Make money 3d printing 2023

11 Ways to Make Money 3D Printing in 2022 – Clever Creations

Our site is reader-supported. When you buy via the affiliate links on this site, we will receive a commission at no cost to you. All opinions remain our own. Learn more

Ever wondered about turning your 3D printing hobby into a profitable business venture? We’re here to tell you that there are several ways to make money with 3D printing even as a beginner.

In this guide, we’ll examine the best ways how to make money with a 3D printer, which 3D printing services are most in-demand right now, and what you need to know about running a 3D printing business before you get started.

Best ways to make money with a 3D Printer in 2022

1. Design and sell 3D prints

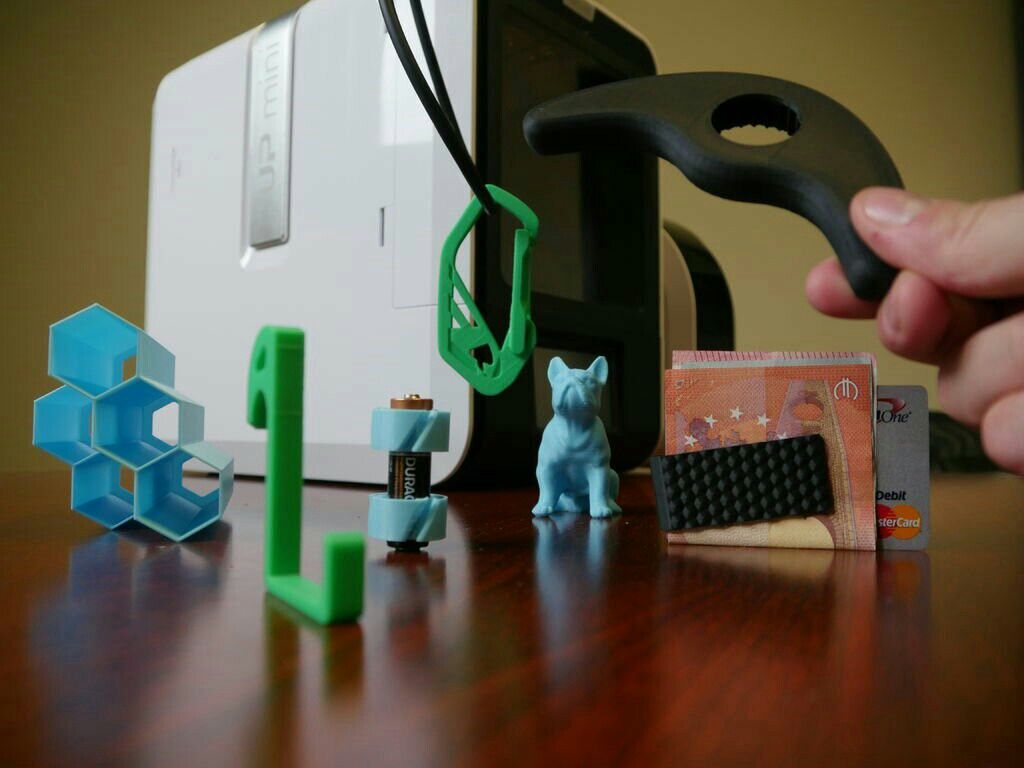

If you want to design, print, and sell your own 3D printed items, there are a few different ways to do it. For example, you’ll need to decide if you want to stick with a set of specific designs or if you want to work on commission.

Personalized or custom items mean you have to make a new 3D model for every order. Offering only pre-designed items allows you to make items ahead of time and ship them out as needed.

There is a market for nearly every type of 3D print you can create, so choose the types of items you enjoy making. After you have decided that, figure out where the customers for those items like to shop so that you can offer your products there.

What can I make and sell with a 3D printer?

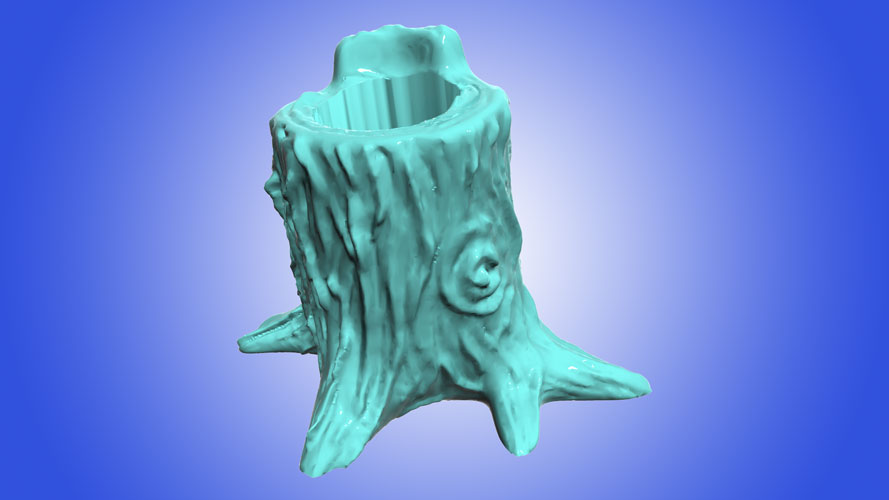

In terms of the things to 3D print and sell, your products can be anything from planters to phone cases to home décor items. Ideally, the products you sell line up with your own passions while still being in high demand from your target audience.

Some of the most popular things to make and sell are:

- (D&D) miniatures. 3D printed miniatures are very popular at the moment. Unlike store-bought miniatures, these can be fully customized to your customers’ liking. You can also paint the miniatures before shipping them out, but many customers don’t mind painting minis for themselves, or they leave them unpainted altogether.

When doing this, we recommend you use a resin 3D printer for miniatures.

When doing this, we recommend you use a resin 3D printer for miniatures. - Jewelry. 3D printed jewelry can be sold at a high mark-up and for more money than other items, but there is a lot of competition in this niche on sites like Etsy. For 3D printing jewelry, a resin 3D printer (or even a high resolution 4K+ resin 3D printer) is ideal.

Image: xfanta via MyMiniFactory

There is a lot of demand for 3D printed jewelry- Cosplay items. Creating and selling cosplay items can be a profitable endeavor. 3D printing helmets, 3D printing armor, or all kinds of other props are valid ways of making money with a 3D printer.

- Planters. Attractive self-watering planters aren’t always easy to find in retail stores. That is one of the reasons why they are popular things to 3D print.

- Toys. Toys are easy to make on FDM printers and barely need any post-processing.

These are just a few examples, but the list is practically endless. Think key chains, customized shoes, personalized crafts, or other one-off items. You can sell designs of others (if the copyright license allows), or create your own designs and your own products.

Think key chains, customized shoes, personalized crafts, or other one-off items. You can sell designs of others (if the copyright license allows), or create your own designs and your own products.

Where to sell 3D prints?

There are many platforms you can use to sell your 3D printed items and make money with a 3D printer, both online and offline. Most sellers choose a few different platforms for selling to reach a variety of markets and audiences, as well as to bring in more money.

While it’s important to not limit yourself to one sales channel, you should also be careful not to spread yourself too thin.

Offline

You have several choices for selling your 3D printed items in person. Events like craft fairs, trade shows, garage sales, and festivals can all give you the opportunity to show off your 3D prints and gain customers. If you have access to electricity at the event, setting up your printer in your booth can be an easy way to attract people to your table.

You can also put your 3D printed items into consignment shops or set up a display in local businesses. This gives your 3D printing business local exposure without committing to a storefront.

