Pirate 3d printer

Pirate3D Finally Lets the Beleaguered Buccaneer 3D Printer Sink - 3DPrint.com

Over two years ago a scrappy 3D printer startup called Pirate3D was founded by three recent college graduates, who promptly launched a crowdfunding campaign on Kickstarter for their first 3D printer, the Buccaneer. It was billed as a 3D printer that anyone can use, and priced low enough that it seemed almost too good to be true. Some early bird pricing came in at under $300, and the average backer of the campaign would still get a 3D printer for less than $500. Word spread fast, and the campaign quickly funded the original goal of $100,000 in less than ten minutes, passed $500,000 in four days and finally ended having raised nearly $1.5 million, becoming (at the time) the most successful 3D printing campaign in Kickstarter history.

Things were looking pretty good for Pirate3D founders Brendan Goh, Tsang You Jun and Roger Chang–they were the talk of the 3D printing industry, flush with heaps of startup cash and even a few industry awards under their belt. But they were also left with the monumental task of manufacturing and shipping out 3,389 3D printers, with an entire ecosystem built around their own custom software. The trio had plenty of money, but unfortunately it seems none of them knew how to spend it.

Naturally, Pirate3D required necessities like office space, new staff that needed to be trained, software developed and hardware to be sourced. In the end, the $1.5 million raised went fast and everything seemed to screech to a halt. Shipment dates were missed, then missed again, then missed again. Then the few delivered Buccaneer printers had specs that didn’t match what was promised, then the electronics started failing, more shipment dates were missed, refunds were promised, and then promised refunds went undelivered. More shipment dates were missed, then the auto calibration didn’t work correctly and the electronics were shoddy and cheap.

For two years a majority of the Buccaneer campaign backers watched as their money was left hanging in limbo, and Pirate3D, admittedly in good faith, tried desperately to fulfill their orders. Even raising an additional two million dollars from private investors couldn’t seem to keep the Pirate3D ship afloat. Incredibly, in an effort to raise capital quickly, the company actually started to deliver units for retail sale while almost 75% of their original backers went unfulfilled.

Even raising an additional two million dollars from private investors couldn’t seem to keep the Pirate3D ship afloat. Incredibly, in an effort to raise capital quickly, the company actually started to deliver units for retail sale while almost 75% of their original backers went unfulfilled.

“End of A Chapter but Not the Book”

And so here we are, more than two years later with 60% of the original orders having still not been fulfilled and no refunds in sight, Pirate3D is finally throwing in the towel and admitting defeat. On October 13th, Brendan Goh sent the original Kickstarter backers a message that was essentially saying that they should abandon their hopes of receiving their Buccaneer any time soon, if ever. According to Goh, not only had Pirate3D operations already been frozen for two months, but they would be frozen for at least three more months due to cashflow problems:

“We are now about 40% through deliveries. The company experienced this situation last year in June as well, because of the same reasons.

Initially, we spent too much on R&D and bit off more than we could chew. Developing an entire ecosystem of our own combination of hardware, software and library was a far more costly engineering project than expected.”

“With our current hardware architecture including an onboard processor, wifi modules and linear rails, costs to build these machines have exceeded what we collected for them.”

“Unlike newer Kickstarter projects which are allowed to charge for shipping after the campaign, we weren’t allowed to. As much as possible, we have tried to bear these costs. However, paying 600 USD each time for just shipping to South America and similar amounts to other places has proved to be too much a burden for the company. Along with handling international deliveries for warranty and repairs, which most Kickstarter projects don’t do (and now we know why), has led us to where we are now.”

After assuring their backers that the Pirate3D team had not simply taken their money and ran, Goh explained that in fact they have put everything that they have into the company in an effort to meet their commitments and simply had no more to give. They suggest that it was a lack of competence not commitment that has caused this, and they have the empty savings accounts and outstanding loans to prove it. So rather than put more money into a failed product they are going to turn their attention to a new product that can be made cheaper and faster. And any new investors that they are seeking have told them, in no uncertain terms, that they would not invest in their debts.

They suggest that it was a lack of competence not commitment that has caused this, and they have the empty savings accounts and outstanding loans to prove it. So rather than put more money into a failed product they are going to turn their attention to a new product that can be made cheaper and faster. And any new investors that they are seeking have told them, in no uncertain terms, that they would not invest in their debts.

“We are sourcing new rounds of investment to continue our work for this project. However, most of the investors we have spoken to want to place us under the covenant that the monies can only be used for working capital and not for fulfilling old obligations. Our backlog has to be cleared out of free cash flow (profits) which will not be for at least 1-2 quarters.”

“This did not surprise us and we find that it would be the wise thing to do, or the company will run into issues ever so frequently which will not be good for either the backers or the company.

Between the two options of having the chance at fulfilling our obligations and closing the book now, we believe it’s a fair choice.”

