World first 3d printed building

Dubai is now home to the world’s first 3D-printed commercial building

Dubai Future Foundation (DFF) achieved a Guinness World Records title for the world’s first 3D-printed commercial building in Dubai, United Arab Emirates.

This further establishes UAE as a record-breaking country with over 400 records to date.

The building measured at 6m (20 feet) high, 36.57 m (120 feet) long, and 12.19m (40 feet) wide and was created with just one 3D printer.

The building took 17 days to print and 3 months to build and adjust the interior design. The building required 50 percent less manpower to complete when compared to traditional methods of building.

Advertisements

Furthermore, printing the building produced 60 percent less construction waste.

The record-breaking office is now home to the Dubai Future Academy (DFAc), a knowledge hub that aims to train and prepare new generations that can master emerging technologies.

This all falls under the Dubai government vision of becoming the world’s most innovative city by 2021.

Advertisements

The achievement was celebrated with a ceremony held at Emirates Towers in Dubai attended by His Excellency Khalfan Belhoul, CEO of Dubai Future Foundation and Talal Omar, Director – MENA at Guinness World Records alongside many employees from the foundation.

Advertisements

Following the Guinness World Records certificate presentation, Khalfan Belhoul stated: “Dubai’s innovative spirit, embodied today with the global recognition of this sustainably-minded office space, continues to set global standards. As we move and grow alongside the fourth industrial revolution, the need to innovate and create new solutions to the world’s most pressing challenges has never been greater.”

As we move and grow alongside the fourth industrial revolution, the need to innovate and create new solutions to the world’s most pressing challenges has never been greater.”

"That we have shown the way to dramatically cut material costs and the environmentally-harmful byproducts that occur during the construction process, is a testament to Dubai’s pioneering attitude to providing future-forward, sustainable solutions, and which reinforces the emirate’s position as a test-bed of new ideas and a home to a spirit of innovation. We are humbled by this award and look forward to continue help shape the future of our nation.” - Khalfan Belhoul, CEO of Dubai Future Foundation

Advertisements

Is your company ready to make history? Learn more about record-breaking events and campaigns and get started today.

What Do We Know About the First 3D-Printed House Inaugurated in Germany?

3D printing news News What Do We Know About the First 3D-Printed House Inaugurated in Germany?

Published on August 5, 2021 by Madeleine P.