Online

To reach a large and varied global market with your 3D printed items, you should sell online. You should ideally have your own online store at some point. In the meantime, there are several eCommerce platforms that can help you get started:

- Etsy

- eBay

- Amazon

- Fiverr

2. Start a local 3D printing business

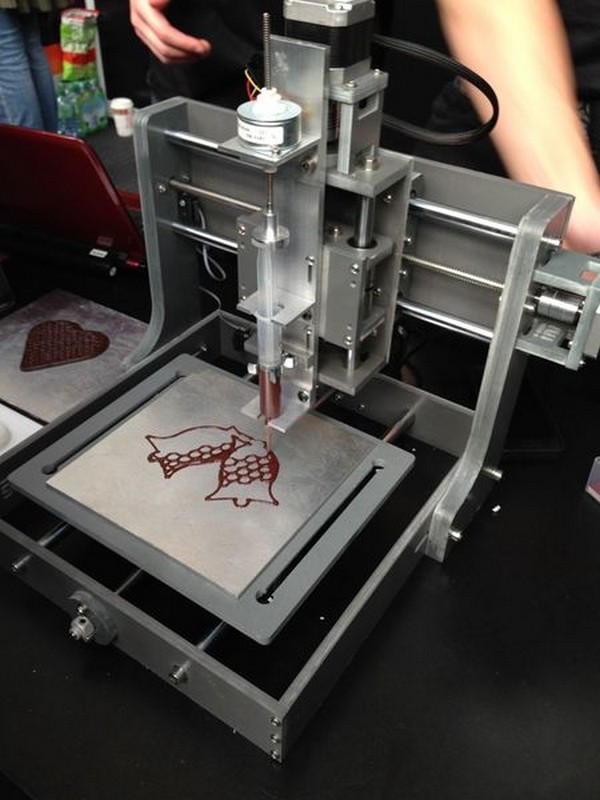

Starting a local 3D printing business is one of the quickest ways to get customers and generate sales. You can manufacture custom parts, tools, and necessities for other local businesses. This is especially true if you live around several factories or plants. You can reach out to your local bakery about cookie cutters, or make trophies or awards for events.

Recommended:

The 5 Best 3D Printers for Making Cookie Cutters

The list goes on. You will be surprised by how much you can contribute to your local community once you just start asking. If you are wondering how to make money with a 3D printer, this option offers you lots of potential.

You will be surprised by how much you can contribute to your local community once you just start asking. If you are wondering how to make money with a 3D printer, this option offers you lots of potential.

While opening your own business sounds complicated, it’s a rather straightforward process. You should contact your local authorities or city council to double-check the ordinances. You may find that you won’t need any permits or zoning updates to run it from your house. That depends on where you live and how your local laws are set up.

What do you need to start a 3D printing business?

3D printer

It goes without saying that if you want to start your own 3D printing business, you need a 3D printer. In this case, it should be a reliable 3D printer that you are already familiar with and have a stock of spare parts for.

You don’t want to start taking requests from customers and have to cancel their orders a week later. Things like this happen when you’re waiting on a replacement part or because something basic went wrong and you don’t know how to fix it. Be prepared with basic troubleshooting knowledge of your machine and backup components before you start.

Be prepared with basic troubleshooting knowledge of your machine and backup components before you start.

You don’t need a top-of-the-line printer to offer your 3D printing services. However, you should aim to have a properly working and time-efficient one. Every minute that you spend re-leveling your build plate because your printer falls out of alignment is a minute that you have to account for through higher printing fees or lost maintenance costs.

Going with a 3D printer under $1000, like the reliable Prusa i3 MK3S, is a good way to save yourself time.

On the other hand, if you decide to go with a budget 3D printer, like the Ender 3 V2, you can make use of the many Ender 3 upgrades that turn it into a more time-efficient machine. One example of this is the BLtouch leveling sensor, which removes the need for manually leveling the build plate.

Business website

You need a website to inform your potential customers about your 3D printing business and to capture leads. You should have this set up by a professional web designer if possible. This will be your main touchpoint for customers to interact with your brand. As such, you want it to look good and reputable to bring in those early clients.

You should have this set up by a professional web designer if possible. This will be your main touchpoint for customers to interact with your brand. As such, you want it to look good and reputable to bring in those early clients.

You should also contract a graphic designer. They will make your logo, company palette, and other branding materials. Your web designer will need them to keep your website design on-brand.

Some web designers can do both (and vice versa). Just be sure that they have a strong foundation in branding if you choose to use one person for everything.

You can go as basic or complex as you would like with your final website design. It depends on what types of services you plan to offer and how much of the pre-purchase and buying phase you want to happen online.

Premium add-ons like an online store, quote generator, appointment scheduling app, and other tools add value to your end customer. They will cost you more money in upfront design charges since they may require adding a web developer to your project as well.

3. Design and build prototypes

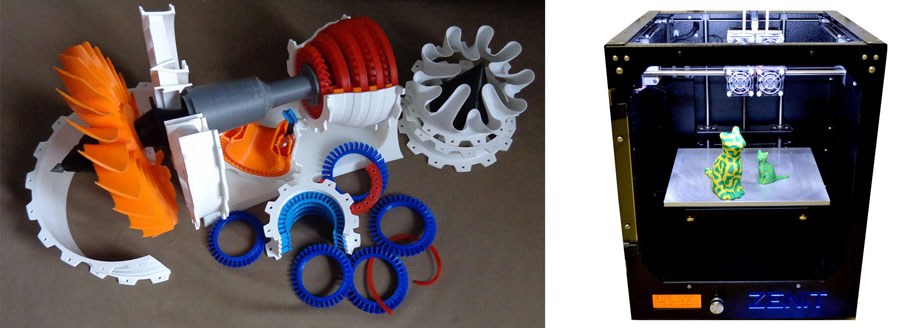

Using your 3D printer to design and build your own (or someone else’s) product prototypes is a great way to monetize your machine. For other people’s prototypes, you can charge them for designing and building them. For your own prototype, you can send it into production and have your own product line thanks to your 3D printer.

4. Rent out your 3D printer

Many people love the idea of 3D printing but don’t have the time, space, or money to buy their own printer. Or sometimes they just need the occasional niche print and don’t think it’s worth it to buy their own machine.

That’s where you and your 3D printer rental services come in! You can charge customers a fee for a printing service where you print their models on your printer. Doing this during your 3D printer’s usual downtime lets you make money 3D printing in moments where you don’t need to use the machine for yourself.

This seems like one of the easier options on this list to try. However, print on demand does have some complicated elements to consider. You have to be properly compensated for all time and materials involved.

However, print on demand does have some complicated elements to consider. You have to be properly compensated for all time and materials involved.

That includes the cost of your time spent leveling and maintaining the printer (as well as the cost of wear and tear on your machine from additional usage). Keeping in mind the 3D printer’s electricity usage and other 3D printer costs is important too.

For your 3D printing service, you also need to consider if you will honor requests for certain colors of filament, what types of filament potential customers can order, and if you will also include services for post-processing for a fee.

Image: Mtar Einbern via MyMiniFactory

Post-processing can also include painting5. Sell digital 3D models

If you’re a skilled modeler, sculptor, or drafter, you can forgo the necessity for physical products and sell your 3D model files online. This option is more of a passive income business model that can work beside or be independent of a physical product line.

