Best 3d printer technology

FDM vs. SLA vs. SLS

Additive manufacturing, or 3D printing, lowers costs, saves time, and transcends the limits of fabrication processes for product development. From concept models and functional prototypes in rapid prototyping to jigs, fixtures, or even end-use parts in manufacturing, 3D printing technologies offer versatile solutions in a wide variety of applications.

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology is suitable for your particular application? What materials are available? What equipment and training do you need to get started? How about costs and return on investment?

In this article, we’ll take a closer look at the three most established plastic 3D printing processes today: fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Trying to decide between FDM and SLA 3D printers? Check out our in-depth FDM vs. SLA comparison.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

Download the high-resolution version of this infographic here.

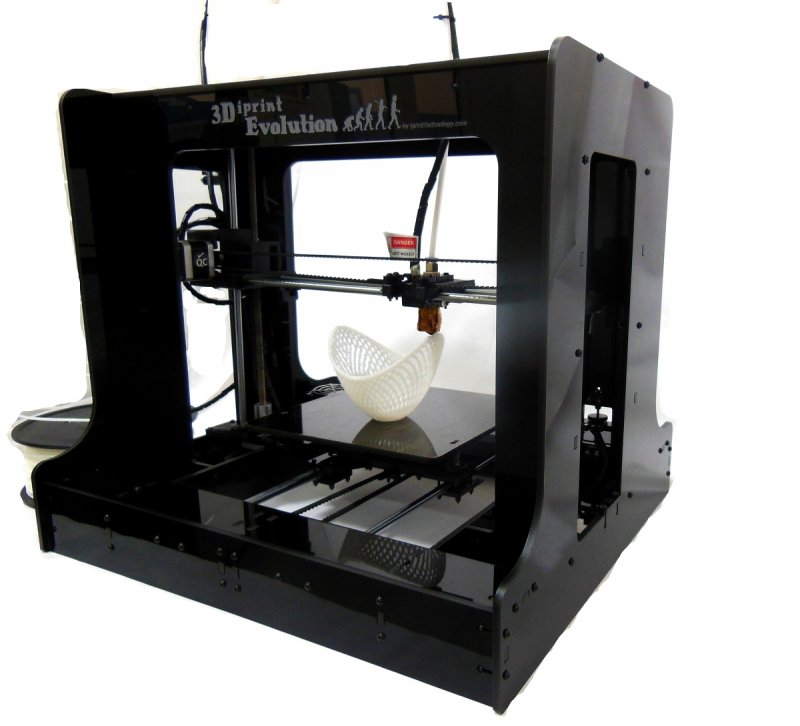

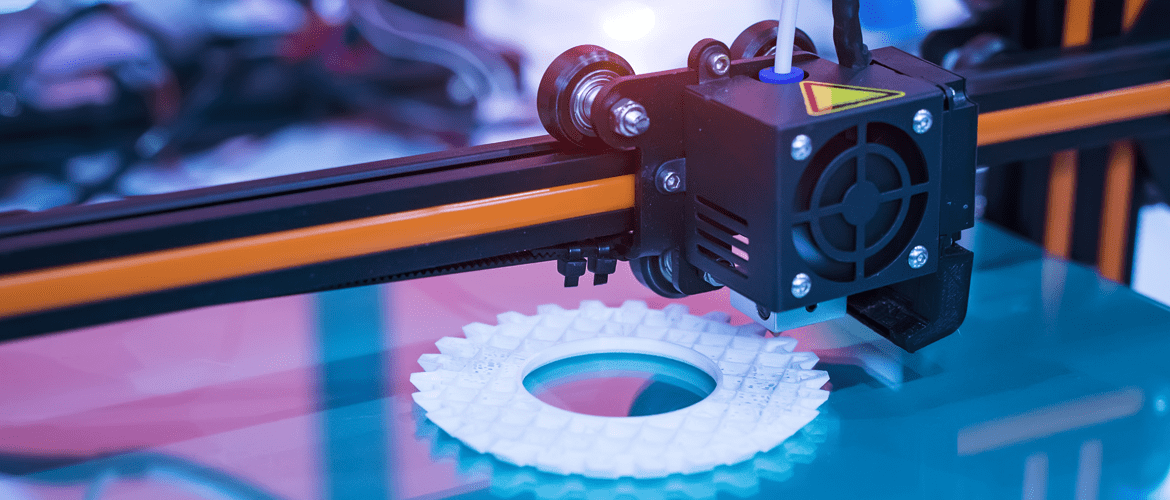

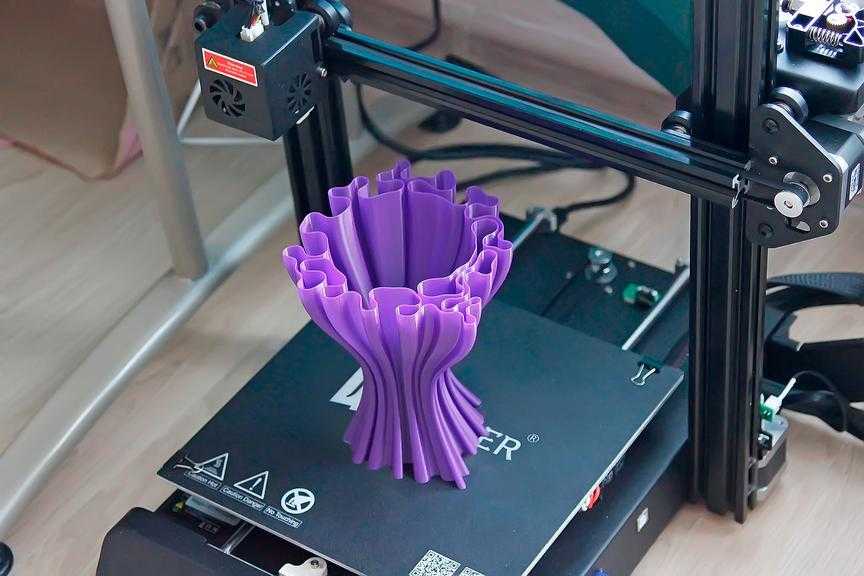

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM works with a range of standard thermoplastics, such as ABS, PLA, and their various blends. The technique is well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

FDM parts tend to have visible layer lines and might show inaccuracies around complex features. This example was printed on a Stratasys uPrint industrial FDM 3D printer with soluble supports (machine starting at $15,900).

