Selling 3d printed products

How to make money with a 3d printer?

How profitable is 3D printing?

But first, let's answer this question. Can you really make money with a 3D printer?

The answer is yes and no. It depends on the niche that you serve. If you're 3D printing for the general consumer, then your profit margin might not be high because it's for personal use. Consumers love cheap stuff. You'll barely cover your cost because of the amount of labor required to finish just one job. But if you're serving clients where 3D printing solves a costly problem that they have, then they are more willing to pay you a lot more to solve it for them.

Here's what we mean by that.

Scenario A: Joe is looking to 3D print a door handle because his door handle broke.

Scenario B: Amanda is looking to 3D print a prototype of a product she plans to sell on Kickstarter.

Believe it or not, we get a lot of Joe's looking to get a quote for their missing appliance part. And most of them are surprised by how expensive 3D printing is and why can't it be as a cheap as Amazon!

We turn them away. Cheap clients are not worth your time.

Best entry level 3D Printer

Don't have a 3D printer already?

Phrozen Sonic Mini 4k 3D Printer

Check out this Phrozen Sonic Mini which is very popular among 3D printed miniatures enthusiasts.

$349.99 from Phrozen3D

Commisions earned

Different ways to make money with 3D printing

We've listed a couple of ways you can make money with a 3D printer. Some of these ideas are really good, some of them are bad. But we're listing them any way and it's up to you to make that decision if it's even worth considering.

Let's dive right in!

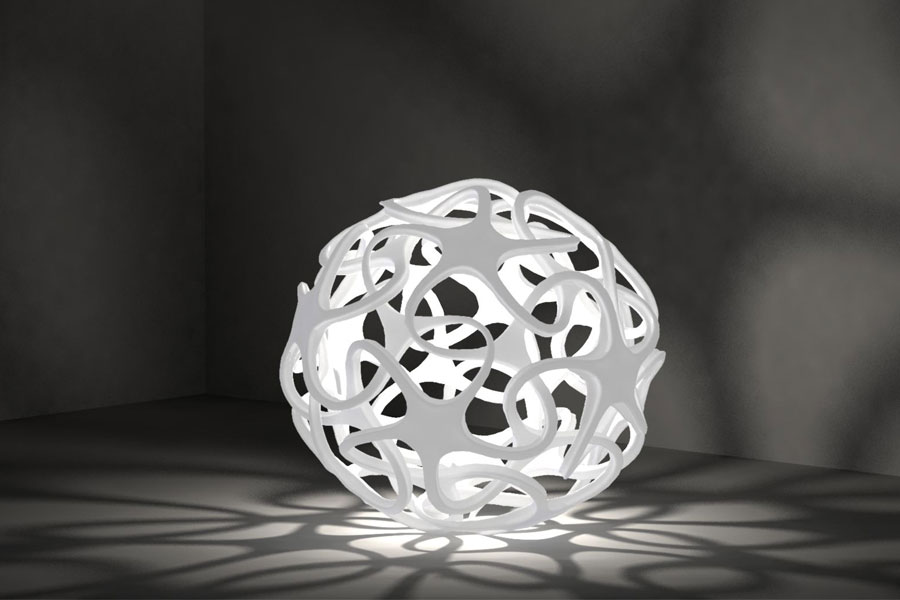

1. Sell pre-made 3D prints on Etsy

Etsy is one of the biggest marketplace for 3D printing. A lot of 3D printing hobbyists and even professional gravitate towards Etsy because of its large audience who are into handcrafted stuff. Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

When we were starting out back in 2016, we were the first ones to start selling 3D printed planters. Made boatloads of money but ultimately had to stop because of copyright issues. But also partly, because it wasn't where we imagined company .

Remember how we said cheap clients aren't worth your time. On Etsy, you will encounter a lot of cheap clients.

Pros

- Quick way to validate your 3D printing idea

- Benefit from Etsy's huge audience

- Running ads are cheaper compared to Google

List of 3D printed products that you can sell on Etsy:

D&D miniatures

Planters

Vase

Freezing Bernie

How do you choose which products to sell?

On Etsy, you will see a lot of people selling different variations of the same thing - planters, iphone holder, headphone holder, etc.

Why?

Because these things sell!

Like it or not, Etsy will be full of copycats and originality doesn't matter. If your product sells, people will copy it. (And vice versa)

How can you stand out on Etsy?

There's a lot you can do to stand out, but here are some of the common ones that we hear over and over again.

Offer something unique that differentiates your product. Whether that's offering higher quality 3D print (resin), custom finishing, etc.

Avoid competing for price. It becomes

Ask your happy clients to leave a review

Take high quality product photos

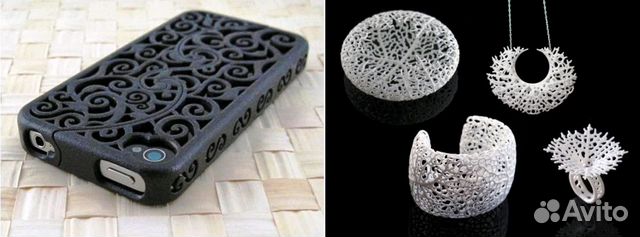

2. Offer a specialized 3D printing

This comes down to finding a niche that you're comfortable to work with or if there's enough margin for you to be profitable.

Here's a list of niches you can offer your 3D printing services to:

Tabletop Miniatures

Toy Designers

Jewelry Designers

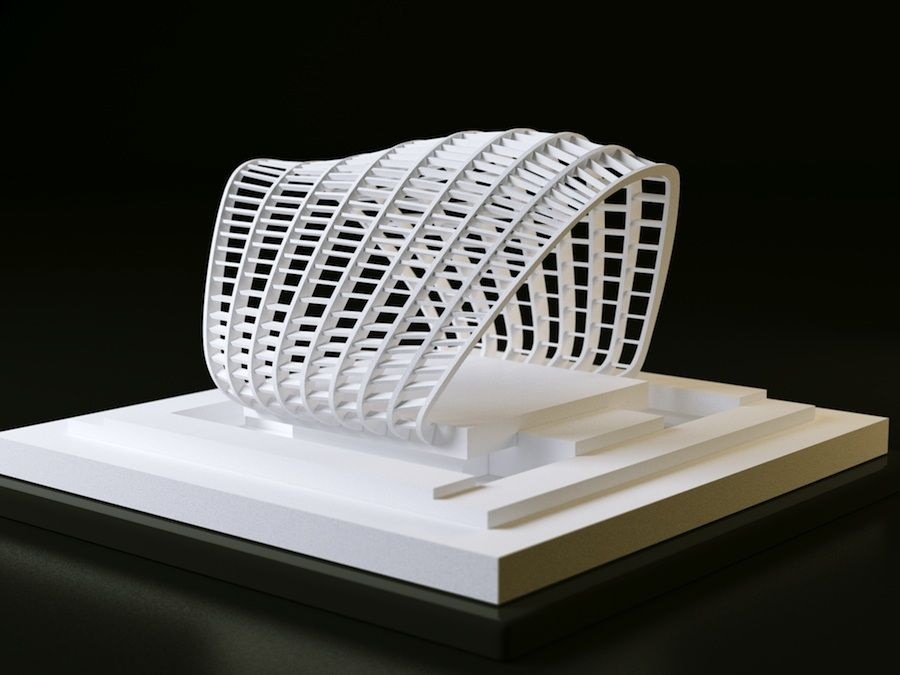

Architecture firms

Engineering firms for prototyping services

Pros

- You can standardize your process

- Repeatable business

- Easier to master one industry than be a jack of all trades

- You can become a known expert in that industry

3.

