Brazo robotico 3d print

▷ brazo robot para imprimir 3d models 【 STLFinder 】

Brazo Robot

grabcad

Brazo Robot

Brazo Robot

thingiverse

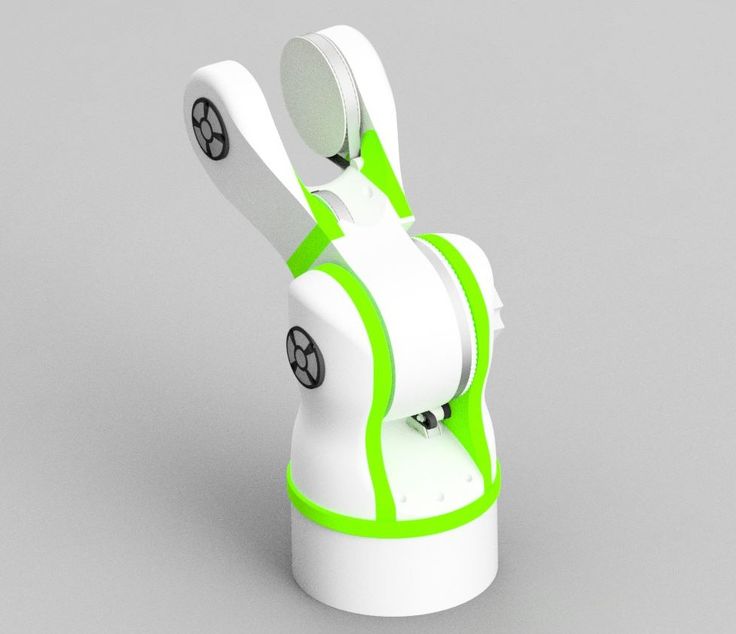

El desarrollo es enfocado en la sencillez del diseño, siendo el peso imprescindible para que los servos no tengan dificultad al mover debido a la robustez del brazo. Grosor de 3mm. El control del brazo es a través de una aplicación para móvil...

