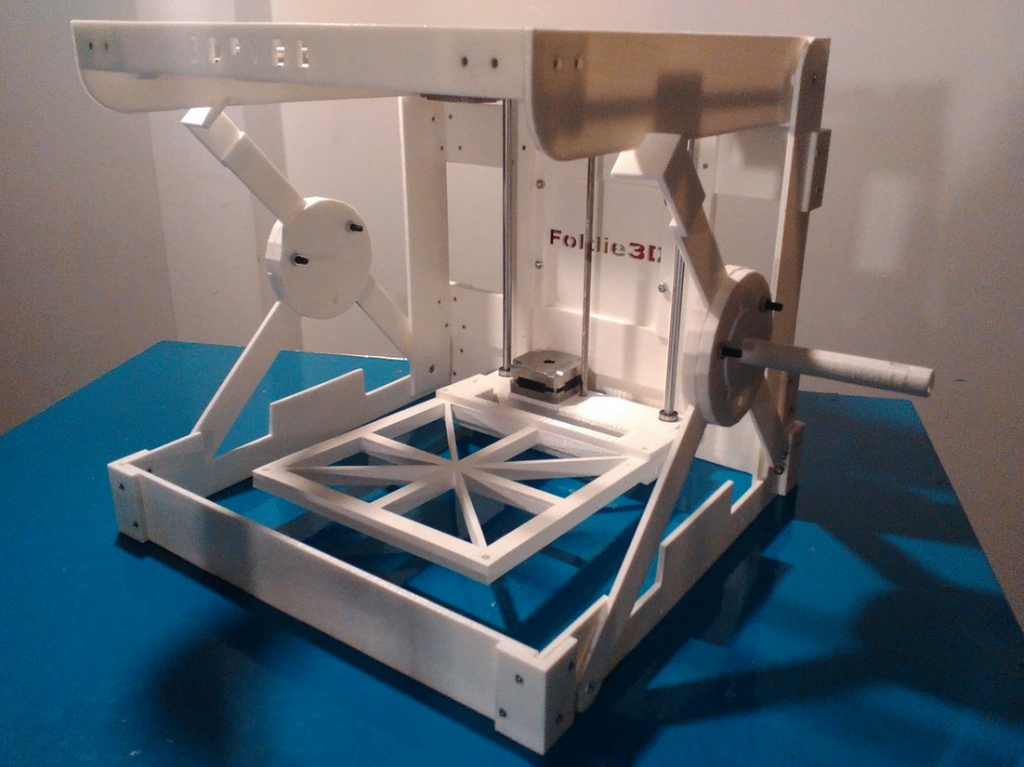

Minolta 3d printer

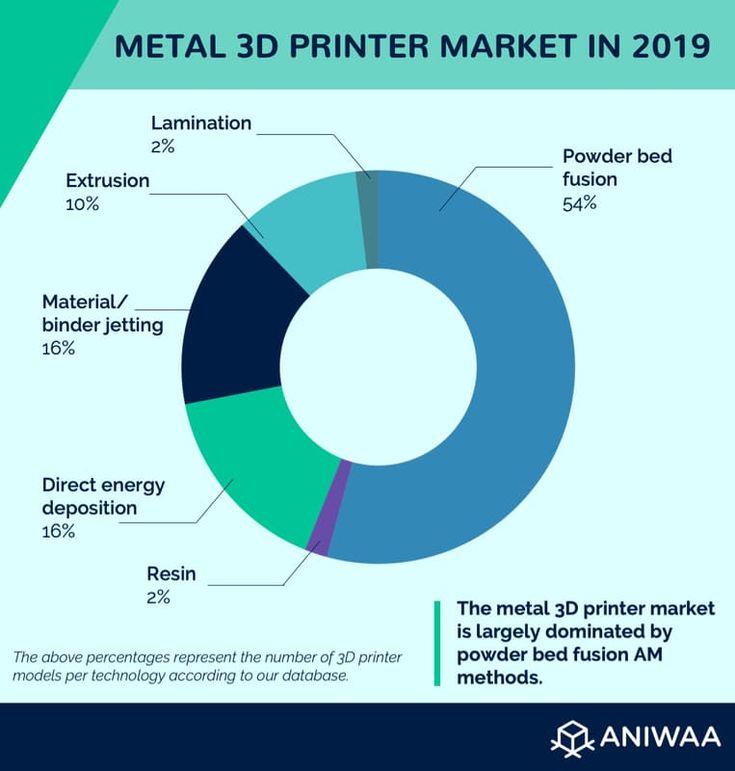

3D Printing - Commercial 3D Printers

Value

Creativity

Protect Ideas

Opportunities

Operational Efficiency

Sustainable Footprint

Value

Print faster, better, simpler … Print Almost Anything. 3D printing delivers the ability for mass customisation of any product. Produce as many widgets, gizmos or spare parts as you want, as easily and cheaply as a standard, generic version of the same product. With a 3D printer, creating a custom-made product is as easy as changing a few values and altering some features in a virtual design on your computer, then pressing, “Print.” Each personalised design can be saved and reprinted anytime the need arises.