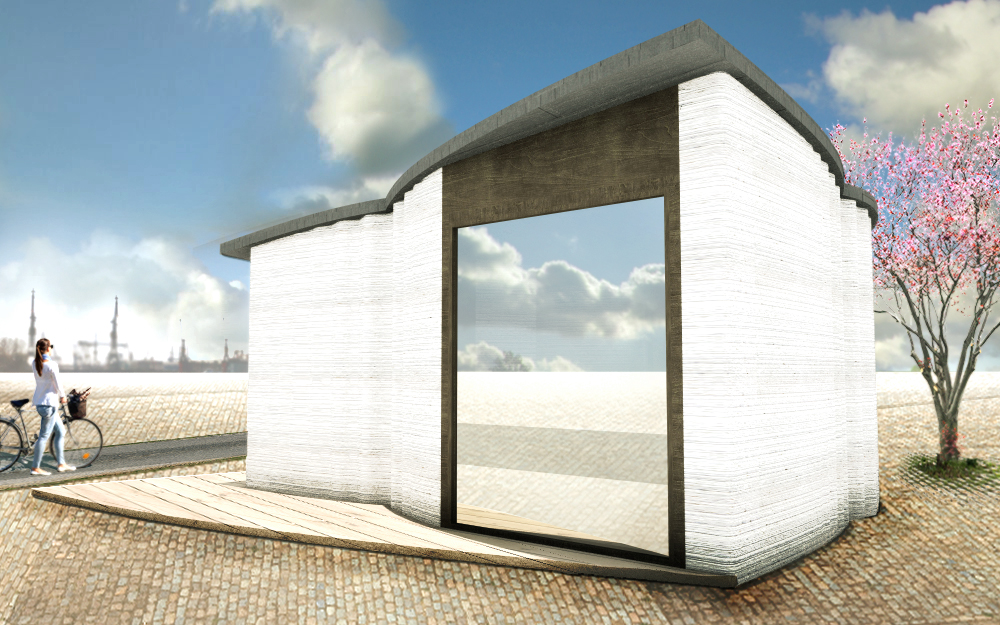

Recently, the first 3D-printed house in Germany was officially inaugurated and has been the talk of the town ever since. This is because the 160-square-meter building is not only an architectural sensation, but has already been awarded the “German Innovation Award” 2021. The single-family house was created using concrete 3D printing and is intended to prove that the technology has reached market maturity. So we decided to take a closer look at the creation of the house from the 3D printing technologies and printer used to its unique design.

Already the exterior facade clearly stands out from the other buildings in the city: the individual concrete layers of the additively manufactured single-family house are clearly recognizable, the shape of the home round instead of angular. The building was planned by the regional architectural office Mense-Korte, and the PERI Group finally turned the plan into reality under Hous3Druck. After around 8 months, all those involved are pleased with the completion of the pilot project and agreed that it heralds a new era. After all, concrete 3D printing is set to become a permanent feature of the construction industry and the 3D-printed house in Beckum, Germany is a great example of the feasibility of such projects, along with some of the others we have seen this year including SQ4D listing the first 3D-printed home in the United States or the first 3D-printed home on Airbnb.

The building was planned by the regional architectural office Mense-Korte, and the PERI Group finally turned the plan into reality under Hous3Druck. After around 8 months, all those involved are pleased with the completion of the pilot project and agreed that it heralds a new era. After all, concrete 3D printing is set to become a permanent feature of the construction industry and the 3D-printed house in Beckum, Germany is a great example of the feasibility of such projects, along with some of the others we have seen this year including SQ4D listing the first 3D-printed home in the United States or the first 3D-printed home on Airbnb.

The chimney inside the residential building was also created layer by layer (photo credits: Robert Szkudlarek)

If you take a look at the interior of the house, you will notice that here, too, the gray concrete layers and round shapes dominate. In the rooms there are also other highlights made of concrete, such as the fireplace or the bathtub. Lisa-Maria Hanhues, the future owner of the house, is planning to move in in 2023. Until then, the building in Beckum will serve as a show house. Hanhues is the sister of the managing partner of Hous3Druck and noted at the inauguration of her new home, “I’m pleasantly surprised that you can find so much space for furniture despite the curves.” In addition to the unusual flair, the house offers other pluses: it is as a smarthome, wherein the temperature is regulated by means of a geothermal heat pump, and all functions can be carried out at the touch of a button.

Until then, the building in Beckum will serve as a show house. Hanhues is the sister of the managing partner of Hous3Druck and noted at the inauguration of her new home, “I’m pleasantly surprised that you can find so much space for furniture despite the curves.” In addition to the unusual flair, the house offers other pluses: it is as a smarthome, wherein the temperature is regulated by means of a geothermal heat pump, and all functions can be carried out at the touch of a button.