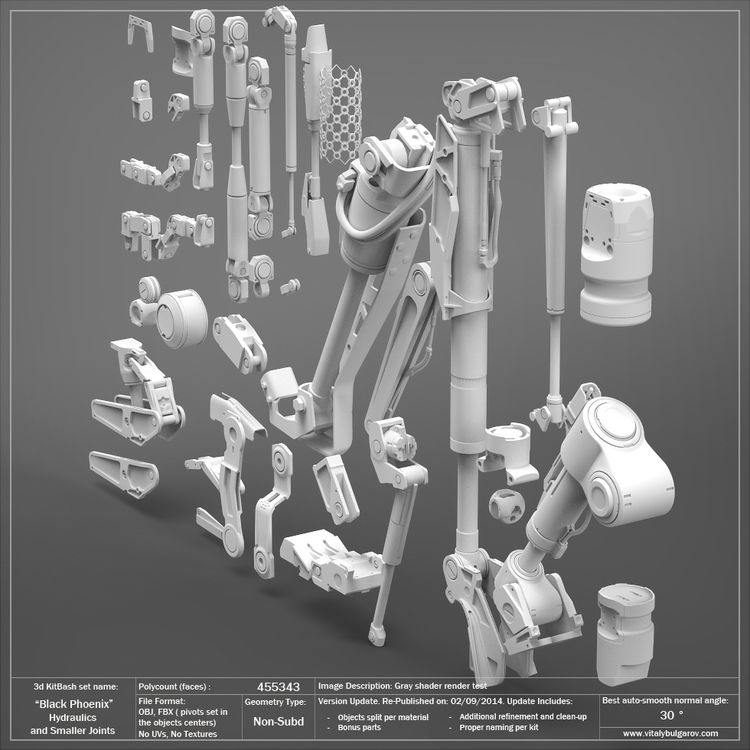

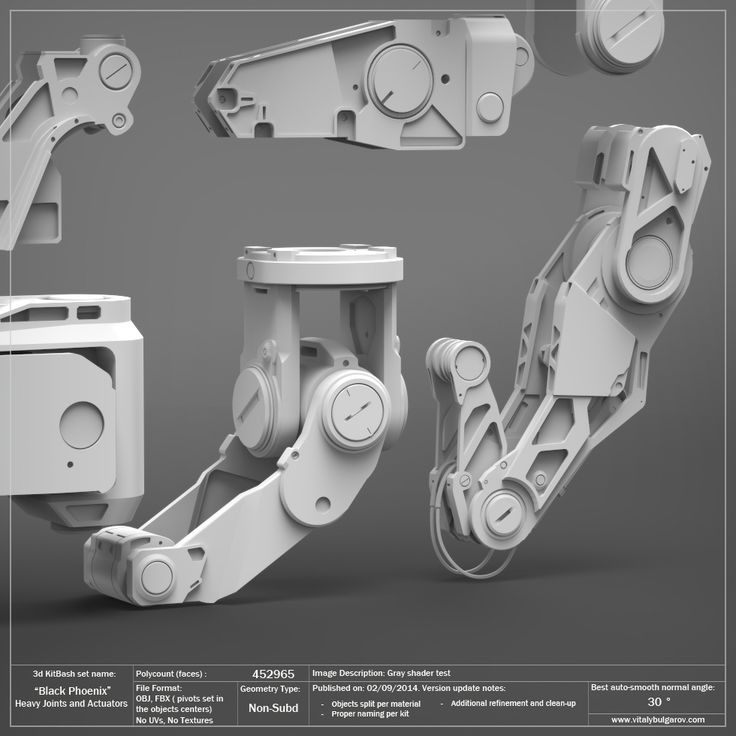

robot brazo

grabcad

robot

Brazo Robot

grabcad

Este es un proyecto de robotica donde este brazo se controla desde una interfaz desarrollada en java, aqui les muestro el diseño 3DContacto: -Facebook: https://www. facebook.com/bofo.bassi-Instagram: https://www.instagram.com/adolfocbg/

Brazo para engranajes

grabcad

Brazo para engranajes

Brazo Aspirador para VinylCare

thingiverse

Repuesto para el brazo aspirador de las lavadoras de vinilos VinylCare, fabricadas en Argentina.

GRIPPER PINZA BRAZO ROBOT

grabcad

GRIPPER , PINZA BRAZO ROBOT PARA FABRICACIÓN EN IMPRESIÓN 3D O CORTE LÁSER

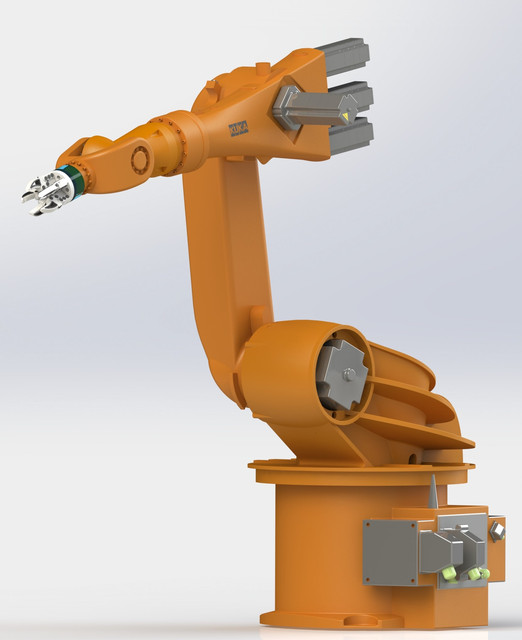

BRAZO ROBOT ARM

grabcad

BRAZO ROBOT 6 GRADOS DE LIBERTAD

Cohete Tintin para imprimir por partes

thingiverse

Basado en mi modelo https://www. thingiverse.com/thing:3195893 pero preparado para imprimir por partes y escalar al máximo que de tu impresora. ...

--

Based on my model https://www.thingiverse.com/thing:3195893 and ready to print by parts and reach...

thingiverse.com/thing:3195893 pero preparado para imprimir por partes y escalar al máximo que de tu impresora. ...

--

Based on my model https://www.thingiverse.com/thing:3195893 and ready to print by parts and reach...

Escala de Vernier o Nonio para imprimir

thingiverse

https://youtu.be/j5Vm13y7_fY Escala usada para ayudar en la lectura para la apertura de la caja fuerte sin conocer la combinación mediante técnicas no destructivas. Escala usada para ayudar en la lectura para la apertura de la caja fuerte sin...

Esquinero Regulable Archivo Para Imprimir 3D

sketchfab

esquinero para barandas de vidrios de grados bariables corner for glass rails of variable degrees

brazo robot 2 ejes

thingiverse

robot 2 ejen nema 17

Brazo Robot_jorge

grabcad

Proyecto de cinemática de robots

Brazo Robotico facil para armar

thingiverse

. .. y completamente funcional. ...El Arduino Nano o Arduino Uno requiere conectarse al PC para controlar el brazo robotico a traves de una aplicacion hecha en Java. ...A Solicitud de un suscriptor agrego archivos para imprimir en impresora Makerbot 10 X 10

.. y completamente funcional. ...El Arduino Nano o Arduino Uno requiere conectarse al PC para controlar el brazo robotico a traves de una aplicacion hecha en Java. ...A Solicitud de un suscriptor agrego archivos para imprimir en impresora Makerbot 10 X 10

Brazo para Microfono // Microphone Arm

thingiverse

-- ESPAÑOL -- Hoy os traigo un brazo para un micrófono de "Singstar de PS2" diseñado en Fusion360. Es capaz de estirarse casi 1m si en el 1º tramo le pones 30cm de varilla y en el 2º tramo le pones 40cm de varilla. Materiales: - 3 Tornillos M5 para...