FDM has the lowest resolution and accuracy when compared to SLA or SLS and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics, but they also come at a steep price.

FDM printers struggle with complex designs or parts with intricate features (left), compared to SLA printers (right).

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

See how stereolithography works.

SLA parts have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies, but the main benefit of SLA lies in its versatility. Material manufacturers have created innovative SLA photopolymer resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA parts have sharp edges, a smooth surface finish, and minimal visible layer lines. This example part was printed on a Formlabs Form 3 desktop SLA 3D printer (machine starting at $3,750).

SLA is a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA is widely used in a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

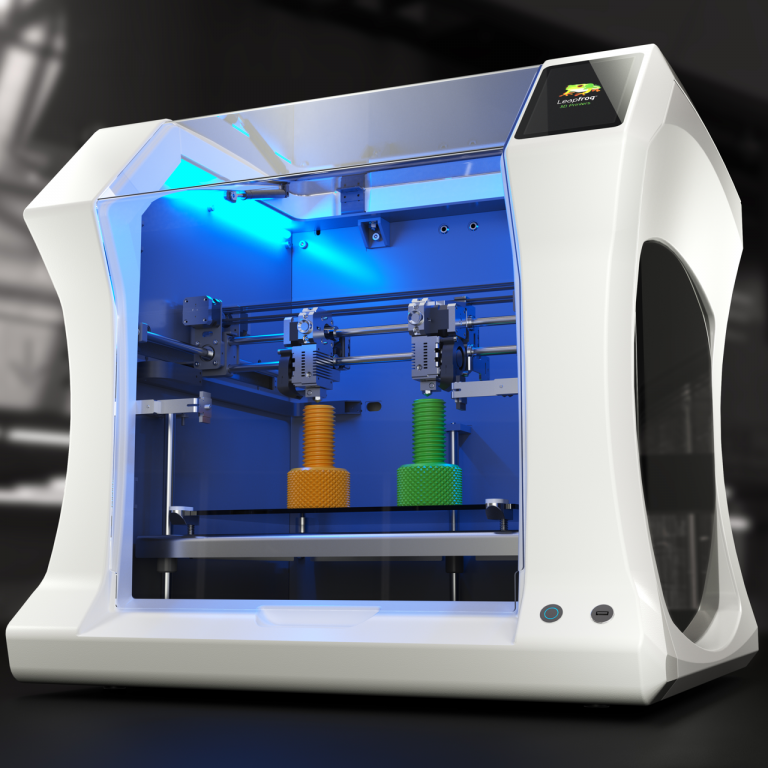

Selective laser sintering is the most common additive manufacturing technology for industrial applications, trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.

See how selective laser sintering works.

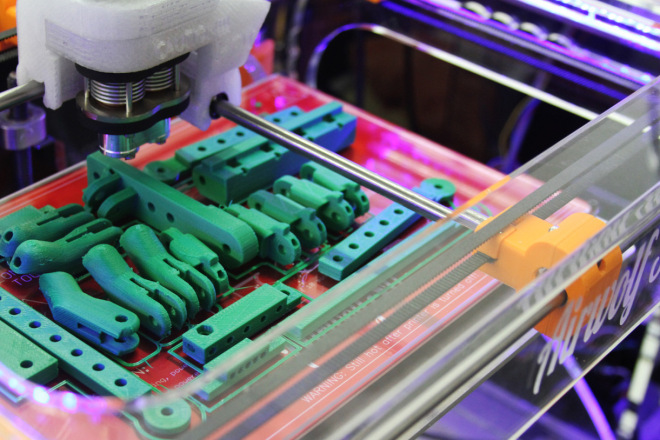

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

SLS parts have a slightly rough surface finish, but almost no visible layer lines. This example part was printed on a Formlabs Fuse 1 benchtop SLS 3D printer (machine starting at $18,500).

The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

The combination of low cost per part, high productivity, and established materials make SLS a popular choice among engineers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Sample part

See and feel Formlabs SLS quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Each 3D printing technology has its own strengths, weaknesses, and requirements, and is suitable for different applications and businesses. The following table summarizes some key characteristics and considerations.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | |

|---|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Accuracy | ★★★★☆ | ★★★★★ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ | ★★★★☆ |

| Throughput | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Complex Designs | ★★★☆☆ | ★★★★☆ | ★★★★★ |

| Ease of Use | ★★★★★ | ★★★★★ | ★★★★☆ |

| Pros | Low-cost consumer machines and materials Fast and easy for simple, small parts | Great value High accuracy Smooth surface finish Fast printing speeds Range of functional applications | Strong functional parts Design freedom No need for support structures |

| Cons | Low accuracy Low details Limited design compatibility | Sensitive to long exposure to UV light | Rough surface finish Limited material options |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Modelmaking | Functional prototyping Short-run, bridge, or custom manufacturing |

| Print Volume | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12, and their composites. |

| Training | Minor training on build setup, machine operation, and finishing; moderate training on maintenance. | Plug and play. Minor training on build setup, maintenance, machine operation, and finishing. | Moderate training on build setup, maintenance, machine operation, and finishing. |

| Facility Requirements | Air-conditioned environment or preferably custom ventilation for desktop machines. | Desktop machines are suitable for an office environment. | Workshop environment with moderate space requirements for benchtop systems. |

| Ancillary Equipment | Support removal system for machines with soluble supports (optionally automated), finishing tools. | Washing station and post-curing station (both can be automated), finishing tools. | Post-processing station for part cleaning and material recovery. |

Ultimately, you should choose the technology that makes the most sense for your business. Prices have dropped significantly in recent years, and today, all three technologies are available in compact, affordable systems.