So basically, any new money brought in to the company has to be used to make new products that can be sold for a profit, not to clear any outstanding debts. Pirate3D would only be able to begin fulfilling orders again if the company was bringing in enough additional cash flow to pay investors and keep the company running. With no existing replacement product in sight, and the team only going back “to the drawing board,” the chances of that happening within “1-2 quarters” honestly seem very unlikely.

The reception from their original backers was, predictably, unpleasant. Thankfully after two years of this, Goh and the rest of the Pirate3D team have probably become used to it. However they are quite adamant that, despite there being little to no realistic chance that they will be able to deliver their outstanding printers any time soon, they would still be trying. Goh even returned to Kickstarter a day after the previous update and promised that despite how everything looks Pirate3D was still going to deliver something to them, they just don’t know what it is yet.

Goh even returned to Kickstarter a day after the previous update and promised that despite how everything looks Pirate3D was still going to deliver something to them, they just don’t know what it is yet.

“To clarify our last update. We are not shedding our obligations to you. What we are doing is stopping building too many of the current machine, go back into serious hardware mode, and build a machine that we can fulfill backers within cost and also to build a healthy foundation for the company.”

“In short, this is us letting you know that we have been working with technology whose foundation was laid 2 years ago (which has its limitations though good in some ways), we are going to throw it out the window, go back to basics and build something even better.”

“Just to clarify things”

It is hard to not feel a little bad for the Pirate3D team. What started out as a dream has quietly devolved into a bit of a nightmare that they are not going to wake up from any time soon. Although the fact that I didn’t back the project and am not out any money makes it pretty easy for me to extend my sympathy to them. It is probably a lot less easy for the nearly two thousand people out five hundred bucks to do the same. My hope is that eventually, no matter how unlikely it seems, Pirate3D will be able to deliver on what they promised, or at the very least are able to refund for the printers that will go unshipped.

Although the fact that I didn’t back the project and am not out any money makes it pretty easy for me to extend my sympathy to them. It is probably a lot less easy for the nearly two thousand people out five hundred bucks to do the same. My hope is that eventually, no matter how unlikely it seems, Pirate3D will be able to deliver on what they promised, or at the very least are able to refund for the printers that will go unshipped.

I also hope that the woeful tale of the doomed Buccaneer acts as a reminder to the Kickstarter community that in the world of crowdfunding, nothing is a sure bet. If a price is too good to be true, then you should always treat it like it was too good to be true. And if you do decide to back a Kickstarter campaign, be prepared to lose any money that you’ve invested. Kickstarter is not a store where you can buy what you want and be guaranteed of its delivery, but rather it’s more like a falling star that you make wish on, and you just have to hope that it drops in your lap.

UPDATED:

3D Hubs has responded in the giving vein of the maker community, setting out to help those who wished to back the Buccaneer 3D printer on Kickstarter. An official statement from the company explains:

“Are you one of the 3,389 who pledged over $300 to receive a Pirate3D Buccaneer 3D printer but have been left without one? We feel for you. Through the rest of 2015, we’re offering Pirate3D backers $25 in 3D Hubs credit to give our service a try. Simply send us proof that you were one of the backers of Pirate3D to [email protected], and we’ll promptly send you a voucher.”

Were you a backer of this project? Let us know your thoughts on this news. Discuss in the Pirate3D forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d hubs • 3d printers on Kickstarter • 3d printing crowdfunding • 3d printing kickstarter campaigns • buccaneer • crowdfunding 3d printer • kickstarter campaign • kickstarter crowdfunding • pirate3d • Pirate3D Buccaneer 3D printer • Pirate3D Kickstarter

Please enable JavaScript to view the comments powered by Disqus.

Dangers of Manufacturing 3D Printers: Why Pirate3D Failed

0Shares

Have you heard of Pirate3D‘s Buccaneer 3D Printer?