Carrinho JEEP monster jam didático para imprimir e montar.

grabcad

Carrinho didático para imprimir e montar!www. [email protected]

[email protected]

Adaptador ender 3 pro extrusor doble para imprimir flexible

thingiverse

Pieza para acoplar a extrusor doble, para poder imprimir filamento flexible en ender 3 pro, hace que el extrusor apriete menos el filamento y así evitar problemas al imprimir con filamento flexible

CONDUCTO VENTILACIÓN PARA IMPRIMIR SIN NECESIDAD DE RETRACCIÓN

thingiverse

Esta pieza esta diseñada para poder ser impresa por una impresora que no hace bien la retracciónes. ...la mejora de la ventilación permitirá imprimir un soplador que requiera retracción con una calidad que alcance al menos la funcionalidad.

...la mejora de la ventilación permitirá imprimir un soplador que requiera retracción con una calidad que alcance al menos la funcionalidad.

Ultraseven modelo 3D para imprimir aquivo stl 3D model

cgtrader

Modelo 3D para impressão Stl,testado. ...

Servo Horn / Brazo para Servo tipo SG90

thingiverse

Se adaptan a la perfeccion en los alojamientos para el robot Kame desarrollado por BQ.

****

This arm that I created to use in SG90 type servos. The attack pinion is 21 teeth and the length is 26 mm.

... They adapt perfectly to the accommodations. ..

..

Poleas correa T5 Brazo Robot MOVEO

thingiverse

Estas son las poleas necesarias para utilizar en el brazo robot MOVEO de BCN Dynamics. ... Dejo el enlace para su descarga: https://github.com/BCN3D/BCN3D-Moveo También estan disponibles en thingiverse los archivos CAD en formato STL para imprimir en...

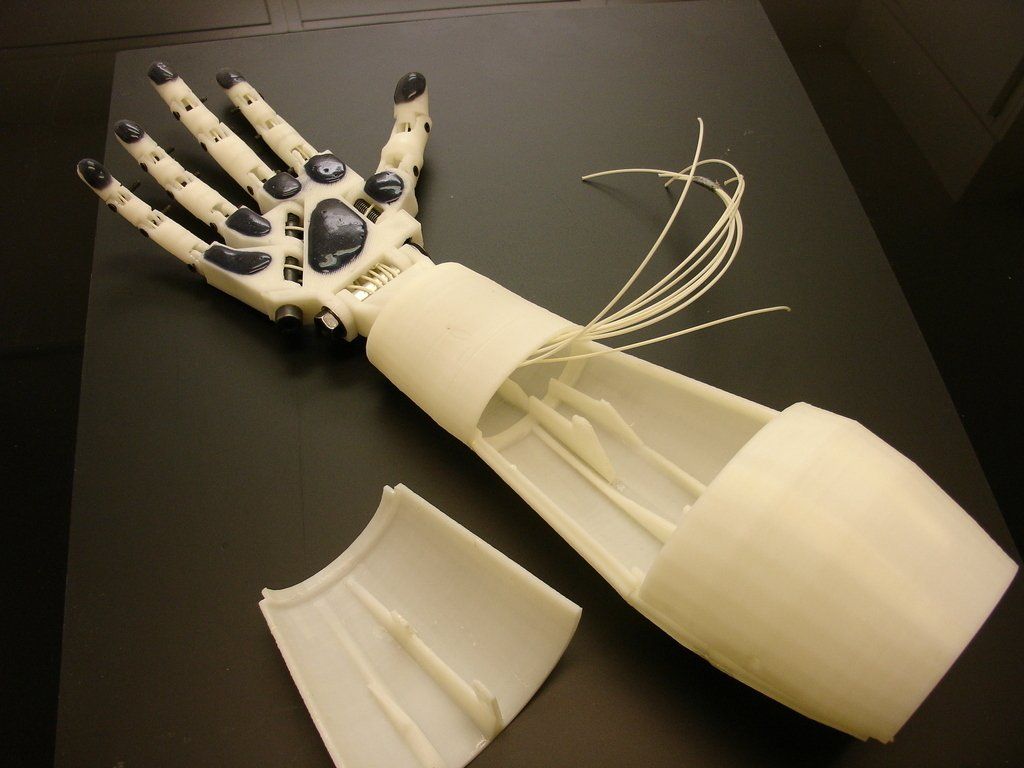

Mejoras para brazo prostetico de Atomic Lab

thingiverse

... -Las piezas del antebrazo se fusionaron y optimizaron para mejorar el tamaño y el peso del brazo. -Se mejoro la rosca del tridente y la cánula para que puedan ajustar de la mejor manera. . .. -Se agregaron mas lugares para los ajustes de velcro.