Calculating 3D printing costs does not end with upfront equipment costs. 3D printing material and labor costs have a significant influence on cost per part, depending on the application and your production needs.

Here’s a detailed breakdown by technology:

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) | |

|---|---|---|---|

| Equipment Costs | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Professional desktop printers start at $3,750, large-format benchtop printers at $11,000, and large-scale industrial machines are available from $80,000. | Benchtop industrial systems start at $18,500, and traditional industrial printers are available from $100,000. |

| Material Costs | $50-$150/kg for most standard and engineering filaments, and $100-200/kg for support materials. | $149-$200/L for most standard and engineering resins. | $100/kg for nylon. SLS requires no support structures, and unfused powder can be reused, which lowers material costs. |

| Labor Needs | Manual support removal (can be mostly automated for industrial systems with soluble supports). Lengthy post-processing is required for a high-quality finish. | Washing and post-curing (both can be mostly automated). Simple post-processing to remove support marks. | Simple cleaning to remove excess powder. |

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

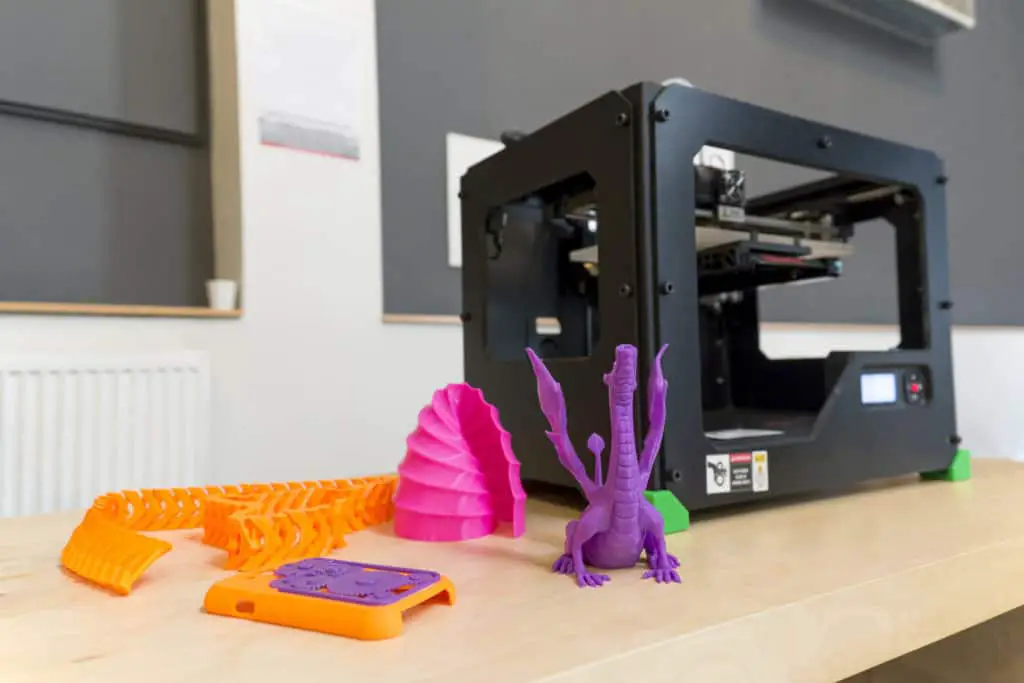

Prototypes of a ski goggles' frame printed with FDM, SLA and SLS technology (from left to right).

We hope this article has helped you focus your search for the best 3D printing technology for your application.

Explore our additional resources to master the intricacies of 3D printing, and dive deeper into each technology to learn more about specific 3D printing systems.

Learn More About 3D Printing

The Best Cheap 3D Printers for 2023

While we'd hesitate to call 3D printing a mature technology, you might say it has reached its teenage years. Through their first decade-and-change, 3D printers have come down in price, grown easier to set up and operate, and become more reliable. And you may pay less than you expect: Many once-high-end features have migrated down to inexpensive models.

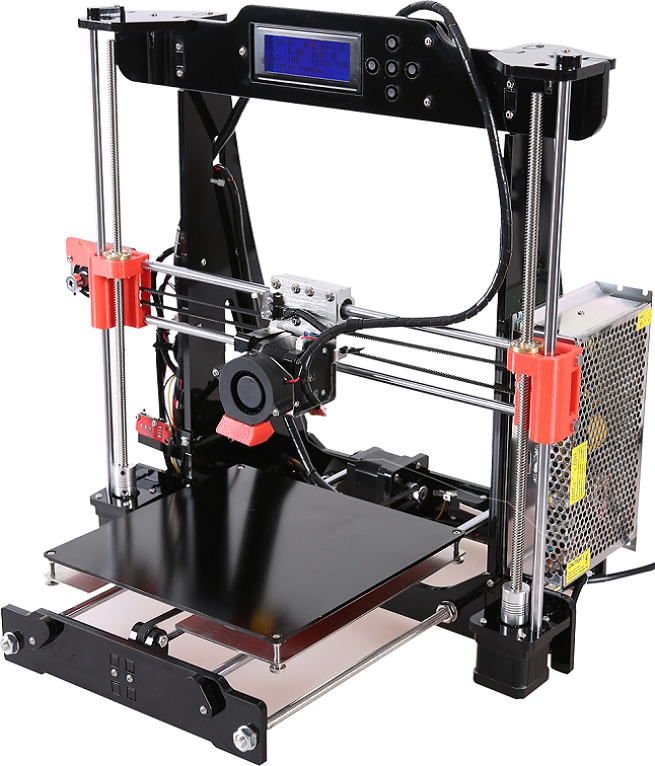

PC Labs has been reviewing 3D printers since 2013. Today, the state of 3D printing is strong, but that wasn’t always the case. For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

For the first several years, it was often an adventure getting one of these printers up and running, let alone successfully through our testing regimen. Issues with filament-based—aka fused filament fabrication (FFF) or fused deposition modeling (FDM)—printers were abundant.