Selling digital files like 3D models lets you make money on one product several times without having to make the item more than once. It becomes even more efficient if the digital files you sell are existing assets from another project that weren’t used anymore and would otherwise have no value.

While you won’t be making money in large sums per sale for 3D models, they can still earn a higher lifetime revenue than a print and sell option of the same model. Digital files simply sell with more regularity than physical objects and have no production cost associated with each extra copy sold.

Where to sell 3D model files

The first place you should consider selling your 3D models is on your own website. If you already have one of those for your local 3D printing business, excellent. If not, start looking for a web designer ASAP.

Third-party platforms charge fees to use their services. Having your own eCommerce site ensures that you get a larger percentage of profit from each sale and increase the money you make 3D printing. The downside to this is that you have to build your audience and website traffic yourself. Most third-party eCommerce platforms bring their audience to you.

The downside to this is that you have to build your audience and website traffic yourself. Most third-party eCommerce platforms bring their audience to you.

Some of the best places to sell your 3D models are:

- Etsy

- MyMiniFactory

- CGTrader

- Cults3D

Image: DarkFigurines via MyMiniFactory

3D models are loaded into a slicer program to generate instructions for the 3D printer6. Start a YouTube channel

You can use your 3D printing knowledge to set up your own YouTube channel. Build your audience by posting cool and helpful 3D printing YouTube videos to your channel.

It is possible for you to earn revenue from ads, donations, affiliate programs, and brand sponsorships. If you get a large enough following, companies might also send you free products to review.

You most likely won’t make a full-time living from YouTube (especially at first). However, if you grow it as one of several monetization strategies, it can be helpful. It’s a great way to push potential customers to your website or online shop. It can also help develop your name as a knowledgeable person in the industry.

It’s a great way to push potential customers to your website or online shop. It can also help develop your name as a knowledgeable person in the industry.

7. Start a blog

You can use a blog to write 3D printer-related content and share your knowledge with others. Like YouTube, you can monetize the content on your blog through ads, affiliate programs, and paid sponsorships. Having a blog gives you more control over the creative process. You also make a lot more from ads on your website than YouTube pre-roll ads.

You can also use your blog as a way to bring readers to your website where you sell your prints, 3D model files, and other products. Your blog content acts as a verification that you know what you’re talking about on the subject of 3D printing.

It shows that you can be looked at as a trusted source. This is called brand authority, and it makes it much easier to convert an audience member into a customer when they already trust what you’re saying.

8. Repair things in your household

A 3D printer is a great tool to have around when something in your house breaks. With basic computer-aided design (CAD) knowledge and (free) 3D modeling software, you can design replacement parts for broken appliances, furniture, and so on.

Normally when something breaks, you have to order a new part from the manufacturer. You potentially have to replace the entire thing if the manufacturer can’t help you. By doing basic repairs, 3D printing your own replacement parts, and keeping your old belongings in functional shape, a 3D printer helps you save money over time.

9. Repair 3D printers for others

There is no denying that 3D printers can be a bit temperamental sometimes. They have a large number of parts to make them operate the way they should. If someone is new to 3D printing or never learned what most of those components are meant to do, they will struggle to fix it when something goes wrong.

Put your technical 3D printer knowledge to good use and offer to fix broken printers for a fee. Most people will be happy to spend money to let someone more capable deal with it. You get paid work from a person who was likely never going to use your 3D printing services or buy your products.

Most people will be happy to spend money to let someone more capable deal with it. You get paid work from a person who was likely never going to use your 3D printing services or buy your products.

10. Flip broken 3D printers

If a 3D printer is broken badly enough that the owner doesn’t want to fix it, you can still salvage it by fixing it up. After you have repaired it, you can then resell it for a profit. You can also keep it for spare parts for another 3D printer and sell that one afterward.

11. Offer 3D printing courses

If you’ve been 3D printing for a while, you probably know quite a bit about the subject. Consider using that knowledge to create an online course or series of online courses that teach new 3D printing enthusiasts the basics.

It will be a big initial investment of your time to plan the course, film it, edit it, compile it, and market it. However, you can continue to sell the course for years to come while doing little to no maintenance work on it.

You can host the course through an online learning platform like:

- Skillshare

- Udemy

- Domestika

- Teachable

You can also host it through your website if you have one (and use your blog to help market it.)

Frequently asked questions

Can you make money with 3D printing?

Yes, there are many ways you can start making money with a 3D printer. Selling 3D prints (like phone cases) or offering 3D printing services are some of the most popular methods, but there are many more you can choose from.

Is it legal to sell 3D prints?

As long as you follow the copyright license on any 3D model you use, you are legally allowed to sell 3D prints of the model. For any models you design yourself, you are the license holder, so you can use the models freely.

If any of the models depict copyrighted or trademarked content, that overrules the designer’s license. For example, if someone designed a 3D model of a well-known cartoon character, they still cannot sell prints of it because the character is not their intellectual property.

For example, if someone designed a 3D model of a well-known cartoon character, they still cannot sell prints of it because the character is not their intellectual property.

Image: edoyola via MyMiniFactory

Always check whether the objects you 3D print are copyrighted or notIs 3D printing a good side hustle?

Yes, 3D printing is a great side hustle if you already know a lot about the subject. If you are brand new to 3D printing and are trying to jump into starting a business with it from day one, it might be a frustrating experience.

Taking some time to learn your 3D printer, understand the settings, and be able to troubleshoot the most common issues are going to be very helpful in the long run. It will also ensure that you don’t guarantee your 3D printing service to someone before you are able to render it.

3D printing is also not much different than beginning any other side business. Starting a 3D print store or print-on-demand service requires niche market research, marketing, social media skills, and some understanding of business management. Those are all skills anyone can and should learn to increase how much money they make with their side business.

Those are all skills anyone can and should learn to increase how much money they make with their side business.

How long does it take to start making money with a 3D printer?

That depends on a few different factors. If you are trying a few of our suggestions on how to make money with a 3D printer, your chances of quickly connecting with new customers are higher than if you only stick to one method or sales platform.

How quickly people buy from or contract you also depends on having things like:

- A professional-looking website

- Clean and effective copy on your website and product listings

- High-quality pictures of your products

- Well-defined policies for shipping, returns, customization, etc.

- Good pricing (that doesn’t mean fighting to be the lowest)

- Accurate market research and a good strategy for your business

Not all of these factors have to be a slam-dunk every time. Online shops with terrible pictures make sales every day, while some with professional product photography do not. People stumble onto products by accident every day, even if their marketing strategy is abysmal. These are just some things that may color your timeline for profitability.

Online shops with terrible pictures make sales every day, while some with professional product photography do not. People stumble onto products by accident every day, even if their marketing strategy is abysmal. These are just some things that may color your timeline for profitability.

How long does it take to learn 3D printing?

If you have a plug-and-play 3D printer that is designed to set up and start 3D printing almost instantly (note that these are usually the more expensive machines on the market), you can start getting serviceable prints within a day.

Cheaper and more hands-on 3D printer models have a steeper learning curve and take more time to become adept with. Many of the tasks that plug-and-play printers do automatically are manual on budget printers. It will likely take you a few days to start producing quality parts. It will take a few months to have a firm understanding of all the 3D printer’s elements.

As far as being able to make your own 3D models, those skills are considerably more time-consuming to learn. You can make very basic models within a day or so by following tutorials. However, it can take months or even years to become a skilled designer who creates original and aesthetically pleasing 3D models.

You can make very basic models within a day or so by following tutorials. However, it can take months or even years to become a skilled designer who creates original and aesthetically pleasing 3D models.