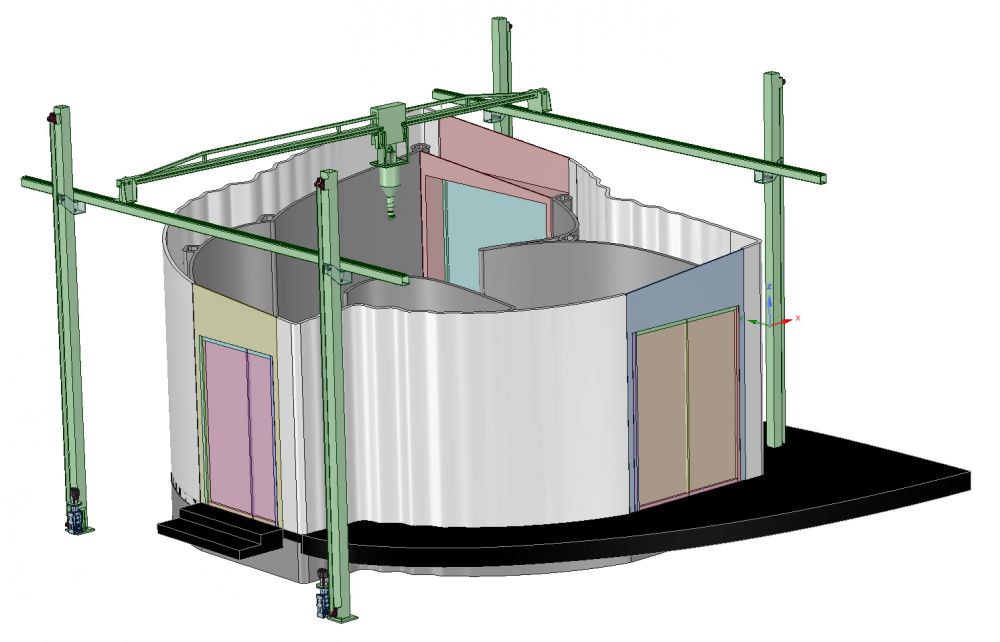

PERI relies on the fastest 3D concrete printer

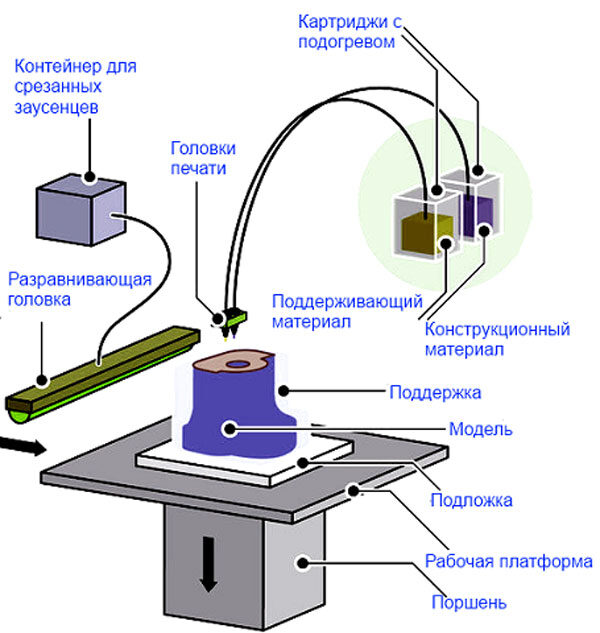

A BOD2 from the Danish manufacturer COBOD was used for the printing process of the two floors, each of which has a living area of over 80 square meters. According to PERI, this is a gantry printer that carries out a movement of the print head over 3 axes on a permanently installed metal frame. The material used was “i.tech 3D”, which was specially developed by HeidelbergCement for 3D printing and is compatible with the BOD2. According to PERI, the BOD2 creates 1m of concrete per second, making it the fastest 3D concrete printer on the market. For example, printing a double-skin wall takes 5 minutes per square meter.

For example, printing a double-skin wall takes 5 minutes per square meter.

Gray in gray in the modern bathroom of the house (photo credits: Robert Szkudlarek)

The fact that additive manufacturing is increasingly gaining acceptance as a pioneering technology in the construction industry is also reflected in the fact that the project in North Rhine-Westphalia was supported with 200,000 euros from the state’s Innovative Construction funding program. At the opening ceremony of the 3D printing house, the responsible minister Ina Scharrenbach (CDU) is certain that this project will be followed by other innovative projects, stating, “With the first 3-D printed residential building in Germany, positive pressure is being generated in the construction industry: for innovative construction with new technologies, for greater attractiveness in construction professions and for modern architecture with new styles. Now we need to gain experience with the building and establish the manufacturing process on the market, because only more housing provides affordable rents. ” Among other things, the state intends to use the funds to further advance innovative technologies for the creation of living space. You can find out more in the video below or in the press release HERE.

” Among other things, the state intends to use the funds to further advance innovative technologies for the creation of living space. You can find out more in the video below or in the press release HERE.