Filament feeders had to be coaxed into delivering filament from the spool to the extruder. Print beds had to be manually aligned. The extruder or hot end had to be positioned just right to minimize the gap between the nozzle and the build plate (the flat surface on which the object is printed). Objects frequently stuck to the build plate, and required careful, sometimes unsuccessful, efforts to pry them off. These and other issues required painstaking effort to resolve, often combined with calls to tech support.

Not so much anymore. While they can still be rebellious at times, 3D printers have grown up a lot, and achieving the 3D printer basics has gotten a lot less likely to end in a shouting match over small things. And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

And they've gotten a lot more affordable, too, for curious DIY-ers and hobbyists to try.

If you're in the market for a beginner or low-cost 3D printer, it's important to know how lower-end models differ. Read on for mini-reviews of the top budget 3D printers we've tested. After that, we go into more detail on understanding the 3D printer specs and tech relevant to beginning buyers. Ready to take the plunge? Read on.

Deeper Dive: Our Top Tested Picks

Original Prusa Mini

Best Overall Budget 3D Printer

4.5 Outstanding

Bottom Line:

It requires assembly and calibration care (plus shipping from the Czech Republic), but the Original Prusa Mini is a compact, open-frame 3D printer that consistently produces superb-quality output for a great price.

PROS

- Top-notch object quality

- Supports a variety of filament types

- Useful, professionally printed user guide

- Great support resources

- Versatile, user-friendly software

CONS

- First-layer calibration can be tricky

- Only includes starter packets of filament

- Requires monitoring if young children or pets are around

| Sold By | List Price | Price | |

|---|---|---|---|

| Prusa Research | $399. 00 00 | $399.00 | See It (Opens in a new window) |

Read Our Original Prusa Mini Review

XYZprinting da Vinci Mini

Best Budget 3D Printer for Schools, Community Centers

4.0 Excellent

Bottom Line:

The XYZprinting da Vinci Mini is a consumer-oriented 3D printer that provides a winning combination of low price, ease of setup and use, solid print quality, and smooth, misprint-free operation.

PROS

- Very low price.

- Reasonably priced filament.

- Good print quality.

- No misprints in testing.

- Easy setup and operation.

- Quiet.

- Prints over a USB or Wi-Fi connection.

CONS

- Occasional problems in trying to launch prints.

- Removing printed objects from the print bed is sometimes tricky.

| Sold By | List Price | Price | |

|---|---|---|---|

| Walmart | $199. 95 95 | $199.95 | See It (Opens in a new window) |

| Amazon | $199.95 | $199.95 | See It (Opens in a new window) |

Read Our XYZprinting da Vinci Mini Review

Toybox 3D Printer

Best Budget 3D Printer for Children

4.0 Excellent

Bottom Line:

The Toybox 3D Printer works well as a model designed for children, offering reliable printing from a browser or mobile device and a few thousand toys to print, plus creative options to output drawings or photos. Just bear in mind the tiny build area.

PROS

- Reliable, misprint-free printing

- Easy setup

- One-touch operation

- Well-composed help resources

- Access to more than 2,000 printable toys and projects

- Lets you create your own printable designs

CONS

- Tiny build area

- Not ideal for importing 3D files created elsewhere

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $299.00 | See It (Opens in a new window) |

| Toybox Labs | $379.00 | $299.00 | See It (Opens in a new window) |

Read Our Toybox 3D Printer Review

Monoprice Mini Delta V2 3D Printer

Best Budget 3D Printer for Beginners, Non-Techies

4.0 Excellent

Bottom Line:

3D printing gurus will be intrigued by the Monoprice Mini Delta V2's use of the delta rather than Cartesian coordinate system, but beginners will just enjoy its low price, ease of use, and speedy printing.

PROS

- Sub-$200 price

- Quick, nearly misprint-free printing

- Easy setup and operation

- Sturdy steel-and-aluminum frame

- Supports multiple filament types

CONS

- Tiny build area

- So-so print quality

- Mere one-year warranty

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $323. 98 98 | $323.98 | See It (Opens in a new window) |

Read Our Monoprice Mini Delta V2 3D Printer Review

Anycubic i3 Mega S

Best Budget 3D Printer With an Open Design, Big Build Area

3.5 Good

Bottom Line:

The Anycubic i3 Mega S, an inexpensive open-frame 3D printer, produced decent-quality prints in our testing. To get the most out of it, though, may require precise calibration.

PROS

- Modestly priced

- Large build area for an inexpensive printer

- Supports a variety of filament types

- Generally solid print quality

- Uses well-known Cura software

CONS

- Finicky print-platform alignment

- Supported coils of filament are small

- Poorly placed spool holder

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $229. 98 98 | $229.98 | Check Stock (Opens in a new window) |

| AnyCubic | $279.00 | $279.00 | Check Stock (Opens in a new window) |

Read Our Anycubic i3 Mega S Review

Anycubic Vyper

Best Budget 3D Printer for the Biggest Build Area Possible

3.5 Good

Bottom Line:

Anycubic's modestly priced Vyper whips up large 3D prints on its open-frame design, and provides automatic print-bed leveling. Just know that some minor assembly is required—and printed objects may require a bit of cleanup.

