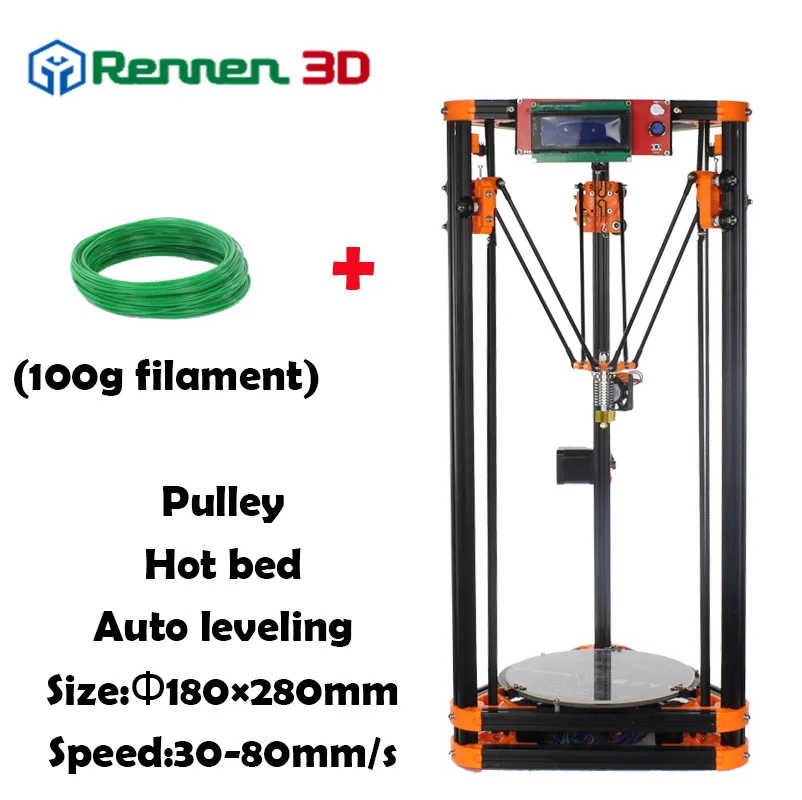

Mp delta pro 3d printer

Monoprice Delta Pro Fully Assembled 3D Printer

- Home

- Store

- Monoprice Delta Pro Fully Assembled 3D Printer

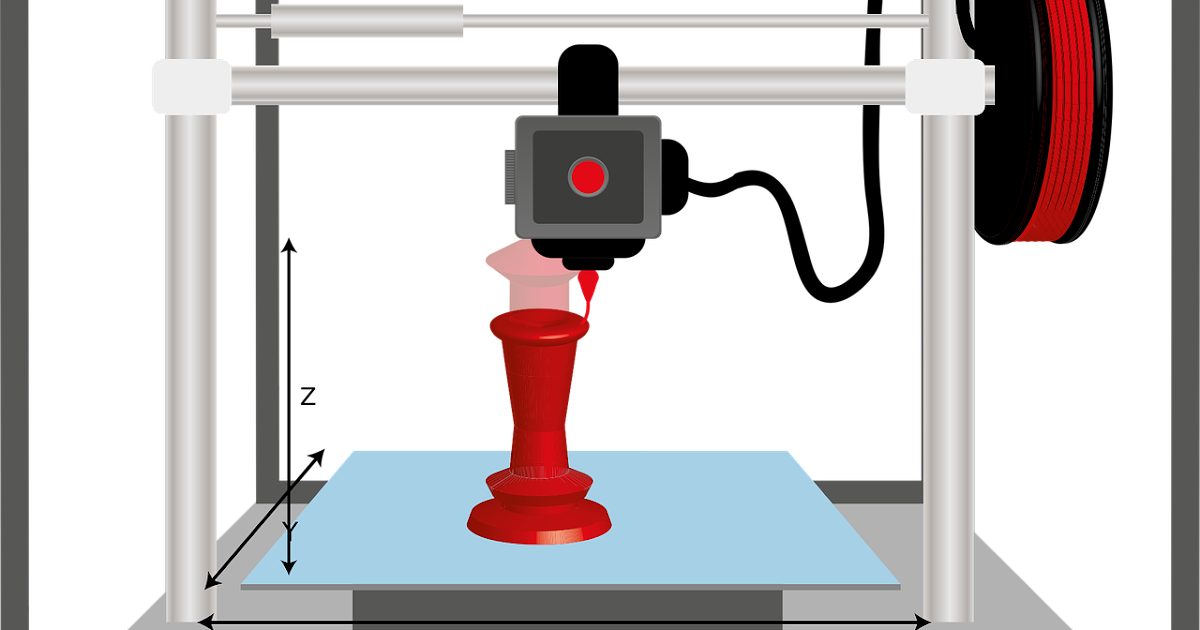

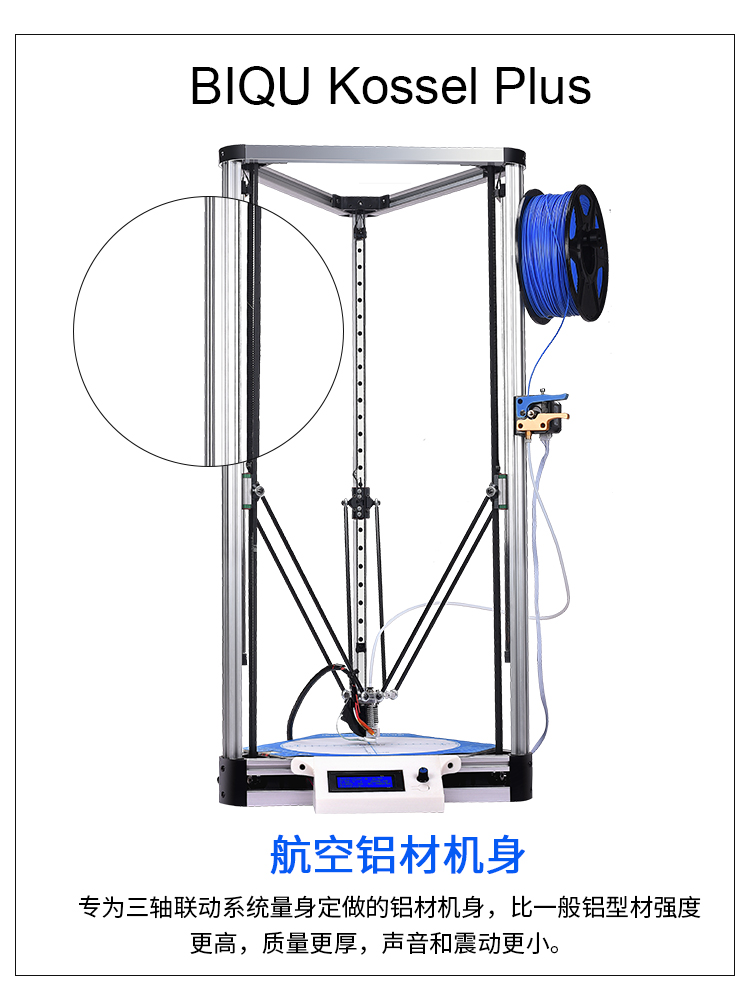

The Monoprice Delta Pro Fully Assembled 3D Printer is a simple, powerful, and robust 3D printer designed for the enthusiast and professional user alike. Constructed from high quality Japanese and German components and loaded with design features accessible on its easy to navigate touchscreen interface, the Delta Pro is built with long term reliability and accuracy in mind.

Remove from wishlist Add to wishlist loading...