.. -Se agregaron mas lugares para los ajustes de velcro.

Brazo largo para servo de 9 gramos

thingiverse

... el punto que necesites. El resto lo puedes cortar con las tenacillas y repasar con lima o lija para dejar un acabado más bonito. Lo he editado en thinkercad con el nombre de brazo largo servo. ...Es público, así que si lo necesitas puedes editarlo.

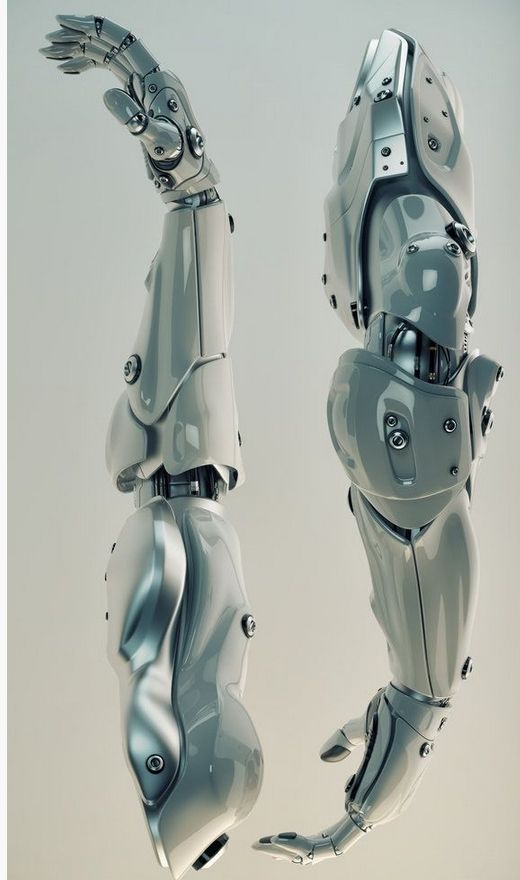

brazo

grabcad

brazo

brazo robot con servos v0.5

grabcad

pequeño brazo robot de 3 grados de libertad, aun no es definitivo, si pueden mejorar la posicion de los servos ayudaria mucho para un mejor control y posicion los servos son diseños en version educacion y solo estan para ayudar a ver las posiciones

Para Imprimir Lucia Buenos Aires

sketchfab

No description provided.

Brazo

grabcad

Diseño para prototipado rapido.

Brazo para motoreductor, 30mm de eje a perforación

thingiverse

Brazo para moto reductor , la impresión en PLA a .15 sea resultados aceptables

Brazo para anillas BPA

sketchfab

www.homeandgym.com

Brazo Para Animar

sketchfab

No description provided.

Diseño, desarrollo y fabricación del prototipo de un brazo robótico articulado controlado por un microcontrolador Arduino para la extracción de piezas en impresoras 3D

CORE🇺🇦 make metadata, not war

- Publication date

- October 10, 2018

- Publisher

- 'Universitat Politecnica de Valencia'