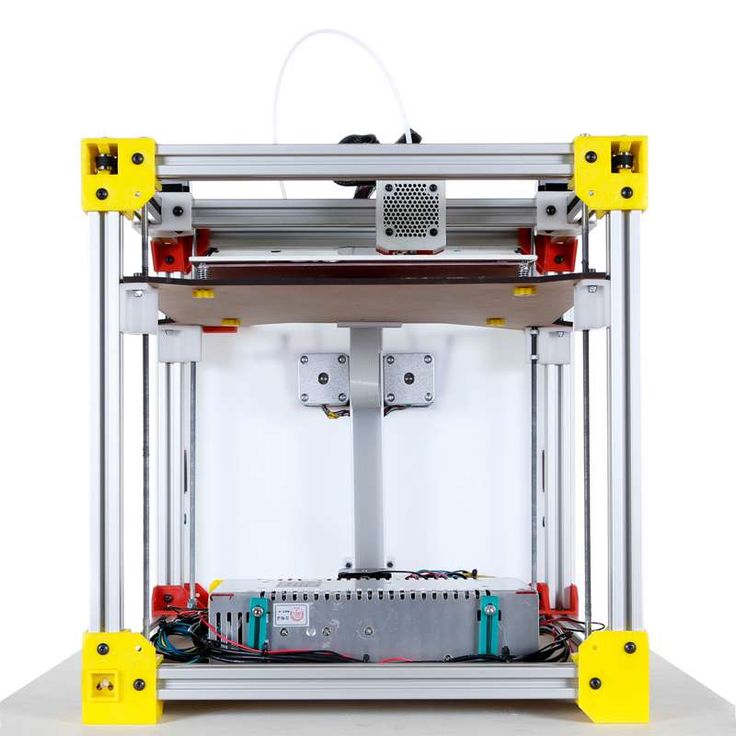

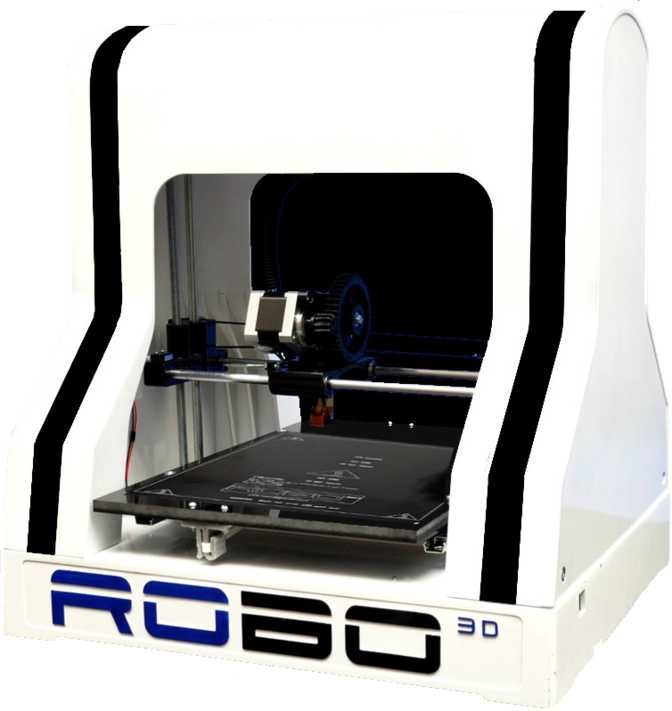

It’s the Jony Ives-inspired 3D printer that never took sail. With a sleek, aluminum body, smooth, crystal clear acrylic housing, and beautiful aesthetics, it’s all beauty and no brains.

If you aren’t in the loop, Pirate3D raised a (then) record-breaking $1.4M+ on Kickstarter for their Buccaneer 3D Printer in 2013.

It was a hit.

Largely because most consumers had never seen such a well thought out 3D printer at such an affordable price point.

At the time, the most well-known printer was Makerbot’s Replicator 2, which ran for $2,200 and Pirate3D claimed to have a better designed, faster printer (The Buccaneer) for just $347.

Truth is: it WAS a well-designed printer and we were just as excited for Pirate3D to pull this off.

Not only that, Pirate3D was ambitious enough to pitch an entire 3D printing ecosystem, instead of just a 3D printer.

They claimed to having a cloud-based component to the Buccaneer 3D printer called Treasure Island that would allow users to directly send 3D printable objects into their printer from any web-enabled device.

It makes a lot of sense and the guys at Pirate3D were definitely thinking about the importance of having a source for rich 3D printable content.

That’s not all.

They also claimed to deliver something called Smart Objects — which was supposed to be an idiot proof 3D design software that anyone could easily use without having any specialized training. With Smart Objects, anyone without design experience could easily manipulate and customize 3D models according to their own needs before printing them.

Again, this is all well thought out and I tip my hat to the Pirate3D founders for their boldness and ambition.

With that said, the biggest reason, I believe, that Pirate3D struggled to deliver printers and eventually failed is because of a tremendous lack of focus.

Manufacturing 3D printers is not an easy task and people underestimate the difficulty of engineering hardware. Not to mention, there are countless successfully funded 3D printers on Kickstarter that failed to deliver the printers. (Remember ez3D’s Phoenix 3D Printer? Or how about Duy Dang’s Eventerbot?)

Keep in mind, this does not even include the gargantuan task of building a software-driven ecosystem around the printer (i.e: Smart Objects, Treasure Island etc..). To make it even more difficult, it was going to be executed by recent college graduates with zero experience in business or manufacturing.

“..it’s just that the current design has heavy costs because it was designed by 3 fresh graduates with no training in industrial design and manufacturing two years ago…” – Brendan Goh, co-founder of Pirate3D

Keep in mind, this is with an additional $2 million dollar investment.

In my opinion, 3D printer manufacturers should focus their energy on hardware, not software

There are benefits for being a jack of all trades, but, when it comes to technology, it is often best to stick to one’s expertise and focus on one area. In fact, Pirate3D is an excellent real world case study highlighting that fact.

In fact, Pirate3D is an excellent real world case study highlighting that fact.

Do you see Lamborghini trying to get into consumer washing machines or Apple coming out with a new line of breakfast cereal? Nope.