Product No. M-U93-NGPW

| List Price: | $1,199.99 |

|---|---|

FEATURES

- Low filament sensor : automatic pauses to reload filament in mid print

- Glass fiber effector arms

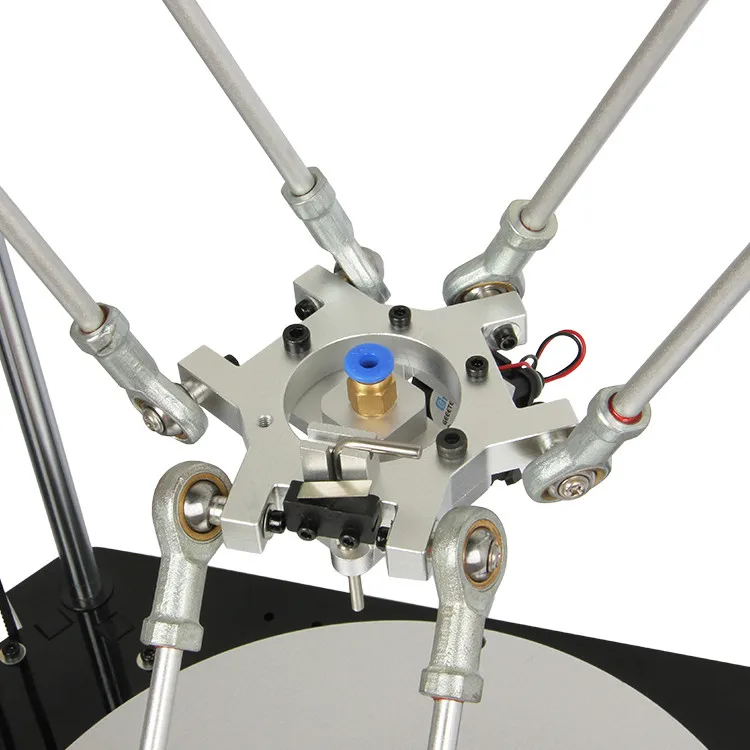

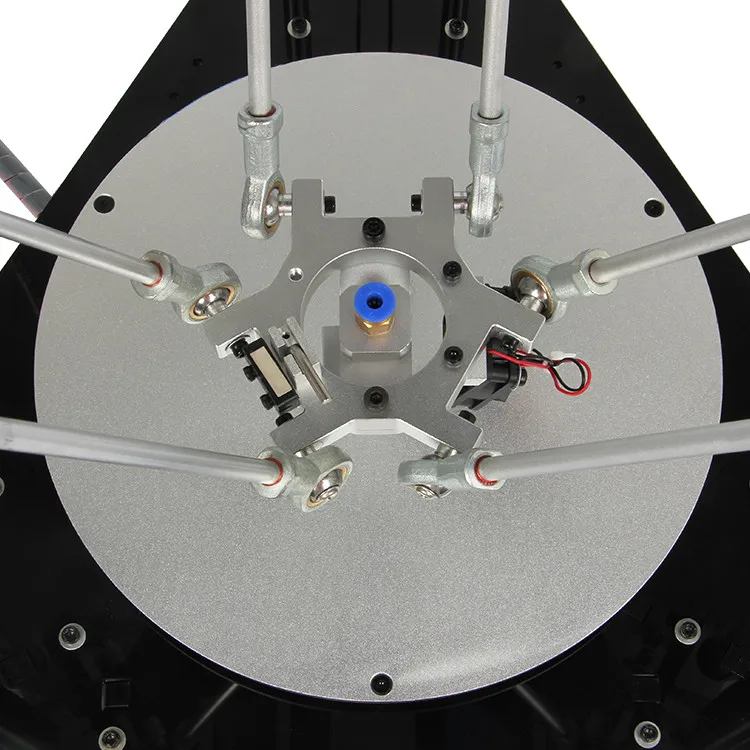

- Includes 2 PTFE-Lined Hotends & 1 Full metal hot end

- Magnetic effector plate

- Solid metal frame

- Extra large build volume

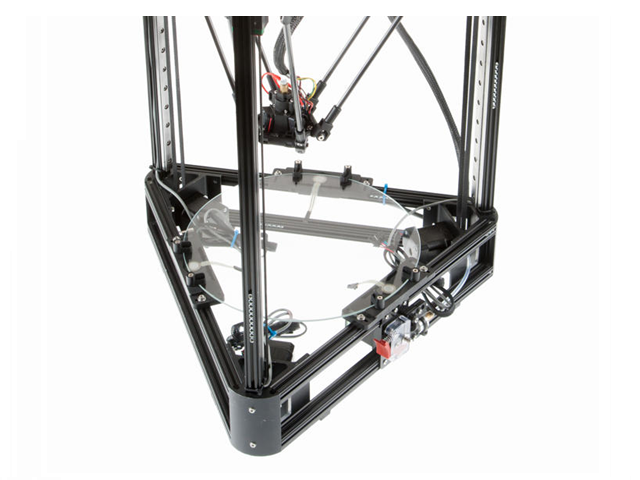

- Heated and tempered glass bed

- 3.

5" color touchscreen

- Fully assembled

- Quiet performance (producing only 50dB of noise)

MAXIMIZE YOUR PRINTERS UP TIME:

Auto bed leveling and PID tuning --- Spend less time getting the perfect print started, Monoprice MP Delta pro includes the new auto bed leveling system with Live Z adjustment feature allowing you to refine your first layer. Delta Pro has functionally built-in PID and requires no external hardware or software. Maintain consistent temperature with the PID tuning.