Start a 3D printing business in your local area

Start a 3D printing business in your local areaWe'll start off by saying that starting a 3D printing business is the most difficult thing to do out of all the other ideas on this list.

Pros

- Potential for high profits

- Local advantage over online only 3D printing companies

We were fortunate that we were located in NYC, where there is huge demand for 3D printing, and that we started in the early days when 3D printing was still new.

We're not saying this because we don't want you to compete with us, but we're saying this because we want you to know the risks involved in the 3D printing business. Many 3D printing companies have gone out of business because they could not make a sustainable profit to keep the lights on.

The amount of work that you have to put in on fulfilling custom orders is a lot. If you don't opt for an automated system, you end up doing a lot of back and forth with clients. And if you do opt in for these instant quoting systems, you can get a lot of low end jobs and lose out on clients with a very custom need.

The real money in offering a 3D printing service, especially if your a small business, is if you can differentiate yourself from merely becoming a commodity.

For us, we had to become more than just a 3D printing service. It sounds corny, but that was the reality. We had to offer other services that would add value to 3D printing. For example, a marketing agency came to us for 3D printed trophy in 24k gold. But we know that we can't 3D print gold. We can either tell them to take it to a metal plating shop or we can do it ourselves and charge on top of it.

We can charge a lot more because:

We're taking all the risk. If that metal plating fails, we have to 3D print again.

We're making their lives so much easier by being an expert at this field.

And if they're on a really tight deadline, we can charge even more because we're guaranteeing results.

Clients who care more about their time and results are willing to pay you a lot if you can deliver.

So we've partnered with a local metal plating company and later on started offering metal plating services for 3D printing.

Having capabilities more than 3D printing will allow you to charge more than just the 3D print by itself.

Whether that's painting, or creating molds. Whatever it is, you need to find the right clients.

Bonus: Offer 3D scanning services

3D scanning and printing services are perfect way to increase money you can make from owning 3D printer. Although this would require buying a 3D scanner, it's a good option to think about when increasing your chances of landing a 3D printing client.

4. Sell your 3D printing designs

Making money with 3D printing isn't only limited to running your 3D printer 24 hours a day. You can also make money from selling 3D models!

This might be hard if you don't have any design skills. You can either learn or hire a designer on Fiverr or Upwork.

Pros

- You can make money while you sleep

- More scaleable than running a 3D printing business

Patreon Business Model

Here's how it works. People pay you an X amount every month for you to publish 3D models for them.

People pay you an X amount every month for you to publish 3D models for them.

This business model is very popular among the tabletop miniature community.

The above picture is from LordOfThePrint's Patreon. They're one of the popular designers focused on building 3D designs for tabletop gaming. They currently have 1,933 subscribers as of this writing. Assuming only 5% of that is merchants, (about 100) that's $3,866 of monthly recurring revenue!

Take this WallStreetBets 3D model by ChaosCoreTech for example. We spent $50 to have the rights to sell their design for a month. Imagine having 10 Etsy sellers wanting to sell your 3D model. That's have $500 of passive income every month for a few hours of design work!

Merchants/Etsy sellers are great target to sell your 3D models to because:

They'll use it to make more money

They know that your 3D model would print properly because you also know how to 3D print. You might also include supports to make it easier for them

You can show them how it would like 3D printed, thus, making it even easier to sell.

Marketplace Business Model

Some prefer to sell their designs as one-off product that people can just buy online without having to subscribe monthly.

Places where you can sell your 3D models

MyMiniFactory

CGTrader

TurboSquid

5. Start a YouTube Channel

We know that this is easier said than done. Creating content requires time, effort and consistency. With the amount of 3D printing related youtube channels out there, it might be hard to stand out.

But we're not here to stop you from starting your own channel. We're just here to tell you that you can make money with it.

Pros

- Potential for high earnings

- You can use your audience to make more money aside from YouTube Ads

6. Sell an online 3D printing course

If your confident enough with your 3D printing skills and you have knack for teaching others, then selling an online course about 3D printing can

What should you teach?

Again, you need to find a problem where people are willing to pay money for. If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

It doesn't have to be "how to operate a 3D printer", it can be a course on "how to operate a profitable 3D printing business". With this strategy, you'll attract clients who are willing to pay money to make more money.

Pros

- Passive income

The following ideas are not so good

So you can probably skip to the end if you wish to.

7. Rent your 3D printer for events

With the pandemic and all, this is probably not a good idea. But it's still an idea right?

The business is very similar to a photo booth. A bar mitzvah will hire you for 3 hours to 3D print keychains for them.

But 3D printing takes a long time. They are going to complain that you didn't 3D print for everyone.

Yup, bad idea.

8. Sell your 3D printer

You can quickly make money if you sell the 3D printer you just bought. Guaranteed.

Guaranteed.

All jokes, aside

9. 3D print the word "money"

You will literally make "money" with a 3D printer with this strategy.

In summary

Yes, you can make money with a 3D printer. And there are a lot of ways that you can do it, whether that's selling 3D printed items, digital goods, or even offering a 3D printing service in your local area. Is it easy to make money 3D printing? It's not. You still need to work hard(and smart) to become successful in the 3D printing business.

How to make money with a 3d printer?

How profitable is 3D printing?

But first, let's answer this question. Can you really make money with a 3D printer?

The answer is yes and no. It depends on the niche that you serve. If you're 3D printing for the general consumer, then your profit margin might not be high because it's for personal use. Consumers love cheap stuff. You'll barely cover your cost because of the amount of labor required to finish just one job. But if you're serving clients where 3D printing solves a costly problem that they have, then they are more willing to pay you a lot more to solve it for them.

But if you're serving clients where 3D printing solves a costly problem that they have, then they are more willing to pay you a lot more to solve it for them.

Here's what we mean by that.

Scenario A: Joe is looking to 3D print a door handle because his door handle broke.

Scenario B: Amanda is looking to 3D print a prototype of a product she plans to sell on Kickstarter.

Believe it or not, we get a lot of Joe's looking to get a quote for their missing appliance part. And most of them are surprised by how expensive 3D printing is and why can't it be as a cheap as Amazon!

We turn them away. Cheap clients are not worth your time.

Best entry level 3D Printer

Don't have a 3D printer already?

Phrozen Sonic Mini 4k 3D Printer

Check out this Phrozen Sonic Mini which is very popular among 3D printed miniatures enthusiasts.

$349.99 from Phrozen3D

Commisions earned

Different ways to make money with 3D printing

We've listed a couple of ways you can make money with a 3D printer. Some of these ideas are really good, some of them are bad. But we're listing them any way and it's up to you to make that decision if it's even worth considering.

Some of these ideas are really good, some of them are bad. But we're listing them any way and it's up to you to make that decision if it's even worth considering.

Let's dive right in!

1. Sell pre-made 3D prints on Etsy

Etsy is one of the biggest marketplace for 3D printing. A lot of 3D printing hobbyists and even professional gravitate towards Etsy because of its large audience who are into handcrafted stuff. Some of them have even made a name for themselves on Etsy, whether that's selling pre-made items with a little bit of customization or selling full on 3D printed objects.

When we were starting out back in 2016, we were the first ones to start selling 3D printed planters. Made boatloads of money but ultimately had to stop because of copyright issues. But also partly, because it wasn't where we imagined company .

Remember how we said cheap clients aren't worth your time. On Etsy, you will encounter a lot of cheap clients.

Pros

- Quick way to validate your 3D printing idea

- Benefit from Etsy's huge audience

- Running ads are cheaper compared to Google

List of 3D printed products that you can sell on Etsy:

D&D miniatures

Planters

Vase

Freezing Bernie

How do you choose which products to sell?