Do you need a license to 3D print?

Anyone with access to a 3D printer can print 3D models for non-commercial uses. However, the rules are slightly different when you intend to sell the finished product. Any models used need to have a commercial use license.

That means only choosing ready-made models online that have the proper license. You can also contact the designer to inquire about obtaining commercial rights. Many designers are willing to charge you a licensing fee in those situations, but some will still refuse. It’s important to be respectful either way.

What software do I need?

To start 3D printing, you need a 3D modeling program and a slicer program. The 3D modeling software lets you create 3D models to print, while your slicer turns your models into lines of code that your 3D printer can read.

For help picking out a 3D modeling program, we have an in-depth comparison between the best free modeling software options.

Is 3D printing expensive?

The expenses of 3D printing depend on several factors. These include what type of material you use, what type of 3D printer you have, if you keep your printer well-maintained, and how you store your materials.

Paying attention during 3D model slicing and set up can cut down costly or wasteful mistakes. Keeping your 3D printer clean and lubricated extends the life of its parts. Storing your filaments or 3D printer resins away from moisture and light will extend its working life and help you save money.

Conclusion

There are several options to make money 3D printing, which means there is something suitable for everyone. Do you make money with a 3D printer? What do you find most challenging about running a 3D printing business or side hustle? Let us know in the comments!

Scroll to Top

How to Make Money with a 3D Printer

Share on Social Media

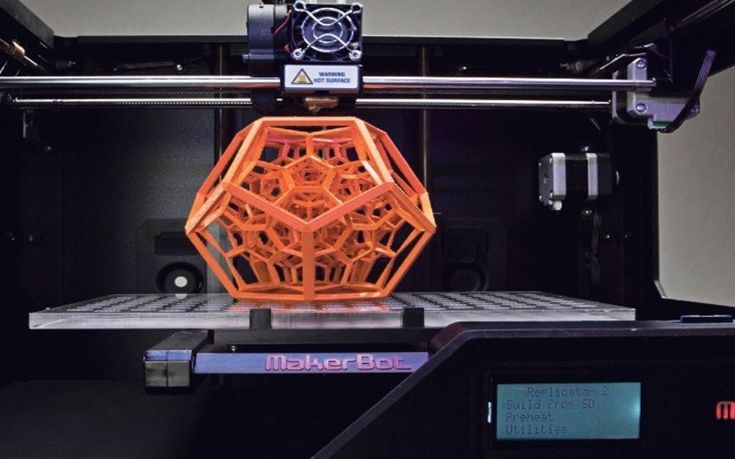

3D printers have been all the rage in current years and you’ve probably considered some of the severely extraordinary objects that come out of these things.

But did you ever suppose of searching into how to make cash with a 3D printer rather than simply searching at what it can produce? You can also make money with the best printer for stickers.

Table of Contents

- 1 How to Make Money with a 3d Printer

- 1.1 1. Sell 3D Prints design

- 1.2 2. Start a blog on 3D Printing

- 1.3 3. Providing 3D Printing Course

- 1.4 4. Launch a Youtube channel or Tiktok account

- 1.5 5. Freelance with your 3D Printing Skills

- 1.6 6. Build your very own websites for 3D Printing

- 1.7 7. Create Prototypes

- 1.8 8. Rent your 3D Printer for events

- 1.9 9. Jewelry Companies

- 1.10 10 . Start a Local 3D Printing Business

- 1.11 FAQ’S

There are virtually countless approaches to monetizing a 3D printer, whether or not you make money promoting 3D models, providing 3D printed merchandise on-demand, or a bunch of different items.

So if you think you have the skills to profit off your 3D printer or are want to learn how then keep reading to find out some options you may want to consider. Also, try Best Printer under $200.

Also, try Best Printer under $200.

10 best techniques to make money with a 3D printer – At a Glance

1. Sell 3D Prints designSelling the 3D printed objects that you’ve made on eBay, Etsy, or different committed shops. Shopify is additionally an awesome region to promote your 3D printed objects. You can promote your 3D prints on Facebook as well.

Just create a Facebook web page for your 3D printing commercial enterprise and you can begin selling. You can additionally promote your 3D prints. Tell them that you can print 3D objects for them. They solely want to locate an order and wait for the 3D prints.

If you choose to succeed, you must create special 3D prints that clients sincerely prefer to purchase. 3D printers can additionally assist you to create ingenious gadgets that surpass those that are already out on the market.

2. Start a blog on 3D PrintingIf you have acquired something to say on the difficulty of 3D printers, then this is an awesome way to do it.

For instance, your blog should be focused on novices who choose to make their first steps into the world of making matters on-demand with a 3D printer. Alternatively, you should goal a precise area of interest through supporting human beings to make a positive kind of object greater effortlessly or with extra variety.

Bloggers make cash thru a variety of exceptional avenues, inclusive of being paid with the aid of corporations to write weblog posts on their behalf and strolling show commercials from sponsorships. Most of the time you can try Best DTG Printer for your 3D printing needs.

3D printing can assist faculties and companies in enhancing the instructional system and lowering the value of training.

You can take benefit of this possibility by way of educating 3D printing courses. For instance, you can educate them on how to create 3D designs. You can promote yourself on job provide websites and social media websites to let human beings be aware of that you are providing 3D printing courses.

You can additionally promote your publications via online structures like:

Skillshare

Udemy

Teachable

Domestika

You can Use your 3D printing understanding to set up your very own youtube or Tiktok account. Build your target audience through posting cool and beneficial videos On your channel this is way to earn from this.

It is feasible for you to earn income from ads, donations, affiliate programs, and manufacturer sponsorship. If you get a giant ample following, groups would possibly additionally ship you free merchandise to review.

5. Freelance with your 3D Printing SkillsAnother way that you can make cash with a 3D printer is via providing your abilities for freelance work. It’s already an especially area of interest market, however, you’ll regularly locate the quality possibilities in fields the place there are now not many humans who have your expertise, such as if you’re in a position to specialize in a sure item.

You need to begin by means of imparting your offerings on websites like Upwork, and Fiverr. That way, you can begin to construct your portfolio as a way to entice greater clients going forward.

6. Build your very own websites for 3D PrintingBuilding your very own 3D printing provider internet site is a wonderful notion for a number of reasons. Number one, you manage the fees of the entirety of it. Number two, construct repeat enterprise daily.

You have to additionally contract an image designer. They will make your logo, organization palette, and different branding materials. Your internet dressmaker will want them to preserve your internet site layout on-brand.

Having constructed a company around your 3D printers if your clients are joyful and want greater printing they are in all likelihood to maintain coming returned to your brand.