Creativity

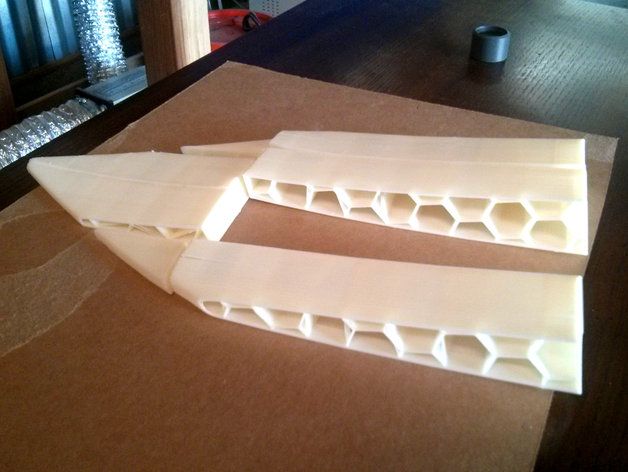

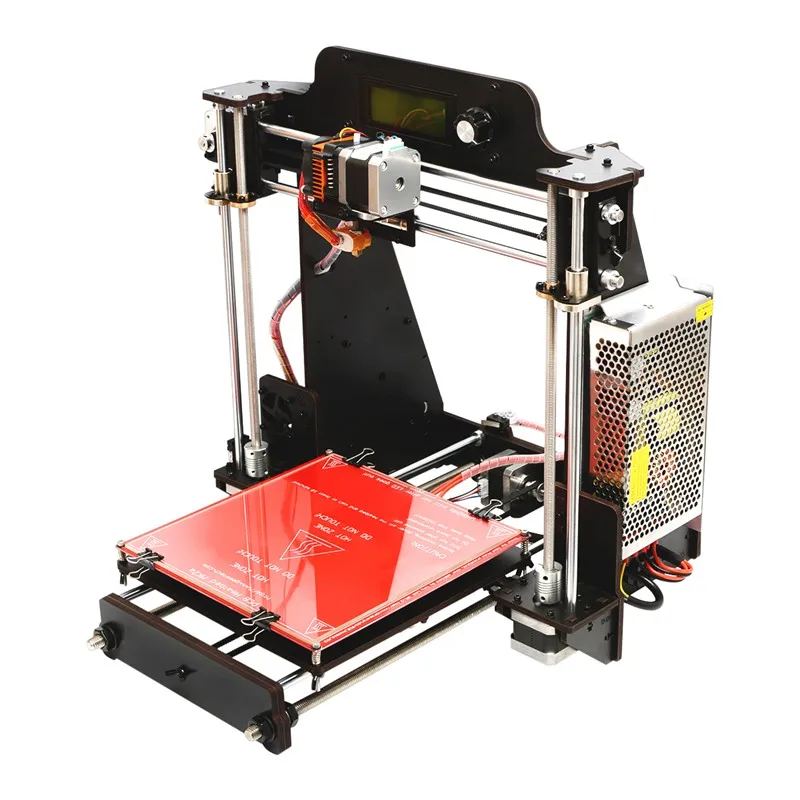

Professional grade 3D printers can be used for established products and prototyping. Have a new design for a product you’d like to produce and sell? A 3D printer can make one immediately, allowing you to test it, adjust the design, and work out the bugs much more quickly. You can also use it to print replacement parts, like a new brake disc out of titanium. From vehicles to machines, 3D printers can keep your company running smoothly. Industrial 3D printers can manufacture much bigger, more complex objects from scratch, and produce them en masse. Fill any size order on demand, without having to warehouse any parts.

Protect Ideas

Create more complex, higher quality products. Secure your designs and keep your valuable product and manufacturing information away from unauthorised individuals. Bringing 3D printing in-house means that you can ensure your designs and product information remain in-confidence.

Bringing 3D printing in-house means that you can ensure your designs and product information remain in-confidence.

Opportunities

Create higher quality products - better designs, better products. 3D printing gives design engineers a new ability to be able to collaborate, iterate and test-fit designs, allowing them to be able to design better products. Accelerated prototyping allows designers to focus on the function of products, creating a new ability to innovate faster and make modifications as needed.

The result? Better collaboration between engineers, designers and production teams, and more opportunities to refine designs. Ultimately, this means better products, designed faster than ever before.

Operational Efficiency

Develop and produce your ideas with 3D printing and increase speed to market output. Print a concept the same day it is designed, reducing the development process from months to just a few days. Getting your product to market quicker ultimately means greater profits. Achieve cost-effective product development and fast go-to-market with new, more efficient 3D print manufacturing processes. 3D printing can revolutionise your processes at every stage of the manufacturing process, from concept to prototyping and testing, pre-production, and even direct-parts manufacturing using a range of new materials with greater functional purposes.