Building a software-driven ecosystem for consumer 3D printers is an incredibly complex task. Which is why it should only be left for companies with expertise in software.

Personally, I have been advocating against 3D printer manufacturers building their own 3D printer operating systems for this exact reason. In fact, in August 2015, I even used Pirate3D as an example of a company that is contributing to the market fragmentation of 3D printer software.

Not only that, Brendon from Pirate3D seems to agree with me:

“..Developing an entire ecosystem of our own combination of hardware, software and library was a far more costly engineering project than expected…” – Brendan Goh, co-founder of Pirate3D

When 3D printer manufacturers lose focus and start branching off into software, the result is an incessantly fragmented marketplace filled with complex software and lack of compatibility.

In Pirate3D’s case, a potentially successful Kickstarter that went belly up, leaving most of their backers empty handed.

Were you a backer of Pirate3D’s Buccaneer printer? What do you think?

Dilanka

Dilanka is a technologist, crypto-anarchist, writer, speaker and internet hacktivist. He is currently leading growth at Astroprint, which develops software for consumer 3D Printers. He studied Computer Engineering at the University of California in San Diego before dropping out to pursue other interests. He occasionally writes about technology at Greymask.com.

Top 20 3D printed toys

Why 3D print toys? What toys can be 3D printed? 1. Mini monster truck 2. Surprise eggs 3. Gliders with elastic band 4. Folding sword 5. Micro catapult 6. Spinning top 7. Moving animals 8. Spirograph 9. Transformers 10. Toy tool set 11. Castle 12. Lego bricks 13 14. Edible toys 15. Anti-stress keychain 16. Chunky Trucks set 17. Sword rattles 18. Vikings Squigglepeeps 19. Math Spinner 20. Jumping Turtles Results

Math Spinner 20. Jumping Turtles Results

Today, 3D printing is developing and spreading very rapidly, gaining more and more popularity. And no wonder, because 3D printing is an invaluable tool for prototyping designs, creating mockups, fabricating parts, and more. At the same time, it is no longer difficult to buy a 3D printer at an affordable price even for home use. However, a 3D printer is not only a tool, it is also a kind of toy. A toy capable of creating other toys! Using a 3D printer to make toys gives you control over the material, color, size and other components, so the models you create with 3D printing will be unique!

But what if you don't have your own 3D printer and you need to print a toy or some part of it? It doesn't matter, in this case our 3D printing studio will help you! You only need to place an order by uploading the file of the desired finished model, after which our specialists will contact you to calculate the cost and resolve other possible issues.

Why 3D printed toys?

This is probably the first question that comes to mind, and it is not surprising, because often 3D printing can cost you more than the cost of such a toy in the store. But there are also a number of advantages of 3D printing, as well as cases when it would be more profitable and appropriate to turn to creating models on a 3D printer.

- As already mentioned, a toy printed on a 3D printer can be absolutely unique due to the ability to give it exactly the shapes, sizes and colors that you and your child want.

- Some toys can be difficult to find in the store, and their cost may exceed the cost of their printed copy.

- Sometimes you only need to replace one or a few broken or missing parts of a toy, such as a building toy. In this case, it will be much more profitable and more expedient to use a 3d printer than to buy a whole set for a high price.

- An important factor is, of course, the impressions of the 3d printing process itself, which will captivate both a child and an adult.

And the positive emotions of your child from the toy you created will be the best reward!

And the positive emotions of your child from the toy you created will be the best reward! - And for those who are just getting acquainted with their printer and 3d printing in general, the process of creating toys will be an excellent, exciting simulator to improve their skills and gain experience.

Which toys can be 3D printed?

In the context of constant development and increase in the possibilities of 3D printing technology, you can create almost any toy on a 3D printer, but the result largely depends on the capabilities of your device, your abilities, as well as the time, resources and effort that you are willing to devote to this process. Therefore, more or less simple projects are most often created on a 3D printer. But the relative ease of manufacture does not mean boring finished products! Below we will give you a list of 20 interesting 3D printed toys that are not particularly difficult to create. Among these crafts you will find toys for children of all ages, including the smallest: mechanical products, motion figures, building blocks and even rattles! For each toy from the list, we leave a link to the finished model so that you can try them yourself. So let's get to know them better!

So let's get to know them better!

1. Mini monster truck

Two monster trucks. Source: Thingiverse

Not everyone can afford a monster truck, but if you have a 3D printer you can print yourself a mini copy of it... which is almost as cool. Thanks to the all-printed suspension and removable discs that attach easily and without the aid of glue to the body, this truck is perfect straight from the printed surface.

You can even choose from a variety of body styles and wheels. And for a two-tone tire, stop printing the wheel at 19.8 mm and replace the filament.

Model files for download can be found here.

2. Surprise eggs

Surprise! Source: Twitter

Bigger is not always better. And often the most interesting thing is just a small size, and these 3D printed eggs with a surprise are an example of this.