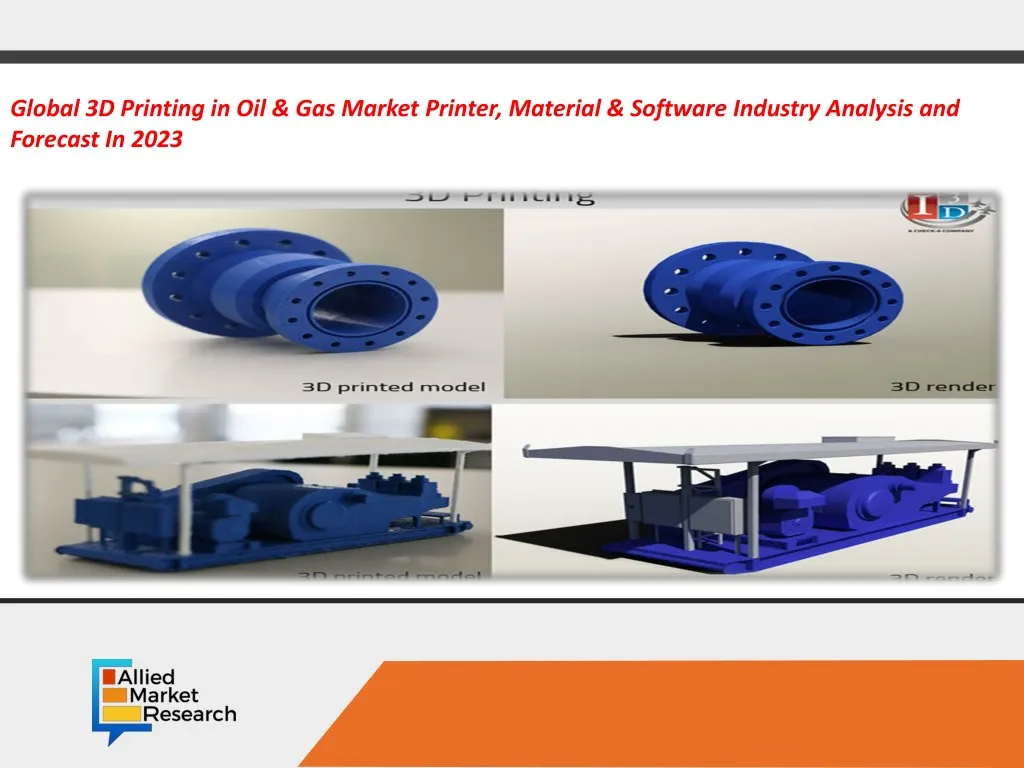

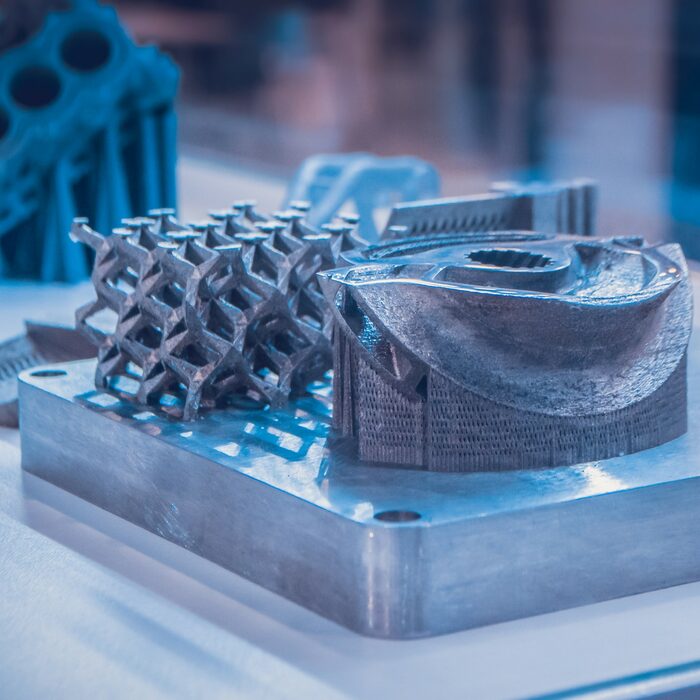

7. Create PrototypesYou can make 3D prototypes for nearby engineering companies to earn money. Rapid prototyping is in demand amongst organizations and specialists working in construction, architecture, design, and engineering.

Rapid prototyping is in demand amongst organizations and specialists working in construction, architecture, design, and engineering.

3D printing science permits authorities to produce and use scale prototypes to supply conceptual presentations, check a product’s viability, and exhibit their designs.

Through this technology, they can minimize expenses in the improvement and make cash quickly due to the fact they can produce components greater quickly. You can businesses in these industries with the aid of prototyping for them the use of your 3D printer.

8. Rent your 3D Printer for eventsYou can cost clients a price for a printing carrier the place you print their fashions on your printer. Doing this at some point of your 3D printer’s regular downtime lets you make cash 3D printing in moments the place you don’t want to use the computer for yourself.

9. Jewelry CompaniesJewellery organizations are an amazing instance of perfect money-making with the 3D printing process. Now, an extensive variety of preferred custom-made jewellery designs can be created immediately with these printers. From wedding ceremony rings to necklaces to bangles; the whole thing can be created with these printers.

Now, an extensive variety of preferred custom-made jewellery designs can be created immediately with these printers. From wedding ceremony rings to necklaces to bangles; the whole thing can be created with these printers.

All minute important points of designing can be taken care of with this technology. Owners of jewellery corporations pay a massive quantity of cash to 3D printing groups due to the fact it cuts down the labour fee as nicely as the time required to put together designs.

10 . Start a Local 3D Printing BusinessStarting a 3D printing enterprise can reap big income for humans dwelling in massive cities. This is due to the fact your commercial enterprise encounters many clients all the time.

Once you’ve located the best niches and produced top-notch items, there’s no doubt that your enterprise can flourish. You can promote the bodily gadgets in character and furnish printing offerings to different people. And you can also earn printing money with Best Printer for Sublimation.

| Steps | Process |

|---|---|

| Step 1 | Sell printed objects |

| Step 2 | Etsy shop |

| Step 3 | Amazon |

| Step 4 | Craig list |

| Step 5 | Simple tools |

1. Can I make money using a 3D printer?

Yes, as we can sell different items with a 3D printer also you can rent them.

2. Is 3D printing expensive?

It can cost you from $3 to many thousands of dollars as we can’t give you an estimate on a 3D printer.

3. How long does it take to make something in a 3D printer?

It all depends on the size, height, and technology you are using for printing.

4. How much money can you make with a 3D printer?

There are many approaches that you will rapidly explore that a person can make more than $1,000 or $5,000+ with 3D printing depending on the amount of time and exertion they are slanted placed it in. Any man or lady with an insignificant aptitude for fabric physical science or making will become skilled to take reasoning and print it out with astonishing components.

Any man or lady with an insignificant aptitude for fabric physical science or making will become skilled to take reasoning and print it out with astonishing components.

5. What should I charge for 3D printing?

For an hour of 3D printing time, the quantity of filament used would be 15.6 gm (=0.26 x 60 min). This offers us the filament value of ninety-four cents per hour of 3D printing (=15.6 gm x 6 cents). So, for the cost-recovery of filament only, I get roughly $1 per hour of 3D printing time.

6. What 3D prints sell the most?

Cosplay props, planters, and miniatures are some of the largest sellers. The reputation relies upon which platform you are promoting. For example, on Etsy, the predominant patron base is searching for pretty, state-of-the-art things.

7. Is 3D printing worth investing in?

Considered to be a worthwhile market amongst investors, the enterprise is set to attain larger heights. According to the facts supplied via Statista, the international 3D printing merchandise and offerings market is predicted to develop at an annual charge of around 17% until 2023, with values anticipated to attain $37. 2 billion by using the 12 months 2026.

2 billion by using the 12 months 2026.

