Are 3d printers hard to use

How Hard Is 3D Printing? 7 Things To Know – Printing It 3D

3D printing is the process of making 3-dimensional solid objects from a digital file. Although this technology has been around for more than 30 years, it has only recently gained popularity. That said, how hard is 3D printing?

3D printing is quite hard, especially for beginners. It requires creativity, math, and computer-aided design (CAD) skills to master. However, once you have the necessary hardware and software, modeling skills, and an understanding of how this technology works, 3D printing becomes easier.

This article will explain why 3D printing can be complex and the technology needed to do it. Read on for insights into these and the benefits and limitations of this technology.

Why 3D Printing Is Hard

3D printing is complex because it attempts to combine the processes of creating and assembling a physical object from start to finish. Before making a 3D printed product, one must first design it with CAD software. This process may require creativity, engineering, and math skills.

Even for simpler objects, designing takes time because there are no common standards when using CAD software. Every company has its ways of interacting with these programs, and designs vary from one program to another.

A lot more goes into 3D printing than just clicking “Print” on your computer screen. Different materials have different properties that must be taken into consideration before designing a product.

For example, the thickness of material matters when it comes to how its design will be printed, but it may also affect how the product works. If a material is too thin, it may snap or break easily when handled.

Once you have designed an object and selected the suitable material, the printing process is no longer as simple as clicking a button. The printer must be configured by choosing where to start and stop printing, called the build area.

There is also the build volume, or the size of an object one can create in a single printing session.

Here is a video summary of how 3D printing works:

7 Crucial Things To Know About 3D Printing

Here are 7 things every beginner should know about 3D printing.

1. What Is 3D Printing?

3D printing is the process of creating physical objects from digital models. A “file,” usually in STL format, is sent to a 3D printer that will build up the product layer by layer until it has been completely printed.

3D printing is the successor to CNC machining and has been around since 1984 when Chuck Hull invented stereolithography. Since then, 3D printers have been used for everything, from art-making to scientific research, but they are still gaining mainstream popularity.

2. The Software Needed

CAD software allows users to create and manipulate 3D models. It gives designers the ability to create things that have never existed before in a virtual environment, from simple shapes to complex structures.

CAD software is highly customizable and can allow users complete freedom of design when working on their projects. For example, the Autodesk Fusion 360 will enable users to share designs with others through cloud-sharing so that more people can participate or even improve on the initial design.

With so many CAD software options, choosing a program to get started with is difficult. Programs like SketchUp and Tinkercad are good introductions. However, they may be too basic for an experienced designer looking to do something more complex.

For something more advanced, you may have to pay for a commercial program like SolidWorks or AutoCAD.

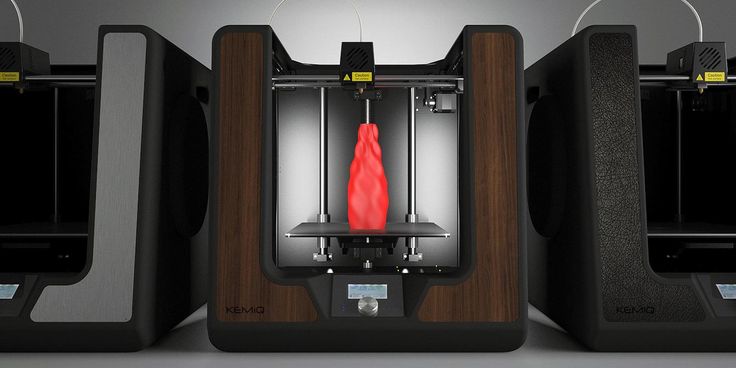

3. The Hardware Needed

To create models and send them to a 3D printer, you need computer hardware. The most recent Mac and Windows computers have the power necessary for CAD software.

The most recent Mac and Windows computers have the power necessary for CAD software.

However, if you’re using an older system or want something better for your specific needs, there are alternatives.

If you’re working on an Apple computer, a good graphics card is essential. You can use the built-in graphics card for basic tasks like editing photos. However, for more complex activities such as 3D printing, you will need an additional graphics processing unit (GPU).