Print a concept the same day it is designed, reducing the development process from months to just a few days. Getting your product to market quicker ultimately means greater profits. Achieve cost-effective product development and fast go-to-market with new, more efficient 3D print manufacturing processes. 3D printing can revolutionise your processes at every stage of the manufacturing process, from concept to prototyping and testing, pre-production, and even direct-parts manufacturing using a range of new materials with greater functional purposes.

Sustainable Footprint

3D printing saves energy and creates less waste, significantly reducing the manufacturer’s environmental impact. It promotes manufacturing locally, which eliminates the need for shipping things all over the country and the extra pollution that causes. And producing items on an as-needed basis, helps eliminate costly warehousing and inventory management fees.

Whether you’re a small, local company or a large, multi-location corporation, 3D printing can save time and money, as well as lessen your carbon footprint.

Konica Minolta boosts 3D portfolio with Markforged deal

Konica Minolta says its new partnership with US-based 3D printing technology manufacturer Markforged will equip Australia with next-generation tools to manufacture “the factories of the future.”

| Markforged X5 Industrial 3D Printer |

| "A real shift in the industry": Konica Minolta's Eric Holtsmark |

“With an already impressive range of 3D Systems’ printers in its portfolio, Konica Minolta Australia, a leading supplier of 3D printing equipment and services in Australia, has announced a partnership with Markforged, a leading provider of atomic diffusion metal printers and composite carbon fibre 3D printers,” says a KM media release. “This rounds out an impressive portfolio that lets Konica Minolta address any industry application requirements and budget.”

“This rounds out an impressive portfolio that lets Konica Minolta address any industry application requirements and budget.”