8. Can you legally sell 3D prints?

To commence with, it is absolutely secure and criminal to promote your 3D printed components on e-commerce websites like eBay, Amazon, and Etsy. People are making a truthful dwelling by providing their printing skills on special platforms.

successful business based on innovative technologies

“The most difficult moment was when I had to stop designing and start selling”

A good engineer is not always a good entrepreneur: it often happens that many developments never reach the stage where you can build a business on them. But Fyodor Antonov and his Anisoprint team succeeded: they not only developed a technology that makes it possible to obtain durable composites - materials based on carbon fiber, but also successfully entered Western markets with their product. Fyodor Antonov, the founder of Anisoprint, told Biz360.ru about how to make money on an innovative project.

Fyodor Antonov, the founder of Anisoprint, told Biz360.ru about how to make money on an innovative project.

Dossier

Fedor Antonov , 34 years old, founder and director of the company Anisoprint . In 2007 he graduated from the Mekhmat of Moscow State University. After that, he worked as an engineer at the Salyut engine building plant for 3.5 years. At the same time he wrote and defended his PhD thesis. From 2010 to 2013, he worked at the Rostec Composite Materials Center. Then he worked for two years at the Skolkovo Institute of Science and Technology (Skoltech). In 2015, together with fellow scientists, he founded the Anisoprint company, which manufactures and sells composite 3D printers and materials for them.

Problem becomes business opportunity

Fedor Antonov has been designing and optimizing products made of composite materials for almost 10 years. In his experience, when working with composites, an approach is usually taken that does not allow them to reveal their maximum potential. They are handled in the same way as traditional materials (such as metals), although their properties are different.

They are handled in the same way as traditional materials (such as metals), although their properties are different.

- Composite is a material consisting of two or more components with a clear interface between them . As a rule, one component is called reinforcing filler or reinforcement - the strength and rigidity of the composite depends on it. The second component is the matrix or binder. The result is a material with unique characteristics that neither the reinforcement nor the binder individually possess.

The simplest and most famous example of a composite is reinforced concrete. Polymer composites in the form of carbon fiber (or carbon fiber) are also not new - they have existed for more than 50 years. Airplanes, racing cars, etc. are made from this material. This is a composite, where the filler is carbon fibers, and the binder is polymers.

The problem with composite materials lies in their structure. All the unique properties of composites (for example, increased strength and stiffness) appear only along the direction of the fibers. And when loaded across the fibers, the strength is very low and corresponds to the strength of the binder material. This property is called anisotropy: different material properties appear in different directions. It is considered the main disadvantage of composites.

And when loaded across the fibers, the strength is very low and corresponds to the strength of the binder material. This property is called anisotropy: different material properties appear in different directions. It is considered the main disadvantage of composites.

They are trying to fight anisotropy. For example, in "classic" carbon fiber sheets of unidirectional fibers are laid layer by layer at different angles. But here another problem arises. If such material is drilled or cut, its fibers are damaged. There is a stratification of the material - its properties are lost.

“We decided to make the technology of manufacturing products from composites as flexible as possible. It would allow at any point in the structure to change the direction of the fibers and their concentration. Thus, we would receive the optimal material for a specific design. And then you do not need to drill holes in the material - it will be printed with the "correct" direction of the fibers around the hole. There are many such examples in nature. One of them is wood fibers that go around the place where the branch is attached,” says Fedor Antonov.

There are many such examples in nature. One of them is wood fibers that go around the place where the branch is attached,” says Fedor Antonov.

Prototyping

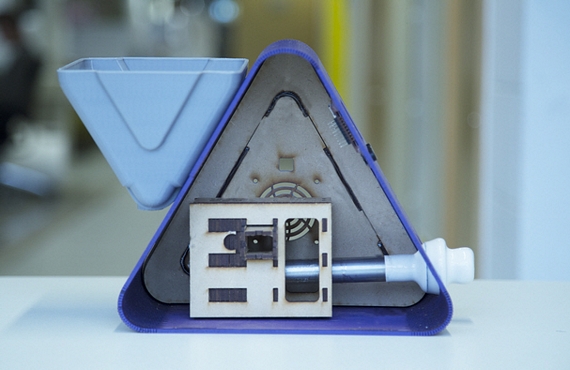

While working at Skoltech, Fedor and his colleagues developed a new technology for manufacturing composites with increased strength. By 2015, they managed to create this technology - anisoprinting. During the 3D printing process, the developers added specially processed carbon fibers to the plastic. Due to this, the strength of the plastic increased by 30 times! The resulting material was twice as strong and lighter than aircraft aluminum.

The inventors faced another question: how to produce such composites in the best way and at no extra cost. For this, Fedor and his colleagues developed a special 3D printer. Its presence made it possible not only to “theoretically” design structures, but also to manufacture them. In early 2015, a team of engineers led by Fedor Antonov patented their solution.

In the summer of 2015, they registered a legal entity - Anisoprint, for which they issued the status of a Skolkovo resident. At the same time, the new company sold its product for the first time. The print head of the 3D printer was bought by an American, the former head of the laboratory at Skoltech. He purchased the device for the University of South Carolina, where it is still in use today.

After that, several more 3D printer prototypes were sold. The buyers were universities and research institutes. Among them was the Central Research Institute of Special Machine Building - one of the largest experimental and scientific centers for composite materials.

Search for investors

For two years, Fedor Antonov tried to find funding for his developments. According to him, it was almost impossible to do this: investors and funds rarely allocate money to "manufacturers", preferring IT projects.

But here the company was lucky. In the spring of 2017, Fedor took part in a competition for industrial startups, which was held at the initiative of one of the business angels. Anisoprint took one of the prizes in the competition.

In the spring of 2017, Fedor took part in a competition for industrial startups, which was held at the initiative of one of the business angels. Anisoprint took one of the prizes in the competition.

For six months, Fedor discussed the terms of the deal with the business angel. And when they had already reached a preliminary agreement, the founder of Anisoprint began to doubt his future partner. Just at that moment, the novice entrepreneur was introduced to another potential investor who was also interested in the project. The founder of Anisoprint does not disclose the name of the investor, the size of his investments and the terms of cooperation.

“Having the first offer in hand, I could already choose. And I immediately told the second investor that I needed more favorable conditions. Quite quickly, without long disputes and discussions, we agreed on everything. Until the end of 2018, we signed a preliminary agreement with a new partner. In the end, he invested in us. With this money, we started full-fledged development,” says Fedor.

Quite quickly, without long disputes and discussions, we agreed on everything. Until the end of 2018, we signed a preliminary agreement with a new partner. In the end, he invested in us. With this money, we started full-fledged development,” says Fedor.