Abstract

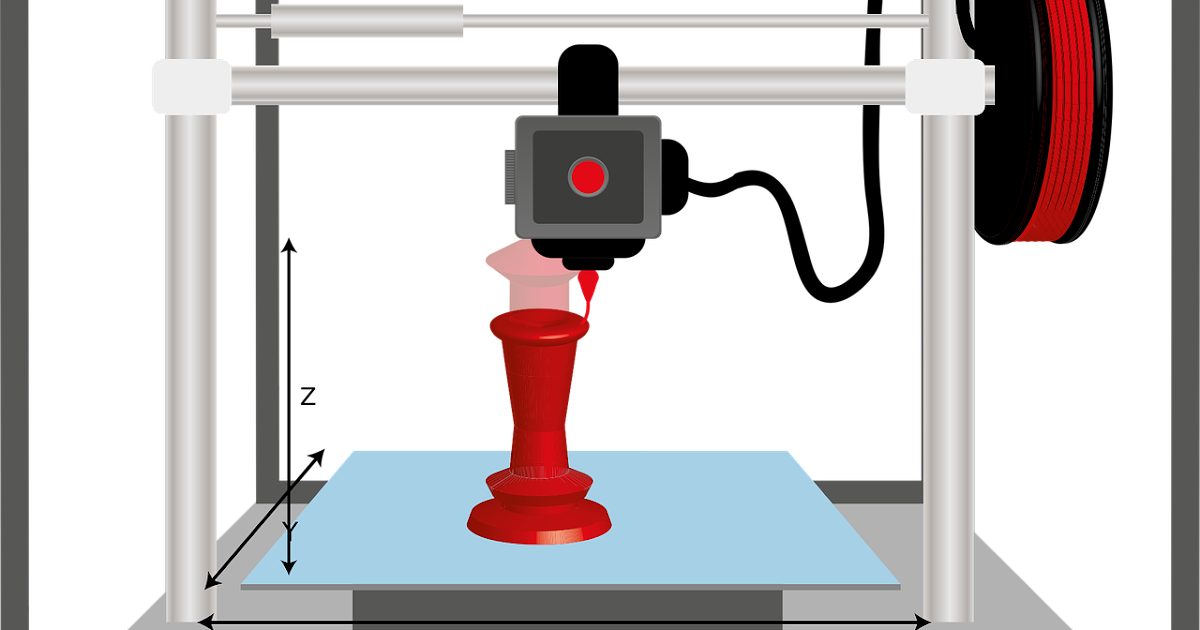

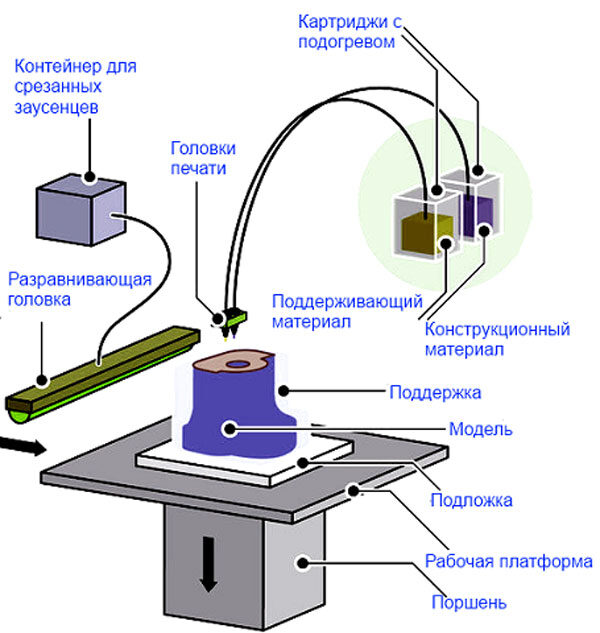

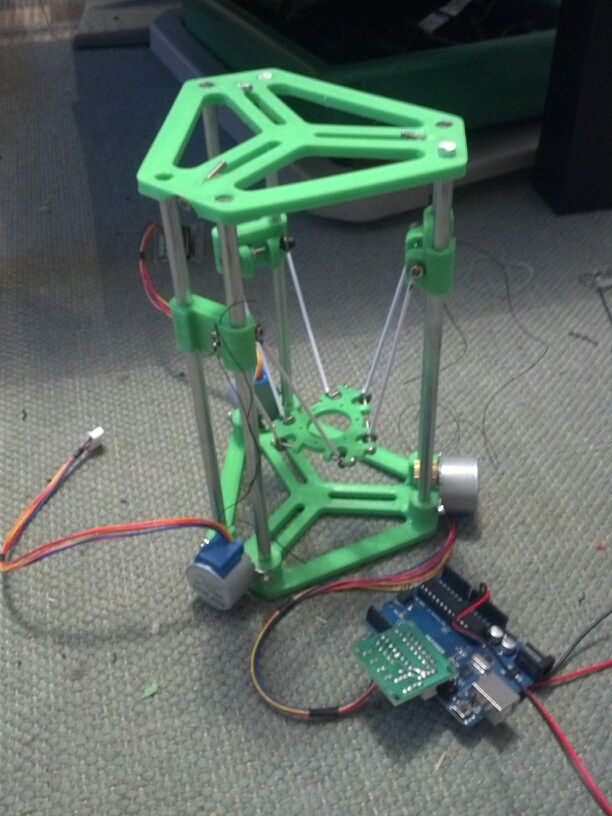

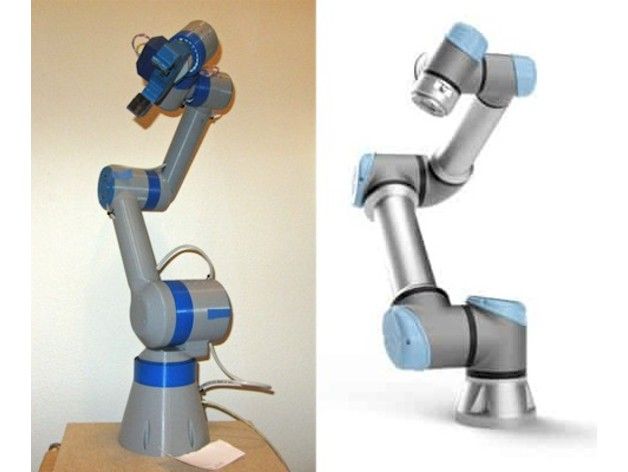

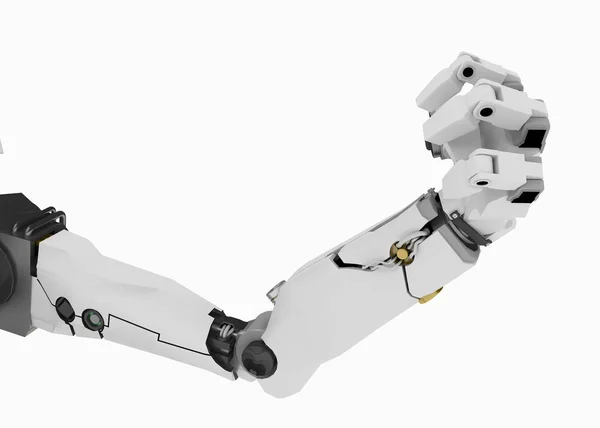

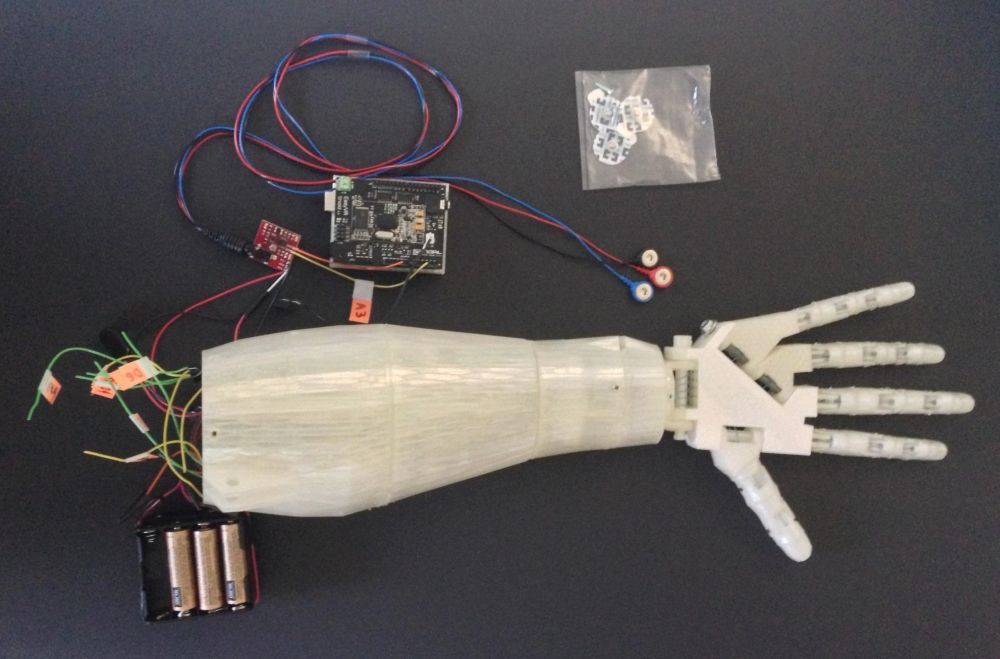

[ES] Actualmente se está desarrollando una nueva industria en torno al prototipado rápido o impresión 3D que posibilita a los consumidores tener acceso a un bajo coste. Es posible diseñar un producto utilizando software CAD y realizar un prototipo real del mismo enviándolo a imprimir, como si de un archivo de texto se tratase. A lo largo del documento se muestra el desarrollo de producto de un brazo robótico destinado a la extracción de piezas en impresoras 3D, abordando la fase de fabricación y de ensamblaje como parte del diseño. En primer lugar, se especifican las características geométricas del prototipo y los elementos clave que sentarán las bases del diseño. A continuación, se realiza un análisis del movimiento utilizando un mecanismo de barras simple, dando como resultado el par de torsión necesario para mover el brazo robótico y en consecuencia el tamaño de los servomotores, necesario para modelar el conjunto de piezas.

En la fase de modelado de las piezas se muestran las líneas de diseño, pensando en todo momento en la fabricación (dividiendo piezas en dos componentes para optimizar el proceso de impresión) y el montaje, sin renunciar al componente estético que se persigue. A continuación, se ensamblan todas las piezas en un modelo digital del brazo robótico, lo que posibilita realizar ajustes de posicionamiento de los elementos o correcciones geométricas antes de proseguir a la siguiente fase.

Tras esto, cada pieza se fabrica utilizando una impresora 3D doméstica con el fin de realizar el montaje de todas las partes y crear un prototipo funcional.

En primer lugar, se especifican las características geométricas del prototipo y los elementos clave que sentarán las bases del diseño. A continuación, se realiza un análisis del movimiento utilizando un mecanismo de barras simple, dando como resultado el par de torsión necesario para mover el brazo robótico y en consecuencia el tamaño de los servomotores, necesario para modelar el conjunto de piezas.