Markforged, based in Massachusetts, makes industrial 3D printers for manufacturing and factory floors that print metal, carbon fibre, stainless steel, fiberglass, and more.

“There is now a real shift in the industry from prototyping to end-use applications,” said Eric Holtsmark, general manager – strategy, transformation and technology, Konica Minolta Australia. “With Markforged 3D printers, the ability to produce affordable, strong parts in a range of exciting new materials will accelerate manufacturers speed-to-market in way never seen before, giving them a massive competitive advantage.”

Markforged offers an end-to-end 3D printing system with a wide range of manufacturing-ready materials. The Markforged solutions rival traditional manufacturing processes in speed, quality, and cost, and expand the applications for additive manufacturing with purpose-built industrial technologies, says Konica Minolta.

“In today’s global market, Australian manufacturers and designers are rapidly becoming leaders with the next generation of additive technologies. They’re bringing composite and metal materials to market that are easy to implement and operate and are backed up by uncompromising service and support.

| A Markforged print head |

“Adding Markforged to Konica Minolta’s 3D line-up extends its industry-leading capability in delivering high-performance, advanced 3D printing solutions to Australian innovators in many industries including: manufacturing, aerospace, engineering, automotive, medical, and universities. These industries will have unprecedented access to both groundbreaking technology and essential fundamental infrastructure.”

Ved Narayan, Vice President, APAC, Markforged, said, “We’re thrilled to be partnering with Konica Minolta to provide Australian manufacturers with the essential tools to unlock their manufacturing potential and to help build the factory of the future. Konica Minolta has the experience and skills to help Markforged provide unprecedented levels of access and support to the world’s leading manufacturing providers.”

Konica Minolta has the experience and skills to help Markforged provide unprecedented levels of access and support to the world’s leading manufacturing providers.”

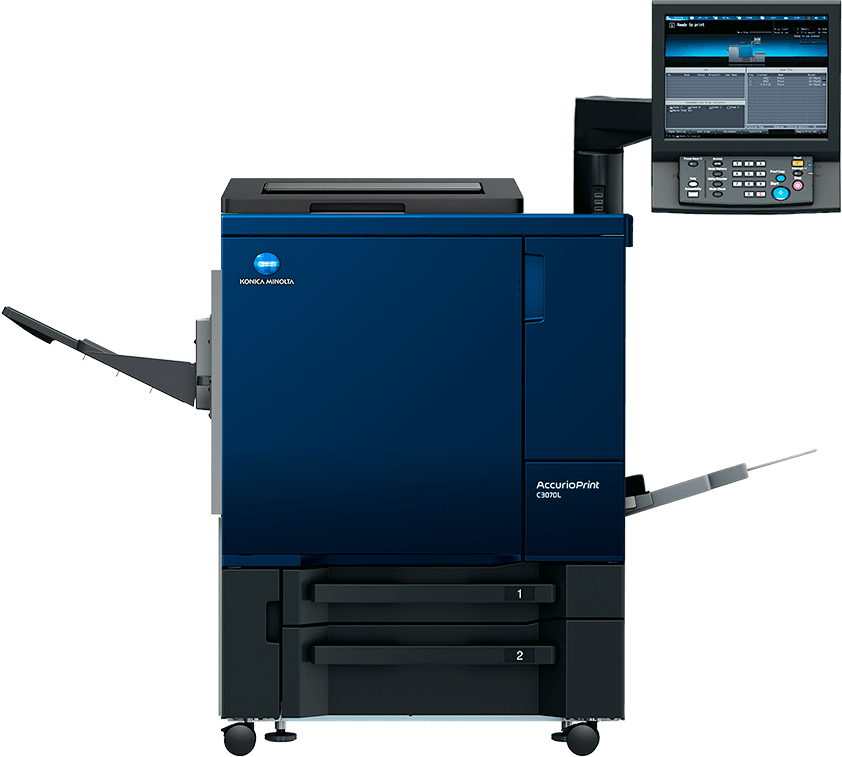

Konica-Minolta magicolor 7450 - A3 color printer

Simitri HDFine Polymerized TonerThe Konica-Minolta magicolor 7450 II printer uses a new generation of Simitri HD toner, which is obtained by particle growth. | |