Lab-to-market entry

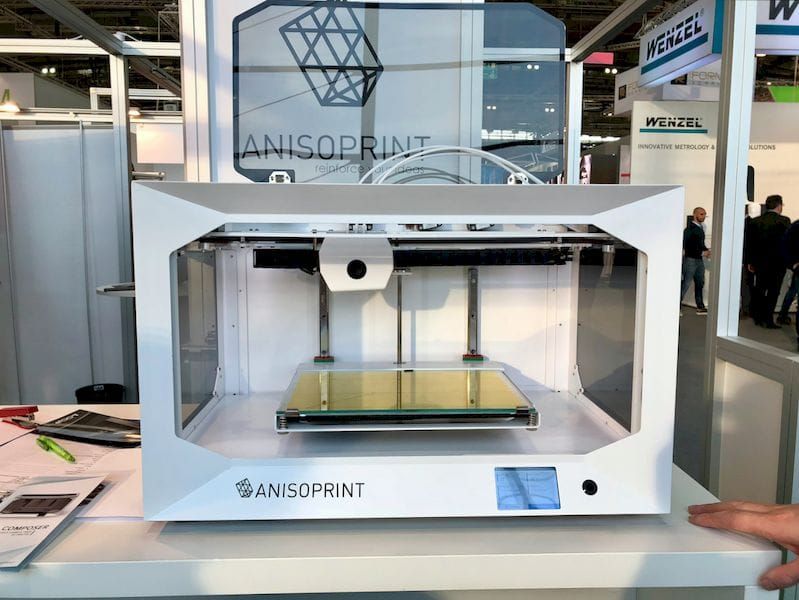

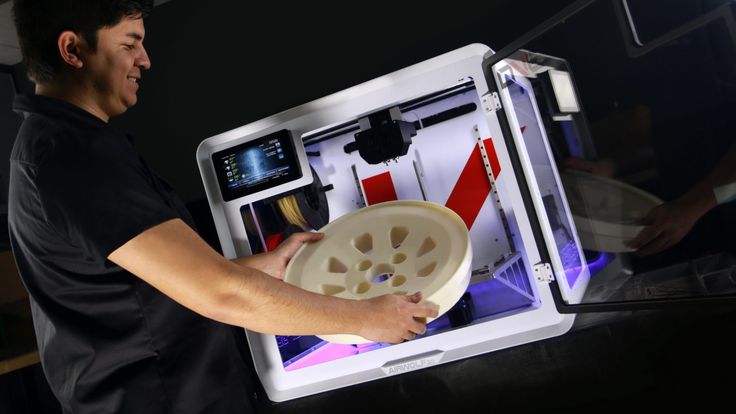

At the end of 2017, after two years of work, Anisoprint had a prototype of a new 3D printer model ready. It was first shown at the main 3D printing exhibition Formnext in Frankfurt in November 2017. After that, the company received the first pre-orders for its product.

Almost the whole of 2018 was spent on finalizing the prototype and launching mass production. At the same Frankfurt trade show at the end of 2018, Anisoprint officially started selling its device. The first batch of 30 printers was shipped to customers that same year. Investments in the development phase before the launch of mass production of the product amounted to approximately $ 700,000.

“The most difficult moment was the transition “from the laboratory to the market”: when it was necessary to stop designing and start selling. For us, it was a step into the absolute unknown. I had no business experience and no business education. And my whole team was also not commercial, but scientific and engineering. It's one thing when there is a prototype in the laboratory, and you "play" with it. And it’s quite another when you need to ship products to customers who have their own expectations and requirements,” Fedor Antonov admits.

For us, it was a step into the absolute unknown. I had no business experience and no business education. And my whole team was also not commercial, but scientific and engineering. It's one thing when there is a prototype in the laboratory, and you "play" with it. And it’s quite another when you need to ship products to customers who have their own expectations and requirements,” Fedor Antonov admits.

Not only 3 D - printers

Today Anisoprint offers three types of products: 3D printers, reinforcing fibers and software. The company does not sell plastic for the production of composites - its customers buy it themselves. The technology allows the use of different types of plastics as a binder.

When buying a printer, the package includes basic software and one reel of reinforcing fiber. During the printing process, it is applied together with plastic to form a composite. The program based on the 3D model allows you to create various types and trajectories of reinforcement (strengthening) of the material.

Anisoprint manufactures two desktop printer formats. One of them has an A4 size workspace and costs 12,000 euros. A larger printer with an A3 working area sells for 19,000 euros. Along with the printer, they often buy an additional set of fibers, spare printheads or other spare parts, as well as a training course on working with the device. In the future, customers turn to the company for new batches of reinforcing fiber.

“Now the main income comes from iron. But the bigger the customer base, the bigger the fiber sales will be. According to our plan, in a few years the sale of the material will account for half of the total revenue,” Fedor notes.

The company employs 17 people: 10 engineers, 2 marketing specialists, and an administrative team. Two employees are employed in production in Skolkovo.

Transfer of production abroad

Anisoprint produced the first batch of 15 printers in Russia. After that, it was decided to move production abroad. The main reason for this decision is the focus of the project on foreign markets. The company found a production facility in Germany, where they made several test samples, after which they signed a contract.

The main reason for this decision is the focus of the project on foreign markets. The company found a production facility in Germany, where they made several test samples, after which they signed a contract.

“To export something from Russia for export is long, expensive, difficult and unpredictable. There are many problems to be solved: customs, export permits, duties, etc. When we exported the first printers, there were so many headaches that we decided: we don’t want this anymore,” Fedor explains.

The contracting company Anisoprint is located in Bavaria, near the city of Augsburg. There they make a frame for the printer, perform final assembly, acceptance and packaging of products. Pilot production of printers, as well as the manufacture of printheads and fiber, remained in Skolkovo.

Applications

The main consumers of Anisoprint products are educational and research institutions: institutes, universities, laboratories. With the help of such printers, they conduct various studies. First of all, their work relates to the design of new composite materials.

With the help of such printers, they conduct various studies. First of all, their work relates to the design of new composite materials.

Also among the company's clients are research centers at large corporations. They are looking for opportunities and applications for anisoprinting technology in the future. For example, one of the buyers is the research center of the BMW automaker.

The founders of the Anisoprint project are confident that their technology will be in demand in aviation, space, and the automotive industry. With its help, you can make parts for aircraft or cars. But before the start of industrial use, anisoprinting technology, materials and equipment must be certified. This procedure is costly and time consuming.

“We offer one of the newest and most promising 3D printing technologies. It opens up many new possibilities. Many large companies understand this and invest in its research. And when they are convinced that there are areas of application and opportunities to benefit, they will be ready to invest in certification and bringing the technology to industrial use,” Fedor Antonov is sure.

It opens up many new possibilities. Many large companies understand this and invest in its research. And when they are convinced that there are areas of application and opportunities to benefit, they will be ready to invest in certification and bringing the technology to industrial use,” Fedor Antonov is sure.

Another market segment for Anisoprint products is the manufacture of parts for various tools. These are clamps, grips, clamps for welding, assembly, milling, as well as for automated lines. All these devices have one thing in common: they have a rather large load. 3D printing technology allows you to make them right on the spot - quickly, cheaply and with high precision. Certification is not required in this case.

End customers

Since the majority of clients represent the research and development segment, they have a good understanding of the technology for manufacturing high-strength composites and are able to work with the necessary equipment. There are not so many buyers without experience with 3D printers - they are mainly from the industrial sector. The company pays special attention to them: they train and help them get used to the equipment.

There are not so many buyers without experience with 3D printers - they are mainly from the industrial sector. The company pays special attention to them: they train and help them get used to the equipment.

“In inexperienced customers, we sometimes encounter inflated expectations regarding the capabilities of the technology. Many people think that a 3D printer is a miracle. You press the button and everything magically prints by itself. For some reason, when buying a milling machine, no one thinks so. But while we do not have so many clients, we manage to communicate with everyone. We train them, and they gradually start to succeed, ”says Fedor.

As with any new technology, Anisoprint's products sometimes had some minor technical hiccups. However, they were quickly eliminated. According to the founder of the project, there were no cases of serious complaints about the products or the return of purchases. At the same time, repeated orders have already met more than once. Some customers ordered one or more printers after purchasing one device.

Some customers ordered one or more printers after purchasing one device.

Sales through dealers

The main markets for Anisoprint are Germany and France. The company's products are also sold in England, Italy, the Scandinavian countries and Eastern Europe. In each of these countries or regions, the company has official distributors.