PROS

- Relatively large build area

- Automatic bed leveling

- Simple assembly

CONS

- Short (one-year) warranty

- Includes only a small starter filament coil

- Using Cura software with the Vyper requires tweaking a couple of settings

- Test prints showed some "hairy" filament residue

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $499. 00 00 | $429.99 | See It (Opens in a new window) |

| AnyCubic | $369.00 | $319.00 | See It (Opens in a new window) |

Read Our Anycubic Vyper Review

Creality Ender-3 V2

Best Budget 3D Printer for Tinkerers and DIY Types

3.5 Good

Bottom Line:

Hands-on tweaking defines Creality's budget-price Ender-3 V2, an open-frame 3D printer that you build from a kit. It produces generally above-par prints, but its print bed can be tricky to keep leveled.

PROS

- Inexpensive

- Slightly above-average print quality

- Good-size build area for its price

- Supports several filament types

CONS

- Manual print-bed leveling can be tricky

- Setup instructions could be deeper, more legible

- Questionable quality control on some parts

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299. 00 00 | $246.00 | See It (Opens in a new window) |

Read Our Creality Ender-3 V2 Review

Flashforge Finder 3D Printer

Best 3D Printer for the Very Tightest Budgets

3.5 Good

Bottom Line:

The Flashforge Finder 3D Printer is moderately priced and offers good print quality, but it proved tricky to get up and running in our tests.

PROS

- Quiet.

- Good print quality.

- Connects via USB 2.0 cable, USB thumb drive, or Wi-Fi.

- Reasonably priced.

CONS

- Some objects pulled off the platform during testing.

- Poor documentation.

- Modest build volume.

- Limited to printing with polylactic acid filament (PLA).

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $259.90 | $259.90 | Check Stock (Opens in a new window) |

Read Our Flashforge Finder 3D Printer Review

Polaroid PlaySmart 3D Printer

Best Budget 3D Printer for Dabbling in Small Objects

3. 5 Good

5 Good

Bottom Line:

The Polaroid PlaySmart 3D Printer is a compact, stylish 3D printer with above-par overall print quality, but, alas, a tiny build area for the money.

PROS

- Small, lightweight for a desktop 3D printer.

- Easy to set up and use.

- Supports PLA, PETG, and wood composite filaments.

- Multiple-color support.

- Wi-Fi camera monitors print jobs.

- Prints from USB drives, SD cards, or mobile devices.

CONS

- High price for its capabilities.

- Small build area.

- Too-brief warranty.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $699.00 | $699.00 | See It (Opens in a new window) |

Read Our Polaroid PlaySmart 3D Printer Review

XYZprinting da Vinci Jr. 1.0 A Pro

Best Budget 3D Printer With Closed Design, Roomy Build Area

3. 5 Good

5 Good

Bottom Line:

The XYZprinting da Vinci Jr. 1.0 A Pro is a moderately priced closed-frame 3D printer with a large build volume and overall good performance, but a potentially balky filament-feeding system.

PROS

- Spacious build area

- Works with third-party filaments

- Self-leveling print bed

CONS

- Build plate is not heated

- Limited to PLA- and PETG-based filaments

- Guide tube is prone to detaching

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $299.95 | $199.95 | See It (Opens in a new window) |

| Best Buy | $449.95 | $449.95 | Check Stock (Opens in a new window) |

Read Our XYZprinting da Vinci Jr. 1.0 A Pro Review

Monoprice Voxel 3D Printer

Best Budget 3D Printer for Cheap Filament

3. 0 Average

0 Average

Bottom Line:

The Monoprice Voxel is an under-$400 3D printer that's easy to set up and use. It exhibits generally good print quality, but it was unable to print two of our test objects.

PROS

- Easy to set up and use.

- Budget price for printer and filament spools.

- Supports PLA, ABS, and several composite filament types.

- Versatile software.

- Prints over Ethernet or Wi-Fi, or from a USB thumb drive.

CONS

- Frequent misprints on certain test objects.

- Slightly balky touch screen.

| Sold By | List Price | Price | |

|---|---|---|---|

| Amazon | $449.99 | $369.26 | See It (Opens in a new window) |

| Walmart | $429.99 | $369.26 | See It (Opens in a new window) |

Read Our Monoprice Voxel 3D Printer Review

Buying Guide: The Best Cheap 3D Printers for 2023

How to Buy a Cheap 3D Printer

The biggest changes to 3D printers over the last few years have come to the cheaper models. Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

Nowadays, many of those classic, ornery 3D-printing issues have been resolved (most of the time, anyway), even for consumer and bargain-priced 3D printers. Automatic print-bed leveling is the norm, and you can usually remove 3D-printed objects from heated and/or flexible build plates with a minimum of coaxing. And most 3D printer manufacturers have either developed and refined their own software, or have adapted an open-source printing platform such as Cura(Opens in a new window).

(Credit: Zlata Ivleva)

What separates more expensive 3D printers from cheap ones ("cheap" defined as $500 or less, for the purposes of this article) is often a select group of features. These include the build volume, the type of frame, the varieties of supported filament, the software, and the connectivity mix. Let's run through those in turn.

What's the Right Build Volume for a 3D Printer?

A 3D printer’s build volume is the maximum dimensions (HWD) of a part that it can print. (We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(We say “a part” because a 3D-printed object can consist of multiple parts that are printed, then glued or otherwise pieced together.) While the smallest build volume of any 3D printer we have tested is 3.9 by 3.9 by 4.9 inches, we consider any build volume smaller than 6 by 6 by 6 inches to be small, any between that and 10 by 10 by 10 inches as medium, and any printer with at least one build dimension of more than 10 inches as having a large build volume.