What do you think of the inauguration of the first 3D-printed house in Germany? Are there any 3D-printed houses in your country? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

*Thumbnail Photo Credits: Robert Szkudlarek

In the UAE, for the first time in the world, an office building was printed on a 3D printer - RBC

adv.rbc.ru

adv. rbc.ru

rbc.ru

adv.rbc.ru

Hide banners

What is your location ?

YesSelect other

Categories

Euro exchange rate on January 28

EUR CB: 75.41 (+0.07) Investments, 27 Jan, 16:26

Dollar exchange rate on January 28

USD Central Bank: 69.34 (+0.21) Investments, 27 Jan, 16:26

The Ministry of Defense announced the occupation of advantageous positions in the Donetsk direction Politics, 14:54

Business, adrenaline and sports: how to build character RBC and Gazprombank, 14:49

Military operation in Ukraine. Online Politics, 14:46

Online Politics, 14:46

adv.rbc.ru

adv.rbc.ru

Djokovic wins the Australian Open for the tenth time and will lead the ATP rankings Sport, 14:44

Al Arabya learned of US involvement in strikes on missile depot in Iran Politics, 14:33

Moskalkova appealed to the UN after the shelling of a hospital in the LPR by the Armed Forces of Ukraine Politics, 14:31

In the Kursk region, the village came under mortar fire from the Armed Forces of Ukraine Politics, 14:21

Networking: how to make useful acquaintances

In 5 days you will learn how to make the right impression and benefit from new contacts

Improve your skill

The Prime Minister of Estonia called the decision to admit Russians to the Olympic Games spineless Sport, 14:11

"Social media is a cream bun": what should be the "digital diet" Pro, 13:57

Rogozin announced the preparation of Marker robots for shipment to Donbass Politics, 13:29

Scholz promised to prevent escalation between Russia and NATO Politics, 13:28

The Ministry of Foreign Affairs called the strike of the Armed Forces of Ukraine on the hospital in Novoaydar a war crime Politics, 13:23

The figure skater who returned to Russia rated her first start with the word “terrible” Sport, 13:19

Super champion Bivol called the consequences of not boxing at the Olympics Sport, 13:00

adv. rbc.ru

rbc.ru

adv.rbc.ru

adv.rbc.ru nine0003

Dubai has the world's first 3D printed office building. The project cost 50% less than the traditional construction of a similar building, the UAE government said. Dubai (Photo: Reuters/Pixstream)

The world's first 3D-printed office building has opened in Dubai, according to the website of the government of the United Arab Emirates (UAE).

The building is located in the city center near the Dubai International Financial Centre, Reuters notes. It was called "Office of the Future" (Office of the Future). It will house the temporary headquarters of the Dubai Future Foundation, the organization that initiated the project.

The area of a one-story building is about 250 square meters. m, according to a government statement. In order to ensure the stability of the structure, the roof was made rounded. The building is fully suitable for human work: electricity, telecommunications, water supply and an air conditioning system are installed in it. nine0003

In order to ensure the stability of the structure, the roof was made rounded. The building is fully suitable for human work: electricity, telecommunications, water supply and an air conditioning system are installed in it. nine0003

UAE Prime Minister Mohammed bin Rashid Al Maktoum visiting the "Office of the Future", the world's first 3D printed office. Dubai (Photo: Reuters/Pixstream)

A 3D printer 20 feet (6 m) high, 120 feet (37 m) long and 40 feet (12 m) wide was used to create the structure, according to the post. During the construction, a special cement mixture and materials developed and produced in the UAE and the USA were used. Reliability tests of building materials were carried out in China and the UK. nine0003

adv.rbc.ru

The labor costs of this project were 50% lower than the traditional construction of a building of the same size, the government said. A team of 19 people took part in the work on the building: one of them monitored the operation of the 3D printer, eight assembled the house from printed elements on site, the rest were engaged in conducting electricity and ensuring the operation of other systems. The creation of the structure took 17 days, two more were spent on decorating the office inside. nine0003

A team of 19 people took part in the work on the building: one of them monitored the operation of the 3D printer, eight assembled the house from printed elements on site, the rest were engaged in conducting electricity and ensuring the operation of other systems. The creation of the structure took 17 days, two more were spent on decorating the office inside. nine0003

According to Reuters, construction cost approximately $140,000. UAE Government Minister Muhammad Al Gergawi noted that Dubai's development strategy suggests that by 2030, 25% of the buildings in the emirate will be created using a 3D printer.

