Why was the 3d printer invented

When Was 3D Printing Invented? The History of 3D Printing -

May 15, 2020

When you first heard the words “3D printing” did you imagine a super futuristic technology, like in the movies but, when was it really invented?

While the term 3D printing may sound like something you’d expect to hear in a science fiction novel, the history of 3D printing, also known as additive manufacturing, is longer than you might think.

Keep reading to learn about the history of 3D printing, and our BCN3D predictions on where we see this technology going in the future.

The History of 3D Printing in 3 PhasesThe 1980s: When Was 3D Printing Invented?The first documented iterations of 3D printing can be traced back to the early 1980s in Japan. In 1981, Hideo Kodama was trying to find a way to develop a rapid prototyping system. He came up with a layer-by-layer approach for manufacturing, using a photosensitive resin that was polymerized by UV light.

Although Kodama was unable to file the patent requirement of this technology, he is most often credited as being the first inventor of this manufacturing system, which is an early version of the modern SLA machine.

Across the world a few years later, a trio of French researchers was also seeking to create a rapid prototyping machine. Instead of resin, they sought to create a system that cured liquid monomers into solids by using a laser.

Similar to Kodama, they were unable to file a patent for this technology, but they are still credited with coming up with the system.

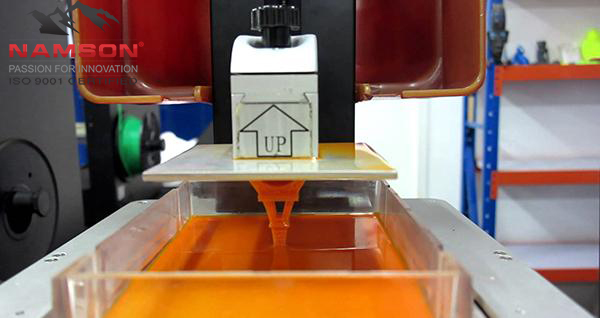

That same year, Charles Hull, filed the first patent for Stereolithography (SLA). An American furniture builder who was frustrated with not being able to easily create small custom parts, Hull developed a system for creating 3D models by curing photosensitive resin layer by layer.

In 1986 he submitted his patent application for the technology, and in 1988 he went on to found the 3D Systems Corporation. The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988.

The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988.

But SLA wasn’t the only additive manufacturing process being explored during this time.

In 1988, Carl Deckard at the University of Texas filed the patent for Selective Laser Sintering (SLS) technology. This system fused powders, instead of liquid, using a laser.

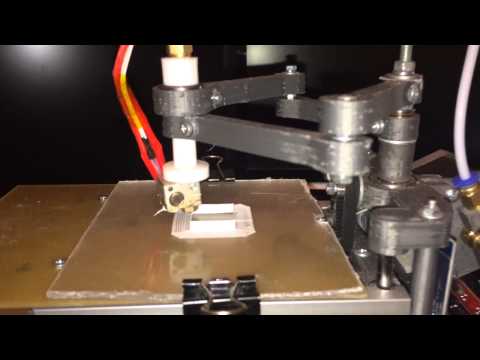

SLS fabrication machines in the Fundació CIM warehouseFused Deposition Modeling (FDM) was also patented around the same time by Scott Crump. FDM, also called Fused Filament Fabrication, differs from SLS and SLA in that rather than using light, the filament is directly extruded from a heated nozzle. FFF technology has gone on to become the most common form of 3D printing we see today.

These three technologies are not the only types of 3D printing methods that exist. But, they are the three that serve as the building blocks that would lay the groundwork for the technology to grow and for the industry to be disrupted.

In the 90s, many companies and startups began popping up and experimenting with the different additive manufacturing technologies. In 2006, the first commercially available SLS printer was released, changing the game in terms of creating on-demand manufacturing of industrial parts.

CAD tools also became more available at this time, allowing people to develop 3D models on their computers. This is one of the most important tools in the early stages of creating a 3D print.

During this time, the machines were very different from those that we use now. They were difficult to use, expensive, and many of the final prints required a lot of post-processing. But innovations were happening every day and discoveries, methods, and practices were being refined and invented.