(Credit: Molly Flores)

As a general rule, inexpensive 3D printers have small build volumes, while more expensive ones have larger build volumes. This depends in part on the type of printer. Closed-frame 3D printers—and most semi-open models, which have a rigid top, base, and sides but are open in front and, often, back—tend to have small build volumes, while open-frame printers, lacking as rigid a physical structure, often have relatively large build volumes for the price. You'll want to weigh the build volume against the kinds of objects you will print.

Should I Get an Open-Frame or Closed-Frame 3D Printer?

Which brings us to the frame "form factor" question: open-frame versus closed-frame. Closed-frame 3D printers are boxlike devices, with a rigid base, walls (with a see-through door in front), and top. Among their advantages? They muffle the operating noise, as well as reduce the odor from melted filament (which is potentially an issue with ABS plastic), and they provide some protection for people or pets who might inadvertently touch the hot extruder. A downside: They tend to have smaller build volumes than open-frame 3D printers, which have fewer (often, no) walls to constrict them.

(Credit: Zlata Ivleva)

Low-cost 3D printers include both open-frame and closed-frame models, as well as a few stereolithography printers. If a relatively large build volume is a priority, you’re likely to get more bang for the buck with an open-frame model. Open-frames do have some clear downsides by definition: They tend to be noisy, emit odors when certain plastics are melted, and provide little protection for someone who might touch the hot extruder.

(Credit: Molly Flores)

Also, recognize some potential negatives of open frames, depending on the model. Some require assembly, being essentially kits, and most require more setup care than a closed-frame printer, plus more maintenance to keep them running smoothly. Still, these very traits should not deter—and may even appeal to—hobbyists and DIY folks.

What Should I Look for in 3D Printer Software and Connectivity?

Gone are the days when tinkerers had to cobble together several different programs to get a 3D printer to run. Manufacturers either include their own 3D printing program or modify an existing platform such as the open-source Cura.

3D printing software performs three main functions: processing an object file (resizing, moving, rotating, and in some cases duplicating it), slicing it (into virtual layers, based on your chosen resolution), and printing it. These are almost universally combined into a seamless process. Some high-end printers have software that supports a wider range of settings you can tweak, but even the basic suites work at least reasonably well.

More likely to vary among the cheaper set is the array of connection options from model to model. Nearly all have a USB Type-A port to fit a thumb drive for printing from document files. Most also have a USB Type-B port for connecting directly to a computer, and some offer Wi-Fi, too (or as an alternative), while a handful let you connect via Ethernet to share the printer across a local network.

Some printers support storing 3D files on an SD or microSD card (which may also contain the printer’s system files). Most 3D printer manufacturers (even the discount ones) have a mobile app to launch and monitor print jobs, and a few provide access to cloud services from which you can print.

While high-end 3D printers tend to have an abundance of connection choices, discount models vary widely in their choices. Some are generous and some are basic, so it pays to assess what a given model offers.

What Should I Look for in Filament Support?

Filament support tends to be a key area that separates the cheaper models from the higher-end ones. (See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

(See our guide to understanding 3D printing filaments for more particulars.) Inexpensive 3D printers tend to support a limited number of plastic filament types, some of them only PLA and/or ABS.

Recommended by Our Editors

3D Printing: What You Need to Know

3D Printer Filaments Explained

(Credit: Molly Flores)

PLA (polylactic acid) is a biodegradable, plant-based polymer, while ABS (acrylonitrile butadiene styrene) is the same tough plastic that Legos are made from. Objects printed from ABS are durable and nontoxic, though the material can be tricky to work with. ABS can emit an acrid, unpleasant odor during printing, and the bottom corners of objects being printed with it have a tendency to curl upward a bit, especially if you are using a non-heated print bed. This can lead to unsightly prints, and/or prints prematurely pulling off the build plate, ruining them.

Many entry-level and low-price 3D printers stick exclusively to PLA. If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

If you want to experiment with a larger variety of filaments—which include water-soluble filament, wood- and metal-laced composites, and both tough and flexible varieties—you may have to pay more, although a few discount models support a wide range of materials.

Should I Consider a 3D Printing Pen Instead?

Although they aren’t printers per se, inexpensive 3D pens are close kin to 3D printers—using the same filament types and a similar extrusion system—and we include them in the 3D printing category. Rather than tracing out a programmed pattern, you use the 3D pen much like a normal pen, except that you draw with molten plastic. You can trace a pattern or draw freehand, and even draw in three dimensions as the plastic quickly solidifies and hardens once extruded.

(Credit: 3Doodler)

Most 3D pens cost less than $100, and some cost $50 or less. At a glance, 3D pens may appear to be toys, but some artists and craftspeople have taken to them, as it is possible to make quite complicated and beautiful objects with them. If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

If your aim in 3D printing is something closer to freehand design and free expression than computer-centric, structured, and repeatable output, you might give one a try.

So, What Is the Best Cheap 3D Printer to Buy?

Buying a budget 3D printer needn’t mean a world of sacrifice. Plenty of capable and reliable models sell at less than $500, and while they may not be as feature-rich as their more expensive cousins, there's no sense in paying for things you don’t need.

Many casual 3D-printing experimenters will be fine with printing over a USB cable or from a thumb drive, and sticking to PLA may be the best choice for a starter 3D printer. If you focus just on the features you want, you may be pleasantly surprised at what you find. Below, check out a spec breakdown of the best under-$500 3D printers we have reviewed, paralleling our picks above. Also, for a look at the broader market, see our guide to our favorite 3D printers overall.

3D printing technologies.