These tiny cars with moving wheels and other accessories are amazing! Plus, you have plenty to choose from, as you can print surprise eggs with just about anything inside, be it a fire truck or even a fighter plane!

No support required for these models. We advise you to use at least 40% infill to make sure that small elements are both beautiful and durable. Given the number of such tiny parts these machines have, be prepared that printing them can be a real challenge for you, but with good calibration and fine tuning of your machine, everything will work out in the best way!

We advise you to use at least 40% infill to make sure that small elements are both beautiful and durable. Given the number of such tiny parts these machines have, be prepared that printing them can be a real challenge for you, but with good calibration and fine tuning of your machine, everything will work out in the best way!

3. Elastic Gliders

Get ready to take off! Source: Thingiverse

With 3D printed gliders you will be able to “pull out” even more fun from ordinary rubber band ! Just 3 simple steps, and your glider will take off: hook it with an elastic band, pull it towards you and release it.

With this model on Thingiverse, you and your friends can take to the skies a whole fleet of these rubber gliders!

100% infill and a layer height of 0.1 mm are recommended for greater aircraft strength and longer life for thin wings.

4. Folding sword

Telescopic pirate sword. Source: Thingiverse

This toy may not be best given to a child when there are breakable items nearby. But in the right environment, telescopic swords will bring tons of fun and enjoyment to kids! From the designer of this folding pirate sword, you can also find models of telescopic katana, daggers and even lightsabers!

But in the right environment, telescopic swords will bring tons of fun and enjoyment to kids! From the designer of this folding pirate sword, you can also find models of telescopic katana, daggers and even lightsabers!

This Telescopic Pirate Sword is designed for printing at low speed using a 0.4mm nozzle. Also, successful printing requires a printer with a good retract and precise settings for Coast (turning off extrusion at the end of the layer print) and Wipe (“wiping” the nozzle at the end of the layer).

5. Micro Catapult

Hit all your enemies (or at least your deskmates). Source: Thingiverse

This little catapult is a great toy for kids and bored office workers alike. She can throw small crumpled pieces of paper and any other small things that will fit in her. Selected ammunition can fly about 2 meters, which is enough to hit unsuspecting victims at another table!

This model is an all-printed prefabricated assembly that does not require any supports or special adjustments. A minimum filling and layer height of 0.25 mm is sufficient.

A minimum filling and layer height of 0.25 mm is sufficient.

Despite the fact that many catapults are made from PLA plastic, the author of the design still insists that this model is not for PLA, but for ABS plastic. We can also recommend PETG filament for this printing, which has the best qualities of PLA and ABS.

6. Top

The oldest toy for the whole family. Source: Thingiverse

As far as we know, the spinning top is one of the oldest toys in the world. In ancient times, tops were made from almost any material: from stone and wood to fruits and nuts. And now additive technologies allow you to make your own spinning top using a 3D printer! All you have to do is print this model, glue the pieces together and have fun with this simple yet fun toy!

Offered 0.2 mm layer height and 20% infill.

7. Moveable animals

Cute articulated octopus. Source: Thingiverse

Making flexible prints with a 3D printer has become completely affordable and common practice thanks to special filaments such as TPU. But what if we said that you don't have to use flexible plastics to create flex parts?

But what if we said that you don't have to use flexible plastics to create flex parts?

Using excellent hinges that are printed in one piece with the entire model, you can create movable flexing toys even from plastics such as PLA, ABS and PETG, without any additional settings and adjustments.

The standard specifies a layer height of 0.2 mm and an infill of at least 15%.

Most popular models:

- Octopus

- T-Rex

- Lizard

8. Spirograph

Convenient case for creativity at any time. Source: Thingiverse

Everyone knows the children's toy spirograph, which allows you to easily draw masterpieces with repeating geometric patterns. But this model has gone a little further and is a whole case containing a platform for drawing and a compartment for storing gears and paper. It fits easily into your pocket, backpack and bag, so you can take it with you and paint whenever you want!

The case has several levels. The lower level holds slips of paper for notes, drawing gears and, if desired, a small pencil or pen, if, of course, you can find one. The next level provides a secure, flat drawing surface so you can make art while walking! The top level has fixed gear teeth and holds the piece of paper in place.

The lower level holds slips of paper for notes, drawing gears and, if desired, a small pencil or pen, if, of course, you can find one. The next level provides a secure, flat drawing surface so you can make art while walking! The top level has fixed gear teeth and holds the piece of paper in place.

A layer height of 0.2 mm and an infill of 20% or more is recommended. As a loop, a regular straightened 1.75 mm filament thread is used.

9. Transformers

Toys from the planet Cybertron. Source: Thingiverse

Transformers are a hugely popular children's toy to this day, so these Optimus Prime and Megatron are sure to please your kids.

This printed Optimus Prime transforms from a classic Optimus truck into a fully functional standing robot. And it's amazing, considering that you immediately get a ready-to-use all-printed model right from the printing platform, which does not even require supports!