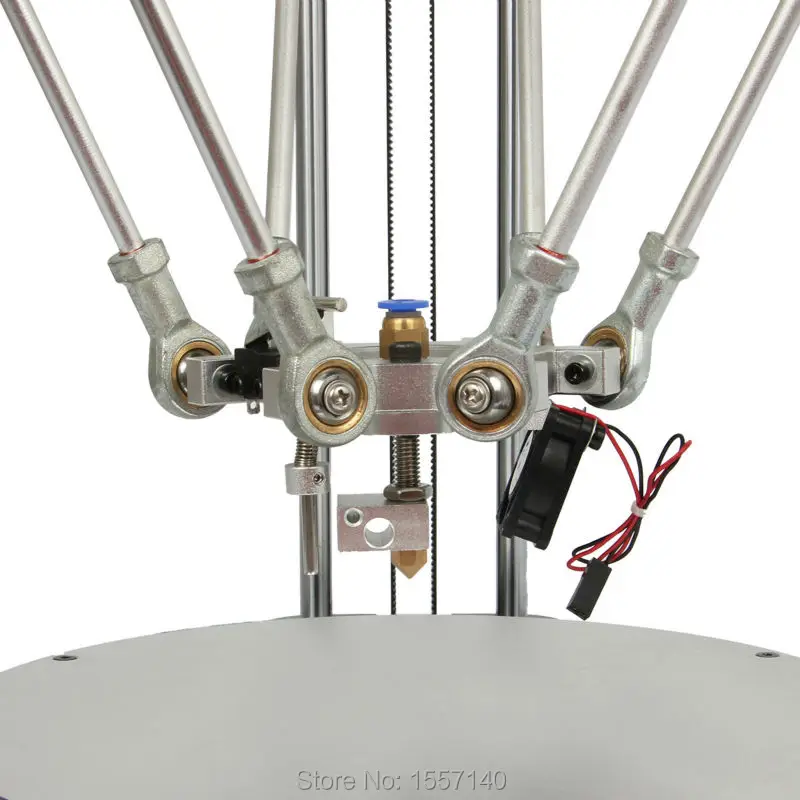

DOUBLE FAN COOLING SYSTEM:

Monoprice MP Delta Pro boasts double fan cooling systems surrounding the hotend. Stabilize and maintain hotend temperatures with one fan while the other provides accelerated filament cooling to allow extreme overhangs and bridges to print with minimal to no supports.

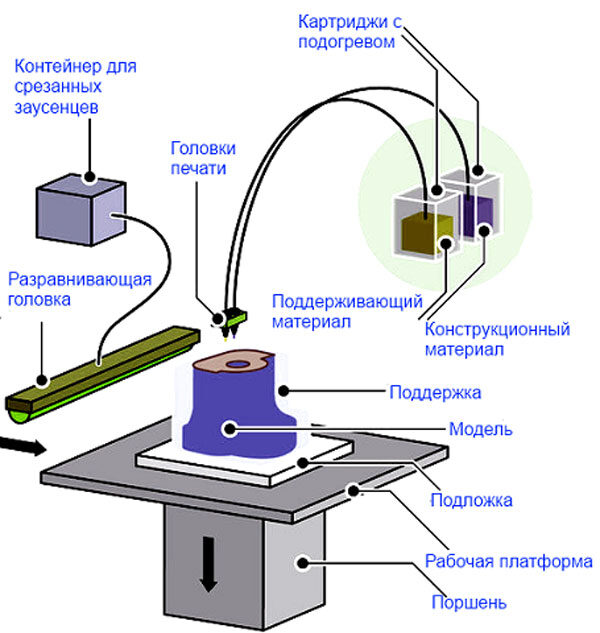

“SIMPLE-SWAP” HOTEND MAKES MULTI-MATERIAL PRINTING AN EASE:

Take full advantage of simple-swap hotend feature to fit your printing needs. Capable of switching out different nozzle sizes, nozzle types, or switching to full metal hotend. Simply loosen the screws and unplug the hotend to swap it out!

Simply loosen the screws and unplug the hotend to swap it out!