Then, in 2005, Open Source changed the game for 3D printing, giving people more access to this technology. Dr. Adrian Bowyer created the RepRap Project, which was an open-source initiative to create a 3D printer that could build another 3D printer, along with other 3D printed objects.

In 2008, the first prosthetic leg was printed, propelling 3D printing into the spotlight and introducing the term to millions across the globe.

Then, in 2009, the FDM patents filed in the 80s fell into the public domain, altering the history of 3D printing and opening the door for innovation. Because the technology was now more available to new companies and competition, the prices of 3D printers began to decrease and 3D printing became more and more accessible.

3D Printing NowIn the 2010s, the prices of 3D printers started to decline, making them available to the general public. Along with the lowering prices, the quality and ease of printing also increased.

The materials that printers use have also evolved. Now there are a variety of plastics and filaments that are widely available. Materials like Carbon Fiber and Glass Fiber can also be 3D printed. Some creatives are even experimenting with printing materials like chocolate or pasta!

Some creatives are even experimenting with printing materials like chocolate or pasta!

In 2019, the world’s largest functional 3D printed building was completed. 3D printing is now consistently used in developing hearing aids and other healthcare applications, and many industries and sectors have adopted the technology into their everyday workflow.

It’s safe to say that the history of 3D printing is still being written.

Innovations and ideas are created every day. We’re very excited to see what’s next!

Why 3D printing was invented: A look at the history of 3D printing

Very few people outside of the tech community tend to realize, that 3D printing is a technology that had been talked and hypothesized about since the 1970s.

The first recorded mention of 3D printing can be traced back to an article written by famed technology columnist David E. H. Jones for the New Scientist journal in 1974.

Written under the pseudonym, “Daedalus”, David E. H. Jones explained in his article, the possibility of forming and creating 3D models by shining precise lasers onto a vat of photosensitive monomers. This idea would serve the basis of the very first 3D printers less than a decade later.

Origins of 3D printing – why it was inventedIt was not until 1981 that the first patent to describe the principle technology of a resin-curing 3D printer was applied for with the US Patent Office. Doctor Hideo Kodama of Nagoya Municipal Industrial Research Institute applied for the patent of two methods of 3D printing objects. He called it rapid prototyping at the time. A term that carried on today to mean the creation of the initial design of a product or object intended for proof of concept and pre-production testing.

Both approaches utilized the photo-hardening property of certain thermosetting plastics when selectively exposed to ultraviolet light by way of either a mask pattern or through the use of a scanning fiber transmitter.

Alas, however, the patent application was rejected by the patent office for failure to file the patent within the one-year deadline. Despite Doctor Kodama’s failure to secure a patent, the intrigue in this then-novel technology by no means diminished.

Three French scientists: Jean-Claude André at the French National Centre for Scientific Research (CNRS). Olivier de Witte at CILAS, and Alain le Méhauté at Compagnie Générale d’Electricité (CGE, now Alcatel-Alsthom), collectively worked on a stereolithography-based 3D printer design. The trio presented the design to the CNRS in 1984, only to have it turned down. CNRS reluctantly concluded that the technology greatly lacks viable areas of application. Their patent filing too was destined for inconsequential doom, as both CILAS and CGE abandoned the project along with the patent filing.

For 3D Printing then, it would seem that the third time was indeed the charm.

Charles “Chuck” Hull, globally recognized now as the pioneering founder of 3D printing, forming the company, 3D Systems Inc. He filed for his patent for “Stereolithography” in 1984, just three weeks after the French trio.

Hull’s idea for the resin-curing technique was developed out of his frustration at the lead times that were common back then for the manufacture of custom parts. Hull was convinced that parts could be manufactured by curing resin via the UV lamps already used to cure furniture topcoats.

The tabletop and furniture manufacturer that he worked for provided him with a small lab to test and work on his idea. Thankfully, for the future of 3D printing, Chuck’s patent was granted in 1986.

Hull founded his now globally recognized company in the same year and produced the first commercially available stereolithography-based 3D printer, the SLA-1, in 1988.