What to choose 3D printing with metal or 3D printing with plastic? 3D printer technologies FDM VS SLA VS SLM

What to choose 3D printing with metal or 3D printing with plastic? 3D printer technologies FDM VS SLA VS SLM

Hello everyone, Friends! 3DTool is with you!

3D printing or additive manufacturing is a general term covering several kinds of processes. Each type of 3D printing has its own advantages and disadvantages. And each of them is designed for specific purposes.

In this article, we provide some simple tips to help you choose the right type of 3D printing for your needs. The graphs and tables provided in this article are intended as a quick reference to determine which type of 3D printing best suits your needs. nine0003

Type selection 3 D printing by supply

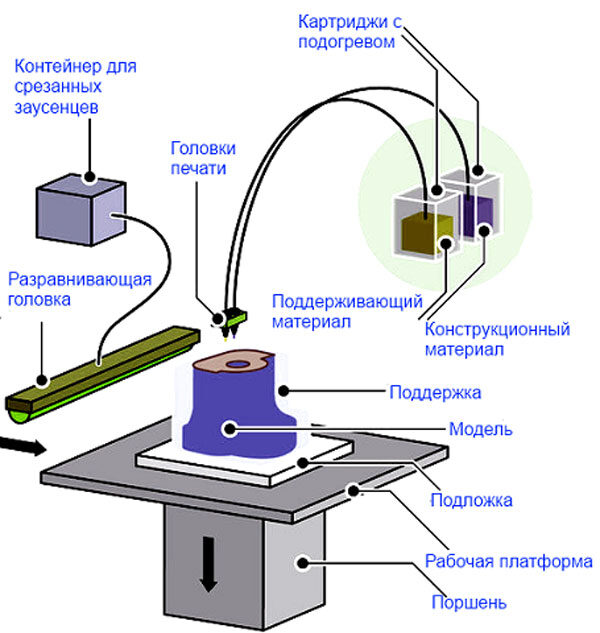

Materials for 3D printing usually come in the form of filament, powder, or resin (liquid photopolymer). Polymers (plastics) and metals are the two main groups of materials for 3D printing. Other materials (e.g. ceramics or composites) are also available. Polymers can be broken down into thermoplastics and thermosets.

Other materials (e.g. ceramics or composites) are also available. Polymers can be broken down into thermoplastics and thermosets.

-

3D printers FDM/FFF for plastic printing

-

3D printers for 3D printing with liquid photopolymers

-

3D printers for metal

If the required material is already known, the choice of 3D printing technology is relatively simple, since only a few additive technologies produce parts from the same materials. In these cases, the selection process is usually reduced to a comparison of costs and physical properties. nine0003

3 D plastic printing (thermoplastics)

Thermoplastics are best suited for functional applications, including the production of end-use parts and functional prototypes.

They have good mechanical properties, high impact resistance, wear resistance. They may also be filled with carbon, glass, or other additives to improve their physical properties. 3D printed thermoplastics (such as ePA, Nylon, Formax) are widely used to produce parts for functional industrial use. nine0003

They may also be filled with carbon, glass, or other additives to improve their physical properties. 3D printed thermoplastics (such as ePA, Nylon, Formax) are widely used to produce parts for functional industrial use. nine0003

SLS parts have better mechanical and physical properties, as well as higher dimensional accuracy. FDM is more economical, and with this type of 3D printing, the speed of order fulfillment is increased.

The diagram below shows the most common thermoplastic materials for 3D printing.

Explanation of diagram : The higher the material is in the pyramid, the stronger its mechanical properties and the more difficult and expensive it is to print: nine0003

3 D printing with liquid photopolymer resins

Liquid photopolymers (resins) are better suited for applications where detail and precision are important, as parts made using this technology will have smooth surfaces. Details up to 5cm will be printed with higher quality than 3D printing with plastics like in FDM or SLS.

Details up to 5cm will be printed with higher quality than 3D printing with plastics like in FDM or SLS.

Generally, photopolymer resins have high stiffness, but are more brittle than thermoplastics, so they are not suitable for functional applications. Special resins are available for engineering applications (simulating the properties of ABS plastic or Nylon). For example, a wide range of resins with various properties is in the arsenal of the American company FormLabs. nine0003

Metal 3D printing

Metal 3D printed parts have excellent mechanical properties and can withstand high temperatures and loads. Free-form 3D printing capabilities make them ideal for industrial applications.

Parts printed using DMLS or SLM technology have excellent mechanical properties and precision.

Use of other materials in 3D printing:

Other materials can also be used in 3D printing, but they are not widely used due to their limited specificity. These materials include ceramics and sand.

These materials include ceramics and sand.

Note:

Due to the nature of additive manufacturing, 3D printed parts will have anisotropic mechanical properties, meaning that they will be weaker in the z-direction. For functional machine parts, this characteristic should be taken into account when designing the model. nine0003

Early on, it is important to determine whether a part needs to be functional, or if it just needs to have good visual characteristics. This will greatly help in choosing the most appropriate 3D printing process.

Generally, parts made from thermoplastic polymers (FDM technology) are best suited for functional parts, while thermosetting materials (liquid resins) SLA or DLP technology are best suited for 3D printing small and complex geometric parts, such as jewelry or for dentists. . nine0003

Functionality 3 D printed parts:

The diagram below defines the most appropriate type of 3D printing for functional requirements.

Additive Manufacturing Essentials :

- When developing a prototype, it is important to determine what accuracy is required for the product. Generally, choosing an additive technology with higher precision increases the cost of 3D printing. nine0034

- The overall strength of the part depends on various mechanical and physical properties. When high strength and rigidity are required, metal 3D printing or FDM printing reinforced with continuous carbon fibers are the best solutions. An example of FDM 3D printing with reinforcing fiber is Anisoprint Composer A4 3D printer

- Do not forget that there are engineering materials for 3D printing with special. properties such as heat resistance, flame retardance, chemical resistance, or which are certified biocompatible (e.g. for dental applications). nine0034

Appearance 3 D printed parts.