Interior of the "Office of the Future" (Photo: twitter.com/DXBMediaOffice)

In November 2015, the Financial Times reported that the president of the Chinese real estate development company Zhuoda Group, Yang Zhoshu, announced his intention to supply 3D-printed houses to Russia. In a video message to investors, the businessman showed photos of a contract with Russia, the value of which he estimated at $94 billion. The video message was a response to allegations of fraud. A subsidiary of Zhuoda Group raised money from 400,000 private investors in Hebei province, promising a return of 20-30% per annum for the placement of funds for a period of four years, after which regulators began investigating Zhuoda's operations. nine0003

In a video message to investors, the businessman showed photos of a contract with Russia, the value of which he estimated at $94 billion. The video message was a response to allegations of fraud. A subsidiary of Zhuoda Group raised money from 400,000 private investors in Hebei province, promising a return of 20-30% per annum for the placement of funds for a period of four years, after which regulators began investigating Zhuoda's operations. nine0003

Office of the Future Interior (Photo: twitter.com/DXBMediaOffice)

Authors

Tags

Julia Kotova

Killa Design: 3D Printing Buildings of the Future

Over the past two decades, architects have had more design freedom than ever, thanks to advanced CAD tools and their construction methods. Projects are becoming more organic, complex and dynamic, enabling architecture firms to push the boundaries of what is possible.

Projects are becoming more organic, complex and dynamic, enabling architecture firms to push the boundaries of what is possible.

Killa Design is one of the leading companies focusing on unique, iconic and timeless design projects such as the world's first 3D printed office building. nine0003

When ordinary is not enough

Designing a building with an unusual shape is a challenge both in terms of design and construction. Architects need to have a complete understanding of the structure and shape of future buildings as early as possible, and to do this, they create physical models of buildings. But for complex and organic projects like the Museum of the Future, traditional modeling methods are inefficient and sometimes even unfeasible.

Killa Design and 3D printing

The architects at Killa Design use 3D models to both coordinate

and prepare the building for construction

Landmark creation and construction Mohammed bin Rashid Al Maktoum, Ruler of Dubai, Vice President and Prime Minister of the United Arab Emirates.

The Museum of the Future, while still under construction, is already becoming a landmark in the UAE: it is 78 meters high and has almost no straight lines in its elliptical design! nine0017

The Museum of the Future, while still under construction, is already becoming a landmark in the UAE: it is 78 meters high and has almost no straight lines in its elliptical design! nine0017 Dubai Museum of the Future has almost no straight lines in its design

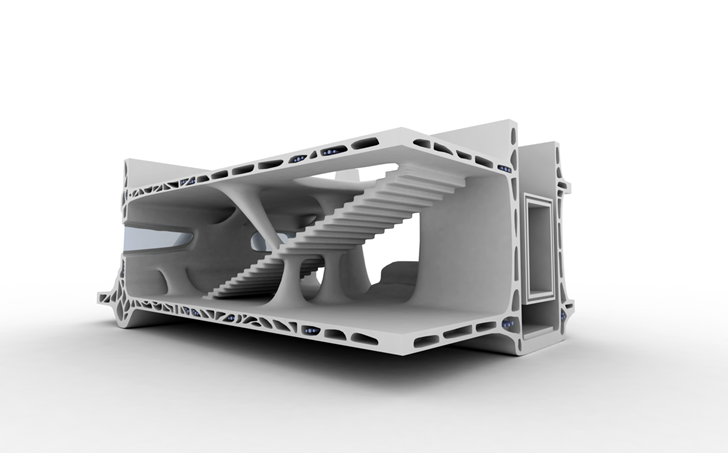

Killa Design used 3D models to give contractors, fabricators and government analysts a complete picture of the building before construction begins. In addition to the exterior shape, the company printed a 3D sectional model of the building to show its basic structure.