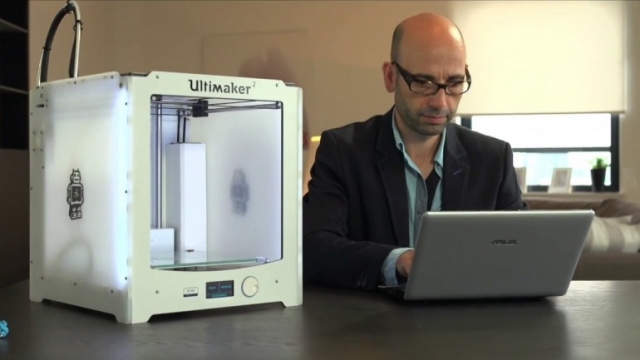

3D Systems SLA_13D printing technology has only just begun to truly come within the reach of the average consumer. Even now, experts believe that the proliferation of affordable 3D printers has ways to go before the technology could be considered mainstream. If we were to ask the average consumer when they first heard about 3D printing, surely the answer would not be more than five years, or at most, a decade and a half ago.

Even now, experts believe that the proliferation of affordable 3D printers has ways to go before the technology could be considered mainstream. If we were to ask the average consumer when they first heard about 3D printing, surely the answer would not be more than five years, or at most, a decade and a half ago.

Just as Charles Hull’s SLA-1 was hitting the market in 1988, Carl Deckard, a University Of Texas (Austin) undergraduate, was busy developing an entirely different method of printing 3D models.

By using lasers to selectively bond together granules of powder, Deckard was able to demonstrate what he called SLS, Selective Laser Sintering, as a viable method of rapid prototyping. While Deckard’s first machine, “Betsy” was only able to produce small pieces of plastics…still, this was enough for Deckard to continue refining his design throughout his Masters and Ph. D. In doing so, he acquired the help of Professor Joe Beaman at UT-Austin till he applied for a patent on SLS technology in 1994.

D. In doing so, he acquired the help of Professor Joe Beaman at UT-Austin till he applied for a patent on SLS technology in 1994.

SLS would still take a long time to become commercially available. A similar technology, but one that worked with metal powders, Selective Laser Melting, was developed at the Fraunhofer Institute in Auchen Germany in the 1995. Additive Manufacturing makers EOS deposited the name Direct Metal Laser Sintering to the same process. This breakthrough allowed for 3D printing to finally be seen as a means of industrial manufacturing.

In 1989, Steven Scott Crump, after a frustrating attempt to craft a toy frog for his daughter made from a hot glue gun, invented fused deposition modelling (FDM). He later co-founded one of the juggernauts of the 3D printing world, Stratasys, with his wife Lisa Crump. The Crumps filed for a patent on FDM in the same year.

Slowly but surely, the moniker of rapid prototyping began to lose its value for the underlying technologies. Inventors and innovators had begun to view 3D printing as a means of efficient, precise, additive and rapid manufacturing. While its value as a prototyping technology has only increased with time, it is arguably the vaste range of possibilities that it enables which has baffled and amazed even the most ardent of skeptics.

Inventors and innovators had begun to view 3D printing as a means of efficient, precise, additive and rapid manufacturing. While its value as a prototyping technology has only increased with time, it is arguably the vaste range of possibilities that it enables which has baffled and amazed even the most ardent of skeptics.

Today rapid prototyping is use by inventors, engineers, and developers as part of the manufacturing or development workflow.

Dr. Anthony Atala holdng a 3D printed kidneyOne such innovation reared its head onto the media in 1999. Doctor Anthony Atala of the Wake Forest Institute for Regenerative Medicine used a modified inkjet printer with biological tissue forming material, to successfully 3D print a synthetic scaffold of a human bladder. Mr. Atala’s work paved the way for bioprinting. He and his team successfully transplanted 3D printed human bladders in at least seven young patients by 2006.

Birth of the RepRap ProjectNo account of the history of 3D printing could ever be complete without mention of Dr. Adrian Bowyer.

Adrian Bowyer.