If the appearance is the main task of your prototypes, then the choice of additive technology is subject to the scheme below:

Here is some more information:

- SLA or DLP 3D printing produces parts with a smooth, cast-like surface. Details will be as from the store. nine0034

- SLA/DLP parts print translucent, but can be post-processed to be nearly 100% optically transparent.

-

Selection of 3D printing technology according to production possibilities.

It is important to have an understanding of the main types of 3D printing in order to fully understand their key advantages and disadvantages. .

Here are some handy rules to help you: nine0003

The platform size determines the maximum dimensions of a part that the 3D printer can produce. For parts that are larger than the printer bed, consider switching to an alternative 3D printing technology or cutting the part into multiple pieces that can be glued together after printing into a single model.

The need for supports determines the level of design freedom. Processes that do not require supports, such as SLS, or when using dissolvable materials (as in FDM printing with 2 extruders), have fewer disadvantages and can create free-form structures more easily. nine0003

To summarize:

-

First of all, determine what task you set for 3D printing. Functionality or appearance of a part.

-

If more than one type of 3D printing is suitable for the task, then the selection process is reduced to a comparison of financial costs.

-

For functional details, choose FDM technology over printing with SLA or DLP liquid photopolymers.

- nine0006 For appearance and aesthetics, SLA or DLP technologies are the best option.

- For functional metal parts, CNC milling can also be considered. As an alternative to 3D metal printing.

And that's all we have! See you soon!

You can purchase a 3D printer or a CNC machine from our company. You can contact us in one of the following ways: nine0003

You can contact us in one of the following ways: nine0003

• By email: [email protected]

• By phone: 8(800)775-86-69

• Or on our website: http://3dtool.ru

Also, don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

Comparison of 3D printing technologies: FDM, SLA and SLS

Additive manufacturing or 3D printing reduces costs, saves time and expands the technological possibilities in product development. 3D printing technologies offer versatile solutions for applications ranging from rapid concept and functional prototypes in the field of prototyping to fixtures and clamps or even final parts in manufacturing. nine0003

Over the past few years, high resolution 3D printers have become more affordable, more reliable and easier to use. As a result, more companies have been able to use 3D printing technology, but choosing between different competing 3D printing solutions can be difficult.

Which technology is right for your needs? What materials are available for her? What equipment and training is needed to get started? What are the costs and payback? nine0003

In this article, we take a closer look at three of today's most well-known plastic 3D printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Choosing between FDM and SLA 3D printer? Check out our detailed comparison of FDM and SLA technologies.

Download this high resolution infographic here.

VIDEO MANUAL

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing. nine0003

Watch Video

Fused Deposition Modeling (FDM), also known as Fused Filament Manufacturing (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the rise of consumer 3D printers. On FDM printers, models are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer to the model being built.

On FDM printers, models are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer to the model being built.

The FDM method uses a range of standard plastics such as ABS, PLA and their various blends. It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined. nine0003

FDM models often show layer lines and may have inaccuracies around complex features. This sample was printed on a Stratasys uPrint FDM industrial 3D printer with soluble support structures (price starting at $15,900).

FDM printers have the lowest resolution and accuracy of SLA or SLS and are not the best option for printing complex designs or parts with complex features. Surface quality can be improved by chemical and mechanical polishing processes. To address these issues, industrial FDM 3D printers use soluble support structures and offer a wider range of engineering thermoplastics, but they are also expensive. nine0003

nine0003

FDM printers do not handle complex designs or parts with complex features (left) compared to SLA printers (right).

Invented in the 1980s, stereolithography is the world's first 3D printing technology and is still one of the most popular technologies among professionals today. SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

See stereolithography in action.

Models printed on SLA printers have the highest resolution and accuracy, the sharpest detail and the smoothest surface of all plastic 3D printing technologies, but the main advantage of the SLA method is its versatility. Materials manufacturers have developed innovative formulas for SLA polymers with a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics. nine0003

Models created using SLA technology have sharp edges, a smooth surface and almost invisible layer lines. This sample was printed on a Formlabs Form 3 Desktop Stereolithographic 3D Printer (price starting at $3499).

This sample was printed on a Formlabs Form 3 Desktop Stereolithographic 3D Printer (price starting at $3499).

SLA is an excellent option for making highly detailed prototypes that require tight tolerances and smooth surfaces such as molds, templates and functional parts. SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education. nine0003

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can be useful in your work.

Download white paper

free sample

Experience Formlabs print quality first hand. We will send a free 3D printing sample directly to your office.

Request a free sample

Selective laser sintering is the most common additive manufacturing technology used in industry.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts. nine0003

Models created with SLS technology have a slightly rough surface, but almost no visible layer lines. This sample was printed on the Formlabs Fuse 1 SLS workshop 3D printer (price starting at $18,500).

The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt. nine0003

The combination of low part cost, high productivity, and widely used materials makes SLS a popular method for engineering functional prototyping and a cost-effective alternative to injection molding where production runs are limited.

White Paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products. nine0379

nine0386

nine0386 Either way, you should choose the technology that best suits your business. Prices have dropped significantly in recent years, and today all three technologies are offered in compact and affordable systems.

3D printing costing doesn't end with initial equipment costs. Material and labor costs have a significant impact on the cost of each part, depending on the application and production needs. nine0386

INTERACTIVE MATERIAL

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

FDM, SLA and SLS printed ski goggle frame prototypes (left to right).

We hope this article has helped you narrow down your search for the 3D printing technology best suited to your needs.