Quad-core processors are also recommended because they work faster and save time in some CAD programs.

Maybe you don’t work on a computer at all. With an app like Autodesk’s 123D Circuits, you can create 3D models of objects such as PCB boards without having to buy expensive equipment. Computer hardware is also available for Android phones, giving users the ability to design and print from anywhere.

4. The Skills Needed

As I mentioned, creativity, math, and engineering skills come in handy in ensuring you get the best results from 3D printing. In addition to these, beginners need CAD skills to master 3D printing.

In addition to these, beginners need CAD skills to master 3D printing.

CAD software is user-friendly, but it still takes time to learn its many nuances. While there are online resources and tutorials available, the best way to learn CAD is by using it every day.

There are usually a few different ways to design something, so don’t be afraid to experiment until you understand how your program works.

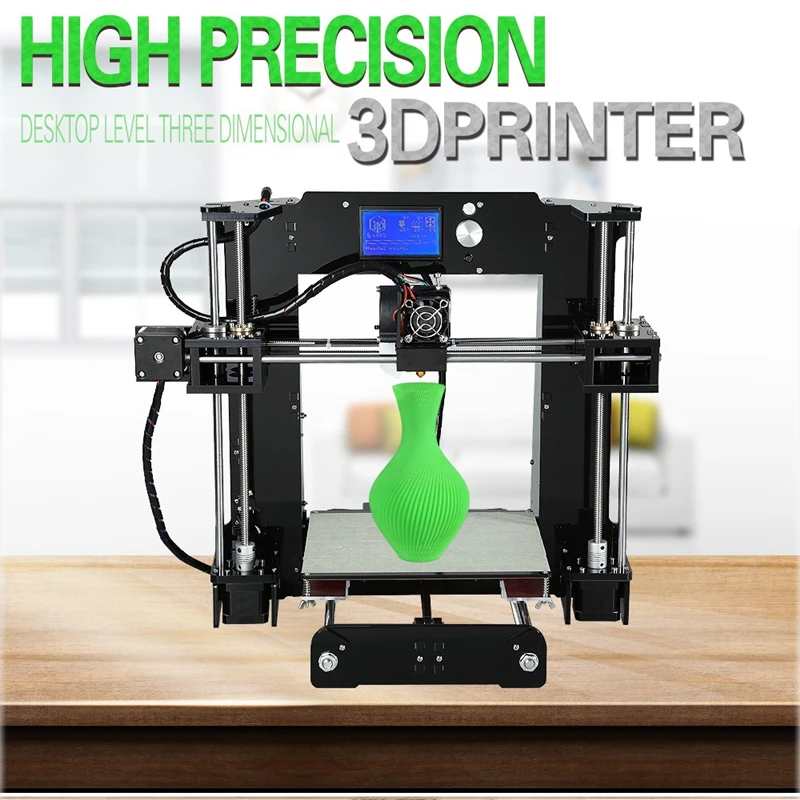

While CAD programs have user-friendly interfaces, 3D printers are far less intuitive. For instance, machines like MakerBot, FlashForge, and Anycubic may look simple.

However, they have complex inner workings that aren’t always easy to troubleshoot.

Learning basic mechanical engineering skills will help you diagnose problems with your printer and use it more effectively.

For more information on 3D printing, I recommend reading Getting Started with 3D Printing: A Hands-on Guide to the Hardware, Software, and Services That Make the 3D Printing Ecosystem (available on Amazon. com).

com).

As the title suggests, the book gives an overview of the nuances of 3D printing, the knowledge, skills, and technology required, making it a worthwhile starting point for any beginner.

5. What 3D Printers Can Make

3D printers have been used to create just about anything, from jewelry and firearms to medical devices. They can even print food, like chocolate and marshmallows.

That being said, there are still some legal restrictions on what can be printed with these technologies. For instance, you can’t print some types of weapons, explosive devices, or patented substances or objects. Doing so could land you in trouble with law enforcement!

6. The Benefits of 3D Printing

3D printers have many practical applications, such as testing new products and making repairs on machinery.