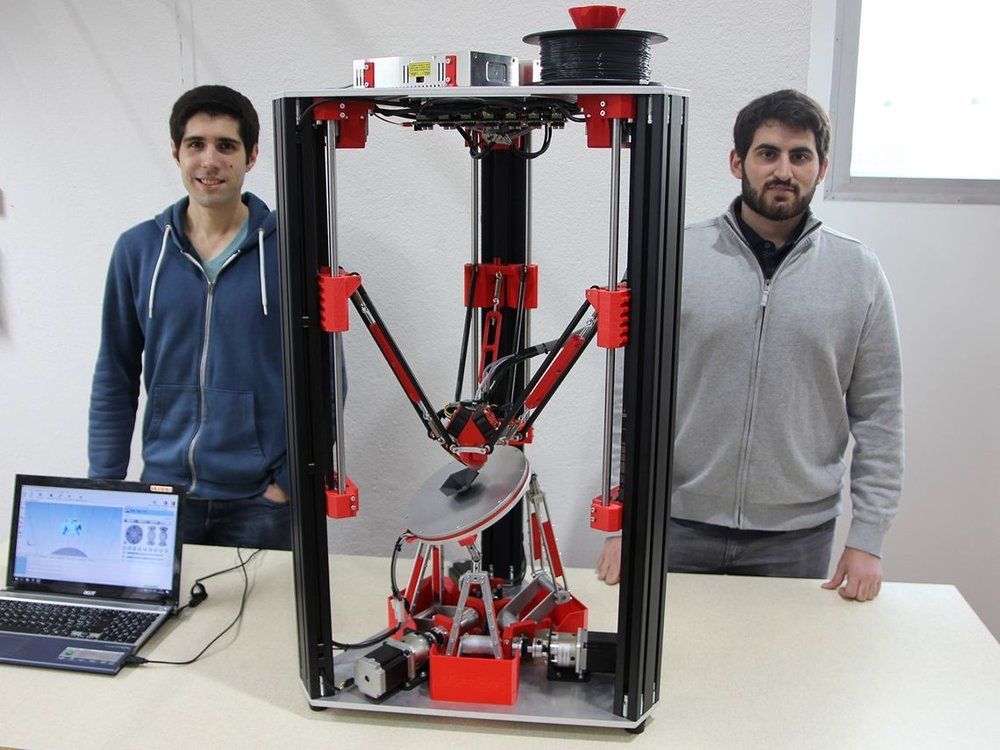

Doctor Adrian Bowyer of University of Bath, England founded the Open-source Replicating Rapid prototyper (RepRap) project in 2005. The goal was to design a 3D printer that could completely self-replicate all its parts, so that anyone with access to a reprap printer could print and assemble another completely functional 3D printer. This self-replicating ability would allow for the proliferation of 3D printers as desktop manufacturing units among the masses and enable distribution of manufacture, instead of distribution of manufactured goods.

Now made up of hundreds of collaborators around the world, the reprap project has shown no signs of slowing down. Already capable of producing all plastic parts of another reprap printer, the project continues to work towards its goal of true self-replication by one day being able to reliably print its own circuit boards as well as metal components by use of different extruder heads.

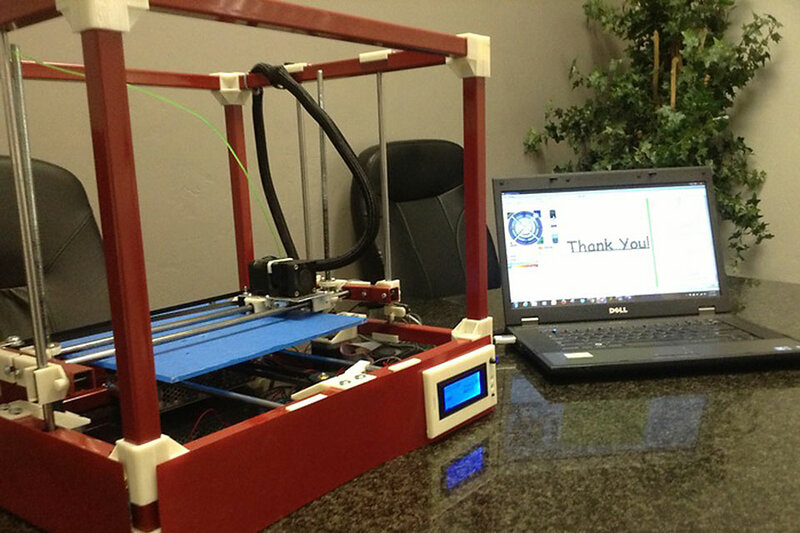

The RepRap project, by virtue of its open design guidelines, kickstarted the market for extrusion-type affordable DIY 3D Printers.