On Etsy, you will see a lot of people selling different variations of the same thing - planters, iphone holder, headphone holder, etc.

Why?

Because these things sell!

Like it or not, Etsy will be full of copycats and originality doesn't matter. If your product sells, people will copy it. (And vice versa)

How can you stand out on Etsy?

There's a lot you can do to stand out, but here are some of the common ones that we hear over and over again.

Offer something unique that differentiates your product. Whether that's offering higher quality 3D print (resin), custom finishing, etc.

Avoid competing for price. It becomes

Ask your happy clients to leave a review

Take high quality product photos

2. Offer a specialized 3D printing

This comes down to finding a niche that you're comfortable to work with or if there's enough margin for you to be profitable.

Here's a list of niches you can offer your 3D printing services to:

Tabletop Miniatures

Toy Designers

Jewelry Designers

Architecture firms

Engineering firms for prototyping services

Pros

- You can standardize your process

- Repeatable business

- Easier to master one industry than be a jack of all trades

- You can become a known expert in that industry

3.

Start a 3D printing business in your local area

Start a 3D printing business in your local areaWe'll start off by saying that starting a 3D printing business is the most difficult thing to do out of all the other ideas on this list.

Pros

- Potential for high profits

- Local advantage over online only 3D printing companies

We were fortunate that we were located in NYC, where there is huge demand for 3D printing, and that we started in the early days when 3D printing was still new.

We're not saying this because we don't want you to compete with us, but we're saying this because we want you to know the risks involved in the 3D printing business. Many 3D printing companies have gone out of business because they could not make a sustainable profit to keep the lights on.

The amount of work that you have to put in on fulfilling custom orders is a lot. If you don't opt for an automated system, you end up doing a lot of back and forth with clients. And if you do opt in for these instant quoting systems, you can get a lot of low end jobs and lose out on clients with a very custom need.

The real money in offering a 3D printing service, especially if your a small business, is if you can differentiate yourself from merely becoming a commodity.

For us, we had to become more than just a 3D printing service. It sounds corny, but that was the reality. We had to offer other services that would add value to 3D printing. For example, a marketing agency came to us for 3D printed trophy in 24k gold. But we know that we can't 3D print gold. We can either tell them to take it to a metal plating shop or we can do it ourselves and charge on top of it.

We can charge a lot more because:

We're taking all the risk. If that metal plating fails, we have to 3D print again.

We're making their lives so much easier by being an expert at this field.

And if they're on a really tight deadline, we can charge even more because we're guaranteeing results.

Clients who care more about their time and results are willing to pay you a lot if you can deliver.

So we've partnered with a local metal plating company and later on started offering metal plating services for 3D printing.

Having capabilities more than 3D printing will allow you to charge more than just the 3D print by itself.

Whether that's painting, or creating molds. Whatever it is, you need to find the right clients.

Bonus: Offer 3D scanning services

3D scanning and printing services are perfect way to increase money you can make from owning 3D printer. Although this would require buying a 3D scanner, it's a good option to think about when increasing your chances of landing a 3D printing client.

4. Sell your 3D printing designs

Making money with 3D printing isn't only limited to running your 3D printer 24 hours a day. You can also make money from selling 3D models!

This might be hard if you don't have any design skills. You can either learn or hire a designer on Fiverr or Upwork.

Pros

- You can make money while you sleep

- More scaleable than running a 3D printing business

Patreon Business Model

Here's how it works. People pay you an X amount every month for you to publish 3D models for them.

People pay you an X amount every month for you to publish 3D models for them.

This business model is very popular among the tabletop miniature community.

The above picture is from LordOfThePrint's Patreon. They're one of the popular designers focused on building 3D designs for tabletop gaming. They currently have 1,933 subscribers as of this writing. Assuming only 5% of that is merchants, (about 100) that's $3,866 of monthly recurring revenue!

Take this WallStreetBets 3D model by ChaosCoreTech for example. We spent $50 to have the rights to sell their design for a month. Imagine having 10 Etsy sellers wanting to sell your 3D model. That's have $500 of passive income every month for a few hours of design work!

Merchants/Etsy sellers are great target to sell your 3D models to because:

They'll use it to make more money

They know that your 3D model would print properly because you also know how to 3D print. You might also include supports to make it easier for them

You can show them how it would like 3D printed, thus, making it even easier to sell.

Marketplace Business Model

Some prefer to sell their designs as one-off product that people can just buy online without having to subscribe monthly.

Places where you can sell your 3D models

MyMiniFactory

CGTrader

TurboSquid

5. Start a YouTube Channel

We know that this is easier said than done. Creating content requires time, effort and consistency. With the amount of 3D printing related youtube channels out there, it might be hard to stand out.

But we're not here to stop you from starting your own channel. We're just here to tell you that you can make money with it.

Pros

- Potential for high earnings

- You can use your audience to make more money aside from YouTube Ads

6. Sell an online 3D printing course

If your confident enough with your 3D printing skills and you have knack for teaching others, then selling an online course about 3D printing can

What should you teach?

Again, you need to find a problem where people are willing to pay money for. If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

If you search "3D printing" on Udemy, you'll find 3D printing courses that people are paying for.

It doesn't have to be "how to operate a 3D printer", it can be a course on "how to operate a profitable 3D printing business". With this strategy, you'll attract clients who are willing to pay money to make more money.

Pros

- Passive income

The following ideas are not so good

So you can probably skip to the end if you wish to.

7. Rent your 3D printer for events

With the pandemic and all, this is probably not a good idea. But it's still an idea right?

The business is very similar to a photo booth. A bar mitzvah will hire you for 3 hours to 3D print keychains for them.

But 3D printing takes a long time. They are going to complain that you didn't 3D print for everyone.

Yup, bad idea.

8. Sell your 3D printer

You can quickly make money if you sell the 3D printer you just bought. Guaranteed.

Guaranteed.

All jokes, aside

9. 3D print the word "money"

You will literally make "money" with a 3D printer with this strategy.

In summary

Yes, you can make money with a 3D printer. And there are a lot of ways that you can do it, whether that's selling 3D printed items, digital goods, or even offering a 3D printing service in your local area. Is it easy to make money 3D printing? It's not. You still need to work hard(and smart) to become successful in the 3D printing business.

How to calculate the cost of printing on a 3D printer

For some ideas, 3D printing is the fastest and easiest solution. In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Despite the fact that it is customary to indicate the price per gram of working material, simply multiplying the weight of the model by the cost of 1 gram will be wrong. In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product. nine0003

In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product. nine0003

Each 3D printing technology uses its own consumables. Let's analyze the most popular and affordable of them.