SUPER SIZE YOUR PRINTS WITH AN EXTRA-LARGE GLASS BED:

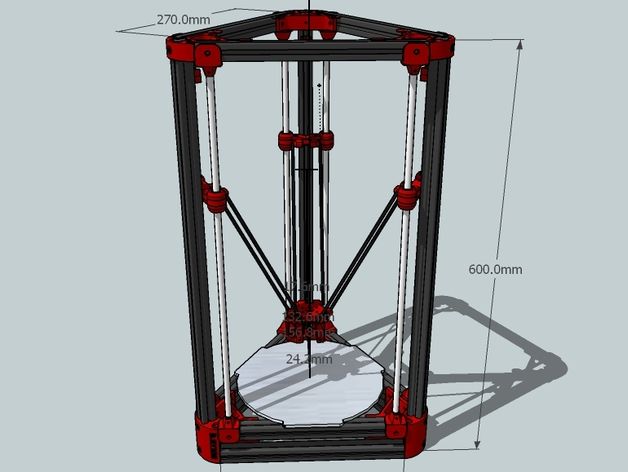

3D print full models with ease! Avoid 3D printing in parts and assembling afterwards, Monoprice Delta Pro saves time, material, and cost with the 270 x 300mm build volume. Glass plate allows simple and easy removal and cleaning.

TECHNICAL SPECS

Build area: 270 x 300mm

Build platform: Heated glass

Extrusion: 1

Nozzle material: Brass

Max nozzle temp: 310°C

Max bed temp: 100°C

Material Support: PLA, ABS, PETG, NYLON

Filament size: 1.75mm

Printing speed: Up to 150 mm/sec

Print cooling: Two part-cooling fans

On-board calibration: Automatic bed leveling and PID

Operating system compatibility: Windows® 10, Mac® OS X®, Web

Supported slicing software: KISSlicer, Cura, Simplify 3D

Interface: Touchscreen, Wi-Fi, USB

Monoprice Delta Pro Review: Everything You Want And More

DT Recommended Product

“The Delta Pro is the Rolls Royce of 3D printers: it’s luxurious as hell but doesn’t drive any better than the competition.”

Pros

- Sturdy construction

- Convenient features

- Large build area

- Reliable print quality

Cons

- Expensive

- Mediocre max resolution

Over the past few years, Monoprice has made a name for itself as the premier purveyor of budget-friendly 3D printers, but its latest printer — the Delta Pro — seems to be a step in a different direction. Unlike the rest of Monoprice’s machines (all of which are priced under $500), this one costs a whopping 1,500 bucks.

Contents

- Standout features and specs

- Setup and configuration

- Design and build quality

- User interface and software

- Print performance

- Our Take

To see if this printer’s high-end features are worth that premium price tag, we put it through its paces for a couple weeks. Here’s how it went.

Here’s how it went.

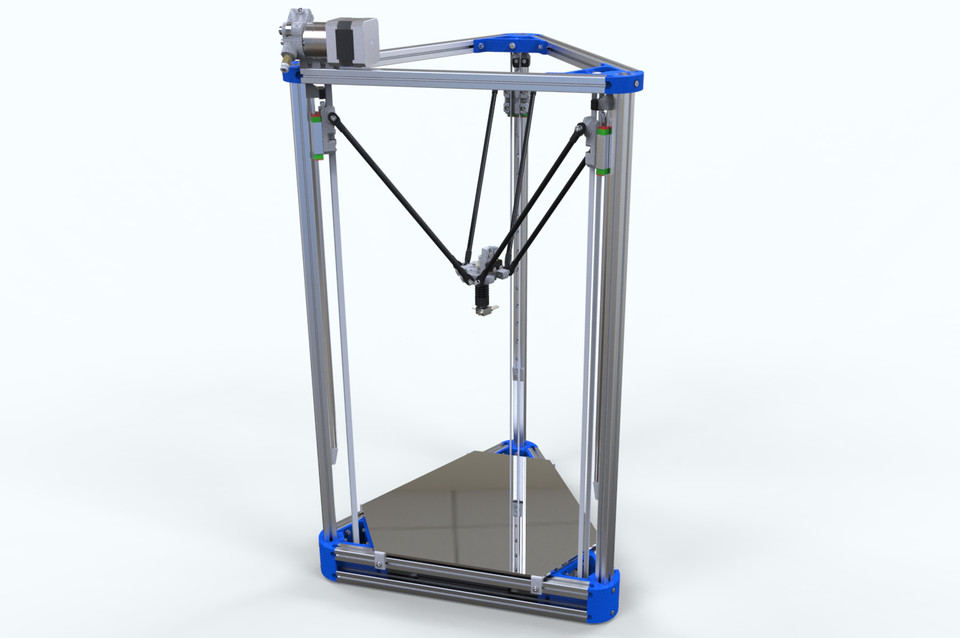

The first thing you’ll notice about this printer is just how big it is. Standing about 3 feet tall and roughly 1.5 feet wide, it’s a pretty sizable machine. The good news, though, is that this beefy skeleton allows a fairly generous build area to sit nestled inside of the printer’s frame. The Delta Pro boasts a build area that’s 300mm tall (exactly 12 inches) and 270mm in diameter. For most users, that’s more than enough room to play with.

Dan Baker/Digital TrendsIn addition to its expansive build envelope, the Delta Pro is outfitted with all the requisite 3D-printing staples that we’ve come to expect on anything with “pro” in the name — things like a heated bed, all-metal construction, auto-leveling functionality, and a 3.5-inch touchscreen LCD interface.

Thing is, all that stuff is par for the course these days. You can find most of the aforementioned features in Monoprice’s $160 Mini Delta, so to make the Pro a bit more special, MP also outfitted it with a handful of innovative new features that you don’t usually see in 3D printers.

Even with the oddball auto-leveling, the Delta Pro is a breeze to set up.

For example, this sucker comes equipped with a low-filament sensor that will automatically pause your print when you run out of plastic, then wait until you load a new spool to resume. It also has swappable hot ends, cooling fans that allow you to print more drastic overhangs, and (our personal favorite) whisper-quiet motors.