|

|

PhotoART 9600 technology and Emperon

processorThe printer uses PhotoART 9600 resolution (600x600x4bit Contone) to print photorealistic images with fine detail and fine lines. By modulating the illumination time of the photosensitive drum with a laser beam, the printer can reproduce higher quality halftones in both full color and monochrome printing. This allows you to implement a 4-bit algorithm or 16 levels of color filling per point (4096 different color shades at each point). By comparison, most printers use a 2-bit algorithm, or two fill levels per dot.

Data processing is performed by the Emperon raster processor, which automatically converts the data to CMYK space. Additional image processing is performed by a special “Azuma” ASIC graphics accelerator located on the printer's motherboard. Emperon processor compatible with various platforms (Mac OS, Windows, etc. )

)

Three-object segmentationThe dual-core “Azuma” ASIC graphics accelerator allows the printer to support 3-object segmentation, a special complex image processing technology:

| |

Print on a wide range of media The Konica-Minolta 7450 printer can be equipped with multiple paper trays (one tray is standard), as well as a multi-function tray for printing on thick media and custom-sized media. The printer successfully bakes paper weighing up to 256gsm. m and above with different textures. The printer supports printing on A3 Wide paper, allowing you to print borderless A3 paper. In addition, you can print on a wide range of media from a minimum size of 90 x 140 mm up to 1200 mm long banners (when the dedicated banner tray is installed). | |

|

The software supports printing large format documents in poster mode, splitting the entire image into smaller pieces. nine0009 |

Specifications

| A3 color laser printer | |

| Print mechanism | |

| Printing principle | Electrographic, laser |

| Print speed | Colour/b&w: 25 / 25 A4 per minute; 13 / 13 A3 min |

| Approval | nine0013 PhotoART 9600 600x600dpi x4 bit Contone|

| Warm-up time | 99 seconds |

| First page out time | Color / B&W : 11. 5 / 9.5 seconds 5 / 9.5 seconds |

| Paper Handling | |

| Duplex | option |

| Paper stock | Standard: 250-sheet trays; 100-sheet bypass tray; Maximum 1850 sheets |

| Output devices | Standard: 350-sheet tray |

| Paper size | A6-A3 Wide; any size (90-311 x 140-1200 mm) |

| Paper weight | 60-256 gsm |

| Data processing | |

| Processor | Freescale PowerPC, 7447A (733 MHz) |

| RAM | 256 MB, max: 1024 MB |

| Page description languages | PostScript 3, PCL XL 2.1, PCL 5e/c |

| Interfaces | Gigabit Ethernet 1000/100/10BaseT; USB 2.0; IEEE 1284; PictBridge |

| Hard disk | Optional |

| Operating systems | Windows: Server 2003, XP (Home/Pro), 2000, NT 4. 0, ME, 98SE, 0, ME, 98SE, Macintosh: OS X 10.2 (or higher), OS 9.1 (or higher), Linux: RedHat 9.0, SuSe 8.2, Netware: 4/5/6 or higher |