Consumer brands such as Prusa, Makerbot, Micro, iTron to name a few, would simply not exist had there been no RepRap.

Recent developments in the 3D printing industryCrump’s key patent on FDM technology expired in 2009. Makers of 3D printers jumped on the opportunity. Complementing the work done by the RepRap project, the expiration opened up FDM technology to even entry-level 3D printers and the prices started to nosedive.

Similarly, the SLS patent expired in 2014 and the market finally opened up for relatively afforadable Sinter-type 3D printers.

As these industry-process patents are slowly but surely coming to an end, competition is bringing down prices ever further. Today, one can affordably consider buying an FDM and SLA printer at the consumer level. And SLS and SLM printers at the industrial level.

Owing to their manufacture promise, 3D printers were adopted by the fashion industry, food industry and construction industry over the course of the first decade of the new century.

While fashion and fine dining are new additions. Work on construction-based 3D printers had been ongoing since at least the 90s, with the Contour Crafting extrusion-based technique being developed in 1995 by Behrokh Khoshnevis of University of Southern California.

In 2005, Enrico Dini in Italy patented the D-Shape technology that employed a massive scaled powder jetting bonding technique.

The future of 3D printing3D printers continue to be used to innovate in sectors that could never have even conceived of benefiting from “Prototyping” technology. Be it food, construction, prototyping, manufacture, medicine or bio-printing. 3D printing was not developed for this.

In true form of unleashed potential, from its humble beginnings as a tech that no organization could see an application for, 3D printing has become a buzzword worthy of its hype. At this rate, we may realistically be headed to live in a world idealized by the RepRap founders. One where distribution of manufacture enables all, and not just the privileged or fortuitous few.

At this rate, we may realistically be headed to live in a world idealized by the RepRap founders. One where distribution of manufacture enables all, and not just the privileged or fortuitous few.

3D printing may not have been developed with such explosive goals in mind. Regardless, however, 3D printing most certainly seems destined to meet them.

How long ago did you first hear about or seen your first 3D printer? Let us know in below.

Tags: 3D printing3D printing timelineHistoryIndustriesInventorsManufacturingRapid prototypingRepRap

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

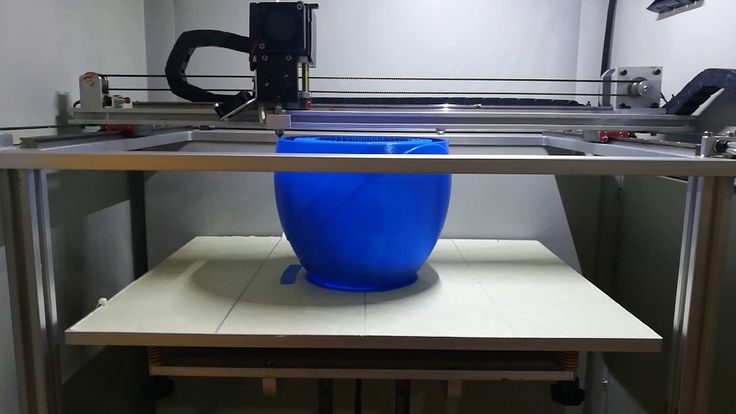

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc.), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0. 1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