All things considered, this machine has all the bells and whistles you could ever want in a 3D printer — and then some.

Setup and configurationIf you pony up the $1,500 to get yourself one of these printers, you’ll be pleased to know that the Delta Pro comes fully assembled and factory calibrated. In other words, you can start using it almost immediately after you free it from its packaging.

Dan Baker/Digital TrendsThe only thing you need to do before printing is load up some filament and run the printer’s auto-leveling sequence. The former is pretty straightforward — just heat up the hot end and run some plastic through the extruder. The latter step, however, isn’t quite as easy. Before you perform the auto-leveling sequence, you’ll need to attach an odd little sensor to the hot end so that it can sense when its touching the build plate. After that, you’re free to initiate the auto-level process and, when it’s complete, you can remove the sensor. It’s not particularly difficult, but it is a fairly unorthodox process — one that’s likely unfamiliar to even the most seasoned 3D-printing enthusiast.

The latter step, however, isn’t quite as easy. Before you perform the auto-leveling sequence, you’ll need to attach an odd little sensor to the hot end so that it can sense when its touching the build plate. After that, you’re free to initiate the auto-level process and, when it’s complete, you can remove the sensor. It’s not particularly difficult, but it is a fairly unorthodox process — one that’s likely unfamiliar to even the most seasoned 3D-printing enthusiast.

Still, even with the oddball auto-leveling, the Monoprice Delta Pro is a breeze to set up. If you can set the clock on your microwave, you can probably configure this machine.

Design and build qualityWhile Monoprice is typically known for selling lower-end electronics in most categories, its 3D printers are a notable exception — and nothing exemplifies this better than the Delta Pro. Simply put, this machine is so well-built that it feels more like an appliance than a 3D printer. Here’s why:

Monoprice has simplified the Delta Pro’s UI so much that initiating a print is no more complex than brewing a pot of coffee.

First of all, it looks great. 3D printers typically put function before form and, as a result, often look very ugly and utilitarian. The Delta Pro, however, is fairly attractive. With its sleek, angular frame, hidden motors, and matte black finish; it’s arguably one of the most aesthetically pleasing 3D printers on the market right now. In other words, you don’t necessarily have to hide this machine in your garage or workshop. We dare say it wouldn’t look out of place in your living room.

Second of all, it’s whisper-quiet and can run in the background without you noticing. Unlike most other printers (which almost always emit an annoying, arrhythmic whine as their motors move the print nozzle to and fro), the Delta Pro is equipped with MP’s “silent drive” technology, which keeps it under 50 decibels no matter what settings you run it at. For context, that’s quieter than normal conversation.

Honestly, I didn’t expect quiet printing to be a standout feature on this printer — but now that I’ve experienced it, I’m not sure I can ever go back. Normally, when I test 3D printers here at Digital Trends, I have to isolate them. I can’t put them at my desk because they’d annoy the hell out of everyone in the bullpen — especially my cubicle neighbor Ryan Waniata, who reviews headphones for a living and could probably hear a mouse fart in the middle of a rock concert. With this printer, I can actually use it at my workspace without driving anyone (myself included) insane. There’s something to be said for that.

Normally, when I test 3D printers here at Digital Trends, I have to isolate them. I can’t put them at my desk because they’d annoy the hell out of everyone in the bullpen — especially my cubicle neighbor Ryan Waniata, who reviews headphones for a living and could probably hear a mouse fart in the middle of a rock concert. With this printer, I can actually use it at my workspace without driving anyone (myself included) insane. There’s something to be said for that.

Lastly, it’s also super-easy and approachable to use. Once it’s all set up, you don’t really need a bunch of specialized knowledge in order to run the machine. Monoprice has simplified the Delta Pro’s UI so much that initiating a print is no more complex than brewing a pot of coffee.

User interface and softwareThe Delta Pro’s onboard UI is pretty great. Despite the fact that this printer has a boatload of different functions and settings for you to fiddle with, Monoprice manages to make navigating between all of them a breeze. Instead of knobs or buttons, you interact with the machine by tapping icons on the printer’s 3.5-inch touchscreen LCD panel, which gives it a very modern yet familiar feel. It’s a lot like using a smartphone: As soon as you figure out what all the icons do when you touch them, you’re basically an expert.

Instead of knobs or buttons, you interact with the machine by tapping icons on the printer’s 3.5-inch touchscreen LCD panel, which gives it a very modern yet familiar feel. It’s a lot like using a smartphone: As soon as you figure out what all the icons do when you touch them, you’re basically an expert.

Getting acquainted does take a minute or two. Monoprice has made a valiant effort to design icons that clearly communicate their purpose to the user, but some of them aren’t particularly obvious

Dan Baker/Digital TrendsThe ancillary software, however, is a bit trickier to get the hang of. As with all of its 3D printers, Monoprice’s Delta Pro doesn’t come bundled with a proprietary slicer program. Instead, it’s designed to work with a broad range of third-party software, including industry standbys like Cura, Kisslicer, and Repetier. The downside of this approach is that, since none of these slicers are built to work specifically with the Delta Pro, the setup process can be a bit daunting for new users. Hell, I review 3D printers for a living and it took me a few minutes to figure out how to configure my slicer properly.

Hell, I review 3D printers for a living and it took me a few minutes to figure out how to configure my slicer properly.

The upside, however, is that you’re also not stuck with a crappy proprietary slicer and can use tried-and-true programs like Cura — many of which have been carefully refined over the years to accommodate both novice and expert users alike.

Print performanceUnfortunately, the only area where the Delta Pro doesn’t quite live up to its name is print performance. Don’t get us wrong — it’s definitely not a bad printer in terms of performance. In fact, it’s quite good. The issue is that, despite costing three times as much as the Monoprice Maker Select Plus, it prints only marginally better. In some regards, we didn’t even notice a difference.

Our only gripe is that the Delta Pro’s maximum print resolution isn’t anything to write home about.