| Direct Print | PDF ver. 1.6, JPEG, TIFF |

| General characteristics | |

| Dimensions (W x D x H) | 648 x 606 x 477 mm |

| Weight | 51 kg |

| Power supply | 220/240V +/- 10%, 50/60Hz |

| Energy consumption | Max. 1450 W |

Consumables

| Name | Part number | Resource |

|---|---|---|

| Toner cartridge black | 8938621 | 15000 |

| Cyan toner cartridge | 8938624 | 12000 |

| Pink Toner Cartridge (Magenta) | 8938623 | 12000 |

| Yellow toner cartridge | 8938622 | 12000 |

| Photoconductor unit black | 4062213 | 50000 |

| Photoconductor unit blue | 4062513 | 30000 |

| Photoconductor unit pink | 4062413 | 30000 |

| Image drum unit yellow | 4062313 | 30000 |

| Waste tank | 4065621 | 30000 |

| Fixing block | 4039R74011 | 120000 |

| Transfer unit | 4039R71600 | 120000 |

Repair of printers and MFPs Konica Minolta

Manufacturers

Brands MFPs, copiers and printers KYOCERA Plotters and MFPs Oce Plotters and MFPs Oce Digital systems Oce VarioPrint DP Line MFPs, scanners, plotters and printers Canon Canon plotters Printers and MFPs Canon Scanners Canon Cartridge Sale MFPs, scanners, plotters and printers HP Printers and MFPs HP HP plotters MFPs, copiers and printers OKI MFPs, copiers and printers Ricoh Stream scanners, MFPs and faxes Panasonic Panasonic Stream Scanners and MFPs Panasonic faxes 3d printers ZPRINTER 3d printers 3D Systems CubeX, Duo, Trio ProJet 1000 and ProJet 1500 ProJet 3510 ProJet x60 ProJet professional 3d printers Felix 3d printers 2. 0,3.0 nine0038 All equipment Copiers and MFPs Printers Dot matrix printers 3D printers shredders Stream Scanners Binders Color MFPs Corporate equipment Laminators Plotters Discontinued Models Paper for plotter

0,3.0 nine0038 All equipment Copiers and MFPs Printers Dot matrix printers 3D printers shredders Stream Scanners Binders Color MFPs Corporate equipment Laminators Plotters Discontinued Models Paper for plotter Vehicles with mileage

Maintenance of office equipment

Office equipment repair

Printers copiers CopiersRepair by manufacturer

Brother Kyocera Konica MinoltaRental of office equipment nine0009

Sale of office equipment

Information about the company

About company Unilever chooses Lekom Qualifications, certificates, awards our clients Beautiful Solutions Interview with Igor Chelebaev: cartridges, ecology and economy Cartridge recycling program

Repair of Konica Minolta printers and MFPs

Repair of Konica Minolta printers and MFPs at Bureau of Office Machines is a professional repair by certified engineers using only original spare parts and consumables. Our specialists guarantee the speed and high quality of work! nine0009

Our specialists guarantee the speed and high quality of work! nine0009

Konica Minolta office equipment is designed to solve all everyday tasks of color and black and white printing both at home and in offices. Considered one of the leaders in the world market, this technique is the guarantor of reliable, trouble-free operation for a long time. A wide range of printers and MFPs in A4 - A3 formats are presented, which are distinguished by their amazing performance and quality.

But despite the high reliability, this technique, like any other, fails over time, technical malfunctions and system errors may appear. With the Bureau of Office Machines Group of Companies, your device will last as long as possible without unforeseen failures and breakdowns! nine0009

Repair of Konica Minolta printers

Since 1995, our company has been repairing Konica Minolta printers of various formats. During this time, a wealth of practical experience has been accumulated in solving any problems that may arise with these devices. Due to this, our engineers will carry out diagnostics as soon as possible, determine the causes of the malfunction and carry out repair work. We have a stock of spare parts and assemblies in our warehouse to quickly solve the most common problems. You do not have to wait for the delivery of spare parts! nine0009

Due to this, our engineers will carry out diagnostics as soon as possible, determine the causes of the malfunction and carry out repair work. We have a stock of spare parts and assemblies in our warehouse to quickly solve the most common problems. You do not have to wait for the delivery of spare parts! nine0009

Here are the most common problems requiring repair of Konica Minolta printers:

- The printer is not found on the computer after installation - as a rule, this is incorrect driver installation, problems with the USB input or cable;

- No response to power on - problem with the main board or power board, the cable is not connected to the mains;

- The appearance of stripes on the produced prints is a consequence of the failure of the photoconductor;

- Paper not picking up or jamming when feeding - a symptom of a malfunction of the feeder, failure of sensors in the tray, or breakage of the rollers; nine0016

- Capturing several sheets at once occurs when the brake pad fails;

- Image displacement on the printout may occur due to damage to the image transfer unit.

