.

Dental Model Resin is ideal for removable dies with detailed edges and contacts, 35 µm accuracy.

Permanent dental models printed in Dental Model Resin.

Draft Resin

The fastest printing material that will help you create a dental model in less than 20 minutes. High detail and smooth surface of the finished product are relevant for:

- thermoformed models;

- orthodontic models, including braces;

- crown and bridge models.

Set the layer thickness to 200 µm for high-speed models that can be used on the same day, or 100 µm for more detailed models.

D Prefabricated thermoformed transparent horseshoe retainer printed with Draft Resin.

Dental SG Resin

This is a Class I autoclavable resin for surgical templates and drill guides.

Autoclavable-ready surgical guide printed in Dental SG Resin on a diagnostic model in Dental Model Resin.

Dental LT Clear Resin

Class IIa polymer is good for splints and night guards, guaranteed to retain its original characteristics during long use. Due to the optical transparency, Dental LT Clear looks great in the mouth.

Finished night mouthguard printed in Dental LT Clear Resin on a diagnostic model in Gray Resin.

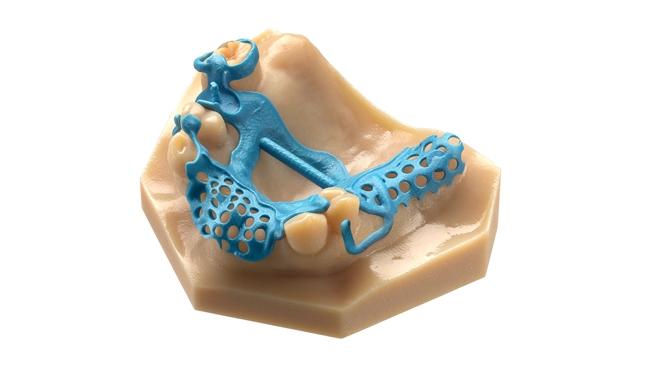

Castable Wax Resin

Valid for:

- castable caps and intraosseous parts of implants;

- manufactured by casting or pressing;

- cast partial removable denture frameworks.

Castable Wax contains 20% wax for quality casting with full burnout and excellent edge fit. The resulting products are so strong that they no longer need post-polymerization, which means that the workflow is accelerated and simplified.

Castable Wax Resin 3-Piece Anterior Bridge and Crown Models printed on Dental Model Resin Removable Die Model.

Custom Tray Resin

Used for making custom impression trays, also good at printing impressions for crowns, bridges, implants and other complex products.

Custom tray printed with Custom Tray Resin on a diagnostic model printed with Model Resin.

Temporary CB Resin

Suitable for:

- crowns;

- bridges;

- inner and outer tabs;

- veneers.

Temporary CB will provide perfect edge fit, strength, aesthetics. Available in 4 VITA shades. Prostheses made from this material can stay in the mouth for up to one year.

Completed 3-piece anterior bridge and posterior crown fabricated with Temporary CB Resin on a working Model Resin model.

The manufacturer is constantly working on expanding and improving the range of polymers. However, their availability depends on the region where the customer is located, since the nuances of using biocompatible polymers are interpreted differently by the laws of different countries.

However, their availability depends on the region where the customer is located, since the nuances of using biocompatible polymers are interpreted differently by the laws of different countries.

Formlabs also has Denture Base Resin for denture bases and trial dentures, and Denture Teeth Resin for Class II dentures. Unfortunately, it's only available in the US for now.

Initial Setup and Preparation

For the Form 3B, you will need a 40 x 53 x 78 cm, flat, stable table to keep the printer from touching walls or other equipment. If your table is tilted even slightly, resin will start to leak out of the printer during printing.

So, we get the printer out of the box.

1. Install the light processing unit correctly. Open the printer case and remove the instruction sheet from the unit. There is a latch on the left side of the block. Turn the screws clockwise by hand, and then loosen and remove them. Now you can turn the latch and remove it together with the screws in the box: they will come in handy if you transport the device.

2. Connect the Form 3B power cable and, if necessary, an Ethernet, USB cable.

3. Now level the print surface. Place the round disc for alignment at the angle indicated in the instructions. To adjust the height, turn the dial clockwise. Due to transportation, the legs are completely retracted into the body, so before starting printing, it is important not to forget to set the printer to the optimal height. When it is reached, a message will appear on the display.

4. When you begin pouring resin, hold the reservoir firmly with both hands so that it does not tilt. It is better to protect the skin of the hands with gloves.

5. To install the resin reservoir, open the printer case, lift the reservoir lid, and remove the packaging. Lift the reservoir while supporting it with your hand, and be careful not to leave fingerprints on its inner surface, as this may adversely affect print quality.

6. Align the tank with the side rails.