Still, there are a lot of things to like about this printer. For starters, it’s very consistent. The machine’s sturdy construction and delta-style configuration give it the advantage of not being quite as prone to Z-axis wobbling, which ultimately means it prints very reliably from one layer to the next. Most of our test prints were free of burrs, banding, aberrations, and other printing artifacts cause by instability.

The machine’s sturdy construction and delta-style configuration give it the advantage of not being quite as prone to Z-axis wobbling, which ultimately means it prints very reliably from one layer to the next. Most of our test prints were free of burrs, banding, aberrations, and other printing artifacts cause by instability.

The Delta Pro is also pretty damn good at handling tricky print elements like steep overhangs and unsupported spans. This is likely due to the printer’s fans, which allow it to control the temperature of the extruded plastic and cool it down quickly. Functionally, this allows you to print a wider range of objects without using supports, which saves you both time and plastic.

Let’s not forget about the huge build area, either. With a full foot of clearance on the Z-axis and over 10.6 inches on X and Y, you’re free to print just about anything you want — oftentimes in a single piece. Gone are the days of printing large objects by breaking them down into a series of smaller pieces, which is one of the most annoying parts of owning a printer with a small build envelope. Bigger is most definitely better, and we had a ton of fun printing giant vases and architectural models just because we could.

Bigger is most definitely better, and we had a ton of fun printing giant vases and architectural models just because we could.

The Delta Pro also scores high marks for reliability, but there’s a catch. This machine comes with a heated bed and a glass build plate. The heated bed helps prevent warping and mitigate the issue of prints breaking free from the build plate mid-print — but the smooth glass plate isn’t ideal for print adhesion. You have to use something like painter’s tape, stick glue, or hairspray in order to get your print to stick. So while it does print reliably, it’s worth mentioning that this reliability can only be attained through modification.

Really, our only gripe is that the Delta Pro’s maximum print resolution isn’t anything to write home about. It’s mediocre at best, and actually pales in comparison to many of the low-cost resin printers that have sprung up over the past couple years.

All things considered, this is still an excellent printer in terms of print performance. You just don’t get much bang for your buck when it comes to resolution.

You just don’t get much bang for your buck when it comes to resolution.

Our Take

This is a great printer. In fact, it’s one of our new favorites. Between the silent drive technology, the big build area, and the attractive looks, there’s a lot to like here.

At the end of the day, though, these are definitely luxury features. They’re nice to have, but you don’t necessarily need them — which makes it difficult to justify the Delta Pro’s $1,500 price tag.

Is there a better alternative?You’ll be hard-pressed to find a more affordable printer that offers so many high-end features and such a large build envelope. But if you aren’t looking for luxury, the Delta Pro might not be the best option.

If your main concern is getting the most bang for your buck, you can definitely find cheaper FDM printers that offer comparable print performance. In fact, Monoprice’s own Maker Select Plus offers many of the same features that the Delta Pro does, yet costs less than $400. If you don’t need luxury features like filament sensing and silent drive, you’d be wise to consider it.

If you don’t need luxury features like filament sensing and silent drive, you’d be wise to consider it.

If your main concern is print quality and resolution, we suggest looking into SLA/DLP printers. These machines use a different printing technique, and are typically capable of reproducing far greater detail. The Form 2 ($3,200) is the gold standard in this category — but luckily a handful of more budget-friendly competitors have sprung up in the past year. For $1,500, you could easily find a great resin printer, such as the Peopoly Moai or the Anycubic Photon. Be warned though: Working with resin is far messier than working with plastic filament.

How long will it last?Years. If properly maintained, there’s no reason this printer can’t keep on ticking for the better part of the next decade.

Should you buy it?Yes. Just keep in mind that the extra money you’re spending here doesn’t get you huge gains in print performance — it mostly gets you luxury features that are really nice to have, but not essential.

Editors' Recommendations

- What is ChatGPT Pro? Everything we know about its response to capacity issues

- Mac Pro 2023: performance, a familiar design, new displays, and more

- A key question for the Mac Pro has been answered — and it’s not good news

- HP Dragonfly Pro vs. Apple MacBook Pro 14: a solid alternative?

- Here’s why people are saying to avoid the entry-level M2 Pro MacBook Pro

Equipment - Regional Engineering Center

Industrial Plant ConceptLaserMLabcusing

Concept Laser Mlab is a production plant that uses selective laser melting technology under the brand name of equipment manufacturer LaserCUSING. Reactive and non-reactive metal powders are used as consumables. It is possible to use titanium and its alloys as consumables.

Carima dp110 3D printer

Production of high-precision prototypes, master models for casting, production of exclusive models, development of prototypes and working samples, templates, cases of individual devices, works with various types of materials: model materials, hot and cold molding materials, casting materials according to melted and burnt out forms. layer thickness: from 0.015 - to 0.2 mm.

layer thickness: from 0.015 - to 0.2 mm.