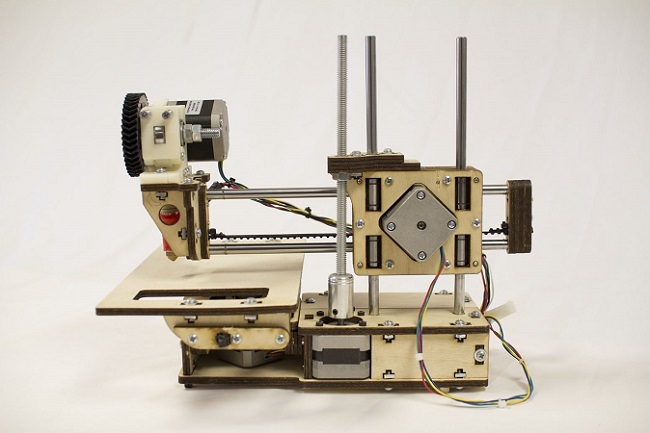

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

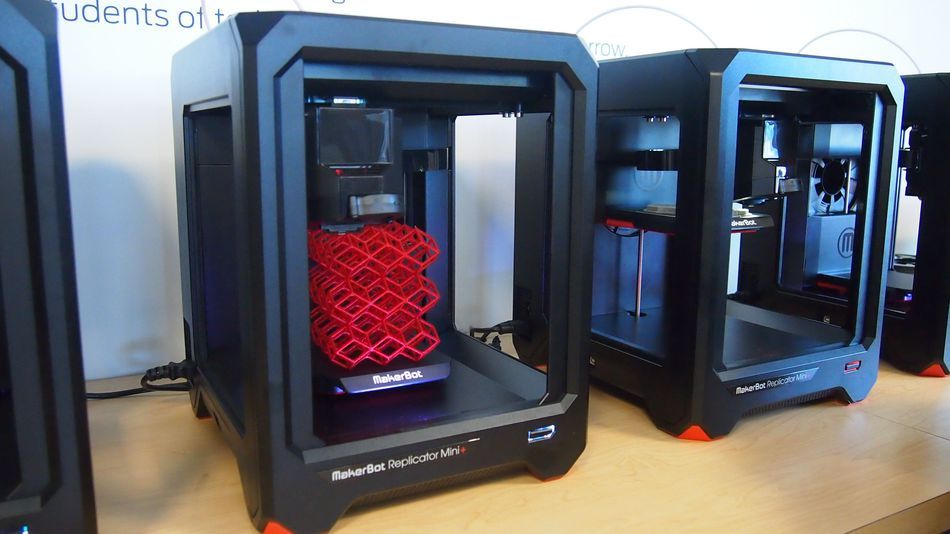

First of all, it is worth mentioning the MakerBot company, which started as a startup, took RepRap ideas as a basis and gradually turned them into a product of a new quality.

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend.

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

In addition to the "classic" scope of 3D printing, today more and more often you can see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells.

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).

3d printing of houses (and other structures) will no doubt also develop, reducing costs and production time, which, together with the development of new approaches in architecture and urban planning (such as modular construction and the prefabricated method), will give a tangible impetus to development the industry as a whole.

Biological 3D printers will be an important tool in scientific research. However, before they appear in hospitals and clinics, where they will print new organs, it is still very, very far away (in fact, this is science fiction).

A Brief History of 3D Printing / Sudo Null IT News

3D printing was born 40 years ago and opened up amazing possibilities for creating various models in prototyping, dentistry, small-scale production, customized products, miniatures, sculptures, mock-ups and much more.

Who invented the 3D printer? What was the first 3D printing technology? And what was the first thing they printed on a 3D printer? Let's open the veil of secrecy over a huge number of interesting facts and stories about the emergence of technology. 9. , which layer-by-layer formed a rigid object from a photopolymer resin with the help of UV illumination.

In fact, he described a modern photopolymer printer, but failed to provide the necessary data for patent registration within a year, as required by patent law, and abandoned the idea. However, in many sources it is he who is called the inventor of 3D printing technology.

However, in many sources it is he who is called the inventor of 3D printing technology.

In 1983, three engineers - Alain Le Meho, Olivier de Witt and Jean-Claude André from the French National Center for Scientific Research, in an attempt to create what they called a "fractal object", came up with the idea of using a laser and a monomer, which, under the influence of a laser, turned into a polymer. They applied for a patent 3 weeks before the American Chuck Hal. The first object created on the apparatus was a spiral staircase. Engineers called the technology stereolithography, and the patent was approved only in 1986 year. Thanks to them, the most famous file format for 3D printing is called STL (from the English stereolithography). Unfortunately, the institute did not see any prospects in the invention and its commercialization, and the patent was not used to create the final product.