They’re also a boon for medical professionals who can create custom prosthetics and better training models for surgeons.

Besides saving lives, they also save money by allowing designers to test things like shoe soles and aerodynamic helmets before making a large investment.

7. The Limitations of 3D Printing

The hype around 3D printing has made it seem like a miracle product that will revolutionize manufacturing and change our lives as we know it. While there is no doubt that 3D printing will eventually be used in countless ways, there are certain limitations to consider before you put one on your wishlist:

- Things take longer than you’d think. While a CAD file may look simple on the screen, it takes time to “slice” into thin layers for printing. As a result, objects that take only 30 minutes to print on FDM printers can sometimes take hours or even days when using more advanced techniques like DLP printing.

- Materials are pricier than they seem. There are many different types of plastics available for purchase, each with unique properties. If you don’t have a top-of-the-line brand printer, these plastics can be quite expensive.

- The print volume is limited. Some FDM printers can print items as large as a basketball, but most are much smaller for convenience.

It’s not always possible to scan an object and then print it perfectly scaled up.

It’s not always possible to scan an object and then print it perfectly scaled up.

- Downtime leads to lost income. Suppose your 3D printer fails during working hours. In that case, it may mean you lose money during a scheduled break or an important presentation.

- There are still many unknowns regarding 3D printing. With new technologies and materials being developed all the time, there may be hidden costs associated with maintenance or repairs of your printer. Because these printers are so complex, it’s not always easy to pinpoint what needs to be fixed when it breaks down.

Final Thoughts

For many, 3D printing is a challenging task to take on successfully from beginning to end. An artist’s creativity must be accompanied by math and engineering skills to accomplish a project. But with proper planning and an understanding of what your limitations are, 3D printing is a great technology to try.

Are 3D Printers Easy or Hard To Use? Learning How to Use Them – 3D Printerly

A key question with 3D printing is, just how hard or easy is it to print something in 3D? Do you need a ton of experience to get started? I decided to put together a quick article to try and help answer this important question.

With the right information, 3D printing is a very simple process. 3D printer manufacturers realize that ease of set-up is a big factor when it comes to 3D printing beginners, so most have specifically made it easy to function from start to finish. Set up can take minutes.

This does sound extremely easy, but for beginners there can be a few barriers that you have to overcome to get a smooth printing process. I will explain these and hopefully lessen your worries about 3D printing.

Are 3D Printers Hard to Use & Learn?