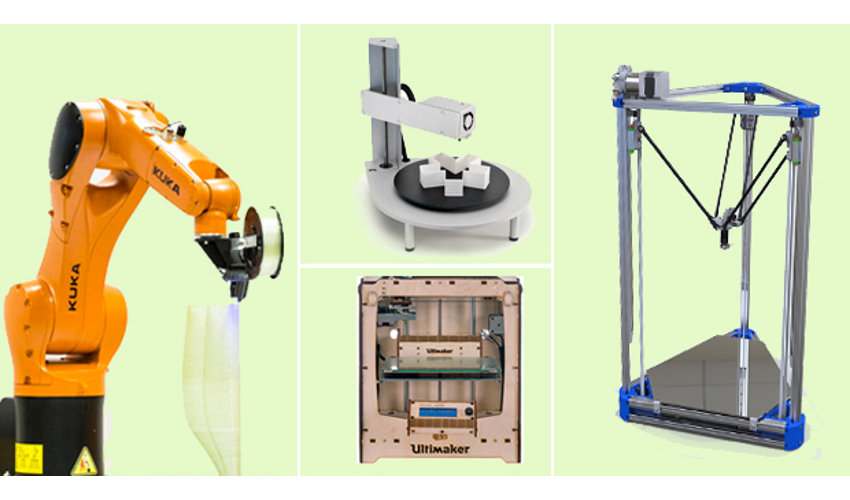

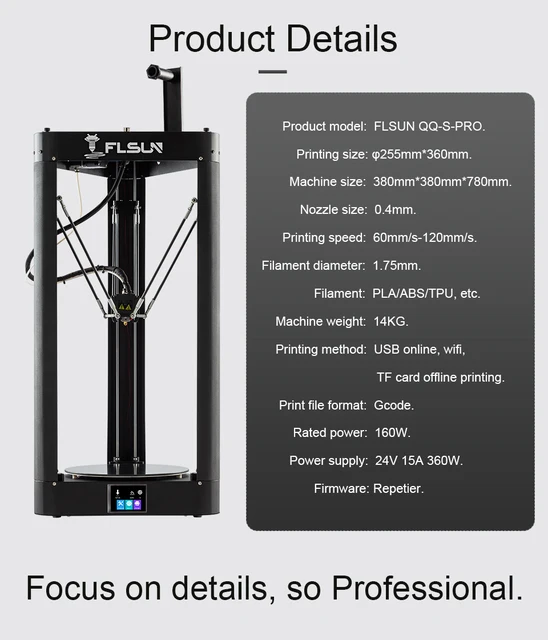

Delta Prism PRO 3D Printer

Professional level FDM printer based on the delta robot design. The main advantage of delta robot based 3D printers is the speed of 3D printing. The speed of building a 3D model is 25-30% higher. Prism PRO is equipped with a closed housing and a heated work surface, which allows you to print with all available consumables (PLA, ABS, PVA, Rubber, HIPS and others). Superior 3D printing quality - 50 microns (0.05 mm) allows you to print 3D models with high detail and quality. nine0005

Delta Prism Mini 3D Printer

Professional level FDM printer based on the delta robot design. The main advantage of delta robot based 3D printers is the speed of 3D printing. The speed of building a 3D model is 25-30% higher. Prism mini is equipped with a heated work surface, which allows you to print with all available consumables (PLA, ABS, PVA, Rubber, HIPS and others). Superior 3D printing quality - 50 microns (0. 05 mm) allows you to print 3D models with high detail and quality. Print area: 150 x 150 x 230.

05 mm) allows you to print 3D models with high detail and quality. Print area: 150 x 150 x 230.

Formlabs Form 2 3D Printer

Formlabs Form 2 3D Printer is Formlabs' latest 3D printer with 40% more printable area, touch screen controls, Wi-Fi connectivity. The Form 2 pushes the boundaries of what's possible in stereolithography. Laser stereolithographic printing makes it possible to achieve a resolution unattainable for the vast majority of printers using the layer-by-layer fusing method: the layer thickness is only 25 microns. The construction area of FORM 2 is 145x145x175 mm. The device is equipped with a system for supplying photopolymer resin through cartridges. nine0005

Picaso Designer 3D printer

PICASO 3D Designer is a 3D printer from PICASO 3D. This easy-to-use device allows you to create real objects using industrial ABS plastic and environmentally friendly PLA plastic based on a virtual 3D model. The high level of security, compact size, and professional print quality allow you to use PICASO 3D Designer at home and in the office and get good results.

PrintBox 270 3D printer

High precision for FDM printers in PrintBox3D is combined with a robust and reliable housing based on an aluminum frame. Allows you to print equally well as PLA or ABS, and flexible plastics such as FLEX, RUBER. The new extruder is equipped with a more efficient cooling system, its body is significantly lighter, which reduces the inertia of the extruder when printing at high speeds. The Printbox3D 270 is equipped with trapezoidal screws to move the print platform along the Z-axis (vertically). The new printer is equipped with a non-contact inductive sensor along the Z axis, which improves the positioning accuracy of the printing platform along the Z axis. An advanced expansion power board responsible for the functioning of the heaters and an autonomous control system. Maximum dimensions of the model, mm: 270x250x240. nine0005

PrintBox One 3D printer

PrintBox3D One is a new Russian 3D printer designed with the participation of the best CNC engineers. Thanks to this, the printing accuracy reaches 50 microns! Due to the high precision of the mechanics, the presence of three fans for blowing and the operation of the software, it is possible to print models with elements hanging in the air without using supports for them. High precision for FDM-class printers in PrintBox3D is combined with a durable and reliable housing based on an aluminum frame. Maximum dimensions of the model, mm: 185x160x150. nine0005

Thanks to this, the printing accuracy reaches 50 microns! Due to the high precision of the mechanics, the presence of three fans for blowing and the operation of the software, it is possible to print models with elements hanging in the air without using supports for them. High precision for FDM-class printers in PrintBox3D is combined with a durable and reliable housing based on an aluminum frame. Maximum dimensions of the model, mm: 185x160x150. nine0005

3D Printer PrintBox3D White

Thanks to the use of the Nema 11 stepper motor with a planetary gearbox, the plastic feed became smoother. The extruder body is still made of aluminum milled parts. The plastic feed is carried out by two combined knurled gears, which gave a stable and efficient feed. To clean the extruder, there is no longer any need for the laborious process of disassembling its body - now it is enough to unscrew one clamping screw and move the lever to the right, which provides full access to both gears and the filament hole. The print platform is made of 2mm aluminum and is perforated to reduce thermal distortion when heated, and has a maximum heating temperature of 140 degrees Celsius. nine0005

The print platform is made of 2mm aluminum and is perforated to reduce thermal distortion when heated, and has a maximum heating temperature of 140 degrees Celsius. nine0005

XFab 3D Printer

The XFAB is an innovative desktop 3D printer featuring the same technology as DigitalWax professional printers. XFAB is ideal for prototyping in industrial design, education and manufacturing environments. XFAB uses a wide range of 3D printing materials designed specifically for industrial applications, jewelry, prototypes and the dental sector.