Available technologies and key differences

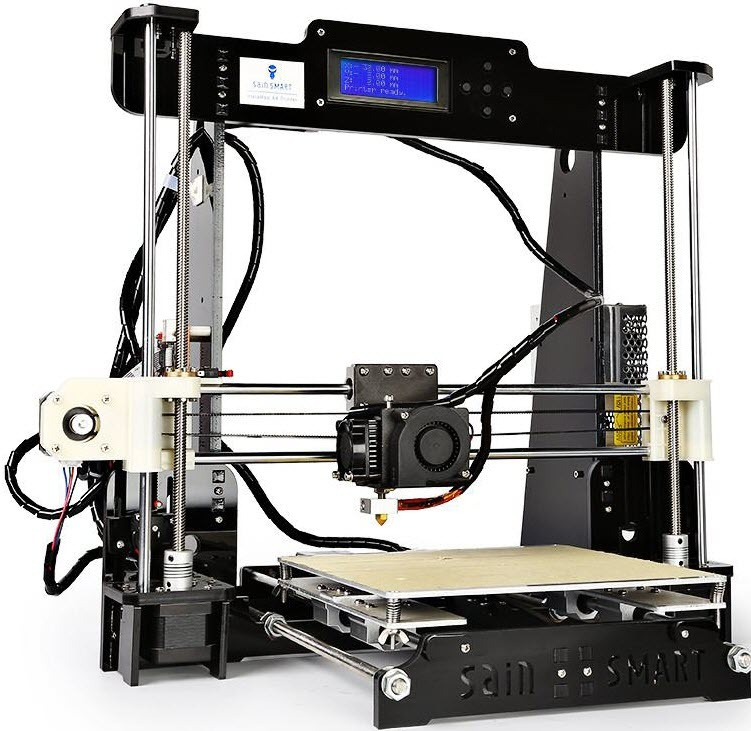

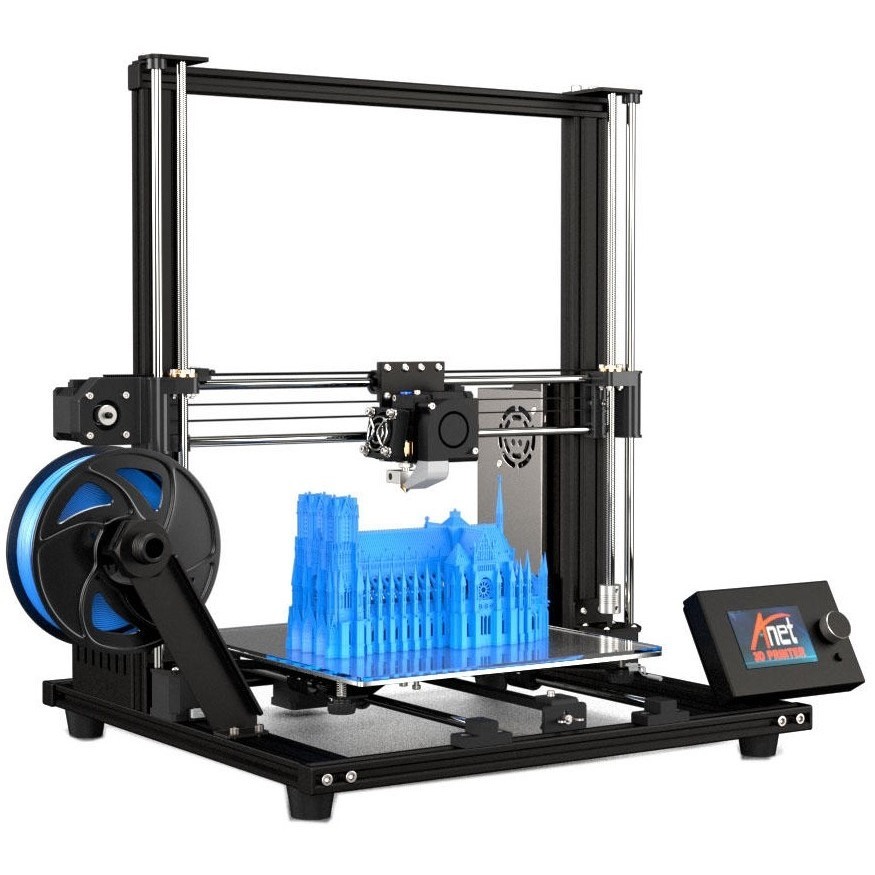

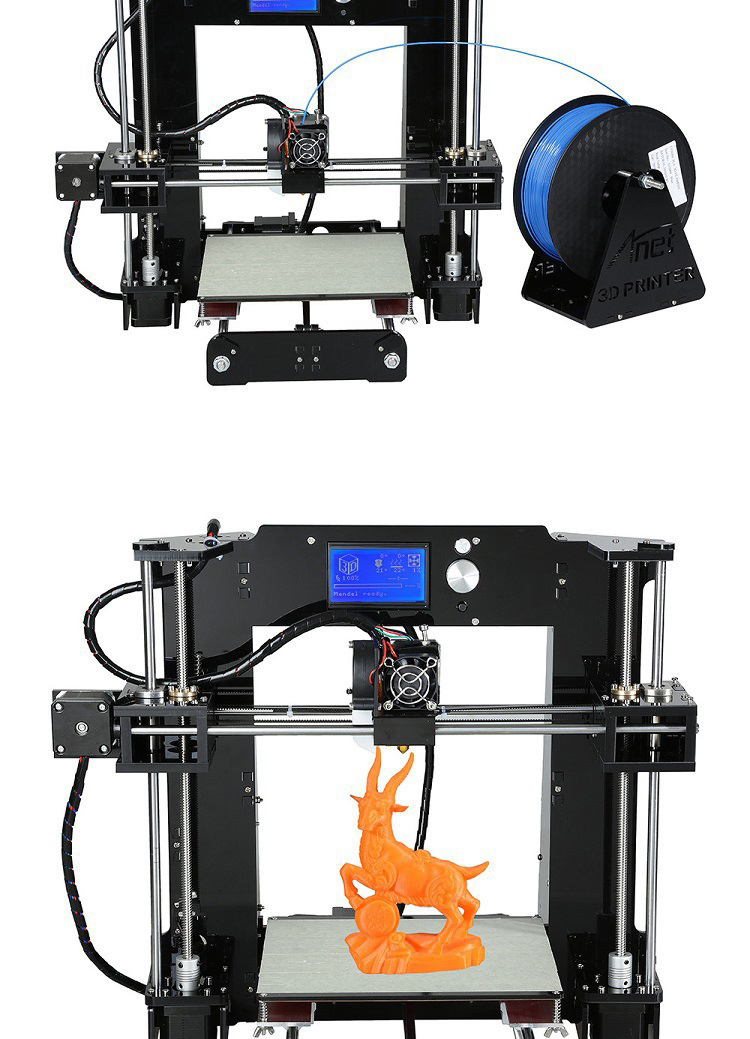

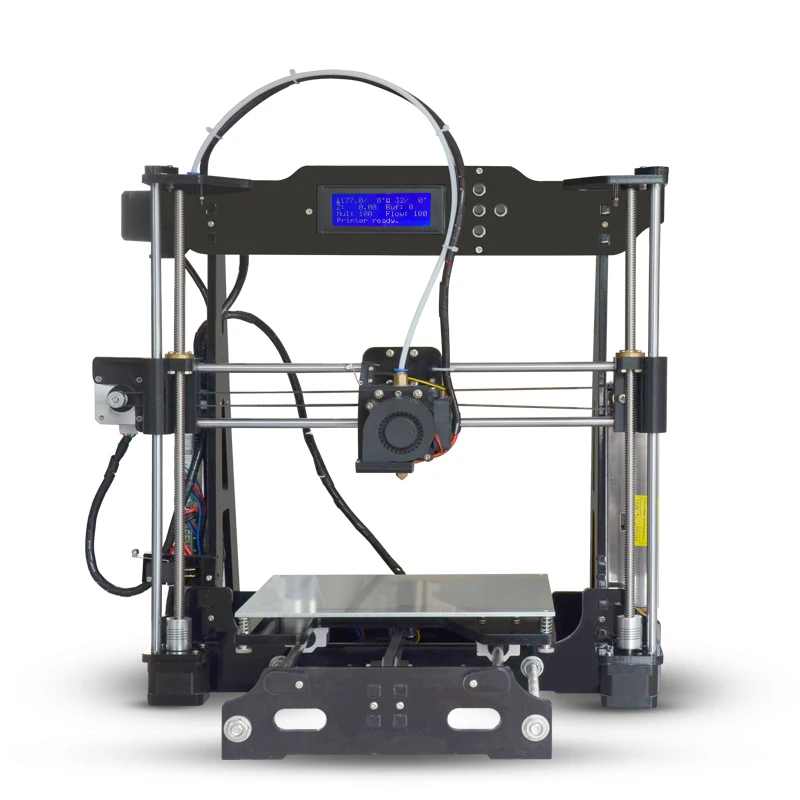

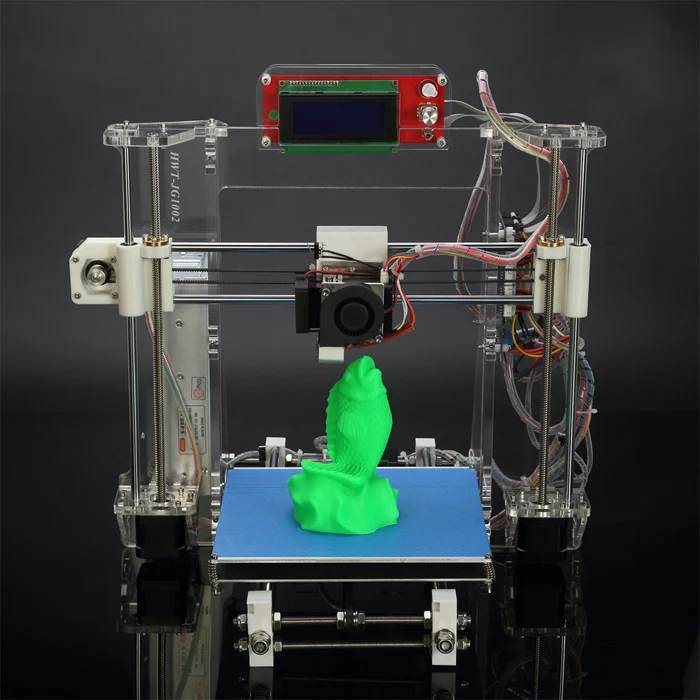

Currently, a huge number of 3D devices have appeared, from small desktop ones that fit on the desktop to huge industrial machines. Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA).

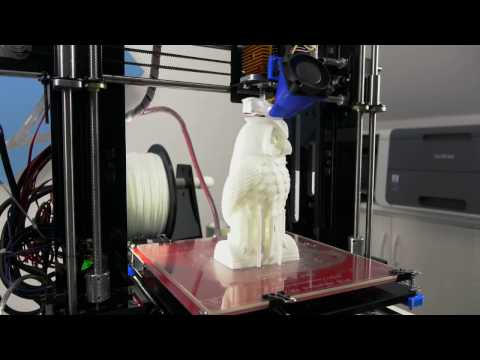

FDM 3D printing