But, of course, every Optimus needs an opponent to fight. Therefore, you can also print Megatron, but it should be noted that his model is more difficult to print and consists of two parts.

Therefore, you can also print Megatron, but it should be noted that his model is more difficult to print and consists of two parts.

10. Set of toy tools

The first tools for little craftsmen. Source: Thingiverse

The Toy Tool Set is a great way to introduce kids to basic tools, their appearance, purpose, and how they work. Print your child's first hammer, screwdriver and pliers and he'll feel like a real craftsman!

The hammer is modeled to fit two pieces together with a screw, but some users simply glue them together, which is just as pretty. You can also use a hammer to assemble pliers: just lay the two pieces on a flat surface with the screw down and tap lightly a couple of times.

Model can be found here.

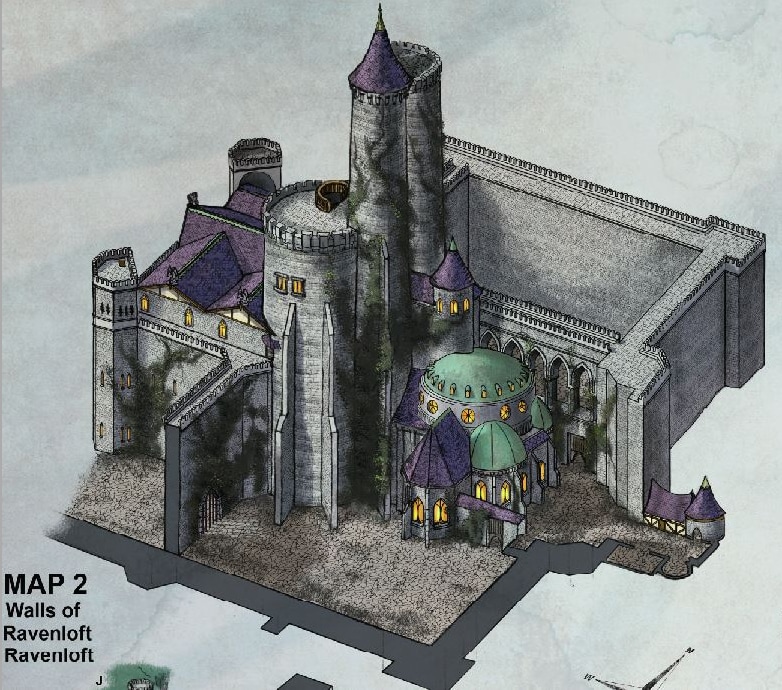

11. Castle

Build your own medieval world! Source: Thingiverse

This medieval castle playset is meticulously designed for 3D printing. Walls and towers are easily attached to each other with a simple connection. You can make as many details as you want to create a large or small original castle layout of your own! The set contains walls, towers, houses, characters, animals and a variety of props to add to the fun of this medieval set.

You can make as many details as you want to create a large or small original castle layout of your own! The set contains walls, towers, houses, characters, animals and a variety of props to add to the fun of this medieval set.

All parts are small enough to be printed comfortably even on 3D printers with a small printable area: 140x140x140mm. For such purposes, the Flashforge Creator Pro 2 3D printer is perfect, equipped with two independent extruders and has excellent printing accuracy. This printer will cope with the study of small details, and two extruders will help you print several parts at once or one part in two colors!

12. Lego bricks

Your favorite constructor is now more accessible! Source: Pinterest

LEGO is one of the most popular toys for children. At the same time, the cubes of this designer are made of ordinary ABS plastic. So, having your own 3D printer, you can print the missing/lost Lego bricks yourself or even some of your author's design of the details of this amazing designer! At the same time, you can use not only ABS, but also other 3D plastics: PLA and PETG are also great.

Thingiverse has a lot of Lego models, and we'll take a look at one of them. It's customizable model of several different LEGO and LEGO DUPLO pieces. These bricks are not completely identical to real Lego, but they are compatible in every way.

13. Ballista

Fire! Source: Thingiverse

Introducing a fully printed ballista model, ready to use right out of the box. One has only to set the string and load the projectile, and this ballista will impress you with its simplicity and good range of the arrow. As a bowstring, you can use several layers of thread or ordinary stationery gum.

Recommended to print in PLA or PETG with 90% coverage and 0.2mm layer height.

14. Edible toys

The Open Toys project turns ordinary vegetables into toys. Source: Thingiverse

The project was originally envisioned as a way to turn commonly discarded residual materials such as wood and cork into toys: helicopters, planes, cars and so on. But soon, wood and cork were replaced by more accessible and easily pierced materials: fruits and vegetables. With this project, you can turn ordinary food items into fun personalized toys.

But soon, wood and cork were replaced by more accessible and easily pierced materials: fruits and vegetables. With this project, you can turn ordinary food items into fun personalized toys.

15. Anti-stress keychain

Entertaining keychain. Source: Thingiverse

Add some flair to your keychain with this cool little toy. She will entertain you wherever you are!