3D sectional model showing the internal structure of the Museum of the Future

The entire museum model was 3D printed on an Ultimaker S5 to develop a strategy for cleaning its façade as well as planning rope access. The printed cross section of the building gave a clear view of the interior of the museum. Another view was printed to show the technology used to create the façade. Each printed 3D model contributed to the understanding and agreement of the project, and also showed that the proposed solutions for architectural problems are effective and feasible. nine0017

nine0017

3D cutaway showing the interior of the museum

Unusual office

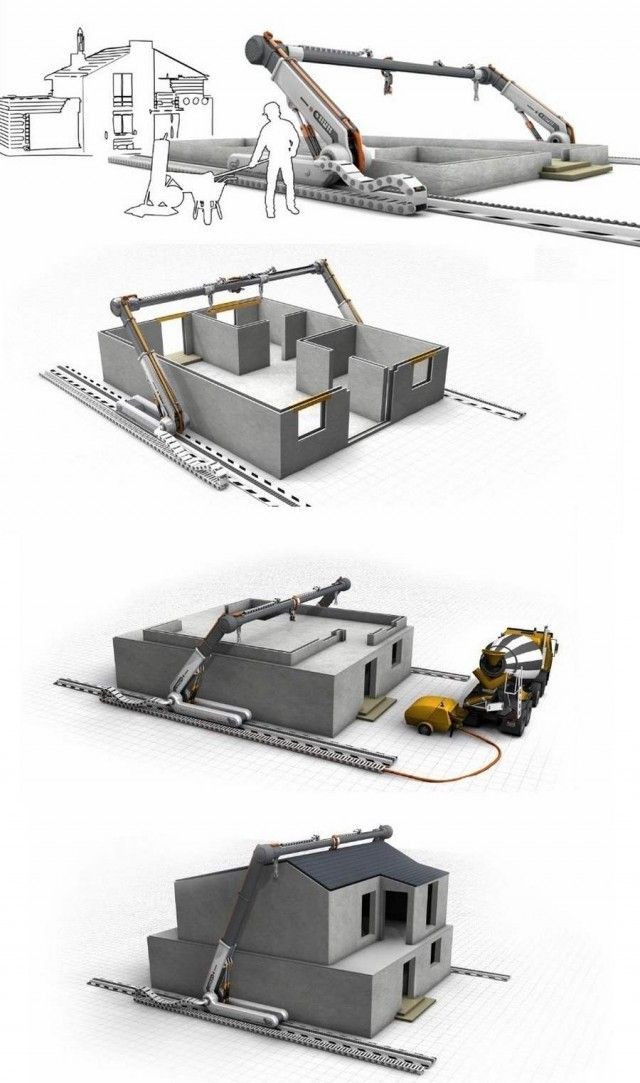

The world's first 3D printed building, the "Office of the Future" is quite a challenge. Its facade was 3D printed, which was 6 meters high, 37 meters long and 12 meters wide, and then all these huge 3D models were assembled together using special cement mixtures. The labor costs of such a project were 50% lower than the traditional construction of a building of the same size, the government said. A team of 19 participated in the work on the building.people: one of them monitored the work of a 3D printer, and 8 assembled a house from printed elements on the spot, the rest were engaged in conducting electricity and ensuring the performance of other systems. The creation of the structure took 17 days, two more were spent on decorating the office inside.

However, before the 3D construction began, Killa Design needed to create a design that would work within the limits set by the Chinese company that printed the actual parts of the building.

Using Ultimaker printers, Killa Design was able to create a design that worked while being energy efficient - perfect for Dubai's climate, where temperatures often reach up to 45°C.