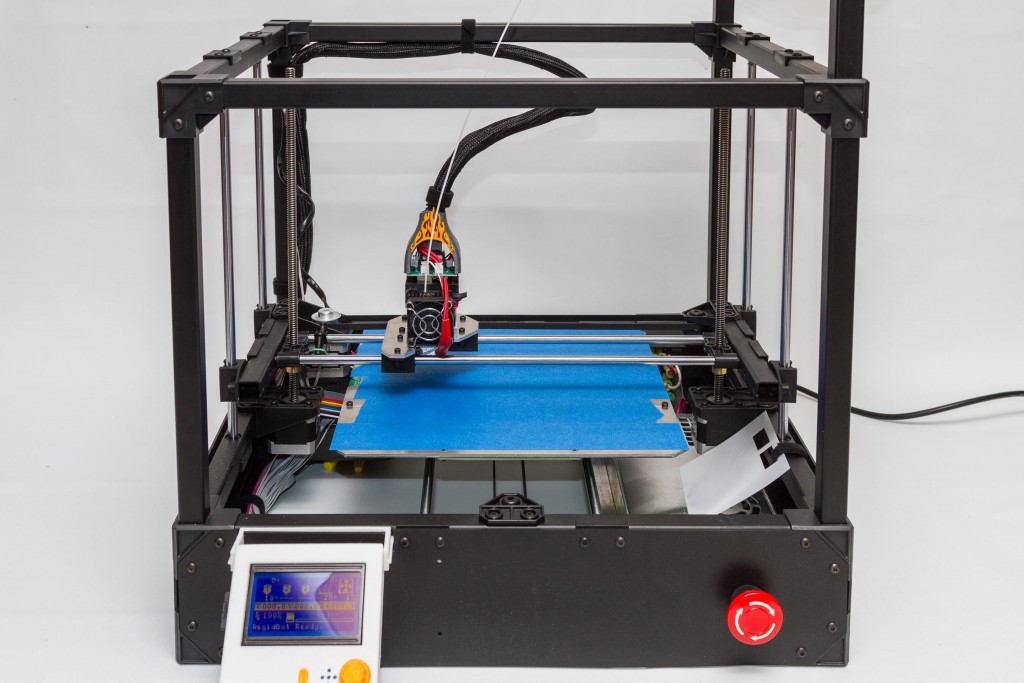

3D printers are not hard to use with a good, reputable brand of 3D printer since they are pre-assembled and have many useful instructions to follow to get them up and running. Slicers such as Cura have default profiles that allow you to 3D print models without much input from users. 3D printers are getting easy to use.

In the past, there was a lot of tinkering and user input that was necessary to get 3D printers to provide a somewhat accurate model from the build plate, but nowadays, even teenagers and kids can handle a 3D printer.

The assembly process is no different than a decent DIY project, only requiring you to put the frame together, along with parts such as the hotend, screen, spool holder, most of which are pre-assembled.

Some 3D printers come completely assembled and calibrated at the factory so you don’t actually need to do much, other than plugging it in and printing from the supplied USB stick.

Nowadays, there are plenty of YouTube videos and articles that you can find to help you with getting started with 3D printing, as well as troubleshooting help that makes things simpler.

Another thing that is making 3D printing easier is how manufacturers are stepping up their skills and making 3D printers easier to assemble and operate, with automatic features, touchscreens, good build surfaces that 3D printing materials stick to nicely, and much more.

Check out the video below for a complete beginners guide to 3D printing. It takes you from step 1 to having a fresh 3D print right off the build plate.

5 Steps to Easy 3D Printing

- Get a beginner-friendly 3D printer – this should have auto-features, easy navigation panels, be compatible with most software. Ideally a pre-assembled 3D printer

- Add your filament of choice – sometimes comes with your 3D printer, or bought separately. I’d recommend using PLA filament as this is the most common, and easy to use type.

- Pick your 3D printer slicing software (Cura is the most popular) and select your 3D printer to autofill settings – keep in mind some 3D printers have brand-specific software such as Makerbot.

- Choose a 3D CAD file of your liking to print – this is the actual design you want to print and the most common place would be Thingiverse.

- Start printing!

What’s the Hard Part About 3D Printing?

3D printing can be made very easy, or very hard depending on what your goals are, how technical you want to get and your experience with DIY.

As I’ve mentioned, setting up your 3D printer and starting the print process can be very easy, but once you start designing your own prints and make unique adjustments this is where things can get difficult.

To get specific prints, it does take a unique understanding of how designs must be put together.

Designing prints can be a complicated process because you have to design your print in a way that it’s supported throughout the print, or it just won’t hold up.

Once you have that knowledge, it should be much easier to get designing and many programs have guides which tell you if your design is well-supported.

Having a high enough infill setting that your print won’t fall apart in the middle of the print is another important factor, so be aware of these things.

Luckily there are Computer-Aided Design (CAD) software out there that caters to different levels of expertise.

This ranges from simply putting shapes together in a program, to putting together small complex shapes to do anything from create a favorite action figure, to replacing a spare part on an appliance.

You can avoid this by taking a shortcut by just using designs from people who already have designs which are proven to work.

Thingiverse is a collective source of 3D print designs (STL files) which is available to everyone. A great thing you can do is look at a design from someone else and make adjustments in your own unique way, if you have the experience.

Like most things, with practice 3D printing will become very easy to do. There are things you can do which do get more complex, but the main process isn’t very hard to get started.

What If I Run Into Some Issues?

The main reason people run into issues is because they’ve jumped into things without doing research. If you bought a 3D printer kit from someone’s recommendation, a lot of the time they can be difficult to put together.