Today, the most affordable 3D printing technology is FDM. A variety of materials and 3D printers allow FDM to be applied to a wide range of applications.

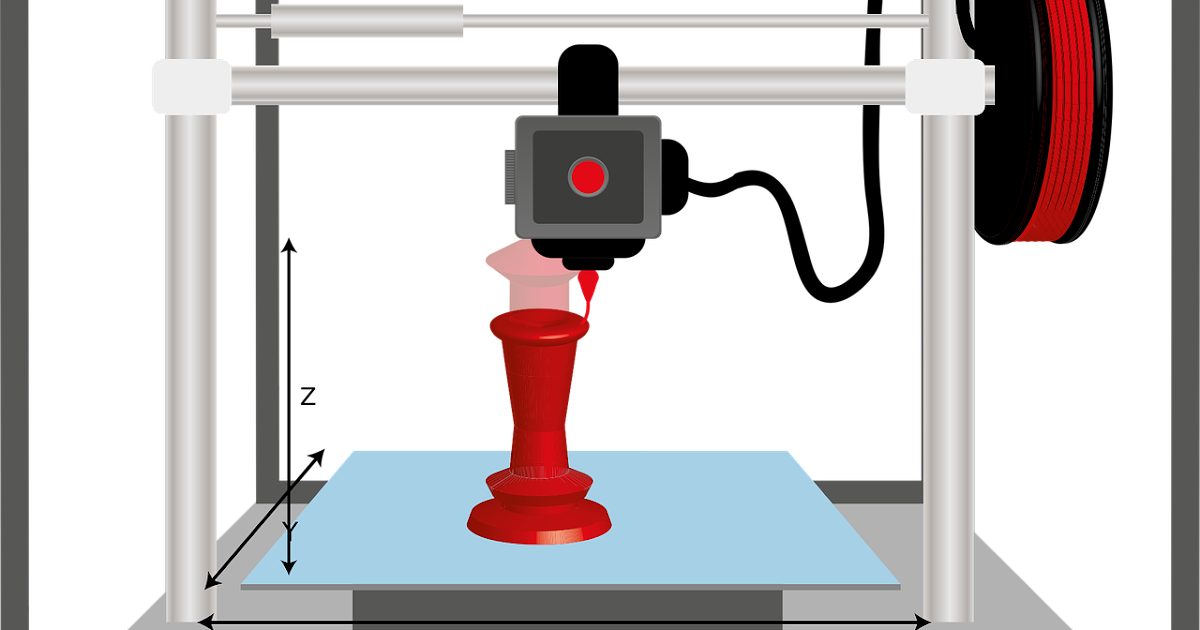

Schematic operation of FDM printer

A large selection makes it easy to choose a 3D printer for a specific task or find a universal device.

The material for printing is a plastic thread - filament. On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc. nine0003

On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc. nine0003

Pros:

Cons:

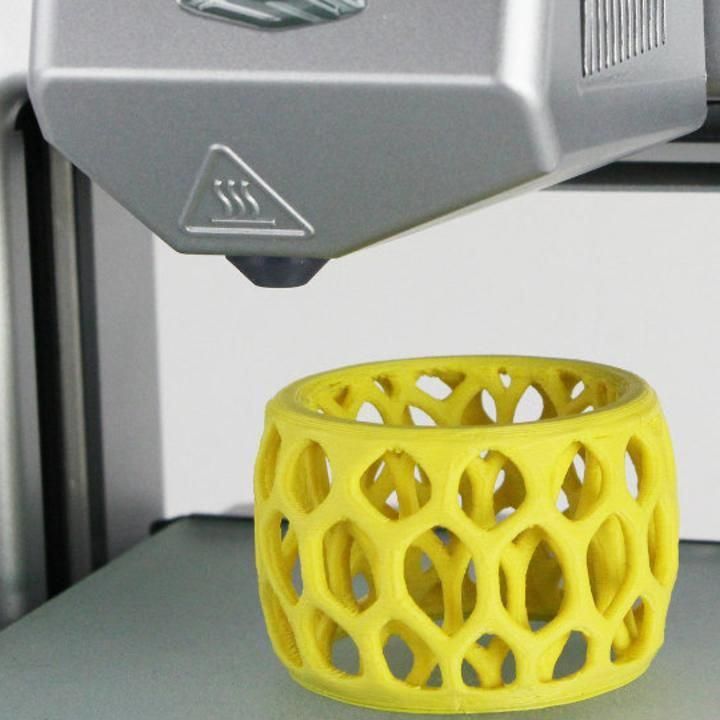

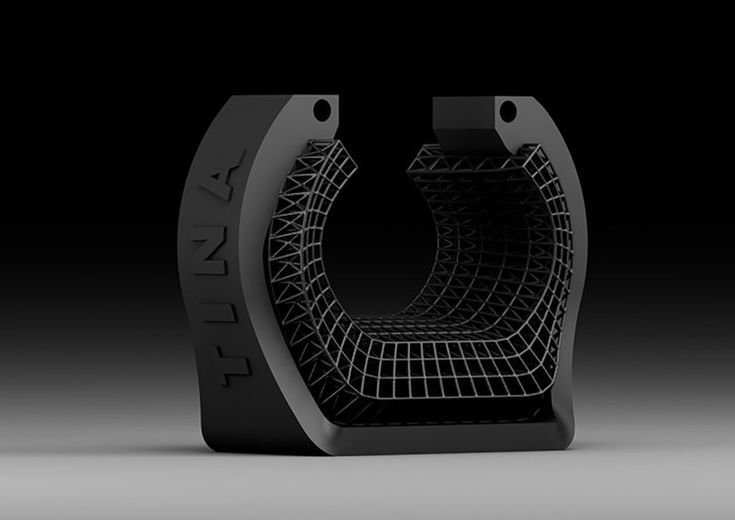

Despite the fact that FDM allows you to print a wide range of plastics with different properties, the technology has some limitations. For example, it is impossible to obtain a perfectly smooth surface, to produce miniature and very thin elements, or to produce parts with very complex internal geometry with high accuracy.

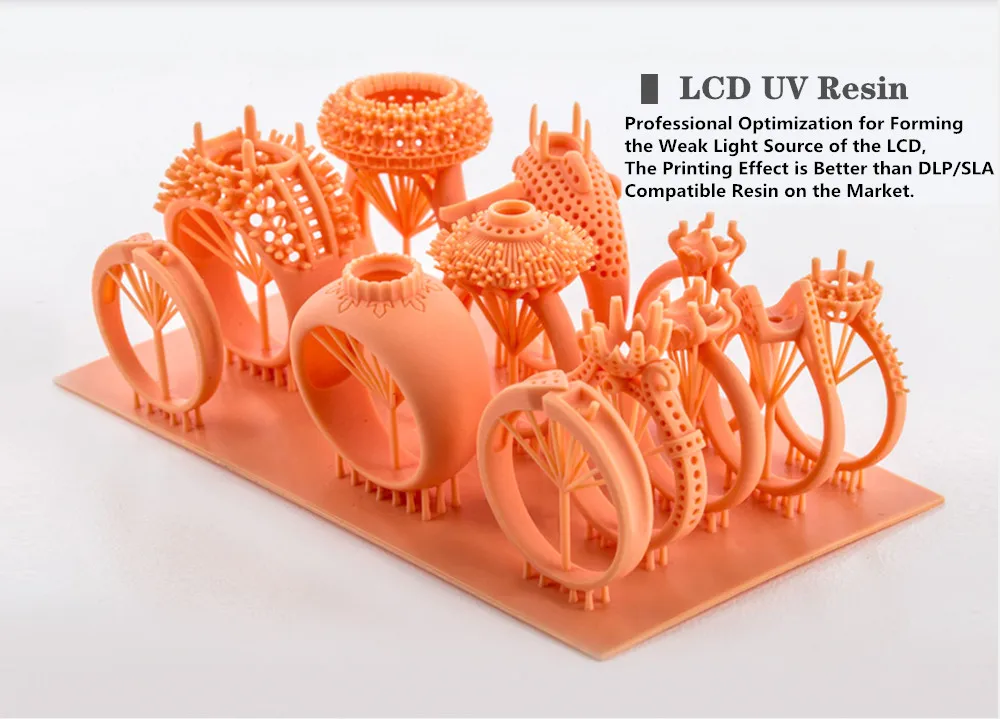

Photopolymer printing

Photopolymer printers can work on one of 3 technologies - SLA, DLP or LCD. These devices will come to the rescue if you need to make a small but very detailed model with many small details. nine0003

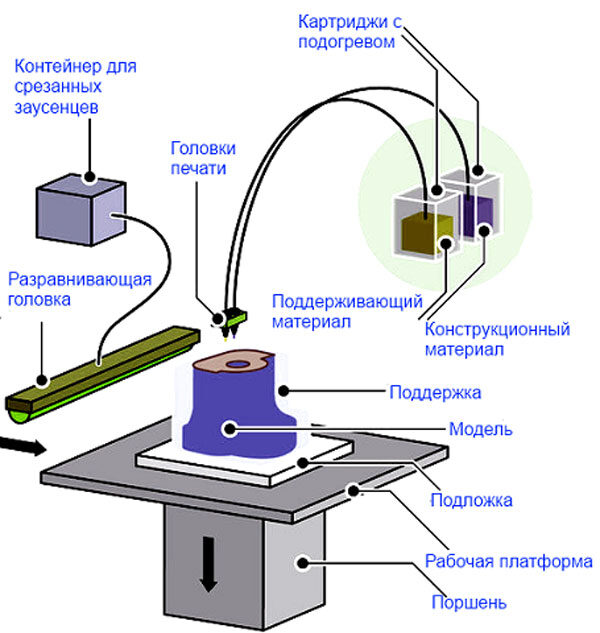

How photopolymer printers work

As a consumable material, a photopolymer resin hardened by UV radiation is used. Now there is a wide variety of photopolymer resins for every taste. From particularly strong and precise engineering or jewelry resins to soft flexes.

From particularly strong and precise engineering or jewelry resins to soft flexes.

Pros:

-

High print precision

nine0060 -

Good surface quality

-

A wide variety of printers and consumables

Minuses:

Photopolymer printers have shown themselves well in a variety of industries that require a perfectly smooth surface and high accuracy. They are used in dentistry, the jewelry industry, for making miniature master models for casting, and much more. nine0003

Industrial printers

These are already industrial machines, which require a separate room and sometimes certain requirements for ventilation, etc. In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

FDM

In addition to desktop devices using FDM technology, industrial printers that work on the same principle are common.

This category includes devices with a large print area (from 30x30x30 cm and more). For example, Raise Pro2 with a print area of 30x30x30 cm.

Raise Pro2

Or machines designed for printing with refractory materials (eg PEEK). Such 3D printers usually have an active thermal chamber, and the extruder can be heated above 400 degrees.

nine0021 CreatBot F160-PEEK designed to work with refractory plastics

Photopolymer printers

Industrial photopolymer devices usually have a much larger working area, compared to their "home" brothers. In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model. nine0003

Prismlab Large Area Industrial Resin Printer Family

3DP

3DP - Three-Dimensional Printing (translated as three-dimensional printing) is a logical continuation of conventional two-dimensional printers. Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored. nine0003

Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored. nine0003

Colored plaster model

Since the plaster model is fragile, a similar principle is used for printing with metals. Only the finished product needs to be treated in an oven to remove the binder and improve strength. But despite the processing, such metal prints will still be inferior in strength to cast products.