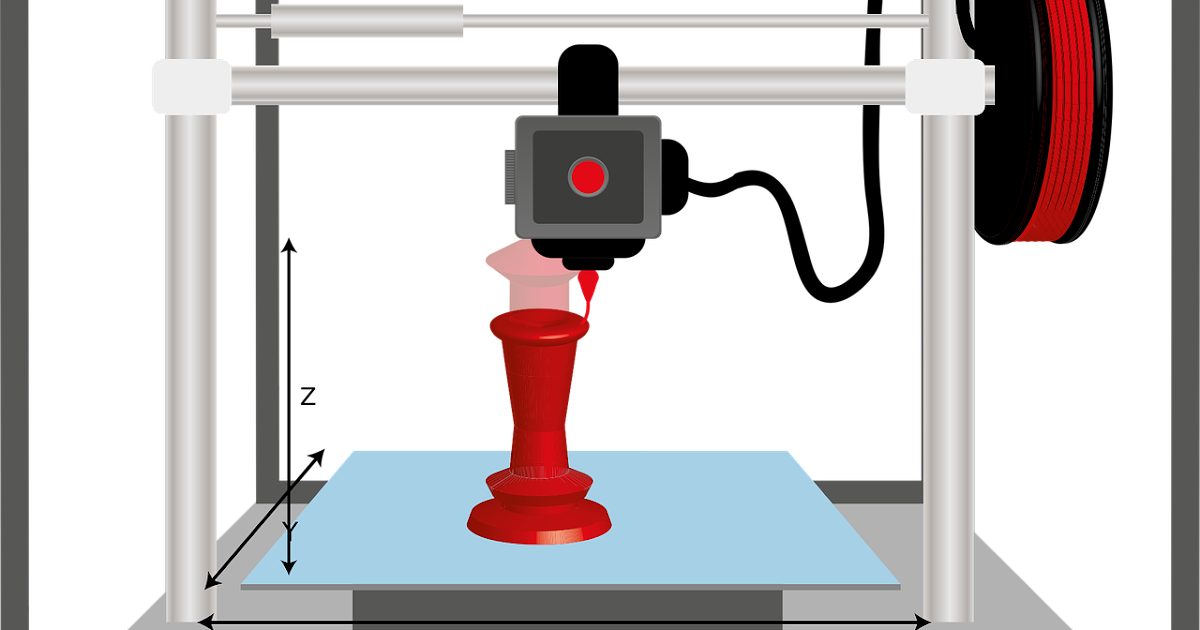

The “Office of the Future” was created using a huge 3D printer

A grand challenge

Another Killa Design project is the SRG Tower, a 111-story residential skyscraper located in the heart of Dubai. Its organic design ensures optimal climate efficiency, thanks to solar panels covering the building, while two wind turbines atop the structure generate up to 500 million watts of electricity peaking.

3D model of the 111-story tower SRG

Building a building as tall as the SRG Tower is a real achievement. And the decision to add two turbines did not come immediately. Killa Design needed a visualization of the project in order to develop possible solutions. And with the help of a 3D printed model of the tower, it has become easier to determine the feasibility of the external structure of the SRG tower.![]() Using 3D printed models, it has become much easier to determine the feasibility of the external structure of the SRG tower. After analyzing a 3D model of the top of the building, Killa Design engineers came up with a solution for installing the turbines. nine0003

Using 3D printed models, it has become much easier to determine the feasibility of the external structure of the SRG tower. After analyzing a 3D model of the top of the building, Killa Design engineers came up with a solution for installing the turbines. nine0003

Imagine, create, iterate!

For most of their architectural models, Killa Design uses the Ultimaker S5 3D printer to create multiple concepts and iterations. It helps a lot to present and explain your ideas during creative brainstorming sessions, and it also speeds up the design process a lot!

Museum of the Future 3D Model

And thanks to the dual extrusion of Ultimaker 3D printers, architects around the world can 3D print any shape at any time. The water soluble PVA serves as a support for the print without getting on the build plate. When the 3D printing is finished, the architects remove the PVA by simply submerging their 3D model in plain water, with no manual processing required.