If you bought a 3D printer kit from someone’s recommendation, a lot of the time they can be difficult to put together.

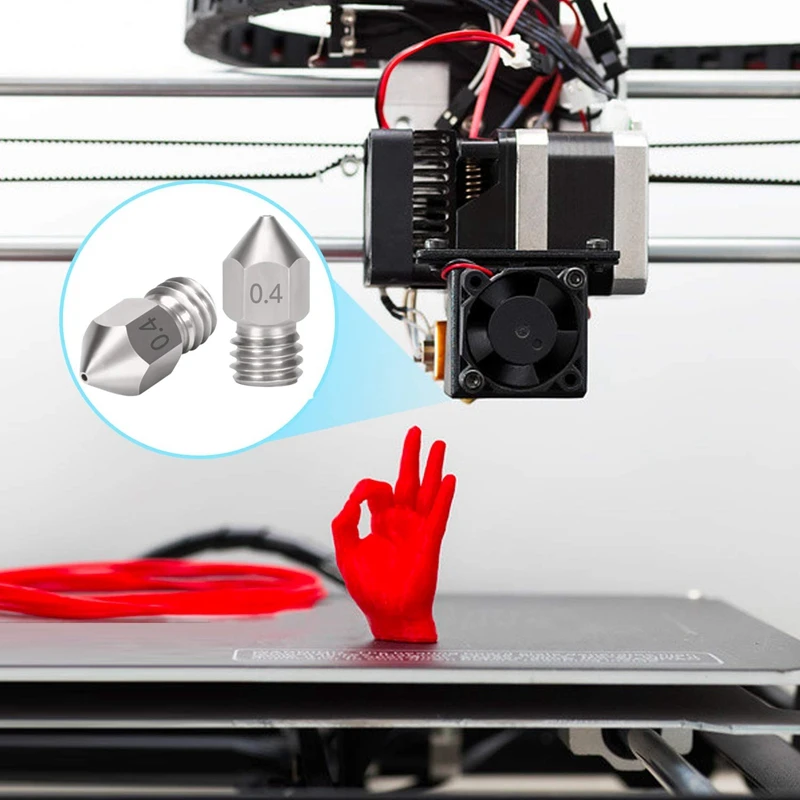

They may also not have features which really help out beginners such as auto-levelling the nozzle to the print bed to ensure precise printing, or have compatibility with beginner-friendly software. This is why it’s important to know the basic stuff before you jump into 3D printing.

There are many troubleshooting issues that people have when it comes to 3D printing, as people get further into the field. This can range from the quality of your filament where it can break, filament material not sticking to the print bed, first layers being messy, prints leaning etc.

If you do run into some issues, the 3D printing community is an extremely helpful one and many questions you have, most likely have already been answered on the many forums that are out there.

In most cases, putting together a 3D printer isn’t too hard if necessary. An example of a simple 3D printer is the Creality3D CR-10, which comes in three parts and takes only 10 minutes to put together.

Once your 3D printer is put together, most settings can be autofilled when selecting your specific 3D printer within your software, so this is a pretty simple step.

After sorting out issues a few times, you should become confident in preventing those issues, and being able to quickly solve them in the future.

Final Thought

3D printers are being used in education at many levels, so if children can do it, I’m pretty sure you can too! There is some technical know-how but once things are up and running you should be printing away.

Mistakes will be made from time to time, but they are all learning experiences. Many times, it takes a few setting adjustments and prints should come out pretty smooth.

There are many levels of knowledge that you’ll need to get to a good level of 3D printing, but this mostly comes with practical experience, and just generally learning about the field. The first few times may seem difficult, but it should get easier as time goes on.

As time goes on, I can only imagine that 3D printer manufacturers and software developers will keep on aiming to make things simpler.

This along with the development in technology and research leads me to think that it will not only become more cost-efficient, but easier to create useful and complex designs.

how we taught 3D printers to print complex parts more economically and twice as fast .