En la fase de modelado de las piezas se muestran las líneas de diseño, pensando en todo momento en la fabricación (dividiendo piezas en dos componentes para optimizar el proceso de impresión) y el montaje, sin renunciar al componente estético que se persigue. A continuación, se ensamblan todas las piezas en un modelo digital del brazo robótico, lo que posibilita realizar ajustes de posicionamiento de los elementos o correcciones geométricas antes de proseguir a la siguiente fase.

Tras esto, cada pieza se fabrica utilizando una impresora 3D doméstica con el fin de realizar el montaje de todas las partes y crear un prototipo funcional. Por último, se realiza el cableado de todos los sistemas eléctricos y se escribe el código de control del brazo robótico, que debe ser capaz de ponerse en funcionamiento una vez terminada la impresión de la pieza a extraer con la siguiente secuencia: aproximarse a la pieza, cogerla y depositarla fuera del perímetro de impresión.[EN] A new industry is currently being developed around rapid prototyping or 3D printing that enables

consumers to access it at a low cost. It is possible to design a product using CAD software and make a

real prototype of it by sending it to print, as if it were a text file.

Throughout the document the product development of a robotic arm for the extraction of parts in 3D

printers is taught, addressing the manufacturing and assembly phase as part of the design.

First, the geometric characteristics of the prototype and the key elements that will form the basis of

the design are specified. A motion analysis is then performed using a simple bar mechanism, resulting

in the torque required to move the robotic arm and hence the size of the servomotors required to

model the set of parts.

Por último, se realiza el cableado de todos los sistemas eléctricos y se escribe el código de control del brazo robótico, que debe ser capaz de ponerse en funcionamiento una vez terminada la impresión de la pieza a extraer con la siguiente secuencia: aproximarse a la pieza, cogerla y depositarla fuera del perímetro de impresión.[EN] A new industry is currently being developed around rapid prototyping or 3D printing that enables

consumers to access it at a low cost. It is possible to design a product using CAD software and make a

real prototype of it by sending it to print, as if it were a text file.

Throughout the document the product development of a robotic arm for the extraction of parts in 3D

printers is taught, addressing the manufacturing and assembly phase as part of the design.

First, the geometric characteristics of the prototype and the key elements that will form the basis of

the design are specified. A motion analysis is then performed using a simple bar mechanism, resulting

in the torque required to move the robotic arm and hence the size of the servomotors required to

model the set of parts. In the modeling phase, the design lines are shown, thinking at all times of the manufacturing (dividing

pieces into two components to optimize the printing process) and the assembly, without renouncing

the aesthetic component that is being pursued. All the parts are then assembled into a digital model

of the robotic arm, which makes it possible to make adjustments to the positioning of the elements or

geometric corrections before proceeding to the next phase.

After this, each part is manufactured using a 3D home printer in order to assemble all the parts and

create a functional prototype.

Finally, all the electrical systems are wired and the control code of the robotic arm is written, which

must be able to be put into operation once the printing of the part to be extracted has been completed

with the following sequence: approach the part, take it and place it outside the printing perimeter.Alandí Martín, G. (2018). Diseño, desarrollo y fabricación del prototipo de un brazo robótico articulado controlado por un microcontrolador Arduino para la extracción de piezas en impresoras 3D.

In the modeling phase, the design lines are shown, thinking at all times of the manufacturing (dividing

pieces into two components to optimize the printing process) and the assembly, without renouncing

the aesthetic component that is being pursued. All the parts are then assembled into a digital model

of the robotic arm, which makes it possible to make adjustments to the positioning of the elements or

geometric corrections before proceeding to the next phase.

After this, each part is manufactured using a 3D home printer in order to assemble all the parts and

create a functional prototype.

Finally, all the electrical systems are wired and the control code of the robotic arm is written, which

must be able to be put into operation once the printing of the part to be extracted has been completed

with the following sequence: approach the part, take it and place it outside the printing perimeter.Alandí Martín, G. (2018). Diseño, desarrollo y fabricación del prototipo de un brazo robótico articulado controlado por un microcontrolador Arduino para la extracción de piezas en impresoras 3D. http://hdl.handle.net/10251/11009

http://hdl.handle.net/10251/11009Similar works

Full text

oai:riunet.upv.es:10251/110093

Last time updated on

12/25/2019

This paper was published in RiuNet.

Is data on this page outdated, violates copyrights or anything else? Report the problem now and we will take corresponding actions after reviewing your request.