Chuck Hull, Inventor of SLA Laser Stereolithography At the same time, Chuck Hull was working for a company that made countertop and furniture coatings using UV lamps. The production of small plastic parts for prototyping new product designs took up to two months. Chuck came up with the idea to speed up this process by combining UV technology and layering thin plastic. The company gave him a small laboratory for experiments, where he worked in the evenings and weekends. As a material, Chuck used acrylic-based photopolymers that harden under the influence of ultraviolet radiation. One night, after months of experimentation, he was finally able to print a sample and was so elated by luck that he walked home. Chuck showed his invention to his wife. It was an eyewash cup, more like a communion cup, according to the wife. It is considered officially the first 3D printed model in the world and is still kept by the Hull family, and after their death will be transferred to the Smithsonian Research Institute in Washington.

The production of small plastic parts for prototyping new product designs took up to two months. Chuck came up with the idea to speed up this process by combining UV technology and layering thin plastic. The company gave him a small laboratory for experiments, where he worked in the evenings and weekends. As a material, Chuck used acrylic-based photopolymers that harden under the influence of ultraviolet radiation. One night, after months of experimentation, he was finally able to print a sample and was so elated by luck that he walked home. Chuck showed his invention to his wife. It was an eyewash cup, more like a communion cup, according to the wife. It is considered officially the first 3D printed model in the world and is still kept by the Hull family, and after their death will be transferred to the Smithsonian Research Institute in Washington.

Chuck Hull filed a patent on August 8, 1984 and was approved on March 11, 1986. The invention was called "Apparatus for creating three-dimensional objects using stereolithography. " Chuck founded his own company - 3D Systems, and in 1988 launched the first commercial 3D printer - the SL1 model.

" Chuck founded his own company - 3D Systems, and in 1988 launched the first commercial 3D printer - the SL1 model.

Another new 3D printing method appeared around the same time as SLA printing. This is selective laser sintering SLS , which uses a laser to turn loose powder (instead of resin) into a solid material. Carl Deckard , a young undergraduate student at the University of Texas at Austin, and his teacher Prof. Dr. Joe Beeman were involved in the development. And the idea belonged to Karl. In 1987, they co-founded Desk Top Manufacturing (DTM) Corp. However, it will take at least another 20 years for SLS 3D printing to become commercially available to the consumer. In 2001, the company was bought out by Chaka Hull, 3D Systems.

Scott Crump, developer of FDM 3D printing (1988) Surprisingly simpler and cheaper 3D printing is FDM (Fused Deposition Modeling) was created after SLA and SLS, in 1988. Its author was aeronautical engineer Scott Crump . Crump was looking for an easy way to make a toy frog for his daughter and used a hot glue gun to melt the plastic and pour it into layers. Thus, the idea of FDM 3D printing was born, a technology for layer-by-layer deposition of a plastic thread. Crump patented a new idea and co-founded Stratasys with his wife Lisa Crump at 1989 year. In 1992, they launched their first production product, the Stratasys 3D Modeler, on the market.

Its author was aeronautical engineer Scott Crump . Crump was looking for an easy way to make a toy frog for his daughter and used a hot glue gun to melt the plastic and pour it into layers. Thus, the idea of FDM 3D printing was born, a technology for layer-by-layer deposition of a plastic thread. Crump patented a new idea and co-founded Stratasys with his wife Lisa Crump at 1989 year. In 1992, they launched their first production product, the Stratasys 3D Modeler, on the market.

Milestone 2: 3D printing becomes available

The first machines built by 3D Systems and Stratasys were bulky and expensive. The cost of one was hundreds of thousands of dollars, and only the largest companies in the automotive and aerospace industries could use them. Printers had a lot of limitations and could not be widely used. The development of technology has been very slow. 20 years later, in 2005, the RepRap (Replicating Rapid Prototyper) project appeared - a self-replicating mechanism for rapid prototyping.

It was inspired by Dr. Adrian Bauer from the University of Bath in the UK. The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. In the photo, all the plastic parts of the "child" are printed on the "parent". But in fact, a group of enthusiasts led by Adrian were finally able to create the budget 3D printer for home or office use .

The idea was quickly taken up by three New York technologists and started a desktop FDM printer company, MakerBot. This was the second turning point in the modern history of 3D printing.

Other technologies were being developed in parallel. One of them is bioprinting. Thomas Boland of Clemson University has patented the use of inkjet printing to 3D print living cells, making it possible to print human organs in the future. Dozens of companies around the world conduct research in this area.

Another important use of the new technology was the creation of prostheses, first conventional, and then bionic.