6871 views

What is the idea

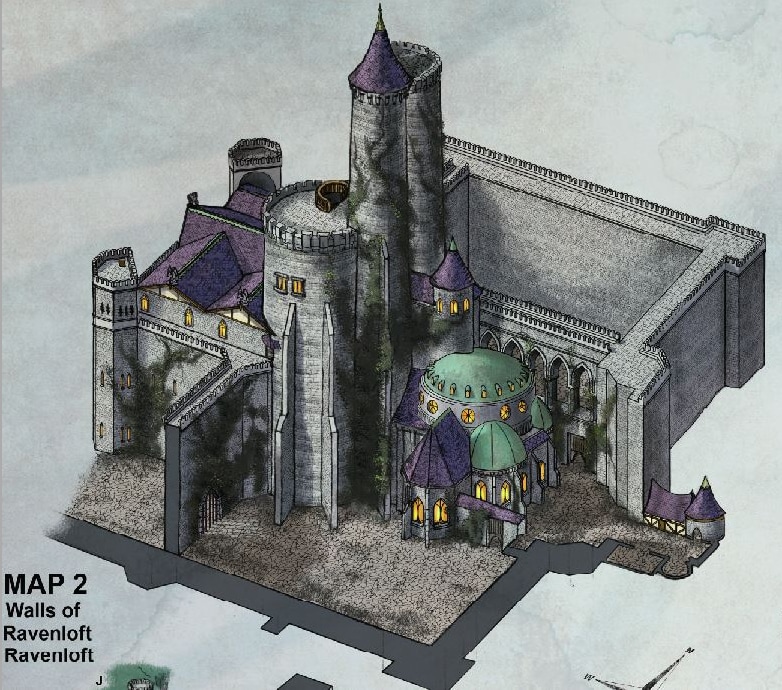

The most popular FDM 3D printers print the parts layer by layer. At the same time, in 70% of cases, “hinged” elements appear during printing - fragments that do not have support under them and hang over the desktop like visors. To fix such details, it is necessary to print special supporting structures (they can take up to 50% of the material).

In addition, after printing, these supports must be removed: such processing is often time consuming and not always safe - the part may break in the hands due to insufficient strength, and then everything will have to be redone. And some designs are simply impossible to produce using this method: the supports will fill almost the entire space of the part.

And some designs are simply impossible to produce using this method: the supports will fill almost the entire space of the part.

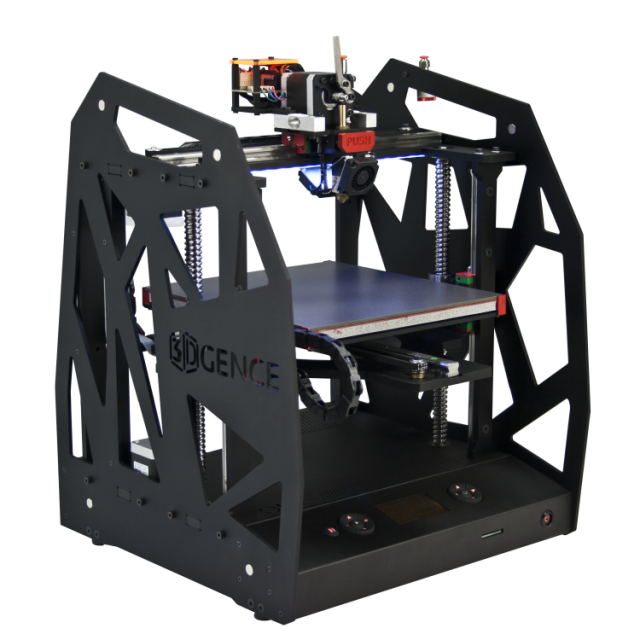

I saw a solution that avoids this problem in the field of metalworking - five-axis milling machines have been used there for a long time. The idea is to equip the 3D printer with a turntable: with its help, the body of the model is always positioned during printing so that each subsequent layer is built based on the already printed elements of the model.

Five Axis 3D Printer

Why do we need a five-axis 3D printer and who are our customers

The 5-axis 3D printer allows you to print complex parts quickly without wasting material on supporting structures and saving time in post-processing. In essence, we allow you to reduce costs and increase productivity: according to our estimates, one machine can replace two previous generation 3D printers.