Robotika-3D-printing doll with a person

3D-rendering

Subscribe to the author

Subscribe

I do not want

6

The source of all photographs in the article Wanhao3dPrinter.com

9000 Article from the Wanhao3DPRINTER site. com translated for you by Top 3D Shop.CAD House made a 3D printed life size doll with fully articulated joints

As 3D modeling software and 3D printers became more accessible and easier to use, many people became fascinated with creating objects with articulated joints, such as - dolls with arms, legs, torso and neck that bend and turn in all joints. Spanish artist Sonia Verdu has created some beautiful 3D printed dolls. nine0003

Spanish artist Sonia Verdu has created some beautiful 3D printed dolls. nine0003

Verdu shared photos of her dolls and their free 3D models on MakerBot Thingiverse. She invites everyone to develop their own doll based on her design.

The South African company CAD House took this idea and printed a model of approximately 1.7 meters, fully movable in all joints.

The company decided to make Robotics as big as possible with existing 3D printers, without having to print parts piece by piece and then glue them together. The robotics model has been increased by 5 times. It was printed with PLA plastic on Wanhao FDM printers. nine0003

It took 240 hours of printing to make the doll. All parts were printed in golden PLA on Wanhao Duplicator 5S and 5S mini 3D printers.

Specifications Wanhao Duplicator 5S (D5S)

Read more about 3D printing on the Top 3D Shop Blog.

3D printing 3D printer 3D printers

Article comments

More interesting articles

arelav

Loading nine0003

01/07/2023

1795

15

Subscribe to the author

Subscribe

Don't want

This project was created a year and a half ago. I printed it, but never put it together until today...

I printed it, but never put it together until today...

Read more

3Dtool

Loading

01/05/2023

1462

-6

Follow author

Subscribe

Don't want

Hello everyone, Friends! With you 3DTool!

This year, at your request, we decided to...

Read more

Leoluch

Loading

07.09.2015

367355

351

Subscribe to the author

Subscribe

Don't want

Good afternoon, dear visitors of the portal. nine0003

Today I decided not to leave for art. ..

..

Read more

Read blogs

Read the article - 3D printing in secondary schools on the example of the New Chernogolovskaya school

In the modern world, additive technologies make it possible to facilitate the solution of many problems and reduce costs in almost all areas of activity. And, of course, the introduction of 3D equipment into the educational process is taking place by leaps and bounds, not only in higher educational institutions, specialized colleges, but also in secondary schools. nine0003

One of these modern schools is the New Chernogolovskaya School (NChSH) with in-depth study of subjects in the city of Chernogolovka near Moscow.

In addition to the implementation of the general education program with fundamental academic knowledge, the NCS pays great attention to building an individual educational trajectory for each student with the possibility of research activities and applied application of the knowledge gained, the development of initiative, creativity and independence of children. nine0003

nine0003

Mikhail Sergeevich Gavrilov, head of the Engineering Center and part-time technology teacher, told us how the educational process is built.

The engineering center located at the school is equipped with Raise3D Pro2, PICASO3D FDM 3D printers, Phrozen Sonic Mighty 4K photopolymer printer and Granbo and Phrozen accessories, 3D scanner and CNC milling machine, as well as turning and drilling machines and various hand tools. nine0003

Mikhail said that the choice of printers was based on personal experience in using various printers and machines. I had experience with Anet, Printbox, Hercules, Anycubic devices. The Raise3D printers proved to be very reliable in operation, they had much less problems with operation compared to others, and they also have a lot of useful features. The ideamaker software that comes with the printers allows you to quickly prepare a file for printing, has many settings, and provides a good print result. nine0003

nine0003

After purchasing the printers, they were immediately put into operation, thanks to a mentor with rich experience in working with CNC machines and 3D printers.

Students begin their acquaintance with 3D printing technology from the 5th grade, and students from 7th to 9th grade are already making various design works, moving mechanisms, souvenirs and much more using 3D printers. Parts of projects or the entire creation are printed on printers. These are not only school work and assignments, often students defend projects within the framework of the session of the Minor Academy of Sciences and present their work at the All-Russian Olympiad for School Students in Technology and at the Moscow Olympiad for School Students. nine0003

Along with 3D printing and scanning, of course, children learn 3D modeling in Compass 3D and Fusion 360. They develop 3D models on their own with tips and advice from a mentor. The teacher also comes up with various practical tasks designed to practice certain techniques for building 3D models.

A few words about the work "Chess"

To create a chess table, a CNC milling machine was used. The chessboard itself is made of a mirror engraved on a laser machine. nine0003

With chess pieces it's still more interesting. First, the authors of the project prepared 3D models of themselves and their classmates using a 3D scanner, then printed them on a 3D printer and, after a little processing, covered them with paint.

In the near future, it is planned to use 3D printers for the manufacture of architectural models, as well as the creation of robots.

According to Mikhail, the introduction of 3D printing into the educational process is very important for modern schoolchildren. This allows you to develop spatial thinking, creativity, technical skills, reveals the ability to project activities. When making their projects, students develop an engineering culture, a desire for their own discoveries and self-development.