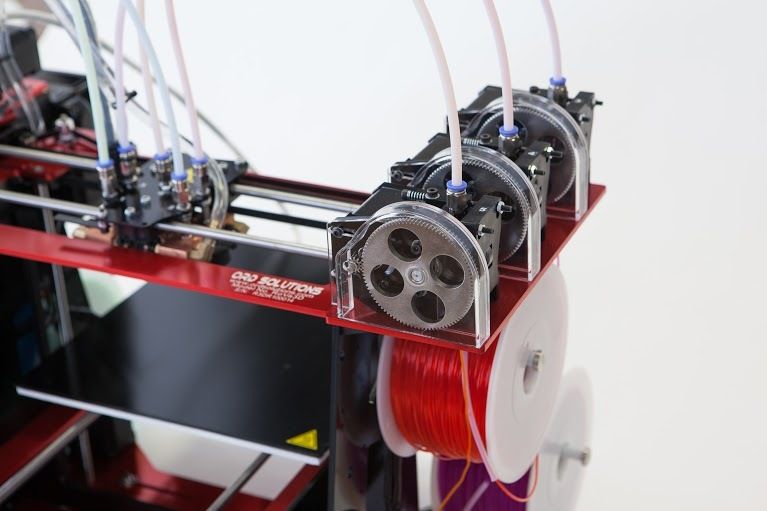

MJM

This is a proprietary technology of 3D Systems. MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

Models made with MJM technology

Such devices can work with photopolymer resins, wax or thermoplastics. You can combine several materials at once - for example, for complex models, you can use wax as a support. nine0003

You can combine several materials at once - for example, for complex models, you can use wax as a support. nine0003

SLM

SLM is the layer-by-layer sintering of metal powder using a powerful laser. There are several similar technologies - SHS/SLS. The principle of operation is the same, only a thermal print head is used instead of a laser beam.

SLM Turbine

As a material for printing, you can use powders of various metals - gold, stainless steel, aluminum, various alloys, etc. nine0003

During printing, the working chamber is filled with an inert gas to prevent oxidation of metals. This allows printing even with titanium powder.

Models made by this method are in no way inferior, and sometimes even superior, to cast products. SLM allows you to produce models with complex internal geometry that cannot be produced by another method (casting or milling).

Cost of 3D printing

The cost of a model usually consists of several factors.

-

Equipment depreciation. The printer, like any machine, requires maintenance and periodic replacement of some parts. During operation, belts gradually stretch, bushings or linear bearings wear out. For example, when bushings or linear bearings are worn; shafts may wear out and need to be replaced.

Cost of materials

The main cost item for a 3D printer is, of course, the printed material.;

FDM (plastic filament)

Since FDM technology is by far the most common, the choice of filaments is very diverse.

-

Engineering plastics are usually nylon with various fillers added to improve the physical characteristics of the finished model. Special cost. plastics starts from 2000r per coil and above. It all depends on the manufacturer and filler (carbon fiber, fiberglass, etc.). nine0003

-

Decorative plastics are used to imitate various materials. Plastic can simply be unusually colored (luminous, transparent plastics) or a special filler is added to it (plastics with metal powder).

The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

A big advantage of FDM is the diverse choice of materials to work with. This allows, having one printer, to produce almost any product - from a child's toy to a complex engineering prototype. nine0003

Photopolymers (resin)

Photopolymer resin printing technology is becoming more and more accessible. There are many different resins.

-

The cost of ordinary colored resin starts from 2500 rubles per 0.5 kg (volume +/- 0.5 l). You can find a smaller volume of resin (250 gr) on sale. You can buy several different resins in small containers and find out in practice which one is best for a particular model. nine0003

-

Engineering resins are resins with increased strength. They can be used not only for printing decorative items, but also for making functional prototypes and models. The cost for 0.

5 kg starts from 5900r and above.

5 kg starts from 5900r and above.

-

Special resins - burnable, dental, soft flexes, etc. Depending on the resin, the price for 0.5 kg can start from 4800 rubles and more. It all depends on the characteristics of the resin. nine0003

Photopolymer resins have not yet reached such a variety as FDM filaments, but they are surely catching up. Although due to the fact that a liter of resin costs significantly more than a spool of filament, the cost of the product is much higher.

Print examples

FDM

Mag Pull (quick release loop) for G3 magazines.

The model was downloaded for free from an open source (the file can be downloaded here). Printing with engineering carbon-filled plastic (price per spool from 4700 rubles). The weight of the model with support is about 25 grams. Post-processing was not needed. The cost of the finished model is 250 rubles. nine0015

nine0015

Plastic fastener

The file was downloaded from an open source (can be downloaded here). Plastic - carbon-filled nylon (price per coil from 4700r). The weight of the finished product is about 20 grams. Print without post-processing. The total cost is 200 rubles.

Model watch

The model is modeled to order (the cost of modeling is from 1000 rubles). The product is printed on an industrial printer using soluble support. Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products). nine0003

Traction prosthesis

The model is taken from an open source (you can download the modified version of the prosthesis here). The weight of the used material is about 600 gr, printed with ABS plastic (the cost of the coil is from 800 r). After printing, post-processing and assembly took place. The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

nine0003

Pedal layout

Production of a 3D model according to the drawing (from 1000 r). The weight of the finished model is about 200 gr. The product was printed with engineering carbon-filled plastic (the cost of the coil is from 4700 r). Post-processing was not needed. The cost of the finished product is about 3000 rubles.

Photopolymer printers

Model jaws for crowns

Files for printing were obtained using a 3D scanner and finalized in a 3D editor (the cost of scanning is from 3000 r, the cost of manual revision is from 1000 r). Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Burnout resin rings

The model is made to order. Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product. nine0003

Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product. nine0003

Miniatures

The models were bought on the myminifactory website (the cost of the model is from $2). Made with a desktop DLP printer. Post-processing was not required. The cost of the finished figurine is from 70 r per gram.

Custom 3D printing

Many owners of 3D printers are thinking about monetizing their hobby. But you should understand that the price of 3D printing “for yourself” and the price of commercial printing are very different. nine0003

When starting to print to order, it is better to have several printers working on different technologies.

Cost of commercial 3D printing

In addition to the cost of the model, to the commercial production of products, you can add:

-

Modeling.

Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make. nine0003

Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make. nine0003

-

Model post-processing. This can be simply the removal of supports, with cleaning of the place of their contact with the product, or a complete processing cycle (puttying, surface grinding, painting, etc.).

It should be borne in mind that it is not always possible to print the model the first time. Sometimes it may take several attempts. And these are additional costs.

nine0167What is unprofitable to print

Despite the wide possibilities of 3D printing, there are models that are unprofitable to make on a 3D printer. For such models, it is better to use other manufacturing methods.

Commercial print examples

Jewelry for further casting

Manufacture of promotional items and souvenirs

Piece miniatures or master model for further casting

3D printed model

Profitable to print on a 3D printer:

If the item is only sold as an assembly.

For example, a small gear broke in the mechanism, but the mechanism is sold only “assembly”. It is much cheaper to make the desired gear on a 3D printer than to buy the entire mechanism. nine0003

A small batch of parts. Small batches, especially models with complex geometry, are more profitable to produce on a 3D printer than by casting or other methods.

Totals

If you need several models or a small project, sometimes it will be more expedient to outsource manufacturing. After all, in addition to buying equipment and materials, you will have to understand the nuances of the settings and the characteristics of various materials. nine0003

Buying a 3D printer for commercial use is justified if you can fully load it with work or then it can be used for other purposes.

To print to order, you need to have several printers working on different technologies. It is better to get several devices with a smaller print area than to buy just one printer, albeit with a large working area.

Requirements for 3D models for 3D printing and CNC processing

01/16/2017 in 3D Modeling Instructions

Contents:

- Introduction

- Product creation process.

- Requirements for models for 3D printing and CNC processing.

- Fixing non-critical bugs with NetFabb.

- Fixing non-critical bugs with MeshMixer.

- Fixing non-critical bugs with Materialize Magic.

- Examples of the most common errors.

Introduction. nine0009

In this article, we will talk about the basic and general parameters that a model must meet in order to obtain high-quality 3D printed products. Let's discuss common errors that occur in the process of creating three-dimensional models in terms of a high-quality polygonal mesh and how to quickly fix them. Requirements for 3D models and quality issues in terms of the accuracy of manufactured parts are described in another article: The actual size of the product after 3D printing.