The 5-axis printer allows you to print parts with complex geometries, such as live piping layouts that companies need during the design phase. Printing this on a conventional 3D printer will not work, and creating it using conventional methods will take a lot of time and effort. In addition, products printed on a five-axis printer are much stronger than conventional ones. When printing, new layers of matter are not just layered on top of each other, but are printed "overlapped" at different angles - it is much more difficult to break such details.

Printing this on a conventional 3D printer will not work, and creating it using conventional methods will take a lot of time and effort. In addition, products printed on a five-axis printer are much stronger than conventional ones. When printing, new layers of matter are not just layered on top of each other, but are printed "overlapped" at different angles - it is much more difficult to break such details.

Of course, not everyone needs to print complex and durable products: potential buyers of the Epit 5.1 5-axis 3D printer are 3D printing service companies, industrial design studios and design departments of manufacturing enterprises. That is, our machine is needed specifically for industrial use.

How we got into this topic

Seven years ago I worked in a company that produced plastic automotive components, responsible for marketing and creating new business lines.

Back then, for one of the projects, it was necessary to make a prototype of a new part: it was expensive and time consuming to do it with traditional methods (I would have to create a mold), so I decided to contact a company that was engaged in 3D printing. At that time, this direction was on the hype, and everyone talked about the fact that soon 3D printers would be in every kitchen and garage.

At that time, this direction was on the hype, and everyone talked about the fact that soon 3D printers would be in every kitchen and garage.

But the reality turned out to be completely discouraging. With our task, we turned to several companies that were engaged in 3D printing in Naberezhnye Chelny, but no one was able to make the part according to our request: it turned out to be too complicated.

Since I am a designer by education, I began to think and look for solutions to the problem myself - and did not find anything similar on the market.

Creating a team proved to be more difficult than finding funding. Initially, I focused on the "iron" component of the project and did not think about the software that is necessary for the efficient operation of a 3D printer, so I began to look for developers.

An expert I knew then told me: “You need people who, like you, do not understand what they are getting into” - because developing software for such a printer turned out to be a rather specific and long task.

I began to apply to the universities of Tatarstan and neighboring regions - to look for students who are ready to take on a non-trivial task. But the students who responded could not move forward in the solution, and as a result, I found Mikhail Ivanov in Innopolis, who became a developer and my partner in a startup.

The second person who was needed in our business was someone who understands electronics, a specialist in the field of digital program management. Unlike a programmer, such a specialist cannot work remotely, so I was looking for a person in Naberezhnye Chelny.

Having spent a lot of effort and nerves, I found only two people who had the necessary level of knowledge and were able to realize my ideas, and fortunately one of them, Pavel Kozhevnikov, took up the project.

Getting funding, finding a team, and working on a printer went gradually - and in April of this year we created an MVP.

What we are doing now

In the spring of 2020, we entered the Pulsar Venture Capital accelerator and are now working on a project together with the company's experts. Acceleration made me run faster, spend even more time on the project, and constantly refine something.

Acceleration made me run faster, spend even more time on the project, and constantly refine something.

On the other hand, due to quarantine, we work remotely, and for me it turned out to be even more convenient - I stayed in the familiar atmosphere with the opportunity to work on the product.

Now we have a finished product, the first pre-orders for it, and an understanding of how we will bring it to the market, how to position it. In addition, during the acceleration we have expanded the horizons of thinking and now we are looking not only at Russia, but also at the global market - this has ceased to seem like an impossible task.

We assessed the economics of the business and set the price for the printer at around $7,000, which is an adequate price for a printer with such a wide range of capabilities, because it allows you to get prototypes of products quickly and with high quality.

I see how 3D printer owners are increasingly thinking about equipment efficiency and the ability to do more. In response to these requests, in recent years, the number of developments in the field of creating a new generation of 3D printers has been growing, and this is encouraging - it means that the topic is really in demand and the market will actively develop.

In response to these requests, in recent years, the number of developments in the field of creating a new generation of 3D printers has been growing, and this is encouraging - it means that the topic is really in demand and the market will actively develop.