These include acrylic resins; ABS-like and polypropylene-like materials; transparent, flexible and rubber-like materials; biocompatible, nanoceramic and wax-like materials. nine0005

RangeVision Spectrum 3D Scanner

RangeVision Spectrum is the latest high resolution 3D scanner with structured illumination technology. This 3D scanner has incorporated the specifications of professional 3D hardware but remains an affordable desktop solution. The scanner has 3 scanning areas, as well as 3.1 megapixel high-resolution color cameras. Included with the scanner are a turntable and a case for even greater convenience in work. This scanner is versatile and allows you to capture even complex geometry and fine details, while maintaining high resolution and accuracy. nine0005

The scanner has 3 scanning areas, as well as 3.1 megapixel high-resolution color cameras. Included with the scanner are a turntable and a case for even greater convenience in work. This scanner is versatile and allows you to capture even complex geometry and fine details, while maintaining high resolution and accuracy. nine0005

Sense 3D Scanner

3D Systems Sense is a handheld 3D scanner designed to be used in combination with Cube 3D printers. The design of the scanner is aimed at maximum convenience and ease of use, coupled with high flexibility in terms of the size of the scanned objects, reaching 3x3x3m. The scanner has automatic settings for handling small, medium and large objects. Digitized models are provided as STL and PLY files. Data transfer is carried out via a cable USB connection. nine0005

RJ 1060 laser engraving machine

The RJ 1060 laser cutting and engraving machine has a 1000×600 mm through table. Existence of a through table allows to carry out a drawing and processing of sheet materials up to one meter wide. In addition, the equipment is equipped with a working table lifting mechanism, the lowering depth of which is 200 mm. Inside the case itself there is an internal illumination of the working area and a tinted protective glass. The blanks for cutting are placed on lamellas, which can be replaced with a honeycomb cover. Yongli R3 laser tube comes standard with 80-9 power0 W and a service life of up to 7500 hours. The machine cuts wood materials up to 8 mm thick and plastics up to 15 mm thick. The machine does not work with metal materials and PVC. The machine engraves on materials up to 18 cm thick. For engraving on cylindrical products, a rotary device is additionally installed on the machine.

In addition, the equipment is equipped with a working table lifting mechanism, the lowering depth of which is 200 mm. Inside the case itself there is an internal illumination of the working area and a tinted protective glass. The blanks for cutting are placed on lamellas, which can be replaced with a honeycomb cover. Yongli R3 laser tube comes standard with 80-9 power0 W and a service life of up to 7500 hours. The machine cuts wood materials up to 8 mm thick and plastics up to 15 mm thick. The machine does not work with metal materials and PVC. The machine engraves on materials up to 18 cm thick. For engraving on cylindrical products, a rotary device is additionally installed on the machine.

Vicsign cutter

Automatic contour detection with optical sensor; Precise contour cutting; Independent work without a computer; High power allows cutting thick reflective film; High-speed 32-bit processor based on ARM Cortex-M3 core; Support for operating systems Windows XP, Windows Vista, Windows 7 32-bit, Windows 7 64-bit, Windows 10; LCD display and ergonomic silica gel control buttons. nine0005

nine0005

3D scanner David Structured Light Scaner SLS-1

David SLS-1 is a stationary projector 3D scanner for digital processing of objects ranging in size from 10 to 600mm. The device allows to obtain color models with high accuracy: the error does not exceed 0.2% of the size of a real object. The scanning time is about 2-4 seconds.

MakerBot Digitzer 3D Scanner

Makerbot Digitzer is an innovative 3-D scanner developed by American engineers and is considered to be the new quality standard in 3-D modeling. The software guarantees the creation of the most homogeneous models with accurate relief and geometry transfer, completely ready for further 3-D printing. nine0076

The 3D printer contains high-speed working parts, so be careful

Please use the 3D printer in an open and well ventilated area.

Please keep the 3D printer away from water.

Recommended temperature for using the 3D printer: 8℃~40℃, humidity 20%~50%, exceeding the allowable range may cause poor printing results. nine0076

nine0076

In the event of an emergency, unplug the printer to directly turn off the power of the 3D printer.

Package Layout Card

- Please check the details according to the list above.

- Find the Memory_card, copy the software and instruction files from the card to the computer, assemble and use the 3D printer according to the instructions. files.

- If you have any questions, please contact us for technical support. nine0132

Check before starting

You must level the print platform for the first time before printing.

Leveling Instruction T1

Note:

- You must level the print platform for the first time before printing.

- Please clean the nozzle before leveling, make sure there are no other material residues.

- For easy adjustment of the gap between the extruder head and the print bed, use A4 paper to drag them between them in a smooth motion.

nine0132

nine0132

Step 1 Smart Leveling

Look at the LCD, enter the menu, and then select "Setup" -> "Smart Leveling". At each breakpoint, use the rotary knob to reduce the gap between the extruder head and paper.

Use the rotary knob to adjust the gap between the extruder head and the paper.

Step 2. Confirmation

Select test file in Memory_card to start print simulation. Pay attention to the gap between the nozzle and the plate when working, the "return bottom" should be pressed when the gap between the nozzle and the greenhouse is too small or too large. Then adjust the z-height using the rotary knob to select "Adjust" -> "Z-height".

Customer advice

Dear customer!

First of all, thank you for purchasing this product. To make it easier for you to install and use our products, here are some tips that may help you. nine0005

- Before installation, check that all parts are in good condition and free from shipping damage.

Learn more