This defect also causes extraneous sound;

This defect also causes extraneous sound;

Konica Minolta MFP Repair

All-In-Ones may experience problems not only with printing functions, but also with copy, scan and fax units (if installed). For example, Konica Minolta MFP repair is needed if it appears:

- Image smearing when copying is the first sign of contamination of the scanning unit;

- Digitizing streaks that occur due to uneven document feed by the ADF;

- Abrupt stop when copying - problems with the scanning bar or feed mechanism;

- Fax not sending - line connection problems; Distorted text of a fax message - may appear when there are problems with both the receiving device itself and due to transmission errors; nine0016

As specialists of the office of office vehicles eliminate typical and unusual problems

Repair of the Konica Minolta Bizhub C25 MFP with an error 0094

This is what the service documentation recommends for this error: 9000 9000 9000 in this case in this case the fault was as follows: Solenoid core SD2 retracts the plastic lever, which releases the gear, as a result of which the transfer roller is wrung out from the transfer belt or pressed against the belt. This lever, when the solenoid core is retracted, rests on one side against the body of the assembly, on which a piece of soft material is glued, probably so that no clicks are heard when the solenoid is triggered. Over time, this material became dirty and sticky, and the lever stuck in the retracted position. The force of the spring on the core was not enough to return the lever to its original position. This led to the error "0094".

This lever, when the solenoid core is retracted, rests on one side against the body of the assembly, on which a piece of soft material is glued, probably so that no clicks are heard when the solenoid is triggered. Over time, this material became dirty and sticky, and the lever stuck in the retracted position. The force of the spring on the core was not enough to return the lever to its original position. This led to the error "0094".

After removing the sticky material and replacing it with a similar but clean one, the error disappeared. You can even do without replacement and do not glue anything, just remove this sticky piece.

REPAIR KONICA MINOLTA BIZHUB C224

One of our customers had a problem with the Konica Minolta Bizhub C224 (counter about 600k): the image was skewed when paper was fed from the first lower tray. Of the other three lower trays, there was no skew.

As a result of the diagnostics, we found out the cause of a strange defect. It turned out that the problem arose due to wear and contamination of one of the bushings of the registration unit and the axles of the registration and pressure rollers. From the first tray, the paper immediately fell into the registration unit, and on the side where the bushing wedged, the rollers were slightly unclenched and the paper was skewed (i.e., the image was skewed due to skewed paper). From other lower trays, the paper got into the registration unit through additional feed rollers, which prevented the paper from skewing in the registration unit, and there was no defect. nine0009

It turned out that the problem arose due to wear and contamination of one of the bushings of the registration unit and the axles of the registration and pressure rollers. From the first tray, the paper immediately fell into the registration unit, and on the side where the bushing wedged, the rollers were slightly unclenched and the paper was skewed (i.e., the image was skewed due to skewed paper). From other lower trays, the paper got into the registration unit through additional feed rollers, which prevented the paper from skewing in the registration unit, and there was no defect. nine0009

The engineer dismantled the registration unit, cleaned the bushings, the axles of the registration and pressure shafts, rearranged the problematic bushing from the side of the gear to the other side. After that, the defect disappeared, and for the next visit, the engineer ordered new bushings and shafts and replaced them at the next trip.

Always pay attention to how hard the registration rollers are turned by hand.

nine0016

nine0016  Duplex printing (optional) on paper weights up to 210gsm is also possible. nine0009

Duplex printing (optional) on paper weights up to 210gsm is also possible. nine0009