This model is not the easiest, but try it and you will definitely succeed! Important print quality settings are "Outer Walls Before Inner Walls" and being extra careful with temperature. It is printed with supports and requires a certain, sometimes lengthy, post-processing. Remove not only supports, but also make sure that the surface of the part is smooth, otherwise it will cling and stutter. A scalpel or a 1 mm drill will do. Periodically rotate the gears to see where it still sticks, which is especially true when using PLA.

16. Chunky Trucks set

Two models from the fun and cute Chunky Trucks set. Source: Thingiverse

Source: Thingiverse

The adorable Chunky Trucks collection includes various unique models of small trucks, fun builders and even a movable barrier. The cars are specially designed so that even the smallest children can play with them. Unlike builders, who are not recommended to be printed for toddlers so that they do not try to put them in their mouths, but which will greatly amuse older children.

All models can be printed without supports. And for long truck life, at least 25% infill and three-wall use are recommended.

17. Rattleswords

Arm your warrior! Source: Thingiverse

Rattles are an integral part of all babies. But what if we move away from banal and boring designs and build a rattle in the form of a sword for your little warrior? This fun design will not only amuse your baby, but also you, as this rattle will be a lot of fun to print!

All corners of the model are rounded for safety. There are also two versions of the tip. Initially, a gem was attached to the tip, but after some concern that the stone could slip off the tip and be swallowed by a child, a second version was created that did not include a gem.

Initially, a gem was attached to the tip, but after some concern that the stone could slip off the tip and be swallowed by a child, a second version was created that did not include a gem.

Print two sets of peas first. Then, while printing the sword, throw them inside the blade. This will ensure that the peas stay inside the rattle forever. After printing all the elements, simply fasten them with superglue.

As with any printed toy, parental guidance is required. Be sure to throw away the toy if it breaks.

18. Viking Squigglepeeps

Three Viking Squigglepeeps set sail. Source: Thingiverse

Squigglepeeps is another kid-safe toy, this time with absolutely no glue required. These fun chubby Vikings and their boat are too big to choke on, making them suitable for kids of all ages. They look funny even in one color, but they will be even more beautiful if you paint them with child-safe paints! The model also absolutely does not require supports.

19. Math Spinner

A great way to have fun learning math! Source: 3Dtoday

This math spinner is the perfect companion for learning math. Moreover, it is suitable for all ages, because it is never too late to brush up on your arithmetic knowledge! You can print this finished model or modify it for yourself by removing or adding rings. This advanced design contains all the signs of addition, subtraction, multiplication, division, equality and inequality, as well as a pointer to the string to be solved! On the central insert there are special grooves for fixing. For this version, you will need to print 2 caps and 8 rings of numbers, the rest of the details are printed in a single copy.

Recommended coverage 25% and layer height 0.2 mm.

20. Jumping turtles

The variety of these turtles is amazing! Source: Thingiverse

Last but not least, jumping turtles! Agree, even the name sounds fun! And a variety of shell design options will give each turtle its own uniqueness. This model uses the same flex concept as the Mini Monster Truck above, making the Turtles bounce when you tap on the body. Also in this turtle, the head can be drawn into the shell.

This model uses the same flex concept as the Mini Monster Truck above, making the Turtles bounce when you tap on the body. Also in this turtle, the head can be drawn into the shell.

The model is assembled with printed H-clamps and does not require glue. All parts are printed without supports. Also note that using the raft (rafts) and brim (margins) options can have a negative effect on the results if you don't then take the time to sand and clean the edges at the base.

If you have problems with head slip, you can try to print 1 of the 3 narrower shaft head files that the author has specially uploaded for this case.

Results

We hope you enjoyed this selection of toys for 3D printing, and you will definitely choose some option for yourself, because 3D printing of toys is not only fun and interesting, it is also a new experience and knowledge for both you and and for the child. But we have considered only some entertaining options from the many existing ones. And, of course, you can create your own unique designs and implement them on your 3D printer or contact our 3D printing studio for this. And toys printed by you can serve as a great unique gift, which is also one of the reasons to buy a 3D printer for your home.

And, of course, you can create your own unique designs and implement them on your 3D printer or contact our 3D printing studio for this. And toys printed by you can serve as a great unique gift, which is also one of the reasons to buy a 3D printer for your home.

3D printer models

Looking for 3D printer models? The Internet is filled with sites that offer them for free. We have collected the TOP 10 catalogs that you can use to search and download free models in STL format. We hope you can find what you are looking for.

- Yeggi

- Yobi 3D

- STLfinder

→ myminifactory.com

My Mini Factory is a 3D model depository operated by iMakr, an online store that sells 3D printers and accessories. It also has one of the biggest 3D printer shops in Central London. The site contains 3D models designed by professionals, and all models stored on it are checked for quality. You can also make a request for the desired model, which their designers will create and put in the public domain. Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

Billing itself as a 3D printing social network, MyMiniFactory is a thriving community of makers who love to showcase their creations. Users vote for the best models, which allows popular creations to rise to the top of the list and gain popularity. The site presents models that are stored on its social network, as well as outside it, for example, on the Thingiverse and YouMagine sites.