According to Fedor Antonov, for a project with an international market, this is the best way to organize sales. Its main advantage is the client base of each of the dealers. It is also important that distributors communicate with customers in the same language, understand their mentality and peculiarities, understand the regional specifics of their country. Sales in Russia are also conducted through distributors. This allows the company not to hire and train its own managers.

“With limited resources, expanding the staff is quite expensive. Moreover, sales in our field are quite long and complex: it usually takes from 3 to 9 to close a deal. months. Until a person learns to sell, it will take quite a long time. And distributors already know how to work with similar products,” says Fedor.

months. Until a person learns to sell, it will take quite a long time. And distributors already know how to work with similar products,” says Fedor.

However, there are also disadvantages in working through dealers. Not all of them know the product as well as the developers themselves. They are not always able to correctly explain to the client the benefits and values of Anisoprint products. Sometimes this leads to disruption of transactions and loss of customers.

“Another disadvantage is that dealers offer their customers not only our products. And they pay more attention to the most famous brands, which are the easiest to sell. As a rule, these are American brands investing millions in marketing. We are also trying to work on recognition, but it is still difficult for us to compete with the budgets of the Americans, ”adds Fedor.

Online and offline promotion

As with most innovative products, Anisoprint's main promotional channel is exhibitions. The project team travels to three or four major events in Europe. Small regional exhibitions are attended by distributors. They have demo printers that they show to potential customers.

The project team travels to three or four major events in Europe. Small regional exhibitions are attended by distributors. They have demo printers that they show to potential customers.

The company also uses all major online promotion channels, primarily content marketing and paid advertising in social networks and search engines. “In terms of customer acquisition cost, they are even more effective than exhibitions. But in our case, it is important to constantly “be in sight”. Exhibitions mean strengthening ties, searching for new partners, recognizing the brand in the market,” Fedor Antonov explains.

What's next

In 2019, about 70 Anisoprint devices were sold. The total revenue for the year is approaching $1 million. Almost all the money earned is invested in increasing production volumes. To scale the project, Fedor plans to attract investments. The investment is expected to pay off in about 3 years.

“With small business volumes, profitability indicators are much worse than with large ones. The sales volume is constantly growing, and the production cycle of printers is quite long - 3.5 months. To move to a new level, additional funding is needed. There are several options for a deal that can be closed at the beginning of 2020. All of them are connected with investments from abroad,” says Fedor Antonov.

The sales volume is constantly growing, and the production cycle of printers is quite long - 3.5 months. To move to a new level, additional funding is needed. There are several options for a deal that can be closed at the beginning of 2020. All of them are connected with investments from abroad,” says Fedor Antonov.

Why mass 3D printing is still not a trend

Photo: asharkyu / Shutterstock, Chris McGrath / Getty Images

The production of goods with individual characteristics is one of the trends in the consumer market. However, personification has not yet become a popular phenomenon. Is this idea promising for business development?

When there was an acute shortage of personal protective equipment (PPE) for doctors, the owners of 3D printers united in the volunteer movement #3Dfor doctors. They began to print adapters, which made it possible to connect diving masks with virus-bacterial filters. Manufacturers were able to quickly develop and release adapters in various configurations for popular types of masks found in stores, quickly covered burning needs and saved many lives - and then began to make full-fledged protective masks and shields.

Adapters for masks - example of a customized product (made to order. - RBC Trends ), that is, adapted to different types of masks. How quickly manufacturers were able to design and release a new product with unique characteristics demonstrates the main advantages of 3D printing.

3D printing allows you to create products based on the preferences or personal characteristics of the buyer - personalized goods. This idea arose in the early 2000s, but so far, contrary to forecasts and the rapid development of additive technologies, has not become a mass phenomenon.

Personalization challenges

Since 2012, Nike and Adidas have been experimenting with 3D printing in the production of sneakers. The goal is to create sports shoes in the presence of the buyer according to the individual characteristics of his foot. For example, Adidas announced in 2015 that a consumer could walk into a store, spend a couple of minutes on the treadmill, and immediately receive a printed pair of running shoes that take into account the contours of the foot and pressure points while running. At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

At the same time, Nike announced the possibility of printing shoes directly at the customer's home. To do this, you just need to download the file with the parameters of the sneakers and the characteristics of the foot from the corporation's website to your home 3D printer.

However, by 2020, these opportunities remained unrealized. In practice, everything turned out to be more difficult.

The point is the high cost of such products: the consumer is not ready to pay many times more for customized sneakers when you can choose the right model from thousands of more affordable options.

Customization does not take root among automakers either. For example, in 2017, BMW launched the MINI Yours Customized service, which allows you to customize a new or previously purchased MINI car using decorative elements printed on a 3D printer. For example, it was possible to order individual side body inserts, trim parts, LED door sills and LED door projectors. However, the service is currently unavailable.

However, the service is currently unavailable.

Where personification has taken root

So far, 3D printing is most actively used in medicine, where it is vital to take into account the individual characteristics of a person. First of all, the technology is useful in orthopedics and dentistry for the manufacture of prostheses and implants. Customization is especially in demand in the production of prosthetic limbs. With the help of 3D scanning, the parameters of the patient are determined, a digital model of the prosthesis is created, which is printed on a 3D printer. In this case, you can create a unique design of the artificial limb. For example, they produce children's prostheses stylized as favorite movie characters.

Another area where 3D printing is being used to customize products is in the jewelry and fashion jewelry industry. There are enterprises that produce mass products using 3D printing, for example, the American brands LACE, Nervous System and others. Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Customization is carried out, first of all, by small studios and workshops offering exclusive jewelry. They print digital models created according to customer sketches or cast them from precious materials using 3D printed molds.

Economics of innovation Living hand: who creates bionic prostheses in Russia

As for the majority of goods, the price works here in 99% of cases. Especially when the share of online sales is growing. You type in Google "buy a fountain pen is the cheapest" - and no matter where you are, you buy this fountain pen cheaper. This is where mass production wins.

You can think of many products that could be customized. But you need to be clear about who you will sell them to. Are there enough people willing to overpay for customization to keep your business alive? “In your calculations, you need to take into account real consumer demand, and not the desire to make money on hype,” says Vlasov. “The conclusion is simple: personalized production is possible when it will give approximately the same price as mass production. ”

”

Denis Alekseev, Head of R&D and Production at JSC ROBBO (educational robotics, Skolkovo resident), is sure that personalized production will become a popular trend of the future. But in order to attract the mass consumer to this segment, it is necessary to overcome a number of technical and organizational issues. For the end user, the process of ordering a customized product should be as simple as possible: with a few steps, order what he wants, while receiving the finished product quickly and conveniently. The cost of individual products may be higher, but this increase must be of value to the customer.

Main disadvantages of 3D printing:

-

low production rate;

-

often low quality products;

-

high cost of the product when trying to mass production.

How to reduce the cost of a customized product?

The cost of the finished product primarily depends on the materials for 3D printing. One way to cut costs is to produce consumables yourself.

Another option to reduce the cost of consumables is possible with the development of additive technologies and the development of new printing materials.

The main question is: who will buy it?

Entrepreneurs who will find the answer to the question: who will buy them will be able to develop the production of personalized goods? Businesses that already operate in a particular market and feel the needs of their audience can feel the demand. It is almost impossible to guess - you need to be sure of the demand.

Artur Gerasimov notes that small-scale production is promising for business development using additive technologies. One of the areas of work of his company Innovax is the production of parts and mechanisms by order of industrial enterprises from the automotive industry, instrument making, and the aerospace industry.