For example, the scientific community is working on the creation of algorithms and principles for processing models. The new generation of 3D printers is being made by our competitors from Europe and Asia, but so far they have not announced the launch of mass production.

Therefore, it will be great if we, Russian companies, manage to become market leaders in the creation of third-generation 3D printers that can work even more efficiently and change attitudes towards additive manufacturing.

Top 5 misconceptions about 3D printing

Even before you decide to use 3D printing in your production, there may be questions and concerns about this technology. In this blog, we'll take a look at 5 of the biggest misconceptions about 3D printing and clear up some of the myths surrounding the technology. All this will allow you to make an informed decision for the development of your business at the right time.

All this will allow you to make an informed decision for the development of your business at the right time.

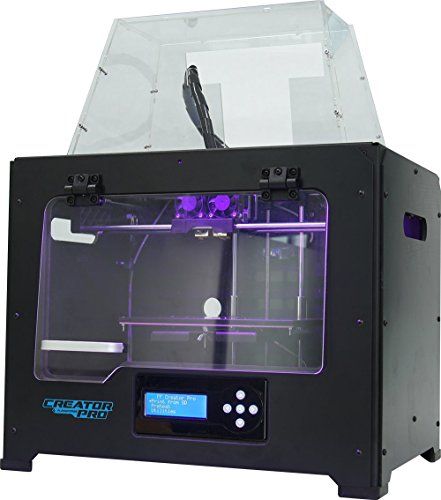

3D printers are very difficult to use

If you are used to outsourcing the production of goods, layer-by-layer synthesis technology may seem something incredible and incomprehensible. However, this process cannot be called "complex".

Ultimaker 3D printers are ready to go right out of the box. The device is ready to print in a few minutes: you just need to connect the device to the network and go through a step-by-step calibration. Preparing a model file for printing is also a breeze, and using reliable software such as Ultimaker Cura will help you with this.

Ultimaker also offers extensively tested print profiles for 11 media types. Pre-configured print profiles for these materials will eliminate the manual input of parameters before 3D printing and save you time. If you are working with third party materials and want to get the most out of your use, the Ultimaker Marketplace offers over 150 profiles from leading filament suppliers.

3D printing is expensive

A 3D printer is an investment. Compared to other manufacturing solutions, a 3D printer requires minimal investment. However, you should be careful not to invest in unreliable devices or a closed ecosystem that will force you to depend on expensive consumables and service contracts. By choosing the right hardware, software and materials for your needs, you can increase your bottom line with a potential payback period of several months.

Need proof? Use the ROI Calculator, a handy online service that will determine how long your investment will pay off. You can also check out the detailed article 3D Printing: Total Cost of Technology Ownership for a detailed analysis of the costs and benefits of using 3D printing.

3D printing suffers from a lack of material diversity

3D printing is about much more than just plastic. Through the Ultimaker Material Alliance, Ultimaker offers a wide range of materials to the market. The Alliance provides the freedom and diversity of 3D printing and allows you to create exactly what you want, without relying solely on the materials of the company's own production. 3D printers are able to create high-quality products from a huge variety of raw materials, ranging from carbon fiber reinforced materials to metal.

3D printers are able to create high-quality products from a huge variety of raw materials, ranging from carbon fiber reinforced materials to metal.

3D Printing - Prototypes Only

Although Fused Filament Manufacturing (FFF) technology lends itself very well to rapid prototyping, companies around the world use 3D printers to create tools and fixtures for both specific and and for universal applications such as in a Ford assembly line or a Heineken bottling plant. Some companies even create end-use products in one-off or low-volume printing, thereby avoiding long production costs and downtime.

3D printing - for core industries only

3D printing is not industry specific. Companies in the fields of architecture, aerospace, manufacturing, automotive, education, and many other industries are using Fused Filament Manufacturing (FFF) technology. They manage to achieve results that go beyond traditional manufacturing methods, forever changing the way they work - whether it's a military jet, a Formula 3 car, or an industrial microscope.