The process of creating a product. nine0009

Structure of the additive manufacturing process for the production of products:

Designer / 3Dartist 3D printing service Discussed errors 1. Creating a 3D model of 2. Export/convert 3D model to required format 3. Checking the model for suitability 4. Pass/Fail to minimum allowable thicknesses. nine0458 6. Preparation of control program for 3D printer (GCode) 5. Compliance / non-compliance with the requirements for the polygonal mesh of the 3D model. 7. 3D printing process. 9. Quality control. 8. Post-processing process. In accordance with the presented algorithm, at the first stage of product creation, a 3D model is developed using modeling programs in accordance with the terms of reference and standards requirements.

After that, it is necessary to export the data of the simulation result program file to a format accepted by the program of the additive manufacturing control machine (for example, “STL”). The modeling process can now be done not only in solid format, but also immediately in STL. Before the next stage, possible defects in the model are identified. A model intended for 3D printing must be hermetic, monolithic and not contain cavities and gaps in the walls, which is ensured using special programs. Next, the information from the STL file is converted into commands, following which the 3D printer produces a product, this is the so-called GCode. nine0003

During this procedure, you should select the desired scale of the part, the correct position in space, and accurately position the model on the work surface. The result of the whole process, strength, surface roughness of the part and material consumption depend on this . After the settings are made, the model is divided into layers of material, which are “fitted” into the body of the part in one working cycle of the additive machine.

This process is called slicing. Slicing is done using the software supplied with the machine, or using special tools (Simplify, Skein-forge, Slic3r, KISSlicer, MakerWare, etc.). The G-code obtained in the previous step is transferred to the 3D printer via flash memory or via a USB cable. In the process of preparing and setting up the additive machine, calibration, preheating of the working bodies, selection of the model material and setting the parameters of the equipment operation modes that depend on it are performed. On professional level devices, this step can be combined with the slicing process procedures. After all the preparatory operations are completed, the printing process starts, that is, the layer-by-layer combination of materials. Its duration depends on the type of technology and the selected parameters for the accuracy and quality of the part. nine0003

Requirements for models for 3D printing and CNC processing.

- List of file formats by 3D technologies.

- FDM (ABS, PLA, FLEX, HIPS, etc.): .STL .OBJ

- SLS (polyamide): .STL .OBJ

- SLA, DLP (photopolymer): .STL .OBJ

- SLM (metal): .STL+STP(STEP) .OBJ+STP(STEP)

- Multicolour plaster: .OBJ+texture .WRL+texture

- Polygon mesh.

- The mesh must be uniform and closed. A model consisting of several polygonal meshes is not allowed! Intersection of polygonal meshes is not allowed! Holes in the grid are not allowed!

- Multiple models in one file are not allowed. Each object needs to be saved as a separate file.

- The number of polygons must not exceed 500,000.

- Wall thickness must be at least the specified values for each technology. nine0060

- Inverted normals are not allowed! The outer normal should face outward. This problem is especially common when mirroring the model in some 3D modeling programs.

- The dimensions of the model must correspond to the dimensions of the real object.

In 95% of cases, errors in files are not critical and can be easily corrected using specialized programs that can be easily found on the Internet. Even if you are sure that everything is in order with the model, it does not hurt to check it once again for correctness. nine0003

NETFABB - as a solution to most file errors.

MESHMIXER is a powerful and convenient alternative.

- Wall thickness analysis of the model.

It should be understood that there are several 3D printing technologies. They differ not only in the materials used, but also in the accuracy of the equipment. Different equipment has its own resolution. Therefore, before sending the file for printing, it is necessary to make sure the quality of the model in terms of the specified thicknesses in the walls, rods, mesh ceilings. Detailed article about checking models for thickness.

nine0003

Fixing non-critical bugs with NetFabb.

NETFABB (download for PC or download for Mac) is a program that allows you to solve almost any issue related to 3D printing. Let's go through the main functions of this software, which AutoDesk itself bought at one time.

The program shows the outer part of the polygon in green, its inner normal in red. Ideally, the model should be all green. If you observe red spots, then these are polygons that are turned outward. If the entire model is highlighted in red, then the entire mesh is turned inside out. nine0003

Even if the model is green, but there are errors in your file, the program will display a big exclamation mark in the lower right corner of the screen, and will also not be able to calculate the volume of your model.

To treat the model, click on the red cross on the toolbar at the top of the screen. The program will put you into the treatment mode, and will indicate in yellow the breaks in the polygonal mesh, if any.

This program has functions for removing or adding polygons, changing sizes or proportions. (I will leave these functions for independent study). I recommend that you study the entire toolbar in order to easily understand how, where and which polygons we can select and what we can change. nine0003

To invert normals, select the polygons that look “in the wrong direction” and click on the “invert normals” button. Then click on the “Apply Repair” button.

If your model was initially all green or inverting the normals didn't remove the exclamation mark, and the volume has not yet been calculated, you need to apply automatic treatment. To do this, go back to the treatment mode by clicking on the red plus. In the treatment mode, select "Automatic treatment", then select "Default Repair" and click "Extrude". nine0003

The program has now done its best to repair the model automatically. Click "Apply Repair".

Typically, these steps should have fixed your model.

If after the performed operations an exclamation mark is on and there is still no volume, then you are among those 5% when the model has critical errors and errors are laid down at the modeling stage.

Fixing non-critical bugs with MeshMixer.

Autodesk MeshMixer is a free program for working with 3D mesh models. You can download the program from the link. The program does not have tools for creating 3D models, but a wide range of tools for modifying them and preparing them for 3D printing. The main difference between this software and NETFABB is that MESHMIXER officially supports the latest versions of macOS. For me, this is a decisive factor, because I always carry a MacBook with me, and a Windows computer is only in the office. In turn, NetFabb stopped supporting software for macOS. nine0003

As in the case of Netfabb, you need to drop the model in STL format into the MeshMixer program window.

At first glance, the model looks good, but let's try to test it for suitability for 3D printing (mesh requirements).

To do this, you need to analyze the model for errors. To do this, go to the “Analisis” section, then click on the “Inspector” button.

On the screen, we see how the program has highlighted areas on the model with bright colors that do not meet the requirements, which means they have errors. nine0003

In order to fix (cure) these errors, click on the “Auto Repair All” button. The program will try to remove errors automatically. Checking before 3D printing is a must. Even if outwardly the model seems suitable to you, it is still worth checking. In the picture below, you can see the errors that are inside the mesh, although everything looks good with the model.

However, this treatment does not always help. For example, if the model has a huge number of errors that the program is not able to remove automatically, then you will have to correct the model yourself in the program where the model was originally created. In case of a large number of errors, the program will indicate their presence even after you have tried to do automatic treatment.

The picture below is an example of a very large number of shortcomings and errors that the program is not able to remove by itself. nine0003

This usually happens when the model is being prepared for rendering rather than 3D printing. That is, there is a huge number of surfaces, but they are not connected into a single grid.

Fixing non-critical errors with Materialize Magic

The 3D model healing feature in Materialize Magic is located in the Fix tab.

After that, select the “Correction Wizard” command. Next, you need to alternate the “Update” and “Autocorrect” buttons. nine0003

Do this several times. Sometimes for a long time. Until the moment when the number of errors becomes minimal or disappears altogether.

After the upgrade, the result shown below can be considered successful. All checkboxes must be green.

Complete the treatment by following the recommendations and save the corrected model!

A very important point! Treatment in automatic mode occurs according to the principle of adding or removing polygons.

Learn more