→ thingiverse.com

The most popular and famous site among 3D printer users, Thingiverse is owned by MakerBot Industries, the creator of the popular Replicator 3D printer series. The site allows users to store and share 3D model files that are used with 3D printers. It's a very popular site and has a large community of people hosting various categories of files on it. So if you're looking for "cool" printable stuff, Thingiverse is worth a visit. It is a portal designed to provide its users with ways to share their designs and to help print 3D creations. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be.

The more you interact with the site, downloading and evaluating various developments, the better its recommendations will be.

→ 3dshook.com

Another online community for 3D printing hobbyists showcasing interesting 3D printer accessories, electronics and most importantly 3D models. The site contains many very interesting models of cars and buildings, as well as various add-ons and spare parts for your 3D printer. A huge catalog of paid and free models for a 3D printer. There are original unique products. Convenient search, navigation, rubricator. 3DShook has over 40 categories and adds over 100 new models to its collection every month. On 3DShook you can always find something for your home, animals, kids or something special for yourself.

→ youmagine.com

YouMagine catalog for Cube series consumer 3D printers manufactured by 3D Systems. The site mainly offers various ways to buy 3D printer supplies and files, but it also has a number of cool free items available, mostly in the Kids section. Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

Some of these elements can be customized by children using an online application. The company offers 3D modeling and publishing tools on its website for both hobbyists and professionals. The site offers a content warehouse where the community hosts and shares models. Registration is required to download files.

→ 123dapp.com

Autodesk 123D is a suite of computer-aided design (CAD) and 3D modeling tools aimed specifically at hobbyists. Along with the toolkit, Autodesk also has a website where users can record their designs and share them with other users. Many of these models can be downloaded and printed using Autodesk as a utility to interface with the MakerBot 3D printer. The goal of the Autodesk website is to "help engineers build products faster." The site offers tools to help them collaborate on their files. For the casual 3D printing enthusiast, the best part of the site is the large library of free files created by a community of over a million engineers. Registration on the site is required, but the number of files that are then available is worth it.

Registration on the site is required, but the number of files that are then available is worth it.

→ cgtrader.com

Being primarily a place to buy and sell a variety of 3D models (not necessarily just those designed for 3D printers), CGTrader does offer a selection of free models that can be used on 3D printers. The site has a system that tries to find out what you like. The more you interact with the site, downloading and evaluating various developments, the body will have better recommendations.

→ cults3d.com

A French community and marketplace where developers can share or sell their creations. The site has a collection of high quality models that you can download. Users can follow the work of the designers they like and get instant updates when a new creation is posted on the site. The site's name, Cults, is a backwards spelling of St. Luc, the patron saint of artists. The site also supports English. This is a relatively new community, so the number of its users is not very large yet.

→ instructables.com

The Instructables website is a community where users can share their DIY projects. This also includes products obtained using 3D printers. The site also provides explanations and instructions describing how to build 3D elements, and some designers take the time to answer questions from site members. Instructables allows users to store and organize their 3D printing projects. This is done to help them work together in the future. You can think of this site as a GitHub 3D printing site where users can share their files, discuss projects, and participate in them. The site also offers the ability to make a request, so if you can't find what you're looking for, you can ask the site's community about it.

→ pinshape.com

Pinshape, a marketplace for 3D models, is similar in style (layout, look, and ability to capture likes) to the well-known site Pinterest. You can buy models from designers, or download them for printing yourself if they are offered for free. Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

Pinshape allows users to host and share 3D model files on it. Basically, this site acts as an online store where you can buy 3D printed parts, or order your own 3D model to be printed. But if you look closely enough, you can find people who sell their products and also offer the files you need so you can print them yourself.

→ 3dfilemarket.com

A new and growing repository of 3D File Market models. All models are tested for suitability for 3D printing. You can download as many models as you like without registration, although you must provide your email address to access the 3D model files. This is a very simple site aimed at being a repository of model files for 3D printers, and nothing more. The basic design of the site allows users to put files on it for public access, and download files that they would like to use. The site contains many small, simple 3D models ready to be printed, as well as a good selection of everyday items and even spare parts for 3D printers.

Search engines for 3D models in various formats, including STL for a 3D printer. Use queries in English, these search services collect information about models from all over the Internet.

→ yeggi.com

Yeggi is a search engine that will browse major 3D printing websites to find files compatible with 3D printers. You can also browse some popular searches to get an idea of what the community is currently interested in.

→ yobi3d.com

When in doubt, use yobi3D to search for files that match the desired 3D printer. This tool is useful if you want to search for one thing across all sites at once. A very convenient format filter, fast search, high-quality previews and stl models prepared for 3D printing for printing.

→ stlfinder.com

This is another STLfinder that surfs the web looking for 3D printing. To select files compatible with 3D printers, he goes through many 3D modeling sites.